Nanostructure Engineering by Oblique Angle Deposition for Photodetectors and Other Applications

Abstract

1. Introduction

2. Basic OAD Design and Optical Property Modulation Mechanism

3. OAD Photodetector

3.1. Performance Parameters of Photodetectors

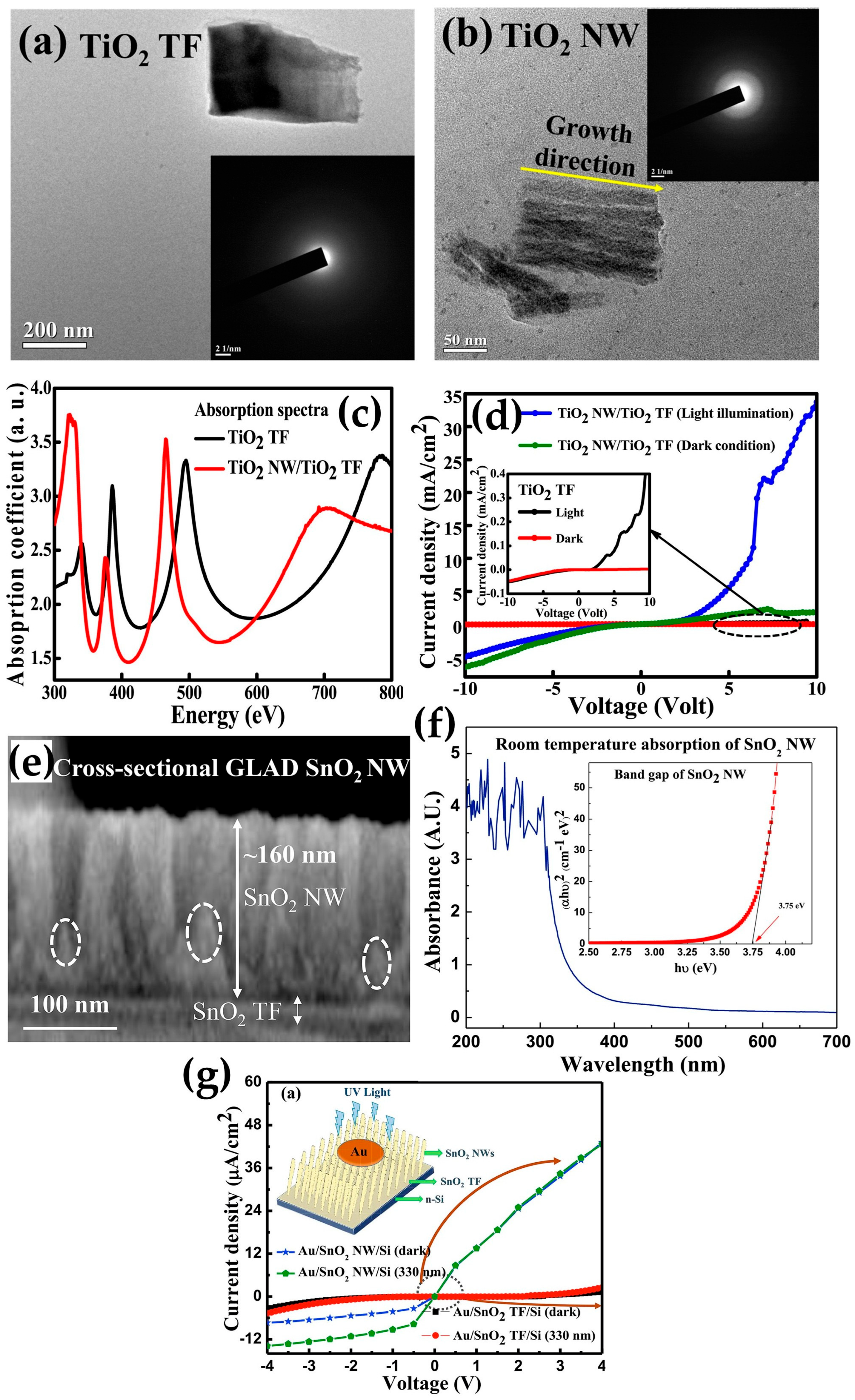

3.2. OAD Photodetectors Deposited by E-Beam Evaporation

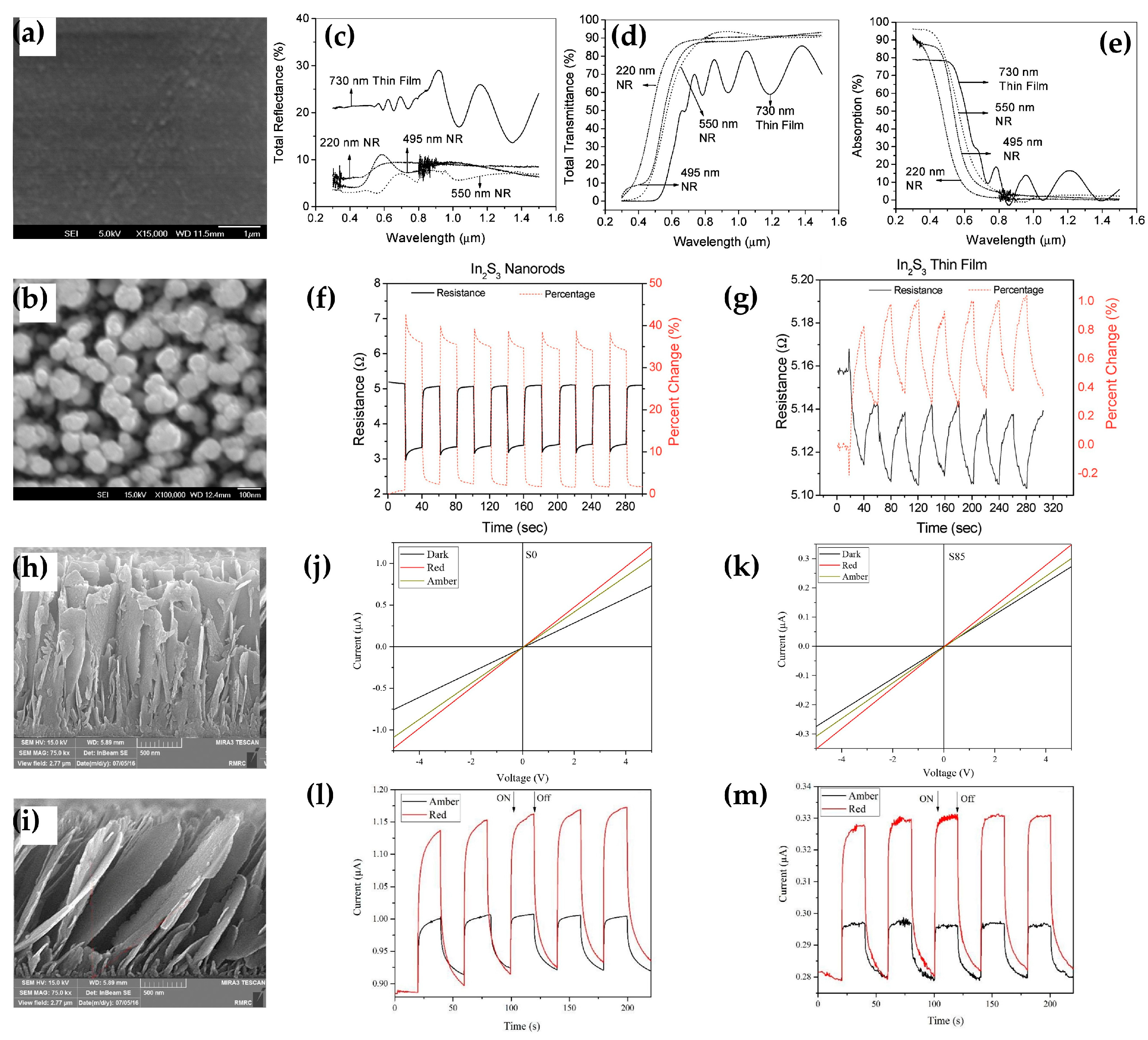

3.3. OAD Photodetectors Deposited by Thermal Evaporation

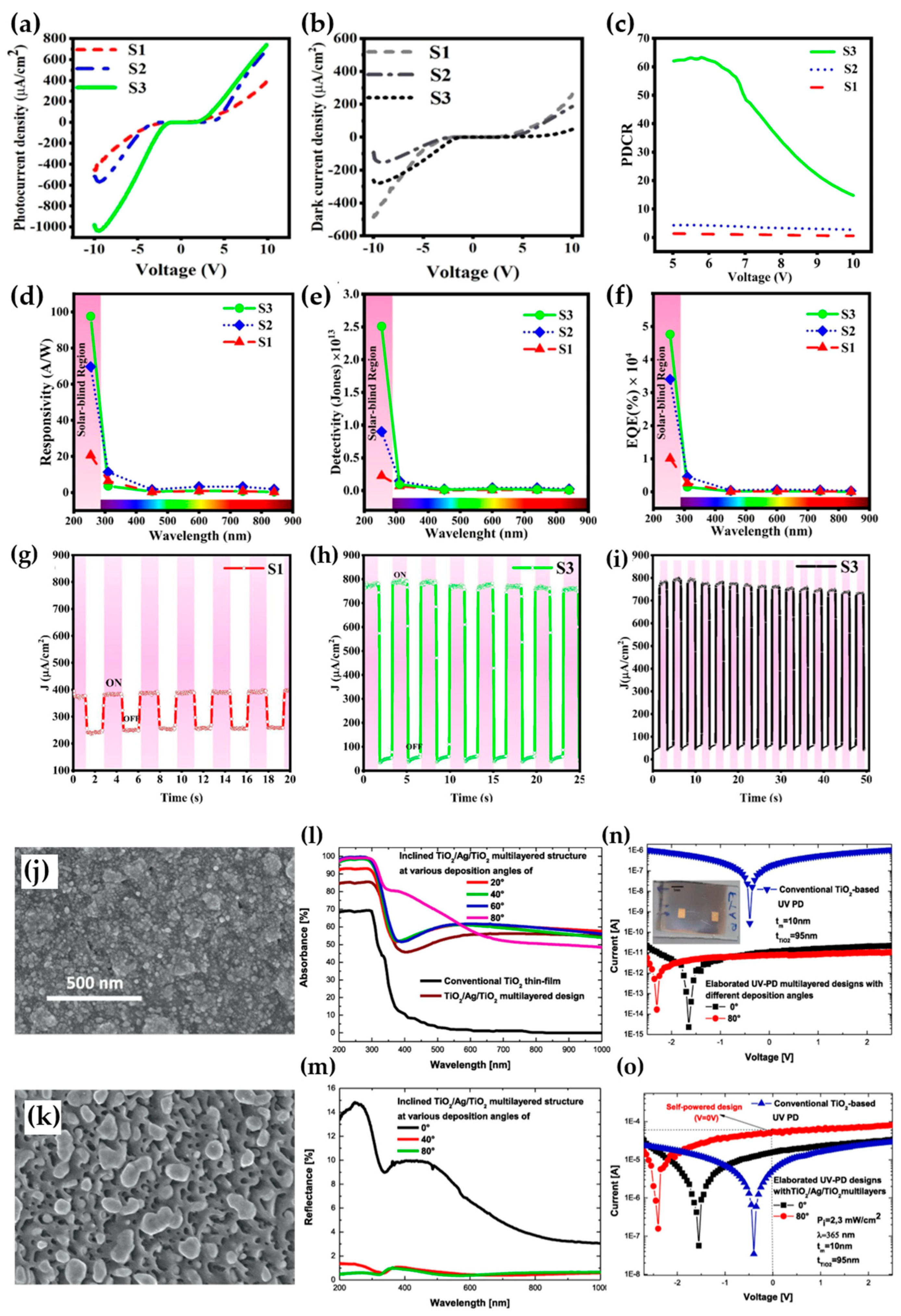

3.4. OAD Photodetectors Deposited by Sputtering

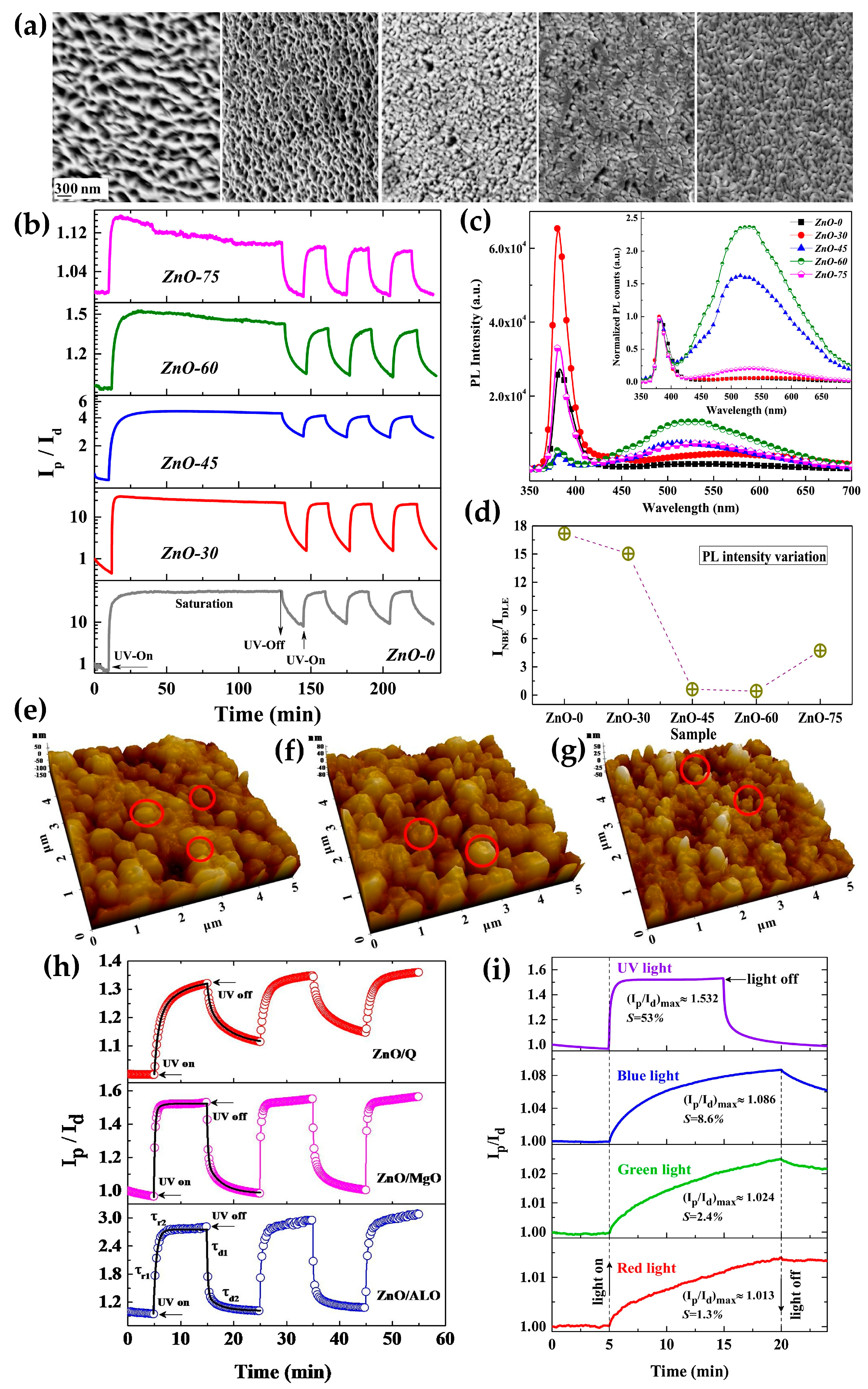

3.5. OAD Photodetectors Deposited by Pulsed Laser Deposition

4. Extended Applications of OAD-Engineered Nanostructures

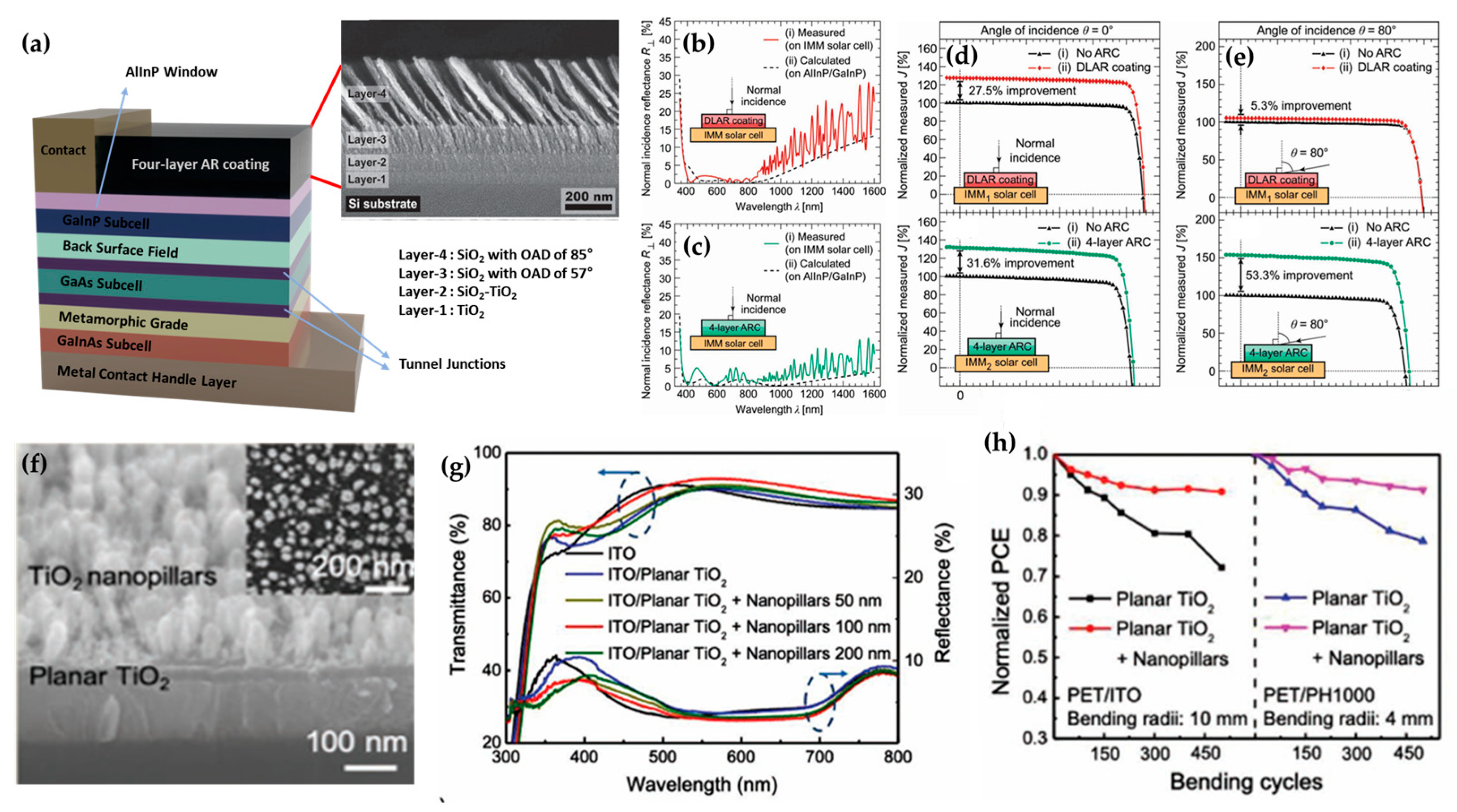

4.1. OAD-Engineered Nanostructures for Solar Cell Applications with AR Coating

4.2. OAD-Engineered Nanostructures for Memory/Synaptic Devices

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pan, X.; Bai, L.; Wang, H.; Wu, Q.; Wang, H.; Liu, S.; Xu, B.; Shi, X.; Liu, H. Metal–organic-framework-derived carbon nanostructure augmented sonodynamic cancer therapy. Adv. Mater. 2018, 30, 1800180. [Google Scholar] [CrossRef]

- Deng, Z.; Jiang, H.; Hu, Y.; Liu, Y.; Zhang, L.; Liu, H.; Li, C. 3D Ordered Macroporous MoS2@C Nanostructure for Flexible Li-Ion Batteries. Adv. Mater. 2017, 29, 1603020. [Google Scholar] [CrossRef]

- Zhou, K.; Wang, H.; Jiu, J.; Liu, J.; Yan, H.; Suganuma, K. Polyaniline films with modified nanostructure for bifunctional flexible multicolor electrochromic and supercapacitor applications. Chem. Eng. J. 2018, 345, 290–299. [Google Scholar] [CrossRef]

- Jeon, Y.; Seo, J.; Yoo, H. Air-stable ambipolar charge transport behaviors of organic-inorganic hybrid bilayer and application to Au nanoparticle-based floating gate memory. J. Alloys Compd. 2023, 938, 168687. [Google Scholar] [CrossRef]

- Garratt, E.; Prete, P.; Lovergine, N.; Nikoobakht, B. Observation and Impact of a “Surface Skin Effect” on Lateral Growth of Nanocrystals. J. Phys. Chem. C 2017, 121, 14845–14853. [Google Scholar] [CrossRef]

- Miccoli, I.; Prete, P.; Lovergine, N. Mass-transport driven growth dynamics of AlGaAs shells deposited around dense GaAs nanowires by metalorganic vapor phase epitaxy. CrystEngComm 2015, 17, 5998–6005. [Google Scholar] [CrossRef]

- Lovergine, N.; Liaci, L.; Ganière, J.D.; Leo, G.; Drigo, A.; Romanato, F.; Mancini, A.M.; Vasanelli, L. Inhomogeneous strain relaxation and defect distribution of ZnTe layers deposited on (100)GaAs by metalorganic vapor phase epitaxy. J. Appl. Phys. 1995, 78, 229–235. [Google Scholar] [CrossRef]

- Barranco, A.; Borras, A.; Gonzalez-Elipe, A.R.; Palmero, A. Perspectives on oblique angle deposition of thin films: From fundamentals to devices. Prog. Mater. Sci. 2016, 76, 59–153. [Google Scholar] [CrossRef]

- Pyun, M.W.; Kim, E.J.; Yoo, D.-H.; Hahn, S.H. Oblique angle deposition of TiO2 thin films prepared by electron-beam evaporation. Appl. Surf. Sci. 2010, 257, 1149–1153. [Google Scholar] [CrossRef]

- Mark, A.G.; Gibbs, J.G.; Lee, T.-C.; Fischer, P. Hybrid nanocolloids with programmed three-dimensional shape and material composition. Nat. Mater. 2013, 12, 802–807. [Google Scholar] [CrossRef]

- Lintymer, J.; Gavoille, J.; Martin, N.; Takadoum, J. Glancing angle deposition to modify microstructure and properties of sputter deposited chromium thin films. Surf. Coat. Technol. 2003, 174, 316–323. [Google Scholar] [CrossRef]

- Kesapragada, S.; Victor, P.; Nalamasu, O.; Gall, D. Nanospring pressure sensors grown by glancing angle deposition. Nano Lett. 2006, 6, 854–857. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, T.; Wang, Q.; Mayrhofer, P.H. Nanostructured zig-zag γ-Mo2N thin films produced by glancing angle deposition for flexible symmetrical solid-state supercapacitors. Mater. Des. 2023, 225, 111432. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, J. Chiroptically active metallic nanohelices with helical anisotropy. Small 2017, 13, 1701883. [Google Scholar] [CrossRef]

- Chen, L.; Andrea, L.; Timalsina, Y.P.; Wang, G.-C.; Lu, T.-M. Engineering epitaxial-nanospiral metal films using dynamic oblique angle deposition. Cryst. Growth Des. 2013, 13, 2075–2080. [Google Scholar] [CrossRef]

- Cansizoglu, H.; Cansizoglu, M.F.; Watanabe, F.; Karabacak, T. Enhanced photocurrent and dynamic response in vertically aligned In2S3/Ag core/shell nanorod array photoconductive devices. ACS Appl. Mater. Interfaces 2014, 6, 8673–8682. [Google Scholar] [CrossRef]

- Smith, W.; Zhao, Y. Enhanced photocatalytic activity by aligned WO3/TiO2 two-layer nanorod arrays. J. Phys. Chem. C 2008, 112, 19635–19641. [Google Scholar] [CrossRef]

- Kwon, H.; Sung, J.H.; Lee, Y.; Jo, M.-H.; Kim, J.K. Wavelength-dependent visible light response in vertically aligned nanohelical TiO2-based Schottky diodes. Appl. Phys. Lett. 2018, 112, 043106. [Google Scholar] [CrossRef]

- Maudet, F.; Lacroix, B.; Santos, A.J.; Paumier, F.; Paraillous, M.; Hurand, S.; Corvisier, A.; Marsal, C.; Giroire, B.; Dupeyrat, C. Optical and nanostructural insights of oblique angle deposited layers applied for photonic coatings. Appl. Surf. Sci. 2020, 520, 146312. [Google Scholar] [CrossRef]

- Tajik, N.; Ehsani, M.; Moghadam, R.Z.; Dizaji, H.R. Effect of GLAD technique on optical properties of ZnS multilayer antireflection coatings. Mater. Res. Bull. 2018, 100, 265–274. [Google Scholar] [CrossRef]

- Chaikeeree, T.; Mungkung, N.; Kasayapanand, N.; Lertvanithphol, T.; Nakajima, H.; Horprathum, M. Characterization broadband omnidirectional antireflection ITO nanorod films coating. Opt. Mater. 2021, 121, 111545. [Google Scholar] [CrossRef]

- Kim, S.H.; Lee, S.H.; Yu, J.S. Broadband and antireflective characteristics of glancing angle deposited titanium dioxide nanostructures for photovoltaic applications. Thin Solid Films 2019, 685, 53–58. [Google Scholar] [CrossRef]

- Moon, H.G.; Han, S.D.; Kang, M.-G.; Jung, W.-S.; Kwon, B.; Kim, C.; Lee, T.; Lee, S.; Baek, S.-H.; Kim, J.-S. Glancing angle deposited WO3 nanostructures for enhanced sensitivity and selectivity to NO2 in gas mixture. Sens. Actuators B Chem. 2016, 229, 92–99. [Google Scholar] [CrossRef]

- Singh, A.; Sharma, A.; Tomar, M.; Gupta, V. Growth of highly porous ZnO nanostructures for carbon monoxide gas sensing. Surf. Coat. Technol. 2018, 343, 49–56. [Google Scholar] [CrossRef]

- Martín, M.; Salazar, P.; Álvarez, R.; Palmero, A.; López-Santos, C.; González-Mora, J.L.; González-Elipe, A.R. Cholesterol biosensing with a polydopamine-modified nanostructured platinum electrode prepared by oblique angle physical vacuum deposition. Sens. Actuators B Chem. 2017, 240, 37–45. [Google Scholar] [CrossRef]

- Zhang, N.; Su, X.; Free, P.; Zhou, X.; Neoh, K.G.; Teng, J.; Knoll, W. Plasmonic metal nanostructure array by glancing angle deposition for biosensing application. Sens. Actuators B Chem. 2013, 183, 310–318. [Google Scholar] [CrossRef]

- Adhikari, D.; Junda, M.M.; Bastola, E.; Koirala, P.; Ellingson, R.J.; Collins, R.W.; Podraza, N.J. Glancing angle deposited CdTe: Nanostructured films and impact on solar cell performance. Surf. Coat. Technol. 2020, 381, 125127. [Google Scholar] [CrossRef]

- Hu, Z.; García-Martín, J.M.; Li, Y.; Billot, L.; Sun, B.; Fresno, F.; Garcia-Martin, A.; González, M.U.; Aigouy, L.; Chen, Z. TiO2 nanocolumn arrays for more efficient and stable perovskite solar cells. ACS Appl. Mater. Interfaces 2020, 12, 5979–5989. [Google Scholar] [CrossRef]

- Kwon, H.; Ham, J.; Kim, D.Y.; Oh, S.J.; Lee, S.; Oh, S.H.; Schubert, E.F.; Lim, K.G.; Lee, T.W.; Kim, S. Three-Dimensional Nanostructured Indium-Tin-Oxide Electrodes for Enhanced Performance of Bulk Heterojunction Organic Solar Cells. Adv. Energy Mater. 2014, 4, 1301566. [Google Scholar] [CrossRef]

- Zhen, C.; Wu, T.; Chen, R.; Wang, L.; Liu, G.; Cheng, H.-M. Strategies for modifying TiO2 based electron transport layers to boost perovskite solar cells. ACS Sustain. Chem. Eng. 2019, 7, 4586–4618. [Google Scholar] [CrossRef]

- Chen, H.; Wang, P.; Wang, X.; Wang, X.; Rao, L.; Qian, Y.; Yin, H.; Hou, X.; Ye, H.; Zhou, G. 3D InGaN nanowire arrays on oblique pyramid-textured Si (311) for light trapping and solar water splitting enhancement. Nano Energy 2021, 83, 105768. [Google Scholar] [CrossRef]

- Limwichean, S.; Kasayapanand, N.; Ponchio, C.; Nakajima, H.; Patthanasettakul, V.; Eiamchai, P.; Meng, G.; Horprathum, M. Morphology-controlled fabrication of nanostructured WO3 thin films by magnetron sputtering with glancing angle deposition for enhanced efficiency photo-electrochemical water splitting. Ceram. Int. 2021, 47, 34455–34462. [Google Scholar] [CrossRef]

- Kim, J.H.; Choi, I.Y.; Kim, J.H.; Kim, J.; Kim, Y.K.; Kim, J.K.; Lee, J.S. ZnFe2O4 Dendrite/SnO2 Helix 3D Hetero-Structure Photoanodes for Enhanced Photoelectrochemical Water Splitting: Triple Functions of SnO2 Nanohelix. Small 2021, 17, 2103861. [Google Scholar] [CrossRef]

- Xie, F.; Lu, H.; Xiu, X.; Chen, D.; Han, P.; Zhang, R.; Zheng, Y. Low dark current and internal gain mechanism of GaN MSM photodetectors fabricated on bulk GaN substrate. Solid-State Electron. 2011, 57, 39–42. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Devarajan, M.; Afzal, N. Fabrication and characterization of high performance MSM UV photodetector based on NiO film. Sens. Actuators A Phys. 2017, 262, 78–86. [Google Scholar] [CrossRef]

- Oh, S.; Kim, C.-K.; Kim, J. High responsivity β-Ga2O3 metal–semiconductor–metal solar-blind photodetectors with ultraviolet transparent graphene electrodes. ACS Photonics 2017, 5, 1123–1128. [Google Scholar] [CrossRef]

- Choi, W.; Park, T.; Yoo, H.; Hur, J. Vertical asymmetric metal-semiconductor-metal photodiode based on β-Ga2O3 thin films fabricated via solution process for arc discharge detection. J. Alloys Compd. 2023, 953, 170169. [Google Scholar] [CrossRef]

- Ishii, A.; Miyasaka, T. Direct detection of circular polarized light in helical 1D perovskite-based photodiode. Sci. Adv. 2020, 6, eabd3274. [Google Scholar] [CrossRef]

- Lischke, S.; Peczek, A.; Morgan, J.; Sun, K.; Steckler, D.; Yamamoto, Y.; Korndörfer, F.; Mai, C.; Marschmeyer, S.; Fraschke, M. Ultra-fast germanium photodiode with 3-dB bandwidth of 265 GHz. Nat. Photonics 2021, 15, 925–931. [Google Scholar] [CrossRef]

- Shin, J.; Kim, S.; Jang, B.C.; Yoo, H. Dielectric surface-dependent photogating phenomenon in C8-BTBT leading to broad spectral ultraviolet to near-infrared photoresponse and linearly-weighted synaptic phototransistors. Dyes Pigments 2023, 208, 110882. [Google Scholar] [CrossRef]

- Kim, S.; Hong, S.; Yoo, H. Location-dependent multi-parameter detection behaviors using hetero-interfaced organic anti-ambipolar phototransistors. Sens. Actuators A Phys. 2021, 330, 112888. [Google Scholar] [CrossRef]

- Jiang, J.; Hu, W.; Xie, D.; Yang, J.; He, J.; Gao, Y.; Wan, Q. 2D electric-double-layer phototransistor for photoelectronic and spatiotemporal hybrid neuromorphic integration. Nanoscale 2019, 11, 1360–1369. [Google Scholar] [CrossRef]

- Pedapudi, M.C.; Dhar, J.C. Ultrasensitive p-n junction UV-C photodetector based on p-Si/β-Ga2O3 nanowire arrays. Sens. Actuators A Phys. 2022, 344, 113673. [Google Scholar] [CrossRef]

- Meitei, P.N.; Singh, N.K. Self-powered photodetector based on a Ag nanoparticle-decorated Gd2O3 nanorod. ACS Appl. Electron. Mater. 2023, 5, 1521–1525. [Google Scholar] [CrossRef]

- Castillo-Seoane, J.; Contreras-Bernal, L.; Obrero-Perez, J.M.; García-Casas, X.; Lorenzo-Lázaro, F.; Aparicio, F.J.; Lopez-Santos, C.; Rojas, T.C.; Anta, J.A.; Borras, A. Highly Anisotropic Organometal Halide Perovskite Nanowalls Grown by Glancing-Angle Deposition. Adv. Mater. 2022, 34, 2107739. [Google Scholar] [CrossRef]

- Jensen, M.O.; Brett, M.J. Periodically structured glancing angle deposition thin films. IEEE Trans. Nanotechnol. 2005, 4, 269–277. [Google Scholar] [CrossRef]

- Wang, S.; Xia, G.; He, H.; Yi, K.; Shao, J.; Fan, Z. Structural and optical properties of nanostructured TiO2 thin films fabricated by glancing angle deposition. J. Alloys Compd. 2007, 431, 287–291. [Google Scholar] [CrossRef]

- Hahn, N.T.; Ye, H.; Flaherty, D.W.; Bard, A.J.; Mullins, C.B. Reactive ballistic deposition of α-Fe2O3 thin films for photoelectrochemical water oxidation. ACS Nano 2010, 4, 1977–1986. [Google Scholar] [CrossRef]

- Flaherty, D.W.; Dohnálek, Z.; Dohnálková, A.; Arey, B.W.; McCready, D.E.; Ponnusamy, N.; Mullins, C.B.; Kay, B.D. Reactive ballistic deposition of porous TiO2 films: Growth and characterization. J. Phys. Chem. C 2007, 111, 4765–4773. [Google Scholar] [CrossRef]

- He, Y.; Basnet, P.; Murph, S.E.H.; Zhao, Y. Ag nanoparticle embedded TiO2 composite nanorod arrays fabricated by oblique angle deposition: Toward plasmonic photocatalysis. ACS Appl. Mater. Interfaces 2013, 5, 11818–11827. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Huang, J.-H.; Song, J.; Zhou, Y.; Lin, L.; Huang, P.-C.; Zhang, Y.; Liu, C.-P.; He, J.-H.; Wang, Z.L. Anisotropic outputs of a nanogenerator from oblique-aligned ZnO nanowire arrays. ACS Nano 2011, 5, 6707–6713. [Google Scholar] [CrossRef]

- Kannan, V.; Inamdar, A.I.; Pawar, S.M.; Kim, H.-S.; Park, H.-C.; Kim, H.; Im, H.; Chae, Y.S. Facile route to NiO nanostructured electrode grown by oblique angle deposition technique for supercapacitors. ACS Appl. Mater. Interfaces 2016, 8, 17220–17225. [Google Scholar] [CrossRef]

- Han, J.H.; Kim, D.; Kim, J.; Kim, G.; Fischer, P.; Jeong, H.H. Plasmonic nanostructure engineering with shadow growth. Adv. Mater. 2023, 35, 2107917. [Google Scholar] [CrossRef]

- Wang, T.; Dong, P.; Zhu, C.; Sha, P.; Gao, W.; Wu, Y.; Wu, X. Trace detection of anthrax protective antigens via a competitive method based on surface-enhanced Raman scattering. Sens. Actuators B Chem. 2021, 346, 130467. [Google Scholar] [CrossRef]

- Chu, H.O.; Song, S.; Li, C.; Gibson, D. Surface enhanced Raman scattering substrates made by oblique angle deposition: Methods and applications. Coatings 2017, 7, 26. [Google Scholar] [CrossRef]

- Hang, Z.Y.; Thompson, C.V. Effects of oblique-angle deposition on intrinsic stress evolution during polycrystalline film growth. Acta Mater. 2014, 77, 284–293. [Google Scholar] [CrossRef]

- Yadav, S.; Senapati, S.; Kumar, S.; Gahlaut, S.K.; Singh, J.P. GLAD based advanced nanostructures for diversified biosensing applications: Recent progress. Biosensors 2022, 12, 1115. [Google Scholar] [CrossRef]

- Poxson, D.J.; Mont, F.W.; Schubert, M.F.; Kim, J.K.; Schubert, E.F. Quantification of porosity and deposition rate of nanoporous films grown by oblique-angle deposition. Appl. Phys. Lett. 2008, 93, 101914. [Google Scholar] [CrossRef]

- Ye, D.; Karabacak, T.; Lim, B.; Wang, G.; Lu, T. Growth of uniformly aligned nanorod arrays by oblique angle deposition with two-phasesubstrate rotation. Nanotechnology 2004, 15, 817. [Google Scholar] [CrossRef]

- Alvarez, R.; Garcia-Martin, J.M.; Lopez-Santos, M.C.; Rico, V.; Ferrer, F.J.; Cotrino, J.; Gonzalez-Elipe, A.R.; Palmero, A. On the deposition rates of magnetron sputtered thin films at oblique angles. Plasma Process. Polym. 2014, 11, 571–576. [Google Scholar] [CrossRef]

- Chowdhury, N.; Bedanta, S. Controlling the anisotropy and domain structure with oblique deposition and substrate rotation. AIP Adv. 2014, 4, 027104. [Google Scholar] [CrossRef]

- Xu, X.; Huang, H.; Jin, L.; Wen, T.; Liao, Y.; Tang, X.; Li, Y.; Zhong, Z. Micromorphology and uniaxial magnetic anisotropy of oblique-sputtered Ni80Fe20 films on periodically rippled Al2O3 substrates. Surf. Interfaces 2023, 37, 102694. [Google Scholar] [CrossRef]

- Xiao, X.; Dong, G.; Shao, J.; He, H.; Fan, Z. Optical and electrical properties of SnO2: Sb thin films deposited by oblique angle deposition. Appl. Surf. Sci. 2010, 256, 1636–1640. [Google Scholar] [CrossRef]

- He, Y.; Fu, J.; Zhao, Y. Oblique angle deposition and its applications in plasmonics. Front. Phys. 2014, 9, 47–59. [Google Scholar] [CrossRef]

- Starke, R.; Schober, G. Why history matters: Ab initio rederivation of Fresnel equations confirms microscopic theory of refractive index. Optik 2018, 157, 275–286. [Google Scholar] [CrossRef]

- Hung, K.-Y.; Liao, J.-C. The application of Fresnel equations and anti-reflection technology to improve inclined exposure interface reflection and develop a key component needed for Blu-ray DVD-micro-mirrors. J. Micromech. Microeng. 2008, 18, 075022. [Google Scholar] [CrossRef]

- Zhou, Y.; Chan, K.K.; Lai, T.; Tang, S. Characterizing refractive index and thickness of biological tissues using combined multiphoton microscopy and optical coherence tomography. Biomed. Opt. Express 2012, 4, 38–50. [Google Scholar] [CrossRef]

- Xiao, G.Z.; Adnet, A.; Zhang, Z.; Sun, F.G.; Grover, C.P. Monitoring changes in the refractive index of gases by means of a fiber optic Fabry-Perot interferometer sensor. Sens. Actuators A Phys. 2005, 118, 177–182. [Google Scholar] [CrossRef]

- Sobahan, K.; Park, Y.J.; Kim, J.J.; Shin, Y.S.; Kim, J.B.; Hwangbo, C.K. Nanostructured optical thin films fabricated by oblique angle deposition. Adv. Nat. Sci. Nanosci. Nanotechnol. 2010, 1, 045005. [Google Scholar] [CrossRef]

- Parra-Barranco, J.; Garcia-Garcia, F.J.; Rico, V.; Borras, A.; Lopez-Santos, C.; Frutos, F.; Barranco, A.; Gonzalez-Elipe, A.R. Anisotropic in-plane conductivity and dichroic gold plasmon resonance in plasma-assisted ITO thin films e-beam-evaporated at oblique angles. ACS Appl. Mater. Interfaces 2015, 7, 10993–11001. [Google Scholar] [CrossRef]

- Oh, M.-K.; Shin, Y.-S.; Lee, C.-L.; De, R.; Kang, H.; Yu, N.E.; Kim, B.H.; Kim, J.H.; Yang, J.-K. Morphological and SERS properties of silver nanorod array films fabricated by oblique thermal evaporation at various substrate temperatures. Nanoscale Res. Lett. 2015, 10, 259. [Google Scholar] [CrossRef]

- Hurand, S.; Corvisier, A.; Lacroix, B.; Santos, A.J.; Maudet, F.; Dupeyrat, C.; Roja, R.G.; Morales, F.M.; Girardeau, T.; Paumier, F. Anisotropic optical properties of indium tin oxide thin films prepared by ion beam sputtering under oblique angle deposition. Appl. Surf. Sci. 2022, 595, 152945. [Google Scholar] [CrossRef]

- Aiempanakit, C.; Aiempanakit, K. Structural development and phase transformation behavior of thermally-oxidization Ti by sputtering power and OAD technique. Mater. Chem. Phys. 2022, 280, 125814. [Google Scholar] [CrossRef]

- Qi, Z.; Tang, J.; Huang, J.; Zemlyanov, D.; Pol, V.G.; Wang, H. Li2MnO3 thin films with tilted domain structure as cathode for Li-ion batteries. ACS Appl. Electron. Mater. 2019, 2, 3461–3468. [Google Scholar] [CrossRef]

- Lamichhane, S.; Sharma, S.; Tomar, M.; Chowdhuri, A. Studies on photovoltaic properties of BFO/WO3 bilayer thin films for solar energy harvesting applications. Results Opt. 2023, 13, 100539. [Google Scholar] [CrossRef]

- Lee, S.; Park, T.; Hur, J.; Yoo, H. Calcium titanate orthorhombic perovskite-nickel oxide solar-blind UVC photodetectors with unprecedented long-term stability exceeding 500 days and their applications to real-time flame detection. ACS Photonics 2022, 9, 4005–4016. [Google Scholar] [CrossRef]

- Yang, D.; Ma, D. Development of organic semiconductor photodetectors: From mechanism to applications. Adv. Opt. Mater. 2019, 7, 1800522. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Y.; Wang, Y.; Zhang, X.; Zuo, C.; Shen, L.; Ding, L. Lead-free perovskite photodetectors: Progress, challenges, and opportunities. Adv. Mater. 2021, 33, 2006691. [Google Scholar] [CrossRef]

- Wu, D.; Guo, J.; Wang, C.; Ren, X.; Chen, Y.; Lin, P.; Zeng, L.; Shi, Z.; Li, X.J.; Shan, C.-X. Ultrabroadband and high-detectivity photodetector based on WS2/Ge heterojunction through defect engineering and interface passivation. ACS Nano 2021, 15, 10119–10129. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Z. Electron beam evaporation deposition. In Advanced Nano Deposition Methods; Chemical Industry Press: Beijing, China, 2016; pp. 33–58. [Google Scholar] [CrossRef]

- He, L.-J.; Li, C.; Liu, X.-Z. The optical properties of alumina films prepared by electron beam evaporation at oblique incidence. Mater. Lett. 2013, 101, 1–4. [Google Scholar] [CrossRef]

- Ripain, A.A.; Lim, Y.; Lim, C.; Zakaria, R. Tailoring of optical and wetting properties of electron beam deposited Ag nanostructure films by oblique angle deposition. J. Opt. 2023, 52, 1258–1268. [Google Scholar] [CrossRef]

- Mazumder, J.T.; Mayengbam, R.; Nath, A.; Sarkar, M.B. Investigation of structural, optical and electrical properties of TiO2 thin film-nanowire-based device for photodetector application. Opt. Mater. 2022, 133, 112936. [Google Scholar] [CrossRef]

- Chetri, P.; Dhar, J.C. Self-powered UV detection using SnO2 nanowire arrays with Au Schottky contact. Mater. Sci. Semicond. Process. 2019, 100, 123–129. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Zou, S.; Martin, P.; Bendavid, A. Atomic force microscopy study on topography of films produced by ion-based techniques. J. Appl. Phys. 1996, 80, 2658–2664. [Google Scholar] [CrossRef]

- Jain, R.K.; Kaur, J.; Arora, S.; Kumar, A.; Chawla, A.K.; Khanna, A. Effects of oblique angle deposition on structural, electrical and wettability properties of Bi thin films grown by thermal evaporation. Appl. Surf. Sci. 2019, 463, 45–51. [Google Scholar] [CrossRef]

- Hassan, N.; Hashim, M.; Bououdina, M. One-dimensional ZnO nanostructure growth prepared by thermal evaporation on different substrates: Ultraviolet emission as a function of size and dimensionality. Ceram. Int. 2013, 39, 7439–7444. [Google Scholar] [CrossRef]

- Cansizoglu, M.F.; Engelken, R.; Seo, H.-W.; Karabacak, T. High optical absorption of indium sulfide nanorod arrays formed by glancing angle deposition. ACS Nano 2010, 4, 733–740. [Google Scholar] [CrossRef]

- Yang, Z.-P.; Ci, L.; Bur, J.A.; Lin, S.-Y.; Ajayan, P.M. Experimental observation of an extremely dark material made by a low-density nanotube array. Nano Lett. 2008, 8, 446–451. [Google Scholar] [CrossRef]

- Shahidi, M.; Ehsani, M.; Dizaji, H.R.; Ghazi, M. Photoresponsivity enhancement of SnS porous film. Surf. Interfaces 2020, 21, 100790. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, H.; Liang, J.; Li, T.; Luo, Y.; Lu, S.; Shi, X.; Zheng, B.; Du, J.; Sun, X. Magnetron sputtering enabled synthesis of nanostructured materials for electrochemical energy storage. J. Mater. Chem. A 2020, 8, 20260–20285. [Google Scholar] [CrossRef]

- Jain, R.K.; Gautam, Y.K.; Dave, V.; Chawla, A.K.; Chandra, R. A study on structural, optical and hydrophobic properties of oblique angle sputter deposited HfO2 films. Appl. Surf. Sci. 2013, 283, 332–338. [Google Scholar] [CrossRef]

- Al-Salman, H.S.; Abdullah, M. RF sputtering enhanced the morphology and photoluminescence of multi-oriented ZnO nanostructure produced by chemical vapor deposition. J. Alloys Compd. 2013, 547, 132–137. [Google Scholar] [CrossRef]

- Yaghoubizadeh, P.; Eshraghi, M.J.; Hajati, S.; Naderi, N. Ultrahigh performance of β-Ga2O3-based MSM solar-blind photodetectors fabricated via the glancing angle deposition technique. ACS Appl. Electron. Mater. 2023, 5, 4220–4232. [Google Scholar] [CrossRef]

- Ferhati, H.; Djeffal, F.; Martin, N. Highly improved responsivity of self-powered UV-Visible photodetector based on TiO2/Ag/TiO2 multilayer deposited by GLAD technique: Effects of oriented columns and nano-sculptured surface. Appl. Surf. Sci. 2020, 529, 147069. [Google Scholar] [CrossRef]

- Plonczak, P.; Bieberle-Hütter, A.; Søgaard, M.; Ryll, T.; Martynczuk, J.; Hendriksen, P.V.; Gauckler, L.J. Tailoring of LaxSr1-xCoyFe1-yO3-δ nanostructure by pulsed laser deposition. Adv. Funct. Mater. 2011, 21, 2764–2775. [Google Scholar] [CrossRef]

- Soni, A.; Mulchandani, K.; Mavani, K. Crystallographically oriented porous ZnO nanostructures with visible-blind photoresponse: Controlling the growth and optical properties. Materialia 2019, 6, 100326. [Google Scholar] [CrossRef]

- Soni, A.; Mulchandani, K.; Mavani, K.R. Effects of substrates on the crystalline growth and UV photosensitivity of glancing angle deposited porous ZnO nanostructures. Sens. Actuators A Phys. 2020, 313, 112140. [Google Scholar] [CrossRef]

- Liu, S.; Qian, Y.; Lin, Y.; Sun, L.; Zhu, Y.; Li, D. Multilayer anti-reflective coating with ultra-low refractive index SiO2 nanopillars for high efficiency multi-junction GaAs solar cells. Sol. Energy Mater. Sol. Cells 2024, 266, 112679. [Google Scholar] [CrossRef]

- Khan, S.B.; Irfan, S.; Zhang, Z. Fabrication and characterization of MgF2 anti-reflective films comprising dual-layer prepared by physical vapor deposition technique for optoelectronic applications. J. Mater. Res. Technol. 2024, 31, 1616–1625. [Google Scholar] [CrossRef]

- Bruynooghe, S.; Tonova, D.; Sundermann, M.; Koch, T.; Schulz, U. Antireflection coatings combining interference multilayers and a nanoporous MgF2 top layer prepared by glancing angle deposition. Surf. Coat. Technol. 2015, 267, 40–44. [Google Scholar] [CrossRef]

- De, R.; Haque, S.M.; Sikdar, M.; Sahoo, P.; Rao, K.D. Fabrication of TiO2-based broadband single-layer anti-reflection coating by collimated glancing angle deposition technique. Nanotechnology 2021, 32, 245708. [Google Scholar] [CrossRef]

- Khan, S.B.; Wu, H.; Fei, Z.; Ning, S.; Zhang, Z. Antireflective coatings with enhanced adhesion strength. Nanoscale 2017, 9, 11047–11054. [Google Scholar] [CrossRef]

- Feng, C.; Zhang, W.; Wang, J.; Ma, H.; Liu, S.; Yi, K.; He, H.; Shao, J. Broadband antireflection film by glancing angle deposition. Opt. Mater. 2021, 111, 110720. [Google Scholar] [CrossRef]

- Guo, X.; Quan, X.; Li, Z.; Li, Q.; Zhang, B.; Zhang, X.; Song, C. Broadband anti-reflection coatings fabricated by precise time-controlled and oblique-angle deposition methods. Coatings 2021, 11, 492. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Y.; Feng, Y.; Shen, J.; Liang, X.; Huang, J.; Min, J.; Wang, L.; Shi, W. The influence of incident angle on physical properties of a novel back contact prepared by oblique angle deposition. Appl. Surf. Sci. 2016, 363, 252–258. [Google Scholar] [CrossRef]

- Ferhati, H.; Djeffal, F.; Martin, N.; Benhaya, A. Tunable properties of SnOx sputter-deposited by RGPP and GLAD techniques: A potential candidate for photosensing and all-oxide solar cells. Sol. Energy 2024, 268, 112305. [Google Scholar] [CrossRef]

- Rana, N.K.; Debata, S.; Panda, S.K.; Singh, D.P.; Chander, N. Towards water-resistant perovskite solar cells: Electron-beam deposited SiO2 layers for highly stable perovskite solar cells. Sol. Energy 2024, 280, 112874. [Google Scholar] [CrossRef]

- Leem, J.W.; Yu, J.S.; Heo, J.; Park, W.-K.; Park, J.-H.; Cho, W.J.; Kim, D.E. Nanostructured encapsulation coverglasses with wide-angle broadband antireflection and self-cleaning properties for III–V multi-junction solar cell applications. Sol. Energy Mater. Sol. Cells 2014, 120, 555–560. [Google Scholar] [CrossRef]

- Yan, X.; Poxson, D.J.; Cho, J.; Welser, R.E.; Sood, A.K.; Kim, J.K.; Schubert, E.F. Enhanced omnidirectional photovoltaic performance of solar cells using multiple-discrete-layer tailored-and low-refractive index anti-reflection coatings. Adv. Funct. Mater. 2013, 23, 583–590. [Google Scholar] [CrossRef]

- Soydan, M.C.; Ghobadi, A.; Yildirim, D.U.; Duman, E.; Bek, A.; Erturk, V.B.; Ozbay, E. Lithography-free random bismuth nanostructures for full solar spectrum harvesting and mid-infrared sensing. Adv. Opt. Mater. 2020, 8, 1901203. [Google Scholar] [CrossRef]

- Wu, Z.; Li, P.; Zhao, J.; Xiao, T.; Hu, H.; Sun, P.; Wu, Z.; Hao, J.; Sun, C.; Zhang, H. Low-Temperature-Deposited TiO2 Nanopillars for Efficient and Flexible Perovskite Solar Cells. Adv. Mater. Interfaces 2021, 8, 2001512. [Google Scholar] [CrossRef]

- Waita, S.M.; Aduda, B.O.; Mwabora, J.M.; Granqvist, C.G.; Lindquist, S.-E.; Niklasson, G.A.; Hagfeldt, A.; Boschloo, G. Electron transport and recombination in dye sensitized solar cells fabricated from obliquely sputter deposited and thermally annealed TiO2 films. J. Electroanal. Chem. 2007, 605, 151–156. [Google Scholar] [CrossRef]

- Cho, I.; Sim, Y.C.; Lee, K.; Cho, M.; Park, J.; Kang, M.; Chang, K.S.; Jeong, C.B.; Cho, Y.H.; Park, I. Nanowatt-Level Photoactivated Gas Sensor Based on Fully-Integrated Visible MicroLED and Plasmonic Nanomaterials. Small 2023, 19, 2207165. [Google Scholar] [CrossRef]

- Lee, K.; Cho, I.; Kang, M.; Jeong, J.; Choi, M.; Woo, K.Y.; Yoon, K.-J.; Cho, Y.-H.; Park, I. Ultra-low-power e-nose system based on multi-micro-led-integrated, nanostructured gas sensors and deep learning. ACS Nano 2022, 17, 539–551. [Google Scholar] [CrossRef]

- Kwon, Y.; Lee, K.; Kang, M.; Kim, C.; Ha, J.-H.; Han, H.; Yang, S.; Yang, D.; Seo, J.H.; Park, I. Room-temperature rapid oxygen monitoring system in high humidity hydrogen gas environment towards water electrolysis application. Sens. Actuators B Chem. 2025, 422, 136693. [Google Scholar] [CrossRef]

- Wisitsoorat, A.; Ahmad, M.Z.; Yaacob, M.H.; Horpratum, M.; Phakaratkul, D.; Lomas, T.; Tuantranont, A.; Wlodarski, W. Optical H2 sensing properties of vertically aligned Pd/WO3 nanorods thin films deposited via glancing angle rf magnetron sputtering. Sens. Actuators B Chem. 2013, 182, 795–801. [Google Scholar] [CrossRef]

- Wolcott, A.; Smith, W.A.; Kuykendall, T.R.; Zhao, Y.; Zhang, J.Z. Photoelectrochemical study of nanostructured ZnO thin films for hydrogen generation from water splitting. Adv. Funct. Mater. 2009, 19, 1849–1856. [Google Scholar] [CrossRef]

- Wolcott, A.; Smith, W.A.; Kuykendall, T.R.; Zhao, Y.; Zhang, J.Z. Photoelectrochemical water splitting using dense and aligned TiO2 nanorod arrays. Small 2009, 5, 104–111. [Google Scholar] [CrossRef]

- Shi, X.; Jeong, H.; Oh, S.J.; Ma, M.; Zhang, K.; Kwon, J.; Choi, I.T.; Choi, I.Y.; Kim, H.K.; Kim, J.K. Unassisted photoelectrochemical water splitting exceeding 7% solar-to-hydrogen conversion efficiency using photon recycling. Nat. Commun. 2016, 7, 11943. [Google Scholar] [CrossRef]

- Yadav, J.; Singh, J. Surface plasmonic hot hole driven Ag2S/Au/Al2O3 photocathode for enhanced photoelectrochemical water splitting performance. Renew. Energy 2024, 228, 120615. [Google Scholar] [CrossRef]

- Yadav, J.; Bhardwaj, L.; Singh, J. Magnetic field-augmented photoelectrochemical water splitting in Co3O4 and NiO nanorod arrays. Mater. Today Energy 2024, 45, 101682. [Google Scholar] [CrossRef]

- Kawase, Y.; Higashi, T.; Obata, K.; Kishimoto, F.; Pihosh, Y.; Domen, K.; Takanabe, K. Simple Immersing Method of Nanocoating on Uneven Surfaces Applicable to Highly Durable Ta3N5 Nanorod Photoelectrode for Water Splitting. Chem. Mat. 2024, 36, 2390–2401. [Google Scholar] [CrossRef]

- Pihosh, Y.; Turkevych, I.; Mawatari, K.; Uemura, J.; Kazoe, Y.; Kosar, S.; Makita, K.; Sugaya, T.; Matsui, T.; Fujita, D. Photocatalytic generation of hydrogen by core-shell WO3/BiVO4 nanorods with ultimate water splitting efficiency. Sci. Rep. 2015, 5, 11141. [Google Scholar] [CrossRef]

- Wu, S.; Ou, K.; Zhang, W.; Ni, Y.; Xia, Y.; Wang, H. TiO2 nanorod arrays/Ti3C2Tx MXene nanosheet composites with efficient photocatalytic activity. Nanotechnology 2024, 35, 155705. [Google Scholar] [CrossRef]

- Swathi, S.; Makkaramkott, A.; Subramanian, A. Tin oxide nanorod array-based photonic memristors with multilevel resistance states driven by optoelectronic stimuli. ACS Appl. Mater. Interfaces 2023, 15, 15676–15690. [Google Scholar] [CrossRef]

- Jeon, Y.; Lee, G.; Kim, Y.J.; Jang, B.C.; Yoo, H. Dual Synapses and Security Devices from Ternary C60-Pentacene-TiO2-x Nanorods Heterostructures. Adv. Funct. Mater. 2024, 34, 2409578. [Google Scholar] [CrossRef]

- Priyadarshini, B.G.; Sharma, A.K. Design of multi-layer anti-reflection coating for terrestrial solar panel glass. Bull. Mat. Sci. 2016, 39, 683–689. [Google Scholar] [CrossRef]

- Hiller, J.A.; Mendelsohn, J.D.; Rubner, M.F. Reversibly erasable nanoporous anti-reflection coatings from polyelectrolyte multilayers. Nat. Mater. 2002, 1, 59–63. [Google Scholar] [CrossRef]

- Lee, G.; Kim, Y.E.; Kim, H.; Lee, H.K.; Park, J.Y.; Oh, S.; Yoo, H. Organic Synaptic Transistors and Printed Circuit Board Defect Inspection with Photonic Stimulation: A Novel Approach Using Oblique Angle Deposition. Small 2025, 21, 2501997. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, J.; Yang, L.; Qu, M.; Qi, D.C.; Zhang, K.H. Wide bandgap oxide semiconductors: From materials physics to optoelectronic devices. Adv. Mater. 2021, 33, 2006230. [Google Scholar] [CrossRef]

- Pei, J.; Wu, X.; Liu, W.-J.; Zhang, D.W.; Ding, S.-J. Photoelectric logic and in situ memory transistors with stepped floating gates of perovskite quantum dots. ACS Nano 2022, 16, 2442–2451. [Google Scholar] [CrossRef]

- Fang, X.; MacDonald, K.F.; Zheludev, N.I. Controlling light with light using coherent metadevices: All-optical transistor, summator and invertor. Light Sci. Appl. 2015, 4, e292. [Google Scholar] [CrossRef]

- Cheng, J.; Wang, C.; Zou, X.; Liao, L. Recent advances in optoelectronic devices based on 2D materials and their heterostructures. Adv. Opt. Mater. 2019, 7, 1800441. [Google Scholar] [CrossRef]

| Wavelength | Deposited Angle | R (AW−1) | (Jones) | τr (s) | τd (s) |

|---|---|---|---|---|---|

| 595 nm (Amber) | 0° | 2.46 × 10−3 | 8.38 × 106 | 2.15 | 12.21 |

| 85° | 0.46 × 10−3 | 4.99 × 106 | 0.69 | 8.48 | |

| 650 nm (Red) | 0° | 1.45 × 10−3 | 2.58 × 106 | 3.59 | 11.18 |

| 85° | 0.29 × 10−3 | 1.78 × 106 | 1.49 | 8.77 |

| Material | Structure | Deposition Angle (°) | Porosity (%) | Deposition Technique | Detecting Wavelength (nm) | R (A·W−1) | (Jones) | τr (s) | τr (s) | Year | Ref |

|---|---|---|---|---|---|---|---|---|---|---|---|

| TiO2 | Nanowire | 85 | - | E-beam evaporation | 300~900 | - | - | - | - | 2022 | [83] |

| SnO2 | Nanowire | 85 | - | E-beam evaporation | 370 | 0.36 × 10−3 | 3.02 × 109 | 0.72 | 1.78 | 2019 | [84] |

| β-Ga2O3 | Nanorod | 65 | - | Sputtering | 254 | 95.28 | 2.51 × 1013 | 0.09 | 0.04 | 2023 | [88] |

| TiO2 | Nano sculpture | 80 | - | Sputtering | 365 | 205 × 10−3 | 5.3 × 1013 | - | - | 2020 | [90] |

| ZnO | Nano structure | 0~85 | ~31.42 | PLD | 365 | - | - | - | - | 2024 | [94] |

| ZnO | Nano structure | 85 | ~26.32 | PLD | 254 | - | - | 9 | 7 | 2020 | [95] |

| In2S3 | Nanorod | 85 | 31.1 | Thermal evaporation | 465 | - | - | - | - | 2010 | [97] |

| SnS | Nanoplate | 85 | - | Thermal evaporation | 595, 650 | 0.46 × 10−3, 0.29 × 10−3 | 4.99 × 106, 1.78 × 106 | 0.69, 1.49 | 8.48, 8.77 | 2020 | [98] |

| Application | Material | Deposition Technique | Deposition Angle (°) | Year | Ref. |

|---|---|---|---|---|---|

| AR coating | ITO | E-beam evaporation | 85 | 2021 | [21] |

| SiO2 | E-beam evaporation | 85 | 2024 | [99] | |

| MgF2 | E-beam evaporation | 0–86 | 2024 | [100] | |

| MgF2 | E-beam evaporation | - | 2015 | [101] | |

| TiO2 | E-beam evaporation | 86 | 2021 | [102] | |

| HfO2 | E-beam evaporation | 88 | 2017 | [103] | |

| SiO2 | E-beam evaporation | 30–80 | 2021 | [104] | |

| SiO2 | Sputtering | 67 | 2021 | [105] | |

| Ag | Sputtering | 5–60 | 2016 | [106] | |

| Solar cell | CdTe | Sputtering | 20–80 | 2020 | [27] |

| SnOx | Sputtering | 80 | 2023 | [107] | |

| SiO2 | E-beam evaporation | - | 2024 | [108] | |

| Au | E-beam evaporation | 80 | 2014 | [109] | |

| SiO2 | E-beam evaporation | 57, 85 | 2013 | [110] | |

| Bi | Thermal evaporation | - | 2020 | [111] | |

| TiO2 | E-beam evaporation | 85 | 2021 | [112] | |

| TiO2 | Sputtering | - | 2007 | [113] | |

| Gas sensor | In2O3 | Sputtering | 85 | 2023 | [114] |

| In2O3 | Sputtering | 85 | 2023 | [115] | |

| In2O3 | E-beam evaporation | 85 | 2025 | [116] | |

| WO3 | Sputtering | 85 | 2013 | [117] | |

| Water splitting | ZnO | Pulsed laser deposition | 86 | 2009 | [118] |

| TiO2 | E-beam evaporation | 86 | 2009 | [119] | |

| ITO | Sputtering | 70 | 2016 | [120] | |

| Ag | Thermal evaporation | 85 | 2024 | [121] | |

| Co3O4, NiO | E-beam evaporation | 85 | 2024 | [122] | |

| Ta3N5 | Sputtering | 85 | 2024 | [123] | |

| WO3 | Sputtering | - | 2015 | [124] | |

| TiO2 | E-beam evaporation | 85 | 2024 | [125] | |

| Memory/ synaptic device | SnOx | E-beam evaporation | 80 | 2023 | [126] |

| TiO2−x | E-beam evaporation | 70 | 2024 | [127] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, G.; Ko, R.; Kang, S.; Kim, Y.J.; Kim, Y.-J.; Yoo, H. Nanostructure Engineering by Oblique Angle Deposition for Photodetectors and Other Applications. Micromachines 2025, 16, 865. https://doi.org/10.3390/mi16080865

Lee G, Ko R, Kang S, Kim YJ, Kim Y-J, Yoo H. Nanostructure Engineering by Oblique Angle Deposition for Photodetectors and Other Applications. Micromachines. 2025; 16(8):865. https://doi.org/10.3390/mi16080865

Chicago/Turabian StyleLee, Gyeongho, Raksan Ko, Seungme Kang, Yeong Jae Kim, Young-Joon Kim, and Hocheon Yoo. 2025. "Nanostructure Engineering by Oblique Angle Deposition for Photodetectors and Other Applications" Micromachines 16, no. 8: 865. https://doi.org/10.3390/mi16080865

APA StyleLee, G., Ko, R., Kang, S., Kim, Y. J., Kim, Y.-J., & Yoo, H. (2025). Nanostructure Engineering by Oblique Angle Deposition for Photodetectors and Other Applications. Micromachines, 16(8), 865. https://doi.org/10.3390/mi16080865