Rapid Prototyping of a Micromotor with an Optical Rotary Encoder

Abstract

:1. Introduction

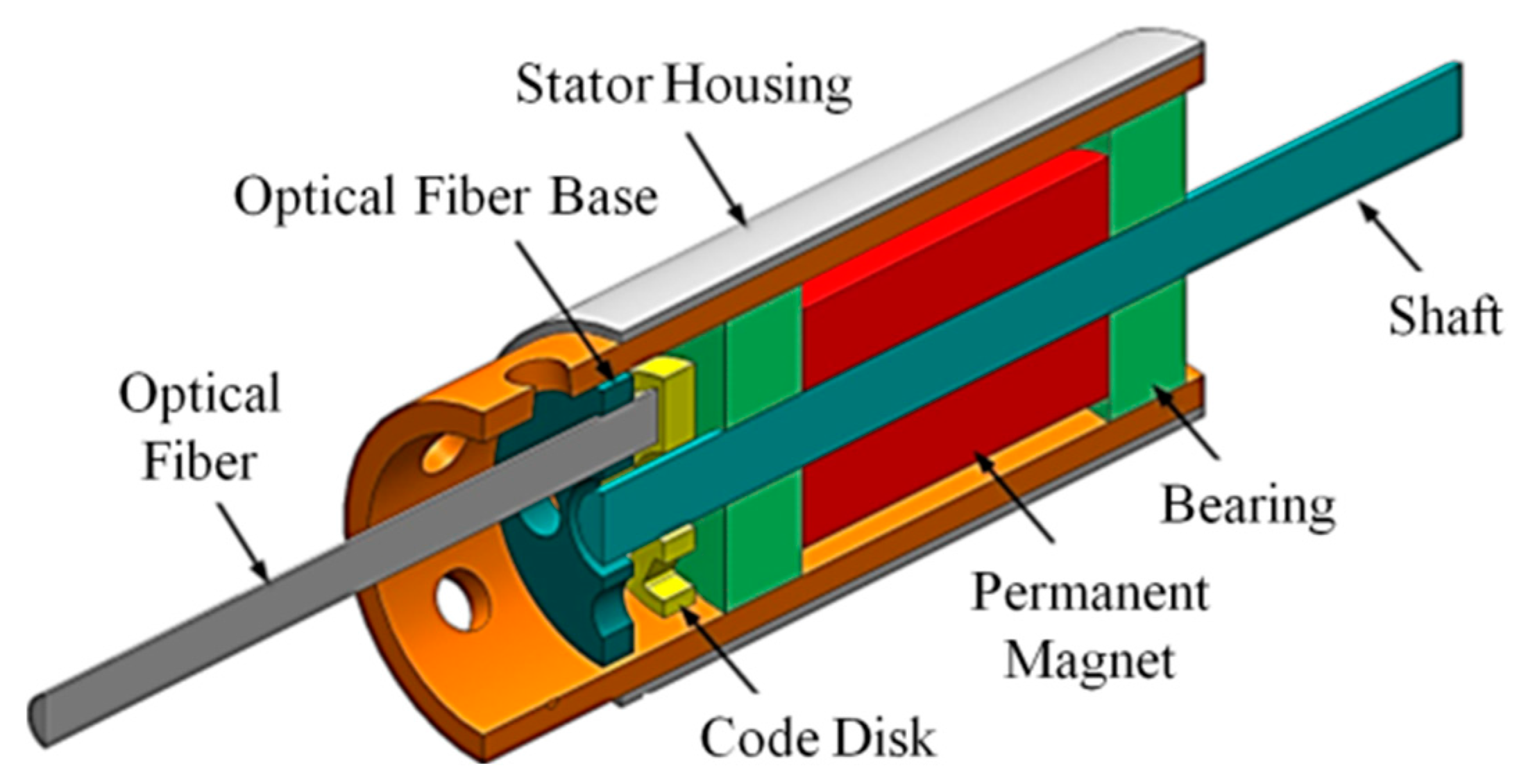

2. Micromotor Design and Analysis

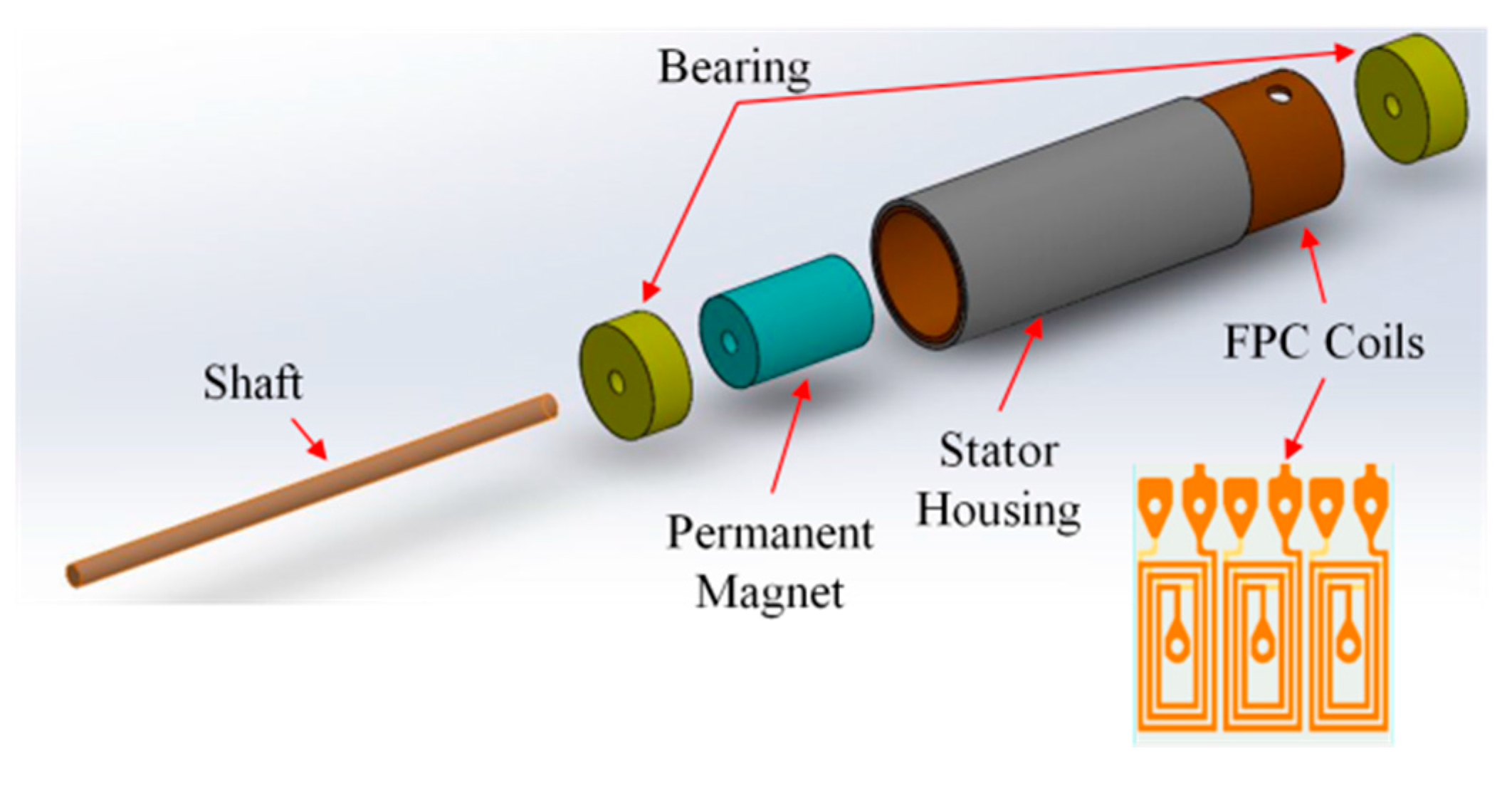

2.1. Micromotor Designs

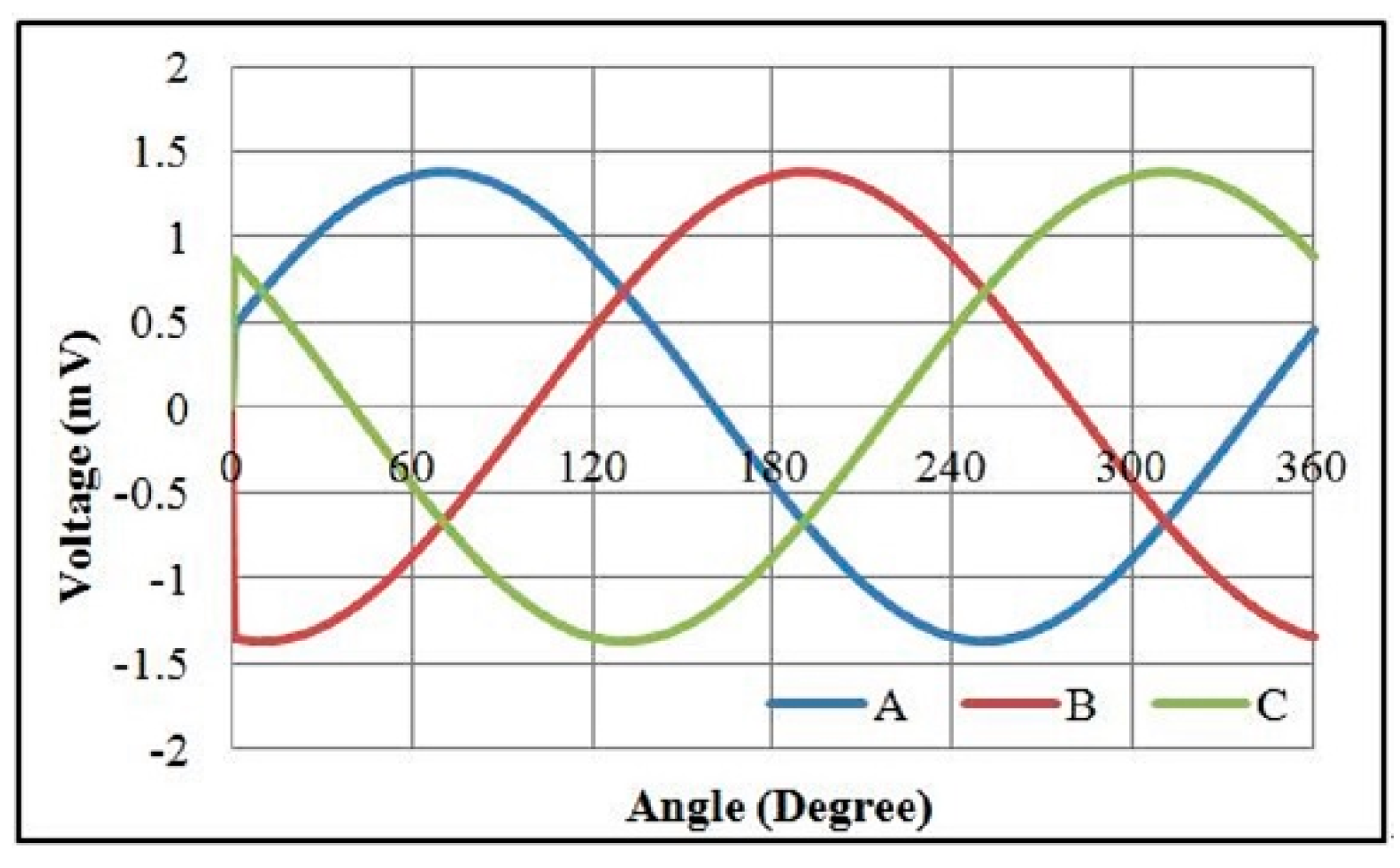

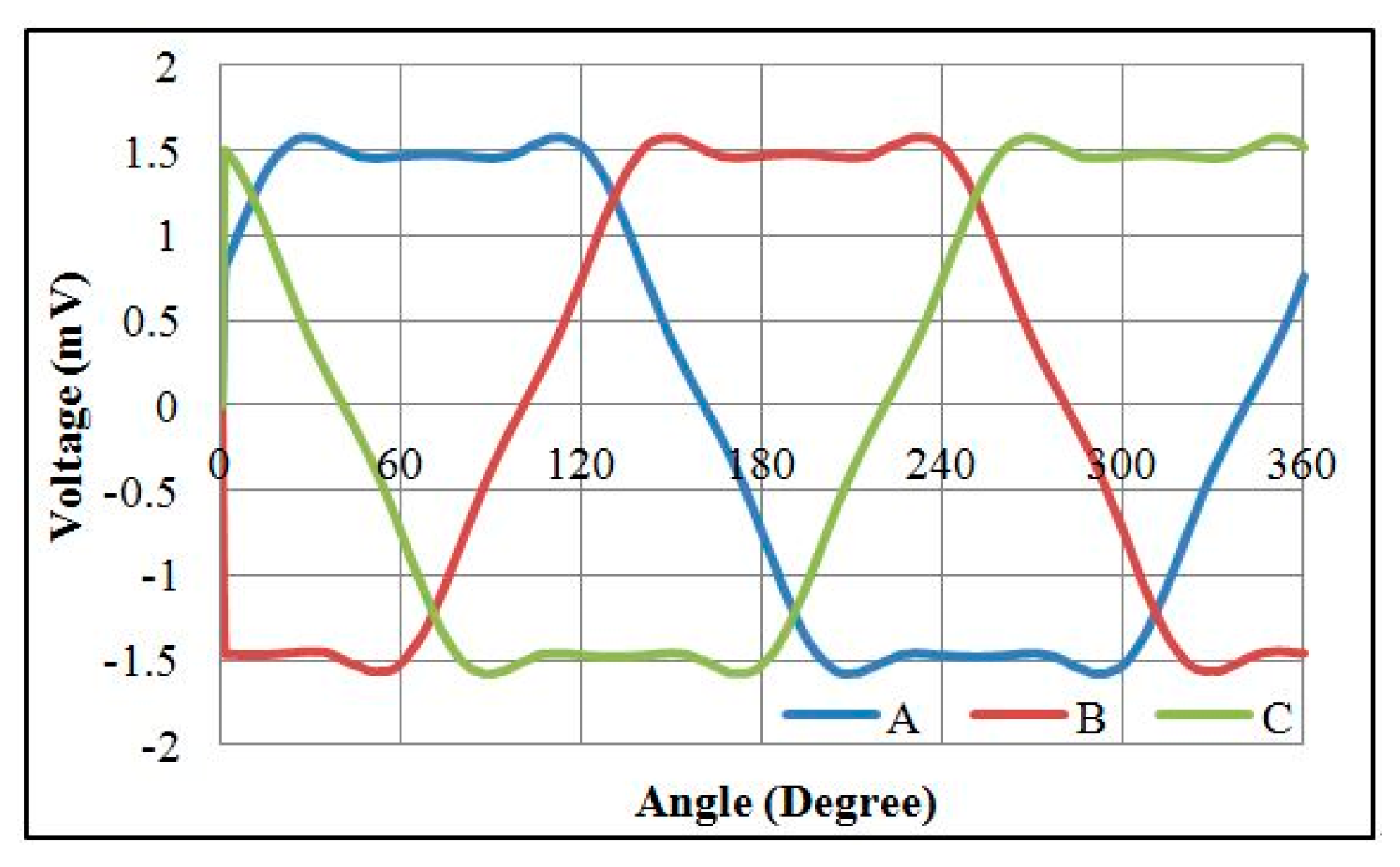

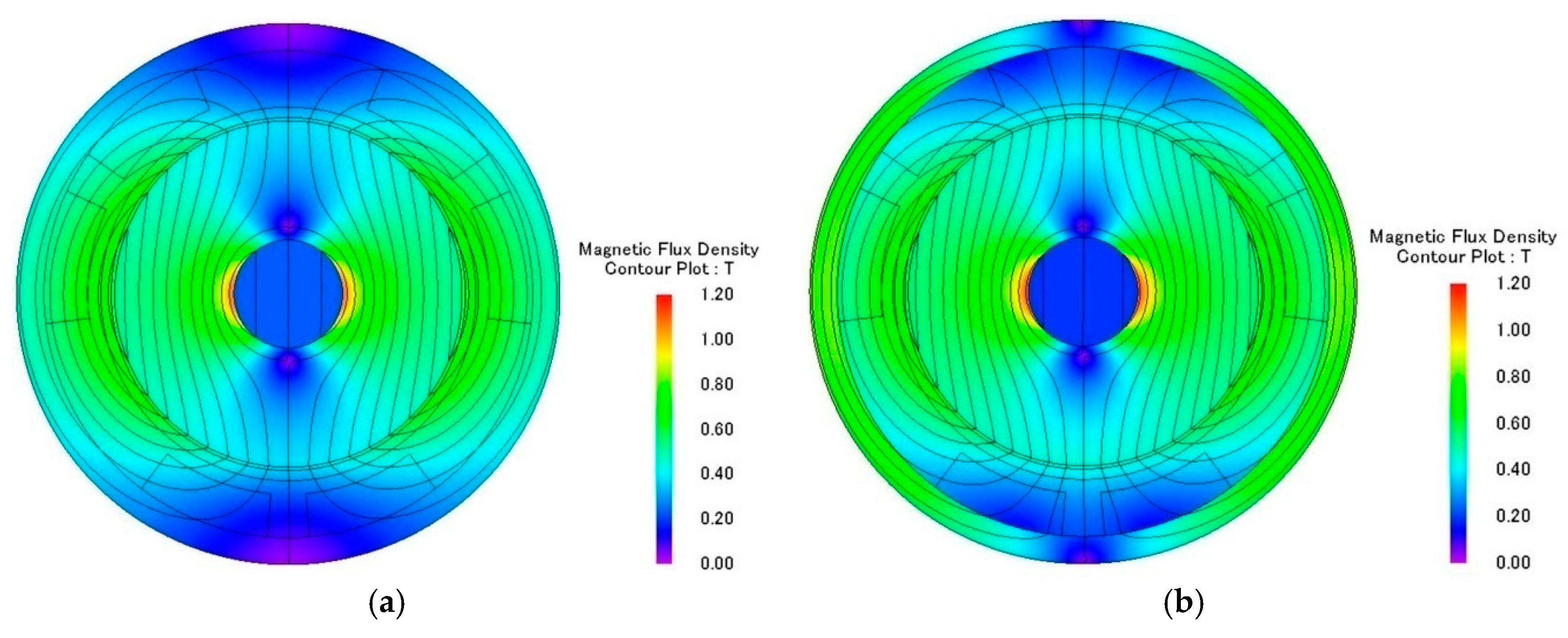

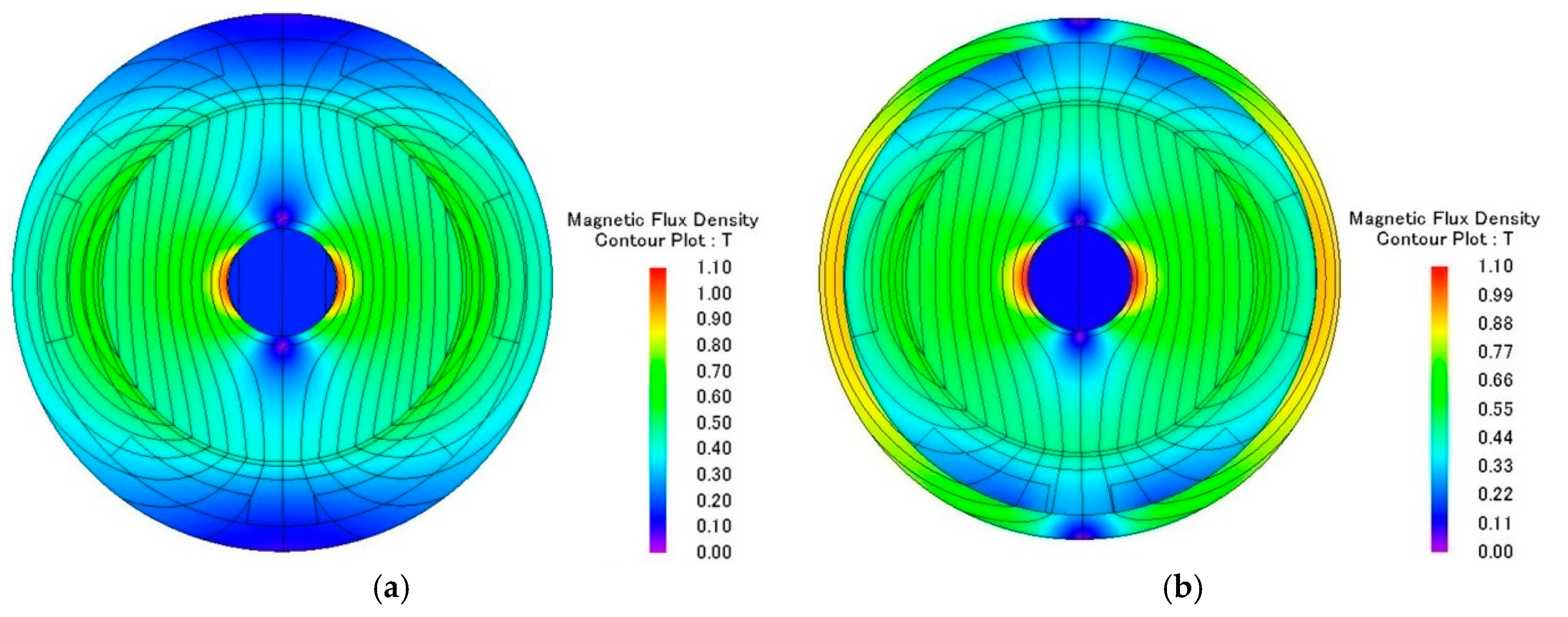

2.2. Electromagnetic Analysis of Micromotors

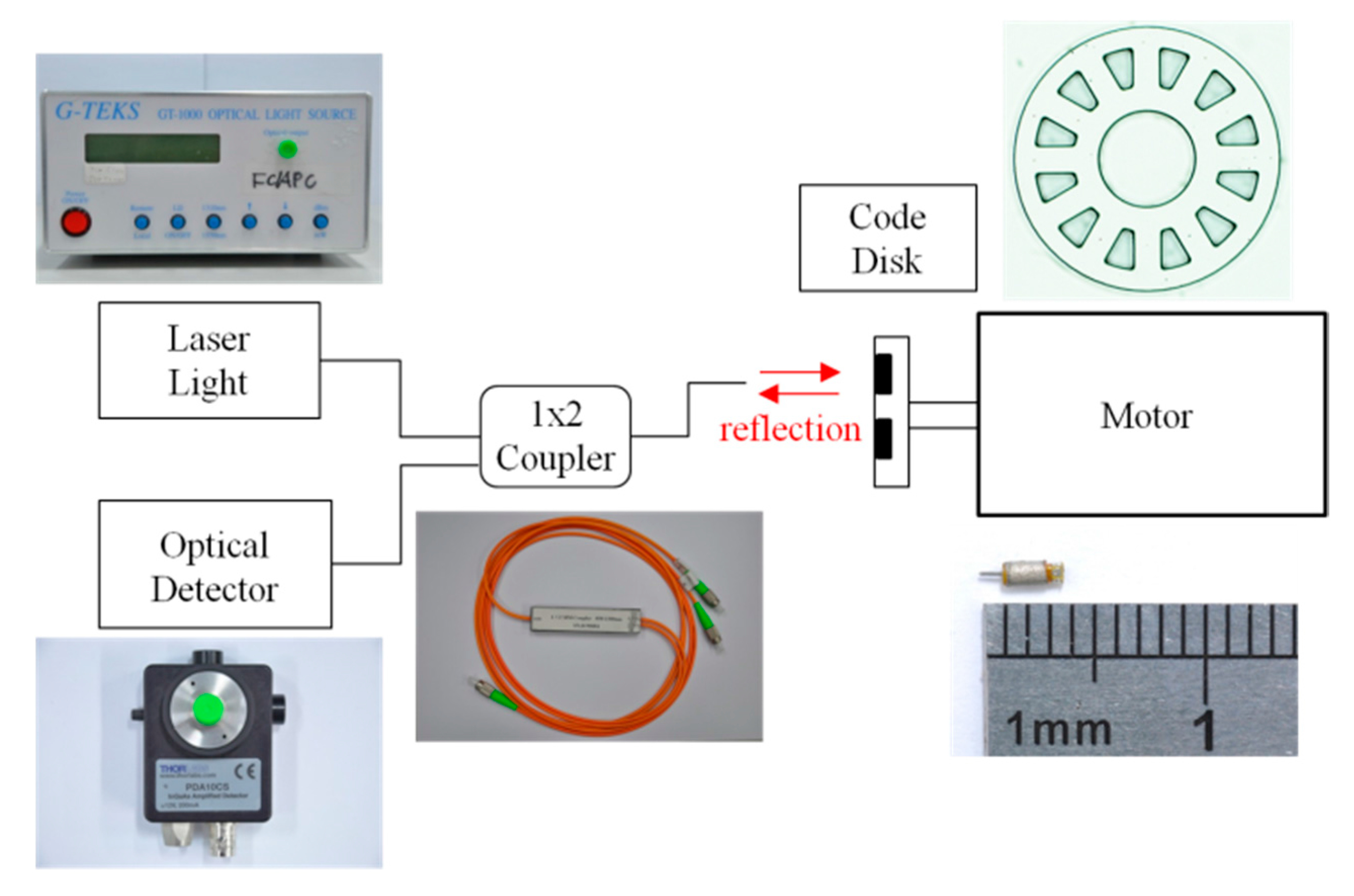

3. Development of an Optical Rotary Encoder

4. Micromotor Fabrication and Testing

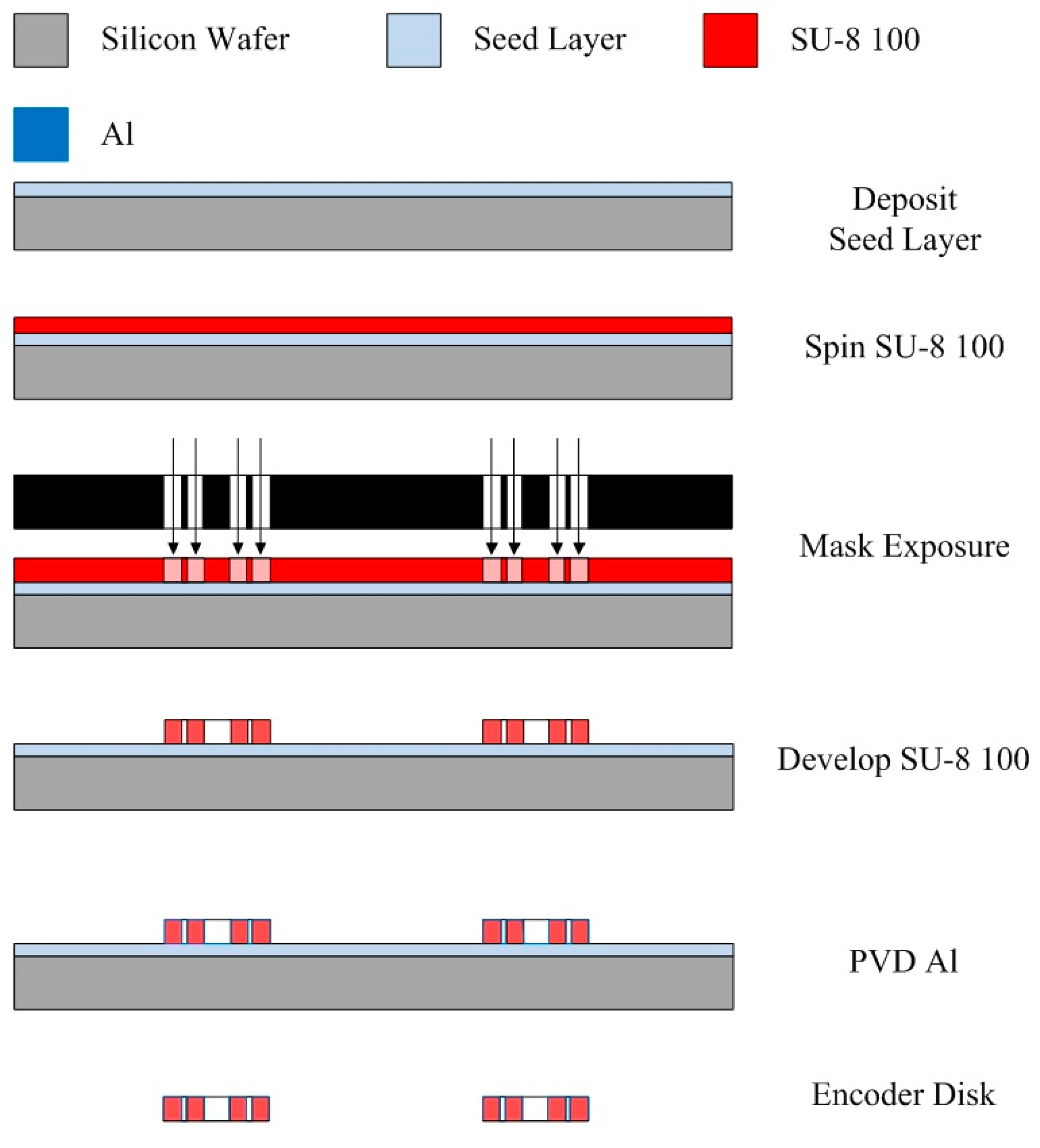

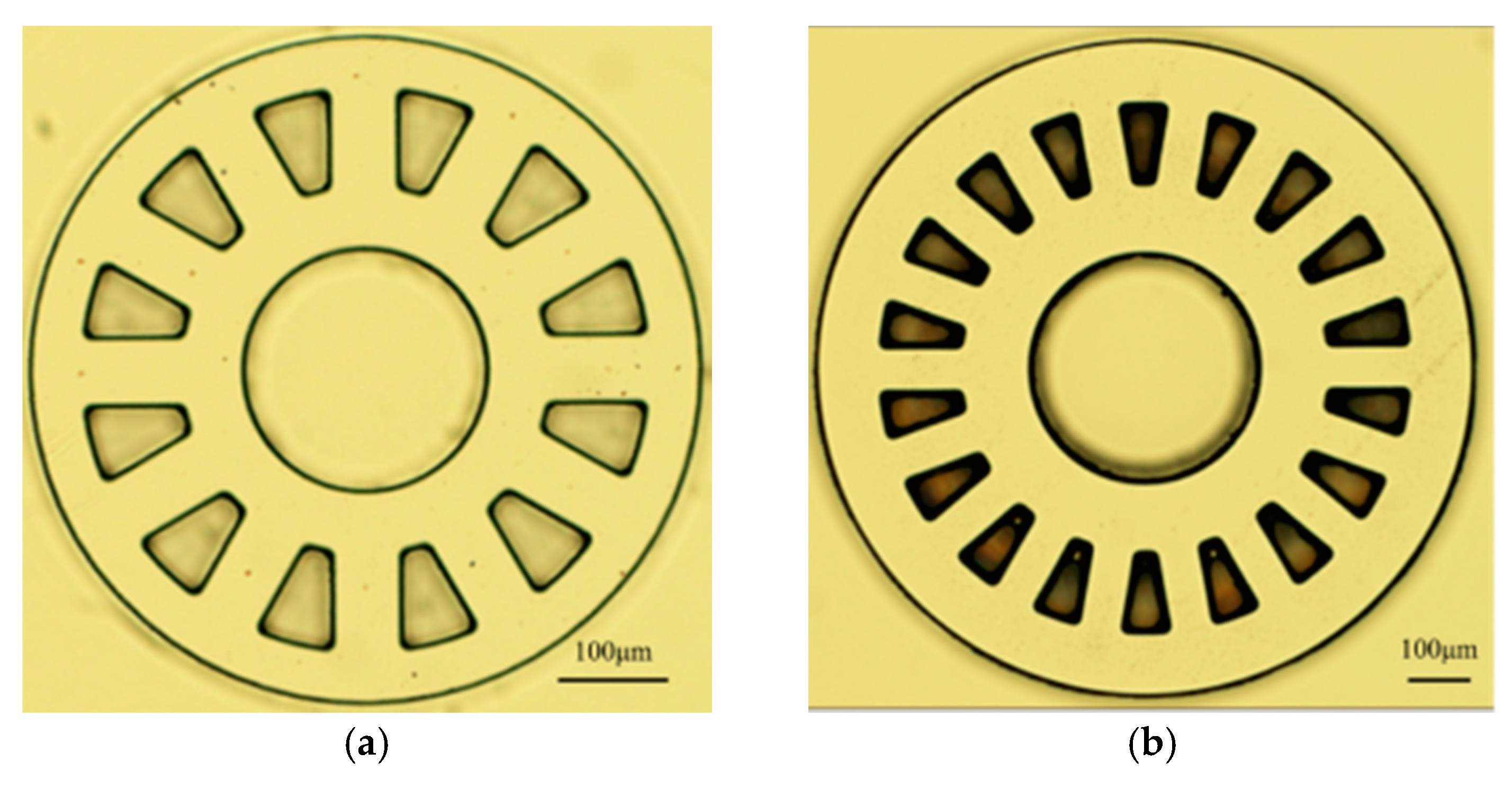

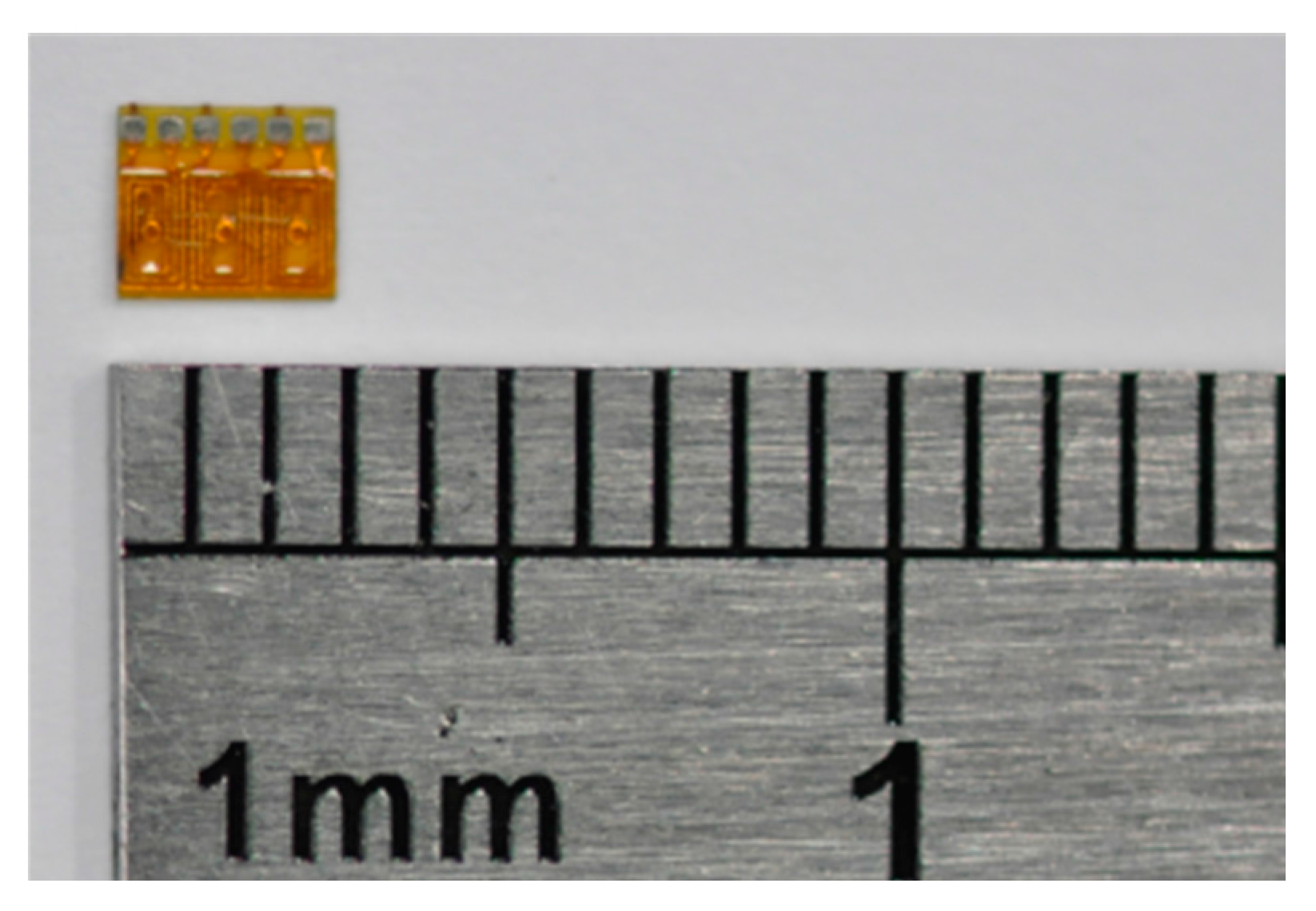

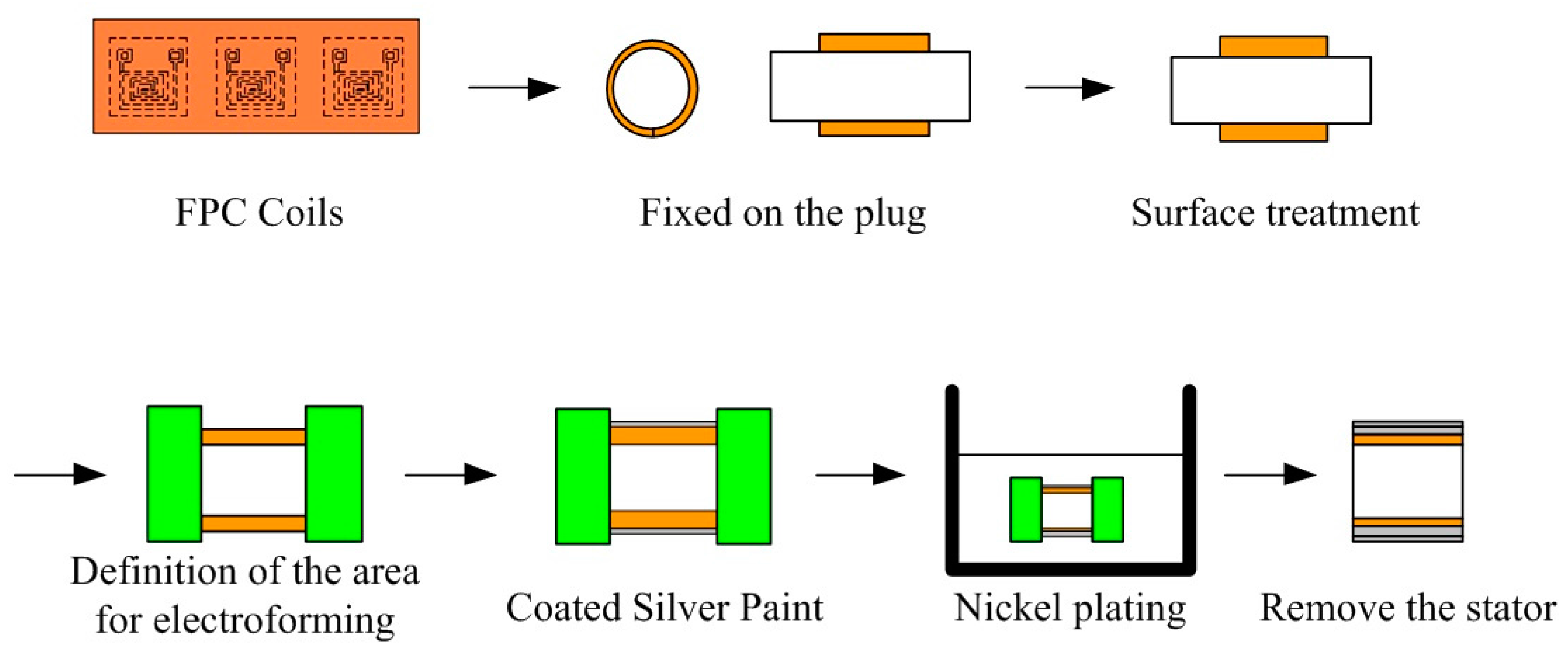

4.1. Micromotor Fabrication

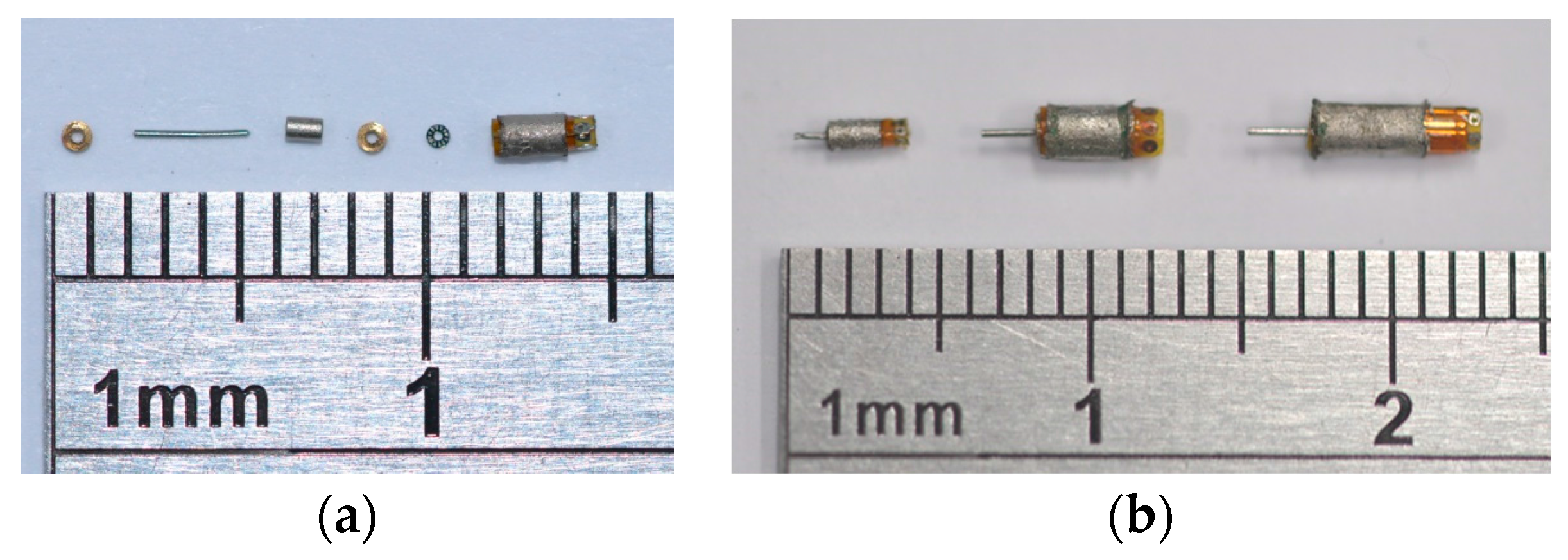

4.2. Micromotor Assembly

5. Micromotor and Optical Encoding Board Testing

5.1. Measurement of Motor Characteristics

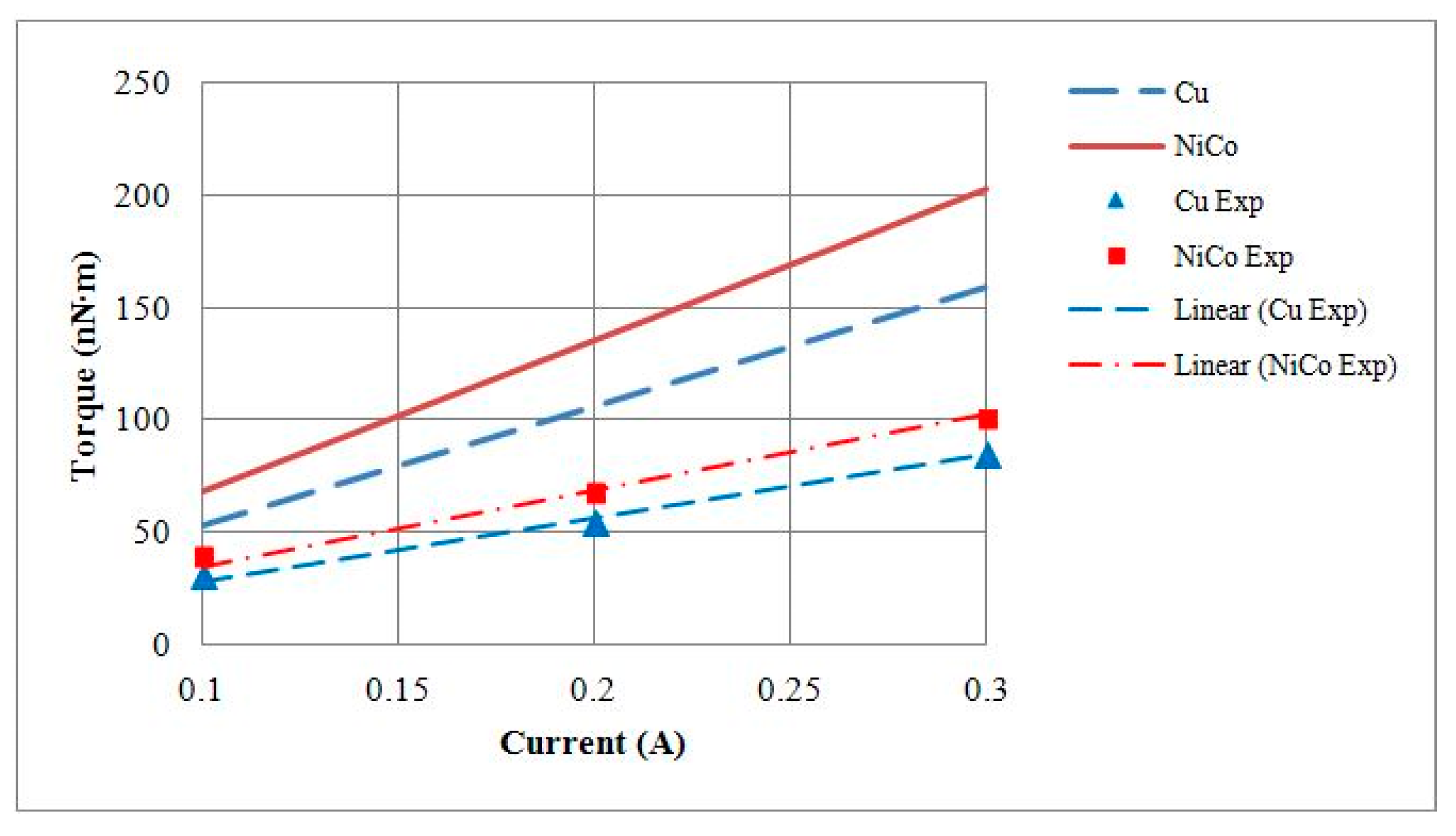

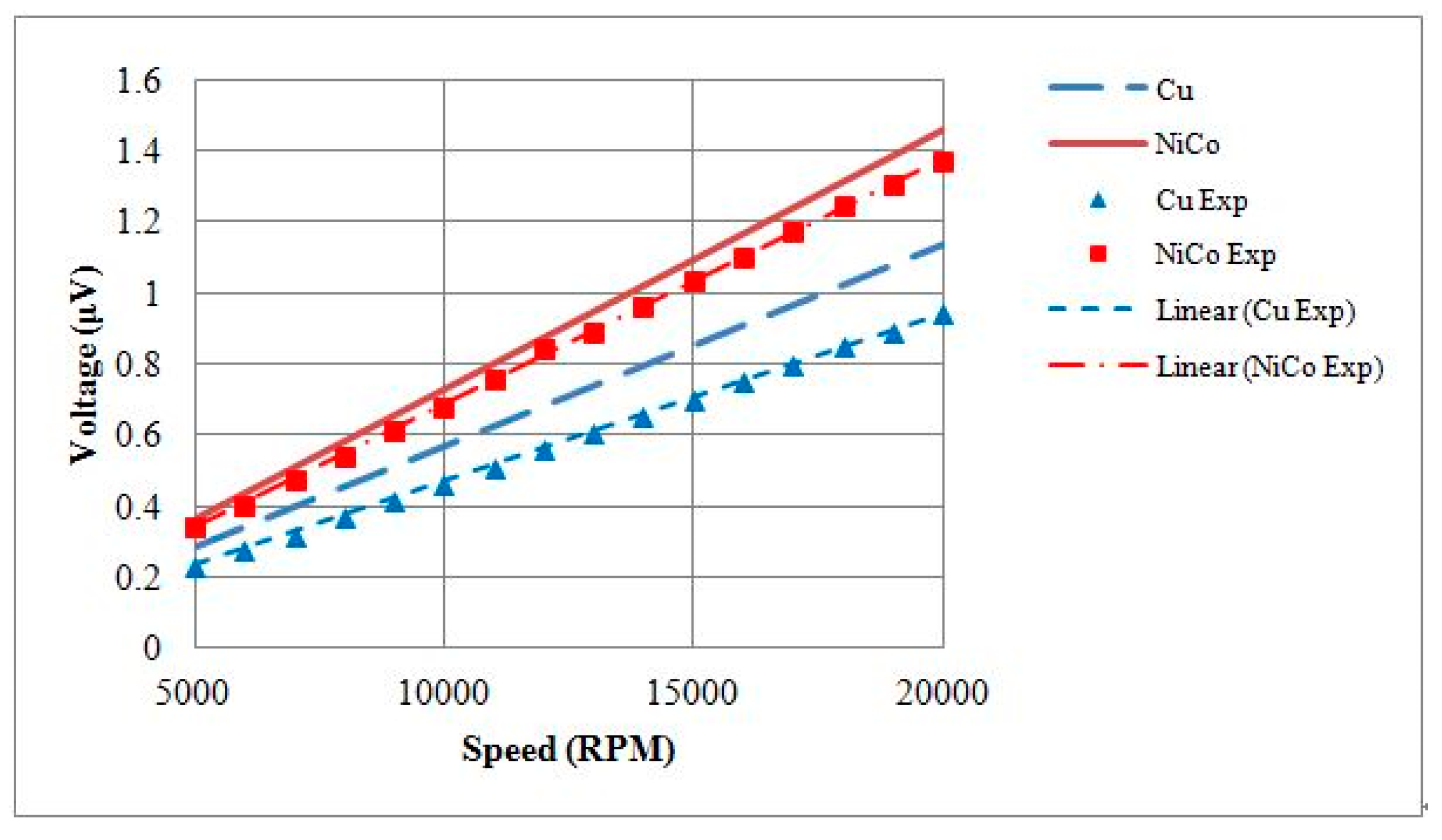

5.1.1. Characteristics of 1 mm Diameter Motors

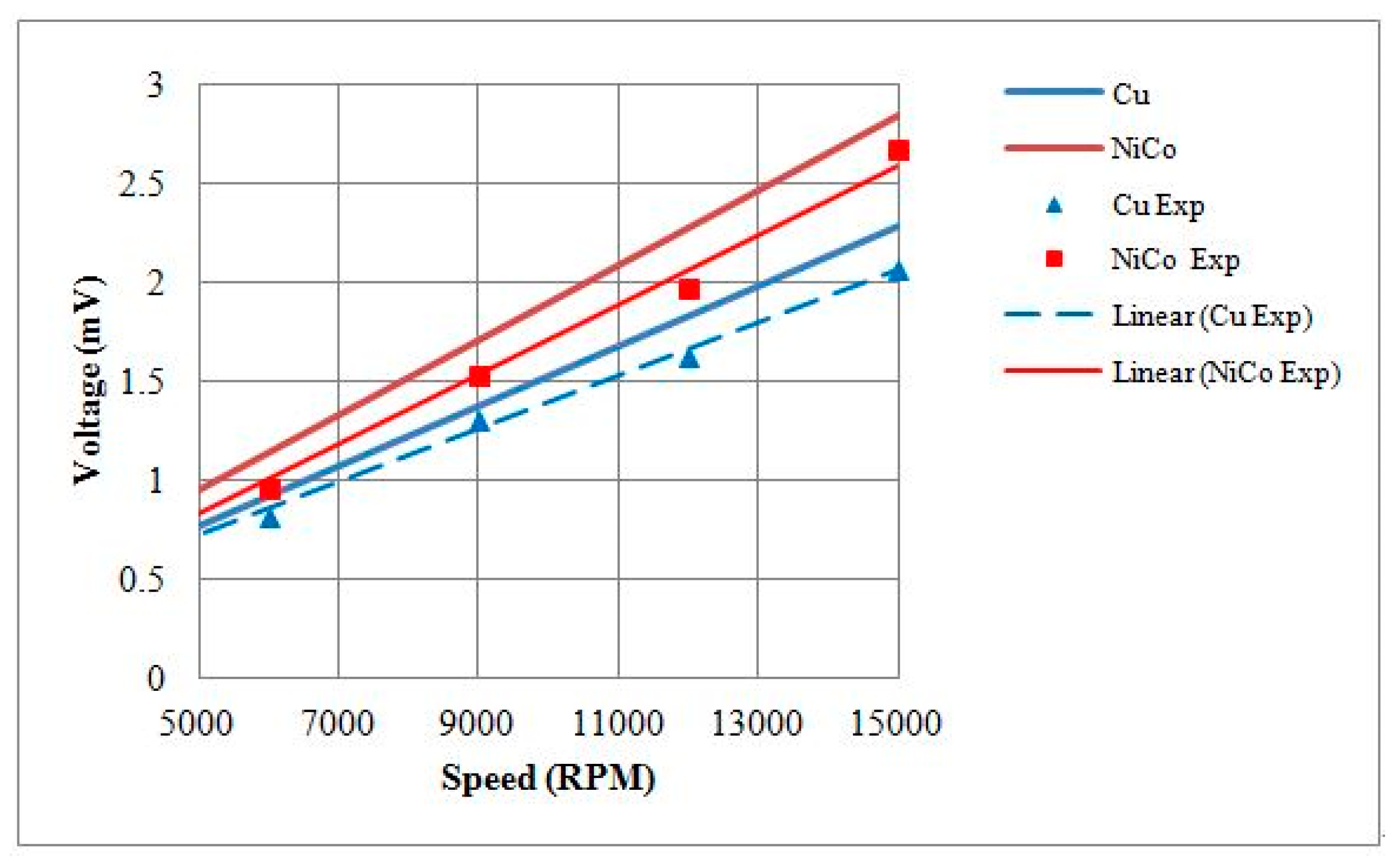

5.1.2. Characteristics of 1.5 mm Diameter Motors

5.2. Motor Run-Out Test

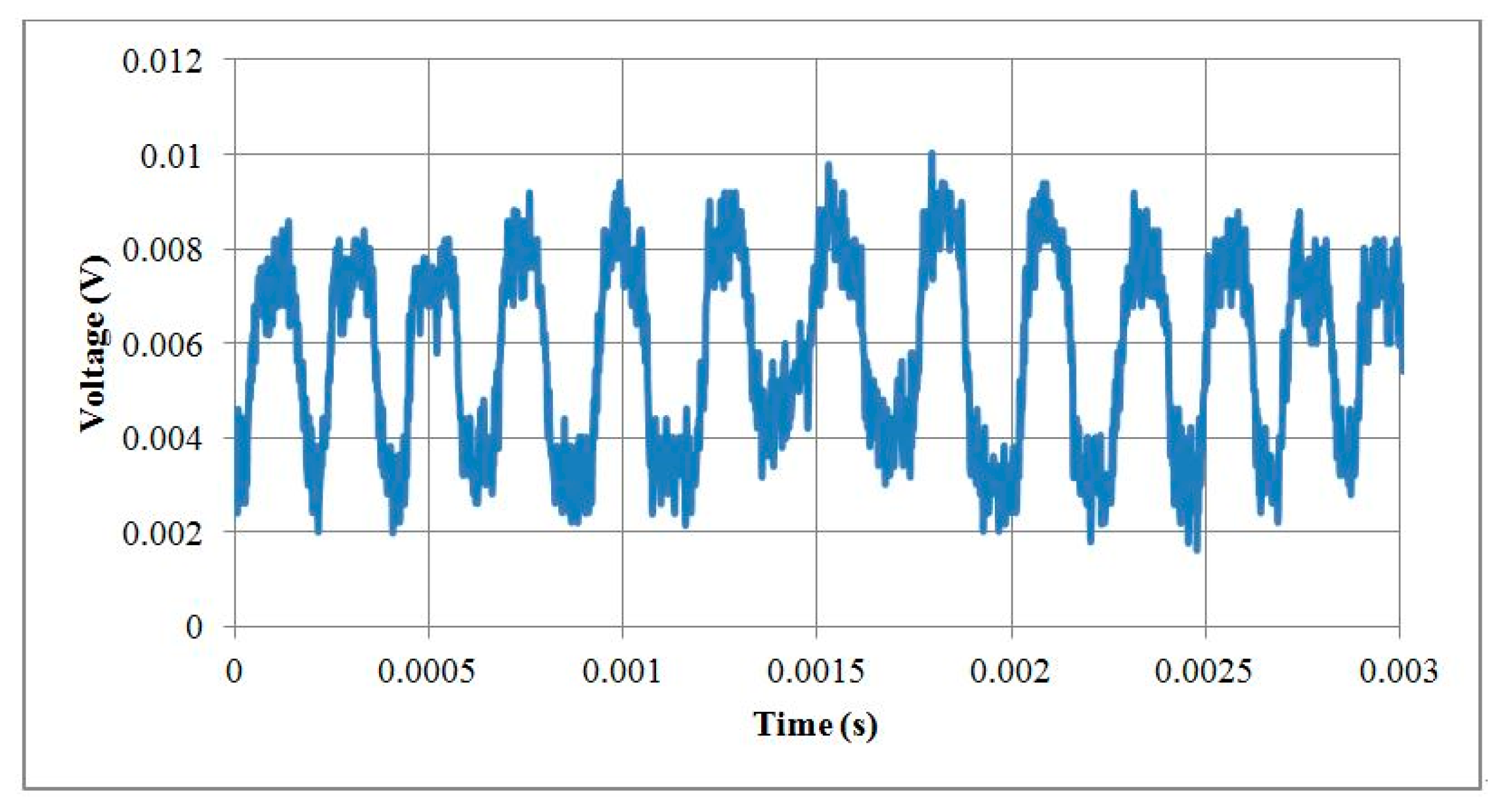

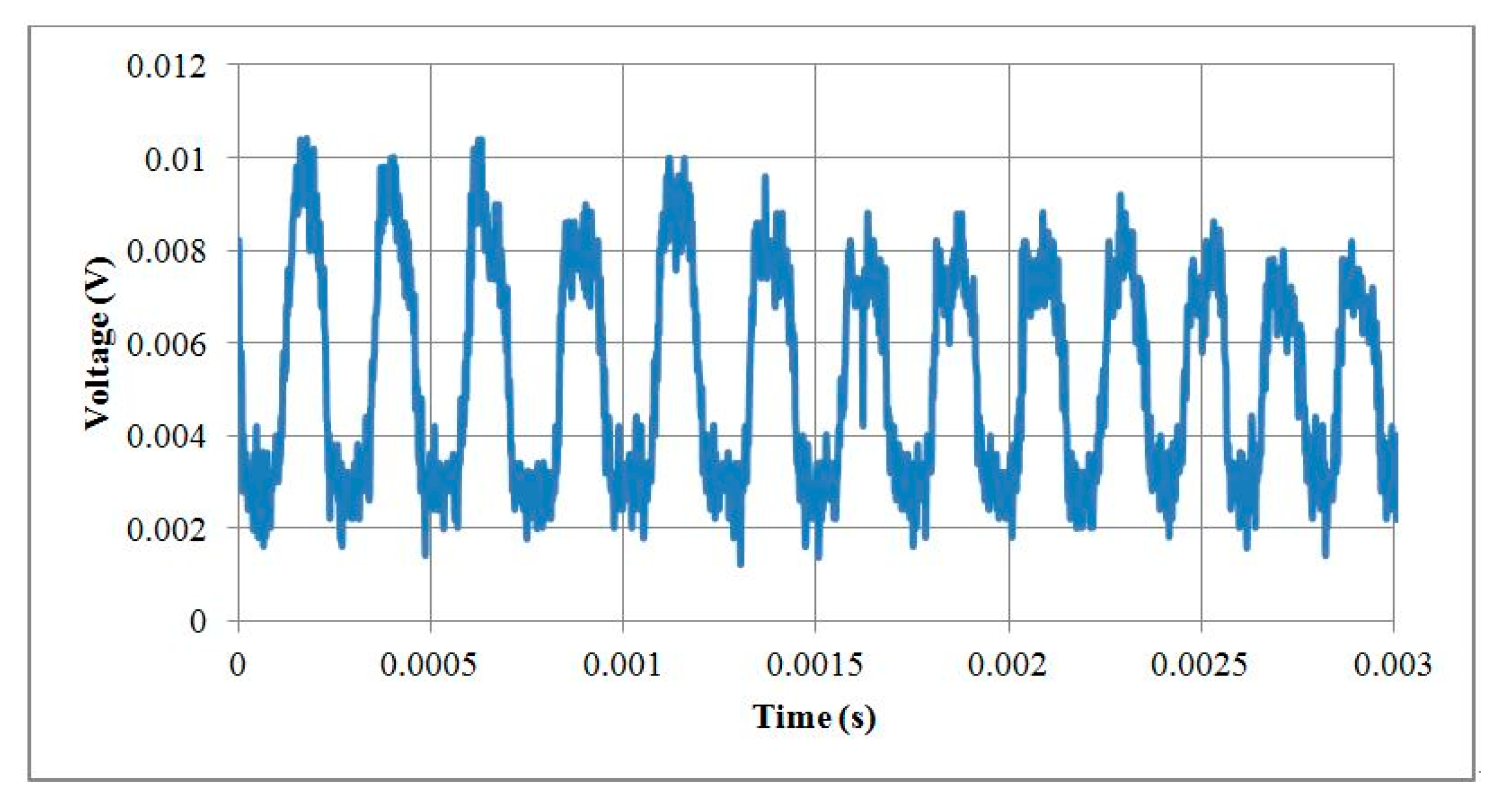

5.3. Testing Motors with a Rotary Encoder

6. Discussion

- Due to the difficulties in measuring magnetic flux density in micromotors, only the motor constant values could be tested to support the theoretical analysis. A comparison of the theoretical and the experimental KV and KT data showed that losses were caused by friction, which led to lower efficiency.

- Brass was used to make the micromotor bearings developed in this study. The run-out was relatively large. The use of bearings made from ruby or other high-quality materials could solve the issue of the high run-out in the motors.

- Due to the restrictions on the FPC, such as line width, line space, and thickness, the maximum current was only 0.3 A. This resulted in a lower maximum flux density, leading to a limited performance in the output torque.

- The run-out in the developed micromotors was relatively large. Moreover, the core of the optical fiber was 50 µm, which limited the number of reflection gratings of the encoder. This led to poor signal transmission and sensor resolution. Further improvements are required with respect to optical fiber equipment and the run-out in order to increase the resolution.

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fan, L.S.; Tai, Y.C.; Muller, R.S. IC-processed electrostatic micro-motors. In Proceedings of the IEEE International Electron Devices Meeting, San Francisco, CA, USA, 11–14 December 1988; pp. 666–669. [Google Scholar]

- Mehregany, M.; Nagarkar, P.; Senturia, S.D.; Lang, J.H. Operation of microfabricated harmonic and ordinary side-drive motors. In Proceedings of the IEEE Workshop on Micro Electro Mechanical Systems, Nappa Valley, CA, USA, 11–14 February 1990; pp. 1–8. [Google Scholar]

- Guckel, H.; Skrobis, K.J.; Christenson, T.R.; Klein, J.; Han, S.; Choi, B.; Lovell, E.G.; Chapman, T.W. Fabrication and testing of the planar magnetic micro motor. J. Micromech. Microeng. 1991, 1, 135–138. [Google Scholar] [CrossRef]

- Guckel, H.; Christenson, T.R.; Skrobis, K.J.; Jung, T.S.; Klein, J.; Hartojo, K.V.; Widjaja, I. A first functional current excited planar rotational magnetic micro motor. In Proceedings of the IEEE Micro Electro Mechanical Systems, Fort Lauderadle, FL, USA, 10–10 February 1993; pp. 7–11. [Google Scholar]

- Wanger, B.; Kreutzer, M.; Benecke, W. Permanent Magnet Micromotors on Silicon Substrates. J. Microelectromech. Syst. 1993, 2, 23–29. [Google Scholar]

- Ota, H.; Oda, T.; Kobayashi, M. Development of coil winding process for radial gap type electromagnetic micro-rotating machine. In Proceedings of the IEEE Micro Electro Mechanical Systems, Amsterdam, The Netherlands, 29 January–2 February 1995; p. 197. [Google Scholar]

- Kim, J.H.; Jung, I.S.; Sung, H.G. Design and Manufacturing of Ultra Small Actuator. In Proceedings of the IEEE International Conference on Mechatronics, Budapest, Hungary, 3–5 July 2006; pp. 23–26. [Google Scholar]

- Waldschik, A.; Feldmann, M.; Buttgenbach, S. Novel Synchronous Linear and Rotatory Micro Motors based on Polymer Magnets with Organic and Inorganic Insulation Layers. J. Sens. Transducers 2008, 3, 3–13. [Google Scholar]

- Merzaghi, S.; Koechli, C.; Perriard, Y. Development of a Hybrid MEMS BLDC Micromotor. IEEE Trans. Ind. Appl. 2011, 47, 3–11. [Google Scholar] [CrossRef]

- Wang, T.; Lancée, C.; Beurskens, R.; Meijer, J.; Knapen, B.; van der Steen, A.F.; van Soest, G. Development of a high-speed synchronous micro motor and its application in intravascular imaging. Sens. Actuators A Phys. 2014, 218, 60–68. [Google Scholar] [CrossRef]

- Büttgenbach, S. Electromagnetic micromotors—Design, fabrication and applications. Micromachines 2014, 5, 929–942. [Google Scholar] [CrossRef]

- Sawada, R.; Tanaka, H.; Ohguchi, O.; Shimada, J.; Hara, S. Fabrication of active integrated optical micro-encoder. In Proceedings of the IEEE Workshop on Micro Electro Mechanical Systems (MEMS’91), Nara, Japan, 30 January–2 February 1991; pp. 233–238. [Google Scholar]

- Sawada, R.; Ohguchi, O.; Mise, K.; Tsubamoto, M. Fabrication of advanced integrated optical micro-encoder chip. In Proceedings of the IEEE Workshop on Micro Electro Mechanical (MEMS’94), Oiso, Japan, 25–28 January 1994; pp. 337–342. [Google Scholar]

- Miyajima, H.; Yamamoto, E.; Yanagisawa, K. Optical micro encoder using a twin-beam VCSEL with integrated microlenses. In Proceedings of the International Conference on Solid State Sensors and Actuators, Chicago, IL, USA, 16–19 June 1997; pp. 1233–1235. [Google Scholar]

- Sawada, R.; Higurashi, E.; Jin, Y. Hybrid Microlaser Encoder. J. Lightwave Technol. 2003, 21, 815–820. [Google Scholar] [CrossRef]

- Nagao, S.; Oohira, F.; Hosogi, M.; Hashiguchi, G. Rotary Comb Drive Actuator with an Optical Fiber Encoder. In Proceedings of the IEEE/LEOS International Conference on Optical MEMS and Their Applications Conference, Big Sky, MT, USA, 21–24 August 2006; pp. 98–99. [Google Scholar]

- Shinozaki, R.; Oohira, F.; Terao, K.; Suzuki, T.; Simokawa, F.; Takao, H. Design and fabrication of electrostatically driven in-plane MEMS rotational mirror with electrostatic rotary encoder. In Proceedings of the International Conference on Optical MEMS and Nanophotonics (OMN), Banff, AB, Canada, 6–9 August 2012; pp. 107–108. [Google Scholar]

| Mechanical Specifications of a 1 mm Diameter Motor | |||||

| Stator | External Diameter | 1 mm | Rotor | External Diameter | 0.64 mm |

| Internal Diameter | 0.74 mm | Internal Diameter | 0.2 mm | ||

| Length | 2.5 mm | Length | 1 mm | ||

| Air gap | 0.1 mm | Number of Poles | 2 | ||

| Mechanical Specifications of a 1.5 mm Diameter Motor | |||||

| Stator | External Diameter | 1.5 mm | Rotor | External Diameter | 1 mm |

| Internal Diameter | 1.4 mm | Internal Diameter | 0.3 mm | ||

| Length | 4.1 mm | Length | 1.5 mm | ||

| Air Gap | 0.2 mm | Number of Poles | 2 | ||

| Electrical Specifications of Motors | |||||

| Number of Phases | 3 | Exciting Current | 0.3 A | ||

| Line Width 1 mm/1.5 mm | 50 µm/60 µm | Line Space 1 mm/1.5 mm | 50 µm/60 µm | ||

| Coil Turns 1 mm/1.5 mm | 6 turns/10 turns | Coil Resistance 1 mm/1.5 mm | 5.225 Ω/1 Ω | ||

| Diameter | Shell | Torque (nN∙m) | BEMF (mV) | Power (µW) |

|---|---|---|---|---|

| 1 mm | Cu | 159 | 1.14 | 89 |

| NiCo | 203 | 1.46 | 108 | |

| 1.5 mm | Cu | 430 | 3.04 | 154 |

| NiCo | 527 | 3.78 | 206 |

| Motor Type & Model | KT (nN∙m/A) | KV (nV/(rad/s)) |

|---|---|---|

| Copper shell analysis | 530.5 | 544.2 |

| Copper shell test | 282.5 | 448.3 |

| Nickel-cobalt shell analysis | 677.0 | 695.5 |

| Nickel-cobalt shell test | 343.3 | 656.3 |

| Motor Type & Model | KT (nN∙m/A) | KV (nV/(rad/s)) |

|---|---|---|

| Copper shell analysis | 1432.3 | 1452.2 |

| Copper shell test | 929.3 | 1323.5 |

| Nickel-cobalt shell analysis | 1755.3 | 1806.7 |

| Nickel-cobalt shell test | 1217.6 | 1638.4 |

| Bearing Type | Run-Out |

|---|---|

| Double-bearing | 5 µm |

| Single-bearing (L = 0.5 mm) | 20 µm |

| Single-bearing (L = 1 mm) | 2 µm |

| Housing Material | Run-Out |

|---|---|

| Copper | 20 µm |

| Nickel-cobalt | 40 µm |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, D.-C.; Lai, Y.-W. Rapid Prototyping of a Micromotor with an Optical Rotary Encoder. Micromachines 2017, 8, 174. https://doi.org/10.3390/mi8060174

Pang D-C, Lai Y-W. Rapid Prototyping of a Micromotor with an Optical Rotary Encoder. Micromachines. 2017; 8(6):174. https://doi.org/10.3390/mi8060174

Chicago/Turabian StylePang, Da-Chen, and Yi-Wei Lai. 2017. "Rapid Prototyping of a Micromotor with an Optical Rotary Encoder" Micromachines 8, no. 6: 174. https://doi.org/10.3390/mi8060174

APA StylePang, D.-C., & Lai, Y.-W. (2017). Rapid Prototyping of a Micromotor with an Optical Rotary Encoder. Micromachines, 8(6), 174. https://doi.org/10.3390/mi8060174