Nanophotonic Materials and Devices: Recent Advances and Emerging Applications

Abstract

1. Introduction

2. Core Principles of Nanophotonics-Based Nanomaterials

2.1. Plasmonic Nanomaterials

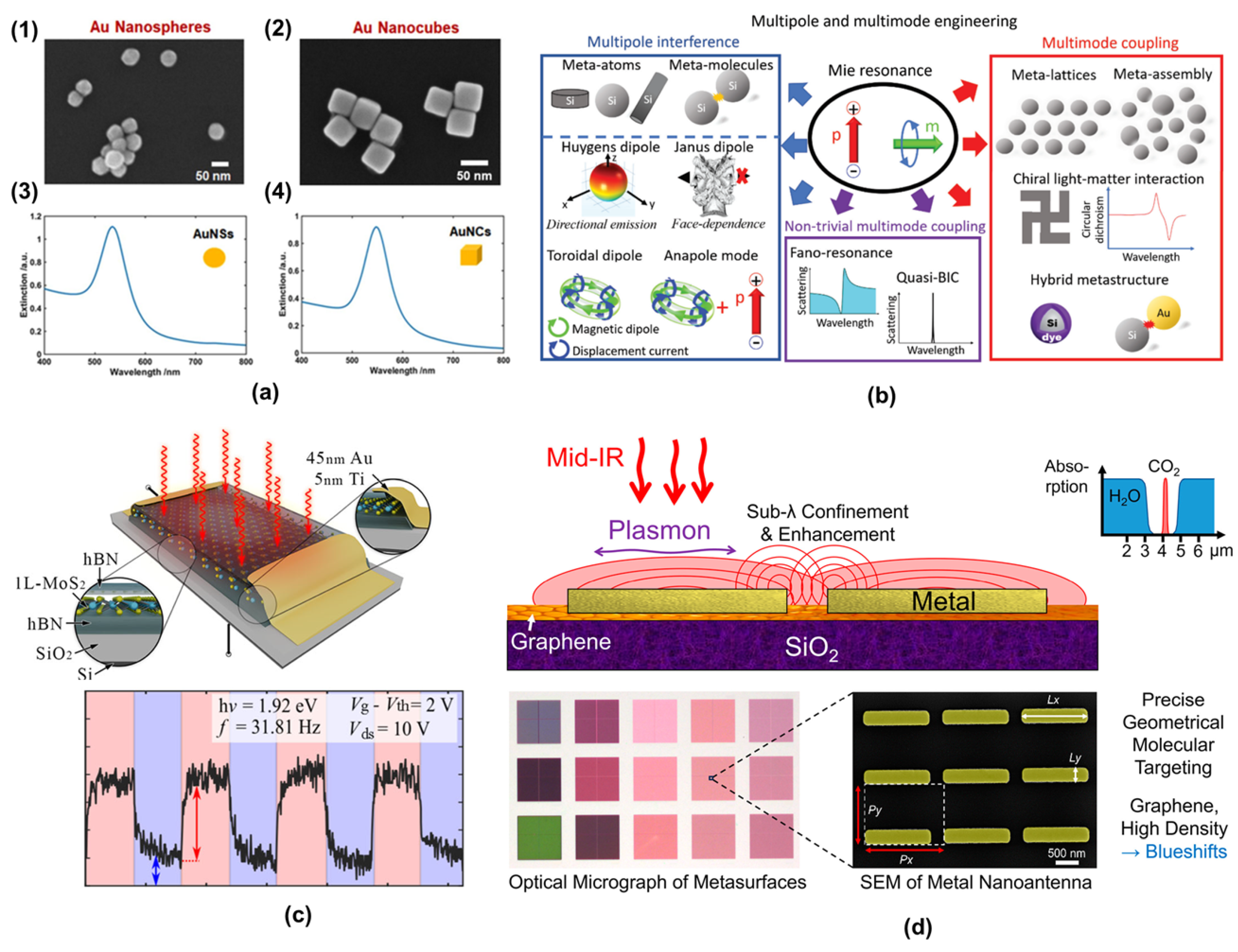

Plasmonic Nanostructures

2.2. Dielectric Nanomaterials

2.3. Two-Dimensional (2D) Materials

2.4. Hybrid Nanophotonic Systems

3. Fabrication Techniques

3.1. Top-Down Approaches

- (1)

- Electron beam lithography (EBL): EBL uses a focused electron beam to write patterns directly into a resist film on a substrate. It is widely used for prototyping nanophotonic structures due to its superb resolution (feature sizes < 10 nm are achievable). Complex shapes such as photonic crystal lattices or metasurface patterns can be precisely defined. However, EBL is a serial process (writing patterns point-by-point) and thus is time-consuming and expensive for large areas. It is most suitable for research-scale fabrication or mask manufacturing but not for high-volume manufacturing.

- (2)

- Focused ion beam (FIB) milling: FIB directs a focused beam of ions (commonly Ga+ ions) to sputter material from a surface, effectively ‘carving’ nanostructures. FIBs can also be used to deposit materials via ion-beam-induced deposition and provide great flexibility in 2D and shallow 3D patterning (for example, drilling nanopores or waveguide facets) with resolution on the order of a few tens of nanometers. FIB is often used for rapid prototyping, mask repair, or post-fabrication trimming of photonic devices; although like EBL, it is slow and not easily scalable to large wafer areas [73]. However, one limitation of Ga+-based FIB is ion implantation: the gallium ions can become embedded in the patterned material, leading to contamination and defects in nanophotonic structures [74]. This phenomenon is known to alter optical properties (e.g., increasing loss or changing refractive index) in sensitive devices. To address this, researchers have explored alternate milling sources (such as He+ or Ne+ ion beams) and post-fabrication treatments to reduce Ga-induced damage [75,76,77].

- (3)

- Photolithography: Photolithography uses ultraviolet (UV) or deep-UV light and masks to pattern large areas in parallel. Modern photolithography (including 193 nm immersion lithography and extreme ultraviolet (UV) lithography at 13.5 nm wavelength) can produce features below 50 nm on entire wafers with high throughput, using the same processes that drive semiconductor chip production. Although photolithography is extremely scalable and fast for repeated patterns, it typically requires expensive masks and is less accessible for rapid iteration compared to EBL. It is commonly used for mass-manufacturing integrated photonic circuits (e.g., silicon photonics) where feature sizes are within the resolution limits.

- (4)

- Nanoimprint lithography (NIL): Nanoimprint is a technique that bridges some advantages of top-down and replication methods. In NIL, a hard mold (stamp) containing nanostructures is pressed into a resin on a substrate, physically imprinting the nanopattern, which is then cured (by heat or UV light) and lifted off. NIL can achieve extremely high resolution (down to ~10 nm features) and, being a parallel process, can pattern large areas rapidly once a master mold is made. It has emerged as a promising method for the high-throughput fabrication of metasurfaces and other nanophotonic devices. The challenge in NIL lies in making a defect-free mold and avoiding defects during the imprint step (e.g., due to the sticking of the particles or resist sticking). However, roll-to-roll nanoimprint processes have been developed for flexible substrates, pointing toward industrial-scale nanophotonics manufacturing [78].

- (5)

- Bilayer resist lithography: Bilayer resist lithography is an advanced top-down approach now mentioned in our review. In this technique, two different resist layers (with different sensitivities or etch characteristics) are used during EBL to achieve enhanced patterning outcomes. For instance, a bilayer EBL process can create a reentrant or undercut resist profile, enabling clean lift-off of nanostructures with very fine features, or it can improve the aspect ratio by using a sturdier underlayer as an etch mask. We have included a brief description of this method and its utility in the definition of high-resolution nanophotonic structures [79,80]. Additionally, we have introduced template stripping as a fabrication technique. Template stripping involves fabricating nanostructures on a super-smooth template substrate and then bonding and peeling off a target substrate to transfer the nanostructures. This method produces extremely smooth metallic nanostructures (inherited from the atomic flatness of the template) and has been used to produce low-loss plasmonic surfaces and nanohole arrays at the wafer scale [81,82,83]. By incorporating bilayer lithography and template stripping into our discussion, we acknowledge these important techniques and the role they play in pushing the limits of nanofabrication for photonic devices.

3.2. Bottom-Up Approaches

- (1)

- Chemical Synthesis of Nanomaterials: A diverse range of nanostructures can be synthesized in solution with precise control over their size, shape, and composition. Common examples include colloidal semiconductor quantum dots, metallic nanoparticles (such as nanospheres, nanorods, and nanostars), and dielectric nanocrystals. This solution-based approach enables tunable optical and electronic properties, making it highly valuable for applications in photonics, catalysis, and biomedical imaging. These solution-grown nanomaterials can exhibit the desired optical resonances (e.g., plasmonic or excitonic peaks) and can be subsequently deposited or arranged on surfaces for device integration. Wet chemical synthesis is relatively low-cost and can produce nanomaterials in large quantities, but arranging these colloids into functional devices often requires additional steps [89].

- (2)

- Chemical Vapor Deposition (CVD): CVD and related epitaxial growth techniques can produce thin films and nanostructures on substrates. For instance, large-area graphene and TMDC monolayers are commonly grown by CVD on catalytic substrates. Similarly, semiconductor nanowires can be grown by vapor–liquid–solid epitaxy. These as-grown materials often form the basis of nanophotonic devices (e.g., a monolayer MoS2 integrated into a photonic cavity). The bottom-up CVD approach excels in producing high-crystallinity materials and novel heterostructures (such as vertically stacked 2D materials), although placement and patterning must be achieved by templating the growth or by post-growth lithography [90,91].

- (3)

- Self-Assembly and Template-Assisted Assembly: In self-assembly, components (such as nanoparticles, block copolymers, or molecules) spontaneously organize into ordered structures driven by thermodynamics. For nanophotonics, self-assembly can create periodic nanoparticle arrays, photonic crystals, or metamaterial structures over large areas without expensive tools. For example, colloidal nanospheres can self-assemble into 2D or 3D periodic lattices (acting as natural photonic crystals), and block-copolymer lithography can produce dense periodic patterns at the sub-20 nm scale by phase separation of polymers. However, purely self-assembled structures may lack the long-range order or registration needed for complex circuits. Template-assisted self-assembly combines top-down and bottom-up: lithographically defined templates (like shallow topographical patterns or chemically functionalized sites on a substrate) guide the assembly of nanomaterials into predetermined locations and arrangements. This hybrid strategy can produce ordered nanostructures in large areas by using chemical forces to conduct placement, thus marrying precision with scalability.

- (4)

- Bottom-up approaches offer cost-effective fabrication over large areas and access to material systems that may be difficult to pattern with lithography (for example, growing crystalline materials with atomic precision or creating nanostructures in a chemical beaker) [92]. The trade-off is that achieving arbitrary or complex patterns is challenging; self-assembled structures are often limited to relatively simple or periodic patterns, and positioning of specific features (like a single quantum dot in a cavity) can be stochastic. However, bottom-up fabrication is essential to build the materials foundation of nanophotonics (such as single-crystal nanomaterials or quantum emitters) and is often combined with top-down patterning for device integration [93].

3.3. Hybrid Fabrication Strategies

- (1)

- Template-Guided Self-Assembly: As noted above, a lithographically defined template can be used to direct bottom-up growth or assembly. For example, electron beam lithography can define an array of nanoscale trenches or chemically modified sites on a substrate, and solution-assisted colloidal nanoparticles (or nanowires, etc.) can preferentially attach to these sites [95]. This results in an ordered array of nanoparticles aligned with the template pattern. Such approaches have been used to fabricate plasmonic nanoparticle arrays and even DNA-directed assembly of quantum dots on photonic chips, achieving placement accuracy better than random self-assembly.

- (2)

- Nanoimprint and Transfer Techniques: Nanoimprint lithography itself is a hybrid method—the mold is typically made by top-down means (EBL, for example) but once created, it can be used repetitively as a stamp to replicate patterns in a bottom-up fashion. Another hybrid concept is transfer printing: nanostructures (such as nanowires, 2D material flakes or prefabricated nanopillars) can be fabricated or grown on one substrate and then transferred and embedded on a target photonic chip using polymer stamps or adhesion layers [96]. This enables the integration of materials that are incompatible with standard lithography (for example, placing a single-crystal nanowire laser on a silicon photonic waveguide) [97].

- (3)

- Direct laser writing (multiphoton lithography): Advances in additive manufacturing allow true 3D nano- and micro-fabrication via two-photon polymerization. In this technique, a focused femtosecond laser causes localized polymerization in a photosensitive resin at the focal point, which can be scanned in 3D to ‘print’ arbitrary 3D microstructures such as photonic woodpiles, microlenses, or even complex free-form meta-optics. Direct two-photon laser writing is a maskless technique that combines top-down control (the laser focus defines the pattern) with a bottom-up building of structure. The resolution can reach ~100 nm. While currently serial and relatively slow, it offers design geometries not achievable by planar lithography and has been used to create 3D photonic crystals and gradient-index micro-optics for nanophotonics.

- (4)

- Laser-Assisted Fabrication and Growth: Techniques such as laser interference lithography (which uses laser interference patterns to expose periodic patterns on a resist) and laser annealing can rapidly produce large-area periodic nanostructures or activate material growth [98]. For example, interference lithography can create a photonic crystal pattern in one step over a wafer, and pulsed laser deposition can create non-equilibrium material films with unique optical properties. These methods are hybrids in the sense that they leverage optical fields (bottom-up in effect) to drive top-down patterning.

4. Applications

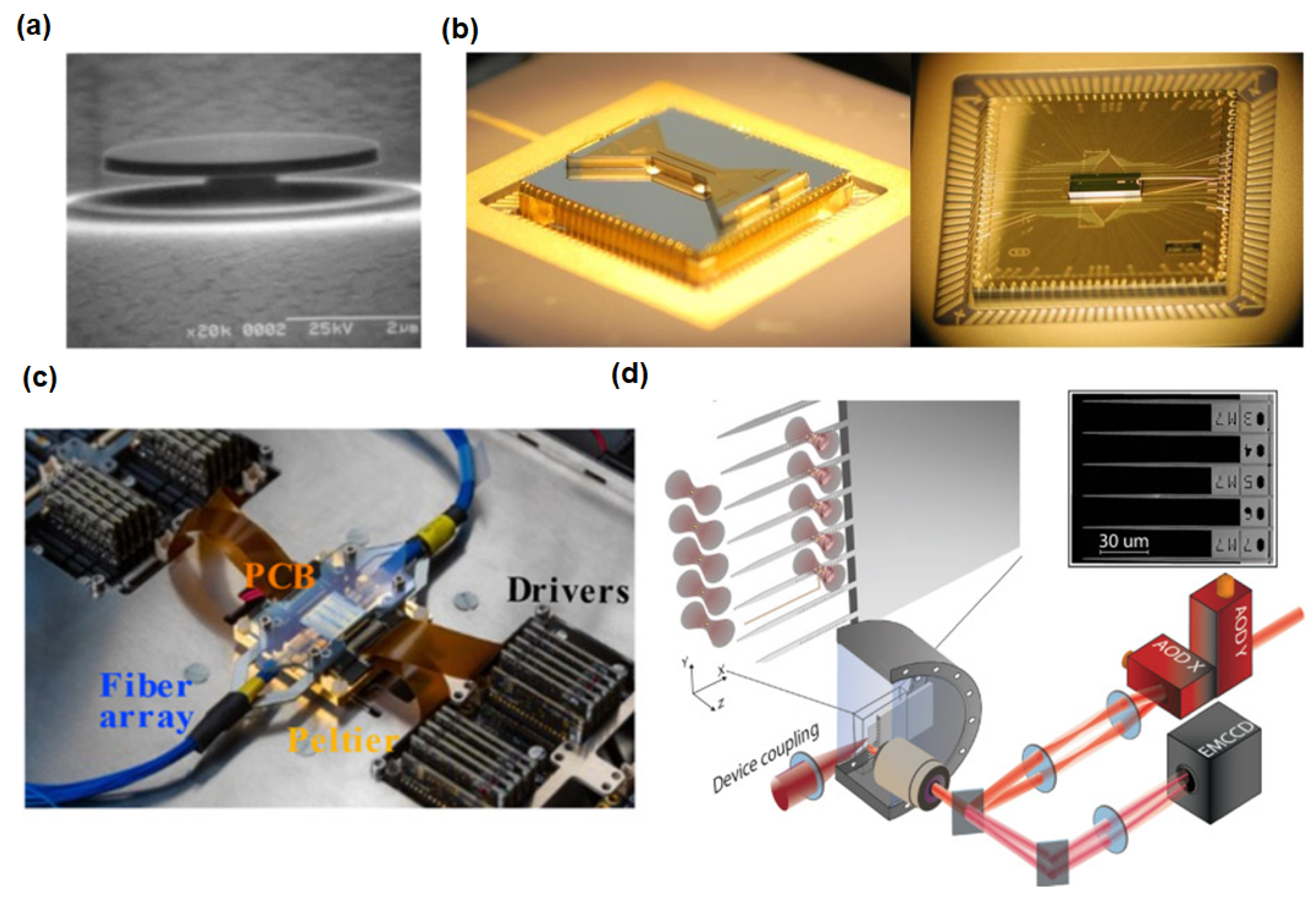

4.1. Quantum Photonics

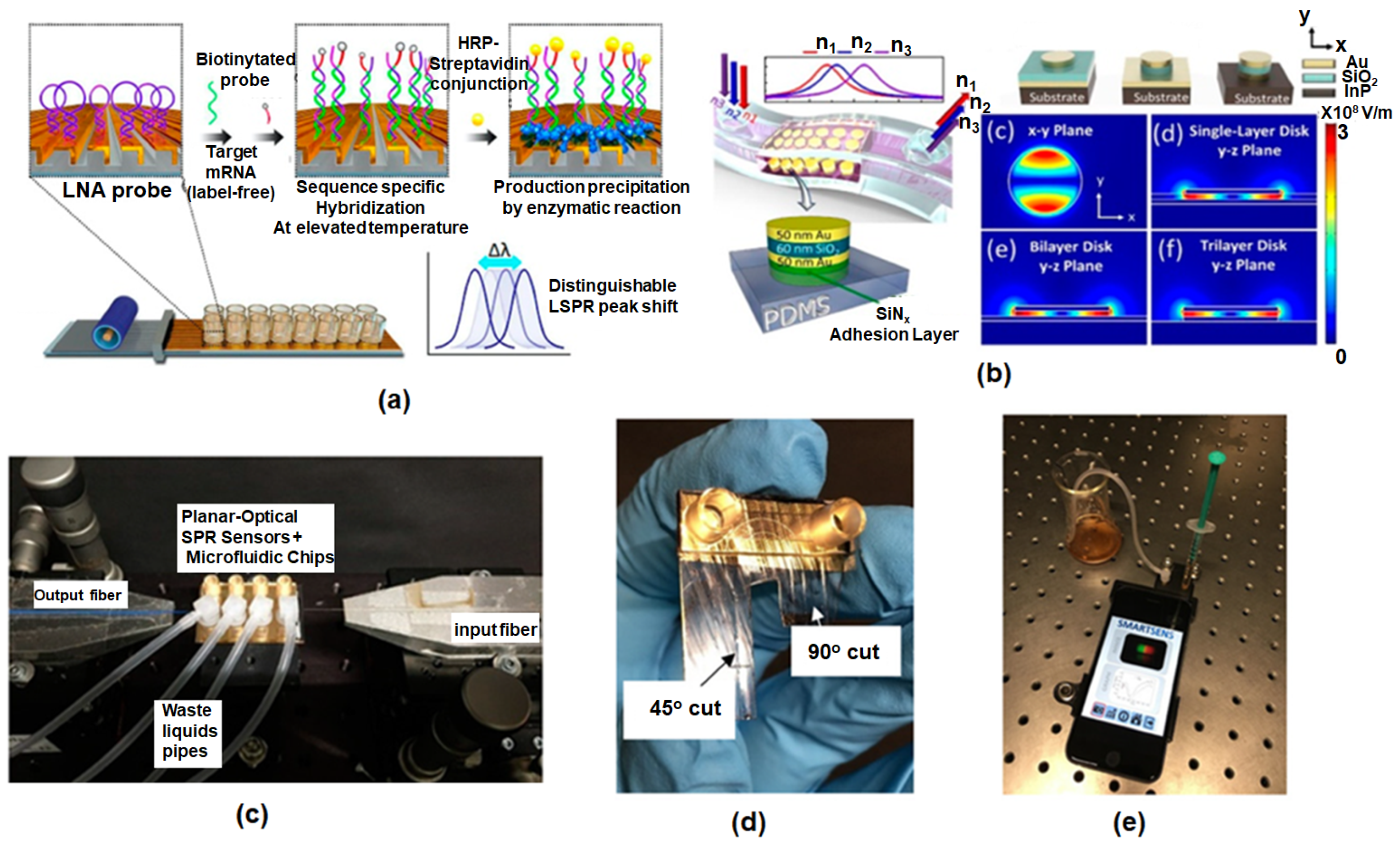

4.2. Biosensing

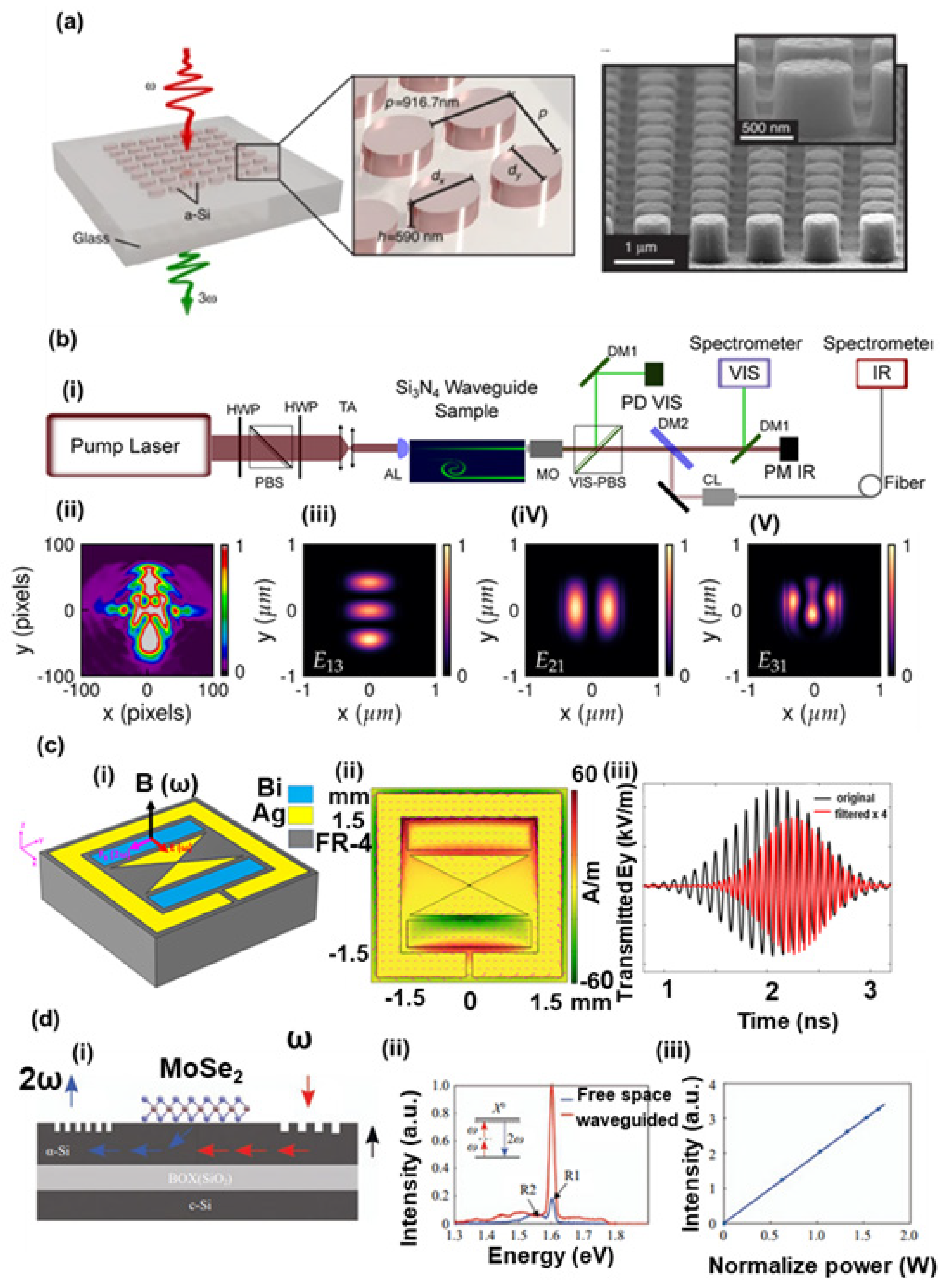

4.3. Nonlinear Optics

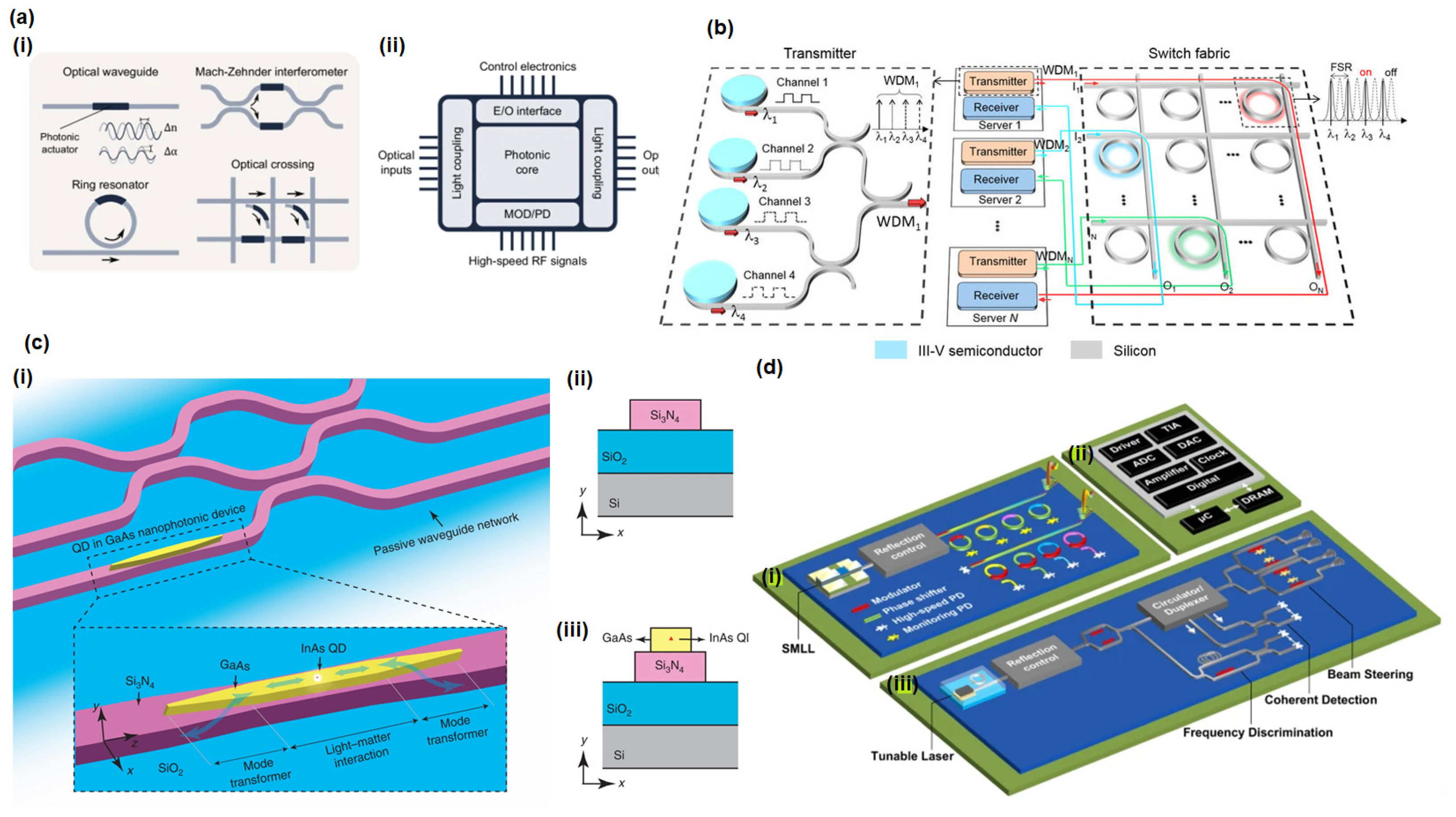

4.4. Photonic Integrated Circuits (PICs)

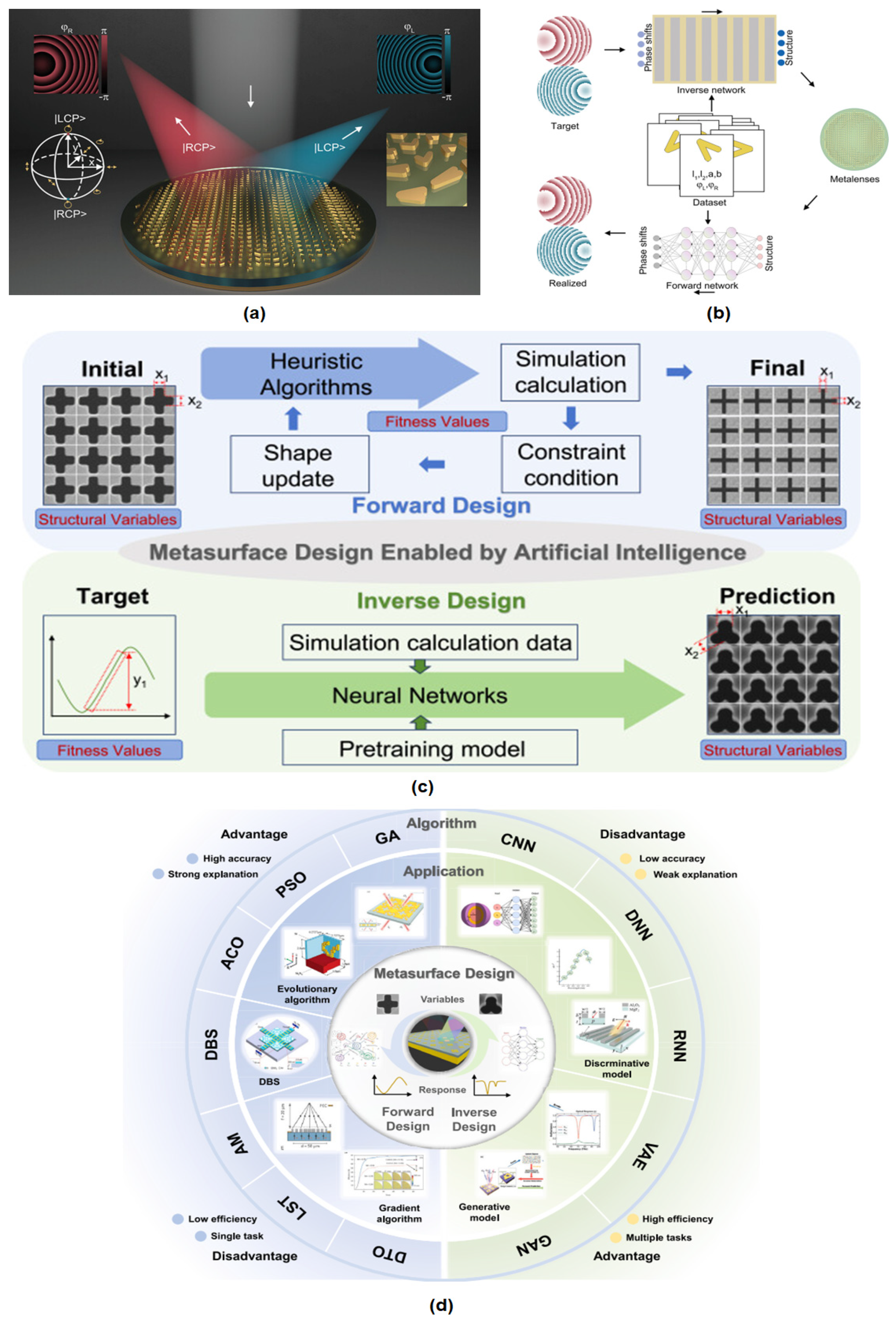

4.5. Metasurfaces and Flat Optics

- (1)

- Phase-change materials (eg, Ge2Sb2Te5, GST): These can reversibly switch between amorphous and crystalline states with vastly different refractive indices. Thus, a GST-integrated metasurface can be reconfigured between two (or more) different optical functions by a heating pulse [153].

- (2)

- Liquid crystals: By integrating liquid crystal layers above a metasurface and applying electric fields, one can continuously tune the refractive index that the metasurface elements experience, thus adjusting the output phase pattern. This approach has been used to produce tunable focal length metalenses and beam steerers.

- (3)

- Graphene and other 2D materials: Graphene’s optical conductivity can be electrically tuned, enabling metasurface modulation, especially in the infrared and terahertz ranges. A graphene-based metasurface can act as a dynamic mirror or filter controlled by a gate voltage [154].

- (4)

- Microelectromechanical systems (MEMS): Some metasurfaces use MEMS actuators to physically reconfigure the meta-atom positions or orientations. For example, a series of nanomirrors on tiny actuators can tilt to steer beams (used in some LiDAR systems). Metasurfaces can also be made tunable via various mechanisms (electrical, thermal, mechanical, etc.), as discussed later in Section 5. For example, MEMS-actuated metasurface elements allow dynamic reconfiguration of the optical response (see Section 5.1 for details).

- (5)

- Electro-Optical and Carrier Injection Tuning: Incorporating materials such as indium tin oxide (ITO) near its ENZ point, or using carrier injection in semiconductors, can modulate the refractive index of meta-atoms with nanosecond response times, acting as a high-speed spatial light modulator [155].

4.6. Optical Trapping and Plasmonic Tweezers

4.7. Polarization-Sensitive Field Distributions

4.8. Near-Field Scanning Optical Microscopy

5. Recent Advances and Trends

5.1. Tunable and Active Nanophotonics

- (1)

- Electrically Tunable Devices: Graphene, ITO, and other conductive oxides have been used to make electro-optic modulators and variable absorbers at the nanoscale. For instance, graphene integrated on plasmonic antennas can modulate mid-IR light by changing its carrier density. When operating near its ENZ frequency, ITO can function as a high-speed optical modulator, as small changes in carrier concentration induce large refractive index shifts. These approaches enable ultracompact modulators for telecommunications and dynamically tunable filters or absorbers for beam shaping [188].

- (2)

- Phase-Change and Thermally Tunable Devices: Phase-change materials (PCMs) such as GST have been incorporated into photonic elements including metasurfaces. By toggling the PCM state, one can switch a device between two distinct optical functions (reconfigurable mirror to diffuser, lens to flat window, etc.). Although thermal tuning tends to be slower (micro to milliseconds) and requires heating, it is nonvolatile, which means the state is retained without power. Other materials such as VO2 (which undergoes an insulator–metal transition around 68 °C) have been used for all-optical and thermal switching in nanophotonics [189].

- (3)

- Mechanical and MEMS Tuning: There is a resurgence of interest in nano-optomechanical systems. One example is MEMS-based metasurfaces, where nanostructures can be physically reoriented or displaced by tiny actuators. Another example is stretchable or flexible nanophotonic devices (using polymer substrates) in which mechanical stress adjusts the lattice spacing or orientation of nanostructures, thus changing their optical response [190].

- (4)

- Nonlinear and All-Optical Tuning: Rather than external electrical control, high-intensity optical pulses can, themselves, reconfigure a nanophotonic device through nonlinear effects. Ultrafast lasers can transiently change the refractive index via the optical Kerr effect or by free carrier excitation, enabling phenomena like all-optical switching. In nanophotonic cavities, even a single or few photons can alter the resonator conditions (in the quantum regime), which is relevant for quantum photonics [191].

5.2. Large-Area and Scalable Fabrication

- (1)

- Nanoimprint Lithography (NIL): As mentioned in Section 3, nanoimprint lithography (NIL) offers a path to high-throughput nanopatterning; here, we highlight that recent advancements in NIL have enabled wafer-scale patterning of metasurfaces with sub-50 nm features, greatly improving scalability. Likewise, deep-UV projection lithography, already capable of mass-producing nanophotonic structures, has been pushed to its limits (and complemented by emerging EUV lithography) to fabricate complex metasurface designs across entire wafers, addressing the scalability challenge. Researchers have demonstrated wafer-scale fabrication of metalenses and holographic metasurfaces using NIL, achieving feature resolutions down to tens of nanometers with excellent uniformity. Roll-to-roll nanoimprint systems now exist that can continuously print nanopatterns onto flexible films, producing meter-scale nanophotonic films (useful for, say, large-area diffractive waveplates or anticounterfeiting holograms on banknotes). A specific example is the roll-to-roll fabrication of plasmonic color metasurfaces, which was performed by continuously embossing a polymer resist with a nanograting pattern and then coating it with metal. Progress in NIL is making it possible to leave the confines of the cleanroom for production and use techniques similar to a printing press or film casting for nanophotonics [192].

- (2)

- Soft Lithography and Self-Assembly: Soft lithography uses elastomeric stamps (often patterned by an initial top-down method) to replicate patterns through contact printing or molding. This technique has been used to create large-area nanopatterned surfaces (for example, microlens arrays or photonic crystal patterns) at low costs, albeit with a slightly lower resolution than rigid methods. Self-assembly (e.g., nanosphere lithography or block copolymers) has been improved to yield more ordered patterns over larger areas, sometimes combined with shear alignment or electric fields to improve order. These approaches are being refined to fabricate, for example, antireflection coatings composed of self-assembled nanopillars on entire wafers or plasmonic nanoparticle arrays formed by self-assembly on substrates for biosensing.

- (3)

- Advances in Photolithography: The semiconductor industry’s push to extreme ultraviolet (EUV) lithography has incidentally benefitted nanophotonics, as commercial foundries can now pattern 10 nm-scale features on 300 mm wafers. Although expensive, this means that complex photonic circuits, including subwavelength metasurface features or photonic crystal patterns, can potentially be manufactured in large quantities using adapted CMOS processes. Additionally, multiproject wafer services for silicon photonics have made it easier for researchers to obtain chip-scale photonic devices fabricated with high quality, accelerating development of PICs (as noted in Section 4.4).

- (4)

- Materials Integration at Scale: Scalable fabrication is not only about patterning but also about material deposition and integration on large substrates. Techniques such as sputtering and atomic layer deposition (ALD) allow the deposition of high-purity nanometer films (for example, TiO2 or HfO2 for dielectric metasurfaces) uniformly across wafers. As an example, ALD was used to create high-quality TiO2 metasurfaces on 4-inch wafers by depositing TiO2 over nanoimprinted molds and lifting off [193]. Moreover, wafer bonding techniques have scaled to bonding entire III-V wafers to silicon, or polymer films to glass, enabling heterogeneous integration at scale (mentioned earlier for laser integration).

5.3. Integration with Other Platforms

- (1)

- Lab-on-Chip and Microfluidics: By combining photonic circuits with microfluidic channels, one can create smart lab-on-chip systems capable of real-time, high-throughput analysis of biochemical samples. Nanophotonic sensors (ring resonators, LSPR sensors, etc.) embedded in microfluidic flow cells can detect biomarkers or chemical reactions in tiny volumes. For example, a photonic chip with a microring array was integrated into a microfluidic device to simultaneously monitor multiple analytes in a medical diagnostic panel. The synergy lies in photonics providing a set of sensitive, multiplexed detectors, while microfluidics handles sample delivery and mixing. These hybrid devices are finding use in point-of-care diagnostics, environmental toxin detection, and pharmaceutical research. Nanophotonics enhances the sensitivity and reduces the footprint of such devices, which is crucial for field-deployable sensors [194].

- (2)

- MEMS and MOEMS (Micro-Opto-Electro-Mechanical Systems): MEMS techniques are used not only for tuning metasurfaces as mentioned, but also for integrating movable optical components like micromirrors and tunable filters on the chip. There are micro-optical benches where tiny mirrors and lenses (sometimes with nanopatterned surfaces for better performance) are assembled on a silicon MEMS chip to make miniaturized spectrometers or optical switches. The convergence of MEMS and nanophotonics yields devices like optomechanical crystals, where nanophotonic cavities are coupled to mechanical resonators, enabling ultrasensitive displacement sensors and quantum optomechanic experiments on chip [195].

- (3)

- Electronic–Photonic Integration: We mentioned electronic–photonic cointegration in the context of PICs and tunable devices. A continuing trend is the integration of CMOS electronics (drivers, amplifiers, and digital logic) with nanophotonic devices in the same package or die. This could be heterogeneous (chip-on-chip bonding) or monolithic (fabricating photonic devices in a CMOS line alongside transistors). The result is optical systems-on-a-chip that have both the ‘brain’ (electronics for control and processing) and the ‘eyes/ears’ (photonic interfaces and sensors). For example, a fully integrated optical gyroscope chip with photonic waveguides and MEMS accelerometers together with on-chip electronics was demonstrated for signal processing, drastically reducing size compared to conventional fiber gyroscopes [196].

- (4)

- Wearables and Flexible Photonics: Integration of photonics on to flexible substrates (polymers or thin glass) is enabling wearable photonic sensors, e.g., a nanophotonic sensor array laminated on skin to monitor pulse, blood oxygen, or glucose noninvasively using optical signals. These devices require nanostructures that can be fabricated on or transferred to flexible substrates and still function reliably. Recent work achieved flexible metasurface holograms that maintain performance under bending, as well as textile-integrated optical waveguides for sensing [197].

5.4. Artificial Intelligence in Nanophotonic Design

6. Challenges

6.1. Material Losses and Thermal Effects

6.2. Fabrication Complexity and Reproducibility

6.3. Environmental Stability and Durability

- (1)

- Protective coatings: A thin conformal layer (a few nanometers) of a material, such as Al2O3 or SiO2 deposited by ALD, can seal a nanophotonic structure from the environment without significantly altering its optical function (if the coating is sufficiently thin and uniform). This is common for plasmonic structures; for example, gold nanoantennas could be coated with a ~5 nm SiO2 film to prevent contamination or melting into polymers [219].

- (2)

- Encapsulation: Placing the nanophotonic devices between two glass layers or within a polymer waveguide matrix can protect them from humidity and mechanical damage. Many integrated photonic chips are now packaged similarly to electronic chips (in sealed modules) [220].

- (3)

- Material choices: Using more inert materials is a straightforward approach. For example, choosing gold instead of silver (gold is much less reactive, though slightly more lossy at blue wavelengths), or using aluminum oxide or titanium nitride (TiN) as plasmonic materials: TiN is chemically stable and has plasmonic behavior in the visible and NIR. In dielectric metasurfaces, this means choosing materials like TiO2 or HfO2 (hard, stable ceramics) instead of something like porous silicon that can oxidize or absorb moisture [221].

- (4)

- Ultraviolet and laser damage: High optical intensities or UV exposure can cause photoinduced changes (e.g., color centers forming in a material or ablation). Using UV-resistant materials and distributing optical power (for example, not having a single hotspot that exceeds the damage threshold) is part of a robust design. Some groups have also developed self-healing materials (e.g., certain polymers or chalcogenides that can partially reflow or reconfigure under heat to heal cracks or deformities) [222].

6.4. Integration and Interconnectivity

- (1)

- Optical I/O (Input/Output): The efficient transfer of light to and off a nanophotonic chip efficiently is nontrivial. For silicon photonics, grating couplers or edge couplers are used to interface fibers to the chip. For free-space metasurfaces, one might need the metasurface carefully tilted or spaced relative to a detector or source. Misalignment of a micrometer can drastically reduce coupling efficiency. Thus, packaging often involves active alignment (tuning position while monitoring signal) and then fixing components in place with epoxy, which is time-consuming and costly. Developing self-aligned connectors or tolerantly designed couplers is a huge need. Some progress includes vertical grating couplers that have > 80% coupling efficiency with a moderate alignment tolerance, and the use of microlenses to expand and collimate beams from the chips to ease alignment [225].

- (2)

- Electronic Integration: While we can cointegrate electronics and photonics on a chip, connecting them at high density is difficult because of thermal and crosstalk concerns. Driving many optical modulators at GHz frequencies means routing many electrical lines; these lines can heat up and also induce electrical noise. Monolithic integration (fabricating transistors and waveguides together) is challenging because processes may be incompatible (e.g., high-temperature steps for photonics can damage CMOS metals). One approach is monolithic but with process tweaks (like IBM’s CMOS-integrated silicon photonics platform, which adds photonics after transistor formation). Another is 3D integration, stacking a photonic die on an electronic die with dense microbump or even optical interconnects [226].

- (3)

- Mechanical and Thermal Matching: Different materials have different thermal expansion coefficients. When bonding, say, an InP laser onto a silicon chip, differences in expansion can cause strain or even delamination over temperature changes. Material compatibility is important for mechanical reliability. In addition, many nanophotonic setups in the laboratory are in temperature-stabilized stages; replicating this in a product means adding thermoelectric coolers or heaters, which adds power overhead [227].

- (4)

- Size and Form Factor: For consumer electronics or portable systems, nanophotonic components need to be integrated in a way that does not add bulk. Flat optics (metasurfaces) help reduce the form factor, but then those need to be integrated with image sensors or sources in a compact module (like Metalenz did with ST: metasurface mounted directly on the sensor package). This kind of integration, bridging the nano-optic to the device-level packaging, required developing new assembly techniques similar to how camera modules are assembled but with finer precision.

7. Future Outlook

- (1)

- Advanced low-loss and nonlinear materials: Developing new materials with lower optical losses and higher nonlinearities is a priority. One promising avenue is the presence of near-zero (ENZ) epsilon materials, where the real part of permittivity approaches zero. ENZ materials (such as doped metal oxides or novel metamaterial composites) allow unusual light concentration and phase propagation properties, which can be harnessed for ultrastrong nonlinear interactions and tailored radiation patterns. We anticipate breakthroughs in the use of ENZ modes for ultrafast optical switching and frequency conversion at relatively low power levels. Similarly, topological photonic materials are emerging using concepts from electronic topological insulators. By designing nontrivial topology photonic band structures, one can achieve robust light transport (e.g., edge modes immune to scattering) and new localized states. Topologically protected waveguides and cavities could significantly improve device performance by reducing backscattering losses and disorder sensitivity. Already, nanophotonic topological waveguide arrays have shown the propagation of light around sharp corners with almost no loss, which is very promising for dense photonic circuits. In the coming years, we expect new material platforms (such as lithium niobate on insulation with quasiphase matching for nonlinear optics, or van der Waals heterostructures for tunable photonics) to be integrated into nanophotonic devices, combining multiple functionalities in a single device [232].

- (2)

- Machine Learning-Driven Design and Control: The role of AI in photonics will probably expand further. Inverse design using AI will become a standard tool, and we might see the most complex photonic components (filters, couplers, modulators) being designed by algorithms that output geometries not easily conceived by humans, but which meet tight specs. This could lead to performance leaps in metrics such as bandwidth, efficiency, and footprint as devices reach theoretical limits. Moreover, AI might be embedded on chip for real-time control, giving rise to self-optimizing photonic systems. For instance, a photonic sensor network might continuously learn from its output and adjust itself (perhaps through tunable elements) to maintain optimal sensitivity or calibration. Such intelligent photonic systems would be highly adaptable to changing conditions, which is very useful in environments where optical properties drift (like wearable sensors subject to body temperature changes, etc.). We also foresee automated fabrication optimization: AI algorithms that adjust fabrication parameters on the fly (within advanced lithography or deposition tools) to achieve target device outcomes, reducing trial-and-error cycles [204].

- (3)

- Programmable and Digital Metasurfaces: Closely related to AI control is the development of programmable metasurfaces, sometimes called spatial light modulators 2.0. Instead of a static metasurface performing one optical function, these would be metasurface platforms whose optical response can be dynamically reprogrammed via electronic signals (much like a field-programmable gate array in electronics). Recent research introduced the concept of digital metasurfaces where meta-atoms have two or more states (like “0” or “1”) that can be toggled to create different phase profiles. In the future, large arrays of tunable meta-atoms (perhaps MEMS-actuated or using phase-change materials) combined with electronic backplanes could yield devices that function as reconfigurable lenses, hologram projectors, or beam steering units with video rate refresh. This could revolutionize applications like AR/VR displays (enabling dynamic focal planes and focus cues), LIDAR (with no moving parts beam scanning), and optical computing (reconfiguring interconnects and weights in photonic neural networks). Achieving high pixel count, speed, and efficiency simultaneously in these dynamic metasurfaces will be a challenge, but progress in materials such as liquid crystal polymers, electro-optic polymers, and low-loss phase-change compounds provides a pathway [233].

- (4)

- Quantum-Enhanced Nanophotonics: The intersection of nanophotonics and quantum technology will deepen. Nanophotonic devices will enhance quantum systems (as covered in Section 4.1) by enabling better single-photon sources, detectors, and compact quantum gates. However, quantum mechanics might enhance nanophotonics—for example, quantum illumination techniques use entangled photons to detect objects with lower energy than classical light would require, which could be integrated into nanoscale sensors for sensing with super-resolved or improved signal-to-noise ratios. Nanophotonics will also play a role in quantum networks, where quantum repeaters and transducers (converting photons from one wavelength to another or to other quantum systems) will likely rely on optical nanocavities and waveguides coupling to quantum memories (atoms, ions, and solid-state qubits). We anticipate revolutionary advances by integrating quantum emitters like color centers (e.g., NV or SiV centers in diamond) directly into photonic circuits for chip-scale quantum processors and secure communication nodes. As an example, one could imagine a quantum photonic sensor chip where entangled photons are generated and used to perform a measurement (like interferometric sensing) beyond classical limits, all within a nanophotonic circuit [234].

- (5)

- Interdisciplinary and cross-scale integration: Future nanophotonic systems will increasingly bridge multiple length scales and domains. We will see more multifunctional systems that combine photonics, electronics, fluidics, and even biological components (such as embedding cells on a photonic chip for lab-on-chip diagnostics). This requires collaborative advances: materials scientists delivering better functional materials (gain media, nonlinear crystals, and flexible substrates), electrical engineers co-designing circuits to drive and read photonic devices, chemists devising robust surface chemistries for biosensors, and computer scientists developing architectures to use optical computing advantages. The convergence of these fields, aided by nanophotonics as the optical glue, could produce technologies such as ultracompact spectroscopic sensors that integrate AI on the chip to instantly interpret chemical signatures, or new medical devices that use nanophotonic endoscopes with AI image analysis to identify diseased tissue in real time [124].

- (6)

- Commercial and Societal Impact: Finally, on the horizon is the broad commercialization of nanophotonics. The appearance of metasurface optics in consumer phones in 2022 is likely just the beginning. We expect nanophotonic components to become common in cameras (improving image quality in thinner modules), optical communications (enabling faster internet through integrated photonic transceivers), healthcare (through portable diagnostic chips and improved imaging, such as compact optical coherence tomography devices), and environmental monitoring (ubiquitous sensors for air quality, etc.). As the production volume increases, costs will decrease, creating a positive feedback loop for further adoption. Moreover, sustainability considerations may drive nanophotonics research on, for example, photonic circuits that reduce energy consumption in data centers, or nanostructured surfaces that improve solar cell absorption (leading to greener energy). Nanophotonics can contribute to energy efficiency by enabling optical analog signal processing that might complement digital electronics for tasks like AI inference, with much lower power consumption.

8. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arup, E.M.; Liu, L.; Mekonnen, H.; Bosomtwi, D.; Babicheva, V.E. Metasurfaces with Multipolar Resonances and Enhanced Light–Matter Interaction. Nanomaterials 2025, 15, 477. [Google Scholar] [CrossRef]

- Ding, F.; Bozhevolnyi, S.I. Advances in quantum meta-optics. Mater. Today 2023, 71, 63–72. [Google Scholar] [CrossRef]

- Sun, Y.-S.; Chau, Y.-F.; Yeh, H.-H.; Tsai, D.P. Highly Birefringent Index-Guiding Photonic Crystal Fiber with Squeezed Differently Sized Air-Holes in Cladding. Jpn. J. Appl. Phys. 2008, 47, 3755. [Google Scholar] [CrossRef]

- Iqbal, M.A.; Malik, M.; Anwar, N.; Bakhsh, S.; Javeed, S.; Maidin, S.; Morsy, K.; Capangpangan, R.; Alguno, A.; Choi, J. Basic Concepts, Advances and Emerging Applications of Nanophotonics. Arab. J. Chem. 2023, 16, 105040. [Google Scholar] [CrossRef]

- Gerislioglu, B.; Ahmadivand, A. Advances in Plasmonics and Nanophotonics. Nanomaterials 2021, 11, 3159. [Google Scholar] [CrossRef]

- Chau, Y.-F.; Yang, T.-J.; Lee, W.-D. Coupling technique for efficient interfacing between silica waveguides and planar photonic crystal circuits. Appl. Opt. 2004, 43, 6656–6663. [Google Scholar] [CrossRef]

- Said, Z.; Pandey, A.K.; Tiwari, A.K.; Kalidasan, B.; Jamil, F.; Thakur, A.K.; Tyagi, V.V.; Sarı, A.; Ali, H.M. Nano-enhanced phase change materials: Fundamentals and applications. Prog. Energy Combust. Sci. 2024, 104, 101162. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, T.; Ju, W.; Shi, S. Materials discovery and design using machine learning. J. Mater. 2017, 3, 159–177. [Google Scholar] [CrossRef]

- Chávez-Angel, E.; Eriksen, M.B.; Castro-Alvarez, A.; Garcia, J.H.; Botifoll, M.; Avalos-Ovando, O.; Arbiol, J.; Mugarza, A. Applied Artificial Intelligence in Materials Science and Material Design. Adv. Intell. Syst. 2025, 2400986. [Google Scholar] [CrossRef]

- Yang, K.-Y.; Chau, Y.-F.; Huang, Y.-W.; Yeh, H.-Y.; Ping Tsai, D. Design of high birefringence and low confinement loss photonic crystal fibers with five rings hexagonal and octagonal symmetry air-holes in fiber cladding. J. Appl. Phys. 2011, 109, 093103. [Google Scholar] [CrossRef]

- Shen, L.; Yang, T.-J.; Chau, Y.-F. 50/50 beam splitter using a one-dimensional metal photonic crystal with parabolalike dispersion. Appl. Phys. Lett. 2007, 90, 251909. [Google Scholar] [CrossRef]

- Chau, Y.-F.; Liu, C.-Y.; Yeh, H.-H.; Tsai, D.P. A Comparative Study of High Birefringence and Low Confinement Loss Photonic Crystal Fiber Employing Elliptical Air Holes in Fiber Cladding with Tetragonal Lattice. Prog. Electromagn. Res. B 2010, 22, 39–52. [Google Scholar] [CrossRef]

- Koenderink, A.; Alù, A.; Polman, A. Nanophotonics: Shrinking light-based technology. Science 2015, 348, 516–521. [Google Scholar] [CrossRef] [PubMed]

- McOyi, M.P.; Mpofu, K.T.; Sekhwama, M.; Mthunzi-Kufa, P. Developments in Localized Surface Plasmon Resonance. Plasmonics 2024, 20, 5481–5520. [Google Scholar] [CrossRef]

- García García, B.; Fernández-Manteca, M.G.; Zografopoulos, D.C.; Gómez-Galdós, C.; Ocampo-Sosa, A.A.; Rodríguez-Cobo, L.; Algorri, J.F.; Cobo, A. Plasmonic and Dielectric Metasurfaces for Enhanced Spectroscopic Techniques. Biosensors 2025, 15, 401. [Google Scholar] [CrossRef] [PubMed]

- Dutta, T.; Yadav, N.; Wu, Y.; Cheng, G.J.; Liang, X.; Ramakrishna, S.; Sbai, A.; Gupta, R.; Mondal, A.; Hongyu, Z.; et al. Electronic properties of 2D materials and their junctions. Nano Mater. Sci. 2024, 6, 1–23. [Google Scholar] [CrossRef]

- Khan, H.Z.; Zafar, J.; Jabbar, A.; Kazim, J.u.R.; Rehman, M.U.; Imran, M.A.; Abbasi, Q.H. Advancements in metasurfaces for polarization control: A comprehensive survey. Next Res. 2025, 2, 100407. [Google Scholar] [CrossRef]

- Tian, J.; Cao, W. Reconfigurable flexible metasurfaces: From fundamentals towards biomedical applications. PhotoniX 2024, 5, 2. [Google Scholar] [CrossRef]

- Mascaretti, L.; Chen, Y.; Henrotte, O.; Yesilyurt, O.; Shalaev, V.M.; Naldoni, A.; Boltasseva, A. Designing Metasurfaces for Efficient Solar Energy Conversion. ACS Photonics 2023, 10, 4079–4103. [Google Scholar] [CrossRef]

- Ma, R.; Zhang, X.; Sutherland, D.; Bochenkov, V.; Deng, S. Nanofabrication of nanostructure lattices: From high-quality large patterns to precise hybrid units. Int. J. Extrem. Manuf. 2024, 6, 062004. [Google Scholar] [CrossRef]

- Gu, S.; Chen, B.; Xu, X.; Han, F.; Chen, S.-C. 3D Nanofabrication via Directed Material Assembly: Mechanism, Method, and Future. Adv. Mater. 2025, 37, 2312915. [Google Scholar] [CrossRef] [PubMed]

- Höflich, K.; Hobler, G.; Allen, F.I.; Wirtz, T.; Rius, G.; McElwee-White, L.; Krasheninnikov, A.V.; Schmidt, M.; Utke, I.; Klingner, N.; et al. Roadmap for focused ion beam technologies. Appl. Phys. Rev. 2023, 10, 041311. [Google Scholar] [CrossRef]

- Stokes, K.; Clark, K.; Odetade, D.; Hardy, M.; Goldberg Oppenheimer, P. Advances in lithographic techniques for precision nanostructure fabrication in biomedical applications. Discov. Nano 2023, 18, 153. [Google Scholar] [CrossRef] [PubMed]

- Oh, D.; Lee, T.; Ko, B.S.; Badloe, T.; Ok, J.G.; Rho, J. Nanoimprint lithography for high-throughput fabrication of metasurfaces. Front. Optoelectron. 2021, 14, 229–251. [Google Scholar] [CrossRef] [PubMed]

- Butt, M.A.; Mateos, X. Strategic Insights into Integrated Photonics: Core Concepts, Practical Deployments, and Future Outlook. Appl. Sci. 2024, 14, 6365. [Google Scholar] [CrossRef]

- Lee, T.; Lee, C.; Oh, D.K.; Badloe, T.; Ok, J.G.; Rho, J. Scalable and High-Throughput Top-Down Manufacturing of Optical Metasurfaces. Sensors 2020, 20, 4108. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, J.; Tsai, D.P.; Xiao, S.J. Advanced manufacturing of dielectric meta-devices. Photonics Insights 2024, 3, R04. [Google Scholar] [CrossRef]

- Chau, Y.-F.; Yeh, H.-H.; Tsai, D.P. Significantly Enhanced Birefringence of Photonic Crystal Fiber Using Rotational Binary Unit Cell in Fiber Cladding. Jpn. J. Appl. Phys. 2007, 46, L1048. [Google Scholar] [CrossRef]

- Boretti, A.; Li, Q.; Castelletto, S. Pioneering the future with silicon carbide integrated photonics. Opt. Laser Technol. 2025, 181, 111910. [Google Scholar] [CrossRef]

- Kamal Eddin, F.B.; Fan, H.; Liu, Z.; Donati, P.; Amin, Y.; Fen, Y.W.; Liang, J.; Pompa, P.P.; He, S. Progress in Surface Plasmon and Other Resonance Biosensors for Biomedical Applications. Adv. Mater. Technol. 2025, 10, 2500536. [Google Scholar] [CrossRef]

- Altug, H.; Oh, S.-H.; Maier, S.A.; Homola, J. Advances and applications of nanophotonic biosensors. Nat. Nanotechnol. 2022, 17, 5–16. [Google Scholar] [CrossRef]

- Liu, T.; Xiao, S.; Li, B.; Gu, M.; Luan, H.; Fang, X. Third- and Second-Harmonic Generation in All-Dielectric Nanostructures: A Mini Review. Front. Nanotechnol. 2022, 4, 891892. [Google Scholar] [CrossRef]

- Jiang, H.; Cai, Y.; Han, Z. Enhanced high-harmonic generation with spectral tunability in nonlocal metasurfaces enabled by the excitation of quasiguided modes. Phys. Rev. B 2024, 110, 245424. [Google Scholar] [CrossRef]

- Butt, M.A.; Janaszek, B.; Piramidowicz, R. Lighting the way forward: The bright future of photonic integrated circuits. Sens. Int. 2025, 6, 100326. [Google Scholar] [CrossRef]

- Cuomo, S.; Di Cola, V.S.; Giampaolo, F.; Rozza, G.; Raissi, M.; Piccialli, F. Scientific Machine Learning Through Physics–Informed Neural Networks: Where we are and What’s Next. J. Sci. Comput. 2022, 92, 88. [Google Scholar] [CrossRef]

- Khaireh Walieh, A.; Langevin, D.; Bennet, P.; Teytaud, O.; Moreau, A.; Wiecha, P. A newcomer’s guide to deep learning for inverse design in nano-photonics. Nanophotonics 2023, 12, 4387–4414. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Zhang, J.; Horder, J.; Sukhorukov, A.; Toth, M.; Neshev, D.; Aharonovich, I. Engineering Quantum Light Sources with Flat Optics. Adv. Mater. 2024, 36, e2313589. [Google Scholar] [CrossRef]

- Song, H.; Chen, S.; Sun, X.; Cui, Y.; Yildirim, T.; Kang, J.; Yang, S.; Yang, F.; Lu, Y.; Zhang, L. Enhancing 2D Photonics and Optoelectronics with Artificial Microstructures. Adv. Sci. 2024, 11, 2403176. [Google Scholar] [CrossRef]

- Olawade, D.B.; Ige, A.O.; Olaremu, A.G.; Ijiwade, J.O.; Adeola, A.O. The synergy of artificial intelligence and nanotechnology towards advancing innovation and sustainability—A mini-review. Nano Trends 2024, 8, 100052. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, applications and toxicities. Arab. J. Chem. 2019, 12, 908–931. [Google Scholar] [CrossRef]

- Semaltianos, N.G. Advances in Photonic and Plasmonic Nanomaterials. Nanomaterials 2024, 15, 55. [Google Scholar] [CrossRef]

- Seçkin, S.; Sarkar, S.; König, T.A.F. Advancement in Colloidal Metasurfaces: Approaches for Scalable Photonic Devices. Adv. Mater. Interfaces 2025, 12, 2400934. [Google Scholar] [CrossRef]

- Ren, H.; Maier, S. Nanophotonic Materials for Twisted Light Manipulation. Adv. Mater. 2023, 35, 2106692. [Google Scholar] [CrossRef]

- Tütüncüoğlu, A.; Yüce, M.; Kurt, H. Titanium Nitride as an Alternative Plasmonic Material for Plasmonic Enhancement in Organic Photovoltaics. Crystals 2024, 14, 828. [Google Scholar] [CrossRef]

- Qiu, Y.; Kuang, C.; Liu, X.; Tang, L. Single-Molecule Surface-Enhanced Raman Spectroscopy. Sensors 2022, 22, 4889. [Google Scholar] [CrossRef] [PubMed]

- Gahlaut, S.K.; Pathak, A.; Gupta, B.D. Recent Advances in Silver Nanostructured Substrates for Plasmonic Sensors. Biosensors 2022, 12, 713. [Google Scholar] [CrossRef] [PubMed]

- Serafinelli, C.; Fantoni, A.; Alegria, E.C.B.A.; Vieira, M. Recent Progresses in Plasmonic Biosensors for Point-of-Care (POC) Devices: A Critical Review. Chemosensors 2023, 11, 303. [Google Scholar] [CrossRef]

- Schuller, J.; Barnard, E.; Cai, W.; Jun, Y.; White, J.; Brongersma, M. Plasmonics for extreme light concentration and manipulation. Nat. Mater. 2010, 9, 193–204. [Google Scholar] [CrossRef]

- Zaman, M.A.; Hesselink, L. Plasmonic Response of Nano-C-apertures: Polarization Dependent Field Enhancement and Circuit Model. Plasmonics 2023, 18, 155–164. [Google Scholar] [CrossRef]

- Chou Chau, Y.-F. Multiple-Mode Bowtie Cavities for Refractive Index and Glucose Sensors Working in Visible and Near-infrared Wavelength Ranges. Plasmonics 2021, 16, 1633–1644. [Google Scholar] [CrossRef]

- Rastogi, R.; Dogbe Foli, E.A.; Vincent, R.; Adam, P.-M.; Krishnamoorthy, S. Engineering Electromagnetic Hot-Spots in Nanoparticle Cluster Arrays on Reflective Substrates for Highly Sensitive Detection of (Bio)molecular Analytes. ACS Appl. Mater. Interfaces 2021, 13, 32653–32661. [Google Scholar] [CrossRef]

- Chou Chau, Y.-F.; Lim, C.M.; Chiang, C.-Y.; Voo, N.Y.; Muhammad Idris, N.S.I.; Chai, S.U. Tunable silver-shell dielectric core nano-beads array for thin-film solar cell application. J. Nanoparticle Res. 2016, 18, 88. [Google Scholar] [CrossRef]

- Moran-Mirabal, J.; Craighead, H. Zero-mode waveguides: Sub-wavelength nanostructures for single molecule studies at high concentrations. Methods 2008, 46, 11–17. [Google Scholar] [CrossRef]

- Cambiasso, J.; Grinblat, G.; Li, Y.; Rakovich, A.; Cortés, E.; Maier, S.A. Bridging the Gap between Dielectric Nanophotonics and the Visible Regime with Effectively Lossless Gallium Phosphide Antennas. Nano Lett. 2017, 17, 1219–1225. [Google Scholar] [CrossRef] [PubMed]

- Staude, I.; Schilling, J. Metamaterial-inspired silicon nanophotonics. Nat. Photonics 2017, 11, 274–284. [Google Scholar] [CrossRef]

- Kruk, S.; Kivshar, Y. Functional Meta-Optics and Nanophotonics Governed by Mie Resonances. ACS Photonics 2017, 4, 2638–2649. [Google Scholar] [CrossRef]

- Li, J.; Yang, R.; Li, R.; Grigoropoulos, C.P. Exciton Dynamics in 2D Transition Metal Dichalcogenides. Adv. Opt. Mater. 2025, 13, 2403137. [Google Scholar] [CrossRef]

- Qiu, C.; Zeng, H.; Su, Y. Recent progress in graphene-based optical modulators on silicon photonics platform. Natl. Sci. Open 2022, 1, 20220031. [Google Scholar] [CrossRef]

- Prasad, M.K.; Taverne, M.P.C.; Huang, C.-C.; Mar, J.D.; Ho, Y.-L.D. Hexagonal Boron Nitride Based Photonic Quantum Technologies. Materials 2024, 17, 4122. [Google Scholar] [CrossRef]

- Serafinelli, C.; Fantoni, A.; Alegria, E.C.B.A.; Vieira, M. Hybrid Nanocomposites of Plasmonic Metal Nanostructures and 2D Nanomaterials for Improved Colorimetric Detection. Chemosensors 2022, 10, 237. [Google Scholar] [CrossRef]

- Ma, Q.; Ren, G.; Ou, J. Recent advances on hybrid integration of 2D materials on integrated optics platforms. Nanophotonics 2020, 9, 2191–2214. [Google Scholar] [CrossRef]

- Qin, J.; Jiang, S.; Wang, Z.; Cheng, X.; Li, B.; Shi, Y.; Tsai, D.; Liu, A.-Q.; Huang, W.; Zhu, W. Metasurface Micro/Nano-Optical Sensors: Principles and Applications. ACS Nano 2022, 16, 11598–11618. [Google Scholar] [CrossRef]

- Liu, T.; Xu, R.; Yu, P.; Wang, Z.; Takahara, J. Multipole and multimode engineering in Mie resonance-based metastructures. Nanophotonics 2020, 9, 1115–1137. [Google Scholar] [CrossRef]

- Yager, T.; Chikvaidze, G.; Wang, Q.; Fu, Y. Graphene Hybrid Metasurfaces for Mid-Infrared Molecular Sensors. Nanomaterials 2023, 13, 2113. [Google Scholar] [CrossRef] [PubMed]

- Vaquero, D.; Clericò, V.; Salvador-Sánchez, J.; Martín-Ramos, A.; Díaz, E.; Domínguez-Adame, F.; Meziani, Y.M.; Diez, E.; Quereda, J. Excitons, trions and Rydberg states in monolayer MoS2 revealed by low-temperature photocurrent spectroscopy. Commun. Phys. 2020, 3, 194. [Google Scholar] [CrossRef]

- Matei, A.T.; Visan, A.I.; Negut, I. Laser-Fabricated Micro/Nanostructures: Mechanisms, Fabrication Techniques, and Applications. Micromachines 2025, 16, 573. [Google Scholar] [CrossRef] [PubMed]

- Powell, D.J.; Romero, D.; Gaiardelli, P. New and Renewed Manufacturing Paradigms for Sustainable Production. Sustainability 2022, 14, 1279. [Google Scholar] [CrossRef]

- Wen, B.; Yang, J.; Hu, C.; Cai, J.; Zhou, J. Top-Down Fabrication of Ordered Nanophotonic Structures for Biomedical Applications. Adv. Mater. Interfaces 2023, 11, 2300856. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive Manufacturing: A Comprehensive Review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef]

- Huo, T.; Zhou, L.; Bian, X.; Wen, Y. Advancing microneedle technology for multiple distinct target organs drug delivery through 3D printing: A comprehensive review. Adv. Compos. Hybrid Mater. 2025, 8, 266. [Google Scholar] [CrossRef]

- Roy, S.; Kumar, R.; Acooli, A.; Roy, S.; Chatterjee, A.; Chattaraj, S.; Nayak, J.; Jeon, B.-H.; Basu, A.; Banerjee, S.; et al. Transforming Nanomaterial Synthesis through Advanced Microfluidic Approaches: A Review on Accessing Unrestricted Possibilities. J. Compos. Sci. 2024, 8, 386. [Google Scholar] [CrossRef]

- Paras; Yadav, K.; Kumar, P.; Teja, D.R.; Chakraborty, S.; Chakraborty, M.; Mohapatra, S.S.; Sahoo, A.; Chou, M.M.C.; Liang, C.T.; et al. A Review on Low-Dimensional Nanomaterials: Nanofabrication, Characterization and Applications. Nanomaterials 2022, 13, 160. [Google Scholar] [CrossRef] [PubMed]

- Hildreth, O.; Wong, C. Nano-Metal-Assisted Chemical Etching for Fabricating Semiconductor and Optoelectronic Devices. In Materials for Advanced Packaging; Springer: Cham, Switzerland, 2017; pp. 879–922. [Google Scholar]

- Xia, D.; Jiang, Y.-B.; Notte, J.; Runt, D. GaAs milling with neon focused ion beam: Comparison with gallium focused ion beam milling and subsurface damage analysis. Appl. Surf. Sci. 2020, 538, 147922. [Google Scholar] [CrossRef]

- Rubanov, S.; Suvorova, A. Ion implantation in diamond using 30 keV Ga+ focused ion beam. Diam. Relat. Mater. 2011, 20, 1160–1164. [Google Scholar] [CrossRef]

- Kim, Y.K.; Danner, A.J.; Raftery, J.J.; Choquette, K.D. Focused Ion Beam Nanopatterning for Optoelectronic Device Fabrication. IEEE J. Sel. Top. Quantum Electron. 2005, 11, 1292–1298. [Google Scholar] [CrossRef]

- Samira, R.; Vakahi, A.; Eliasy, R.; Sherman, D.; Lachman, N. Mechanical and Compositional Implications of Gallium Ion Milling on Epoxy Resin. Polymers 2021, 13, 2640. [Google Scholar] [CrossRef]

- Zhan, Y.; Deng, L.; Dai, W.; Qiu, Y.; Sun, S.; Sun, D.; Hu, B.; Guan, J. Fabrication of Large-Area Nanostructures Using Cross-Nanoimprint Strategy. Nanomaterials 2024, 14, 998. [Google Scholar] [CrossRef]

- Liang, J.; Kohsaka, F.; Matsuo, T.; Li, X.; Ueda, T. Improved bi-layer lift-off process for MEMS applications. Microelectron. Eng. 2008, 85, 1000–1003. [Google Scholar] [CrossRef]

- Chen, Y.; Peng, K.; Cui, Z. A lift-off process for high resolution patterns using PMMA/LOR resist stack. Microelectron. Eng. 2004, 73, 278–281. [Google Scholar] [CrossRef]

- Hong, K.Y.; Menezes, J.; Brolo, A. Template-Stripping Fabricated Plasmonic Nanogratings for Chemical Sensing. Plasmonics 2018, 13, 231–237. [Google Scholar] [CrossRef]

- Nair, S.; Gomez-Cruz, J.; Ascanio, G.; Docoslis, A.; Sabat, R.G.; Escobedo, C. Cicada Wing Inspired Template-Stripped SERS Active 3D Metallic Nanostructures for the Detection of Toxic Substances. Sensors 2021, 21, 1699. [Google Scholar] [CrossRef] [PubMed]

- Jia, P.; Wang, X.; Cai, X.; Guo, Q.; Zhang, D.; Sun, Y.; Yang, J. Freestanding Metal Nanomembranes and Nanowires by Template Transfer with a Soluble Adhesive. Nanomaterials 2022, 12, 3988. [Google Scholar] [CrossRef] [PubMed]

- Khonina, S.N.; Kazanskiy, N.L.; Butt, M.A. Grayscale Lithography and a Brief Introduction to Other Widely Used Lithographic Methods: A State-of-the-Art Review. Micromachines 2024, 15, 1321. [Google Scholar] [CrossRef] [PubMed]

- Basu, P.; Verma, J.; Abhinav, V.; Ratnesh, R.K.; Singla, Y.K.; Kumar, V. Advancements in Lithography Techniques and Emerging Molecular Strategies for Nanostructure Fabrication. Int. J. Mol. Sci. 2025, 26, 3027. [Google Scholar] [CrossRef]

- Huff, M. Recent Advances in Reactive Ion Etching and Applications of High-Aspect-Ratio Microfabrication. Micromachines 2021, 12, 991. [Google Scholar] [CrossRef]

- George, M.; Jose, R.; Anju, T.R. Bottom Up Approaches in Nanomaterial Synthesis. In Nanomaterial Green Synthesis; Springer: Cham, Switzerland, 2025; pp. 453–481. [Google Scholar]

- Escudero, A.; Carrillo-Carrión, C.; Romero-Ben, E.; Franco, A.; Rosales-Barrios, C.; Castillejos, M.C.; Khiar, N. Molecular Bottom-Up Approaches for the Synthesis of Inorganic and Hybrid Nanostructures. Inorganics 2021, 9, 58. [Google Scholar] [CrossRef]

- Abbas, R.; Luo, J.; Qi, X.; Naz, A.; Khan, I.A.; Liu, H.; Yu, S.; Wei, J. Silver Nanoparticles: Synthesis, Structure, Properties and Applications. Nanomaterials 2024, 14, 1425. [Google Scholar] [CrossRef]

- Hoang, T.; Qu, K.; Chen, X.; Ahn, J.-H. Large-area synthesis of transition metal dichalcogenides: Via CVD and solution-based approaches and their device applications. Nanoscale 2021, 13, 615–633. [Google Scholar] [CrossRef]

- Sun, L.; Yuan, G.; Gao, L.; Yang, J.; Chhowalla, M.; Heydari Gharahcheshmeh, M.; Gleason, K.; Choi, Y.; Hong, B.; Liu, Z. Chemical vapour deposition. Nat. Rev. Methods Primers 2021, 1, 5. [Google Scholar] [CrossRef]

- Kumar, S.; Bhushan, P.; Bhattacharya, S. Fabrication of Nanostructures with Bottom-up Approach and Their Utility in Diagnostics, Therapeutics, and Others. In Environmental, Chemical and Medical Sensors; Springer: Singapore, 2018; pp. 167–198. [Google Scholar]

- Ren, S.; Ren, L.; Wei, B.; Liu, Y.; Yang, J.; Li, J.; Wang, L. DNA-templated fabrication of metal nanostructures with special shapes. Adv. Sens. Energy Mater. 2025, 4, 100133. [Google Scholar] [CrossRef]

- Tripathy, S. Top-down and Bottom-up Approaches for Synthesis of Nanoparticles. In Nanobiomaterials: Perspectives for Medical Applications in the Diagnosis and Treatment of Diseases; Materials Research Forum LLC: Millersville, PA, USA, 2023; pp. 92–130. [Google Scholar]

- Cheng, X.; Liang, D.; Jiang, M.; Sha, Y.; Liu, X.; Liu, J.; Cao, Q.; Shi, J. Review of Directed Self-Assembly Material, Processing, and Application in Advanced Lithography and Patterning. Micromachines 2025, 16, 667. [Google Scholar] [CrossRef]

- Hong, Y.; Saroj, R.; Park, W.; Yi, G.-C. One-dimensional semiconductor nanostructures grown on two-dimensional nanomaterials for flexible device applications. APL Mater. 2021, 9, 060907. [Google Scholar] [CrossRef]

- Yi, R.-X.; Zhang, X.; Zhang, F.; Gu, L.; Zhang, Q.; Fang, L.; Zhao, J.; Fu, L.; Tan, H.; Jagadish, C.; et al. Integrating a Nanowire Laser in an on-Chip Photonic Waveguide. Nano Lett. 2022, 22, 9920–9927. [Google Scholar] [CrossRef]

- Liu, R.; Cao, L.; Liu, D.; Wang, L.; Saeed, S.; Wang, Z. Laser Interference Lithography—A Method for the Fabrication of Controlled Periodic Structures. Nanomaterials 2023, 13, 1818. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Xu, C.; Yu, X.; Zhang, H.-X.; Han, M. Multilayer Flexible Electronics: Manufacturing Approaches and Applications. Mater. Today Phys. 2022, 23, 100647. [Google Scholar] [CrossRef]

- Einck, V.; Torfeh, M.; McClung, A.; Jung, D.; Mansouree, M.; Arbabi, A.; Watkins, J. Scalable Nanoimprint Lithography Process for Manufacturing Visible Metasurfaces Composed of High Aspect Ratio TiO2 Meta-Atoms. ACS Photonics 2021, 8, 2400–2409. [Google Scholar] [CrossRef]

- Heindel, T.; Kim, J.-H.; Gregersen, N.; Rastelli, A.; Reitzenstein, S. Quantum dots for photonic quantum information technology. Adv. Opt. Photon. 2023, 15, 613–738. [Google Scholar] [CrossRef]

- Gonzalez-Tudela, A.; Reiserer, A.; García-Ripoll, J.; García-Vidal, F. Light–matter interactions in quantum nanophotonic devices. Nat. Rev. Phys. 2024, 6, 166–179. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, W.; Gromyko, D.; Huang, D.; Dong, Z.; Liu, R.; Zhu, J.; Liu, J.; Qiu, C.-W.; Wu, L. Single-photon generation and manipulation in quantum nanophotonics. Appl. Phys. Rev. 2025, 12, 011308. [Google Scholar] [CrossRef]

- Kaur, T.; Peace, D.; Romero, J. On-chip high-dimensional entangled photon sources. J. Opt. 2025, 27, 023001. [Google Scholar] [CrossRef]

- Barreda, A.; Hell, S.; Weissflog, M.A.; Minovich, A.; Pertsch, T.; Staude, I. Metal, dielectric and hybrid nanoantennas for enhancing the emission of single quantum dots: A comparative study. J. Quant. Spectrosc. Radiat. Transf. 2021, 276, 107900. [Google Scholar] [CrossRef]

- Schrinner, P.; Olthaus, J.; Reiter, D.; Schuck, C. Integration of Diamond-Based Quantum Emitters with Nanophotonic Circuits. Nano Letters 2020, 20, 8170–8177. [Google Scholar] [CrossRef]

- Fehler, K.G.; Antoniuk, L.; Lettner, N.; Ovvyan, A.P.; Waltrich, R.; Gruhler, N.; Davydov, V.A.; Agafonov, V.N.; Pernice, W.H.P.; Kubanek, A. Hybrid Quantum Photonics Based on Artificial Atoms Placed Inside One Hole of a Photonic Crystal Cavity. ACS Photonics 2021, 8, 2635–2641. [Google Scholar] [CrossRef]

- Fang, B. Manipulation of photonic quantum states: From generation, engineering, and characterization to storage and retrieval. In Proceedings of the Frontiers in Optics/Laser Science, Washington, DC, USA, 16 September 2018; p. LM1C.4. [Google Scholar]

- Jankowski, M.; Langrock, C.; Desiatov, B.; Marandi, A.; Wang, C.; Zhang, M.; Phillips, C.; Loncar, M.; Fejer, M. Ultrabroadband nonlinear optics in nanophotonic periodically poled lithium niobate waveguides. Optica 2020, 7, 40–46. [Google Scholar] [CrossRef]

- Moody, G.; Sorger, V.J.; Blumenthal, D.J.; Juodawlkis, P.W.; Loh, W.; Sorace-Agaskar, C.; Jones, A.E.; Balram, K.C.; Matthews, J.C.F.; Laing, A.; et al. 2022 Roadmap on integrated quantum photonics. J. Phys. Photonics 2022, 4, 012501. [Google Scholar] [CrossRef]

- Zhong, H.-S.; Deng, Y.-H.; Chen, M.-C.; Peng, L.-C.; Luo, Y.-H.; Qin, J.; Wu, D.; Ding, X.; Hu, Y.; Hu, P.; et al. Quantum computational advantage using photons. Science 2020, 370, 1460–1463. [Google Scholar] [CrossRef]

- Gong, S.-Q.; Chen, M.-c.; Liu, H.-L.; Su, H.; Gu, Y.-C.; Tang, H.-Y.; Jia, M.-H.; Deng, Y.-H.; Wei, Q.; Zhong, H.-S.; et al. Enhanced Image Recognition Using Gaussian Boson Sampling. arXiv 2025, arXiv:2506.19707. [Google Scholar] [CrossRef]

- Knall, E.N.; Knaut, C.M.; Bekenstein, R.; Assumpcao, D.R.; Stroganov, P.L.; Gong, W.; Huan, Y.Q.; Stas, P.-J.; Machielse, B.; Chalupnik, M.; et al. Efficient Source of Shaped Single Photons Based on an Integrated Diamond Nanophotonic System. Phys. Rev. Lett. 2022, 129, 053603. [Google Scholar] [CrossRef]

- Qian, Z.; Shan, L.; Zhang, X.; Liu, Q.; Ma, Y.; Gong, Q.; Gu, Y. Spontaneous emission in micro- or nanophotonic structures. PhotoniX 2021, 2, 21. [Google Scholar] [CrossRef]

- Brown, K.R.; Kim, J.; Monroe, C. Co-designing a scalable quantum computer with trapped atomic ions. npj Quantum Inf. 2016, 2, 16034. [Google Scholar] [CrossRef]

- Taballione, C.; Meer, R.; Snijders, H.; Hooijschuur, P.; Epping, J.; Goede, M.; Kassenberg, B.; Venderbosch, P.; Toebes, C.; Vlekkert, H.; et al. A universal fully reconfigurable 12-mode quantum photonic processor. Mater. Quantum Technol. 2021, 1, 035002. [Google Scholar] [CrossRef]

- Menon, S.G.; Glachman, N.; Pompili, M.; Dibos, A.; Bernien, H. An integrated atom array-nanophotonic chip platform with background-free imaging. Nat. Commun. 2024, 15, 6156. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, T.; Yuan, X.; Wang, Y.; Yue, X.; Wang, L.; Zhang, J.; Wang, J. Plasmonic Nanostructure Biosensors: A Review. Sensors 2023, 23, 8156. [Google Scholar] [CrossRef] [PubMed]

- Butt, M.A. Surface Plasmon Resonance-Based Biodetection Systems: Principles, Progress and Applications—A Comprehensive Review. Biosensors 2025, 15, 35. [Google Scholar] [CrossRef]

- Pradhan, A.; Lahare, P.; Sinha, P.; Singh, N.; Gupta, B.; Kuca, K.; Ghosh, K.K.; Krejcar, O. Biosensors as Nano-Analytical Tools for COVID-19 Detection. Sensors 2021, 21, 7823. [Google Scholar] [CrossRef]

- Versiani, A.; Andrade, L.; Moraes, T.; do Nascimento Martins, E.M.; Bagno, F.; Andrade, L.; Campos, G.; Lopes dos Santos, T.; Moraes, M.; Sérgio, S.; et al. Serologic LSPR-nanosensor against SARS-COV-2 antibodies and related variants outperforms ELISA in sensitivity. npj Biosensing 2025, 2, 11. [Google Scholar] [CrossRef]

- Funari, R.; Chu, K.Y.; Shen, A.Q. Detection of antibodies against SARS-CoV-2 spike protein by gold nanospikes in an opto-microfluidic chip. Biosens. Bioelectron. 2020, 169, 112578. [Google Scholar] [CrossRef]

- Abood, I.; El Soliman, S.; He, W.; Ouyang, Z. Topological Photonic Crystal Sensors: Fundamental Principles, Recent Advances, and Emerging Applications. Sensors 2025, 25, 1455. [Google Scholar] [CrossRef]

- Butt, M.A.; Imran Akca, B.; Mateos, X. Integrated Photonic Biosensors: Enabling Next-Generation Lab-on-a-Chip Platforms. Nanomaterials 2025, 15, 731. [Google Scholar] [CrossRef]

- Wang, A.X.; Kong, X. Review of Recent Progress of Plasmonic Materials and Nano-Structures for Surface-Enhanced Raman Scattering. Materials 2015, 8, 3024–3052. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X. Microfluidics-Based Plasmonic Biosensing System Based on Patterned Plasmonic Nanostructure Arrays. Micromachines 2021, 12, 826. [Google Scholar] [CrossRef] [PubMed]

- Walter, J.-G.; Alwis, L.S.M.; Roth, B.; Bremer, K. All-Optical Planar Polymer Waveguide-Based Biosensor Chip Designed for Smartphone-Assisted Detection of Vitamin D. Sensors 2020, 20, 6771. [Google Scholar] [CrossRef] [PubMed]

- Na, H.-K.; Wi, J.-S.; Son, H.Y.; Ok, J.G.; Huh, Y.-M.; Lee, T.G. Discrimination of single nucleotide mismatches using a scalable, flexible, and transparent three-dimensional nanostructure-based plasmonic miRNA sensor with high sensitivity. Biosens. Bioelectron. 2018, 113, 39–45. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.-Y.; Lin, H.-T.; Lai, M.-S.; Shieh, T.-Y.; Peng, C.-C.; Shih, M.-H.; Tung, Y.-C. Flexible localized surface plasmon resonance sensor with metal–insulator–metal nanodisks on PDMS substrate. Sci. Rep. 2018, 8, 11812. [Google Scholar] [CrossRef]

- Walter, J.-G.; Eilers, A.; Alwis, L.S.M.; Roth, B.W.; Bremer, K. SPR Biosensor Based on Polymer Multi-Mode Optical Waveguide and Nanoparticle Signal Enhancement. Sensors 2020, 20, 2889. [Google Scholar] [CrossRef]

- Sirleto, L.; Righini, G.C. An Introduction to Nonlinear Integrated Photonics Devices: Nonlinear Effects and Materials. Micromachines 2023, 14, 604. [Google Scholar] [CrossRef]

- Gu, L.; Zhou, Y. Nonlinear optics in 2D materials: From classical to quantum. Appl. Phys. Rev. 2025, 12, 011335. [Google Scholar] [CrossRef]

- Baek, S.; Son, H.; Park, H.; Park, H.; Lee, J.; Jeong, S.; Shim, J.-E.; Park, J.; Kim, T.-T. Graphene-based metasurface: Dynamic optical control in ultrathin flat optics. Nanophotonics 2025, 14, 2103–2132. [Google Scholar] [CrossRef]

- Wang, J.T.; Tonkaev, P.; Koshelev, K.; Lai, F.; Kruk, S.; Song, Q.; Kivshar, Y.; Panoiu, N.C. Resonantly enhanced second- and third-harmonic generation in dielectric nonlinear metasurfaces. Opto-Electron. Adv. 2024, 7, 230186-1–230186-15. [Google Scholar] [CrossRef]

- Geng, W.; Fang, Y.; Wang, Y.; Bao, C.; Liu, W.; Pan, Z.; Yue, Y. Nonlinear photonics on integrated platforms. Nanophotonics 2024, 13, 3253–3278. [Google Scholar] [CrossRef]

- Nguyen, D.D.; Lee, S.; Kim, I. Recent Advances in Metaphotonic Biosensors. Biosensors 2023, 13, 631. [Google Scholar] [CrossRef]

- Hähnel, D.; Golla, C.; Albert, M.; Zentgraf, T.; Myroshnychenko, V.; Förstner, J.; Meier, C. A multi-mode super-fano mechanism for enhanced third harmonic generation in silicon metasurfaces. Light Sci. Appl. 2023, 12, 97. [Google Scholar] [CrossRef]

- Porcel, M.A.G.; Mak, J.; Taballione, C.; Schermerhorn, V.K.; Epping, J.P.; van der Slot, P.J.M.; Boller, K.-J. Photo-induced second-order nonlinearity in stoichiometric silicon nitride waveguides. Opt. Express 2017, 25, 33143–33159. [Google Scholar] [CrossRef]

- Chou Chau, Y.-F. Boosting Second Harmonic Generation Efficiency and Nonlinear Susceptibility via Metasurfaces Featuring Split-Ring Resonators and Bowtie Nanoantennas. Nanomaterials 2024, 14, 664. [Google Scholar] [CrossRef]

- Chen, H.; Corboliou, V.; Solntsev, A.S.; Choi, D.-Y.; Vincenti, M.A.; de Ceglia, D.; de Angelis, C.; Lu, Y.; Neshev, D.N. Enhanced second-harmonic generation from two-dimensional MoSe2 on a silicon waveguide. Light Sci. Appl. 2017, 6, e17060. [Google Scholar] [CrossRef]

- Mekawey, H.; Elsayed, M.; Ismail, Y.; Swillam, M. Optical Interconnects Finally Seeing the Light in Silicon Photonics: Past the Hype. Nanomaterials 2022, 12, 485. [Google Scholar] [CrossRef] [PubMed]

- Butt, M.A. Plasmonic Sensors Based on a Metal–Insulator–Metal Waveguide—What Do We Know So Far? Sensors 2024, 24, 7158. [Google Scholar] [CrossRef] [PubMed]

- Marinins, A.; Hansch, S.; Sar, H.; Chancerel, F.; Golshani, N.; Wang, H.-L.; Tsiara, A.; Coenen, D.; Verheyen, P.; Capuz, G.; et al. Wafer-Scale Hybrid Integration of InP DFB Lasers on Si Photonics by Flip-Chip Bonding With sub-300 nm Alignment Precision. IEEE J. Sel. Top. Quantum Electron. 2022, 29, 1–11. [Google Scholar] [CrossRef]

- Hou, S.; Hu, H.; Liu, Z.; Xing, W.; Zhang, J.; Hao, Y. High-Speed Electro-Optic Modulators Based on Thin-Film Lithium Niobate. Nanomaterials 2024, 14, 867. [Google Scholar] [CrossRef]

- Shekhar, S.; Bogaerts, W.; Chrostowski, L.; Bowers, J.E.; Hochberg, M.; Soref, R.; Shastri, B.J. Roadmapping the next generation of silicon photonics. Nat. Commun. 2024, 15, 751. [Google Scholar] [CrossRef]

- Pérez-López, D.; Torrijos-Morán, L. Large-scale photonic processors and their applications. npj Nanophotonics 2025, 2, 32. [Google Scholar] [CrossRef]

- Yao, Z.; Wu, K.; Tan, B.; Wang, J.; Li, Y.; Zhang, Y.; Poon, A. Integrated Silicon Photonic Microresonators: Emerging Technologies. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 1–24. [Google Scholar] [CrossRef]

- Davanco, M.; Liu, J.; Sapienza, L.; Zhang, C.-Z.; De Miranda Cardoso, J.V.; Verma, V.; Mirin, R.; Nam, S.W.; Liu, L.; Srinivasan, K. Heterogeneous integration for on-chip quantum photonic circuits with single quantum dot devices. Nat. Commun. 2017, 8, 889. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Wu, P.C.; Su, V.-C.; Lai, Y.-C.; Chen, M.-K.; Kuo, H.Y.; Chen, B.H.; Chen, Y.H.; Huang, T.-T.; Wang, J.-H.; et al. A broadband achromatic metalens in the visible. Nat. Nanotechnol. 2018, 13, 227–232. [Google Scholar] [CrossRef] [PubMed]

- Neshev, D.; Aharonovich, I. Optical metasurfaces: New generation building blocks for multi-functional optics. Light Sci. Appl. 2018, 7, 58. [Google Scholar] [CrossRef] [PubMed]

- Abdelraouf, O.; Wang, Z.; Liu, H.; Dong, Z.; Wang, Q.; Ye, M.; Renshaw Wang, X.; Wang, Q.; Liu, H. Recent Advances in Tunable Metasurfaces: Materials, Design, and Applications. ACS Nano 2022, 16, 13339–13369. [Google Scholar] [CrossRef]

- Ullah, N.; Zhao, R.; Huang, L. Recent Advancement in Optical Metasurface: Fundament to Application. Micromachines 2022, 13, 1025. [Google Scholar] [CrossRef]

- Tripathi, D.; Hegde, R.S. Phase change material metasurface loading enables an ultrafast all-optically switchable, compact, narrowband freespace optical filter. Opt. Commun. 2024, 569, 130788. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Zong, G.; Hu, W.; Lu, Y. Liquid crystal based tunable terahertz metadevices. J. Mater. 2025, 11, 100888. [Google Scholar] [CrossRef]

- Ma, Z.; Li, Z.; Movahhed, B.; Liu, K.; Ye, C.; Dalir, H.; Sorger, V. Indium-Tin-Oxide for High-performance Electro-optic Modulation. Nanophotonics 2023, 4, 198–213. [Google Scholar] [CrossRef]

- Jakšić, Z. Synergy between AI and Optical Metasurfaces: A Critical Overview of Recent Advances. Photonics 2024, 11, 442. [Google Scholar] [CrossRef]

- Dorrah, A. Compound meta-optics: There is plenty of room at the top. Nanophotonics 2025. [Google Scholar] [CrossRef]

- Li, N.; Xu, Z.; Dong, Y.; Hu, T.; Zhong, Q.; Fu, Y.H.; Zhu, S.; Singh, N. Large-area metasurface on CMOS-compatible fabrication platform: Driving flat optics from lab to fab. Nanophotonics 2020, 9, 3071–3087. [Google Scholar] [CrossRef]

- Hu, T.; Zhong, Q.; Li, N.; Dong, Y.; Xu, Z.; Fu, Y.H.; Li, D.; Bliznetsov, V.; Zhou, Y.; Lai, K.H.; et al. CMOS-compatible a-Si metalenses on a 12-inch glass wafer for fingerprint imaging. Nanophotonics 2020, 9, 823–830. [Google Scholar] [CrossRef]

- She, A.; Zhang, S.; Shian, S.; Clarke, D.R.; Capasso, F. Large area metalenses: Design, characterization, and mass manufacturing. Opt. Express 2018, 26, 1573–1585. [Google Scholar] [CrossRef] [PubMed]

- Crozier, K.B. Quo vadis, plasmonic optical tweezers? Light Sci. Appl. 2019, 8, 35. [Google Scholar] [CrossRef] [PubMed]

- Quidant, R. Plasmonic tweezers—The strength of surface plasmons. MRS Bull. 2012, 37, 739–744. [Google Scholar] [CrossRef]

- Zhang, Y.; Min, C.; Dou, X.; Wang, X.; Urbach, H.P.; Somekh, M.G.; Yuan, X. Plasmonic tweezers: For nanoscale optical trapping and beyond. Light Sci. Appl. 2021, 10, 59. [Google Scholar] [CrossRef]

- Hesselink, L.; Zaman, M. Plasmonic C-Shaped Structures and their Applications in Photonics and Biotechnology; Academic Press: Cambridge, MA, USA, 2023. [Google Scholar]

- Mestres, P.; Berthelot, J.; Aćimović, S.S.; Quidant, R. Unraveling the optomechanical nature of plasmonic trapping. Light Sci. Appl. 2016, 5, e16092. [Google Scholar] [CrossRef]

- Juan, M.; Gordon, R.; Pang, Y.; Eftekhari, F.; Quidant, R. Self-induced back-action optical trapping of dielectric nanoparticles. Nat. Phys. 2009, 5, 915. [Google Scholar] [CrossRef]

- Melzer, J.; McLeod, E. Fundamental Limits of Optical Tweezer Nanoparticle Manipulation Speeds. ACS Nano 2018, 12, 2440–2447. [Google Scholar] [CrossRef]

- Afshinmanesh, F.; White, J.S.; Cai, W.; Brongersma, M.L. Measurement of the polarization state of light using an integrated plasmonic polarimeter. Nanophotonics 2012, 1, 125–129. [Google Scholar] [CrossRef]

- Ziegler, J.; Haglund, R. Plasmonic Response of Nanoscale Spirals. Nano Lett. 2010, 10, 3013–3018. [Google Scholar] [CrossRef]

- Kik, P.; Brongersma, M. Surface Plasmon Nanophotonics; Springer: Berlin/Heidelberg, Germany, 2007; Volume 131, pp. 1–9. [Google Scholar]

- Schnell, M.; Sarriugarte, P.; Neuman, T.; Khanikaev, A.; Shvets, G.; Aizpurua, J.; Hillenbrand, R. Real-Space Mapping of the Chiral Near-Field Distributions in Spiral Antennas and Planar Metasurfaces. Nano Lett. 2015, 16, 663–670. [Google Scholar] [CrossRef]

- Tsai, W.-Y.; Huang, J.-S.; Huang, C.-B. Selective Trapping or Rotation of Isotropic Dielectric Microparticles by Optical Near Field in a Plasmonic Archimedes Spiral. Nano Lett. 2014, 14, 547–552. [Google Scholar] [CrossRef]

- Zaman, M.; Padhy, P.; Hesselink, L. Near-field optical trapping in a non-conservative force field. Sci. Rep. 2019, 9, 649. [Google Scholar] [CrossRef] [PubMed]

- Zaman, M.; Padhy, P.; Hesselink, L. Solenoidal optical forces from a plasmonic Archimedean spiral. Phys. Rev. A 2019, 100, 013857. [Google Scholar] [CrossRef] [PubMed]

- Fleischer, M. Near-field scanning optical microscopy nanoprobes. Nanotechnol. Rev. 2012, 1, 313–338. [Google Scholar] [CrossRef]

- Hsu, J. Near-field scanning optical microscopy of electronic and photonic materials and devices. Mater. Sci. Eng. R Rep. 2001, 33, 1–50. [Google Scholar] [CrossRef]

- Ezugwu, S.; Ye, H.; Fanchini, G. Three-dimensional scanning near field optical microscopy (3D-SNOM) imaging of random arrays of copper nanoparticles: Implications for plasmonic solar cell enhancement. Nanoscale 2014, 7, 252–260. [Google Scholar] [CrossRef]

- Chan, M.L.; Tiranov, A.; Appel, M.H.; Wang, Y.; Midolo, L.; Scholz, S.; Wieck, A.D.; Ludwig, A.; Sørensen, A.S.; Lodahl, P. On-chip spin-photon entanglement based on photon-scattering of a quantum dot. npj Quantum Inf. 2023, 9, 49. [Google Scholar] [CrossRef]

- Grosso, G.; Moon, H.; Lienhard, B.; Ali, S.; Efetov, D.K.; Furchi, M.M.; Jarillo-Herrero, P.; Ford, M.J.; Aharonovich, I.; Englund, D. Tunable and high-purity room temperature single-photon emission from atomic defects in hexagonal boron nitride. Nat. Commun. 2017, 8, 705. [Google Scholar] [CrossRef] [PubMed]

- Alhamid, G.; Tombuloglu, H.; Rabaan, A.A.; Al-Suhaimi, E. SARS-CoV-2 detection methods: A comprehensive review. Saudi J. Biol. Sci. 2022, 29, 103465. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhang, Y.; Cai, G.; Zhuo, J.; Lai, K.; Ye, L. All-dielectric metasurfaces with high Q-factor Fano resonances enabling multi-scenario sensing. Nanophotonics 2022, 11, 4537–4549. [Google Scholar] [CrossRef]

- Chao, C.-T.; Chen, S.-H.; Thotagamuge, R.; Kooh, M.R.R.; Chau, Y.-F. Enhancement of Third-Harmonic Generation Through Plasmonic Gap and Cavity Resonance Modes in Bilayer Graphene/Dielectric/Graphene Metasurfaces. Plasmonics 2025, 1–13. [Google Scholar] [CrossRef]

- Chakraborty, S.K.; Kundu, B.; Nayak, B.; Dash, S.P.; Sahoo, P.K. Challenges and opportunities in 2D heterostructures for electronic and optoelectronic devices. iScience 2022, 25, 103942. [Google Scholar] [CrossRef]

- Baumgartner, Y.; Caimi, D.; Sousa, M.; Hopstaken, M.; Salamin, Y.; Baeuerle, B.; Bitachon, B.I.; Leuthold, J.; Faist, J.; Offrein, B.J.; et al. High-speed CMOS-compatible III-V on Si membrane photodetectors. Opt. Express 2021, 29, 509–516. [Google Scholar] [CrossRef]

- Sharifipour, O.; Keshavarzi, P.; Danaie, M. Ultra-compact all-optical plasmonic switch with triangular resonator and phase-change materials for neuromorphic and advanced optical networks. Opt. Commun. 2025, 591, 132101. [Google Scholar] [CrossRef]

- Luo, Y.; Tseng, M.; Vyas, S.; Hsieh, T.-Y.; Wu, J.-C.; Chen, S.-Y.; Peng, H.-F.; Su, V.-C.; Huang, T.-T.; Kuo, H.; et al. Meta-lens light-sheet fluorescence microscopy for in vivo imaging. Nanophotonics 2022, 11, 1949–1959. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, X.; Gao, J. Spin-controlled wavefront shaping with plasmonic chiral geometric metasurfaces. Light Sci. Appl. 2018, 7, 84. [Google Scholar] [CrossRef]

- Esfandiari, M.; Lalbakhsh, A.; Nasiri Shehni, P.; Jarchi, S.; Ghaffari-Miab, M.; Noori Mahtaj, H.; Reisenfeld, S.; Alibakhshikenari, M.; Koziel, S.; Szczepanski, S. Recent and emerging applications of Graphene-based metamaterials in electromagnetics. Mater. Des. 2022, 221, 110920. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Liu, J. Overview of Phase-Change Materials Based Photonic Devices. IEEE Access 2020, 8, 121211–121245. [Google Scholar] [CrossRef]

- Afridi, A.; Canet-Ferrer, J.; Philippet, L.; Osmond, J.; Berto, P.; Quidant, R. Electrically Driven Varifocal Silicon Metalens. ACS Photonics 2018, 5, 4497–4503. [Google Scholar] [CrossRef]

- Taghinejad, M.; Taghinejad, H.; Xu, Z.; Lee, K.; Rodrigues, S.; Yan, J.; Adibi, A.; Lian, T.; Cai, W. Ultrafast Control of Phase and Polarization of Light Expedited by Hot-Electron Transfer. Nano Lett. 2018, 18, 5544–5551. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kim, W.; Choi, M.; Park, Y.; Kang, D.; Lee, E.; Park, C.; Sung, H.; Lee, H.; Rho, J. Amorphous to Crystalline Transition in Nanoimprinted Sol–Gel Titanium Oxide Metasurfaces. Adv. Mater. 2024, 36, e2405378. [Google Scholar] [CrossRef]

- Baranov, D.G.; Zuev, D.A.; Lepeshov, S.I.; Kotov, O.V.; Krasnok, A.E.; Evlyukhin, A.B.; Chichkov, B.N. All-dielectric nanophotonics: The quest for better materials and fabrication techniques. Optica 2017, 4, 814. [Google Scholar] [CrossRef]

- Dutta, G.; Rainbow, J.; Zupancic, U.; Papamatthaiou, S.; Estrela, P.; Moschou, D. Microfluidic Devices for Label-Free DNA Detection. Chemosensors 2018, 6, 43. [Google Scholar] [CrossRef]

- Dirdal, C.; Thrane, P.; Dullo, F.; Gjessing, j.; Summanwar, A.; Tschudi, J. MEMS-tunable dielectric metasurface lens using thin-film PZT for large displacements at low voltages. Optics Lett. 2022, 47, 1049–1052. [Google Scholar] [CrossRef]

- Wang, Y.; Jiao, Y.; Williams, K. Scaling photonic integrated circuits with InP technology: A perspective. APL Photonics 2024, 9, 050902. [Google Scholar] [CrossRef]

- Wang, J.; Dong, J. Optical Waveguides and Integrated Optical Devices for Medical Diagnosis, Health Monitoring and Light Therapies. Sensors 2020, 20, 3981. [Google Scholar] [CrossRef]

- Li, W.; Shi, T.; Wang, R.; Yang, J.; Ma, Z.; Zhang, W.; Fu, H.; Guo, P. Advances in LiDAR Hardware Technology: Focus on Elastic LiDAR for Solid Target Scanning. Sensors 2024, 24, 7268. [Google Scholar] [CrossRef]

- Chen, W.; Yang, S.; Yiming, Y.; Gao, Y.; Zhu, J.; Dong, Z. Empowering nanophotonic applications via artificial intelligence: Pathways, progress, and prospects. Nanophotonics 2025, 14, 429–447. [Google Scholar] [CrossRef]

- So, S.; Mun, J.; Rho, J. Simultaneous Inverse Design of Materials and Structures via Deep Learning: Demonstration of Dipole Resonance Engineering Using Core-Shell Nanoparticles. ACS Appl. Mater. Interfaces 2019, 11, 24264–24268. [Google Scholar] [CrossRef] [PubMed]

- Cancemi, S.A.; Ambrutis, A.; Povilaitis, M.; Lo Frano, R. AI-Powered Convolutional Neural Network Surrogate Modeling for High-Speed Finite Element Analysis in the NPPs Fuel Performance Framework. Energies 2025, 18, 2557. [Google Scholar] [CrossRef]