Dual-Mode Flexible Pressure Sensor Based on Ionic Electronic and Piezoelectric Coupling Mechanism Enables Dynamic and Static Full-Domain Stress Response

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sensitive Layer Preparation Process

2.3. Assembly of the Sensor Device

2.4. Characterization and Measurement

3. Results

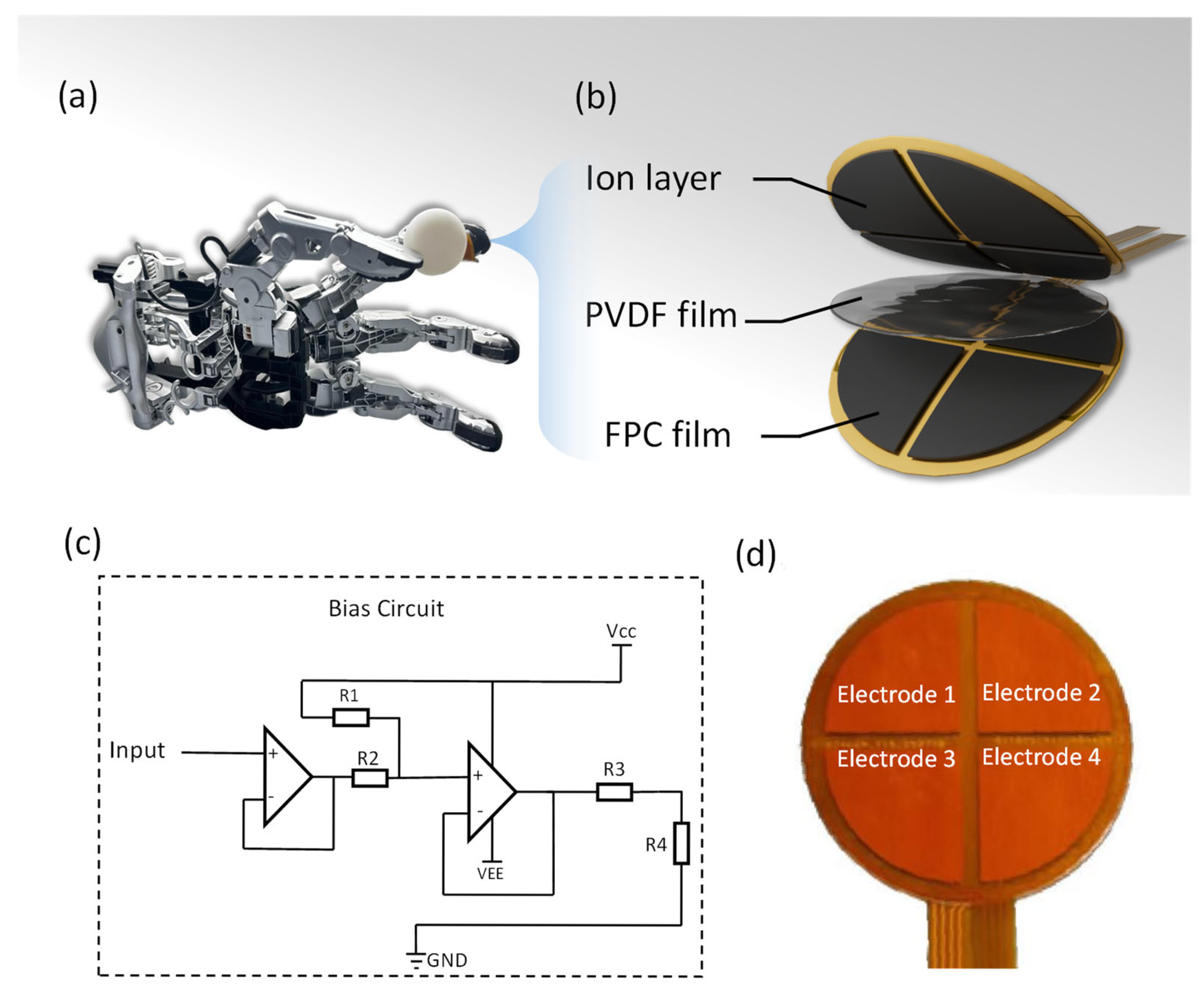

3.1. Design and Application

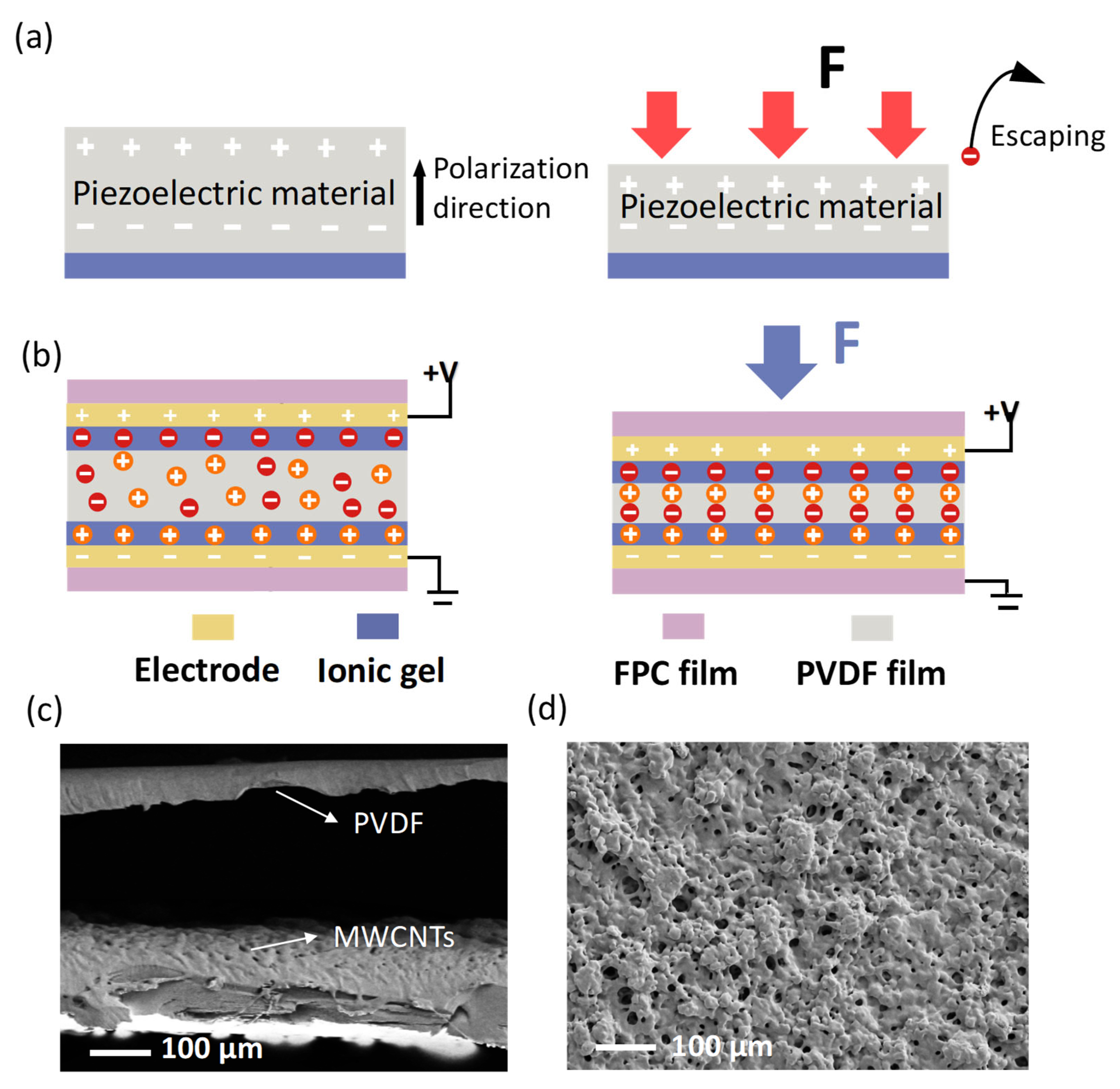

3.2. Sensing Mechanism

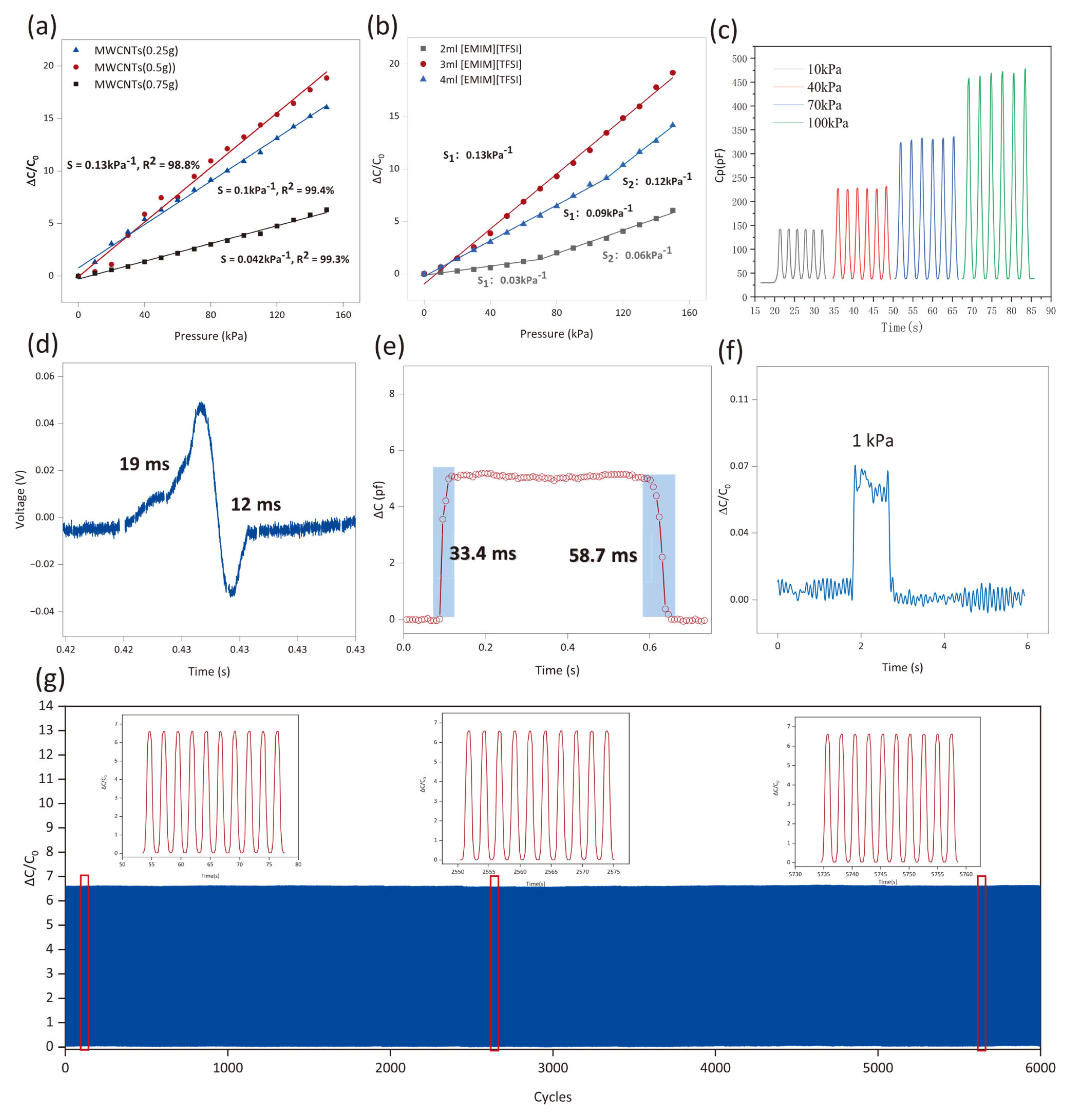

3.3. Sensor Performance Characterization

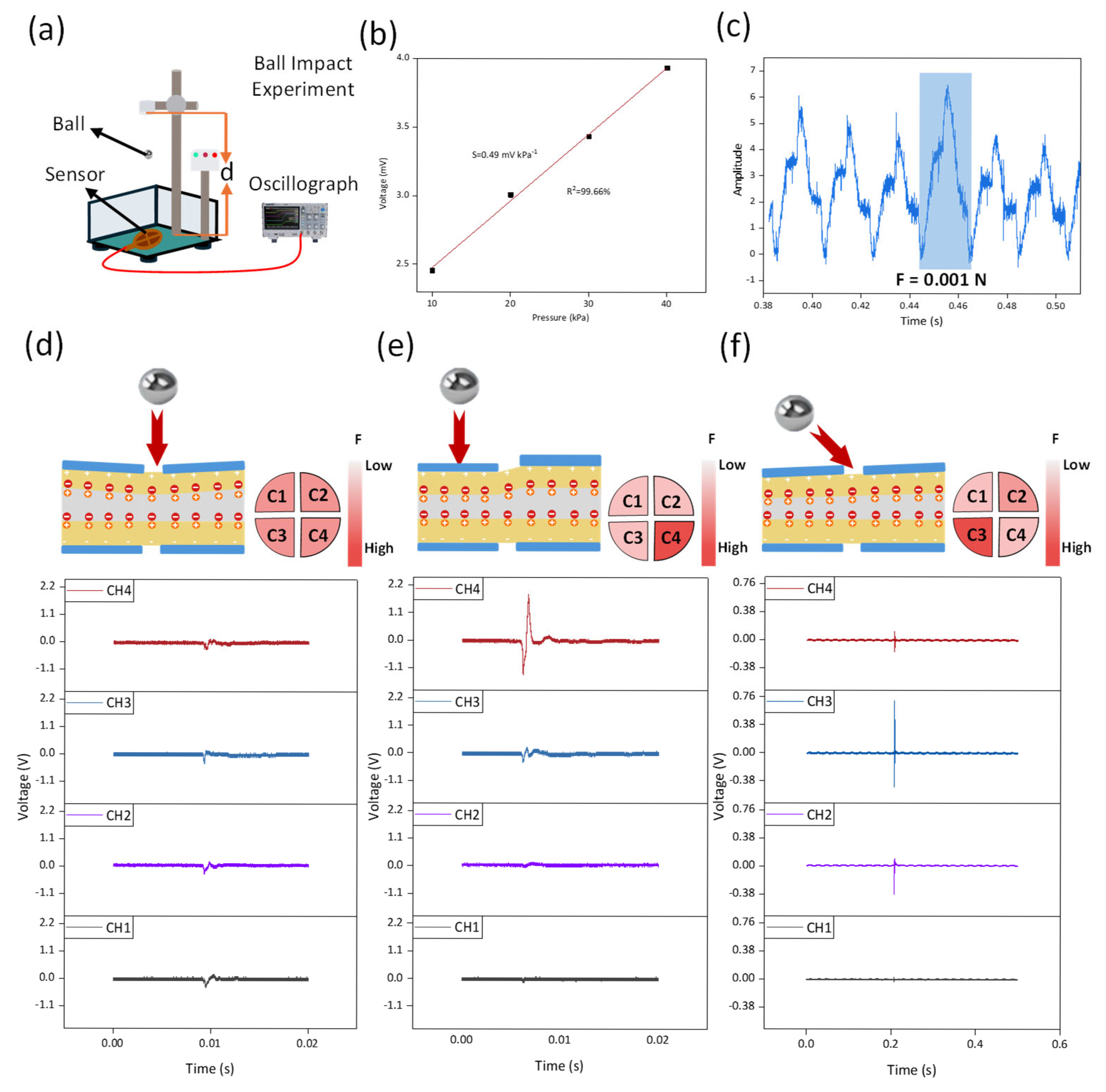

3.4. Impact Detection

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, Y.; Guo, F.Y.; Cao, P.; Liu, J.C.; Li, D.M.; Wu, J.; Wang, N.; Su, Y.W.; Zhao, Y. Winding-Locked Carbon Nanotubes/Polymer Nanofibers Helical Yarn for Ultrastretchable Conductor and Strain Sensor. ACS Nano 2020, 14, 3442–3450. [Google Scholar] [CrossRef] [PubMed]

- Amjadi, M.; Kyung, K.U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Zou, Q.; Lei, Z.M.; Xue, T.; Li, S.H.; Ma, Z.M.; Su, Q. Highly sensitive flexible pressure sensor based on ionic dielectric layer with hierarchical ridge microstructure. Sens. Actuators A Phys. 2020, 313, 112218. [Google Scholar] [CrossRef]

- Sun, Z.J.; Yang, S.; Zhao, P.F.; Zhang, J.M.; Yang, Y.H.; Ye, X.L.; Zhao, X.L.; Cui, N.; Tong, Y.H.; Liu, Y.C.; et al. Skin-like Ultrasensitive Strain Sensor for Full-Range Detection of Human Health Monitoring. ACS Appl. Mater. Interfaces 2020, 12, 13287–13295. [Google Scholar] [CrossRef]

- Hong, W.Q.; Guo, X.H.; Hu, B.; Zhang, T.X.; Zhu, X.W.; Hao, J.H.; Li, X.H.; Chen, Y.U.; Zhu, S.X.; Zhang, H.S.; et al. Mantis Leg-Inspired Flexible Capacitive Pressure Sensor with High Sensitivity and Fast Response for Wearable Devices and Human-Machine Interaction. IEEE Sens. J. 2024, 24, 19698–19705. [Google Scholar] [CrossRef]

- Yang, J.; Li, Z.B.; Wu, Y.; Shen, Y.; Zhang, M.; Chen, B.; Yuan, G.J.; Xiao, S.H.; Feng, J.S.; Zhang, X.; et al. Non-equilibrium compression achieving high sensitivity and linearity for iontronic pressure sensors. Sci. Bull. 2024, 69, 2221–2230. [Google Scholar] [CrossRef]

- Rosales-Cuello, N.; Muñoz, C.; Godoy, M.; Palza, H. All-PDMS capacitive and triboelectric dual sensors for wireless strain, pressure and material detection. Sens. Actuators A Phys. 2025, 383, 116244. [Google Scholar] [CrossRef]

- Dong, X.X.; Song, T.; Ren, D.D.; Dai, K.; Leng, Y.T.; Wang, T.T.; Wang, Y.X.; Sun, M.M.; Liu, D.H.; Zhang, Q.T.; et al. Preparation of wearable strain sensor based on PVA/MWCNTs hydrogel composite. Mater. Today Commun. 2022, 31, 103278. [Google Scholar] [CrossRef]

- Kim, K.; Kim, J.; Jiang, X.N.; Kim, T.; Gasulla, M. Static Force Measurement Using Piezoelectric Sensors. J. Sens. 2021, 2021, 6664200. [Google Scholar] [CrossRef]

- Meng, Y.C.; Li, H.W.; Wu, K.J.; Zhang, S.N.; Li, L.Q. High-Performance Pressure Sensor for Monitoring Mechanical Vibration and Air Pressure. Polymers 2018, 10, 587. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, S.X.; Li, Y.; Lin, Q.B.; Wu, Y.B.; Shi, Q.S. Flexible piezoelectric sensor based on PAN/MXene/PDA@ZnO composite film for human health and motion detection with fast response and highly sensitive. Chem. Eng. J. 2024, 488, 150997. [Google Scholar] [CrossRef]

- Yu, Y.N.; Luo, C.; Suto, T.; Uetsuji, Y.; Narita, F. Fabrication, Evaluation, and Multiscale Simulation of Piezoelectric Composites Reinforced Using Unidirectional Carbon Fibers for Flexible Motion Sensors. Small 2024, 20, e2307689. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.H.; Geng, W.P.; Zhang, H.Y.; Fu, W.X.; Wang, Z.H.; Li, J.H.; Qiao, X.J.; Zhang, Y.C.; Chou, X.J. Enhancing the electric charge output in LiNbO3-based piezoelectric pressure sensors. RSC Adv. 2024, 14, 8313–8321. [Google Scholar] [CrossRef]

- Signore, M.A.; Rescio, G.; Francioso, L.; Casino, F.; Leone, A. Aluminum Nitride Thin Film Piezoelectric Pressure Sensor for Respiratory Rate Detection. Sensors 2024, 24, 2071. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Luo, J.; Wang, X.; Li, Q.; Zhou, L.; Liu, C.; Feng, C. Fabrication and Piezoresistive/Piezoelectric Sensing Characteristics of Carbon Nanotube/PVA/Nano-ZnO Flexible Composite. Sci. Rep. 2020, 10, 8895. [Google Scholar] [CrossRef]

- Shirley, J.A.; Florence, E.S.; Sreeja, B.S.; Sankararajan, R. Bio-compatible piezoelectric material based wearable pressure sensor for smart textiles. Smart Mater. Struct. 2022, 31, 125015. [Google Scholar] [CrossRef]

- Jiang, H.; Zou, X.; Li, P.; Lin, Z.; Liu, X.; Weng, X. Flexible Capacitive Pressure Sensor Enhanced by Black Phosphorus-Au Nanocomposites/Ecoflex Sponge for Pressure and Proximity Detection. IEEE Sens. J. 2024, 24, 17543–17550. [Google Scholar] [CrossRef]

- Wang, Y.H.; Xiang, M.H.; Li, J.H.; Yang, S.T.; Li, J.F.; Wen, Q.; Gao, L.B.; Li, J.Y. Highly Sensitive Flexible Iontronic Pressure Sensor for Marine Pressure Monitoring. IEEE Electron Device Lett. 2024, 45, 2530–2533. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, X.M.; Zhang, N.; Zhu, J.Q.; Bai, N.N.; Hou, X.Y.; Sun, T.; Li, G.; Zhao, L.Y.; Chen, Y.C.; et al. Ultrafast piezocapacitive soft pressure sensors with over 10 kHz bandwidth via bonded microstructured interfaces. Nat. Commun. 2024, 15, 3048. [Google Scholar] [CrossRef]

- Zeng, Y.; Qin, Y.F.; Yang, Y.P.; Lu, X.Y. A Low-Cost Flexible Capacitive Pressure Sensor for Health Detection. IEEE Sens. J. 2022, 22, 7665–7673. [Google Scholar] [CrossRef]

- Wang, H.Z.; Li, Z.; Liu, Z.Y.; Fu, J.K.; Shan, T.Y.; Yang, X.Y.; Lei, Q.Y.; Yang, Y.J.; Li, D.H. Flexible capacitive pressure sensors for wearable electronics. J. Mater. Chem. C 2022, 10, 1594–1605. [Google Scholar] [CrossRef]

- Jung, M.; Kim, S.; Hwang, J.; Kim, C.; Kim, H.J.; Kim, Y.-J.; Jeon, S. Monolithic three-dimensional hafnia-based artificial nerve system. Nano Energy 2024, 126, 109643. [Google Scholar] [CrossRef]

- Kim, N.I.; Yarali, M.; Moradnia, M.; Aqib, M.; Liao, C.H.; AlQatari, F.; Nong, M.; Li, X.; Ryou, J.H. Piezoelectric Sensors Operating at Very High Temperatures and in Extreme Environments Made of Flexible Ultrawide-Bandgap Single-Crystalline AlN Thin Films. Adv. Funct. Mater. 2022, 33, 2212538. [Google Scholar] [CrossRef]

- Ko, J.-B.; Kim, S.-W.; Kim, H.-B.; Jeong, H.-Y.; Moon, S.-Y.; Yang, Y.-J. 3D-Printed Multi-Axis Alignment Airgap Dielectric Layer for Flexible Capacitive Pressure Sensor. Micromachines 2024, 15, 1347. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.F.; Yan, X. Progress in achieving high-performance piezoresistive and capacitive flexible pressure sensors: A review. J. Mater. Sci. Technol. 2020, 43, 175–188. [Google Scholar] [CrossRef]

- Cheng, W.; Yu, L.W.; Kong, D.S.; Yu, Z.W.; Wang, H.T.; Ma, Z.; Wang, Y.M.; Wang, J.Z.; Pan, L.J.; Shi, Y. Fast-Response and Low-Hysteresis Flexible Pressure Sensor Based on Silicon Nanowires. IEEE Electron Device Lett. 2018, 39, 1069–1072. [Google Scholar] [CrossRef]

- Yin, H.; Li, Y.T.; Tian, Z.Y.; Li, Q.C.; Jiang, C.H.; Liang, E.F.; Guo, Y.P. Ultra-High Sensitivity Anisotropic Piezoelectric Sensors for Structural Health Monitoring and Robotic Perception. Nanomicro Lett. 2024, 17, 42. [Google Scholar] [CrossRef]

- Li, T.H.; Jayawardhana, B.; Kamat, A.M.; Kottapalli, A.G.P. Source-Seeking Control of Unicycle Robots with 3-D-Printed Flexible Piezoresistive Sensors. IEEE Trans. Robot. 2022, 38, 448–462. [Google Scholar] [CrossRef]

- Jeong, S.-M.; Son, M.; Kang, Y.; Yang, J.; Lim, T.; Ju, S. Development of multi-angle fiber array for accurate measurement of flexion and rotation in human joints. npj Flex. Electron. 2021, 5, 35. [Google Scholar] [CrossRef]

- Tang, Z.H.; Jia, S.H.; Wang, F.; Bian, C.S.; Chen, Y.Y.; Wang, Y.L.; Li, B. Highly Stretchable Core-Sheath Fibers via Wet-Spinning for Wearable Strain Sensors. ACS Appl. Mater. Interfaces 2018, 10, 6624–6635. [Google Scholar] [CrossRef]

- Sun, C.M.; Liu, H.F.; Wang, J.Q.; Shan, G.K.; Ren, T. Flexible piezoelectric sensor based on PVDF/ZnO/MWCNT composites for human motion monitoring. Org. Electron. 2025, 144, 107290. [Google Scholar] [CrossRef]

- Yu, J.B.; Chen, L.; Hou, X.J.; Mu, J.L.; He, J.; Geng, W.P.; Qiao, X.J.; Chou, X.J. Stretchable and skin-conformal piezo-triboelectric pressure sensor for human joint bending motion monitoring. J. Mater. 2022, 8, 247–256. [Google Scholar] [CrossRef]

- Li, P.; Xie, L.; Su, M.; Wang, P.S.; Yuan, W.; Dong, C.H.; Yang, J. Skin-inspired large area iontronic pressure sensor with ultra-broad range and high sensitivity. Nano Energy 2022, 101, 107571. [Google Scholar] [CrossRef]

- Kurnaz, S.; Öztürk, Ö.; Yılmaz, N.; Çiçek, O. The Parylene C as a Flexible Substrate and Passivation Layer: A Promising Candidate for a Piezoelectric, Piezoresistive, and Capacitive Pressure Sensor in Low-Pressure Range. IEEE Sens. J. 2023, 23, 22277–22284. [Google Scholar] [CrossRef]

- Mahata, C.; Algadi, H.; Lee, J.; Kim, S.; Lee, T. Biomimetic-inspired micro-nano hierarchical structures for capacitive pressure sensor applications. Measurement 2020, 151, 107095. [Google Scholar] [CrossRef]

- Munirathinam, K.; Kwon, K.; Park, J.; Lee, D.-W. Liquid dielectric layer-based microfluidic capacitive sensor for wireless pressure monitoring. Sens. Actuators A Phys. 2023, 357, 114393. [Google Scholar] [CrossRef]

- Pereira, N.; Gonçalves, S.; Barbosa, J.C.; Gonçalves, R.; Tubio, C.R.; Vilas-Vilela, J.L.; Costa, C.M.; Lanceros-Mendez, S. High dielectric constant poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) for capacitive pressure and bending sensors. Polymer 2021, 214, 114393. [Google Scholar] [CrossRef]

- Thorali, N.; Kim, D.S.; Lee, H.; Kim, D.R.; Lee, D.-W. Enhancing sensitivity in wireless capacitive pressure sensors via highly flexible LC circuits utilizing porous polydimethylsiloxane dielectric layer. Sens. Actuators A Phys. 2024, 379, 115973. [Google Scholar] [CrossRef]

- Xia, Y.; Gu, H.; Xu, L.; Chen, X.D.; Kirk, T.V. Extending Porous Silicone Capacitive Pressure Sensor Applications into Athletic and Physiological Monitoring. Sensors 2021, 21, 1119. [Google Scholar] [CrossRef]

- Soares, B.G.; Riany, N.; Silva, A.A.; Barra, G.M.O.; Livi, S. Dual-role of phosphonium—Based ionic liquid in epoxy/MWCNT systems: Electric, rheological behavior and electromagnetic interference shielding effectiveness. Eur. Polym. J. 2016, 84, 77–88. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ouyang, Y.; Huang, S.; Huang, Z.; Wu, S.; Wang, X.; Chen, S.; Zhang, H.; Yang, Z.; Liu, M.; Gao, L. Dual-Mode Flexible Pressure Sensor Based on Ionic Electronic and Piezoelectric Coupling Mechanism Enables Dynamic and Static Full-Domain Stress Response. Micromachines 2025, 16, 1018. https://doi.org/10.3390/mi16091018

Ouyang Y, Huang S, Huang Z, Wu S, Wang X, Chen S, Zhang H, Yang Z, Liu M, Gao L. Dual-Mode Flexible Pressure Sensor Based on Ionic Electronic and Piezoelectric Coupling Mechanism Enables Dynamic and Static Full-Domain Stress Response. Micromachines. 2025; 16(9):1018. https://doi.org/10.3390/mi16091018

Chicago/Turabian StyleOuyang, Yue, Shunqiang Huang, Zekai Huang, Shengyu Wu, Xin Wang, Sheng Chen, Haiyan Zhang, Zhuoqing Yang, Mengran Liu, and Libo Gao. 2025. "Dual-Mode Flexible Pressure Sensor Based on Ionic Electronic and Piezoelectric Coupling Mechanism Enables Dynamic and Static Full-Domain Stress Response" Micromachines 16, no. 9: 1018. https://doi.org/10.3390/mi16091018

APA StyleOuyang, Y., Huang, S., Huang, Z., Wu, S., Wang, X., Chen, S., Zhang, H., Yang, Z., Liu, M., & Gao, L. (2025). Dual-Mode Flexible Pressure Sensor Based on Ionic Electronic and Piezoelectric Coupling Mechanism Enables Dynamic and Static Full-Domain Stress Response. Micromachines, 16(9), 1018. https://doi.org/10.3390/mi16091018