Fabricating High Aspect Ratio Amorphous Alloys Microgrooves by Using Periodically Thinning Jet Electrochemical Milling Method

Abstract

1. Introduction

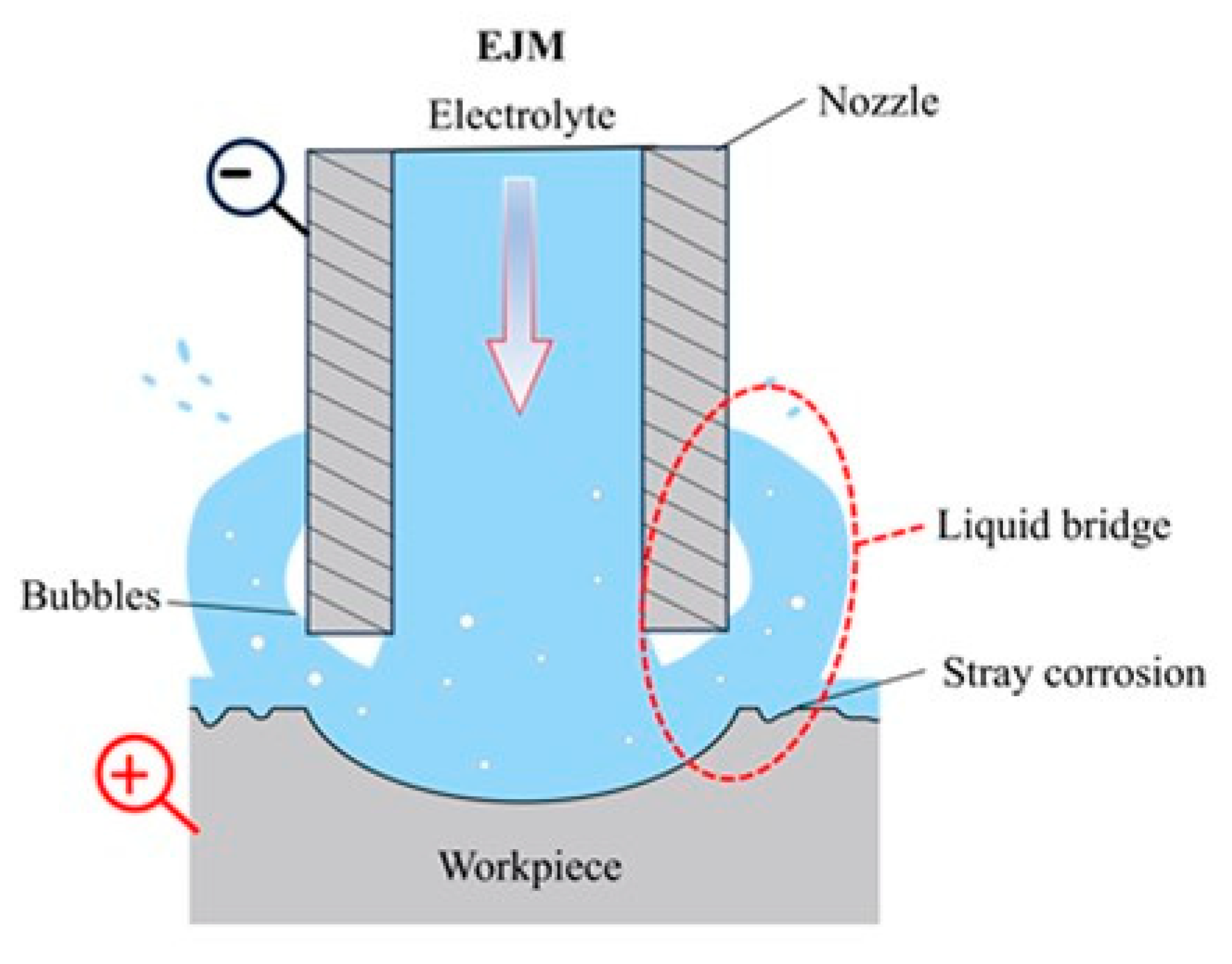

2. Processing Principles and Simulation

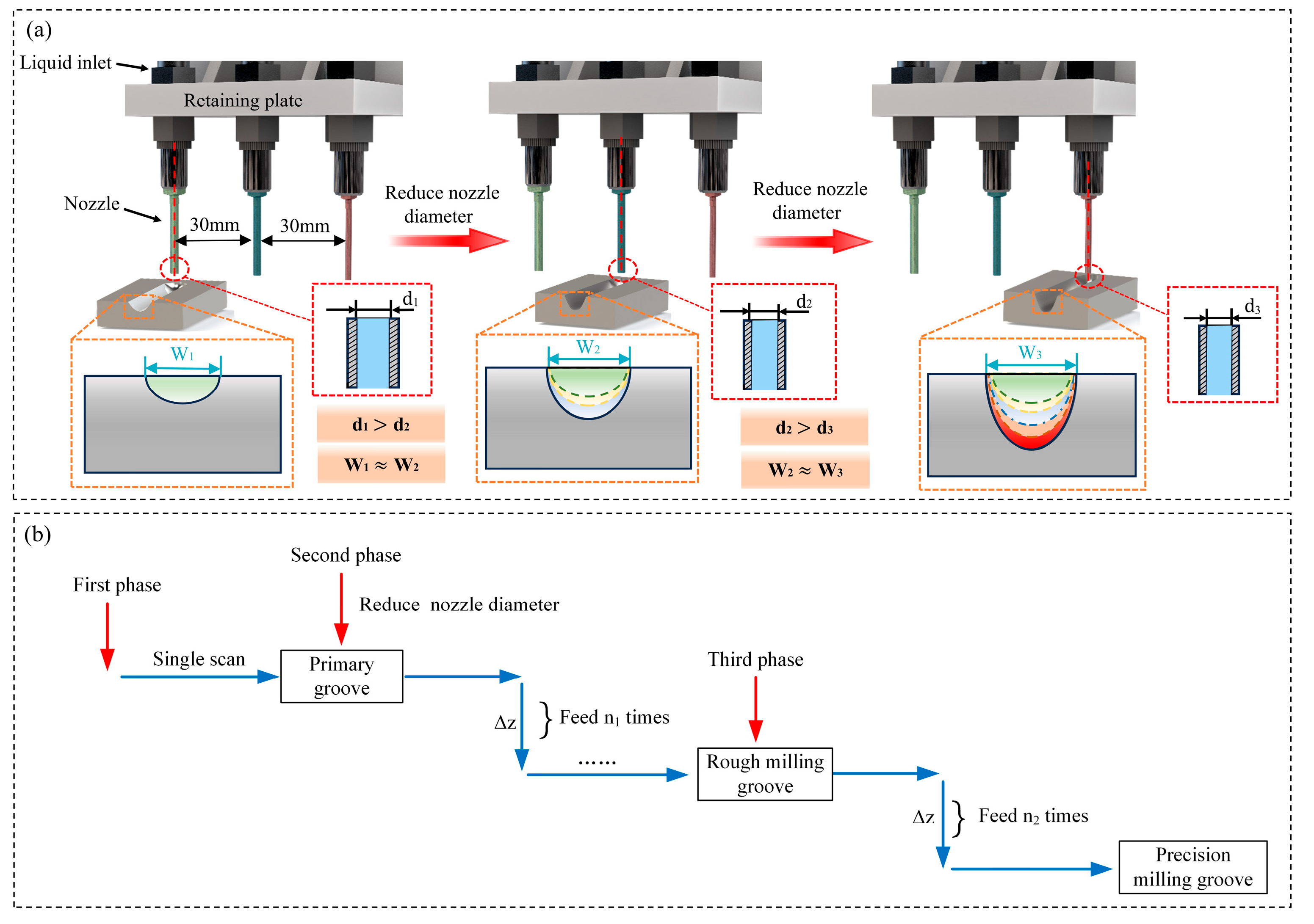

2.1. Concept of Periodically Thinning Jet Electrochemical Milling

2.2. Simulation Analysis

2.2.1. Simulation Model Establishment and Solution

- (1)

- The electrolyte is considered a continuous, incompressible, and viscous fluid;

- (2)

- The flow of the electrolyte is axisymmetric;

- (3)

- The nozzle is rigid.

2.2.2. Simulation Results Analysis

3. Experiments and Methods

3.1. Electrochemical Measurement Setup

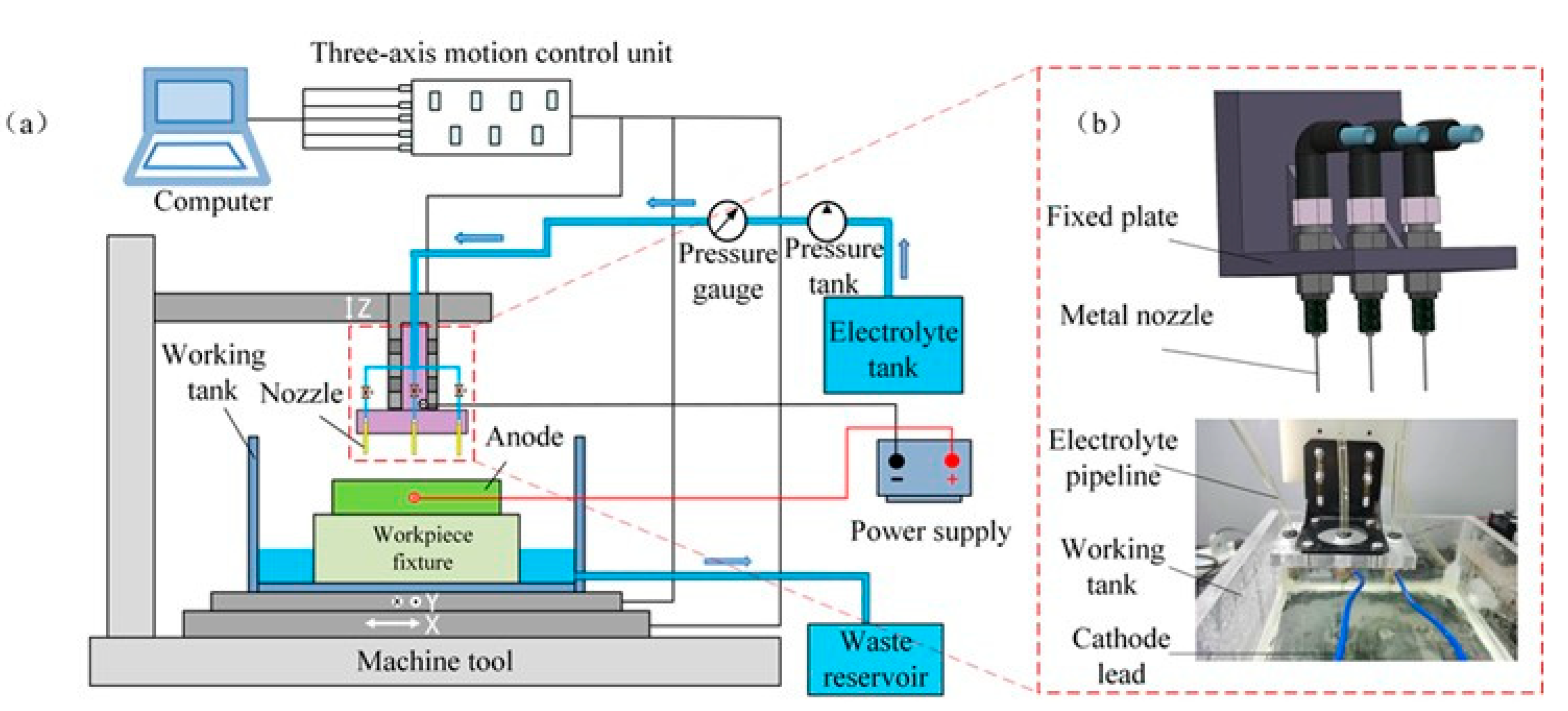

3.2. Experimental Setup and Materials

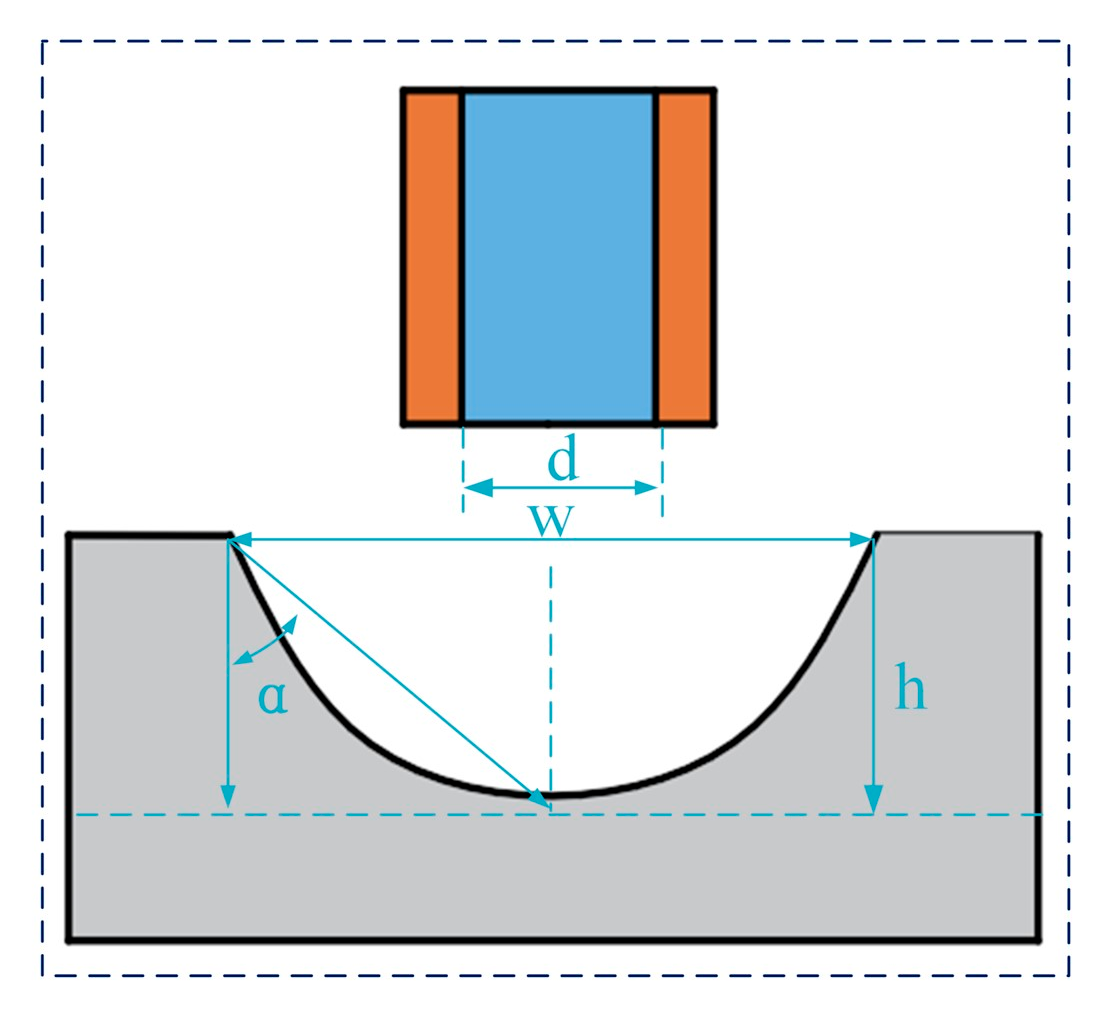

3.3. Machining Effect Evaluation

4. Results and Discussion

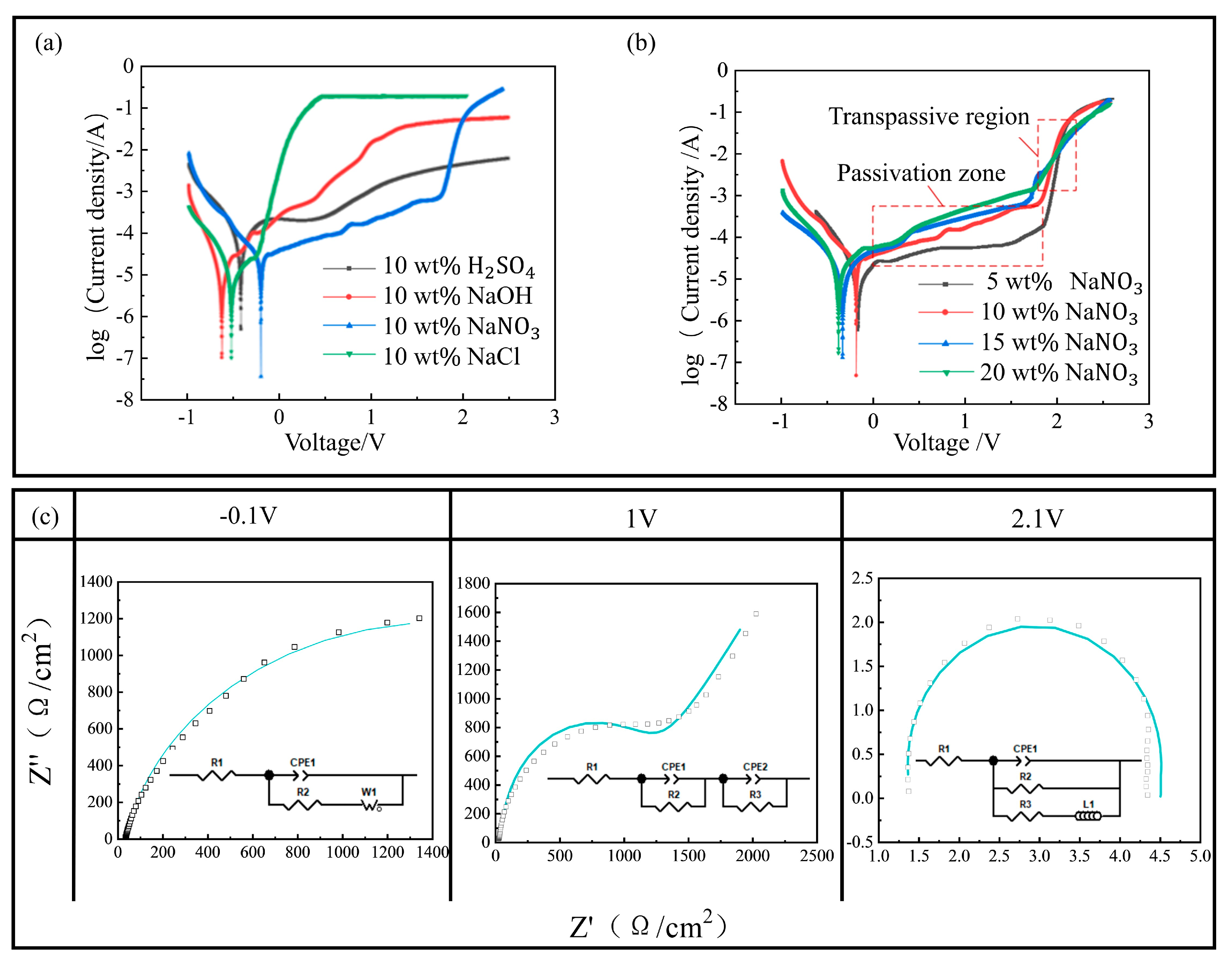

4.1. Electrochemical Characterization of Vit1

4.1.1. Polarization Curve Testing

4.1.2. Electrochemical Impedance Spectroscopy (EIS) Analysis

4.2. Effects of Machining Parameters

4.2.1. Effect of Machining Voltage

4.2.2. Effect of Machining Gap

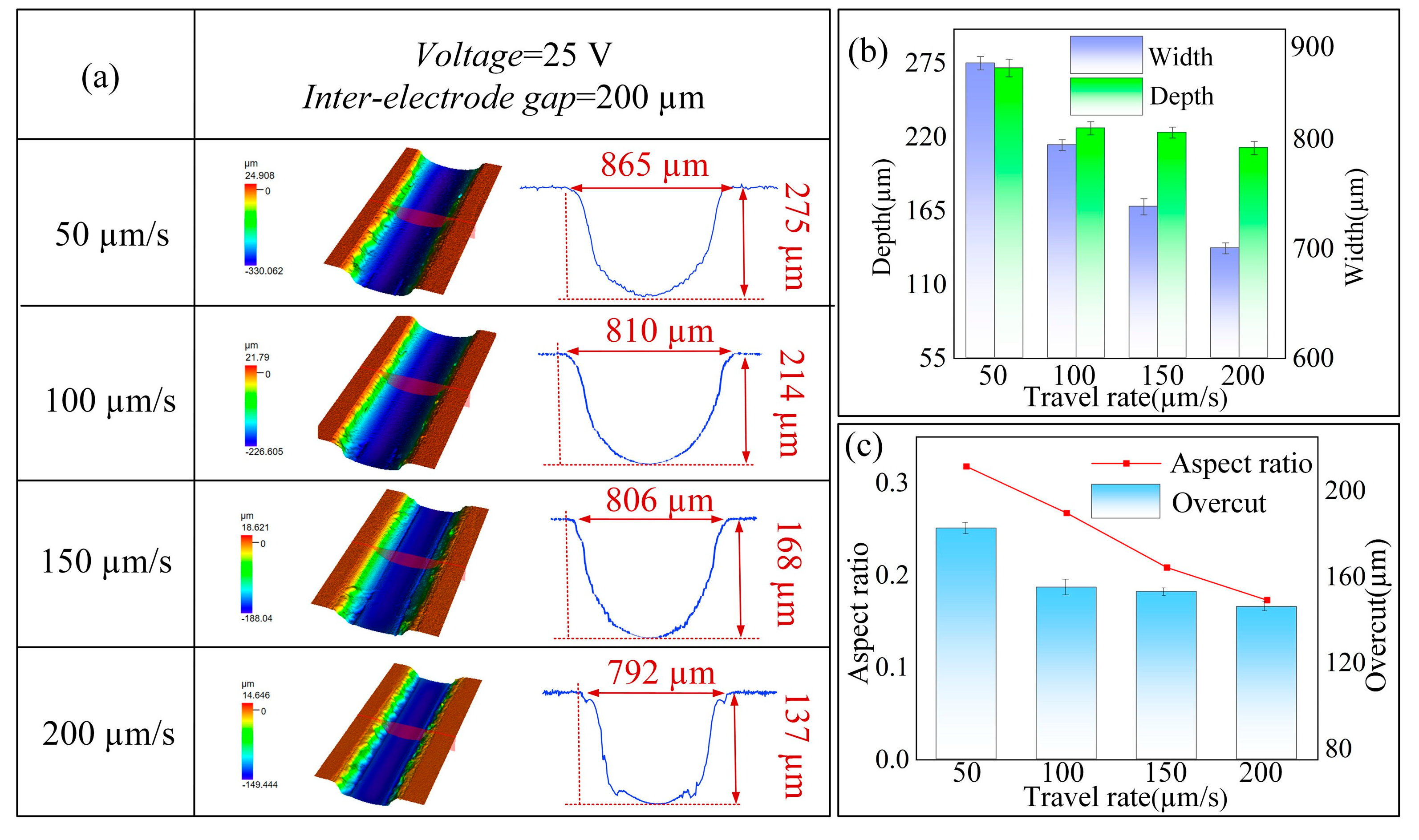

4.2.3. Effect of Nozzle Traverse Speed

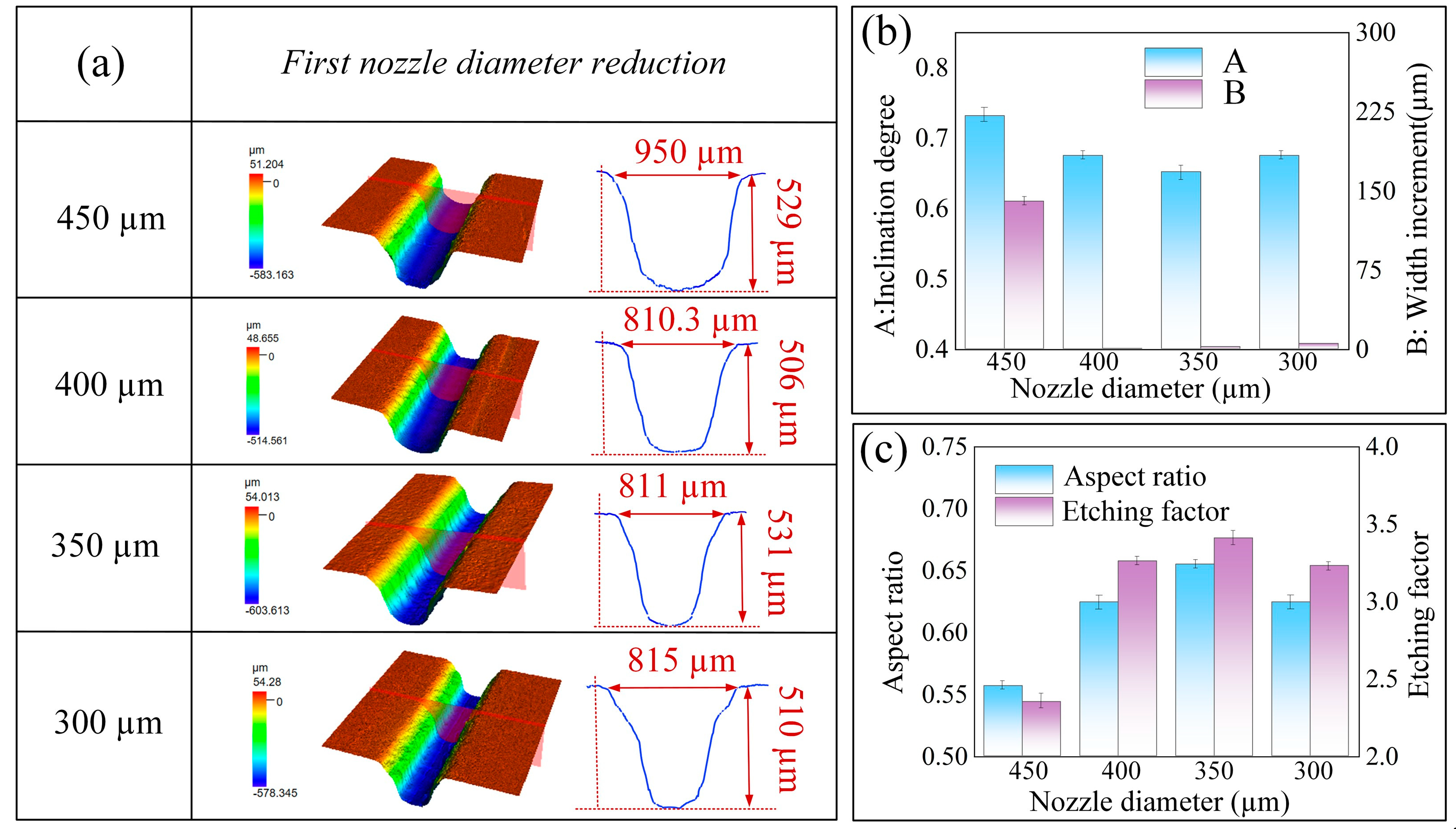

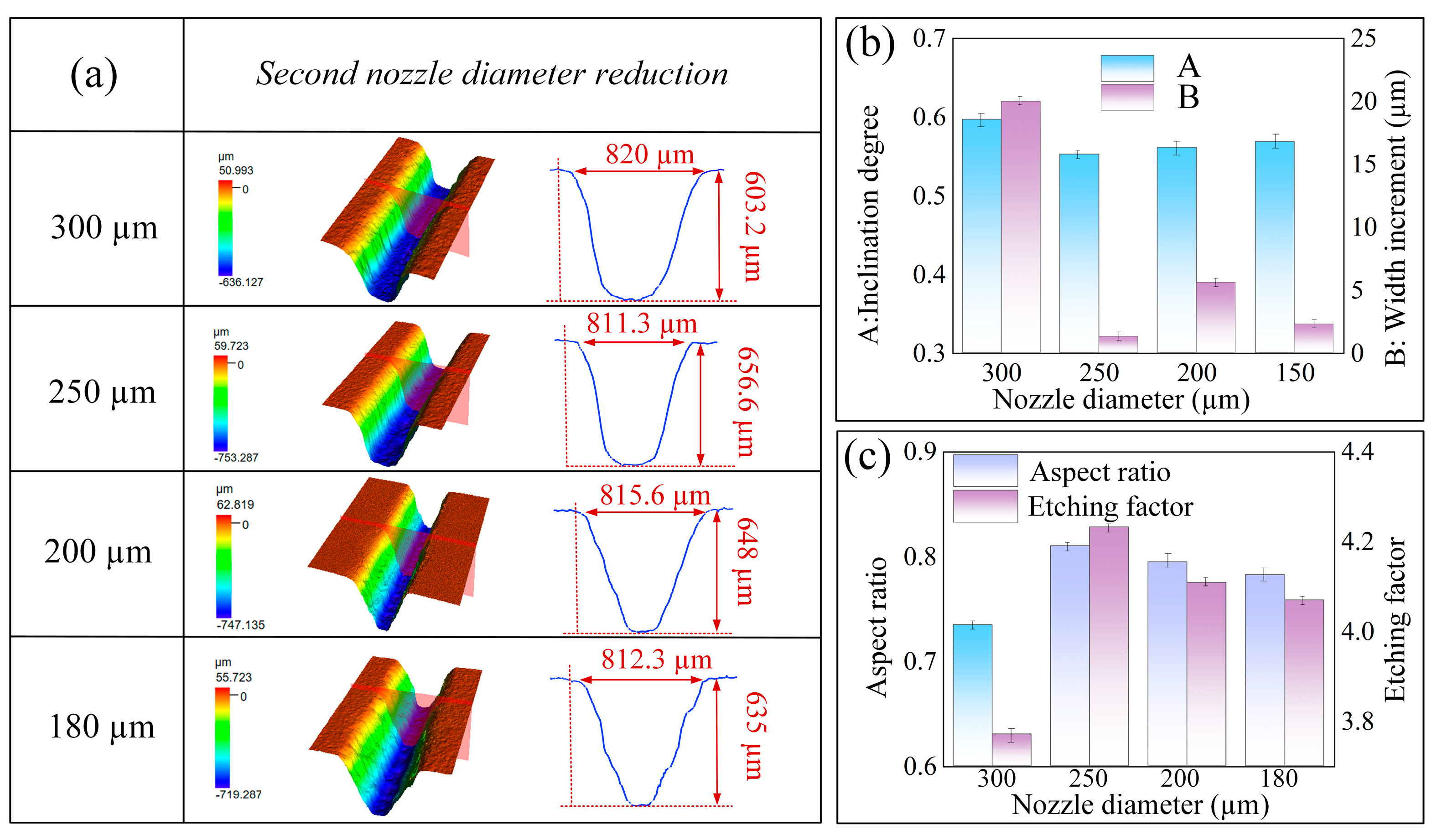

4.3. Tapered Beam Jet Electrochemical Milling of Microgrooves Experiment

4.3.1. The Effect of the First Diameter Reduction

4.3.2. The Effect of the Second Diameter Reduction

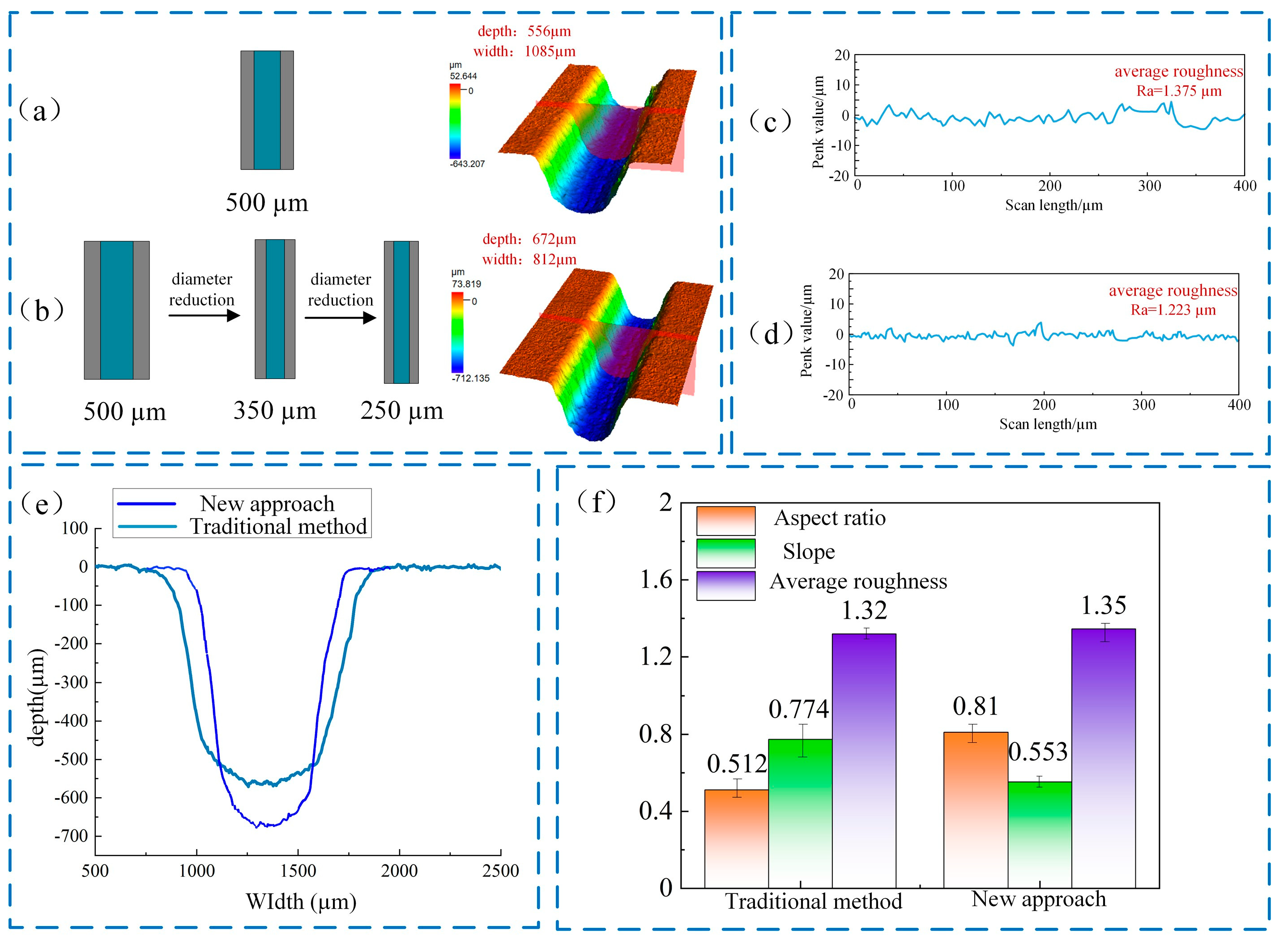

4.4. Comparative Analysis

5. Conclusions

- The gradual reduction in the nozzle diameter effectively regulated the increase in groove width while facilitating a continuous enhancement in groove depth. This approach markedly minimized overcutting during the processing phase, leading to a more consistent improvement of the aspect ratio.

- Simulation analyses indicate that utilizing smaller nozzle diameters enhances the concentration of current density at the bottom of the microgroove, thereby minimizing the region of ineffective material removal. This phenomenon facilitates the accurate machining of deep and narrow grooves. Empirical findings corroborate the simulation results, suggesting that the method of progressively decreasing the nozzle diameter is particularly effective, offering a viable processing technique for the precise fabrication of microgrooves with a high aspect ratio.

- In comparison to conventional techniques, the etching factor of microgrooves produced through the gradual reduction in nozzle diameter method exhibited an increase from 1.896 to 4.318, representing a 128% enhancement. Additionally, the increment in groove width was significantly reduced from 275 μm to 1 μm, indicating an almost complete reduction of 100%. Furthermore, the sidewall tilt angle was decreased from 0.77 radians to 0.54 radians, thereby validating the efficacy of this novel process strategy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, H.; Zheng, Y. Recent Advances in Bulk Metallic Glasses for Biomedical Applications. J. Acta Biomater. 2016, 36, 1–20. [Google Scholar] [CrossRef]

- Inoue, A.; Takeuchi, A. Recent Development and Application Products of Bulk Glassy Alloys. Acta Mater. 2011, 59, 2243–2267. [Google Scholar] [CrossRef]

- Zhang, W.; Haitao, M.; Li, Y.; Chang, C.; Xie, G.; Jia, X. Glass-Forming Ability and Thermoplastic Formability of Ferromagnetic (Fe, Co, Ni)75P10C10B5 Metallic Glasses. J. Alloys Compd. 2017, 707, 57–62. [Google Scholar] [CrossRef]

- Nishiyama, N.; Inoue, A. Glass Transition Behavior and Viscous Flow Working of Pd40Cu30Ni10P20 Amorphous Alloy. Fuel Energy Abstr. 2000, 41, 64–71. [Google Scholar]

- Wang, F.; Zhang, H.; Liang, X.; Gong, F.; Ma, J. Fabrication of Metallic Glass Micro Grooves by Thermoplastic Forming. J. Micromech. Microeng. 2017, 27, 025009. [Google Scholar] [CrossRef]

- Bakkal, M.; Shih, A.J.; McSpadden, S.B.; Scattergood, R.O. Thrust Force, Torque, and Tool Wear in Drilling the Bulk Metallic Glass. Int. J. Mach. Tools Manuf. 2005, 45, 863–872. [Google Scholar] [CrossRef]

- Bakkal, M.; Liu, C.T.; Watkins, T.R.; Scattergood, R.O.; Shih, A.J. Oxidation and Crystallization of Zr-Based Bulk Metallic Glass Due to Machining. Intermetallics 2004, 12, 195–204. [Google Scholar] [CrossRef]

- Bakkal, M.; Shih, A.J.; Scattergood, R.O. Chip Formation, Cutting Forces, and Tool Wear in Turning of Zr-Based Bulk Metallic Glass. Int. J. Mach. Tools Manuf. 2004, 44, 915–925. [Google Scholar] [CrossRef]

- Bakkal, M.; Shih, A.J.; Scattergood, R.O.; Liu, C.T. Machining of a Zr–Ti–Al–Cu–Ni Metallic Glass. Scr. Mater. 2004, 50, 583–588. [Google Scholar] [CrossRef]

- Hsieh, S.F.; Chen, S.L.; Lin, M.H.; Ou, S.F.; Lin, W.H.; Huang, M.S. Crystallization and Carbonization of an Electrical Discharge Machined Zr-Based Bulk Metallic Glass Alloy. J. Mater. Res. 2013, 28, 3177–3184. [Google Scholar] [CrossRef]

- Huang, H.; Yan, J. Microstructural Changes of Zr-Based Metallic Glass during Micro-Electrical Discharge Machining and Grinding by a Sintered Diamond Tool. J. Alloys Compd. 2016, 688, 14–21. [Google Scholar] [CrossRef]

- Huang, H.; Yan, J. On the Surface Characteristics of a Zr-Based Bulk Metallic Glass Processed by Microelectrical Discharge Machining. Appl. Surf. Sci. 2015, 353, 1306–1315. [Google Scholar] [CrossRef]

- Wang, X.; Lu, P.; Dai, N.; Liao, C.; Zheng, Q.; Liu, L. Noncrystalline Micromachining of Amorphous Alloys Using Femtosecond Laser Pulses. Mater. Lett. 2007, 61, 4290–4293. [Google Scholar] [CrossRef]

- Saxena, K.K.; Qian, J.; Reynaerts, D. A Review on Process Capabilities of Electrochemical Micromachining and Its Hybrid Variants. Int. J. Mach. Tools Manuf. 2018, 129, 28–56. [Google Scholar] [CrossRef]

- Skoczypiec, S. Electrochemical Methods of Micropart’s Manufacturing. In Micro and Precision Manufacturing; Springer: Cham, Switzerland, 2018; pp. 21–40. [Google Scholar]

- Hinduja, S.; Pattavanitch, J. Experimental and Numerical Investigations in Electro-Chemical Milling. CIRP J. Manuf. Sci. Technol. 2016, 12, 79–89. [Google Scholar] [CrossRef]

- Wang, Y. Research on Electrochemical Milling of TC4 and Ti40. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2019. [Google Scholar]

- Liu, Y. Fundamental Research on Micro Electrochemical Milling. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2010. [Google Scholar]

- Meng, L.; Zeng, Y.; Fang, X.; Zhu, D. Micropatterning of Ni-Based Metallic Glass by Pulsed Wire Electrochemical Micro Machining. Intermetallics 2017, 83, 16–25. [Google Scholar] [CrossRef]

- Yang, C.; Song, S.; Yan, B.; Huang, F. Improving Machining Performance of Wire Electrochemical Discharge Machining by Adding SiC Abrasive to Electrolyte. Int. J. Mach. Tools Manuf. 2006, 46, 2044–2050. [Google Scholar] [CrossRef]

- Yoneda, K.; Kunieda, M. Numerical Analysis of Cross Sectional Shape of Micro-Indents Formed by the Electrochemical Jet Machining (ECJM). Denki Kako Gakkaishi 2010, 29, 1–8. [Google Scholar] [CrossRef]

- Kozak, J.; Rajurkar, K.P.; Makkar, Y. Selected Problems of Micro-Electrochemical Machining. J. Mater. Process. Technol. 2005, 149, 426–431. [Google Scholar] [CrossRef]

- Lee, E.S.; Shin, T.H.; Kim, B.K.; Beak, S.Y. Investigation of Short Pulse Electrochemical Machining for Groove Process on Ni-Ti Shape Memory Alloy. Int. J. Precis. Eng. Manuf. 2010, 11, 113–118. [Google Scholar] [CrossRef]

- Liu, W. Research on Mechanism and Key Processes of Electrolytic Jet Machining of TB6 Titanium Alloy. Ph.D. Thesis, Tianjin University, Tianjin, China, 2020. [Google Scholar]

- Chen, X.L.; Fan, G.C.; Lin, C.H.; Dong, B.Y.; Guo, Z.N.; Fang, X.L.; Qu, N.S. Investigation on the Electrochemical Machining of Micro Groove Using Masked Porous Cathode. J. Mater. Process. Technol. 2020, 279, 116406. [Google Scholar] [CrossRef]

- Zhao, Y.; Lyu, Z.; Liu, W.; Zhang, B.; Adam, T.C. Submerged Electrochemical Jet Machining with In-Situ Gas Assistance. CIRP Ann. Manuf. Technol. 2024, 73, 117–120. [Google Scholar] [CrossRef]

- Zhang, X.; Song, X.; Ming, P.; Li, X.; Zeng, Y.; Cai, J. The Effect of Electrolytic Jet Orientation on Machining Characteristics in Jet Electrochemical Machining. Micromachines 2019, 10, 404. [Google Scholar] [CrossRef]

- Zhai, K.; Liang, Y.; Li, T.; Ma, S.; Du, L. Research on Jet Electrochemical Machining with Coaxial Megasonic Assistance. Ultrason. Sonochem. 2024, 107, 107054. [Google Scholar] [CrossRef]

- He, B.; Li, H.; Ma, X.; Li, J.; Fan, S. Plane Machining by Inner-Jet Electrochemical Milling of TiB2/7050 Aluminum Matrix Composite. Appl. Sci. 2021, 11, 8087. [Google Scholar] [CrossRef]

| Physics | Boundaries | Conditions | |

|---|---|---|---|

| Geometry | D | 175 μm | 250 μm |

| Electric Field | 7–9 | Potential: φ = 0 Potential: φ = 25 V Inlet: velocity, U0 = 10 m/s Outlet pressure, p0 = 0 Pa | |

| 5–6 | |||

| Flow Field | 1 | ||

| 3–4 | |||

| Parameters | Value |

|---|---|

| Material | Zr41.2Ti13.8Cu12.5Ni10.0Be22.5 |

| Tool electrode | SUS 304 nozzle |

| Electrolyte pressure (MPa) | 1 |

| Machining gap (µm) | 100, 200, 300, 400 |

| Nozzle travel rate (µm/s) | 50, 100, 150, 200 |

| Machining voltage (V) | 15, 20, 25, 30 |

| Potential (V) | R1 (Ω cm−2) | C1 (μF cm−2) | R2 (Ω cm−2) | C2 (μF cm−2) | R3 (Ω cm−2) | L1 (H cm−2) |

|---|---|---|---|---|---|---|

| −0.1 | 1.953 | 0.905 | 1445 | - | - | - |

| 1 | 2.344 | 1.1 | 1063 | 0.6109 | 1.0 × 1020 | - |

| 2.1 | 1.301 | 1.141 | 362 | - | 322.6 | 9.768 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Ming, P.; Li, D.; Zhao, R.; Niu, S. Fabricating High Aspect Ratio Amorphous Alloys Microgrooves by Using Periodically Thinning Jet Electrochemical Milling Method. Micromachines 2025, 16, 979. https://doi.org/10.3390/mi16090979

Li Y, Ming P, Li D, Zhao R, Niu S. Fabricating High Aspect Ratio Amorphous Alloys Microgrooves by Using Periodically Thinning Jet Electrochemical Milling Method. Micromachines. 2025; 16(9):979. https://doi.org/10.3390/mi16090979

Chicago/Turabian StyleLi, Yahui, Pingmei Ming, Dongdong Li, Rongbo Zhao, and Shen Niu. 2025. "Fabricating High Aspect Ratio Amorphous Alloys Microgrooves by Using Periodically Thinning Jet Electrochemical Milling Method" Micromachines 16, no. 9: 979. https://doi.org/10.3390/mi16090979

APA StyleLi, Y., Ming, P., Li, D., Zhao, R., & Niu, S. (2025). Fabricating High Aspect Ratio Amorphous Alloys Microgrooves by Using Periodically Thinning Jet Electrochemical Milling Method. Micromachines, 16(9), 979. https://doi.org/10.3390/mi16090979