Integration of High-Brightness QLED-Excited Diamond Magnetic Sensor

Abstract

1. Introduction

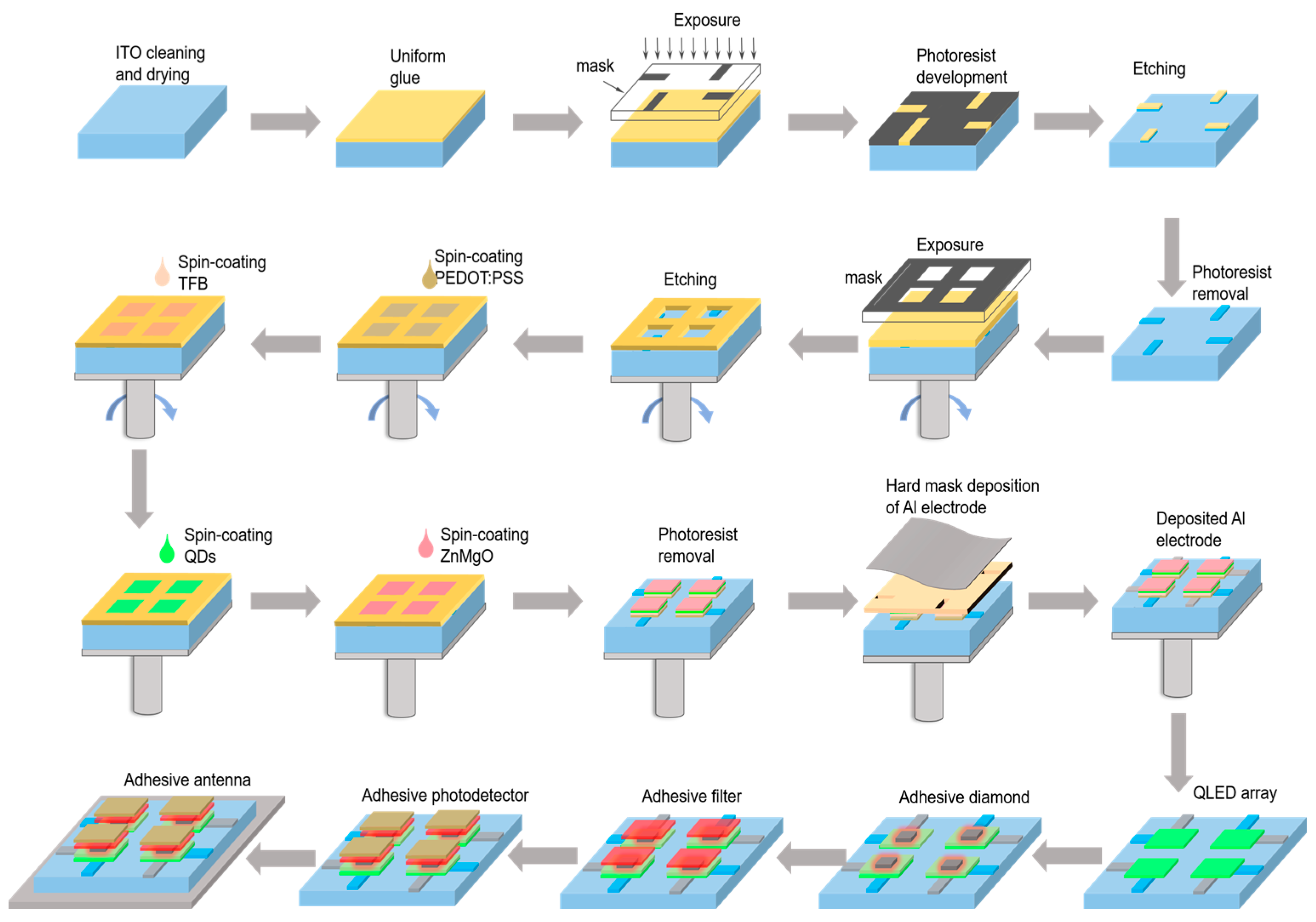

2. Materials and Methods

2.1. Materials and Preparation of QLED

2.2. Preparation of QLED-Excited Diamond Magnetic Sensor

2.3. Characterization of QLEDs

2.4. Characterization of the Magnetometer Array

3. Results and Discussion

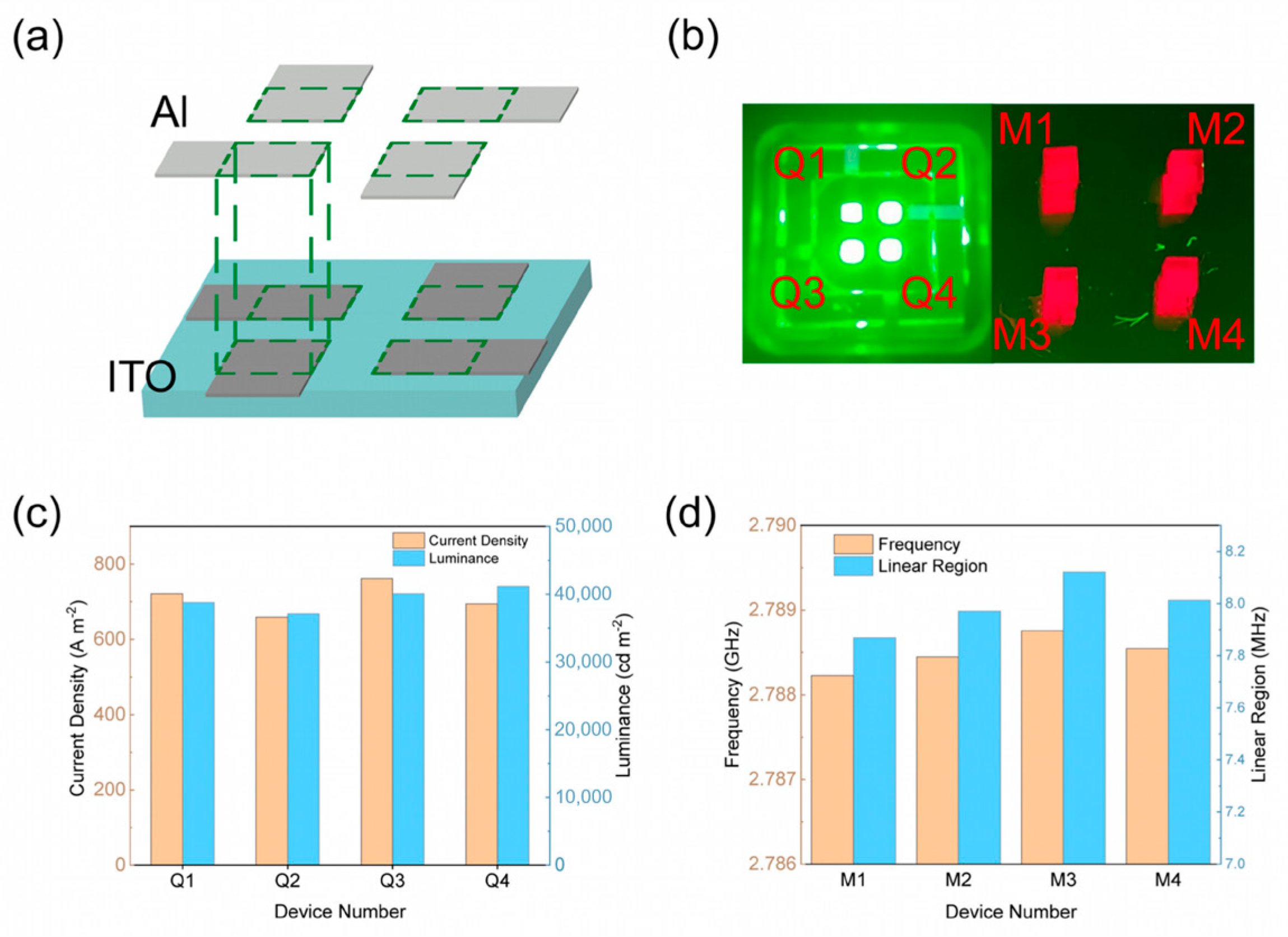

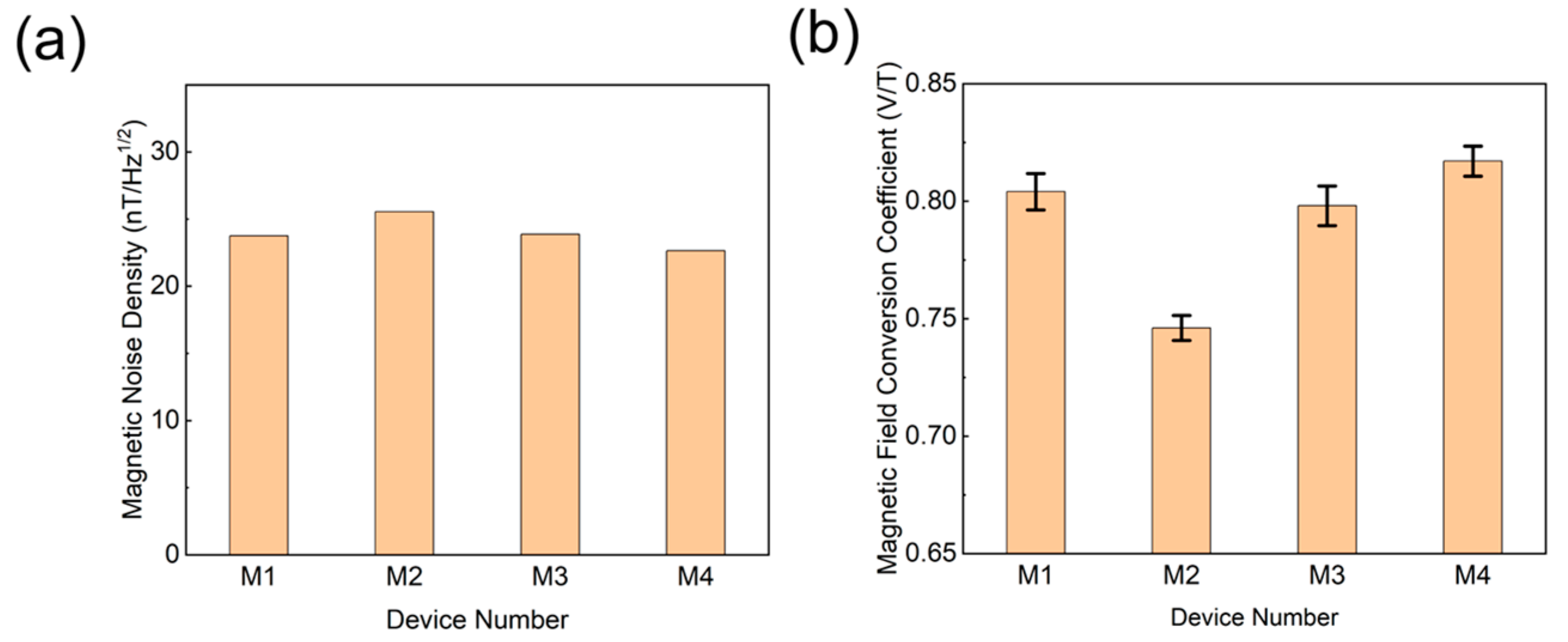

3.1. Design and Characterization of Magnetometer Array

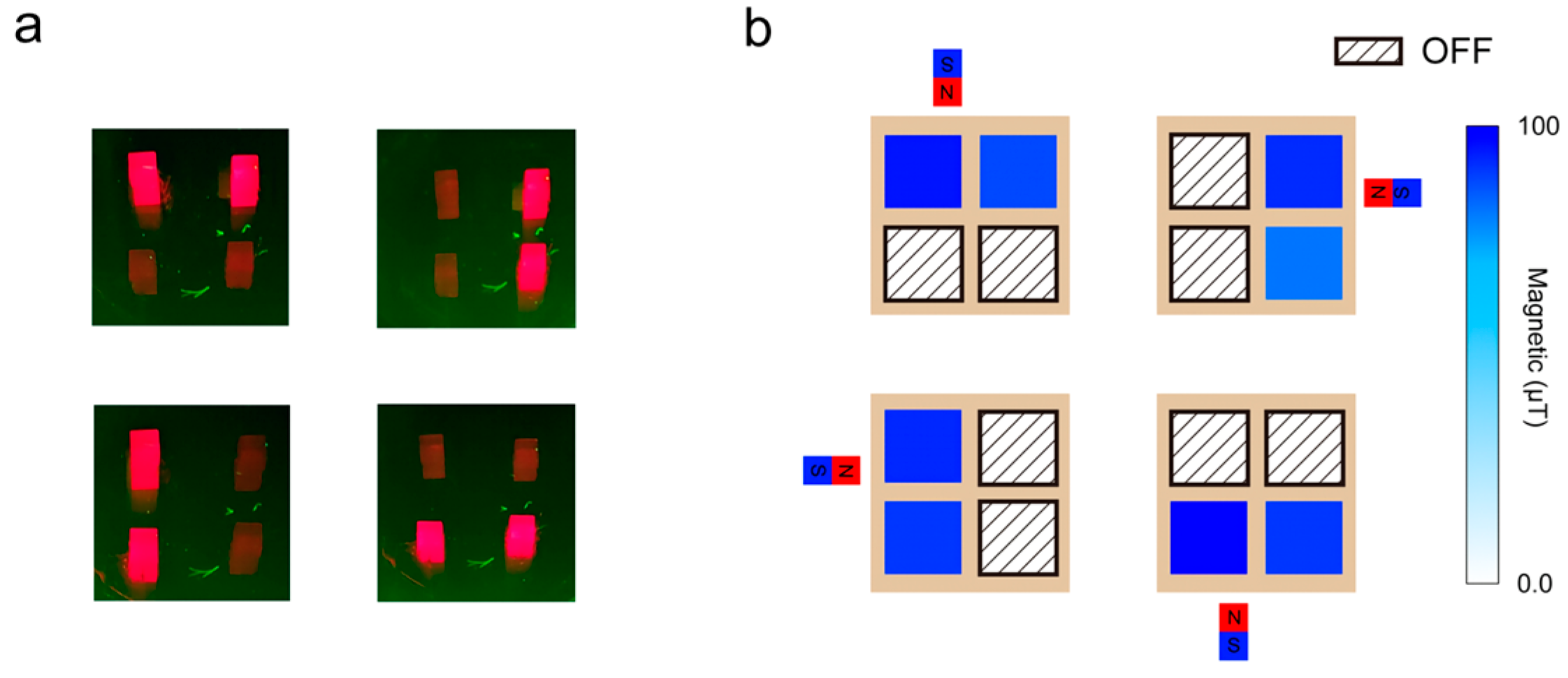

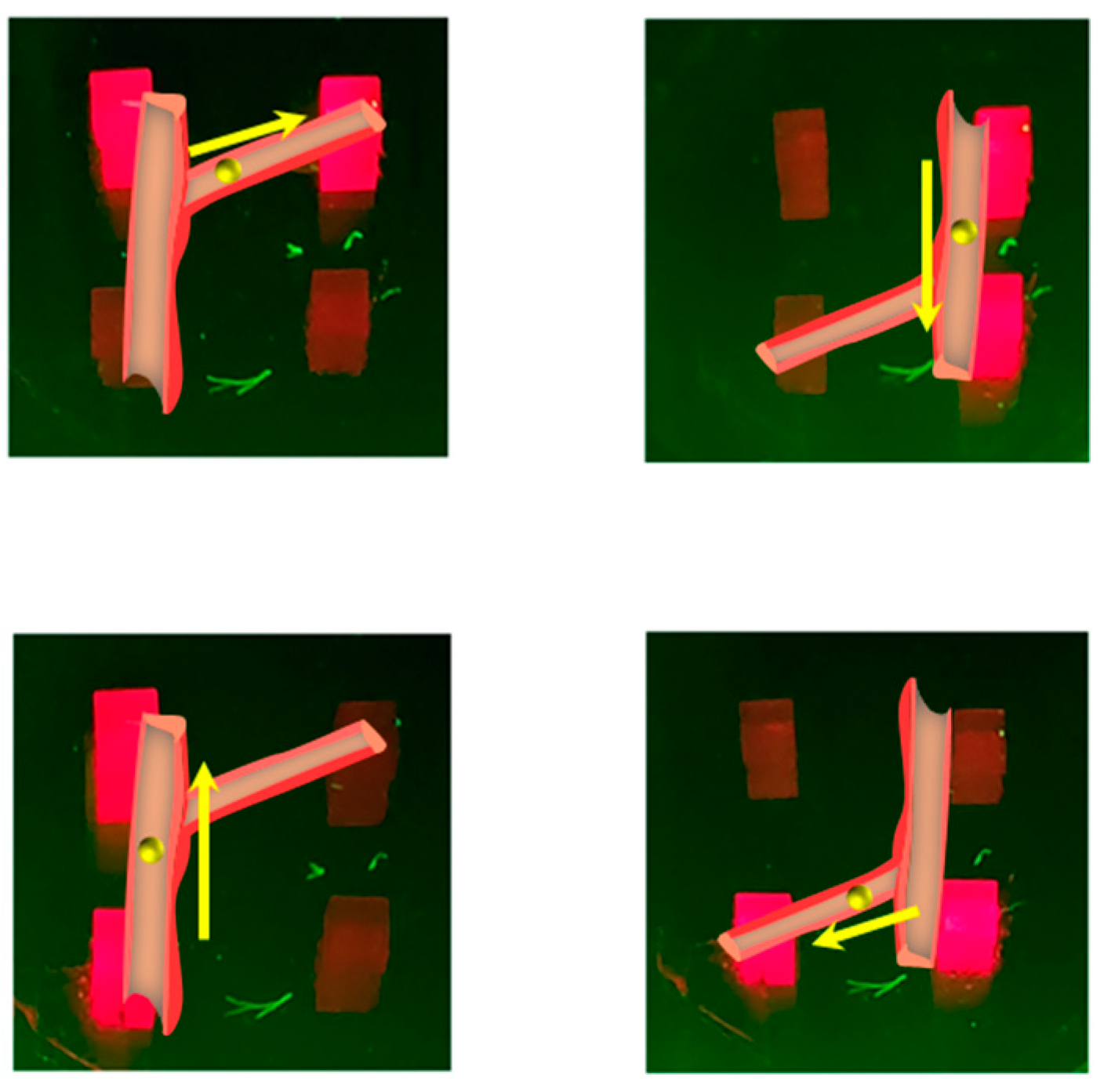

3.2. Detection of Regional Magnetic Field

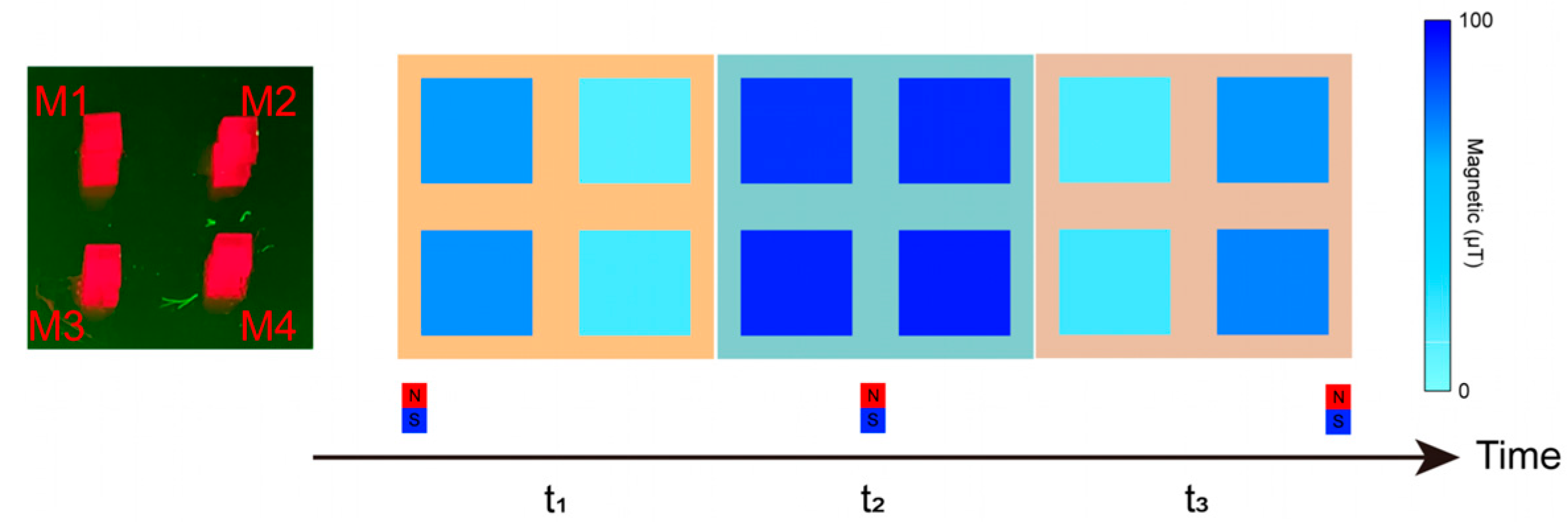

3.3. Detection of Dynamic Magnetic Field

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, P.; Ando, M.; Taguchi, T.; Murase, N. Highly Luminescent CdSe/CdxZn1-xS Quantum Dots with Narrow Spectrum and Widely Tunable Wavelength. J. Phys. Chem. C 2011, 115, 14455–14460. [Google Scholar] [CrossRef]

- Taylor, J.; Cappellaro, P.; Childress, L.; Jiang, L.; Budker, D.; Hemmer, P.; Yacoby, A.; Walsworth, R.; Lukin, M. Erratum: High-sensitivity diamond magnetometer with nanoscale resolution. Nat. Phys. 2011, 7, 270. [Google Scholar] [CrossRef]

- Schoenfeld, R.S.; Harneit, W. Real time magnetic field sensing and imaging using a single spin in diamond. Phys. Rev. Lett. 2011, 106, 030802. [Google Scholar] [CrossRef]

- Gao, W.; Shen, S.; Tai, J.; Wen, H.; Li, X.; Li, Z.; Ma, Z.; Shi, Y.; Guo, H.; Tang, J.; et al. High-efficiency diamond fluorescence detection for magnetic sensing systems using a filter-free narrowband photodetector. Opt. Express 2025, 33, 38364–38372. [Google Scholar] [CrossRef]

- Qin, Y.; Guo, H.; Wu, D.; Ma, Y.; Li, X.; Wen, H.; Li, Z.; Ma, Z.; Tian, H.; Tang, J. Laser writing of spin defects in polymers. Sci. Adv. 2025, 11, eadv1848. [Google Scholar] [CrossRef]

- Granata, C.; Vettoliere, A. Nano Superconducting Quantum Interference device: A powerful tool for nanoscale investigations. Phys. Rep.-Rev. Sect. Phys. Lett. 2016, 614, 1–69. [Google Scholar] [CrossRef]

- Childress, L.; Hanson, R. Diamond NV centers for quantum computing and quantum networks. Mrs Bull. 2013, 38, 134–138. [Google Scholar] [CrossRef]

- Yang, B.; Dong, Y.; Hu, Z.Z.; Liu, G.Q.; Wang, Y.J.; Du, G.X. Noninvasive Imaging Method of Microwave Near Field Based on Solid-State Quantum Sensing. IEEE Trans. Microw. Theory Tech. 2018, 66, 2276–2283. [Google Scholar] [CrossRef]

- Zhou, L.; Patel, R.; Frangeskou, A.; Nikitin, A.; Green, B.L.; Breeze, B.; Onoda, S.; Isoya, J.; Morley, G. Imaging damage in steel using a diamond magnetometer. Phys. Rev. Appl. 2021, 15, 024015. [Google Scholar] [CrossRef]

- Soshenko, V.V.; Bolshedvorskii, S.V.; Rubinas, O.; Sorokin, V.N.; Smolyaninov, A.N.; Vorobyov, V.V.; Akimov, A.V. Nuclear spin gyroscope based on the nitrogen vacancy center in diamond. Phys. Rev. Lett. 2021, 126, 197702. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Qin, Y.; Wang, Z.; Ma, Y.; Wen, H.; Li, Z.; Ma, Z.; Li, X.; Tang, J.; Liu, J. Multilevel encoding physically unclonable functions based on the multispecies structure in diamonds. Adv. Funct. Mater. 2024, 34, 2304648. [Google Scholar] [CrossRef]

- Bi, R.; Chen, R.; Wu, S.; Ma, H.; Zhang, H.; Liu, X.; He, J.; Hu, J. A High-Sensitivity, Low-Noise, and Low-Hysteresis Tunneling Magnetoresistance Sensor Based on Structural Optimization of Magnetic Tunnel Junctions. Sensors 2025, 25, 1730. [Google Scholar] [CrossRef]

- Xie, Y.J.; Yu, H.Y.; Zhu, Y.B.; Qin, X.; Rong, X.; Duan, C.K.; Du, J.F. A hybrid magnetometer towards femtotesla sensitivity under ambient conditions. Sci. Bull. 2021, 66, 127–132. [Google Scholar] [CrossRef]

- Wickenbrock, A.; Zheng, H.; Bougas, L.; Leefer, N.; Afach, S.; Jarmola, A.; Acosta, V.M.; Budker, D. Microwave-free magnetometry with nitrogen-vacancy centers in diamond. Appl. Phys. Lett. 2016, 109, 053505. [Google Scholar] [CrossRef]

- Zhang, T.T.; Pramanik, G.; Zhang, K.; Gulka, M.; Wang, L.Z.; Jing, J.X.; Xu, F.; Li, Z.F.; Wei, Q.; Cigler, P.; et al. Toward Quantitative Bio-sensing with Nitrogen-Vacancy Center in Diamond. ACS Sens. 2021, 6, 2077–2107. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.M.; Zhang, S.W.; Fu, Y.P.; Yuan, H.; Shi, Y.B.; Gao, J.; Qin, L.; Tang, J.; Liu, J.; Li, Y.J. Magnetometry for precision measurement using frequency-modulation microwave combined efficient photon-collection technique on an ensemble of nitrogen-vacancy centers in diamond. Opt. Express 2018, 26, 382–390. [Google Scholar] [CrossRef]

- Zhang, C.; Yuan, H.; Zhang, N.; Xu, L.; Zhang, J.; Li, B.; Fang, J. Vector magnetometer based on synchronous manipulation of nitrogen-vacancy centers in all crystal directions. J. Phys. D Appl. Phys. 2018, 51, 155102. [Google Scholar] [CrossRef]

- Stürner, F.M.; Brenneis, A.; Kassel, J.; Wostradowski, U.; Rölver, R.; Fuchs, T.; Nakamura, K.; Sumiya, H.; Onoda, S.; Isoya, J.; et al. Compact integrated magnetometer based on nitrogen-vacancy centres in diamond. Diam. Relat. Mater. 2019, 93, 59–65. [Google Scholar] [CrossRef]

- Webb, J.L.; Clement, J.D.; Troise, L.; Ahmadi, S.; Johansen, G.J.; Huck, A.; Andersen, U.L. Nanotesla sensitivity magnetic field sensing using a compact diamond nitrogen-vacancy magnetometer. Appl. Phys. Lett. 2019, 114, 231103. [Google Scholar] [CrossRef]

- Wang, S.J.; Gao, W.; Qin, Y.; Guo, H.; Shi, Y.M.; Zhang, J.; Wang, L.L.; Wen, H.F.; Li, Z.H.; Ma, Z.M.; et al. Integration of High-Brightness QLED-Excited Diamond NV Magnetic Sensing Probe. IEEE Sens. J. 2025, 25, 16864–16872. [Google Scholar] [CrossRef]

- Kim, D.; Ibrahim, M.I.; Foy, C.; Trusheim, M.E.; Han, R.; Englund, D.R. A CMOS-integrated quantum sensor based on nitrogen-vacancy centres. Nat. Electron. 2019, 2, 284–289. [Google Scholar] [CrossRef]

- Wang, X.M.; Zheng, D.D.; Wang, X.C.; Liu, X.Y.; Wang, Q.M.; Zhao, J.Z.; Guo, H.; Qin, L.; Tang, J.; Ma, Z.M.; et al. Portable Diamond NV Magnetometer Head Integrated With 520 nm Diode Laser. IEEE Sens. J. 2022, 22, 5580–5587. [Google Scholar] [CrossRef]

- Pogorzelski, J.; Horsthemke, L.; Homrighausen, J.; Stiegektter, D.; Gregor, M.; Glsektter, P. Compact and Fully Integrated LED Quantum Sensor Based on NV Centers in Diamond. Sensors 2024, 24, 16. [Google Scholar] [CrossRef]

- Lee, T.; Kim, B.J.; Lee, H.; Hahm, D.; Bae, W.K.; Lim, J.; Kwak, J. Bright and stable quantum dot light-emitting diodes. Adv. Mater. 2022, 34, 2106276. [Google Scholar] [CrossRef]

- Song, J.; Wang, O.; Shen, H.; Lin, Q.; Li, Z.; Wang, L.; Zhang, X.; Li, L.S. Over 30% external quantum efficiency light-emitting diodes by engineering quantum dot-assisted energy level match for hole transport layer. Adv. Funct. Mater. 2019, 29, 1808377. [Google Scholar] [CrossRef]

- Won, Y.-H.; Cho, O.; Kim, T.; Chung, D.-Y.; Kim, T.; Chung, H.; Jang, H.; Lee, J.; Kim, D.; Jang, E. Highly efficient and stable InP/ZnSe/ZnS quantum dot light-emitting diodes. Nature 2019, 575, 634–638. [Google Scholar] [CrossRef]

- Kim, J.; Shim, H.J.; Yang, J.; Choi, M.K.; Kim, D.C.; Kim, J.; Hyeon, T.; Kim, D.H. Ultrathin quantum dot display integrated with wearable electronics. Adv. Mater. 2017, 29, 1700217. [Google Scholar] [CrossRef]

- Seung, H.; Choi, C.; Kim, D.C.; Kim, J.S.; Kim, J.H.; Kim, J.; Park, S.I.; Lim, J.A.; Yang, J.; Choi, M.K. Integration of synaptic phototransistors and quantum dot light-emitting diodes for visualization and recognition of UV patterns. Sci. Adv. 2022, 8, eabq3101. [Google Scholar] [CrossRef] [PubMed]

- Hahl, F.A.; Lindner, L.; Vidal, X.; Luo, T.; Ohshima, T.; Onoda, S.; Ishii, S.; Zaitsev, A.M.; Capelli, M.; Gibson, B.C. Magnetic-field-dependent stimulated emission from nitrogen-vacancy centers in diamond. Sci. Adv. 2022, 8, eabn7192. [Google Scholar] [CrossRef]

- Moon, H.; Lee, C.; Lee, W.; Kim, J.; Chae, H. Stability of quantum dots, quantum dot films, and quantum dot light-emitting diodes for display applications. Adv. Mater. 2019, 31, 1804294. [Google Scholar] [CrossRef] [PubMed]

- Jung, H.; Sim, S.; Lee, H. Biometric authentication security enhancement under quantum dot light-emitting diode display via fingerprint imaging and temperature sensing. Sci. Rep. 2023, 13, 794. [Google Scholar] [CrossRef]

- Coe, S.; Woo, W.-K.; Bawendi, M.; Bulovic, V. Electroluminescence from single monolayers of nanocrystals in molecular organic devices. Nature 2002, 420, 800–803. [Google Scholar] [CrossRef]

- Qian, L.; Zheng, Y.; Xue, J.G.; Holloway, P.H. Stable and efficient quantum-dot light-emitting diodes based on solution-processed multilayer structures. Nat. Photonics 2011, 5, 543–548. [Google Scholar] [CrossRef]

- Chen, X.-D.; Zhou, L.-M.; Zou, C.-L.; Li, C.-C.; Dong, Y.; Sun, F.-W.; Guo, G.-C. Spin depolarization effect induced by charge state conversion of nitrogen vacancy center in diamond. Phys. Rev. B 2015, 92, 104301. [Google Scholar] [CrossRef]

- Togan, E.; Chu, Y.; Trifonov, A.S.; Jiang, L.; Maze, J.; Childress, L.; Dutt, M.V.G.; Sorensen, A.S.; Hemmer, P.R.; Zibrov, A.S.; et al. Quantum entanglement between an optical photon and a solid-state spin qubit. Nature 2010, 466, 730–734. [Google Scholar] [CrossRef] [PubMed]

- Barry, J.F.; Schloss, J.M.; Bauch, E.; Turner, M.J.; Hart, C.A.; Pham, L.M.; Walsworth, R.L. Sensitivity optimization for NV-diamond magnetometry. Rev. Mod. Phys. 2020, 92, 015004. [Google Scholar] [CrossRef]

- Rondin, L.; Tetienne, J.-P.; Hingant, T.; Roch, J.-F.; Maletinsky, P.; Jacques, V. Magnetometry with nitrogen-vacancy defects in diamond. Rep. Prog. Phys. 2014, 77, 056503. [Google Scholar] [CrossRef] [PubMed]

- Acosta, V.M.; Bauch, E.; Ledbetter, M.P.; Santori, C.; Fu, K.-M.; Barclay, P.E.; Beausoleil, R.G.; Linget, H.; Roch, J.F.; Treussart, F. Diamonds with a high density of nitrogen-vacancy centers for magnetometry applications. Phys. Rev. B-Condens. Matter Mater. Phys. 2009, 80, 115202. [Google Scholar] [CrossRef]

- Clevenson, H.; Pham, L.M.; Teale, C.; Johnson, K.; Englund, D.; Braje, D. Robust high-dynamic-range vector magnetometry with nitrogen-vacancy centers in diamond. Appl. Phys. Lett. 2018, 112, 252406. [Google Scholar] [CrossRef]

- Fu, Y.; Ma, Z.; Zhao, J.; Yuan, H.; Zhang, S.; Shi, Y.; Zhang, X.; Liu, J. Optimization of solid atomic magnetometer with frequency modulation method on ensembles of nitrogen vacancy color centers in diamond. Laser Phys. 2018, 28, 125201. [Google Scholar] [CrossRef]

- Wang, Q.M.; Zheng, D.D.; Liu, X.Y.; Zhao, J.Z.; Shen, Y.Y.; Guo, H.; Li, Z.H.; Tang, J.; Ma, Z.M.; Li, Y.J.; et al. Hybrid NV Center Magnetometer With Directional Vector Resolution Based on Magnetic Flux Concentrators. IEEE Sens. J. 2023, 23, 12719–12726. [Google Scholar] [CrossRef]

- Barry, J.F.; Turner, M.J.; Schloss, J.M.; Glenn, D.R.; Song, Y.Y.; Lukin, M.D.; Park, H.; Walsworth, R.L. Optical magnetic detection of single-neuron action potentials using quantum defects in diamond. Proc. Natl. Acad. Sci. USA 2016, 113, 14133–14138, Erratum in Proc. Natl. Acad. Sci. USA 2017, 114, E6730. https://doi.org/10.1073/pnas.1712523114. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Liu, Z.; Li, Y.; Ma, Z.; Li, Z.; Wen, H.; Guo, H.; Tang, J.; Li, Y.; Liu, J. The fiber self-focusing integrated nitrogen vacancy magnetometer. IEEE Trans. Instrum. Meas. 2024, 73, 1–8. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, P.; Du, J.; Tai, J.; Shang, Z.; Yuan, X.; Shi, Y. Integration of High-Brightness QLED-Excited Diamond Magnetic Sensor. Micromachines 2025, 16, 1021. https://doi.org/10.3390/mi16091021

Zhao P, Du J, Tai J, Shang Z, Yuan X, Shi Y. Integration of High-Brightness QLED-Excited Diamond Magnetic Sensor. Micromachines. 2025; 16(9):1021. https://doi.org/10.3390/mi16091021

Chicago/Turabian StyleZhao, Pengfei, Junjun Du, Jinyu Tai, Zhaoqi Shang, Xia Yuan, and Yuanyuan Shi. 2025. "Integration of High-Brightness QLED-Excited Diamond Magnetic Sensor" Micromachines 16, no. 9: 1021. https://doi.org/10.3390/mi16091021

APA StyleZhao, P., Du, J., Tai, J., Shang, Z., Yuan, X., & Shi, Y. (2025). Integration of High-Brightness QLED-Excited Diamond Magnetic Sensor. Micromachines, 16(9), 1021. https://doi.org/10.3390/mi16091021