Sensitivity and Contrast Characterization of PMMA 950K Resist Under 30 keV Focused Ga+ Ion Beam Exposure

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

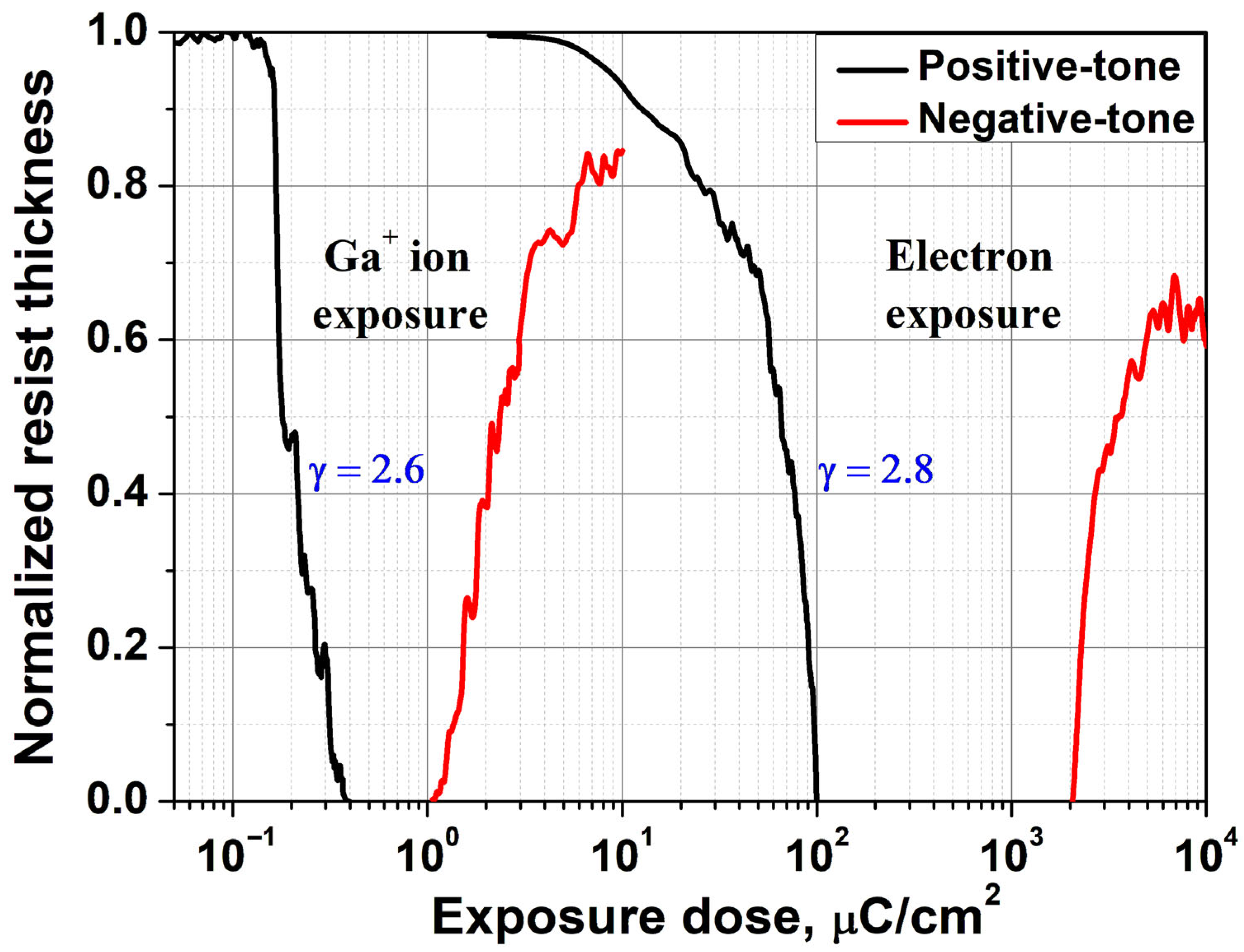

3.1. Sensitivity of PMMA 950K to Ion and Electron Beam Exposure

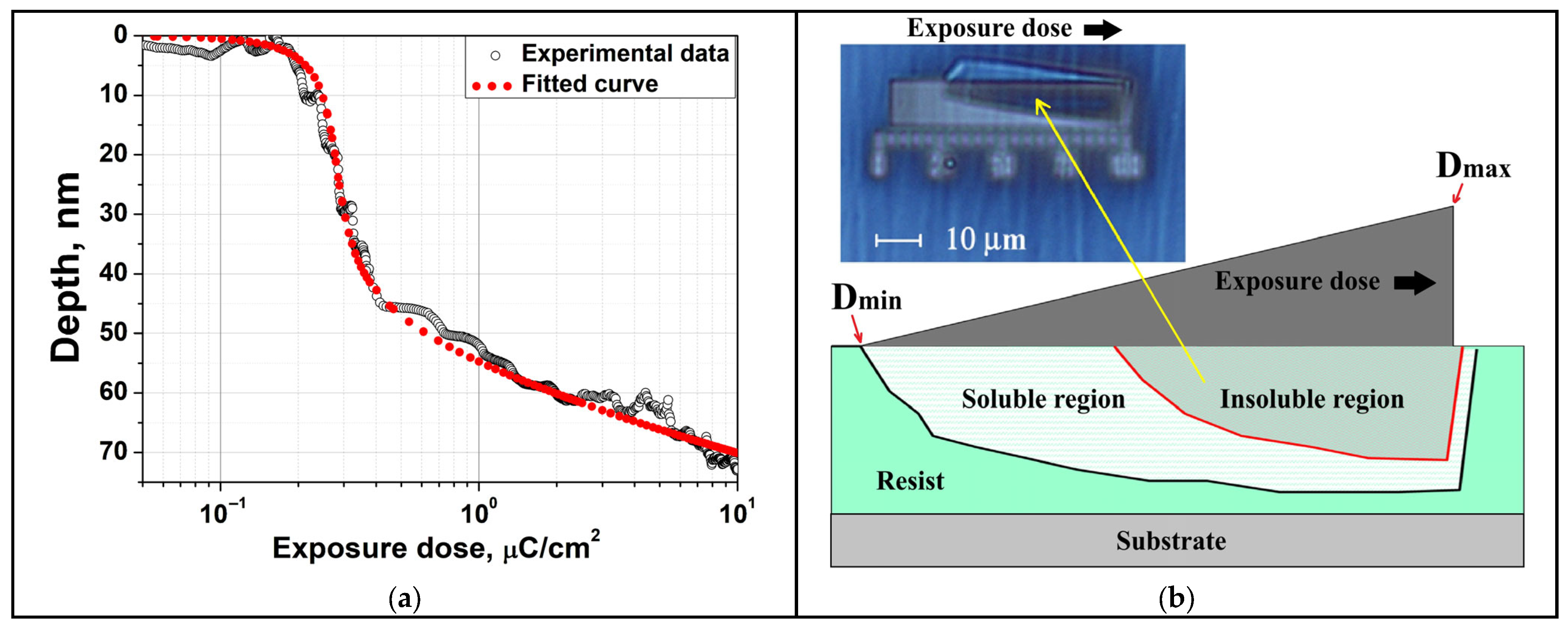

3.2. Depth Profile Analysis in Thick PMMA 950K Films Exposed to Ga+ Ions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bhushan, B. (Ed.) Springer Handbook of Nanotechnology, 4th ed.; Springer: Cham, Switzerland, 2023. [Google Scholar]

- Pehlivan, Z.S.; Ten, A.; Wayman, T.M.; Ringe, E. Plasmonic magnesium arrays with nanosphere lithography. APL Photonics 2024, 9, 071302. [Google Scholar] [CrossRef]

- Stokes, K.; Clark, K.; Odetade, D.; Hardy, M.; Goldberg Oppenheimer, P. Advances in lithographic techniques for precision nanostructure fabrication in biomedical applications. Discov. Nano 2023, 18, 153. [Google Scholar] [CrossRef] [PubMed]

- Neisser, M. International Roadmap for Devices and Systems Lithography Roadmap. J. Micro/Nanopattern. Mater. Metrol. 2021, 20, 044601. [Google Scholar] [CrossRef]

- Lee, H.; Kim, C.; Kim, D. Sub-10 nm near-field localization by plasmonic metal nanoaperture arrays with ultrashort light pulses. Sci. Rep. 2015, 5, 17584. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Zhang, W.; Guo, L.; Zhuang, L. Sub-10 nm imprint lithography and applications. J. Vac. Sci. Technol. B 1997, 15, 2897–2904. [Google Scholar] [CrossRef]

- Yan, B.; Tu, X.; Zhang, C.; Wang, W.; Ye, Z.; Jia, X.; Wu, P. Fabrication of sub-10 nm Gap by using Electron Beam Lithography. In Proceedings of the 2023 24th International Vacuum Electronics Conference (IVEC), Chengdu, China, 25–28 April 2023; pp. 1–2. [Google Scholar] [CrossRef]

- Rommel, M.; Nilsson, B.; Jedrasik, P.; Bonanni, V.; Dmitriev, A.; Weis, J. Sub-10 nm resolution after lift-off using HSQ/PMMA double layer resist. Microelectron. Eng. 2013, 110, 123–125. [Google Scholar] [CrossRef]

- Feng, Z.; Giubertoni, D.; Cian, A.; Valt, M.; Barozzi, M.; Gaiardo, A.; Guidi, V. Nano Hotplate Fabrication for Metal Oxide-Based Gas Sensors by Combining Electron Beam and Focused Ion Beam Lithography. Micromachines 2023, 14, 2060. [Google Scholar] [CrossRef]

- Svintsov, A.A.; Knyazev, M.A.; Zaitsev, S.I. Calculation of the Absorbed Electron Energy 3D Distribution by the Monte Carlo Method, Presentation of the Proximity Function by Three Parameters α, β, η and Comparison with the Experiment. Materials 2022, 15, 3888. [Google Scholar] [CrossRef]

- Kamikubo, T.; Abe, T.; Oogi, S.; Anze, H.; Shimizu, M.; Itoh, M.; Nakasugi, T.; Takigawa, T.; Iijima, T.; Hattori, Y. Proximity Effect Correction for Electron Beam Lithography: Highly Accurate Correction Method. Jpn. J. Appl. Phys. 1997, 36, 7546–7550. [Google Scholar] [CrossRef]

- Gangnaik, A.S.; Georgiev, Y.M.; Holmes, J.D. New Generation Electron Beam Resists: A Review. Chem. Mater. 2017, 29, 1898–1917. [Google Scholar] [CrossRef]

- Yang, X.; Xiao, S.; Wu, W.; Xu, Y.; Mountfield, K.; Rottmayer, R.; Lee, K.; Kuo, D.; Weller, D. Challenges in dot patterning using electron beam lithography for bit-patterned media. J. Vac. Sci. Technol. B 2007, 25, 2202–2209. [Google Scholar] [CrossRef]

- Yang, D.X.; Frommhold, A.; McClelland, A.; Roth, J.; Rosamond, M.; Linfield, E.H.; Osmond, J.; Palmer, R.E.; Robinson, A.P.G. Performance of a high resolution chemically amplified electron beam resist at various beam energies. Microelectron. Eng. 2016, 155, 97–101. [Google Scholar] [CrossRef]

- Höflich, K.; Hobler, G.; Allen, F.I.; Wirtz, T.; Rius, G.; McElwee-White, L.; Krasheninnikov, A.V.; Schmidt, M.; Utke, I.; Klingner, N.; et al. Roadmap for Focused Ion Beam Technologies. Appl. Phys. Rev. 2023, 10, 041311. [Google Scholar] [CrossRef]

- Phaneuf, M.W. Applications of focused ion beam microscopy to materials science specimens. Micron 1999, 30, 277–288. [Google Scholar] [CrossRef]

- Zhang, L.; Thomas, J.P.; Guan, X.; Heinig, N.F.; Leung, K.T. High-energy ion (He+, Si2+, Ga+, Au2+) interactions with PMMA in ion beam lithography. Nanotechnology 2020, 31, 325301. [Google Scholar] [CrossRef] [PubMed]

- Arshak, K.; Mihov, M.; Nakahara, S.; Arshak, A.; McDonagh, D. The mechanism of the ion beam inhibited etching formation in Gallium-FIB implanted resist films. Microelectron. Eng. 2005, 78–79, 39–46. [Google Scholar] [CrossRef]

- Matsui, S.; Kojima, Y.; Ochiai, Y.; Honda, T.; Suzuki, K. High-resolution focused ion beam lithography. Microelectron. Eng. 1990, 11, 427–430. [Google Scholar] [CrossRef]

- Xiao, Y.; Meng, Y.; Feng, X.; He, L.; Shields, P.; Lee, S.; Wang, Y.; Wang, Z.; Ning, P.; Liu, H. A 64 × 64 GaN Micro LED Monolithic Display Array: Fabrication and Light Crosstalk Analysis. Micromachines 2025, 16, 207. [Google Scholar] [CrossRef]

- Ignatane, L.; Ignatans, R.; Prikulis, J.; Trausa, A.; Tipaldi, C.F.; Vanags, E.; Zubkins, M.; Smits, K.; Sarakovskis, A. Fabrication of Large-Area High-Resolution Templates by Focused Ion Beam Combined with Colloidal Nanoparticle Dimer Deposition for SERS Substrates. Nanomaterials 2024, 14, 1784. [Google Scholar] [CrossRef]

- Mandelbaum, Y.; Tkachev, M.; Sanjeev, A.; Zalevsky, Z.; Zitoun, D.; Karsenty, A. Tips versus Holes: ×10 Higher Scattering in FIB-made Plasmonic Nanoscale Arrays for Spectral Imaging. ACS Omega 2024, 9, 46796–46812. [Google Scholar] [CrossRef]

- Schnauber, P.; Schmidt, R.; Kaganskiy, A.; Heuser, T.; Gschrey, M.; Rodt, S.; Reitzenstein, S. Using low-contrast negative-tone PMMA at cryogenic temperatures for 3D electron beam lithography. Nanotechnology 2016, 27, 195301. [Google Scholar] [CrossRef] [PubMed]

- Shabelnikova, Y.; Zaitsev, S. Ion-Beam Lithography: Modelling and Analytical Description of the Deposited in Resist Energy. Tech. Phys. 2022, 92, 919. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The stopping and range of ions in matter (SRIM-2010). Nucl. Instrum. Methods Phys. Res. B 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Biersack, J.P. The Stopping and Range of Ions in Matter. In Treatise on Heavy-Ion Science; Bromley, D.A., Ed.; Springer: Boston, MA, USA, 1985; Volume 6, pp. 93–129. [Google Scholar] [CrossRef]

- Knyazev, M.A.; Dubonos, S.V.; Svintsov, A.A.; Zaitsev, S.I. Fast electron resist contrast determination by “fitting before measurement” approach. Microelectron. Eng. 2007, 84, 1080–1083. [Google Scholar] [CrossRef]

- Bernstein, G.H.; Hill, D.A.; Liu, W.-P. New high-contrast developers for poly(methyl methacrylate) resist. J. Appl. Phys. 1992, 71, 4066–4075. [Google Scholar] [CrossRef]

- Hawkes, P.W. (Ed.) Advances in Imaging and Electron Physics; Academic Press: Cambridge, MA, USA, 1998. [Google Scholar]

- Rai-Choudhury, P. (Ed.) Handbook of Microlithography, Micromachining and Microfabrication; SPIE: Bellingham, WA, USA, 1997; Chapter 2. [Google Scholar]

- Asmussen, F.; Ueberreiter, K. Velocity of dissolution of polymers. Part II. J. Polym. Sci. 1962, 57, 199–208. [Google Scholar] [CrossRef]

- Moreau, W.M. Semiconductor Lithography: Principles, Practices, and Materials; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Neureuther, A.R.; Kyser, D.F.; Ting, C.H. Electron-beam resist edge profile simulation. IEEE Trans. Electron Devices 1979, 26, 686–693. [Google Scholar] [CrossRef]

- Mohammad, M.A.; Dew, S.K.; Stepanova, M. SML resist processing for high-aspect-ratio and high-sensitivity electron beam lithography. Nanoscale Res. Lett. 2013, 8, 139. [Google Scholar] [CrossRef]

- Mühle, R.; Götz, G. Ion beam exposure of PMMA polymer resist. Vacuum 1988, 38, 1005–1006. [Google Scholar] [CrossRef]

- Schirmer, M.; Büttner, B.; Syrowatka, F.; Schmidt, G.; Köpnick, T.; Kaiser, C. Chemical Semi-Amplified positive E-beam Resist (CSAR 62) for highest resolution. In Proceedings of the SPIE 8886, 29th European Mask and Lithography Conference (88860D), Dresden, Germany, 25–27 June 2013. [Google Scholar] [CrossRef]

| Exposure Type | Positive-Tone, [μC/cm2] | Negative-Tone, [μC/cm2] |

|---|---|---|

| Ga+ ions | ~0.4 | ~2.4 |

| Electrons | ~100 | ~2600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muratov, M.; Shabelnikova, Y.; Zaitsev, S.; Nemkayeva, R.; Guseinov, N. Sensitivity and Contrast Characterization of PMMA 950K Resist Under 30 keV Focused Ga+ Ion Beam Exposure. Micromachines 2025, 16, 958. https://doi.org/10.3390/mi16080958

Muratov M, Shabelnikova Y, Zaitsev S, Nemkayeva R, Guseinov N. Sensitivity and Contrast Characterization of PMMA 950K Resist Under 30 keV Focused Ga+ Ion Beam Exposure. Micromachines. 2025; 16(8):958. https://doi.org/10.3390/mi16080958

Chicago/Turabian StyleMuratov, Mukhit, Yana Shabelnikova, Sergey Zaitsev, Renata Nemkayeva, and Nazim Guseinov. 2025. "Sensitivity and Contrast Characterization of PMMA 950K Resist Under 30 keV Focused Ga+ Ion Beam Exposure" Micromachines 16, no. 8: 958. https://doi.org/10.3390/mi16080958

APA StyleMuratov, M., Shabelnikova, Y., Zaitsev, S., Nemkayeva, R., & Guseinov, N. (2025). Sensitivity and Contrast Characterization of PMMA 950K Resist Under 30 keV Focused Ga+ Ion Beam Exposure. Micromachines, 16(8), 958. https://doi.org/10.3390/mi16080958