Liquid Resistive Switching Devices with Printable Electrodes

Abstract

1. Introduction

2. Materials and Methods

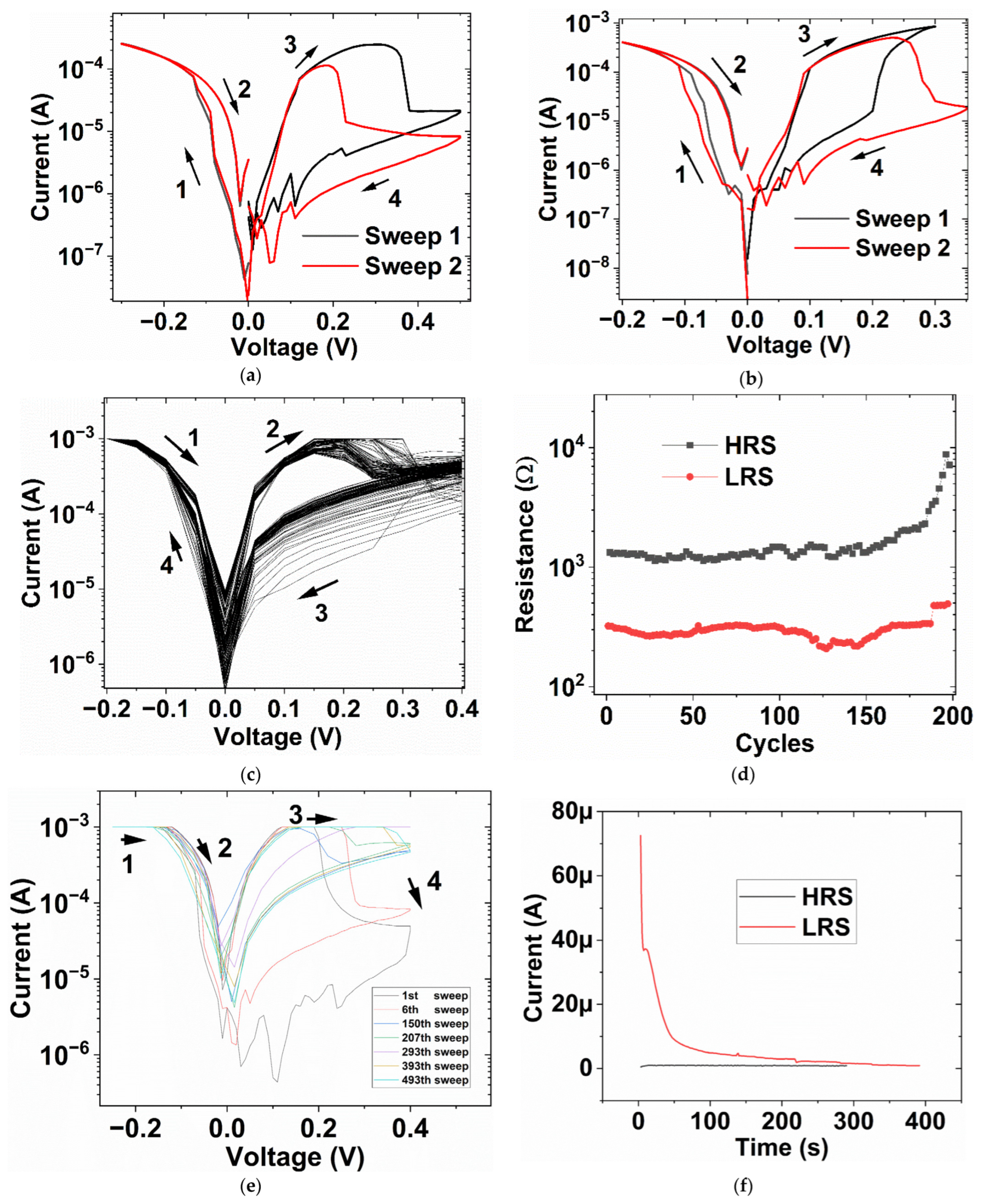

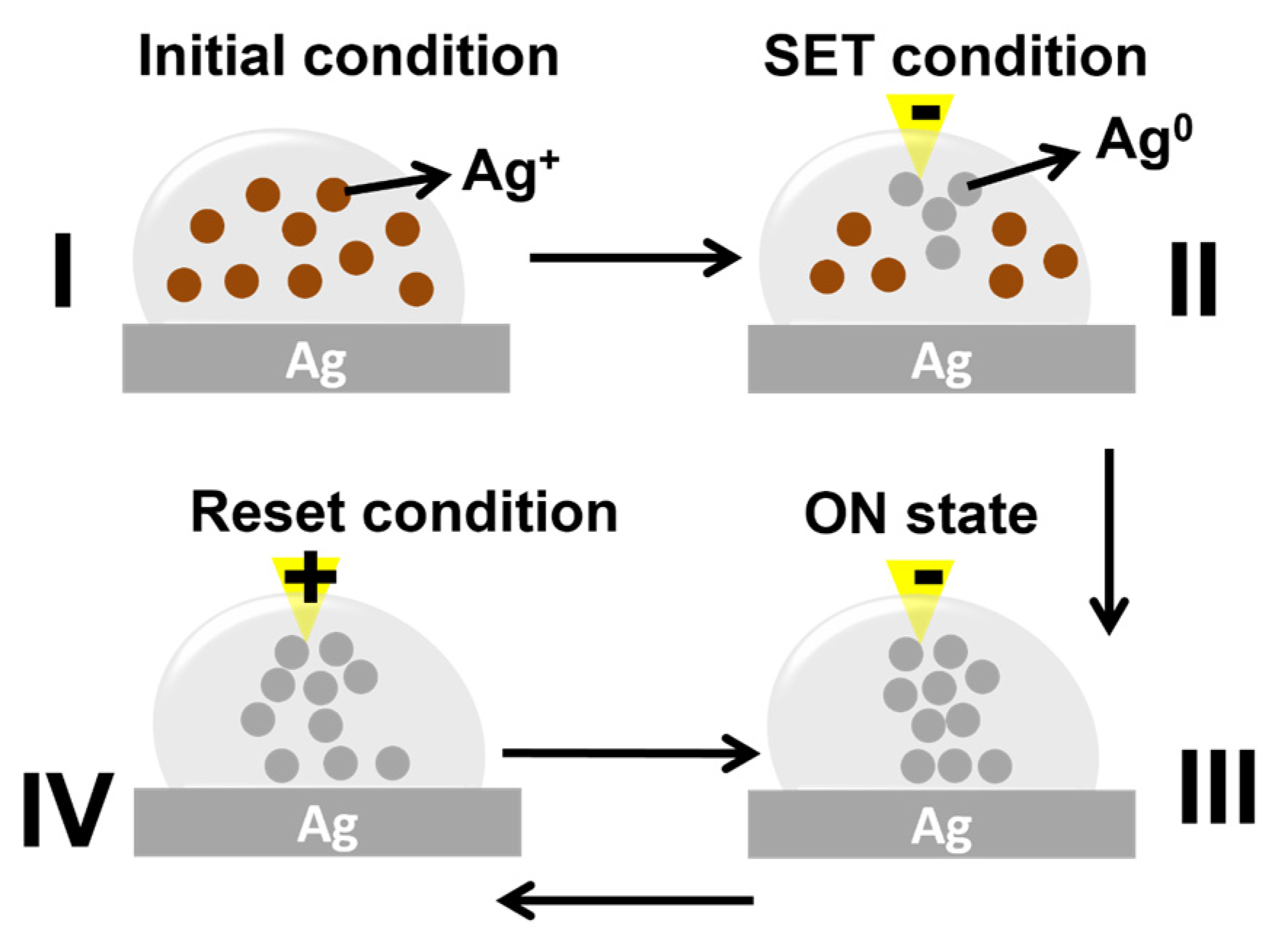

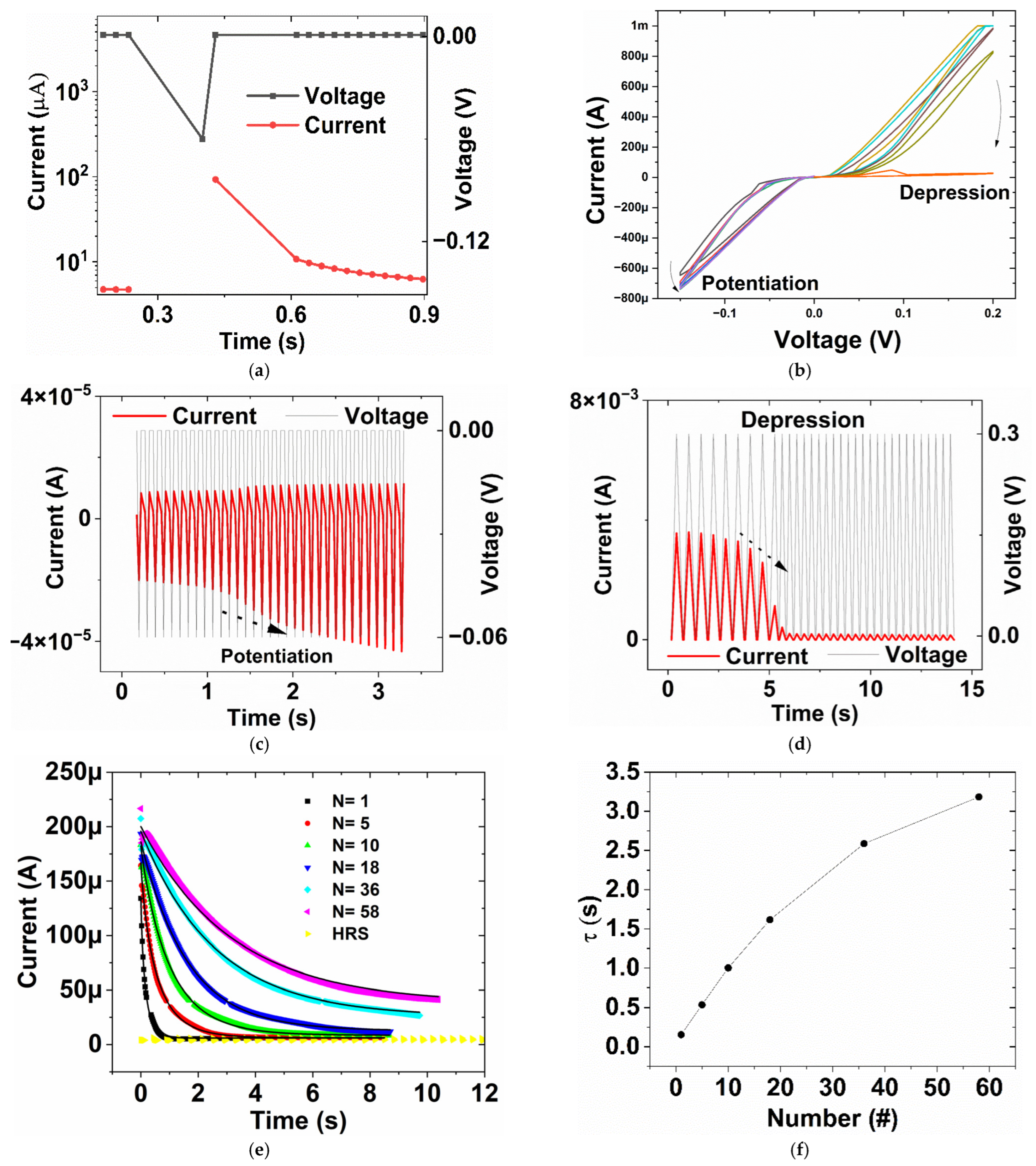

3. Results and Discussion

4. Conclusions

Supplementary Materials

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LRS | Low-Resistance State |

| HRS | High-Resistance State |

| SEM | Scanning Electron Microscopy |

| EDS | Energy Dispersive X-ray Spectroscopy |

| EPSC | Excitatory Post-Synaptic Current |

| C.C | Compliance Current |

| STM | Short-Term Memory |

| LTM | Long-Term Memory |

| SEF | Stretched Exponential Function |

References

- Qian, K.; Nguyen, V.C.; Chen, T.; Lee, P.S. Novel concepts in functional resistive switching memories. J. Mater. Chem. C 2016, 4, 9637–9645. [Google Scholar] [CrossRef]

- Le, M.; Truong, S.N. Research on the Impact of Data Density on Memristor Crossbar Architectures in Neuromorphic Pattern Recognition. Micromachines 2023, 14, 1990. [Google Scholar] [CrossRef] [PubMed]

- Truong, S.N. Single Crossbar Array of Memristors with Bipolar Inputs for Neuromorphic Image Recognition. IEEE Access 2020, 8, 69327–69332. [Google Scholar] [CrossRef]

- Zhou, G.; Sun, B.; Hu, X.; Sun, L.; Zou, Z.; Xiao, B.; Qiu, W.; Wu, B.; Li, J.; Han, J.; et al. Negative Photoconductance Effect: An Extension Function of the TiO-Based Memristor. Adv. Sci. 2021, 8, 2003765. [Google Scholar] [CrossRef]

- Rahmani, M.K.; Khan, S.A.; Kim, H.; Khan, M.U.; Kim, J.; Bae, J.; Kang, M.H. Demonstration of high-stable bipolar resistive switching and bio-inspired synaptic characteristics using PEDOT:PSS-based memristor devices. Org. Electron. 2023, 114, 106730. [Google Scholar] [CrossRef]

- Zhou, G.; Li, J.; Song, Q.; Wang, L.; Ren, Z.; Sun, B.; Hu, X.; Wang, W.; Xu, G.; Chen, X.; et al. Full hardware implementation of neuromorphic visual system based on multimodal optoelectronic resistive memory arrays for versatile image processing. Nat. Commun. 2023, 14, 8489. [Google Scholar] [CrossRef] [PubMed]

- Desai, T.R.; Dongale, T.D.; Patil, S.R.; Tiwari, A.P.; Pawar, P.K.; Kamat, R.K.; Kim, T.G. Synaptic learning functionalities of inverse biomemristive device based on trypsin for artificial intelligence application. J. Mater. Res. Technol. 2021, 11, 1100–1110. [Google Scholar] [CrossRef]

- Kumar, M.; Shin, H.; Choi, H.; Park, J.-Y.; Kim, S.; Seo, H. Point-contact enabled reliable and low-voltage memristive switching and artificial synapse from highly transparent all-oxide-integration. J. Alloys Compd. 2021, 857, 157593. [Google Scholar] [CrossRef]

- Maswoud, S.; Paul, S.; Salaoru, I. 3-D Printing of Flexible Two Terminal Electronic Memory Devices. MRS Adv. 2018, 3, 1603–1608. [Google Scholar] [CrossRef]

- Kaniselvan, M.; Jeon, Y.R.; Mladenović, M.; Luisier, M.; Akinwande, D. Mechanisms of resistive switching in two-dimensional monolayer and multilayer materials. Nat. Mater. 2025, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Rehman, M.M.; Samad, Y.A.; Gul, J.Z.; Saqib, M.; Khan, M.; Shaukat, R.A.; Chang, R.; Shi, Y.; Kim, W.Y. 2D materials-memristive devices nexus: From status quo to Impending applications. Prog. Mater. Sci. 2025, 152, 101471. [Google Scholar] [CrossRef]

- Qian, K.; Tay, R.Y.; Lin, M.-F.; Chen, J.; Li, H.; Lin, J.; Wang, J.; Cai, G.; Nguyen, V.C.; Teo, E.H.T.; et al. Direct Observation of Indium Conductive Filaments in Transparent, Flexible, and Transferable Resistive Switching Memory. ACS Nano 2017, 11, 1712–1718. [Google Scholar] [CrossRef] [PubMed]

- Rehman, M.M.; Siddiqui, G.U.; Gul, J.Z.; Kim, S.-W.; Lim, J.H.; Choi, K.H. Resistive Switching in All-Printed, Flexible and Hybrid MoS2-PVA Nanocomposite based Memristive Device Fabricated by Reverse Offset. Sci. Rep. 2016, 6, 36195. [Google Scholar] [CrossRef] [PubMed]

- Qian, K.; Nguyen, V.C.; Chen, T.; Lee, P.S. Amorphous-Si-Based Resistive Switching Memories with Highly Reduced Electroforming Voltage and Enlarged Memory Window. Adv. Electron. Mater. 2016, 2, 1500370. [Google Scholar] [CrossRef]

- Jung, U.; Kim, M.; Jang, J.; Bae, J.-H.; Kang, I.M.; Lee, S.-H. Formation of Cluster-Structured Metallic Filaments in Organic Memristors for Wearable Neuromorphic Systems with Bio-Mimetic Synaptic Weight Distributions. Adv. Sci. 2024, 11, 2307494. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Du, Y.; Li, Y.; Zhu, B.; Leow, W.R.; Li, Y.; Pan, J.; Wu, T.; Chen, X. Configurable Resistive Switching between Memory and Threshold Characteristics for Protein-Based Devices. Adv. Funct. Mater. 2015, 25, 3825–3831. [Google Scholar] [CrossRef]

- Yoon, J.H.; Wang, Z.; Kim, K.M.; Wu, H.; Ravichandran, V.; Xia, Q.; Hwang, C.S.; Yang, J.J. An artificial nociceptor based on a diffusive memristor. Nat. Commun. 2018, 9, 417. [Google Scholar] [CrossRef] [PubMed]

- Ielmini, D.; Pedretti, G. Resistive Switching Random-Access Memory (RRAM): Applications and Requirements for Memory and Computing. Chem. Rev. 2025, 125, 5584–5625. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Ma, J.; Xiao, X.; Liu, Q.; Shao, L.; Chen, D.; Liu, S.; Niu, J.; Zhang, X.; Wang, Y.; et al. Breaking the Current-Retention Dilemma in Cation-Based Resistive Switching Devices Utilizing Graphene with Controlled Defects. Adv. Mater. 2018, 30, 1705193. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Wang, M.; Ambrosi, E.; Bricalli, A.; Laudato, M.; Sun, Z.; Chen, X.; Ielmini, D. Surface diffusion-limited lifetime of silver and copper nanofilaments in resistive switching devices. Nat. Commun. 2019, 10, 81. [Google Scholar] [CrossRef] [PubMed]

- Wan, C.J.; Liu, Y.H.; Zhu, L.Q.; Feng, P.; Shi, Y.; Wan, Q. Short-Term Synaptic Plasticity Regulation in Solution-Gated Indium–Gallium–Zinc-Oxide Electric-Double-Layer Transistors. ACS Appl. Mater. Interfaces 2016, 8, 9762–9768. [Google Scholar] [CrossRef] [PubMed]

- Chougale, M.Y.; Khan, M.U.; Kim, J.; Shaukat, R.A.; Saqib, Q.M.; Patil, S.R.; Dongale, T.D.; Bermak, A.; Mohammad, B.; Bae, J. Bioinspired Soft Multistate Resistive Memory Device Based on Silk Fibroin Gel for Neuromorphic Computing. Adv. Eng. Mater. 2022, 24, 2200314. [Google Scholar] [CrossRef]

- Kim, D.; Lee, J.-S. Designing artificial sodium ion reservoirs to emulate biological synapses. NPG Asia Mater. 2020, 12, 62. [Google Scholar] [CrossRef]

- Kim, D.; Lee, J.-S. Liquid-based memory and artificial synapse. Nanoscale 2019, 11, 9726–9732. [Google Scholar] [CrossRef] [PubMed]

- Shkodra, B.; Bhardwaj, K.; Petrelli, M.; Altana, A.; Petti, L.; Carrara, S.; Lugli, P. Printed Organic Memristive Devices with Non-Zero-Crossing Hysteresis. BioNanoScience 2025, 15, 422. [Google Scholar] [CrossRef]

- Lv, J.; Thangavel, G.; Li, Y.; Xiong, J.; Gao, D.; Ciou, J.; Tan, M.W.M.; Aziz, I.; Chen, S.; Chen, J.; et al. Printable elastomeric electrodes with sweat-enhanced conductivity for wearables. Sci. Adv. 2021, 7, eabg8433. [Google Scholar] [CrossRef] [PubMed]

- Yuan, R.; Cao, Y.; Zhu, X.; Shan, X.; Wang, B.; Wang, H.; Chen, S.; Liu, J. Liquid Metal Memory. Adv. Mater. 2024, 36, 2309182. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Vogt, D.M.; Hsu, W.-H.; Osborne, J.; Walsh, T.; Foster, J.R.; Sullivan, S.K.; Smith, V.C.; Rousing, A.W.; Goldfield, E.C.; et al. Biocompatible Soft Fluidic Strain and Force Sensors for Wearable Devices. Adv. Funct. Mater. 2019, 29, 1807058. [Google Scholar] [CrossRef] [PubMed]

- Chua, L. Resistance switching memories are memristors. Appl. Phys. A 2011, 102, 765–783. [Google Scholar] [CrossRef]

- Guo, X.; Schindler, C.; Menzel, S.; Waser, R. Understanding the switching-off mechanism in Ag+ migration based resistively switching model systems. Appl. Phys. Lett. 2007, 91, 133513. [Google Scholar] [CrossRef]

- Krishnan, K.; Tsuruoka, T.; Aono, M. Direct observation of anodic dissolution and filament growth behavior in polyethylene-oxide-based atomic switch structures. Jpn. J. Appl. Phys. 2016, 55, 06GK02. [Google Scholar] [CrossRef]

- Kim, K.-S.; Bang, J.-O.; Jung, S.-B. Electrochemical migration behavior of silver nanopaste screen-printed for flexible and printable electronics. Curr. Appl. Phys. 2013, 13, S190–S194. [Google Scholar] [CrossRef]

- Chen, Z.; Yu, Y.; Jin, L.; Li, Y.; Li, Q.; Li, T.; Zhang, Y.; Dai, H.; Yao, J. Artificial synapses with photoelectric plasticity and memory behaviors based on charge trapping memristive system. Mater. Des. 2020, 188, 108415. [Google Scholar] [CrossRef]

- Jo, S.H.; Chang, T.; Ebong, I.; Bhadviya, B.B.; Mazumder, P.; Lu, W. Nanoscale Memristor Device as Synapse in Neuromorphic Systems. Nano Lett. 2010, 10, 1297–1301. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Xiao, Y.; Yan, P.; Sun, F.; Zhang, X.; Sheng, C.; Wang, Q.; Yu, Y. Observation of memristive behavior in PDMS-glass nanofluidic chip. Nano Res. 2025, 18, 94907098. [Google Scholar] [CrossRef]

- Hu, H.; Scholz, A.; Dolle, C.; Zintler, A.; Quintilla, A.; Liu, Y.; Tang, Y.; Breitung, B.; Marques, G.C.; Eggeler, Y.M.; et al. Inkjet-Printed Tungsten Oxide Memristor Displaying Non-Volatile Memory and Neuromorphic Properties. Adv. Funct. Mater. 2024, 34, 2302290. [Google Scholar] [CrossRef]

- Ohno, T.; Hasegawa, T.; Tsuruoka, T.; Terabe, K.; Gimzewski, J.K.; Aono, M. Short-term plasticity and long-term potentiation mimicked in single inorganic synapses. Nat. Mater. 2011, 10, 591–595. [Google Scholar] [CrossRef] [PubMed]

- Chang, T.; Jo, S.-H.; Lu, W. Short-Term Memory to Long-Term Memory Transition in a Nanoscale Memristor. ACS Nano 2011, 5, 7669–7676. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Ni, Y.; Wang, Z.; Wei, S.; Chen, X.e.; Lin, J.; Liu, L.; Yu, B.; Yu, Y.; Lei, D.; et al. Heterointerface-Modulated Synthetic Synapses Exhibiting Complex Multiscale Plasticity. Adv. Sci. 2025, e17237. [Google Scholar] [CrossRef] [PubMed]

- Ni, Y.; Yang, J.; Liao, K.; Li, R.; Wang, Z.; Fu, C.; Jiang, S.; Liang, C.; Chen, P.; Li, Q.; et al. Sodium dopant in pectin mediates ionic-electronic coupling on Na0.67Mg0.28Mn0.72O2 for electrolyte-type artificial synapse with tunable plasticity. Appl. Phys. Lett. 2025, 126, 234101. [Google Scholar] [CrossRef]

- Zhu, L.Q.; Wan, C.J.; Guo, L.Q.; Shi, Y.; Wan, Q. Artificial synapse network on inorganic proton conductor for neuromorphic systems. Nat. Commun. 2014, 5, 3158. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, V.C. Liquid Resistive Switching Devices with Printable Electrodes. Micromachines 2025, 16, 863. https://doi.org/10.3390/mi16080863

Nguyen VC. Liquid Resistive Switching Devices with Printable Electrodes. Micromachines. 2025; 16(8):863. https://doi.org/10.3390/mi16080863

Chicago/Turabian StyleNguyen, Viet Cuong. 2025. "Liquid Resistive Switching Devices with Printable Electrodes" Micromachines 16, no. 8: 863. https://doi.org/10.3390/mi16080863

APA StyleNguyen, V. C. (2025). Liquid Resistive Switching Devices with Printable Electrodes. Micromachines, 16(8), 863. https://doi.org/10.3390/mi16080863