On-Machine Precision Truing and Error Compensation of Cup-Shaped Diamond Grinding Wheels with Arc-Shaped Cutting Edge

Abstract

1. Introduction

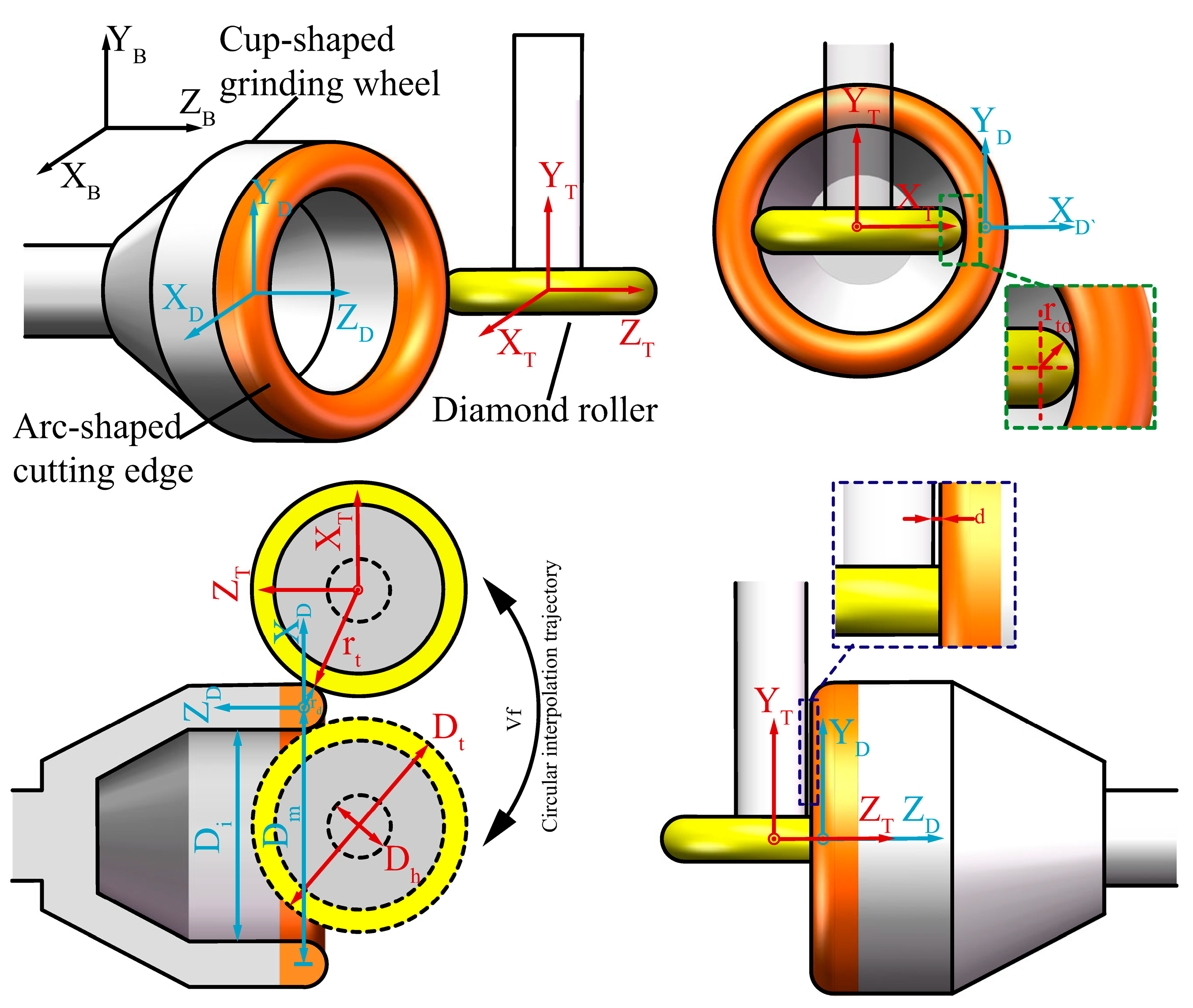

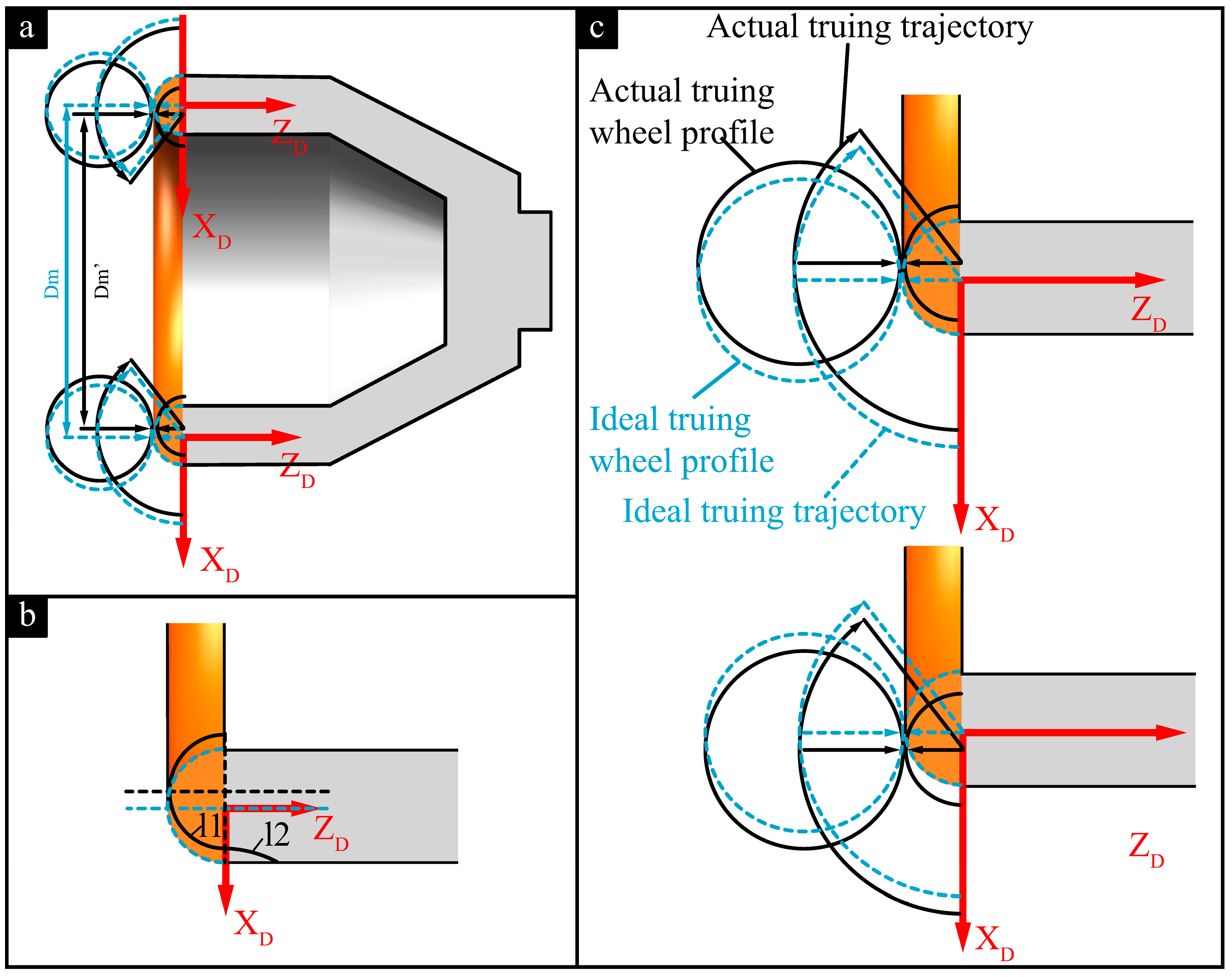

2. Truing Principle of Arc-Shaped Cutting Edge of Grinding Wheels

3. Analysis of Error Sources

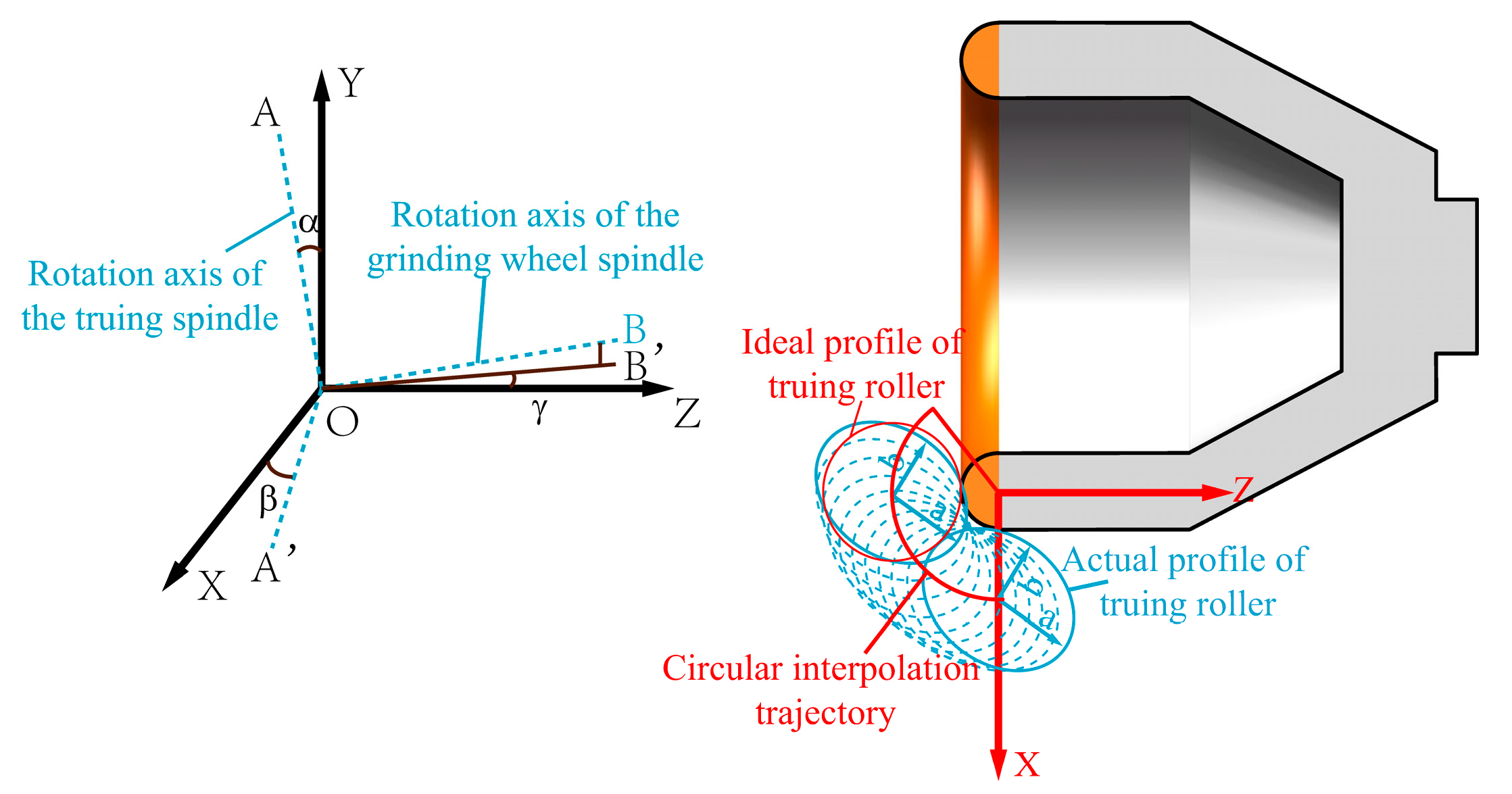

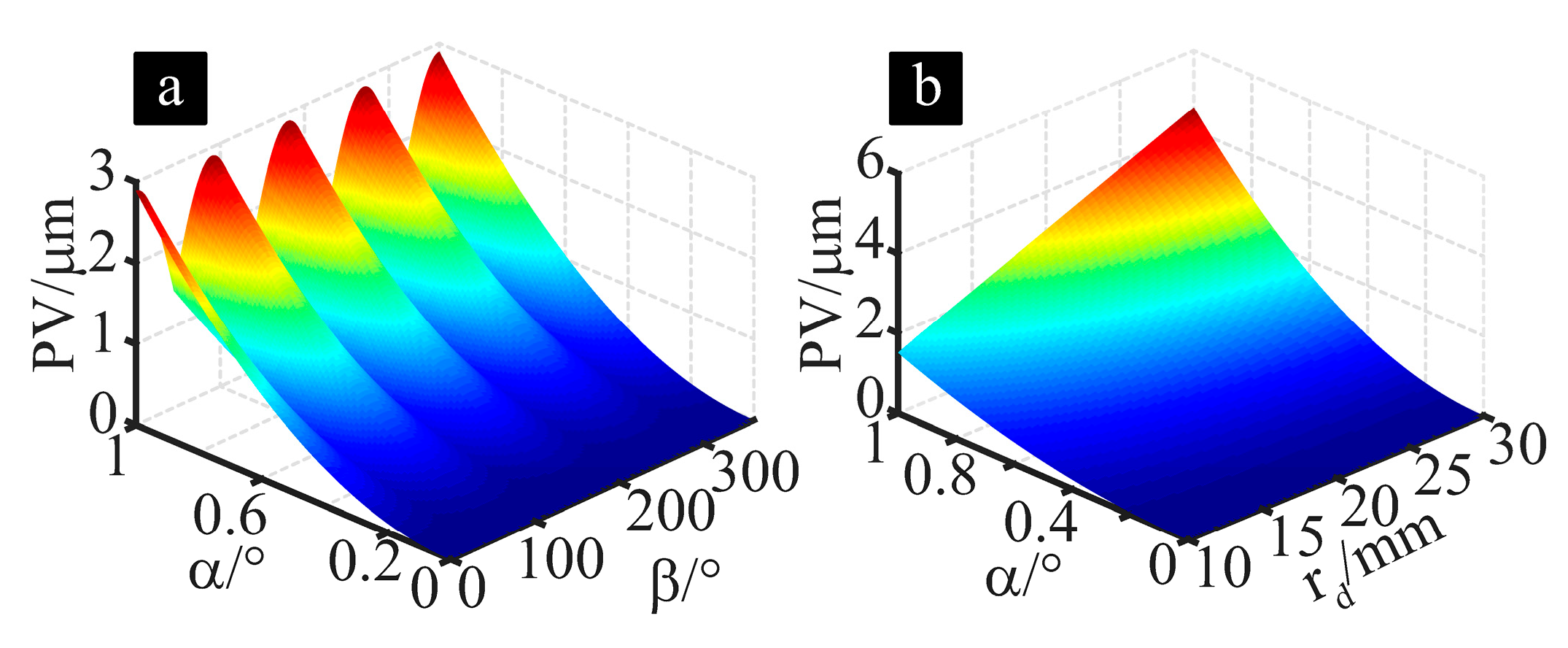

3.1. Pose Error Between the Axis of the Truing Spindle and the Grinding Wheel Spindle

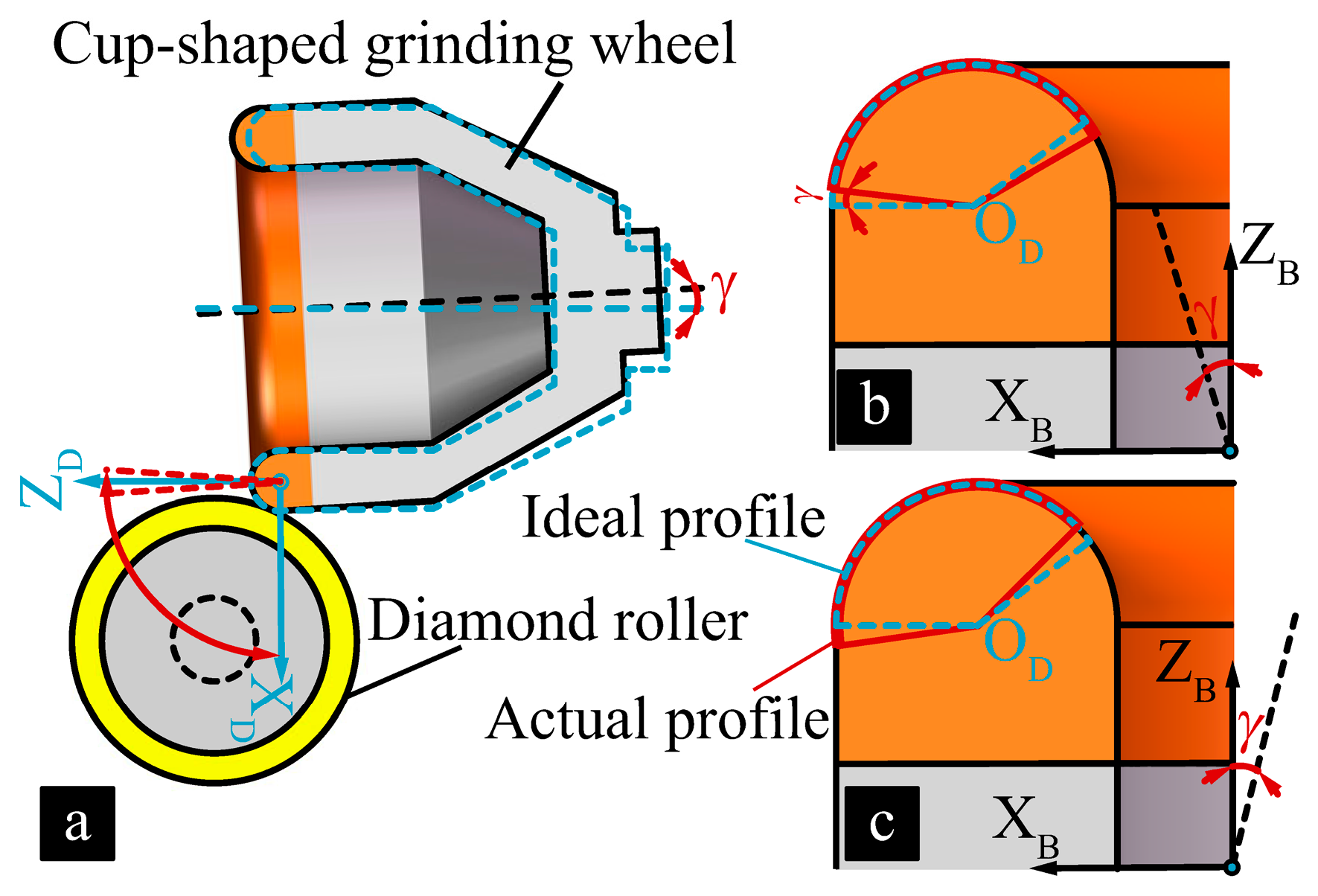

3.2. The Tool Alignment Error

4. Experimental Method

4.1. Experimental Setup

4.2. Experimental Procedure

5. Results and Discussion

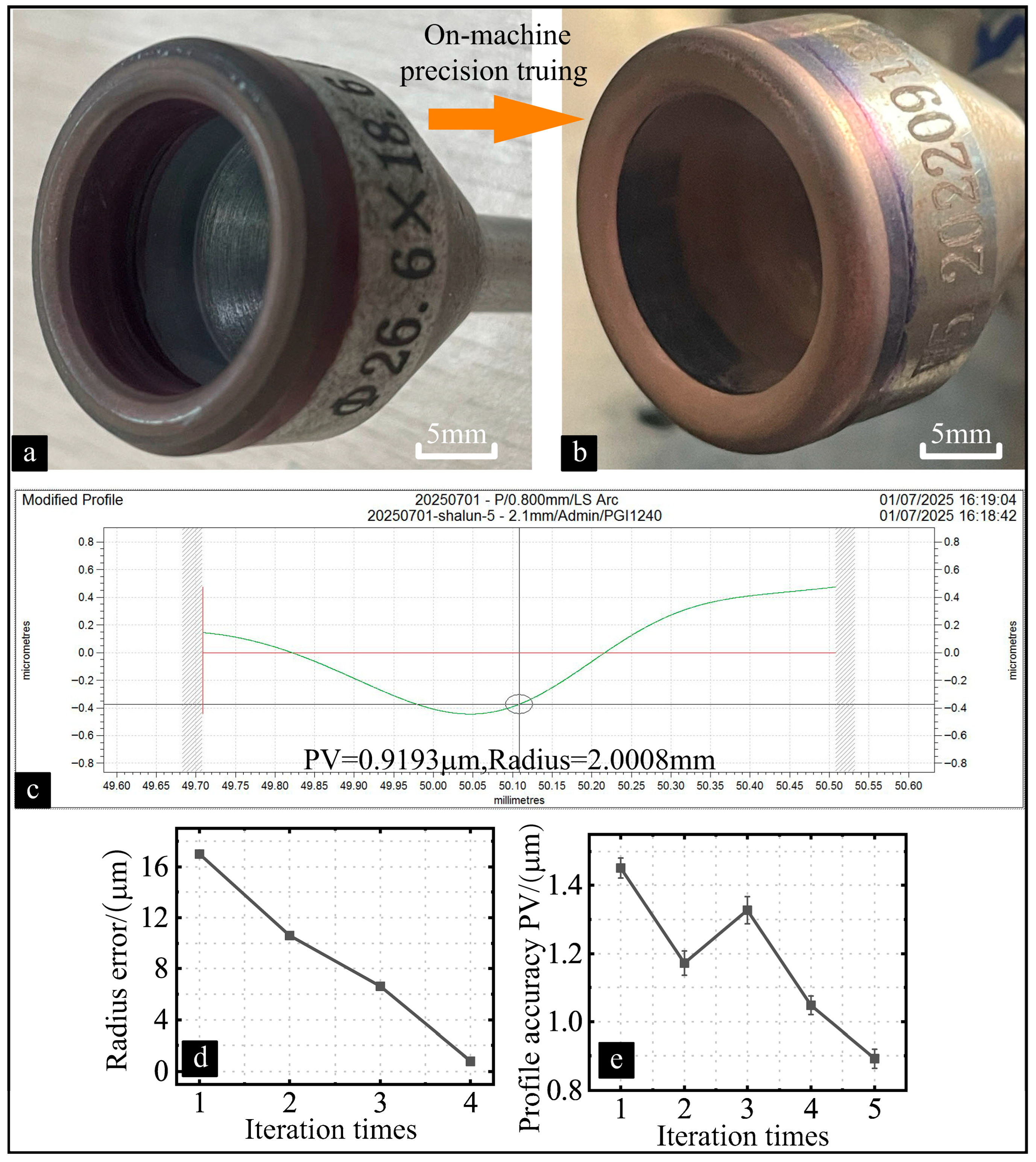

5.1. Analysis and Verification of the Truing Accuracy of the Arc-Shaped Cutting Edge of Cup-Shaped Grinding Wheels

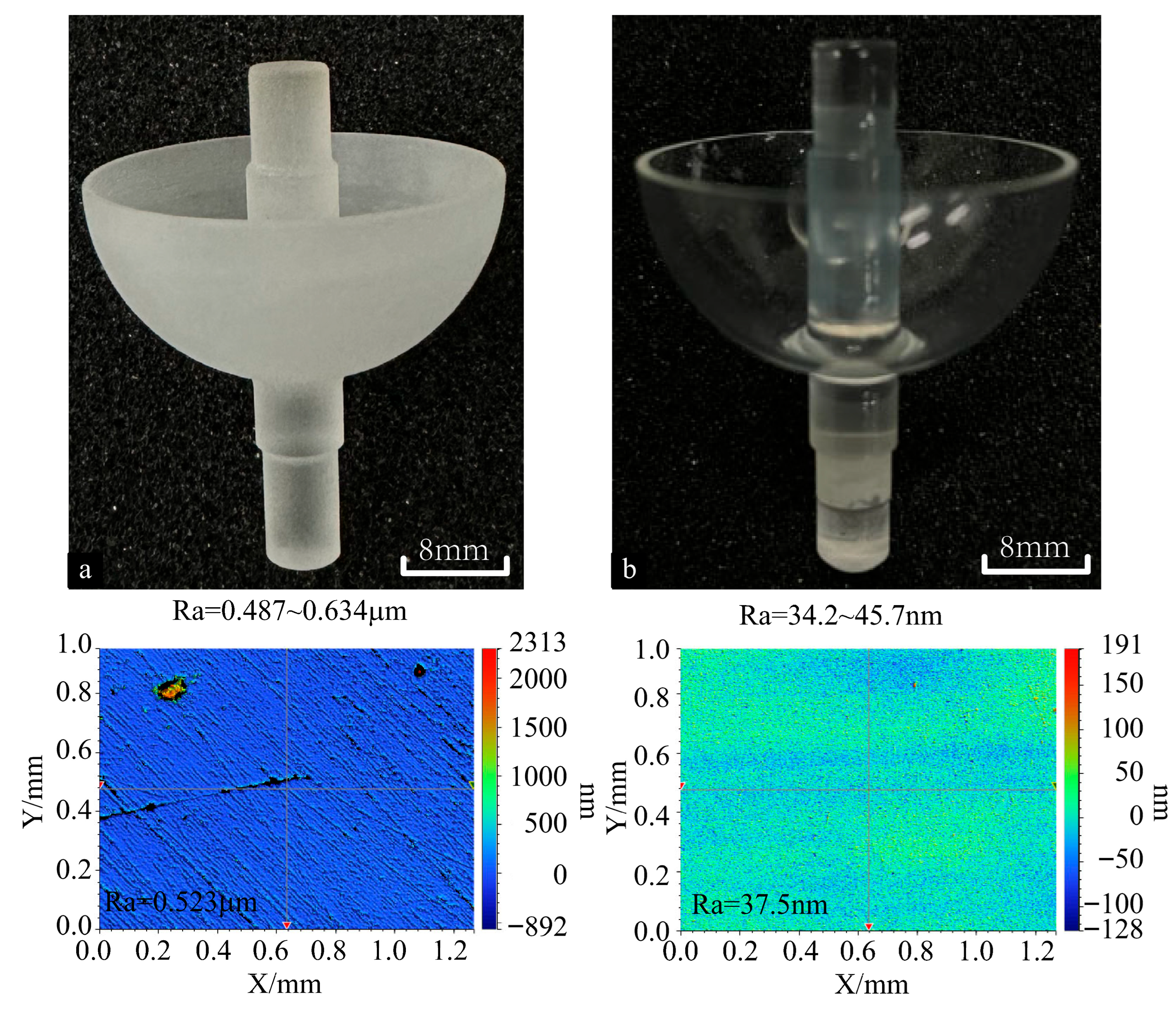

5.2. Grinding of Complex Fused Silica Component

6. Conclusions

- (1)

- Various errors occur during precision truing that significantly impact the profile accuracy of diamond grinding wheels. The primary errors include tooling setting errors, pose errors, and measurement errors in determining the roller radius. Theoretical models of these errors have been developed, and the errors have been categorised and traced to minimise their effect on profile accuracy.

- (2)

- More factors affect cup-shaped grinding wheels’ cutting edge profile accuracy than dimensional accuracy. The main factor affecting profile accuracy is the pose error between the rotating axes of the cup-shaped grinding wheel and the diamond roller. It is worth noting that the larger the dimension of the diamond roller, the greater the impact of pose error on profile accuracy. However, the factor with the greatest impact on dimensional accuracy is the measurement error of the diamond roller dimension.

- (3)

- Compensation truing experiments are conducted based on the error analysis model, resulting in high-precision cup-shaped grinding wheels with arc-shaped cutting edges. Following compensation, the dimensional error of the diamond grinding wheel’s cutting edge decreased by around 92% (from 17.3 μm to 1.5 μm). Profile error is reduced from 1.46 μm to 0.89 μm.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Evans, C.J.; Bryan, J.B. “Structured”, “Textured” or “Engineered” Surfaces. CIRP Ann. 1999, 48, 541–556. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Mutlugünes, Y.; Klocke, F.; Aurich, J.C.; Shore, P.; Ohmori, H. Ultra-precision grinding. CIRP Ann. 2010, 59, 652–671. [Google Scholar] [CrossRef]

- Zhao, Q. Ultraprecision Grinding Technology of Microstructured Optical Functional Molds. J. Mech. Eng. 2011, 47, 177. [Google Scholar] [CrossRef]

- Schfer, H.; Diehl, J.; Urban, L. Grinding and polishing machine for grinding and/or polishing workpieces to an optical quality. U.S. Patent 2007293128A1, 20 December 2007. [Google Scholar]

- Fess, E.; Bechtold, M.; Wolfs, F.; Bechtold, R. Developments in precision optical grinding technology. In Proceedings of the Optifab 2013, Rochester, NY, USA, 14–18 October 2013; Volume 8884, pp. 96–100. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, X.; Zheng, L.; Xue, D. High-performance grinding of a 2-m scale silicon carbide mirror blank for the space-based telescope. Int. J. Adv. Manuf. Technol. 2017, 89, 463–473. [Google Scholar] [CrossRef]

- Kannan, K.; Arunachalam, N. Grinding wheel redress life estimation using force and surface texture analysis. Procedia CIRP 2018, 72, 1439–1444. [Google Scholar] [CrossRef]

- Tran, T.H.; Le, X.H.; Nguyen, Q.T.; Le, H.K.; Hoang, T.D.; Luu, A.-T.; Banh, T.-L.; Vu, N.-P. Optimization of replaced grinding wheel diameter for minimum grinding cost in internal grinding. Appl. Sci. 2019, 9, 1363. [Google Scholar] [CrossRef]

- Chen, B.; Guo, B.; Zhao, Q. On-machine precision form truing of arc-shaped diamond wheels. J. Mater. Process. Technol. 2015, 223, 65–74. [Google Scholar] [CrossRef]

- Liu, Z.; Tang, Q.; Liu, N.; Liang, P.; Liu, W. A novel optimization design method of form grinding wheel for screw rotor. Appl. Sci. 2019, 9, 5079. [Google Scholar] [CrossRef]

- Hwang, Y.; Kuriyagawa, T.; Lee, S.-K. Wheel curve generation error of aspheric microgrinding in parallel grinding method. Int. J. Mach. Tools Manuf. 2006, 46, 1929–1933. [Google Scholar] [CrossRef]

- Wegener, K.; Hoffmeister, H.W.; Karpuschewski, B.; Kuster, F.; Hahmann, W.C.; Rabiey, M. Conditioning and monitoring of grinding wheels. CIRP Ann. Manuf. Technol. 2011, 60, 757–777. [Google Scholar] [CrossRef]

- Deng, H.; Xu, Z. Dressing methods of superabrasive grinding wheels: A review. J. Manuf. Process. 2019, 45, 46–69. [Google Scholar] [CrossRef]

- Qiu, Z.-J.; Zou, D.-C.; Yan, G.-P. Mechanical dressing of resin bond diamond grinding wheel based on dressing force. Guangxue Jingmi Gongcheng/Opt. Precis. Eng. 2015, 23, 996–1003. [Google Scholar] [CrossRef]

- Pombo, I.; Cearsolo, X.; Sánchez, J.A.; Cabanes, I. Experimental and numerical analysis of thermal phenomena in the wear of single point diamond dressing tools. J. Manuf. Process. 2017, 27, 145–157. [Google Scholar] [CrossRef]

- Ding, W.; Li, H.; Zhang, L.; Xu, J.; Fu, Y.; Su, H. Diamond Wheel Dressing: A Comprehensive Review. J. Manuf. Sci. Eng. 2017, 139, 121006. [Google Scholar] [CrossRef]

- Deng, H.; Chen, G.Y.; Zhou, C.; Li, S.C.; Zhang, M.J. Processing parameter optimization for the laser dressing of bronze-bonded diamond wheels. Appl. Surf. Sci. 2014, 290, 475–481. [Google Scholar] [CrossRef]

- Xie, J.; Zhou, R.M.; Xu, J.; Zhong, Y.G. Form-truing error compensation of diamond grinding wheel in CNC envelope grinding of free-form surface. Int. J. Adv. Manuf. Technol. 2010, 48, 905–912. [Google Scholar] [CrossRef]

- Lin, X.H.; Wang, Z.Z.; Guo, Y.B.; Peng, Y.F.; Hu, C.L. Research on the error analysis and compensation for the precision grinding of large aspheric mirror surface. Int. J. Adv. Manuf. Technol. 2014, 71, 233–239. [Google Scholar] [CrossRef]

- Xu, L.M.; Fan, F.; Zhang, Z.; Chao, X.J.; Niu, M. Fast on-machine profile characterization for grinding wheels and error compensation of wheel dressing. Precis. Eng. 2019, 55, 417–425. [Google Scholar] [CrossRef]

- Palmer, J.; Ghadbeigi, H.; Novovic, D.; Curtis, D. An experimental study of the effects of dressing parameters on the topography of grinding wheels during roller dressing. J. Manuf. Process. 2018, 31, 348–355. [Google Scholar] [CrossRef]

- Chen, W.K.; Kuriyagawa, T.; Huang, H.; Yosihara, N. Machining of micro aspherical mould inserts. Precis. Eng. 2005, 29, 315–323. [Google Scholar] [CrossRef]

- Wang, T.; Wu, C.; Liu, H.; Chen, M.; Cheng, J.; Dingning, S. On-machine electric discharge truing of small ball-end fine diamond grinding wheels. J. Mater. Process. Technol. 2020, 277, 116472. [Google Scholar] [CrossRef]

- Zhu, J.; Yao, P.; Wang, W.; Huang, C.; Zhu, H.; Zou, B.; Liu, H. A helical interpolation precision truing and error compensation for arc-shaped diamond grinding wheel. Int. J. Adv. Manuf. Technol. 2019, 100, 167–177. [Google Scholar] [CrossRef]

- Qiao, J.; Wu, H.; Sun, L.; Feng, M.; Zeng, J.; Wu, Y. Experimental Investigation on Ultrasonic-Assisted Truing/Dressing of Diamond Grinding Wheel with Cup-Shaped GC Wheel. Int. J. Adv. Manuf. Technol. 2022, 121, 1717–1730. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, H.; Rao, X.; Mo, R.; Cai, Y. Experimental Study on Dry Electrical Discharge Truing of Metal-Bonded Diamond Wheel. Mater. Today Commun. 2024, 39, 109242. [Google Scholar] [CrossRef]

- Meng, Q.; Guo, B.; Wu, G.; Xiang, Y.; Guo, Z.; Zhao, Q.; Li, K.; Chen, B. Precision Truing of Electroplated Diamond Grinding Wheels via Spray-Mist-Assisted Laser Technology. Mater. Des. 2022, 224, 111409. [Google Scholar] [CrossRef]

- Guo, B.; Meng, Q.; Li, S.; Wu, G.; Xiang, Y.; Zhao, Q. Pulse Laser Precision Truing of the V-Shaped Coarse-Grained Electroplating CBN Grinding Wheel. Mater. Des. 2022, 217, 110650. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, G.; Luo, F.; Zhou, W. Experimental Study on Laser Dressing of Bronze-Bonded Diamond Arc Grinding Wheel Based on Self-Powered Sensor. IEEE Sens. J. 2023, 23, 20817–20824. [Google Scholar] [CrossRef]

| Parameter | ||

|---|---|---|

| Cup-shaped grinding wheel | Bond | Resin-bond |

| Grain size | 5 μm | |

| Diameter Dm | 22.6 mm | |

| Expected radius | 2 mm | |

| Diamond roller | Bond | Metal bond |

| Grain size | 60 μm | |

| Diameter Dt | 19 mm | |

| Radius rto | 2 mm |

| Parameter | Value |

|---|---|

| Speed of the cup-shaped grinding wheel (rpm) | 14,000 |

| Speed of the diamond roller (rpm) | 500 |

| Truing depth per pass (μm) | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Yin, Z. On-Machine Precision Truing and Error Compensation of Cup-Shaped Diamond Grinding Wheels with Arc-Shaped Cutting Edge. Micromachines 2025, 16, 1050. https://doi.org/10.3390/mi16091050

Guo Y, Yin Z. On-Machine Precision Truing and Error Compensation of Cup-Shaped Diamond Grinding Wheels with Arc-Shaped Cutting Edge. Micromachines. 2025; 16(9):1050. https://doi.org/10.3390/mi16091050

Chicago/Turabian StyleGuo, Yawen, and Ziqiang Yin. 2025. "On-Machine Precision Truing and Error Compensation of Cup-Shaped Diamond Grinding Wheels with Arc-Shaped Cutting Edge" Micromachines 16, no. 9: 1050. https://doi.org/10.3390/mi16091050

APA StyleGuo, Y., & Yin, Z. (2025). On-Machine Precision Truing and Error Compensation of Cup-Shaped Diamond Grinding Wheels with Arc-Shaped Cutting Edge. Micromachines, 16(9), 1050. https://doi.org/10.3390/mi16091050