Development and Test of a Novel High-Precision Inchworm Piezoelectric Motor

Abstract

1. Introduction

2. Configuration and Operating Principle

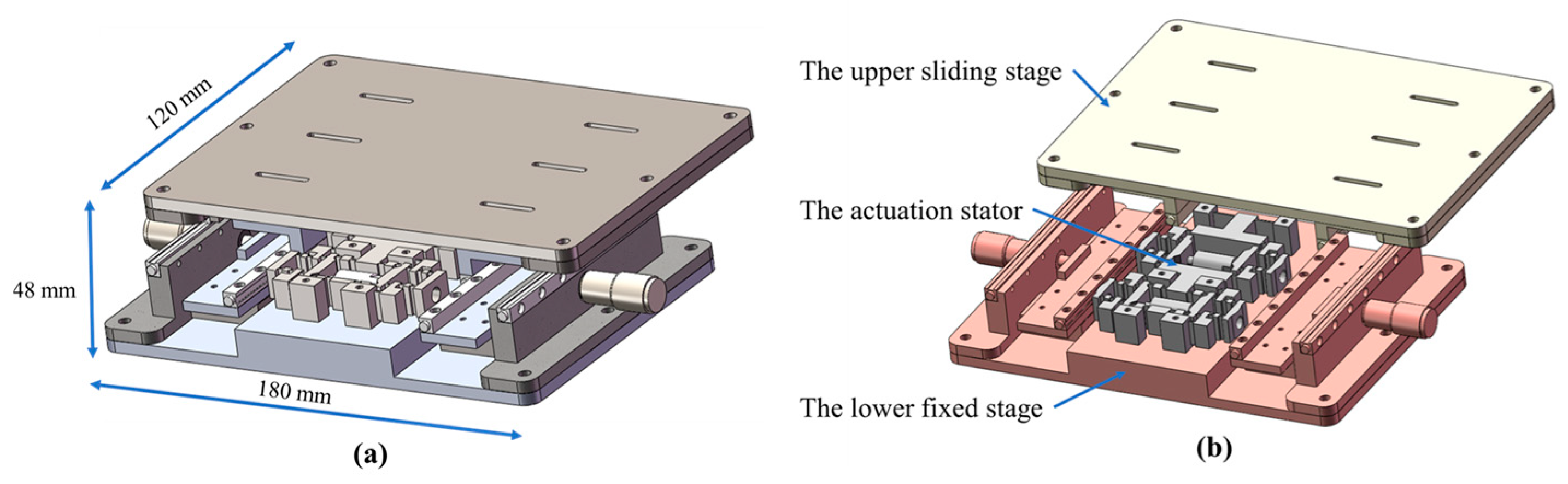

2.1. Structure of the Motor

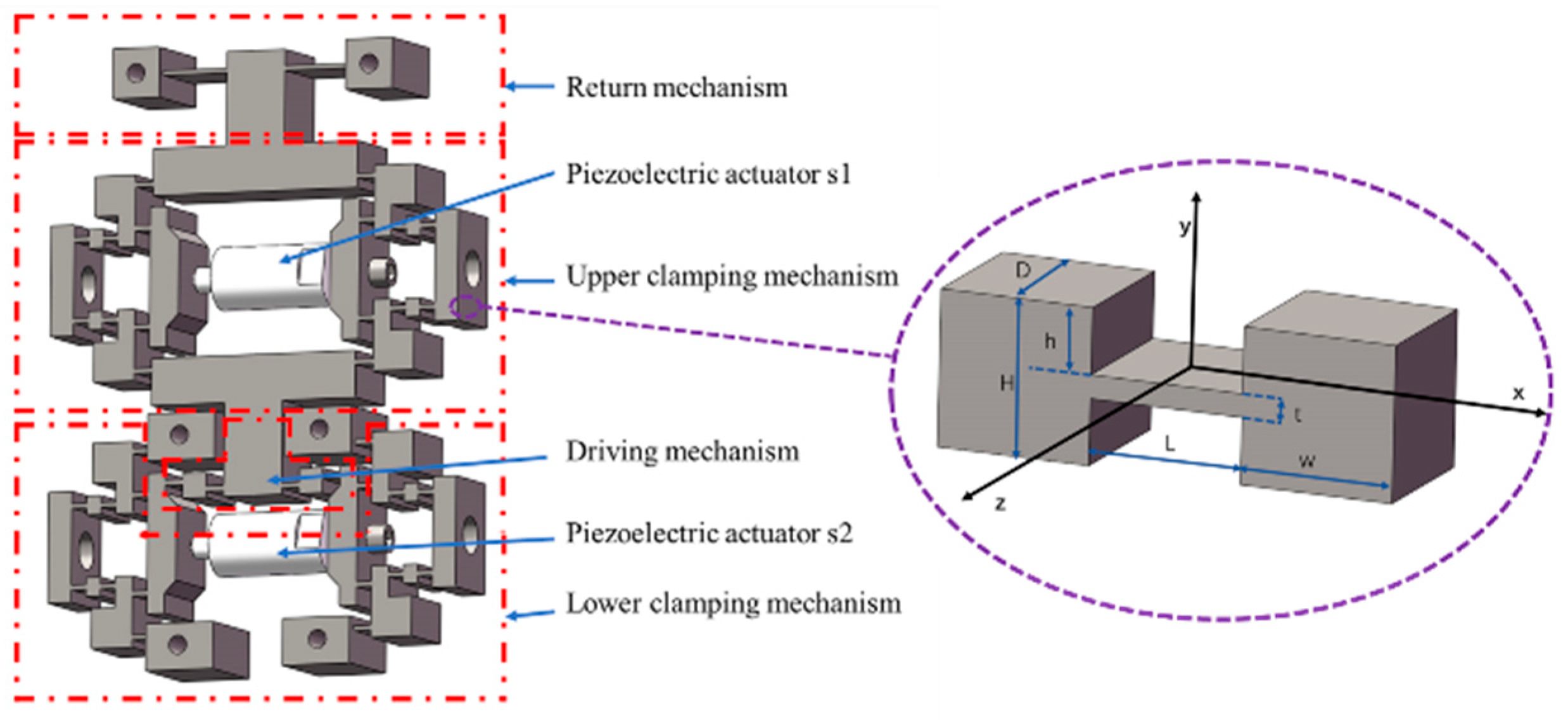

2.2. Actuation Stator

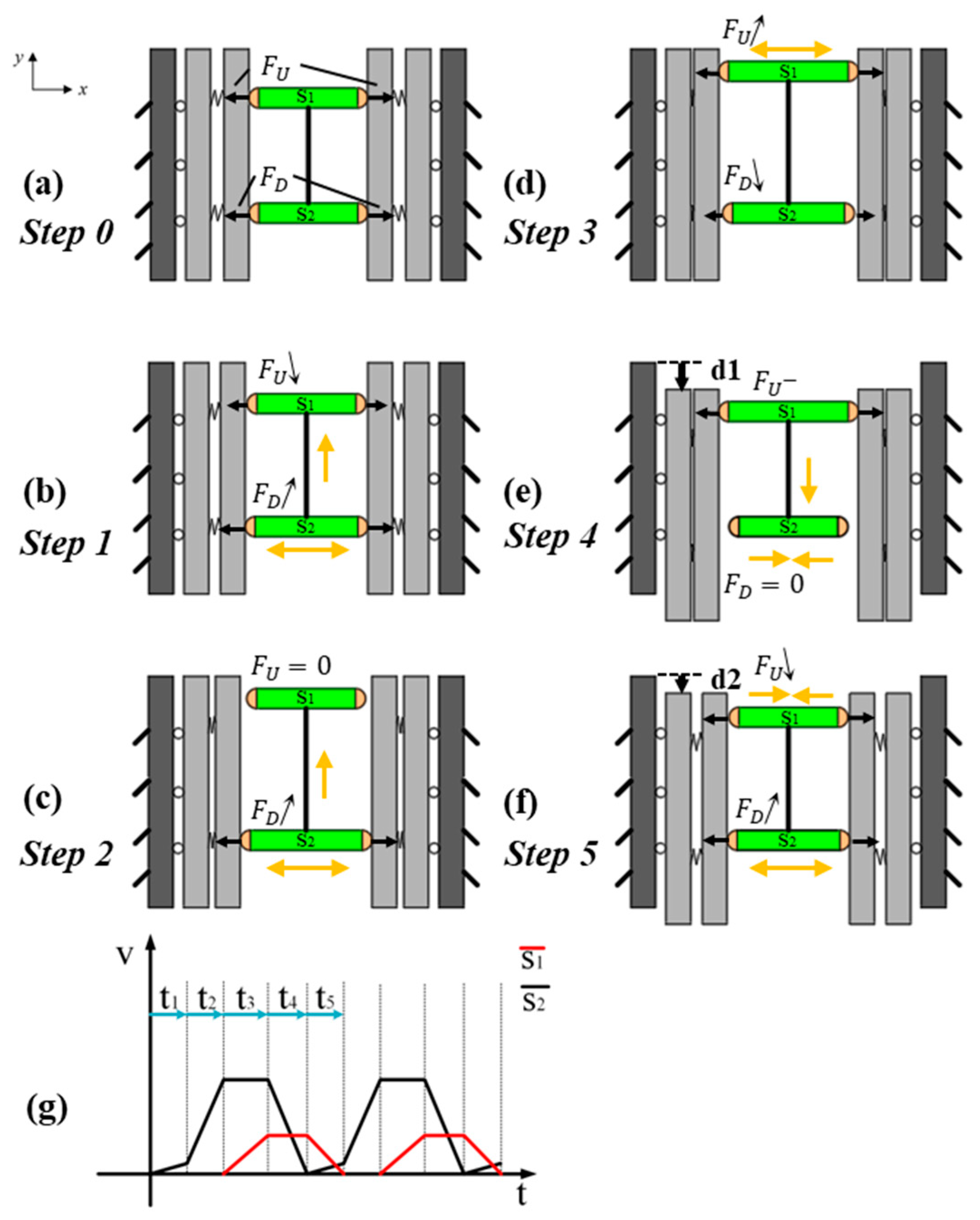

2.3. Operating Principle

3. Establishment of the Kinematic Model for the Actuation Stator

3.1. Modeling of Output Compliance

3.2. Modeling of Input Stiffness

3.3. Mechanical Amplification Ratio

3.4. Development and Analysis of the Kinematic Model

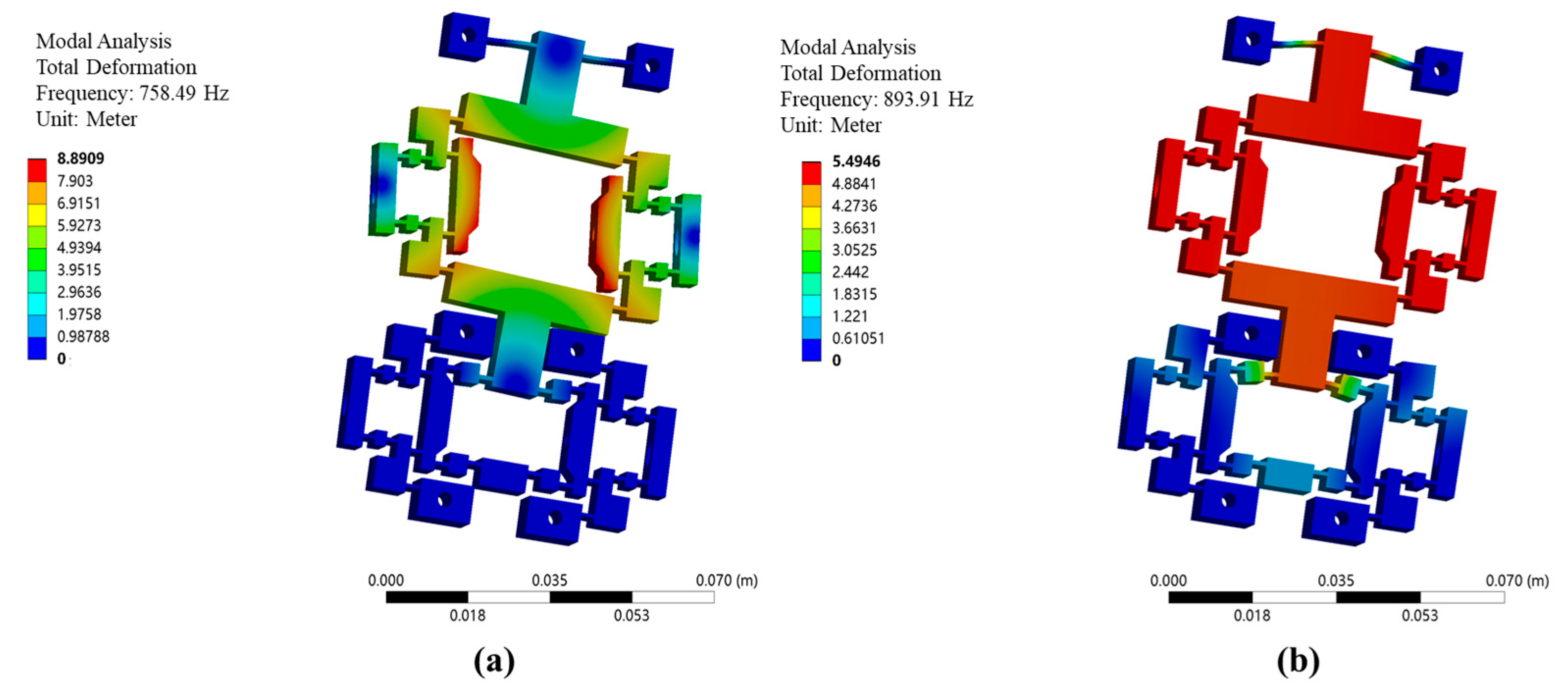

4. Finite Element Analysis and Evaluation

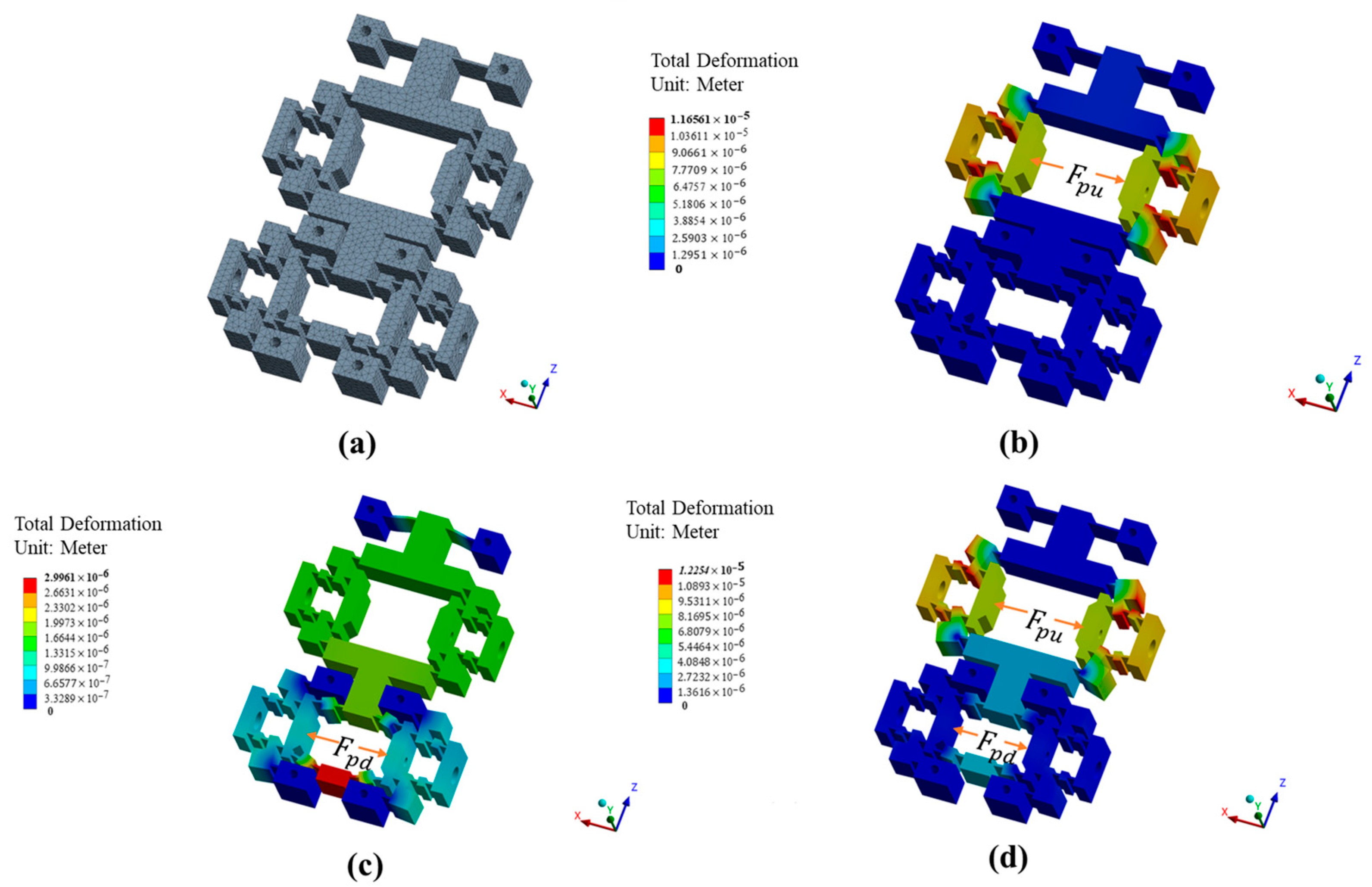

4.1. Finite Element Analysis of Actuation Stator Motion Characteristics

- When only is applied, as shown in Figure 7b, the upper clamping mechanism generates corresponding displacement, with minimal impact on the lower clamping mechanism and the driving mechanism; the coupling rates and reach only 0% and 7%, respectively. With the increase in , the target displacement grows under constant ratios governed by , which remains at 2.18 constantly, validating the linear relationship between input force and output displacement in the upper clamping mechanism.

- When only is applied, as shown in Figure 7c, the lower clamping mechanism and the driving mechanism generate corresponding displacement, with minimal impact on the upper clamping mechanism; the coupling rates and reach only 6% and 2%, respectively. With the increase in , the target displacements grow under constant ratios governed by , which remain at 26.72 and 10.91 constantly, validating the linear relationship between input force and output displacement in the lower clamping mechanism and driving mechanism.

- When both and are applied, as shown in Figure 7d, the mechanism stiffness of the actuation stator undergoes slight variations. Within the input force range of 0–60 N, the stiffness of the upper clamping mechanism increases from 2.15 to 2.19, while the lower clamping mechanism exhibits a stiffness variation of 25.91–26.92. The driving mechanism demonstrates relatively more pronounced stiffness change, ranging from 7.74 to 11.45. Overall, the stiffness interactions between mechanisms due to motion are mutually influential but negligible in practical terms.

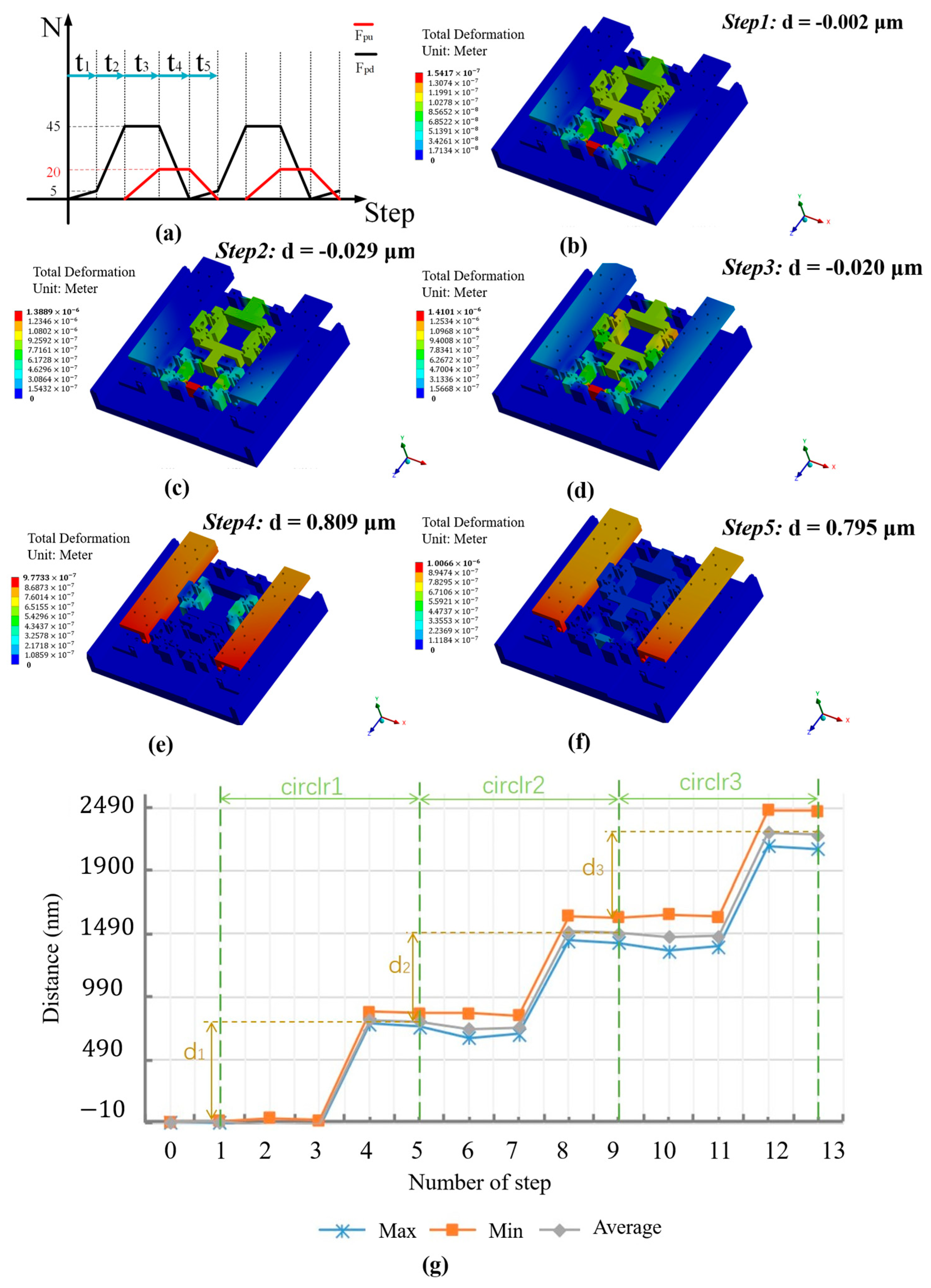

4.2. Finite Element Analysis of Inchworm Piezoelectric Motor Characteristics

4.3. Finite Element Analysis of Actuation Stator Fatigue Life

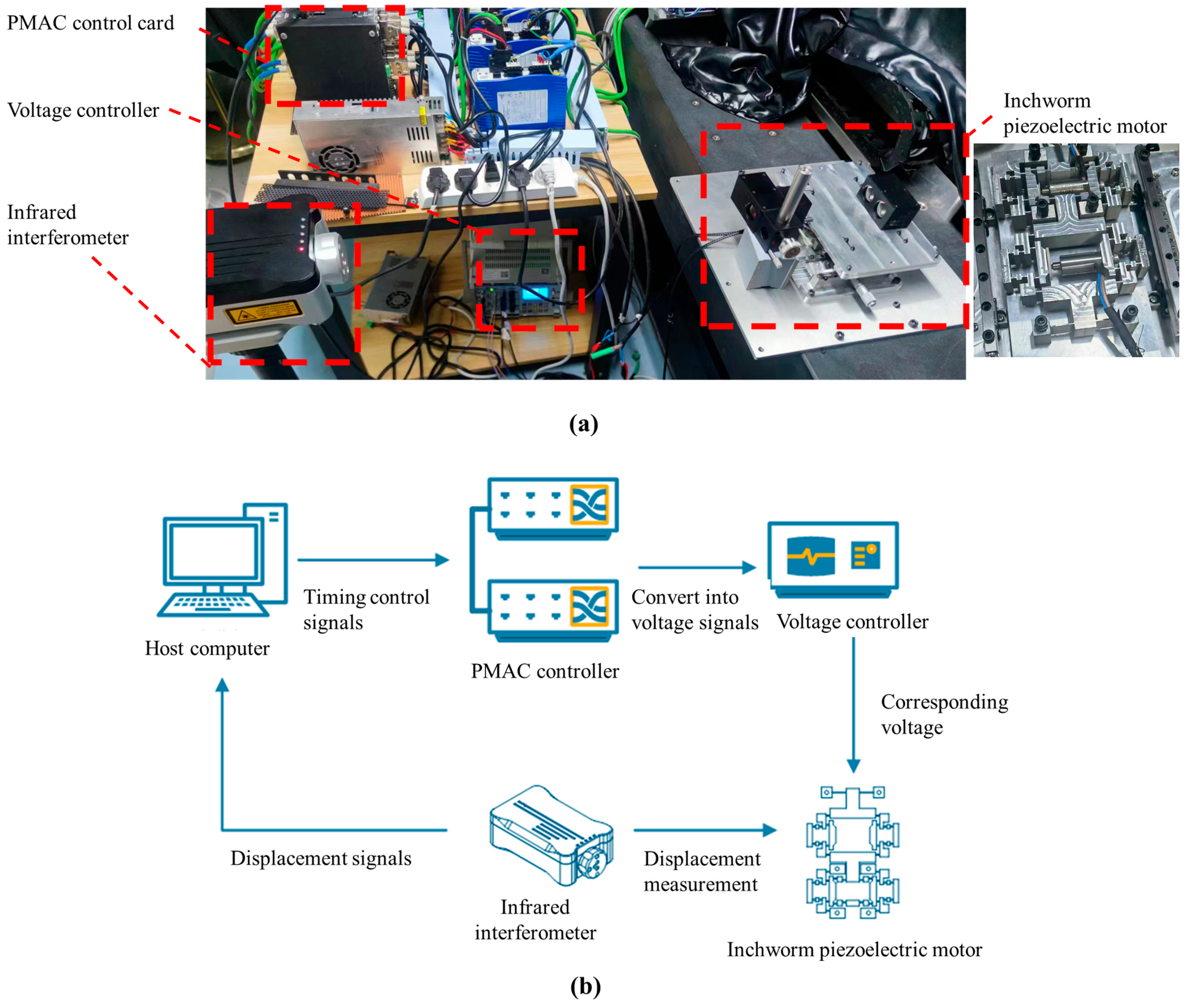

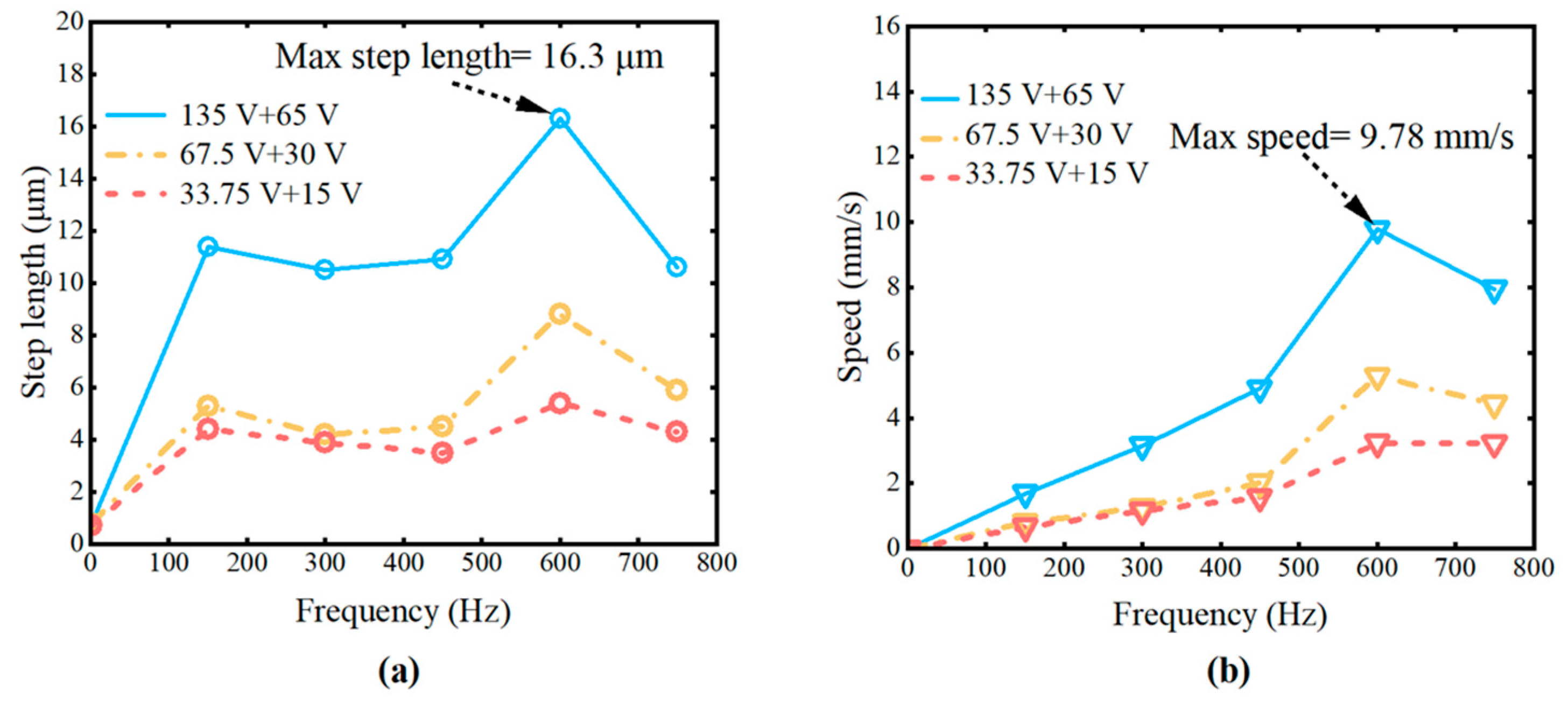

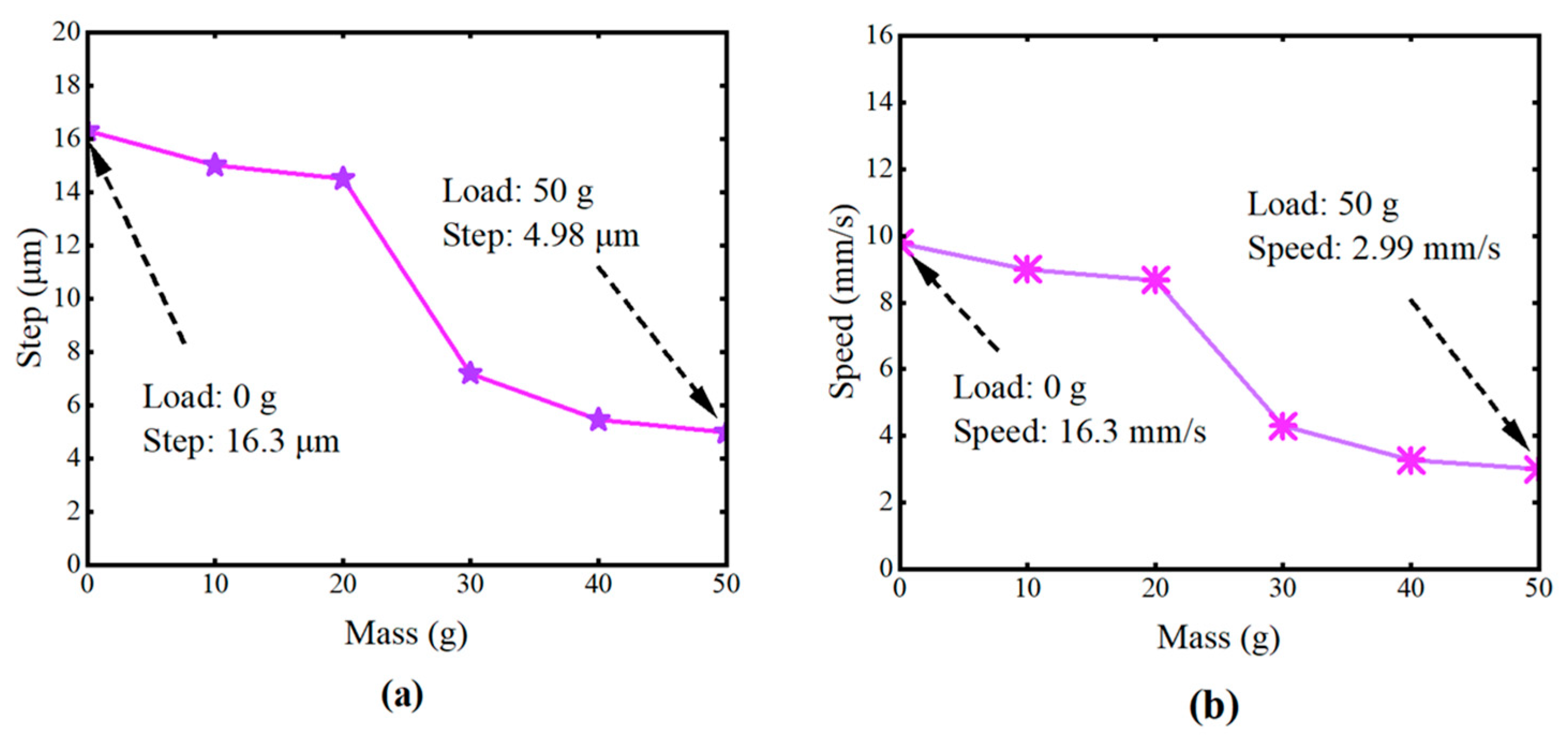

5. Experimental Results

- Under the same operating frequency, the displacement of the piezoelectric motor increases with higher operating voltage;

- Under the same operating frequency, the motion velocity increases with higher operating voltage;

- At the same operating voltage, the motion velocity increases with higher operating frequency;

- When the frequency is 600 Hz and the input voltage is set to 135 V + 65 V, the maximum step size of 16.3 μm and the maximum velocity of 9.78 are achieved.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lyashenko, I.A.; Borysiuk, V.N.; Popov, V.L. Dynamical Model of Asymmetric Actuator of Directional Motion. Meccanica 2019, 54, 1681–1687. [Google Scholar] [CrossRef]

- Zhou, L.; Wu, J. Magnetic Levitation Technology for Precision Motion Systems: A Review and Future Perspectives. Int. J. Autom. Technol. 2022, 16, 386–402. [Google Scholar] [CrossRef]

- Liu, T.; Xie, L.; Price, C.-A.H.; Liu, J.; He, Q.; Kong, B. Controlled Propulsion of Micro/Nanomotors: Operational Mechanisms, Motion Manipulation and Potential Biomedical Applications. Chem. Soc. Rev. 2022, 51, 10083–10119. [Google Scholar] [CrossRef] [PubMed]

- Gu, G.; Zhu, L.; Su, C.; Ding, H.; Fatikow, S. Modeling and Control of Piezo-Actuated Nanopositioning Stages: A Survey. IEEE Trans. Autom. Sci. Eng. 2016, 13, 313–332. [Google Scholar] [CrossRef]

- Mohith, S.; Upadhya, A.R.; Navin, K.P.; Kulkarni, S.M.; Rao, M. Recent Trends in Piezoelectric Actuators for Precision Motion and Their Applications: A Review. Smart Mater. Struct. 2021, 30, 01300. [Google Scholar] [CrossRef]

- Zhou, X.; Wu, S.; Wang, X.; Wang, Z.; Zhu, Q.; Sun, J.; Huang, P.; Wang, X.; Huang, W.; Lu, Q. Review on Piezoelectric Actuators: Materials, Classifications, Applications, and Recent Trends. Front. Mech. Eng. 2024, 19, 6. [Google Scholar] [CrossRef]

- Jin, H.; Gao, X.; Ren, K.; Liu, J.; Qiao, L.; Liu, M.; Chen, W.; He, Y.; Dong, S.; Xu, Z.; et al. Review on Piezoelectric Actuators Based on High-Performance Piezoelectric Materials. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2022, 69, 3057–3069. [Google Scholar] [CrossRef]

- Li, J.; Huang, H.; Morita, T. Stepping Piezoelectric Actuators with Large Working Stroke for Nano-Positioning Systems: A Review. Sens. Actuators A-Phys. 2019, 292, 39–51. [Google Scholar] [CrossRef]

- Wang, L.; Jin, J.; Zhang, H.; Wang, F.; Jiang, Z. Theoretical Analysis and Experimental Investigation on a Novel Self-Moving Linear Piezoelectric Stepping Actuator. Mech. Syst. Signal Process. 2020, 135, 106183. [Google Scholar] [CrossRef]

- Li, J.; Cai, J.; Wen, J.; Yao, J.; Huang, J.; Zhao, T.; Wan, N. A Walking Type Piezoelectric Actuator with Two Umbrella-Shaped Flexure Mechanisms. Smart Mater. Struct. 2020, 29, 085014. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, J.; Zhang, L.; Luo, Y.; Chen, X.; Chen, X.; He, Y. Novel Dynamic Microactuation Method for Tracking-Error Reduction of Permanent Magnet Linear Synchronous Motors. IEEE Trans. Ind. Electron. 2022, 69, 9165–9175. [Google Scholar] [CrossRef]

- Mohith, S.; Karanth, P.N.; Kulkarni, S.M. Recent Trends in Mechanical Micropumps and Their Applications: A Review. Mechatronics 2019, 60, 34–55. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, J.; Chen, X. A Rapid Dynamic Positioning Method for Settling Time Reduction Through a Macro–Micro Composite Stage With High Positioning Accuracy. IEEE Trans. Ind. Electron. 2018, 65, 4849–4860. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, J.; Chen, X.; Chen, Y.; He, Y.; Zhang, Y.; Tang, H.; Yang, Z. Implementation and Experiment of an Active Vibration Reduction Strategy for Macro-Micro Positioning System. Precis. Eng. 2018, 51, 319–330. [Google Scholar] [CrossRef]

- Tanoue, Y.; Morita, T. Opposing Preloads Type Ultrasonic Linear Motor with Quadruped Stator. Sens. Actuators A-Phys. 2020, 301, 111764. [Google Scholar] [CrossRef]

- Uchino, K.; Cagatay, S.; Koc, B.; Dong, S.; Bouchilloux, P.; Strauss, M. Micro Piezoelectric Ultrasonic Motors. J. Electroceramics 2004, 13, 393–401. [Google Scholar] [CrossRef][Green Version]

- Mashimo, T. Miniature Preload Mechanisms for a Micro Ultrasonic Motor. Sens. Actuators A-Phys. 2017, 257, 106–112. [Google Scholar] [CrossRef]

- Qiu, C.; Ling, J.; Zhang, Y.; Ming, M.; Feng, Z.; Xiao, X. A Novel Cooperative Compensation Method to Compensate for Return Stroke of Stick-Slip Piezoelectric Actuators. Mech. Mach. Theory 2021, 159, 104254. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, R.; Wen, J.; Liu, J.-Q. A Low-Frequency Structure-Control-Type Inertial Actuator Using Miniaturized Bimorph Piezoelectric Vibrators. IEEE Trans. Ind. Electron. 2019, 66, 6179–6188. [Google Scholar] [CrossRef]

- Yu, Y.; Gao, Q.; Zhang, X.; Qiao, G.; Han, Y.; Lu, X.; Cheng, T. A Piezoelectric Stick-Slip Nanopositioning Stage with Ultra-High Load Capacity Realizing by Decoupling the Driving and Moving Units. IEEE Access 2019, 7, 142806–142813. [Google Scholar] [CrossRef]

- Qin, F.; Huang, H.; Wang, J.; Zhao, H. Design and Performance Evaluation of a Novel Stick–Slip Piezoelectric Linear Actuator with a Centrosymmetric-Type Flexure Hinge Mechanism. Microsyst. Technol.-Micro-Nanosyst.-Inf. Storage Process. Syst. 2019, 25, 3891–3898. [Google Scholar] [CrossRef]

- Lu, Q.; Ma, J.; Lin, X.; Hu, Y.; Li, J.; Wen, J. The Development of Piezoelectric Inchworm Actuator Clamped with Magnetorheological Elastomer and Its Potential Application in Brain–Computer Interface Implantation. IEEE Trans. Ind. Electron. 2023, 70, 4018–4026. [Google Scholar] [CrossRef]

- Mohammad, T.; Salisbury, S.P. Design and Assessment of a Z-Axis Precision Positioning Stage with Centimeter Range Based on a Piezoworm Motor. IEEE/ASME Trans. Mechatron. 2015, 20, 2021–2030. [Google Scholar] [CrossRef]

- Tahmasebipour, M.; Sangchap, M. A Novel High Performance Integrated Two-Axis Inchworm Piezoelectric Motor. Smart Mater. Struct. 2020, 29, 015034. [Google Scholar] [CrossRef]

- Liang, C.; Wang, F.; Shi, B.; Huo, Z.; Zhou, K.; Tian, Y.; Zhang, D. Design and Control of a Novel Asymmetrical Piezoelectric Actuated Microgripper for Micromanipulation. Sens. Actuators A-Phys. 2018, 269, 227–237. [Google Scholar] [CrossRef]

- Dong, H.; Li, T.; Wang, Z.; Ning, Y. Design and Experiment of a Piezoelectric Actuator Based on Inchworm Working Principle. Sens. Actuators A-Phys. 2020, 306, 111950. [Google Scholar] [CrossRef]

- Ling, J.; Chen, L.; Feng, Z.; Zhu, Y. Development and Test of a High Speed Pusher-Type Inchworm Piezoelectric Actuator with Asymmetric Driving and Clamping Configuration. Mech. Mach. Theory 2022, 176, 104997. [Google Scholar] [CrossRef]

- Deng, J.; Zhang, S.; Li, Y.; Ma, X.; Gao, X.; Xie, H.; Liu, Y. Development and Experiment Evaluation of a Compact Inchworm Piezoelectric Actuator Using Three-Jaw Type Clamping Mechanism. Smart Mater. Struct. 2022, 31, 045020. [Google Scholar] [CrossRef]

- Ma, X.; Liu, Y.; Deng, J.; Gao, X.; Cheng, J. A Compact Inchworm Piezoelectric Actuator with High Speed: Design, Modeling, and Experimental Evaluation. Mech. Syst. Signal Process. 2023, 184, 109704. [Google Scholar] [CrossRef]

- Long, S.X.; Khoo, S.Y.; Ong, Z.C.; Soong, M.F.; Huang, Y.-H.; Prasath, N.; Noroozi, S. A Comprehensive Review on Mechanical Amplifier Structures in Piezoelectric Energy Harvesters. Mech. Adv. Mater. Struct. 2024, 31, 7244–7273. [Google Scholar] [CrossRef]

- Lin, Y.; An, D.; Lin, Z.; Chen, X.; Huang, W. Progress in High-Performance Stick-Slip Piezoelectric Actuators: A Review. Int. J. Smart Nano Mater. 2024, 15, 652–696. [Google Scholar] [CrossRef]

- Li, J.; Deng, J.; Zhang, S.; Liu, Y. Development of a Miniature Quadrupedal Piezoelectric Robot Combining Fast Speed and Nano-Resolution. Int. J. Mech. Sci. 2023, 250, 108276. [Google Scholar] [CrossRef]

- Ding, B.; Li, X.; Li, C.; Li, Y.; Chen, S.-C. A Survey on the Mechanical Design for Piezo-Actuated Compliant Micro-Positioning Stages. Rev. Sci. Instrum. 2023, 94, 101502. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Du, Y.; Jiang, Y.; Zhang, J. Empirical Compliance Equations for Constant Rectangular Cross Section Flexure Hinges and Their Applications. Math. Probl. Eng. 2016, 2016, 5602142. [Google Scholar] [CrossRef]

| Material | Elastic Modulus (GPa) | Yield Strength (MPa) | Poisson’s Ratio | Density (kg/m3) |

|---|---|---|---|---|

| AL7075-T651 | 71.7 | 505 | 0.33 | 2180 |

| μm | μm | μm | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 20.00 | 0.00 | 9.18 | 0.04 | 0.62 | 0.00 | 0.07 | 2.18 | - | - |

| 40.00 | 0.00 | 18.36 | 0.08 | 1.25 | 0.00 | 0.07 | 2.18 | - | - |

| 60.00 | 0.00 | 27.53 | 0.12 | 1.87 | 0.00 | 0.07 | 2.18 | - | - |

| 80.00 | 0.00 | 36.71 | 0.16 | 2.50 | 0.00 | 0.07 | 2.18 | - | - |

| 100.00 | 0.00 | 45.89 | 0.21 | 3.12 | 0.00 | 0.07 | 2.18 | - | - |

| 0.00 | 20.00 | 0.04 | 0.75 | 1.83 | 0.06 | 0.02 | - | 26.72 | 10.91 |

| 0.00 | 40.00 | 0.09 | 1.50 | 3.67 | 0.06 | 0.02 | - | 26.72 | 10.91 |

| 0.00 | 60.00 | 0.13 | 2.25 | 5.50 | 0.06 | 0.02 | - | 26.72 | 10.91 |

| 0.00 | 80.00 | 0.18 | 2.99 | 7.33 | 0.06 | 0.02 | - | 26.72 | 10.91 |

| 0.00 | 100.00 | 0.22 | 3.74 | 9.17 | 0.06 | 0.02 | - | 26.72 | 10.91 |

| 20.00 | 20.00 | 9.26 | 0.77 | 2.46 | - | - | 2.16 | 25.90 | 8.13 |

| 20.00 | 40.00 | 9.29 | 1.49 | 4.29 | - | - | 2.15 | 26.92 | 9.33 |

| 20.00 | 60.00 | 9.19 | 2.30 | 5.24 | - | - | 2.18 | 26.13 | 11.45 |

| 40.00 | 20.00 | 18.31 | 0.79 | 2.48 | - | - | 2.18 | 25.41 | 8.05 |

| 40.00 | 40.00 | 18.27 | 1.57 | 4.39 | - | - | 2.19 | 25.43 | 9.12 |

| 40.00 | 60.00 | 18.23 | 2.31 | 5.40 | - | - | 2.19 | 26.03 | 11.12 |

| 60.00 | 20.00 | 27.47 | 0.77 | 2.58 | - | - | 2.18 | 25.91 | 7.74 |

| 60.00 | 40.00 | 27.42 | 1.53 | 4.50 | - | - | 2.19 | 26.15 | 8.89 |

| 60.00 | 60.00 | 27.35 | 2.28 | 5.57 | - | - | 2.19 | 26.29 | 10.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, N.; Yin, J.; Feng, F.; Zhang, L.; Luo, Y.; Gao, J. Development and Test of a Novel High-Precision Inchworm Piezoelectric Motor. Micromachines 2025, 16, 992. https://doi.org/10.3390/mi16090992

Huang N, Yin J, Feng F, Zhang L, Luo Y, Gao J. Development and Test of a Novel High-Precision Inchworm Piezoelectric Motor. Micromachines. 2025; 16(9):992. https://doi.org/10.3390/mi16090992

Chicago/Turabian StyleHuang, Nan, Jiahao Yin, Fuyuan Feng, Lanyu Zhang, Yuheng Luo, and Jian Gao. 2025. "Development and Test of a Novel High-Precision Inchworm Piezoelectric Motor" Micromachines 16, no. 9: 992. https://doi.org/10.3390/mi16090992

APA StyleHuang, N., Yin, J., Feng, F., Zhang, L., Luo, Y., & Gao, J. (2025). Development and Test of a Novel High-Precision Inchworm Piezoelectric Motor. Micromachines, 16(9), 992. https://doi.org/10.3390/mi16090992