Advances in 3D Printing: Microfabrication Techniques and Forming Applications

Abstract

1. Introduction

2. Microfabrication Approaches for Stainless-Steel

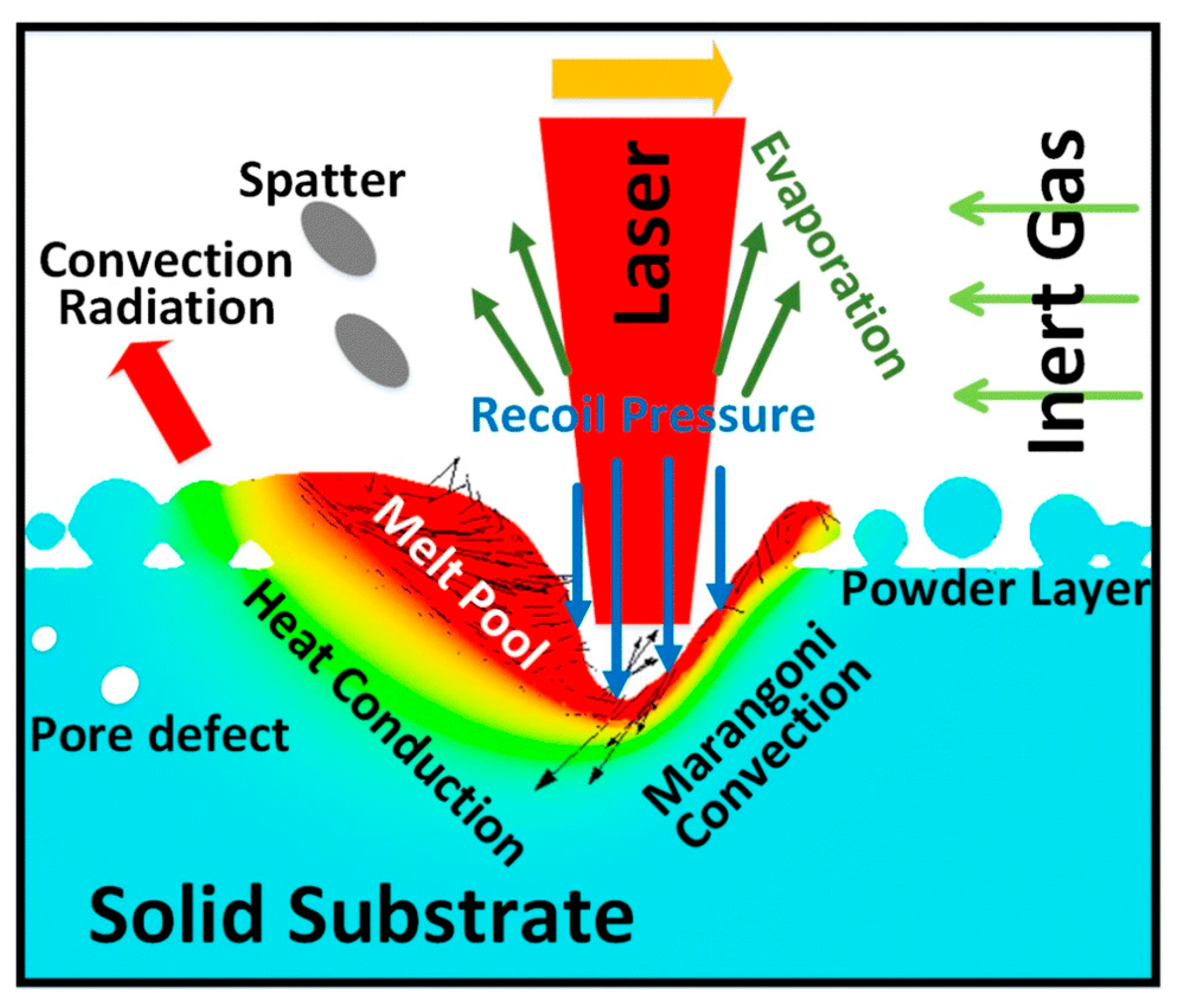

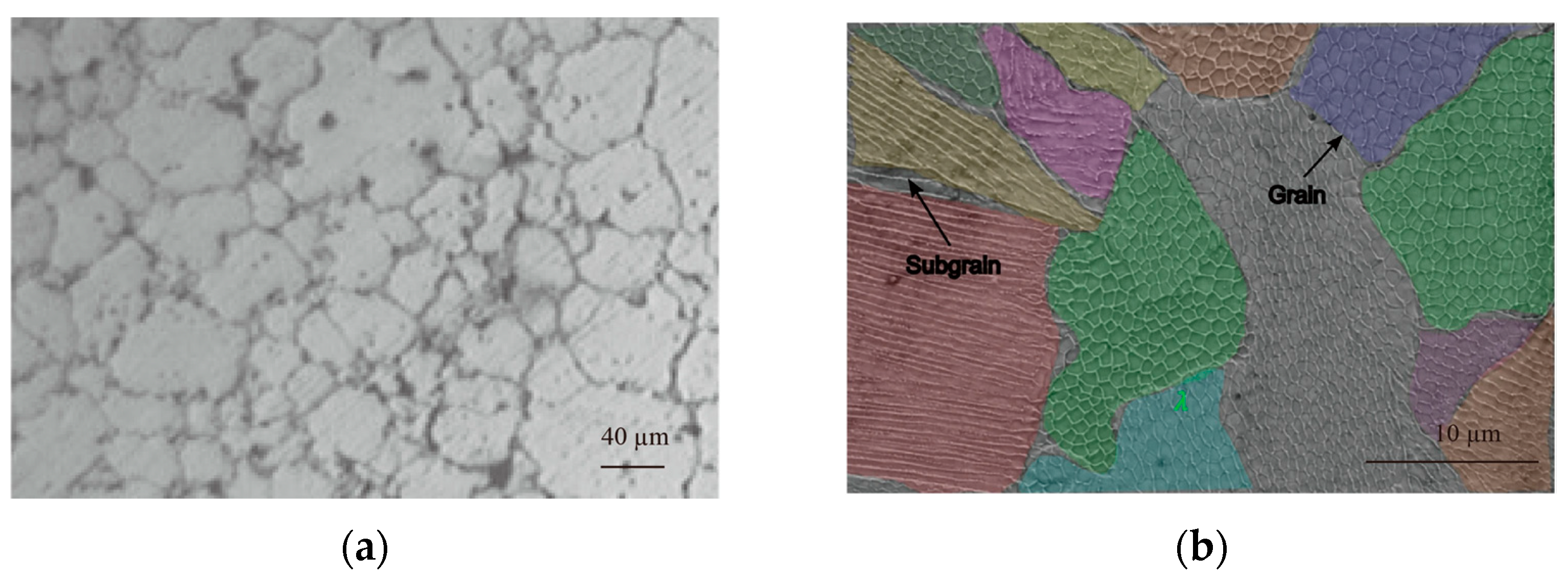

2.1. L-PBF

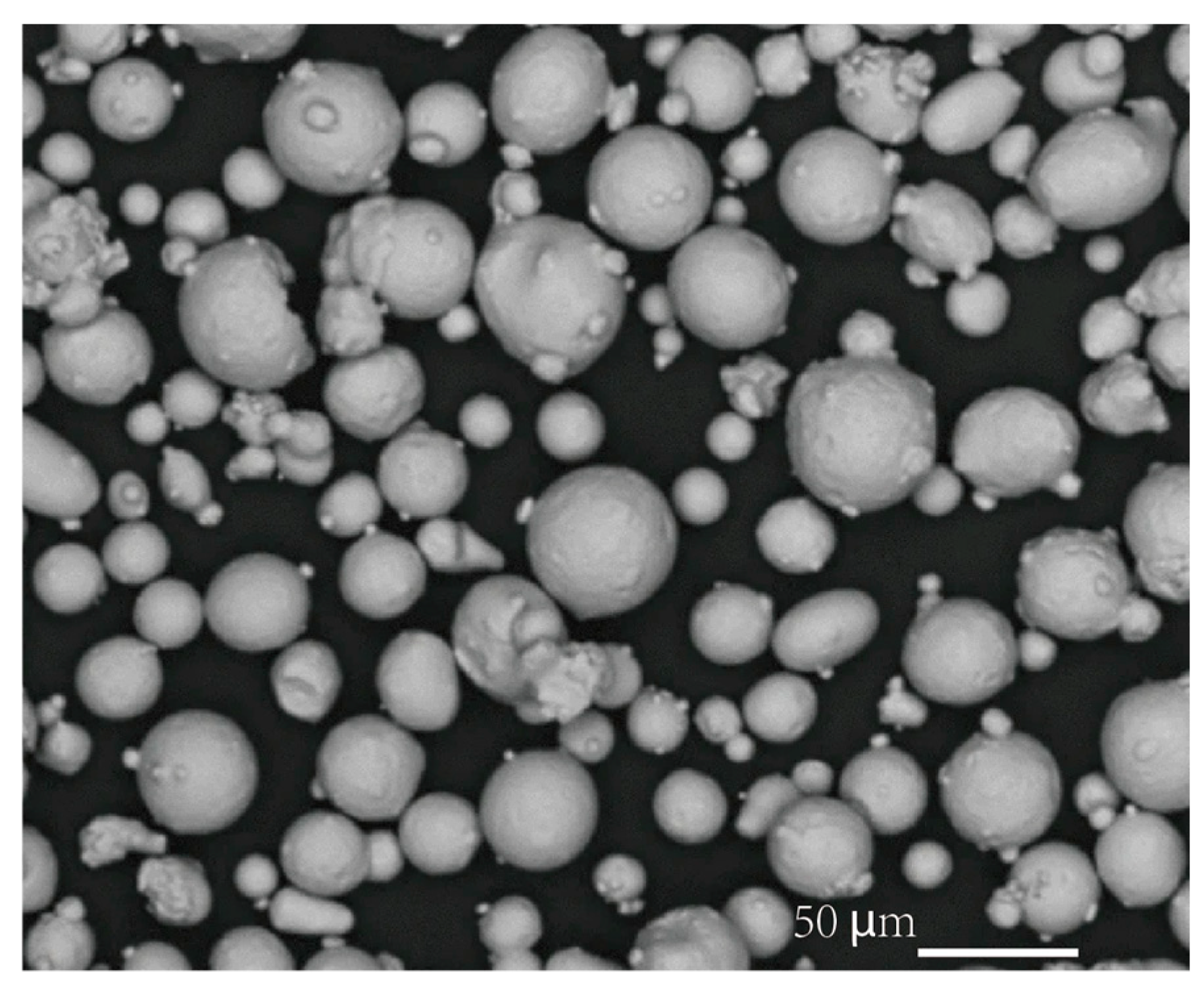

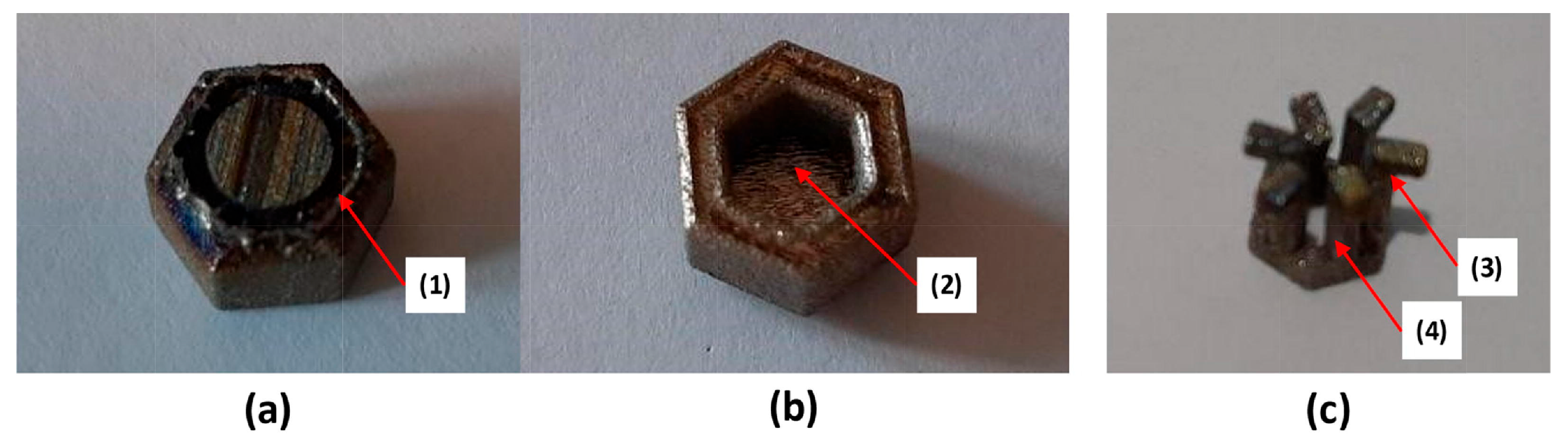

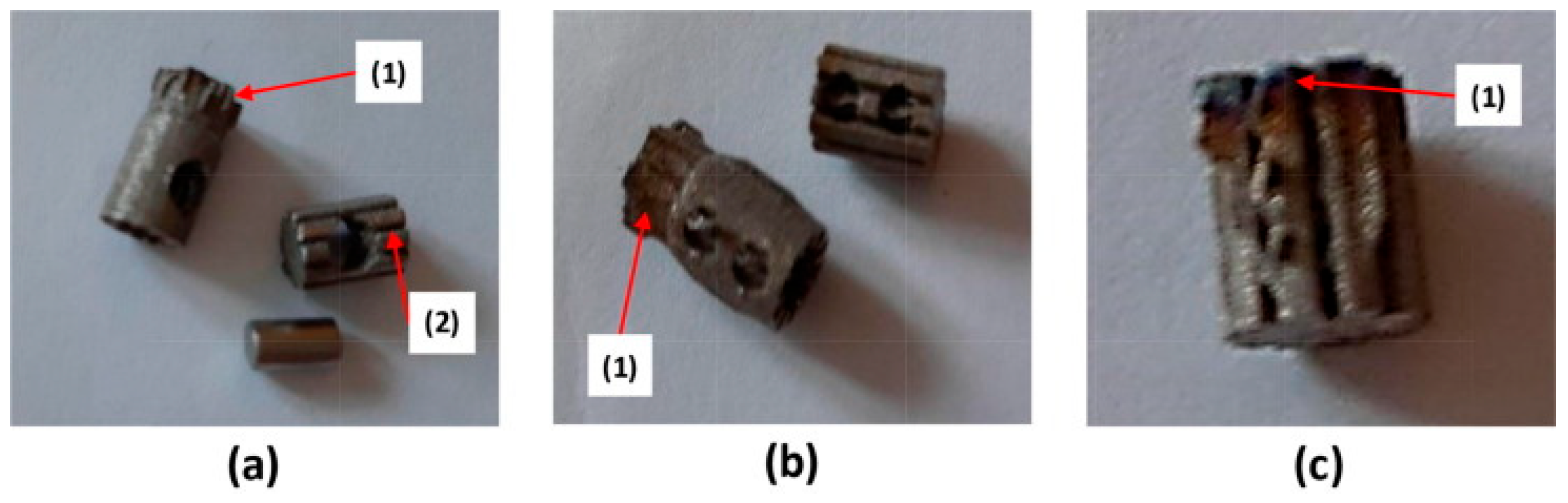

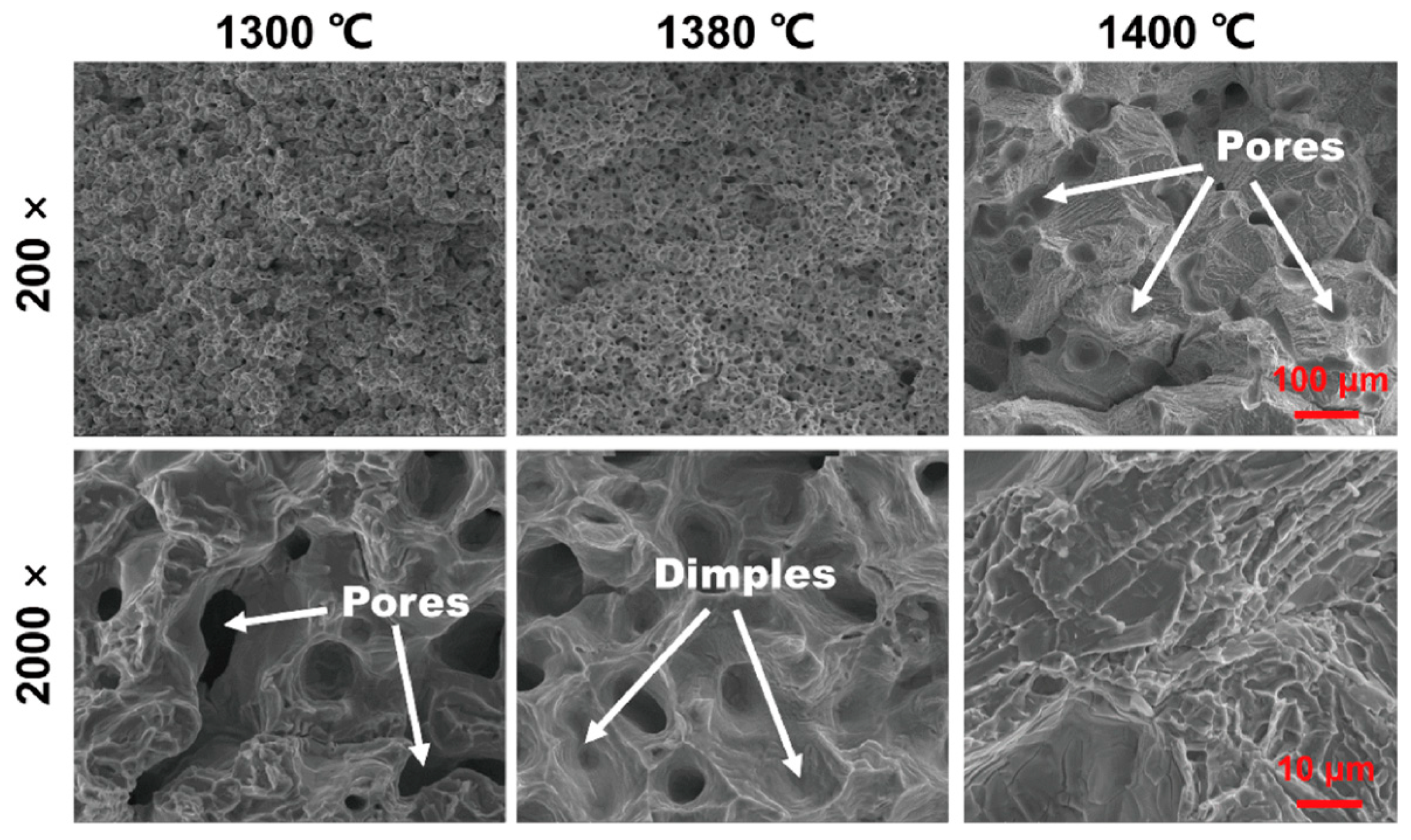

2.2. Binder Jetting

| 1300 °C | 1340 °C | 1360 °C | 1380 °C | 1400 °C | |

|---|---|---|---|---|---|

| Ultimate tensile strength (MPa) | 323.4 ± 22.9 | 368.7 ± 28.4 | 423.3 ± 27.6 | 473.3 ± 7.3 | 387.0 ± 21.8 |

| Yield strength (MPa) | 185.9 ± 3.2 | 171.8 ± 3.9 | 186.4 ± 4.9 | 182.7 ± 3.8 | 247.6 ± 17.1 |

| Elongation at break (%) | 6.1 ± 3.2 | 16.8 ± 2.2 | 26.2 ± 3.3 | 40.2 ± 2.4 | 10.6 ± 2.8 |

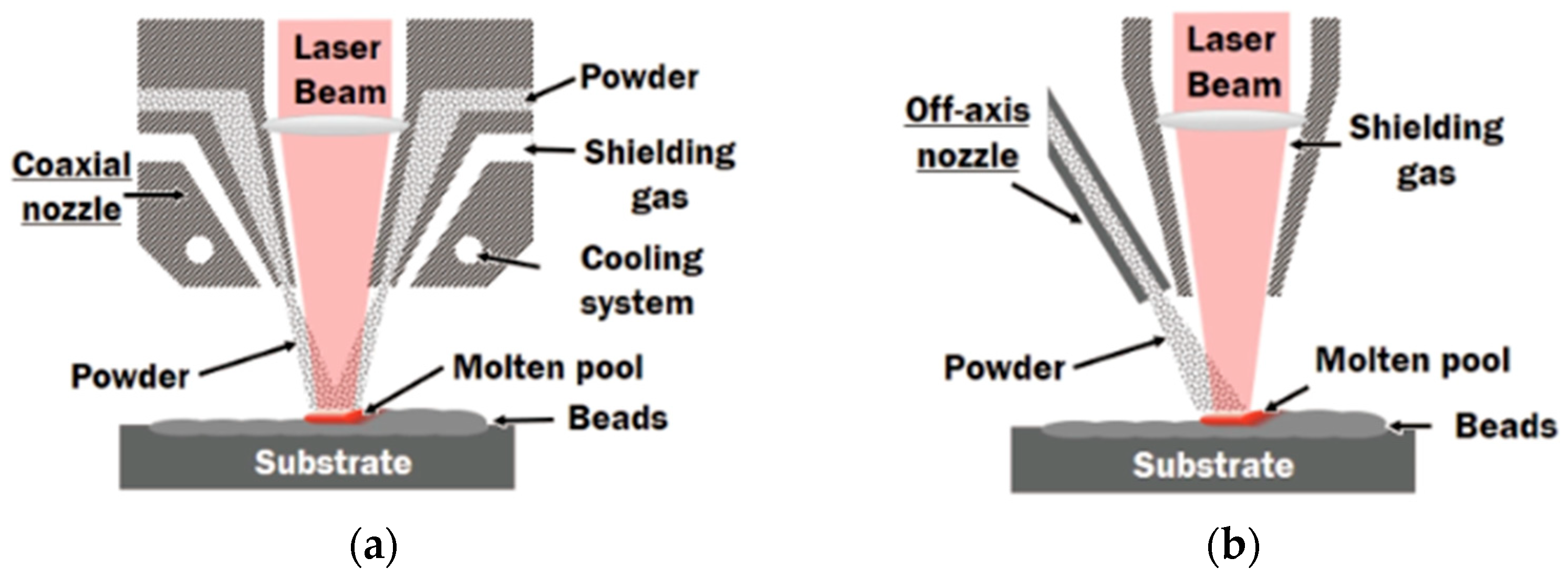

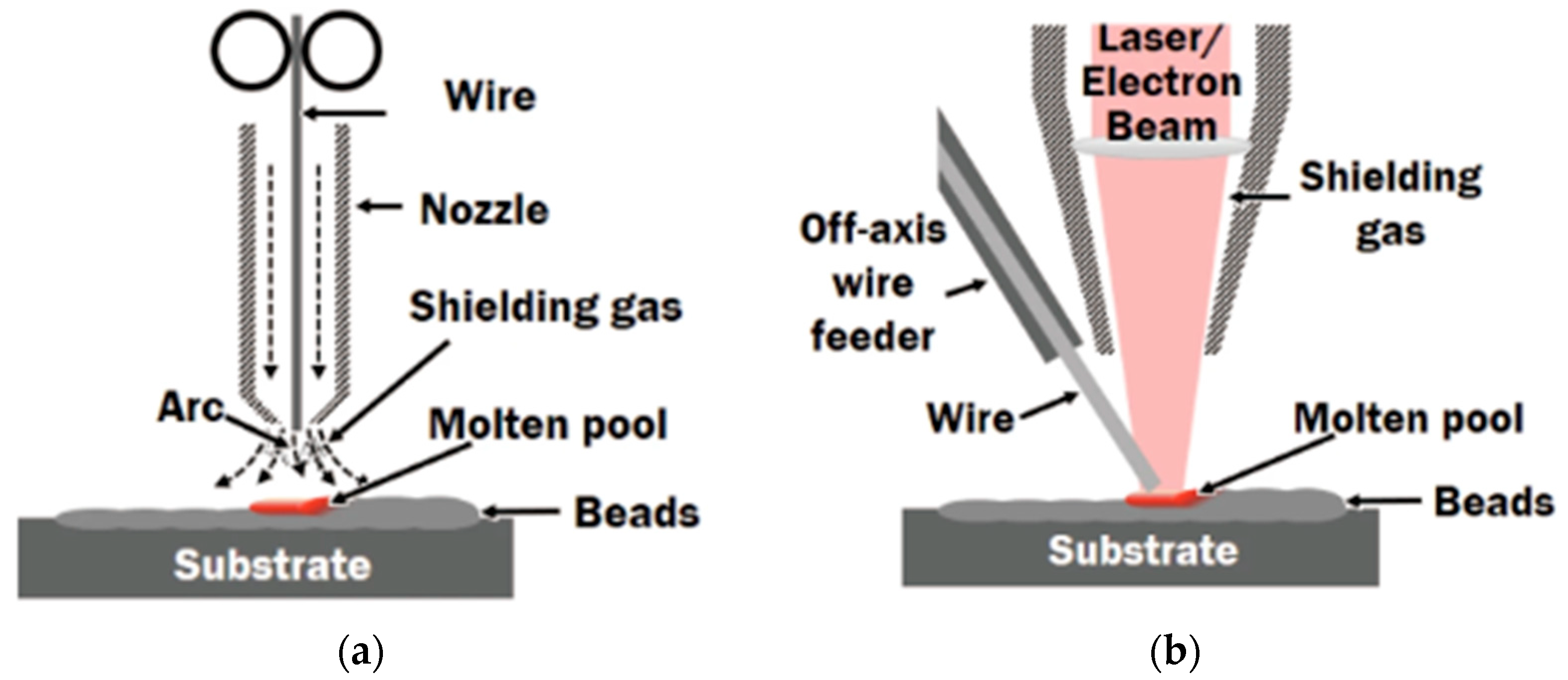

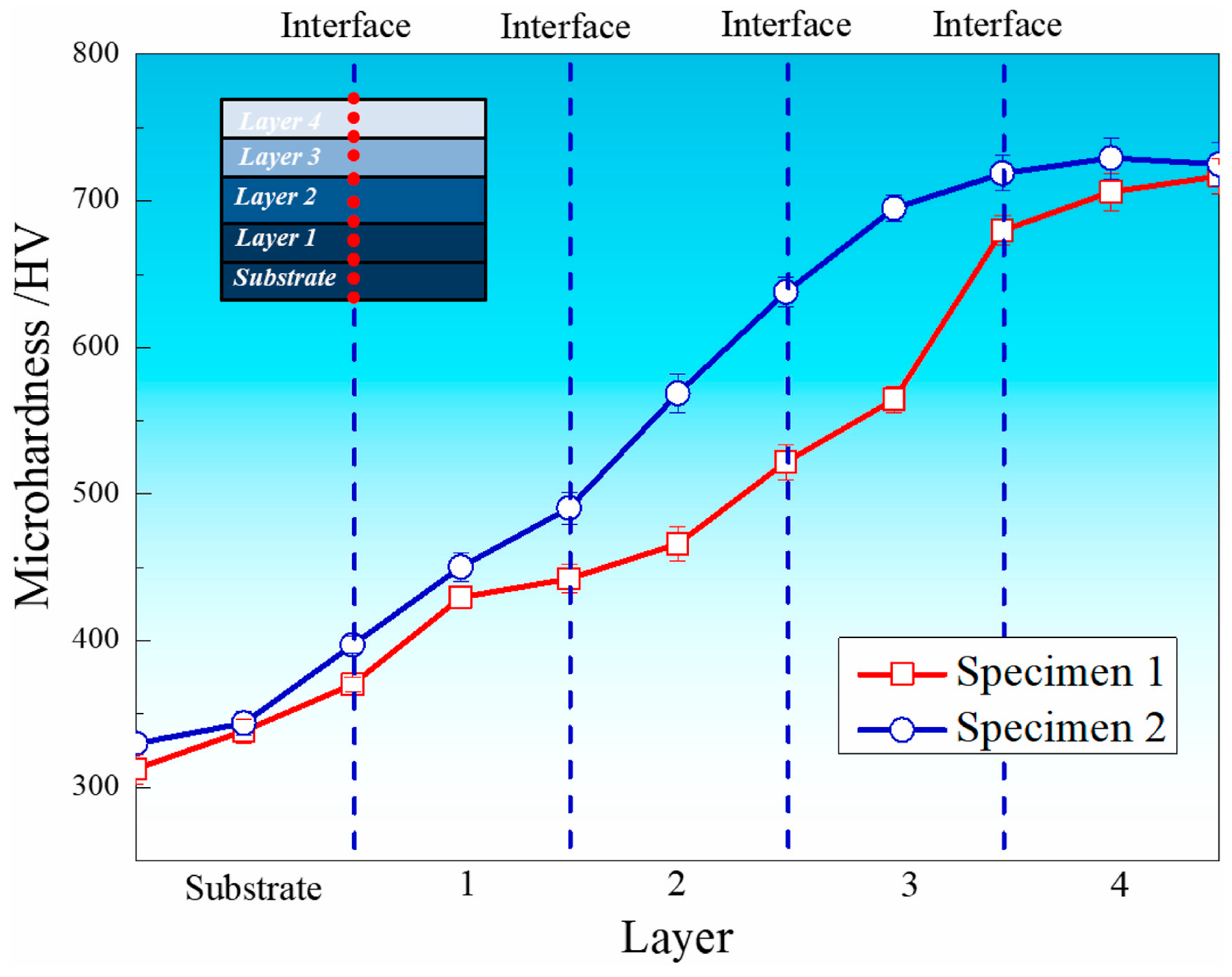

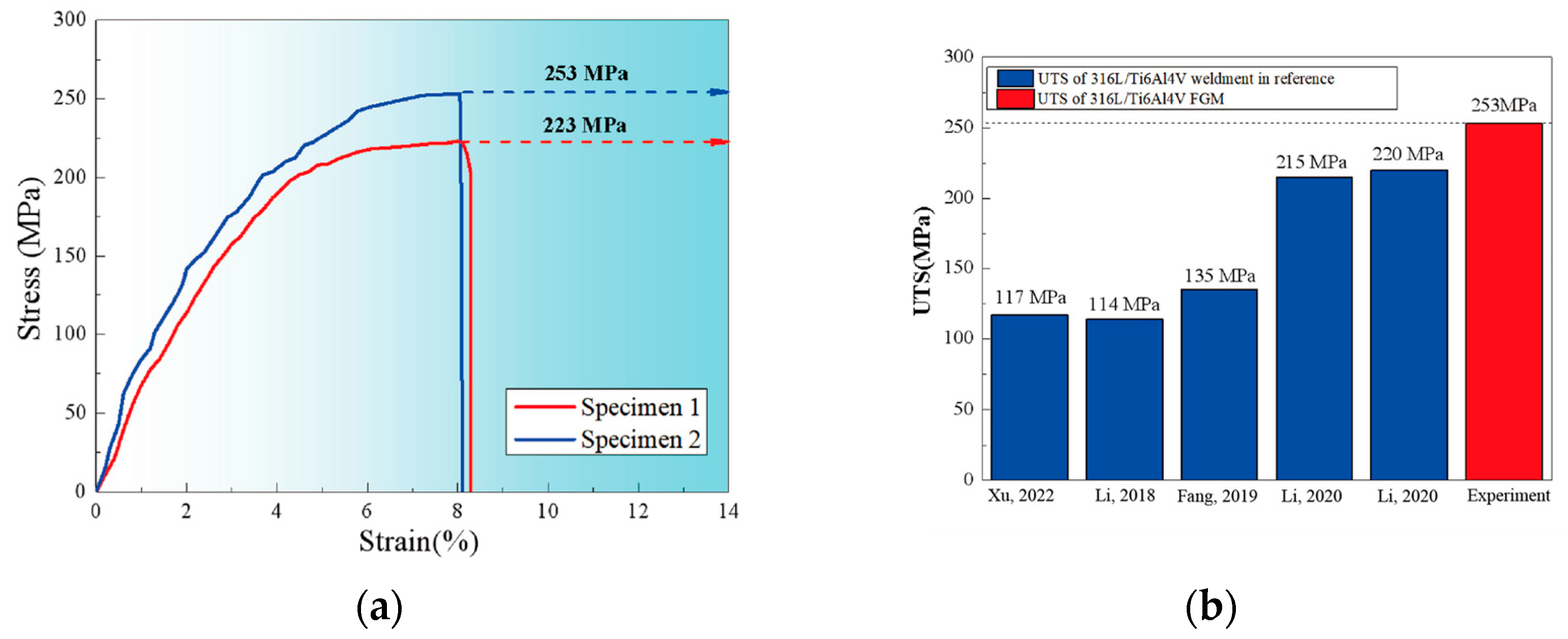

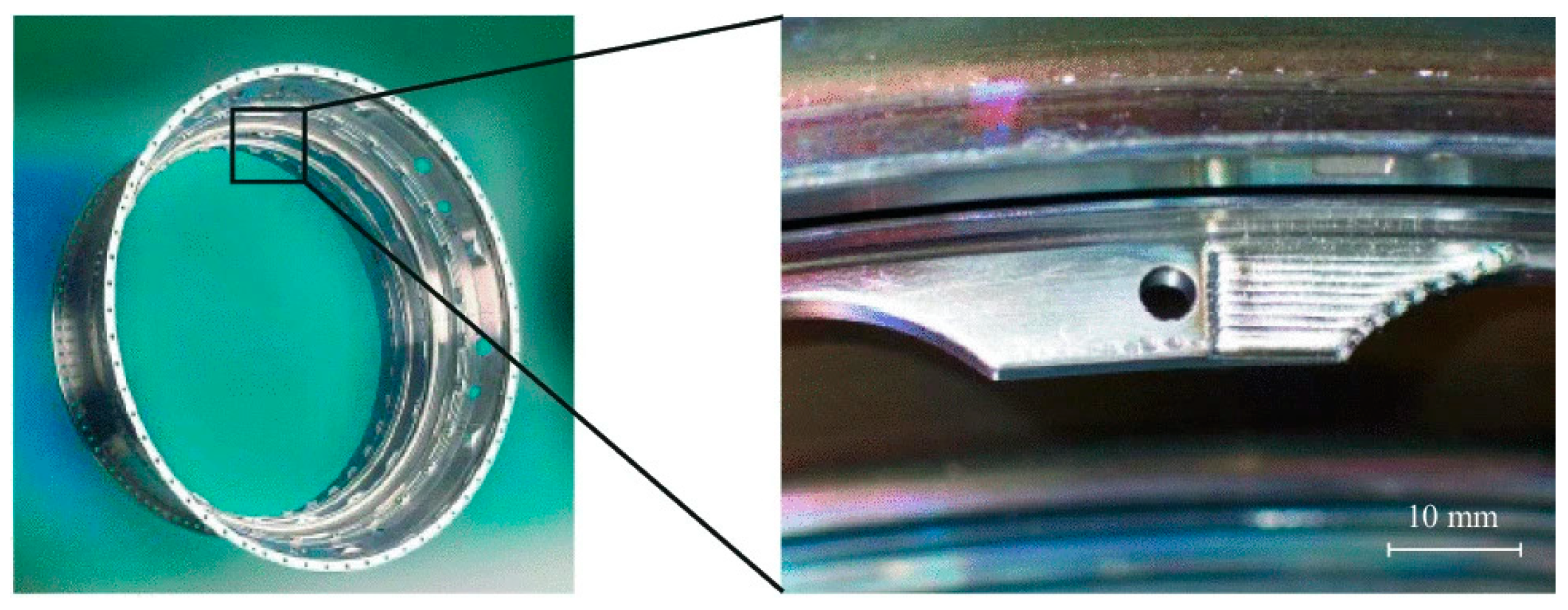

2.3. DED

3. Forming Behaviour and Post-Processing

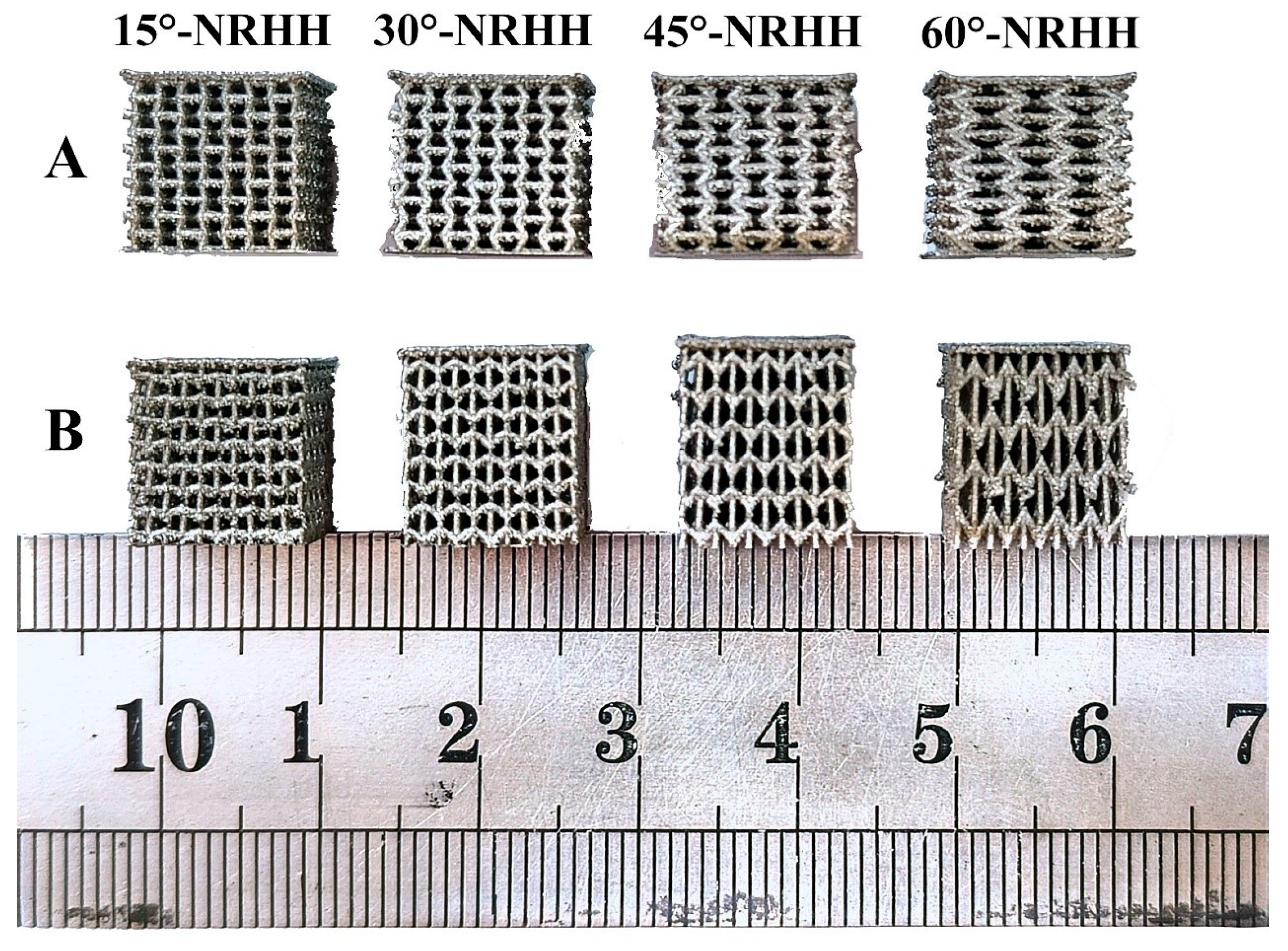

3.1. Forming Performance of AM Stainless-Steel Components

3.2. Heat Treatment and Microstructural Evolution

| Batch | Orientation | fp (%) | σy (MPa) | σu (MPa) | ef (%) |

|---|---|---|---|---|---|

| 1 [63] | ZX | 4.655 ± 0.78 | 190 ± 17 | 548 ± 10 | 67.6 ± 7 |

| XY | 4.2675 ± 0.43 | 193 ± 12 | 553 ± 4.4 | 76 ± 6.7 | |

| 2 | ZX | 2.06 ± 0.12 | 226 ± 3.3 | 575 ± 9.5 | 64 ± 7 |

| XY | 2.55 ± 0.31 | 224 ± 2.8 | 570 ± 6.1 | 76 ± 6.7 | |

| 2 + HIP | ZX | 1.15 ± 0.05 | 205 ± 5.6 | 556 ± 2.7 | 98 ± 6 |

| XY | 1.11 ± 0.05 | 199 ± 3.34 | 551 ± 3 | 93.6 ± 5.6 | |

| CM [63] | - | 0 | 273 ± 4 | 622 ± 6 | 65 ± 10 |

| AM Method | Post-Processing | UTS (MPa) | YS (MPa) | Porosity (%) | Reference |

|---|---|---|---|---|---|

| L-PBF | As-built | ~560–650 | ~480–540 | <1.5 | [2,8] |

| L-PBF | Heat-treated | ~700–800 | ~600–720 | <1.5 | [52,53] |

| L-PBF | HIP + Heat-treated | ~750–820 | ~610–730 | ~0.1 | [60,62] |

| Binder Jetting | Sintered (1380 °C) | ~473.3 | ~182.7 | ~2–5 | [15] |

| Binder Jetting | Sintered (1400 °C) | ~387.0 | ~247.6 | >5 | [15] |

| DED | As-built | ~500–600 | ~380–450 | ~1–2 | [22,24] |

| DED | Functionally graded + heat treated | ~650–730 | ~500–600 | ~1–2 | [32] |

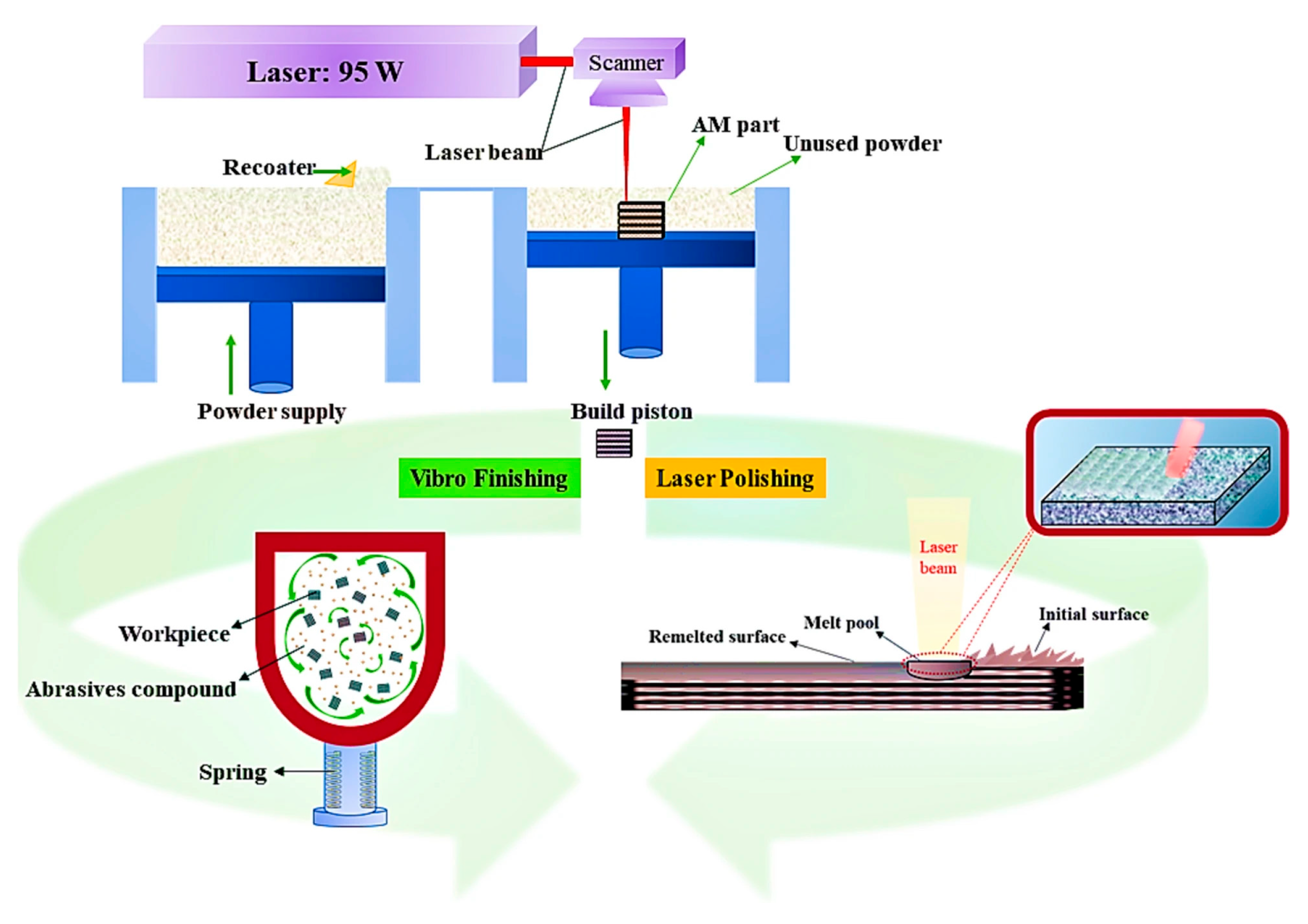

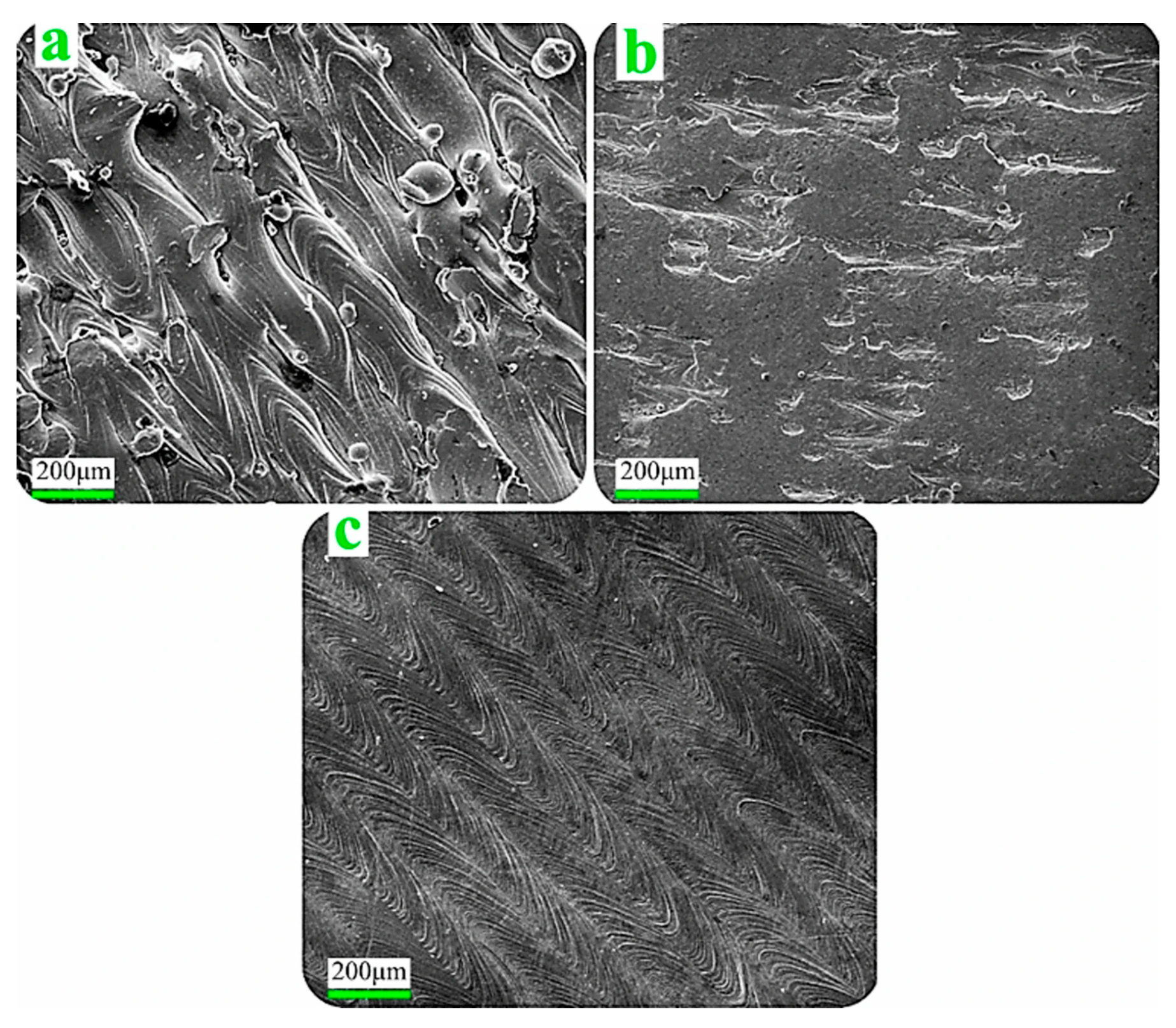

3.3. Surface Finishing

4. Challenges and Innovations

4.1. Formability Challenges in AM Stainless-Steels

4.2. Innovative Solutions and Emerging Techniques

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cheng, B.; Loeber, L.; Willeck, H.; Hartel, U.; Tuffile, C. Computational investigation of melt pool process dynamics and pore formation in laser powder bed fusion. J. Mater. Eng. Perform. 2019, 28, 6565–6578. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; La Fé-Perdomo, I.; Ramos-Grez, J.A.; Walczak, M.; Mendez, P.F. Microstructural differences and mechanical performance of stainless steel 316L conventionally processed versus a selective laser melted. Prog. Addit. Manuf. 2025, 10, 2663–2673. [Google Scholar] [CrossRef]

- Bai, Y.; Wagner, G.; Williams, C.B. Effect of particle size distribution on powder packing and sintering in binder jetting additive manufacturing of metals. J. Manuf. Sci. Eng. 2017, 139, 081019. [Google Scholar] [CrossRef]

- Kurgan, N. Effect of porosity and density on the mechanical and microstructural properties of sintered 316L stainless steel implant materials. Mater. Des. 2014, 55, 235–241. [Google Scholar] [CrossRef]

- Xu, S.; Yang, X.; Hu, X.; Ma, H.; Li, J.; Ren, G. Preparation of Negative Poisson’s Ratio 316L Stainless Steel Porous Bone Scaffolds Based on Finite Element Analysis and 3D Printing Technology. Mater. Res. 2025, 28, e20240479. [Google Scholar] [CrossRef]

- Ng, L.L.; Sing, S.L. Additive manufacturing enabled designs for dental applications: A conceptual study. Mater. Today Proc. 2022, 70, 548–553. [Google Scholar] [CrossRef]

- Ahmed, N.; Barsoum, I.; Haidemenopoulos, G.; Al-Rub, R.A. Process parameter selection and optimization of laser powder bed fusion for 316L stainless steel: A review. J. Manuf. Process. 2022, 75, 415–434. [Google Scholar] [CrossRef]

- Charmi, A.; Falkenberg, R.; Ávila, L.; Mohr, G.; Sommer, K.; Ulbricht, A.; Sprengel, M.; Neumann, R.S.; Skrotzki, B.; Evans, A. Mechanical anisotropy of additively manufactured stainless steel 316L: An experimental and numerical study. Mater. Sci. Eng. A 2021, 799, 140154. [Google Scholar] [CrossRef]

- Sola, A.; Nouri, A. Microstructural porosity in additive manufacturing: The formation and detection of pores in metal parts fabricated by powder bed fusion. J. Adv. Manuf. Process. 2019, 1, e10021. [Google Scholar] [CrossRef]

- Zohdi, N.; Yang, R. Material anisotropy in additively manufactured polymers and polymer composites: A review. Polymers 2021, 13, 3368. [Google Scholar] [CrossRef]

- McCann, R.; Obeidi, M.A.; Hughes, C.; McCarthy, É.; Egan, D.S.; Vijayaraghavan, R.K.; Joshi, A.M.; Garzon, V.A.; Dowling, D.P.; McNally, P.J. In-situ sensing, process monitoring and machine control in Laser Powder Bed Fusion: A review. Addit. Manuf. 2021, 45, 102058. [Google Scholar] [CrossRef]

- Lores, A.; Azurmendi, N.; Agote, I.; Zuza, E. A review on recent developments in binder jetting metal additive manufacturing: Materials and process characteristics. Powder Metall. 2019, 62, 267–296. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Lecis, N.; Mariani, M.; Beltrami, R.; Emanuelli, L.; Casati, R.; Vedani, M.; Molinari, A. Effects of process parameters, debinding and sintering on the microstructure of 316L stainless steel produced by binder jetting. Mater. Sci. Eng. A 2021, 828, 142108. [Google Scholar] [CrossRef]

- Mao, Y.; Cai, C.; Zhang, J.; Heng, Y.; Feng, K.; Cai, D.; Wei, Q. Effect of sintering temperature on binder jetting additively manufactured stainless steel 316L: Densification, microstructure evolution and mechanical properties. J. Mater. Res. Technol. 2023, 22, 2720–2735. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, W.; Chen, L.; Zhu, D.; Chen, Q.; Fu, Z. Influence of initial relative densities on the sintering behavior and mechanical behavior of 316 L stainless steel fabricated by binder jet 3D printing. Mater. Today Commun. 2022, 31, 103369. [Google Scholar] [CrossRef]

- Zago, M.; Lecis, N.F.M.; Vedani, M.; Cristofolini, I. Dimensional and geometrical precision of parts produced by binder jetting process as affected by the anisotropic shrinkage on sintering. Addit. Manuf. 2021, 43, 102007. [Google Scholar] [CrossRef]

- Zago, M.; Segata, G.; Perina, M.; Molinari, A. Binder jet 3D printing of 316L stainless steel: A Taguchi analysis of the dependence of density and mechanical properties on the printing parameters. J. Mater. Res. Technol. 2025, 34, 337–347. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Z.; Chen, L.; Zhu, D.; Fu, Z. Optimization of printing parameters to achieve high-density 316L stainless steel manufactured by binder jet 3D printing. J. Mater. Eng. Perform. 2023, 32, 3602–3616. [Google Scholar] [CrossRef]

- Ziaee, M.; Crane, N.B. Binder jetting: A review of process, materials, and methods. Addit. Manuf. 2019, 28, 781–801. [Google Scholar] [CrossRef]

- Kráľ, J.; Dzuro, T.; Debski, H. Applying binder jetting technology to 316L stainless steel materials and testing its mechanical and dimensional properties depending on the printing method. Materials 2024, 17, 4400. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Microstructure and mechanical properties of AISI 316L produced by directed energy deposition-based additive manufacturing: A review. Appl. Sci. 2020, 10, 3310. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Melzer, D.; Džugan, J.; Koukolíková, M.; Rzepa, S.; Vavřík, J. Structural integrity and mechanical properties of the functionally graded material based on 316L/IN718 processed by DED technology. Mater. Sci. Eng. A 2021, 811, 141038. [Google Scholar] [CrossRef]

- Makarenko, K.; Dubinin, O.; Konev, S.; Shishkovsky, I. Physical and Mechanical Properties of Cu-Fe System Functionally Graded and Multimaterial Structures after the DED. arXiv 2021, arXiv:2110.00103. [Google Scholar] [CrossRef]

- Mazzucato, F.; Aversa, A.; Doglione, R.; Biamino, S.; Valente, A.; Lombardi, M. Influence of process parameters and deposition strategy on laser metal deposition of 316L powder. Metals 2019, 9, 1160. [Google Scholar] [CrossRef]

- Sadeh, S.; Mathews, R.; Zhang, R.; Sunny, S.; Marais, D.; Venter, A.M.; Li, W.; Malik, A. Interlayer machining effects on microstructure and residual stress in directed energy deposition of stainless steel 316L. J. Manuf. Process. 2023, 94, 69–78. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, D.; Wang, P.; Yan, M.; Yang, C.; Chen, Z.; Lu, J.; Lu, Z. Additive manufacturing of metals: Microstructure evolution and multistage control. J. Mater. Sci. Technol. 2022, 100, 224–236. [Google Scholar] [CrossRef]

- Fang, Q.; Xiong, G.; Zhou, M.; Tamir, T.S.; Yan, C.-B.; Wu, H.; Shen, Z.; Wang, F.-Y. Process monitoring, diagnosis and control of additive manufacturing. IEEE Trans. Autom. Sci. Eng. 2022, 21, 1041–1067. [Google Scholar] [CrossRef]

- Ahn, D.-G. Directed energy deposition (DED) process: State of the art. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Li, Y.; Založnik, M.; Zollinger, J.; Dembinski, L.; Mathieu, A. Effects of the powder, laser parameters and surface conditions on the molten pool formation in the selective laser melting of IN718. J. Mater. Process. Technol. 2021, 289, 116930. [Google Scholar] [CrossRef]

- Xu, G.; Wu, L.; Su, Y.; Wang, Z.; Luo, K.; Lu, J. Microstructure and mechanical properties of directed energy deposited 316L/Ti6Al4V functionally graded materials via constant/gradient power. Mater. Sci. Eng. A 2022, 839, 142870. [Google Scholar] [CrossRef]

- Li, P.; Dong, H.; Xia, Y.; Hao, X.; Wang, S.; Pan, L.; Zhou, J. Inhomogeneous interface structure and mechanical properties of rotary friction welded TC4 titanium alloy/316L stainless steel joints. J. Manuf. Process. 2018, 33, 54–63. [Google Scholar] [CrossRef]

- Fang, Y.; Jiang, X.; Song, T.; Mo, D.; Luo, Z. Pulsed laser welding of Ti-6Al-4V titanium alloy to AISI 316L stainless steel using Cu/Nb bilayer. Mater. Lett. 2019, 244, 163–166. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Gao, Y.; Jin, P.; Sun, Q.; Feng, J. Benefits of interfacial regulation with interlayers in laser welding Ti6Al4V/316L steel. Opt. Laser Technol. 2020, 125, 106007. [Google Scholar] [CrossRef]

- Mannucci, A.; Tomashchuk, I.; Bolot, R.; Mathieu, A.; Lafaye, S. Microstructure and mechanical properties of dissimilar Ti/Nb/Cu/steel laser joints. Procedia CIRP 2020, 94, 644–648. [Google Scholar] [CrossRef]

- Dezaki, M.L.; Serjouei, A.; Zolfagharian, A.; Fotouhi, M.; Moradi, M.; Ariffin, M.; Bodaghi, M. A review on additive/subtractive hybrid manufacturing of directed energy deposition (DED) process. Adv. Powder Mater. 2022, 1, 100054. [Google Scholar] [CrossRef]

- Yan, L.; Chen, Y.; Liou, F. Additive manufacturing of functionally graded metallic materials using laser metal deposition. Addit. Manuf. 2020, 31, 100901. [Google Scholar] [CrossRef]

- Piscopo, G.; Iuliano, L. Current research and industrial application of laser powder directed energy deposition. Int. J. Adv. Manuf. Technol. 2022, 119, 6893–6917. [Google Scholar] [CrossRef]

- Kumar, L.J.; Nair, G.K. Laser metal deposition repair applications for Ti-6Al-4V alloy. Mech. Mater. Sci. Eng. J. 2017, 7, hal-01508594. [Google Scholar]

- Li, S.-H.; Kumar, P.; Chandra, S.; Ramamurty, U. Directed energy deposition of metals: Processing, microstructures, and mechanical properties. Int. Mater. Rev. 2023, 68, 605–647. [Google Scholar] [CrossRef]

- Kim, E.S.; Park, J.M.; Karthik, G.M.; Kim, K.T.; Yu, J.-H.; Lee, B.-J.; Kim, H.S. Local composition detouring for defect-free compositionally graded materials in additive manufacturing. Mater. Res. Lett. 2023, 11, 586–594. [Google Scholar] [CrossRef]

- Bertoli, U.S.; MacDonald, B.E.; Schoenung, J.M. Stability of cellular microstructure in laser powder bed fusion of 316L stainless steel. Mater. Sci. Eng. A 2019, 739, 109–117. [Google Scholar] [CrossRef]

- Eskandari, H.; Lashgari, H.; Ye, L.; Eizadjou, M.; Wang, H. Microstructural characterization and mechanical properties of additively manufactured 17–4PH stainless steel. Mater. Today Commun. 2022, 30, 103075. [Google Scholar] [CrossRef]

- Bahl, S.; Mishra, S.; Yazar, K.; Kola, I.R.; Chatterjee, K.; Suwas, S. Non-equilibrium microstructure, crystallographic texture and morphological texture synergistically result in unusual mechanical properties of 3D printed 316L stainless steel. Addit. Manuf. 2019, 28, 65–77. [Google Scholar] [CrossRef]

- Ramirez-Cedillo, E.; Uddin, M.J.; Sandoval-Robles, J.A.; Mirshams, R.A.; Ruiz-Huerta, L.; Rodriguez, C.A.; Siller, H.R. Process planning of L-PBF of AISI 316L for improving surface quality and relating part integrity with microstructural characteristics. Surf. Coat. Technol. 2020, 396, 125956. [Google Scholar] [CrossRef]

- Merot, P.; Morel, F.; Mayorga, L.G.; Pessard, E.; Buttin, P.; Baffie, T. Observations on the influence of process and corrosion related defects on the fatigue strength of 316L stainless steel manufactured by Laser Powder Bed Fusion (L-PBF). Int. J. Fatigue 2022, 155, 106552. [Google Scholar] [CrossRef]

- Mohr, G.; Sommer, K.; Knobloch, T.; Altenburg, S.J.; Recknagel, S.; Bettge, D.; Hilgenberg, K. Process induced preheating in laser powder bed fusion monitored by thermography and its influence on the microstructure of 316L stainless steel parts. Metals 2021, 11, 1063. [Google Scholar] [CrossRef]

- Anderson, M.; Bridier, F.; Gholipour, J.; Jahazi, M.; Wanjara, P.; Bocher, P.; Savoie, J. Mechanical and metallurgical evolution of stainless steel 321 in a multi-step forming process. J. Mater. Eng. Perform. 2016, 25, 1526–1538. [Google Scholar] [CrossRef]

- Sohrabpoor, H.; Salarvand, V.; Lupoi, R.; Chu, Q.; Li, W.; Aldwell, B.; Stanley, W.; O’Halloran, S.; Raghavendra, R.; Choi, C.-H. Microstructural and mechanical evaluation of post-processed SS 316L manufactured by laser-based powder bed fusion. J. Mater. Res. Technol. 2021, 12, 210–220. [Google Scholar] [CrossRef]

- Huang, R.; Zhao, H.; Sun, Y.; Lin, D.; Tang, Z.; Chen, B.; Song, X.; Tan, C. Additive manufacturing of 17-4PH stainless steel: Effect of heat treatment on microstructure evolution and strengthening behavior. Mater. Sci. Eng. A 2024, 908, 146770. [Google Scholar] [CrossRef]

- Salman, O.; Gammer, C.; Chaubey, A.K.; Eckert, J.; Scudino, S. Effect of heat treatment on microstructure and mechanical properties of 316L steel synthesized by selective laser melting. Mater. Sci. Eng. A 2019, 748, 205–212. [Google Scholar] [CrossRef]

- Sghaier, T.A.; Sahlaoui, H.; Mabrouki, T.; Sallem, H.; Rech, J. A comparative study on microstructure and mechanical properties of 17-4PH processed by a laser powder bed fusion vs. rolling process. Prog. Addit. Manuf. 2024, 10, 3711–3727. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, M.; Suhr, J.; Lee, T.; Kim, M. Exploring the Effect of Heat Treatment on the Mechanical Performance of 17-4PH Stainless Steel Specimens Fabricated by Metal Additive Manufacturing. Exp. Mech. 2024, 64, 1333–1342. [Google Scholar] [CrossRef]

- Petroušek, P.; Kvačkaj, T.; Bidulská, J.; Bidulský, R.; Grande, M.A.; Manfredi, D.; Weiss, K.-P.; Kočiško, R.; Lupták, M.; Pokorný, I. Investigation of the properties of 316l stainless steel after am and heat treatment. Materials 2023, 16, 3935. [Google Scholar] [CrossRef]

- Chadha, K.; Tian, Y.; Spray, J.G.; Aranas Jr, C. Effect of annealing heat treatment on the microstructural evolution and mechanical properties of hot isostatic pressed 316L stainless steel fabricated by laser powder bed fusion. Metals 2020, 10, 753. [Google Scholar] [CrossRef]

- Nong, X.; Zhou, X.; Li, J.; Wang, Y.; Zhao, Y.; Brochu, M. Selective laser melting and heat treatment of precipitation hardening stainless steel with a refined microstructure and excellent mechanical properties. Scr. Mater. 2020, 178, 7–12. [Google Scholar] [CrossRef]

- Lashgari, H.; Adabifiroozjaei, E.; Kong, C.; Molina-Luna, L.; Li, S. Heat treatment response of additively manufactured 17-4PH stainless steel. Mater. Charact. 2023, 197, 112661. [Google Scholar] [CrossRef]

- Mehmeti, A.; Lynch, D.; Penchev, P.; Martinez Ramos, R.; Vincent, D.; Maurath, J.; Wimpenny, D.I.; Essa, K.; Dimov, S. The effect of hot isostatic pressing on surface integrity, microstructure and strength of hybrid metal injection moulding, and laser-based powder bed fusion stainless-steel components. Appl. Sci. 2021, 11, 7490. [Google Scholar] [CrossRef]

- Mirzababaei, S.; Pasebani, S. A review on binder jet additive manufacturing of 316L stainless steel. J. Manuf. Mater. Process. 2019, 3, 82. [Google Scholar] [CrossRef]

- Kumar, P.; Jayaraj, R.; Suryawanshi, J.; Satwik, U.; McKinnell, J.; Ramamurty, U. Fatigue strength of additively manufactured 316L austenitic stainless steel. Acta Mater. 2020, 199, 225–239. [Google Scholar] [CrossRef]

- Kumar, P.; Radhakrishnan, J.; Gan, S.S.; Bryl, A.; McKinnell, J.; Ramamurty, U. Tensile and fatigue properties of the binder jet printed and hot isostatically pressed 316L austenitic stainless steel. Mater. Sci. Eng. A 2023, 868, 144766. [Google Scholar] [CrossRef]

- Diller, J.; Blankenhagen, J.; Siebert, D.; Radlbeck, C.; Mensinger, M. Combined effect of surface treatment and heat treatment on the fatigue properties of AISI 316L, manufactured by powder bed fusion of metals using a laser (PBF-LB/M). Int. J. Fatigue 2024, 178, 108025. [Google Scholar] [CrossRef]

- Kaynak, Y.; Kitay, O. Porosity, surface quality, microhardness and microstructure of selective laser melted 316L stainless steel resulting from finish machining. J. Manuf. Mater. Process. 2018, 2, 36. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.-D. As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Kumar, A.; Saha, S.; Kumar, C.; Nath, A. Laser surface re-melting of additive manufactured samples with a line focused beam. Mater. Today Proc. 2020, 26, 1221–1225. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Nie, M.; Chen, Y.; Yang, S.; Gao, N. Microstructure and corrosion performance of 316L stainless steel fabricated by Selective Laser Melting and processed through high-pressure torsion. J. Alloys Compd. 2018, 763, 360–375. [Google Scholar] [CrossRef]

- Samoilenko, M.; Lanik, G.; Brailovski, V. Towards the determination of machining allowances and surface roughness of 3D-printed parts subjected to abrasive flow machining. J. Manuf. Mater. Process. 2021, 5, 111. [Google Scholar] [CrossRef]

- Kaynak, Y.; Kitay, O. The effect of post-processing operations on surface characteristics of 316L stainless steel produced by selective laser melting. Addit. Manuf. 2019, 26, 84–93. [Google Scholar] [CrossRef]

- Mofazali, P.; Dustmohamadi, Z.; Atapour, M.; Sheikholeslam, M.; Saboori, A.; Iuliano, L. Tailoring surface characteristics of laser powder bed fusioned AISI 316L stainless steel for biomedical applications. Prog. Addit. Manuf. 2024, 10, 5009–5024. [Google Scholar] [CrossRef]

- Manogharan, G.; Wysk, R.A.; Harrysson, O.L. Additive manufacturing–integrated hybrid manufacturing and subtractive processes: Economic model and analysis. Int. J. Comput. Integr. Manuf. 2016, 29, 473–488. [Google Scholar] [CrossRef]

- Fang, Z.-C.; Wu, Z.-L.; Huang, C.-G.; Wu, C.-W. Review on residual stress in selective laser melting additive manufacturing of alloy parts. Opt. Laser Technol. 2020, 129, 106283. [Google Scholar] [CrossRef]

- Navarre, C.; Sumarli, S.; Malamud, F.; Polatidis, E.; Strobl, M.; Logé, R.E. In-situ neutron diffraction revealing microstructure changes during laser powder bed fusion and in-situ laser heat treatments of 316L and 316L-Al1. Mater. Des. 2025, 251, 113727. [Google Scholar] [CrossRef]

- An, S.; Eo, D.-R.; Lim, H.; Sohn, I.; Choi, K. Prediction of martensitic transformation and residual stress field on 17–4 PH stainless steel fabricated by laser powder bed fusion. Addit. Manuf. 2024, 91, 104339. [Google Scholar] [CrossRef]

- Kuzminova, Y.O.; Evlashin, S.A.; Belyakov, A.N. On the texture and strength of a 316L steel processed by powder bed fusion. Mater. Sci. Eng. A 2024, 913, 147026. [Google Scholar] [CrossRef]

- Barrionuevo, G.O.; Ramos-Grez, J.A.; Walczak, M.; Sánchez-Sánchez, X.; Guerra, C.; Debut, A.; Haro, E. Microstructure simulation and experimental evaluation of the anisotropy of 316 L stainless steel manufactured by laser powder bed fusion. Rapid Prototyp. J. 2023, 29, 425–436. [Google Scholar] [CrossRef]

- Sakthinathan, S.; Meenakshi, G.A.; Vinothini, S.; Yu, C.-L.; Chen, C.-L.; Chiu, T.-W.; Vittayakorn, N. A Review of Thin-Film Growth, Properties, Applications, and Future Prospects. Processes 2025, 13, 587. [Google Scholar] [CrossRef]

- Li, K.; Zhan, J.; Yang, T.; To, A.C.; Tan, S.; Tang, Q.; Cao, H.; Murr, L.E. Homogenization timing effect on microstructure and precipitation strengthening of 17–4PH stainless steel fabricated by laser powder bed fusion. Addit. Manuf. 2022, 52, 102672. [Google Scholar] [CrossRef]

- Grasso, M.; Colosimo, B.M. Process defects and in situ monitoring methods in metal powder bed fusion: A review. Meas. Sci. Technol. 2017, 28, 044005. [Google Scholar] [CrossRef]

- Sahar, T.; Rauf, M.; Murtaza, A.; Khan, L.A.; Ayub, H.; Jameel, S.M.; Ahad, I.U. Anomaly detection in laser powder bed fusion using machine learning: A review. Results Eng. 2023, 17, 100803. [Google Scholar] [CrossRef]

- Yang, W.; Gan, X.; He, J. Defect Identification of 316L Stainless Steel in Selective Laser Melting Process Based on Deep Learning. Processes 2024, 12, 1054. [Google Scholar] [CrossRef]

- Wang, H.; Li, B.; Zhang, W.; Xuan, F. Microstructural feature-driven machine learning for predicting mechanical tensile strength of laser powder bed fusion (L-PBF) additively manufactured Ti6Al4V alloy. Eng. Fract. Mech. 2024, 295, 109788. [Google Scholar] [CrossRef]

- Ho, S.; Zhang, W.; Young, W.; Buchholz, M.; Al Jufout, S.; Dajani, K.; Bian, L.; Mozumdar, M. DLAM: Deep learning based real-time porosity prediction for additive manufacturing using thermal images of the melt pool. IEEE Access 2021, 9, 115100–115114. [Google Scholar] [CrossRef]

- Muhammad, W.; Batmaz, R.; Natarajan, A.; Martin, E. Effect of binder jetting microstructure variability on low cycle fatigue behavior of 316L. Mater. Sci. Eng. A 2022, 839, 142820. [Google Scholar] [CrossRef]

- Pitrmuc, Z.; Šimota, J.; Beránek, L.; Mikeš, P.; Andronov, V.; Sommer, J.; Holešovský, F. Mechanical and microstructural anisotropy of laser powder bed fusion 316L stainless steel. Materials 2022, 15, 551. [Google Scholar] [CrossRef]

- Irrinki, H. Material-Process-Property Relationships of 17-4 Stainless Steel Fabricated by Laser-Powder Bed Fusion Followed by Hot Isostatic Pressing. Ph.D. Thesis, University of Louisville, Louisville, KY, USA, August 2018. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, D.; Jia, F.; Zhou, M.; Liu, H.; Yan, J.; Zhu, L.; Yang, M.; Jiang, Z. Advances in 3D Printing: Microfabrication Techniques and Forming Applications. Micromachines 2025, 16, 940. https://doi.org/10.3390/mi16080940

Pan D, Jia F, Zhou M, Liu H, Yan J, Zhu L, Yang M, Jiang Z. Advances in 3D Printing: Microfabrication Techniques and Forming Applications. Micromachines. 2025; 16(8):940. https://doi.org/10.3390/mi16080940

Chicago/Turabian StylePan, Di, Fanghui Jia, Muyuan Zhou, Hao Liu, Jingru Yan, Lisong Zhu, Ming Yang, and Zhengyi Jiang. 2025. "Advances in 3D Printing: Microfabrication Techniques and Forming Applications" Micromachines 16, no. 8: 940. https://doi.org/10.3390/mi16080940

APA StylePan, D., Jia, F., Zhou, M., Liu, H., Yan, J., Zhu, L., Yang, M., & Jiang, Z. (2025). Advances in 3D Printing: Microfabrication Techniques and Forming Applications. Micromachines, 16(8), 940. https://doi.org/10.3390/mi16080940