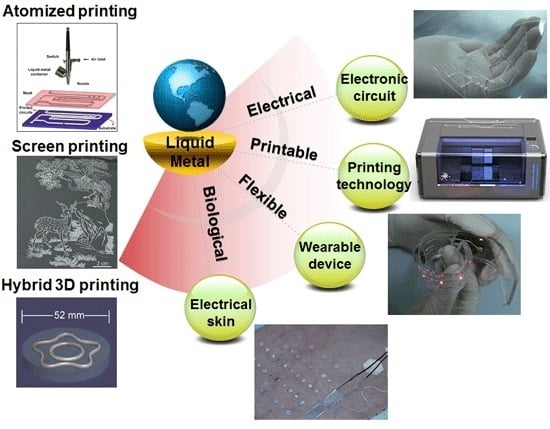

Recent Advancements in Liquid Metal Flexible Printed Electronics: Properties, Technologies, and Applications

Abstract

:1. Introduction

2. Basic Properties of Liquid Metal

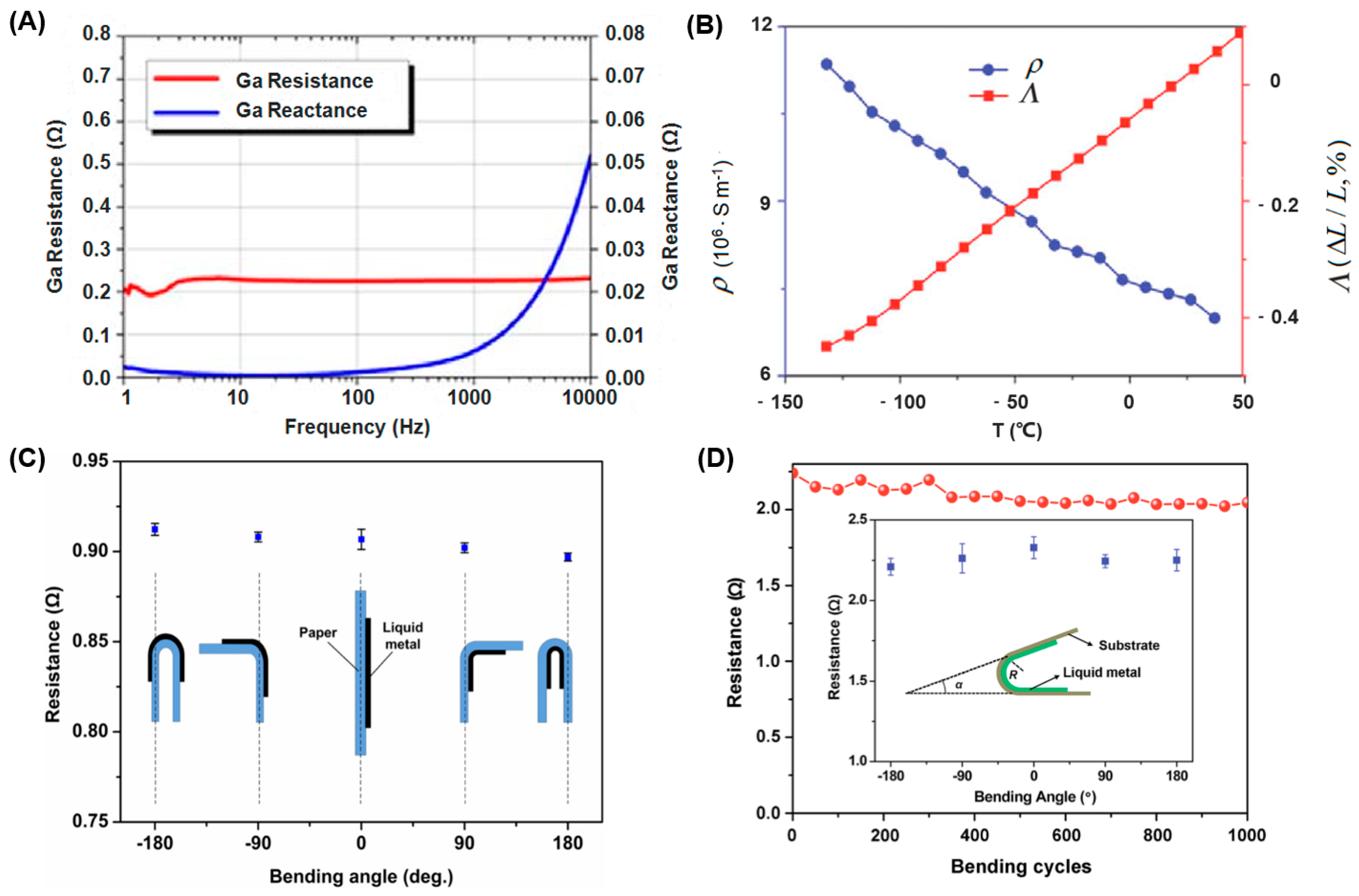

2.1. Resistivity

2.2. Superior Flexibility

2.3. Tunable Adhesion

2.4. Prominent Wettability

3. Printing Technologies and Apparatuses

3.1. Printing Electronic Circuit

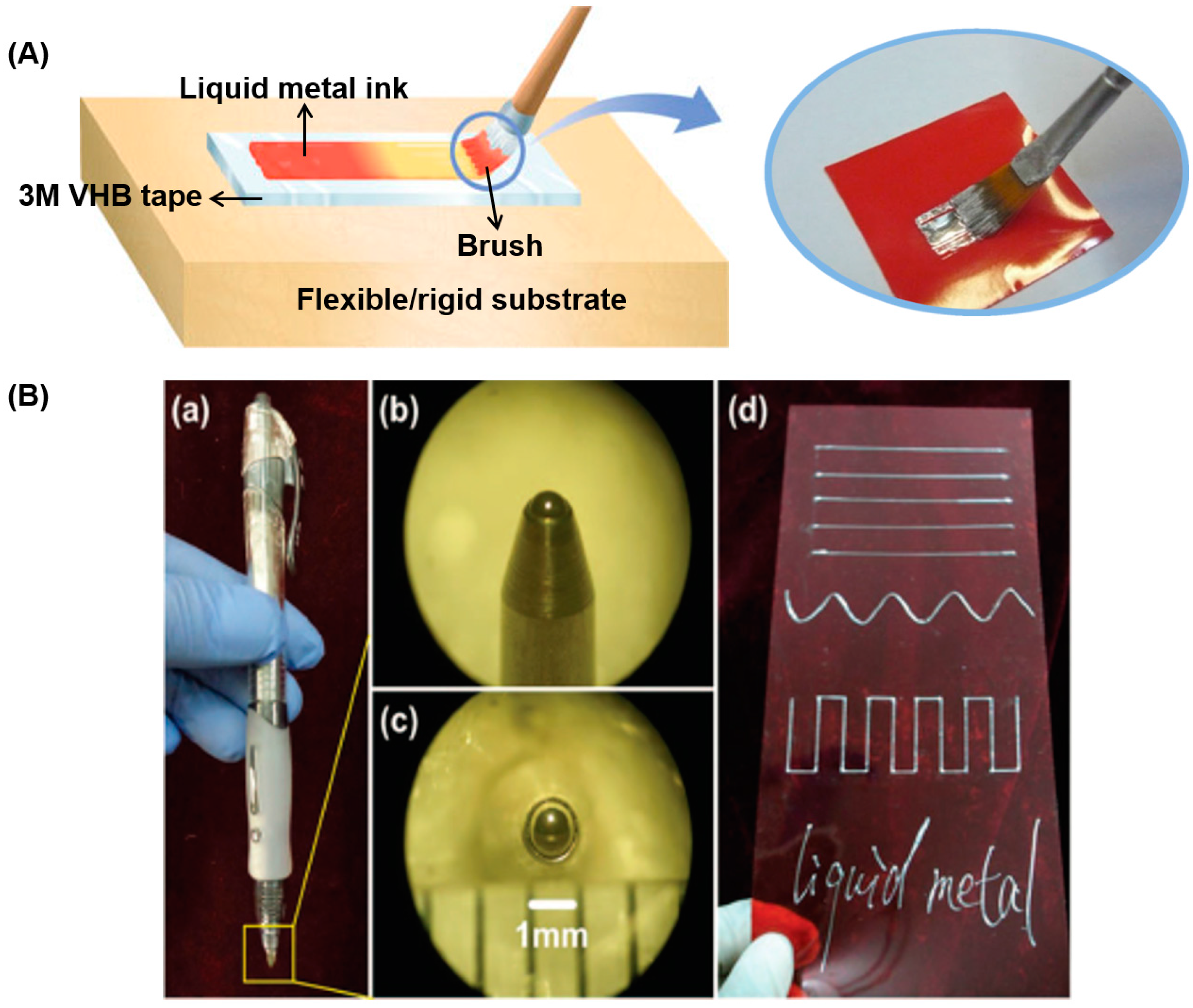

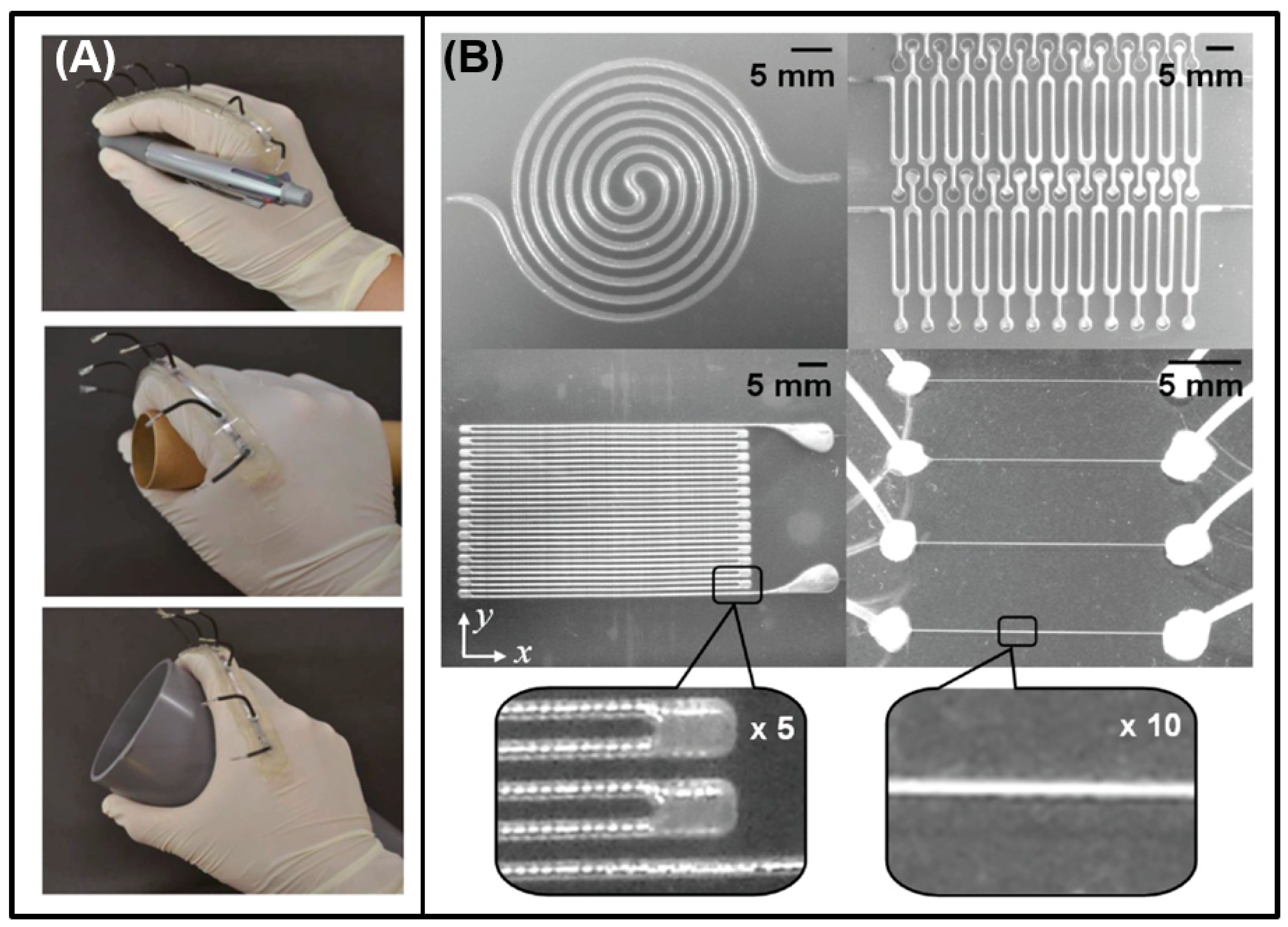

3.1.1. Direct Painting or Writing

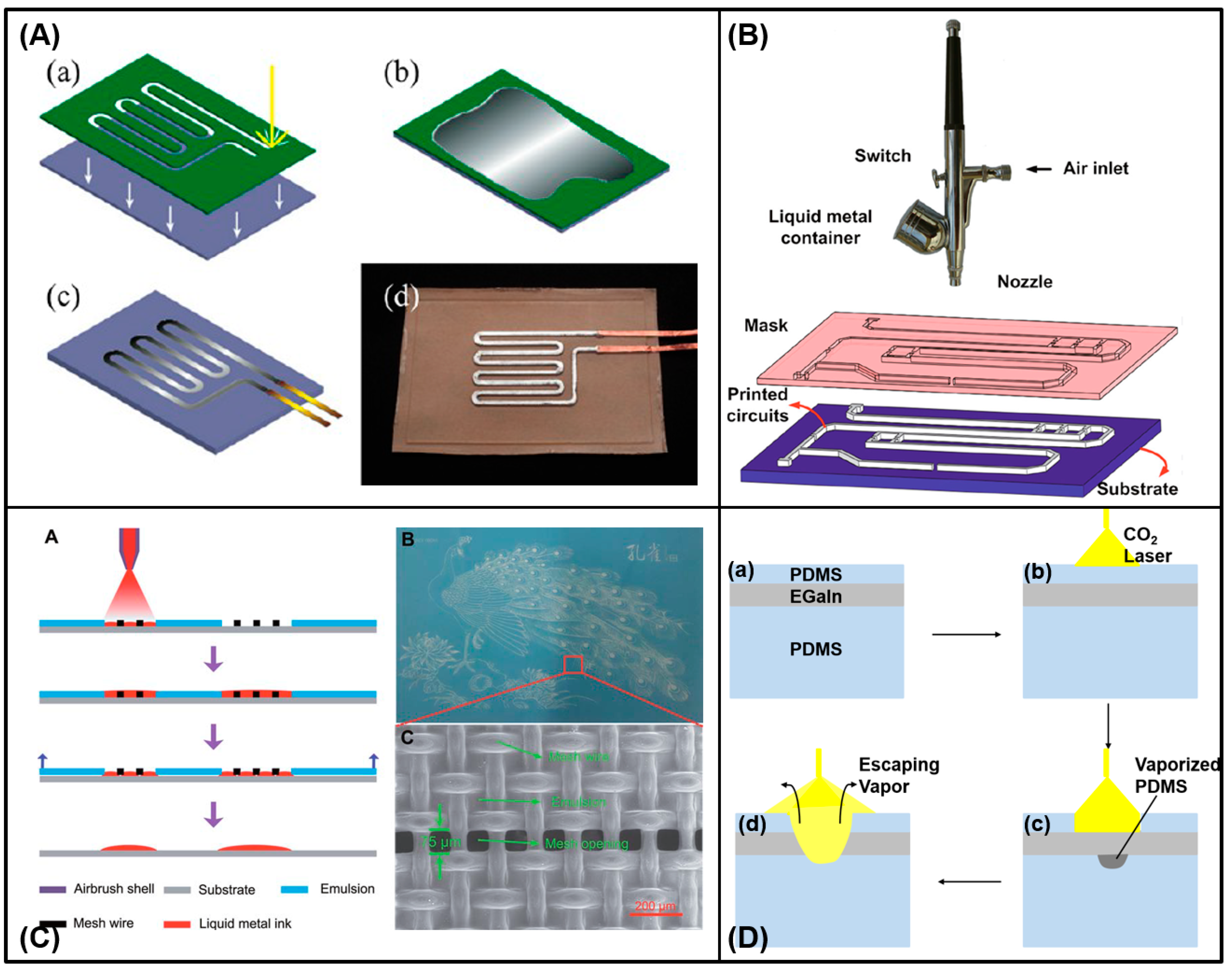

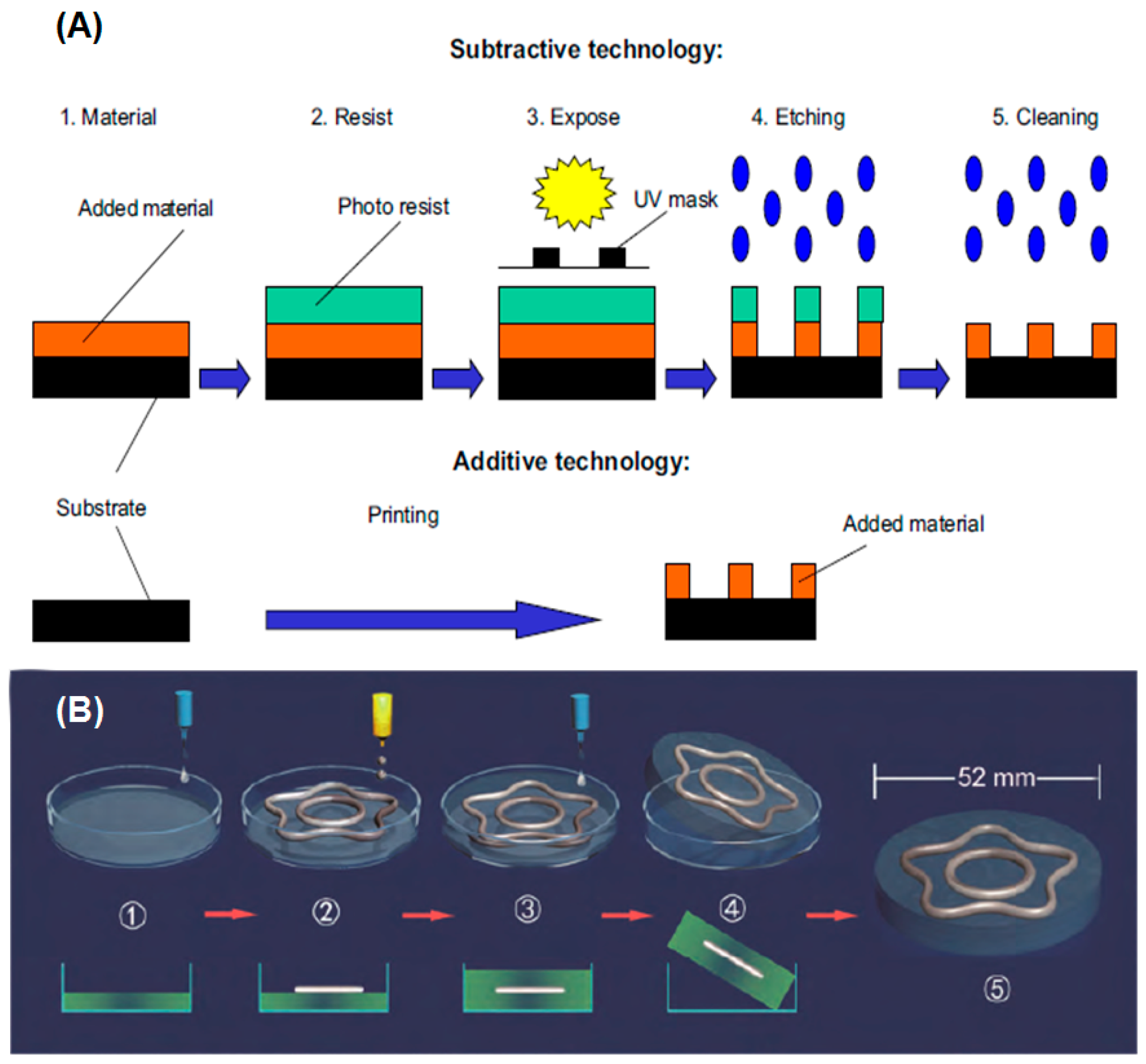

3.1.2. Mechanical Printing Methods

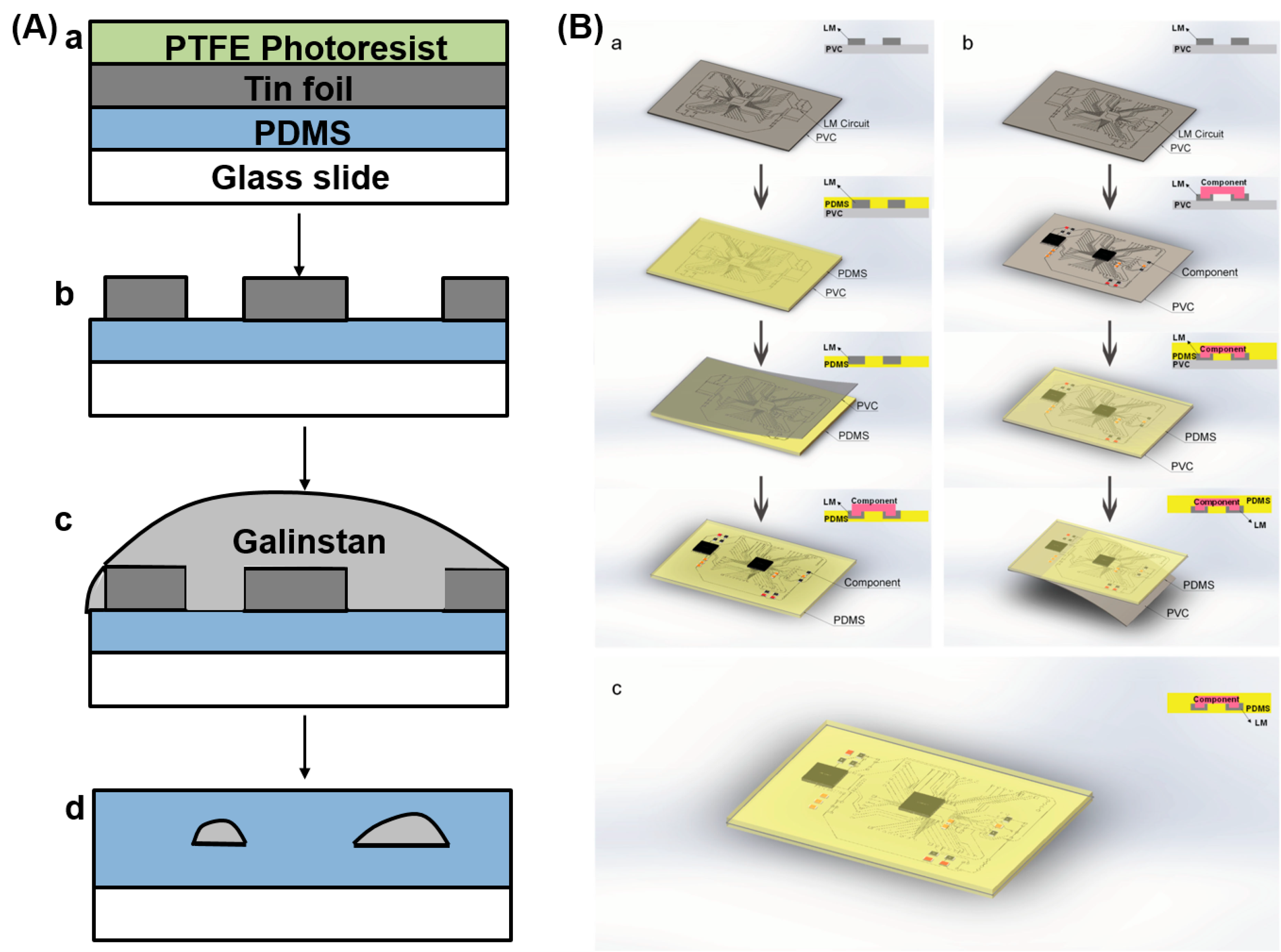

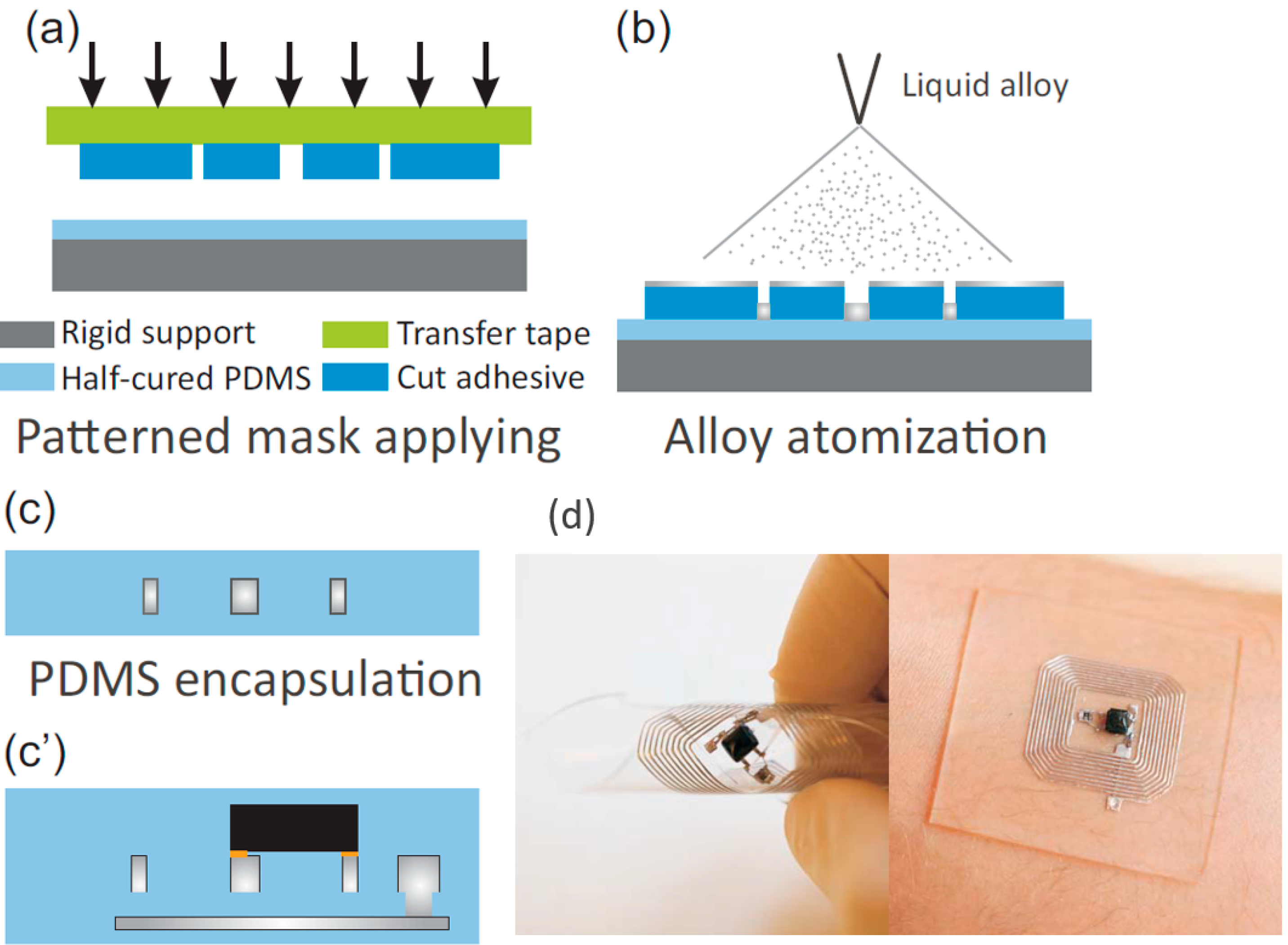

3.1.3. Mask-Based Printing Methods

3.1.4. High-Resolution Nanoimprint Lithography

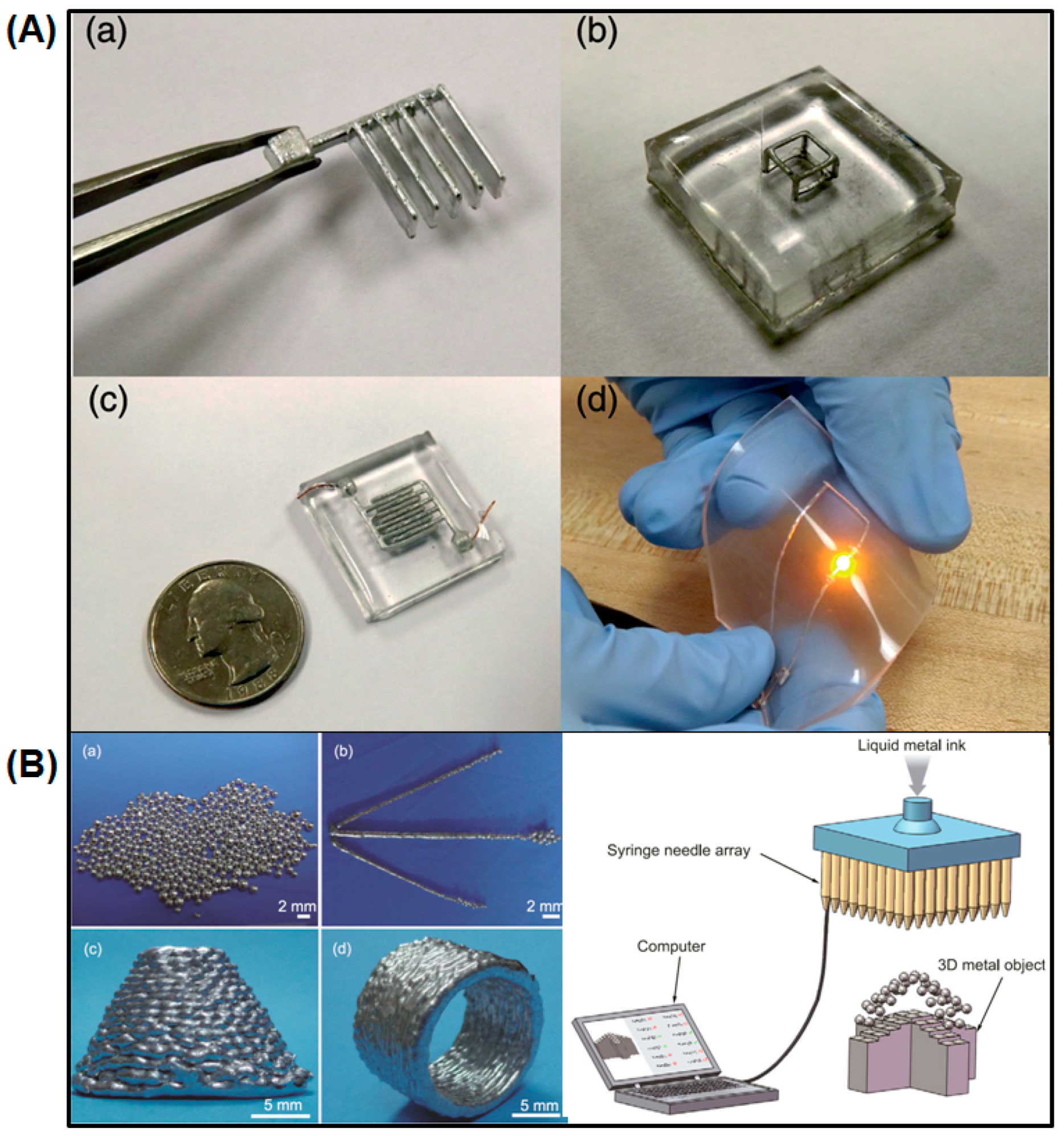

3.2. 3D Printing

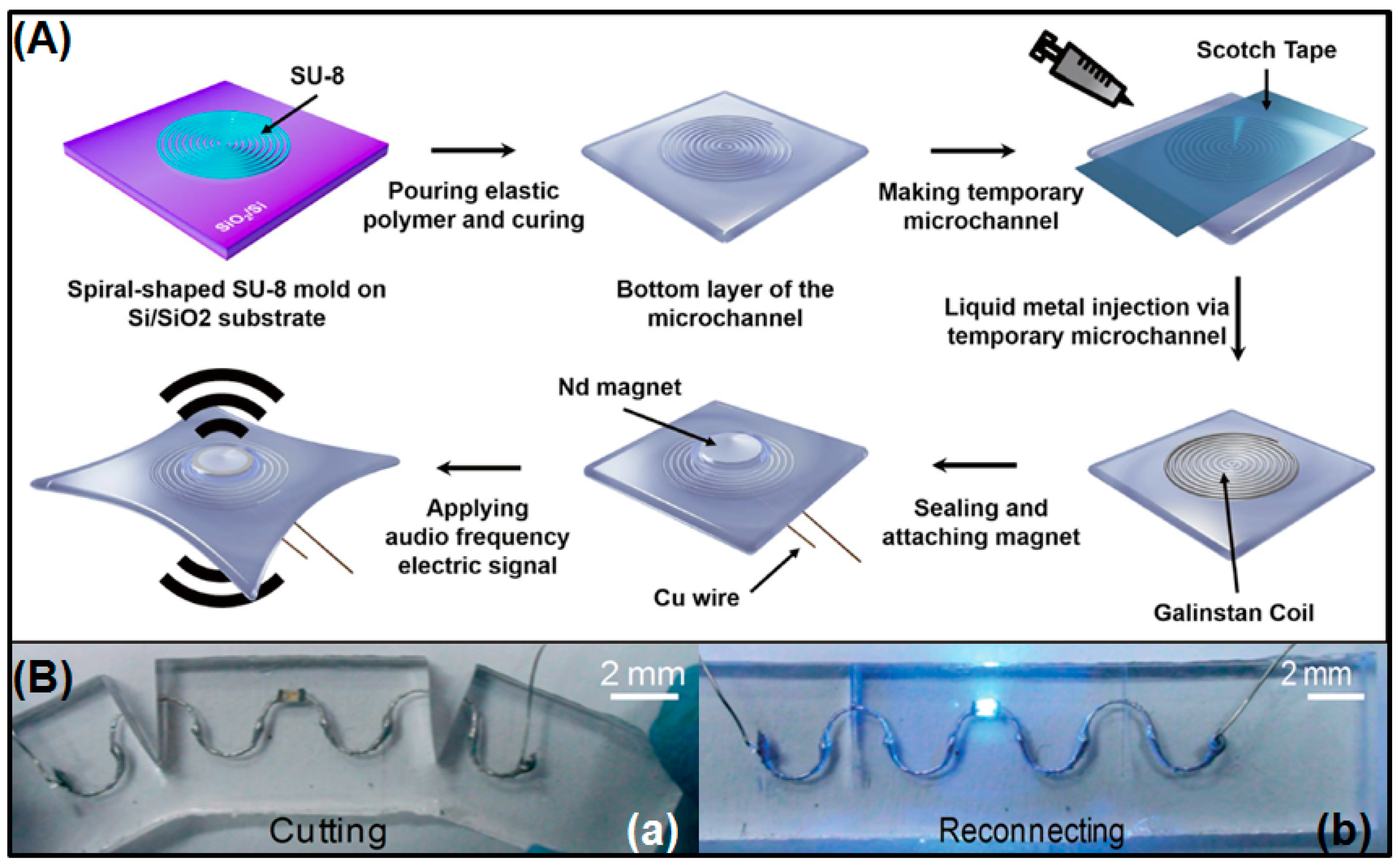

3.3. Printing Devices

4. Typical Applications

5. Discussion and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cui, Z. Printed Electronics: Materials, Technologies and Applications; Higher Education Press: Beijing, China, 2012. [Google Scholar]

- Lin, Y.; Gritsenko, D.; Liu, Q.; Lu, X.; Xu, J. Recent advancements in functionalized paper-based electronics. ACS Appl. Mater. Interfaces 2016, 8, 20501–20515. [Google Scholar] [CrossRef] [PubMed]

- Yin, Z.; Huang, Y.; Bu, N.; Wang, X.; Xiong, Y. Inkjet printing for flexible electronics: Materials, processes and equipments. Chin. Sci. Bull. 2010, 55, 3383–3407. [Google Scholar] [CrossRef]

- Wong, W.S.; Salleo, A. Flexible Electronics: Materials and Applications; Springer: New York, NY, USA, 2009. [Google Scholar]

- Reuss, R.H.; Chalamala, B.R.; Moussessian, A.; Kane, M.G.; Kumar, A.; Zhang, D.C.; Rogers, J.A.; Hatalis, M.; Temple, D.; Moddel, G.; et al. Macroelectronics: Perspectives on technology and applications. Proc. IEEE 2005, 93, 1239–1256. [Google Scholar] [CrossRef]

- Kim, D.-H.; Ahn, J.-H.; Choi, W.M.; Kim, H.-S.; Kim, T.-H.; Song, J.; Huang, Y.Y.; Liu, Z.; Lu, C.; Rogers, J.A. Stretchable and foldable silicon integrated circuits. Science 2008, 320, 507–511. [Google Scholar] [CrossRef] [PubMed]

- Crawford, G.P. Flexible Flat Panel Displays; John Wiley & Sons, Ltd.: New York, NY, USA, 2005. [Google Scholar]

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed]

- Koo, M.; Park, K.-I.; Lee, S.H.; Suh, M.; Jeon, D.Y.; Cho, J.W.; Kang, K.; Lee, K.J. Bendable inorganic thin-film battery for fully flexible electronic systems. NANO Lett. 2012, 12, 4810–4816. [Google Scholar] [CrossRef] [PubMed]

- Reeder, J.; Kaltenbrunner, M.; Ware, T.; Arreaga-Salas, D.; Avendano-Bolivar, A.; Yokota, T.; Inoue, Y.; Sekino, M.; Voit, W.; Sekitani, T.; et al. Mechanically adaptive organic transistors for implantable electronics. Adv. Mater. 2014, 26, 4967–4973. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.-Y.; Kim, T.-I.; Choi, M. Ultrasensitive mechanical crack-based sensor inspired by the spider sensory system. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef] [PubMed]

- Russo, A.; Ahn, B.Y.; Adams, J.J.; Duoss, E.B.; Bernhard, J.T.; Lewis, J.A. Pen-on-paper flexible electronics. Adv. Mater. 2011, 23, 3426–3430. [Google Scholar] [CrossRef] [PubMed]

- Jung, I.; Shin, G.; Malyarchuk, V.; Ha, J.S.; Rogers, J.A. Paraboloid electronic eye cameras using deformable arrays of photodetectors in hexagonal mesh layouts. Appl. Phys. Lett. 2010, 96, 021110. [Google Scholar] [CrossRef]

- Schwartz, G.; Tee, B.C.K.; Mei, J.; Appleton, A.L.; Kim, D.H.; Wang, H.; Bao, Z. Flexible polymer transistors with high pressure sensitivity for application in electronic skin and health monitoring. Nat. Commun. 2013, 4, 54–56. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Dong, L.; Zhang, H.; Yu, R.; Pan, C.; Wang, Z.L. Recent progress in electronic skin. Adv. Sci. 2015, 2, 10. [Google Scholar] [CrossRef]

- Kim, D.-H.; Lu, N.; Ma, R.; Kim, Y.-S.; Kim, R.-H.; Wang, S.; Wu, J.; Won, S.M.; Tao, H.; Islam, A.; et al. Epidermal electronics. Science 2011, 333, 838–843. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.M.; Song, J.; Khang, D.-Y.; Jiang, H.; Huang, Y.Y.; Rogers, J.A. Biaxially stretchable “wavy” silicon nanomembranes. NANO Lett. 2007, 7, 1655–1663. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; He, Z.-Z.; Yang, J.; Liu, J. Personal electronics printing via tapping mode composite liquid metal ink delivery and adhesion mechanism. Sci. Rep. 2014, 4, 101–104. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, D.; Maki, S.P.; Lyons, C.; Theiss, S.D.; Owings, R.R. Hybrid dielectric thin films on flexible substrates for embedded capacitor applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2016, 6, 941–945. [Google Scholar] [CrossRef]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet printing-process and its applications. Adv. Mater. 2010, 22, 673–685. [Google Scholar] [CrossRef] [PubMed]

- MicroPen Technologies. Available online: http://www.Micropen.com/ (accessed on 1 September 2016).

- Kim, S.S.; Na, S.I.; Jo, J.; Tae, G.; Kim, D.Y. Efficient polymer solar cells fabricated by simple brush painting. Adv. Mater. 2007, 19, 4410–4415. [Google Scholar] [CrossRef]

- Jang, J. Displays develop a new flexibility. Mater. Today 2006, 9, 46–52. [Google Scholar] [CrossRef]

- Krebs, F.C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol. Energy Mater. Sol. Cells 2009, 93, 394–412. [Google Scholar] [CrossRef]

- Mayer, A.C.; Scully, S.R.; Hardin, B.E.; Rowell, M.W.; McGehee, M.D. Polymer-based solar cells. Mater. Today 2007, 10, 28–33. [Google Scholar] [CrossRef]

- Someya, T.; Kato, Y.; Sekitani, T.; Iba, S.; Noguchi, Y.; Murase, Y.; Kawaguchi, H.; Sakurai, T. Conformable, flexible, large-area networks of pressure and thermal sensors with organic transistor active matrixes. Proc. Natl. Acad. Sci. USA 2005, 102, 12321–12325. [Google Scholar] [CrossRef] [PubMed]

- Madden, P.G.A. Development and Modeling of Conducting Polymer Actuators and the Fabrication of a Conducting Polymer Based Feedback Loop; Massachusetts Institute of Technology: Cambridge, MA, USA, 2003. [Google Scholar]

- Hammock, M.L.; Chortos, A.; Tee, B.C.K.; Tok, J.B.H.; Bao, Z. 25th anniversary article: The evolution of electronic skin (e-skin): A brief history, design considerations, and recent progress. Adv. Mater. 2013, 25, 5997–6038. [Google Scholar] [CrossRef] [PubMed]

- So, J.-H.; Koo, H.-J.; Dickey, M.D.; Velev, O.D. Ionic current rectification in soft-matter diodes with liquid-metal electrodes. Adv. Funct. Mater. 2012, 22, 625–631. [Google Scholar] [CrossRef]

- Niu, S.; Wang, X.; Yi, F.; Zhou, Y.S.; Wang, Z.L. A universal self-charging system driven by random biomechanical energy for sustainable operation of mobile electronics. Nat. Commun. 2015, 6, 8975. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.; Zhang, H.; Shi, B.; Xue, X.; Liu, Z.; Jin, Y.; Ma, Y.; Zou, Y.; Wang, X.; An, Z.; et al. In vivo self-powered wireless cardiac monitoring via implantable triboelectric nanogenerator. ACS Nano 2016, 10, 6510–6518. [Google Scholar] [CrossRef] [PubMed]

- Rogers, J.A.; Bao, Z.; Baldwin, K.; Dodabalapur, A.; Crone, B.; Raju, V.R.; Kuck, V.; Katz, H.; Amundson, K.; Ewing, J.; et al. Paper-like electronic displays: Large-area rubber-stamped plastic sheets of electronics and microencapsulated electrophoretic inks. Proc. Natl. Acad. Sci. USA 2001, 98, 4835–4840. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Tian, H.; Mohammad, M.A.; Li, C.; Wu, C.; Yang, Y.; Ren, T.-L. A spectrally tunable all-graphene-based flexible field-effect light-emitting device. Nat. Commun. 2015, 6, 37–42. [Google Scholar] [CrossRef] [PubMed]

- Lessing, J.; Morin, S.A.; Keplinger, C.; Tayi, A.S.; Whitesides, G.M. Stretchable conductive composites based on metal wools for use as electrical vias in soft devices. Adv. Funct. Mater. 2015, 25, 1418–1425. [Google Scholar] [CrossRef]

- Zhang, J.; Sheng, L.; Jin, C.; Liu, J. Liquid Metal as Connecting or Functional Recovery Channel for the Transected Sciatic Nerve. Available online: https://arxiv.org/abs/1404.5931 (accessed on 28 September 2016).

- Liu, F.; Yu, Y.; Yi, L.; Liu, J. Liquid metal as reconnection agent for peripheral nerve injury. Sci. Bull. 2016, 61, 939–947. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Yu, R.; Dong, L.; Peng, D.; Zhang, A.; Zhang, Y.; Liu, H.; Pan, C.; Wang, Z.L. Dynamic pressure mapping of personalized handwriting by a flexible sensor matrix based on the mechanoluminescence process. Adv. Mater. 2015, 27, 2324–2331. [Google Scholar] [CrossRef] [PubMed]

- Tee, B.C.K.; Wang, C.; Allen, R.; Bao, Z. An electrically and mechanically self-healing composite with pressure- and flexion-sensitive properties for electronic skin applications. Nat. Nano 2012, 7, 825–832. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Lee, M.; Shim, H.J.; Ghaffari, R.; Cho, H.R.; Son, D.; Jung, Y.H.; Soh, M.; Choi, C.; Jung, S.; et al. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat. Commun. 2014, 5, 5747. [Google Scholar] [CrossRef] [PubMed]

- Tee, B.C.-K.; Chortos, A.; Berndt, A.; Nguyen, A.K.; Tom, A.; McGuire, A.; Lin, Z.C.; Tien, K.; Bae, W.-G.; Wang, H.; et al. A skin-inspired organic digital mechanoreceptor. Science 2015, 350, 313–316. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Li, M.; Wu, J.; Kim, D.-H.; Lu, N.; Su, Y.; Kang, Z.; Huang, Y.; Rogers, J.A. Mechanics of epidermal electronics. J. Appl. Mech. 2012, 79, 031022. [Google Scholar] [CrossRef]

- Webb, R.C.; Ma, Y.; Krishnan, S.; Li, Y.; Yoon, S.; Guo, X.; Feng, X.; Shi, Y.; Seidel, M.; Cho, N.H.; et al. Epidermal devices for noninvasive, precise, and continuous mapping of macrovascular and microvascular blood flow. Sci. Adv. 2015, 1, e1500701. [Google Scholar] [CrossRef] [PubMed]

- Rajan, K.; Bocchini, S.; Chiappone, A.; Roppolo, I.; Perrone, D.; Bejtka, K.; Ricciardi, C.; Pirri, C.F.; Chiolerio, A. Spin-coated silver nanocomposite resistive switching devices. Microelectron. Eng. 2017, 168, 27–31. [Google Scholar] [CrossRef]

- Chiolerio, A.; Roppolo, I.; Bejtka, K.; Asvarov, A.; Pirri, C.F. Resistive hysteresis in flexible nanocomposites and colloidal suspensions: Interfacial coupling mechanism unveiled. RSC Adv. 2016, 6, 56661–56667. [Google Scholar] [CrossRef]

- Tai, Y.L. Preparation and Application of Conductive Ink for Printed Electronics. Ph.D. Thesis, Fudan University, Shanghai, China, 2012. [Google Scholar]

- Rajan, K.; Roppolo, I.; Chiappone, A.; Bocchini, S.; Perrone, D.; Chiolerio, A. Silver nanoparticle ink technology: State of the art. Nanotechnol. Sci. Appl. 2016, 9, 1–13. [Google Scholar] [PubMed]

- Xiong, Z.; Liu, C. Optimization of inkjet printed PEDOT:PSS thin films through annealing processes. Org. Electron. 2012, 13, 1532–1540. [Google Scholar] [CrossRef]

- Chiolerio, A.; Bocchini, S.; Scaravaggi, F.; Porro, S.; Perrone, D.; Beretta, D.; Caironi, M.; Pirri, C.F. Synthesis of polyaniline-based inks for inkjet printed devices: Electrical characterization highlighting the effect of primary and secondary doping. Semicond. Sci. Technol. 2015, 30, 104001. [Google Scholar] [CrossRef]

- Petukhov, D.I.; Kirikova, M.N.; Bessonov, A.A.; Bailey, M.J.A. Nickel and copper conductive patterns fabricated by reactive inkjet printing combined with electroless plating. Mater. Lett. 2014, 132, 302–306. [Google Scholar] [CrossRef]

- Plevachuk, Y.; Sklyarchuk, V.; Yakymovych, A.; Svec, P.; Janickovic, D.; Illekova, E. Electrical conductivity and viscosity of liquid Sn–Sb–Cu alloys. J. Mater. Sci. Mater. Electron. 2011, 22, 631–638. [Google Scholar] [CrossRef]

- Yi, L.; Jin, C.; Wang, L.; Liu, J. Liquid-solid phase transition alloy as reversible and rapid molding bone cement. Biomaterials 2014, 35, 9789–9801. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Yu, Y.; Pan, K.; Liu, J. Liquid metal angiography for mega contrast X-ray visualization of vascular network in reconstructing in vitro organ anatomy. IEEE Trans. Biomed. Eng. 2014, 61, 2161–2166. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Hu, Q.; Lin, Y.; Pacardo, D.B.; Wang, C.; Sun, W.; Ligler, F.S.; Dickey, M.D.; Gu, Z. Transformable liquid-metal nanomedicine. Nat. Commun. 2015, 6, 10066. [Google Scholar] [CrossRef] [PubMed]

- Jin, C.; Zhang, J.; Li, X.; Yang, X.; Li, J.; Liu, J. Injectable 3-D fabrication of medical electronics at the target biological tissues. Sci. Rep. 2013, 3, 3442. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.; Yu, Y.; Liu, J. Rapidly patterning conductive components on skin substrates as physiological testing devices via liquid metal spraying and pre-designed mask. J. Mater. Chem. B 2014, 2, 5739–5745. [Google Scholar] [CrossRef]

- Jeong, S.H.; Hagman, A.; Hjort, K.; Jobs, M.; Sundqvist, J.; Wu, Z. Liquid alloy printing of microfluidic stretchable electronics. Lab Chip 2012, 12, 4657–4664. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Zhang, J.; Liu, J. Biomedical implementation of liquid metal ink as drawable ecg electrode and skin circuit. PLoS ONE 2013, 8, e58771. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Yu, Y.; Yang, J.; Liu, J. Fast fabrication of flexible functional circuits based on liquid metal dual-trans printing. Adv. Mater. 2015, 27, 7109–7116. [Google Scholar] [CrossRef] [PubMed]

- Matsuzaki, R.; Tabayashi, K. Highly stretchable, global, and distributed local strain sensing line using gainsn electrodes for wearable electronics. Adv. Funct. Mater. 2015, 25, 3806–3813. [Google Scholar] [CrossRef]

- Krupenkin, T.; Taylor, J.A. Reverse electrowetting as a new approach to high-power energy harvesting. Nat. Commun. 2011, 2, 73–86. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Liu, J. Research advancement of liquid metal printed electronics ink (in Chinese). Imaging Sci. Photochem. 2014, 32, 382–392. [Google Scholar]

- Zhang, Q.; Zheng, Y.; Liu, J. Direct writing of electronics based on alloy and metal (dream) ink: A newly emerging area and its impact on energy, environment and health sciences. Front. Energy 2012, 6, 311–340. [Google Scholar] [CrossRef]

- Gao, Y.; Li, H.; Liu, J. Direct writing of flexible electronics through room temperature liquid metal ink. PLoS ONE 2012, 7, e45485. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Liu, J. Compatible hybrid 3D printing of metal and nonmetal inks for direct manufacture of end functional devices. Sci. China Technol. Sci. 2014, 57, 2089–2095. [Google Scholar] [CrossRef]

- Tripathi, V.; Loh, Y.L. Thermal conductivity of a granular metal. Phys. Rev. Lett. 2006, 96, 046805. [Google Scholar] [CrossRef] [PubMed]

- Gozen, B.A.; Tabatabai, A.; Ozdoganlar, O.B.; Majidi, C. High-density soft-matter electronics with micron-scale line width. Adv. Mater. 2014, 26, 5211–5216. [Google Scholar] [CrossRef] [PubMed]

- Sivan, V.; Tang, S.-Y.; O’Mullane, A.P.; Petersen, P.; Eshtiaghi, N.; Kalantar-zadeh, K.; Mitchell, A. Liquid metal marbles. Adv. Funct. Mater. 2013, 23, 144–152. [Google Scholar] [CrossRef]

- Du, K.; Glogowski, E.; Tuominen, M.T.; Emrick, T.; Russell, T.P.; Dinsmore, A.D. Self-assembly of gold nanoparticles on gallium droplets: Controlling charge transport through microscopic devices. Langmuir 2013, 29, 13640–13646. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; He, Z.; Gao, Y.; Liu, J. Direct desktop printed-circuits-on-paper flexible electronics. Sci. Rep. 2013, 3, 1786. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J. Pressured liquid metal screen printing for rapid manufacture of high resolution electronic patterns. RSC Adv. 2015, 5, 57686–57691. [Google Scholar] [CrossRef]

- Kim, D.; Lee, Y.; Lee, D.-W.; Choi, W.; Yoo, K.; Lee, J.-B. Hydrochloric acid-impregnated paper for gallium-based liquid metal microfluidics. Sens. Actuators B Chem. 2015, 207, 199–205. [Google Scholar] [CrossRef]

- Kubo, M.; Li, X.; Kim, C.; Hashimoto, M.; Wiley, B.J.; Ham, D.; Whitesides, G.M. Stretchable microfluidic radiofrequency antennas. Adv. Mater. 2010, 22, 2749–2752. [Google Scholar] [CrossRef] [PubMed]

- Boley, J.W.; White, E.L.; Chiu, G.T.C.; Kramer, R.K. Direct writing of gallium-indium alloy for stretchable electronics. Adv. Funct. Mater. 2014, 24, 3501–3507. [Google Scholar] [CrossRef]

- Kim, D.; Thissen, P.; Viner, G.; Lee, D.-W.; Choi, W.; Chabal, Y.J.; Lee, J.-B. Recovery of nonwetting characteristics by surface modification of gallium-based liquid metal droplets using hydrochloric acid vapor. ACS Appl. Mater. Interfaces 2013, 5, 179–185. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Gao, Y.; Liu, J. Atomized spraying of liquid metal droplets on desired substrate surfaces as a generalized way for ubiquitous printed electronics. Appl. Phys. A 2014, 116, 1091–1097. [Google Scholar] [CrossRef]

- Xu, Q.; Oudalov, N.; Guo, Q.; Jaeger, H.M.; Brown, E. Effect of oxidation on the mechanical properties of liquid gallium and eutectic gallium-indium. Phys. Fluids 2012, 24, 063101. [Google Scholar] [CrossRef]

- Schrader, M.E. Young-dupre revisited. Langmuir 1995, 11, 3585–3589. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, M.; Mei, S.; Han, Y.; Liu, J. Ultra-compliant liquid metal electrodes with in-plane self-healing capability for dielectric elastomer actuators. Appl. Phys. Lett. 2013, 103, 064101. [Google Scholar] [CrossRef]

- Tiberto, P.; Gupta, S.; Bianco, S.; Celegato, F.; Martino, P.; Chiolerio, A.; Tagliaferro, A.; Allia, P. Morphology and magnetic properties of island-like Co and Ni films obtained by de-wetting. J. Nanopart. Res. 2011, 13, 245–255. [Google Scholar] [CrossRef]

- Doudrick, K.; Liu, S.; Mutunga, E.M.; Klein, K.L.; Damle, V.; Varanasi, K.K.; Rykaczewski, K. Different shades of oxide: From nanoscale wetting mechanisms to contact printing of gallium-based liquid metals. Langmuir 2014, 30, 6867–6877. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Parmar, M.; Kim, D.; Lee, J.-B.; Lee, D.-W. Pdms based coplanar microfluidic channels for the surface reduction of oxidized galinstan. Lab Chip 2014, 14, 200–209. [Google Scholar] [CrossRef] [PubMed]

- Furmidge, C.G.L. Studies at phase interfaces. I. The sliding of liquid drops on solid surfaces and a theory for spray retention. J. Colloid Sci. 1962, 17, 309–324. [Google Scholar] [CrossRef]

- Kramer, R.K.; Boley, J.W.; Stone, H.A.; Weaver, J.C.; Wood, R.J. Effect of microtextured surface topography on the wetting behavior of eutectic gallium–indium alloys. Langmuir 2014, 30, 533–539. [Google Scholar] [CrossRef] [PubMed]

- Yi, L.T. Injectable Bone Cement Based on Low-Melting-Point Alloy with Liquid-Solid Phase Switchable Capability. Ph.D. Thesis, Tsinghua University, Beijing, China, 2015. [Google Scholar]

- Li, H.; Yang, Y.; Liu, J. Printable tiny thermocouple by liquid metal gallium and its matching metal. Appl. Phys. Lett. 2012, 101, 073511. [Google Scholar] [CrossRef]

- Liu, J.; Li, H. A Liquid Metal Based Printed Circuit Board and Its Fabrication Method. China Patent 201110140156, 14 October 2011. [Google Scholar]

- Tabatabai, A.; Fassler, A.; Usiak, C.; Majidi, C. Liquid-phase gallium–indium alloy electronics with microcontact printing. Langmuir 2013, 29, 6194–6200. [Google Scholar] [CrossRef] [PubMed]

- Kramer, R.K.; Majidi, C.; Wood, R.J. Masked deposition of gallium-indium alloys for liquid-embedded elastomer conductors. Adv. Funct. Mater. 2013, 23, 5292–5296. [Google Scholar] [CrossRef]

- Jeong, J.-A.; Kim, H.-K. Characteristics of inkjet-printed nano indium tin oxide particles for transparent conducting electrodes. Curr. Appl. Phys. 2010, 10, e105–e108. [Google Scholar] [CrossRef]

- Sheng, L.; Teo, S.; Liu, J. Liquid-metal-painted stretchable capacitor sensors for wearable healthcare electronics. J. Med. Biol. Eng. 2016, 36, 265–272. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J. Printing low-melting-point alloy ink to directly make a solidified circuit or functional device with a heating pen. Proc. R. Soc. A Math. Phys. Eng. Sci. 2014, 470, 0609. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Liu, J. Direct printing and assembly of fm radio at the user end via liquid metal printer. Circ. World 2014, 40, 134–140. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, Q.; Liu, J. Pervasive liquid metal based direct writing electronics with roller-ball pen. AIP Adv. 2013, 3, 6459–6463. [Google Scholar] [CrossRef]

- Kim, D.; Yoo, J.H.; Lee, Y.; Choi, W.; Yoo, K.; Lee, J.B.J. Gallium-Based Liquid Metal Inkjet Printing. In Proceedings of the 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014; pp. 967–970.

- Yang, H.; Lightner, C.R.; Dong, L. Light-emitting coaxial nanofibers. ACS Nano 2012, 6, 622–628. [Google Scholar] [CrossRef] [PubMed]

- Lu, T.; Finkenauer, L.; Wissman, J.; Majidi, C. Rapid prototyping for soft-matter electronics. Adv. Funct. Mater. 2014, 24, 3351–3356. [Google Scholar] [CrossRef]

- Jeong, S.H.; Hjort, K.; Wu, Z. Tape transfer atomization patterning of liquid alloys for microfluidic stretchable wireless power transfer. Sci. Rep. 2015, 5, 8419. [Google Scholar] [CrossRef] [PubMed]

- Boley, J.W.; White, E.L.; Kramer, R.K. Mechanically sintered gallium–indium nanoparticles. Adv. Mater. 2015, 27, 2355–2360. [Google Scholar] [CrossRef] [PubMed]

- Kunnari, E.; Valkama, J.; Keskinen, M.; Mansikkamäki, P. Environmental evaluation of new technology: Printed electronics case study. J. Clean. Prod. 2009, 17, 791–799. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J. Liquid phase 3D printing for quickly manufacturing conductive metal objects with low melting point alloy ink. Sci. China Technol. Sci. 2014, 57, 1721–1728. [Google Scholar] [CrossRef]

- Fassler, A.; Majidi, C. 3D structures of liquid-phase gain alloy embedded in pdms with freeze casting. Lab Chip 2013, 13, 4442–4450. [Google Scholar] [CrossRef] [PubMed]

- Ladd, C.; So, J.-H.; Muth, J.; Dickey, M.D. 3D printing of free standing liquid metal microstructures. Adv. Mater. 2013, 25, 5081–5085. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Yang, X.; Jin, C.; Fu, J.; Chen, W.; Liu, J. Development of three-dimension microelectrode array for bioelectric measurement using the liquidmetal-micromolding technique. Appl. Phys. Lett. 2013, 103, 193701. [Google Scholar] [CrossRef]

- Deng, Y.; Liu, J. Flexible mechanical joint as human exoskeleton using low-melting-point alloy. J. Med. Devices 2014, 8, 044506. [Google Scholar] [CrossRef]

- Li, J.; Guo, C.; Wang, Z.; Gao, K.; Shi, X.; Liu, J. Electrical stimulation towards melanoma therapy via liquid metal printed electronics on skin. Clin. Transl. Med. 2016, 5, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Liu, J. Ink spraying based liquid metal printed electronics for directly making smart home appliances. ECS J. Solid State Sci. Technol. 2015, 4, 3057–3062. [Google Scholar] [CrossRef]

- Fassler, A.; Majidi, C. Soft-matter capacitors and inductors for hyperelastic strain sensing and stretchable electronics. Smart Mater. Struct. 2013, 22, 955–966. [Google Scholar] [CrossRef]

- Cheng, S.; Wu, Z. Microfluidic electronics. Lab Chip 2012, 12, 2782–2791. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.; Wu, Z. A microfluidic, reversibly stretchable, large-area wireless strain sensor. Adv. Funct. Mater. 2011, 21, 2282–2290. [Google Scholar] [CrossRef]

- Wu, Z.; Hjort, K.; Jeong, S.H. Microfluidic stretchable radio-frequency devices. Proc. IEEE 2015, 103, 1211–1225. [Google Scholar] [CrossRef]

- Jeong, S.; Hjort, K.; Wu, Z. Tape transfer printing of a liquid metal alloy for stretchable RF electronics. Sensors 2014, 14, 16311–16321. [Google Scholar] [CrossRef] [PubMed]

- Jin, S.W.; Park, J.; Hong, S.Y.; Park, H.; Jeong, Y.R.; Park, J.; Lee, S.-S.; Ha, J.S. Stretchable loudspeaker using liquid metal microchannel. Sci. Rep. 2015, 5, 11695. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Wu, X.; Lee, D.-W. A galinstan-based inkjet printing system for highly stretchable electronics with self-healing capability. Lab Chip 2016, 16, 1366–1373. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.-L.; Majidi, C.; Kramer, R.; Berard, P.; Wood, R.J. Hyperelastic pressure sensing with a liquid-embedded elastomer. J. Micromech. Microeng. 2010, 20, 125029–125034. [Google Scholar] [CrossRef]

| Ink Type | Ink Composition | Conductivity |

|---|---|---|

| Carbon conductive ink | Carbon | 1.8 × 103 S/m |

| CNT | (5.03 ± 0.05) × 103 S/m | |

| Polymer conductive ink | PEDOT:PSS | 8.25 × 103 S/m |

| Nano-silver ink | Ag-DDA | 3.45 × 107 S/m |

| Ag-PVP | 6.25 × 106 S/m | |

| Liquid metal ink | EGaIn | 3.4 × 106 S/m |

| Bi35In48.6Sn16Zn0.4 | 7.3 × 106 S/m |

| Corrosive Behavior | Easy to React with Gallium | Better Resistance for Corrosion | Best Resistance for Corrosion |

|---|---|---|---|

| Metal | Iron, nickel, cadmium, cerium, copper, aluminum, gold, manganese, platinum, silver, tin and vanadium, zirconium | Titanium, tantalum, niobium, molybdenum, beryllium | Tungsten, rhenium, sintering BeO, Al2O3, and fused quartz, graphite |

| Temperature range | Appearing corrosion at 200 °C or even lower | Appearing corrosion above 400 °C | No corrosion even at 800 °C |

| Liquid Metal Printer | Personal Circuit Printer | Ubiquitous Inkjet Printer | 3D Metal Printer |

|---|---|---|---|

| Device type |  |  |  |

| Printed out items |  |  |  |

| Application Fields | circuit; art; devices; rapid prototyping. | electronic circuit; art; radio frequency identification label; antenna. | circuit; radar; antenna; molds. |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Liu, J. Recent Advancements in Liquid Metal Flexible Printed Electronics: Properties, Technologies, and Applications. Micromachines 2016, 7, 206. https://doi.org/10.3390/mi7120206

Wang X, Liu J. Recent Advancements in Liquid Metal Flexible Printed Electronics: Properties, Technologies, and Applications. Micromachines. 2016; 7(12):206. https://doi.org/10.3390/mi7120206

Chicago/Turabian StyleWang, Xuelin, and Jing Liu. 2016. "Recent Advancements in Liquid Metal Flexible Printed Electronics: Properties, Technologies, and Applications" Micromachines 7, no. 12: 206. https://doi.org/10.3390/mi7120206

APA StyleWang, X., & Liu, J. (2016). Recent Advancements in Liquid Metal Flexible Printed Electronics: Properties, Technologies, and Applications. Micromachines, 7(12), 206. https://doi.org/10.3390/mi7120206