Experimental Study on Surface Integrity of Nickel-Based Superalloy in Ultrasonic Elliptical Vibration Cutting

Abstract

1. Introduction

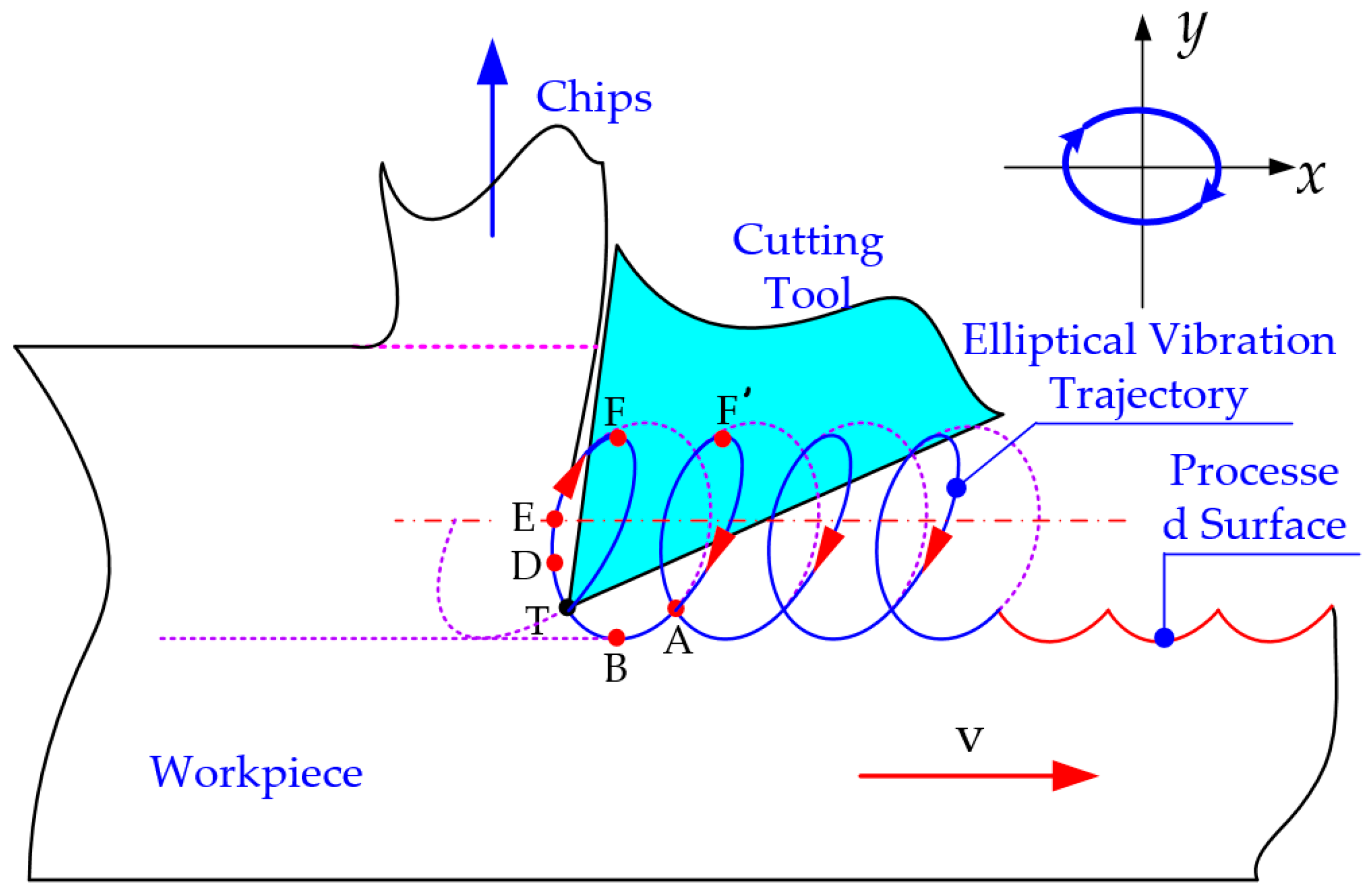

2. The Mechanism of Ultrasonic Elliptical Vibration Cutting

3. The Surface Integrity Experiment of Ultrasonic Elliptical Vibration Cutting for Nickel-Based Superalloys

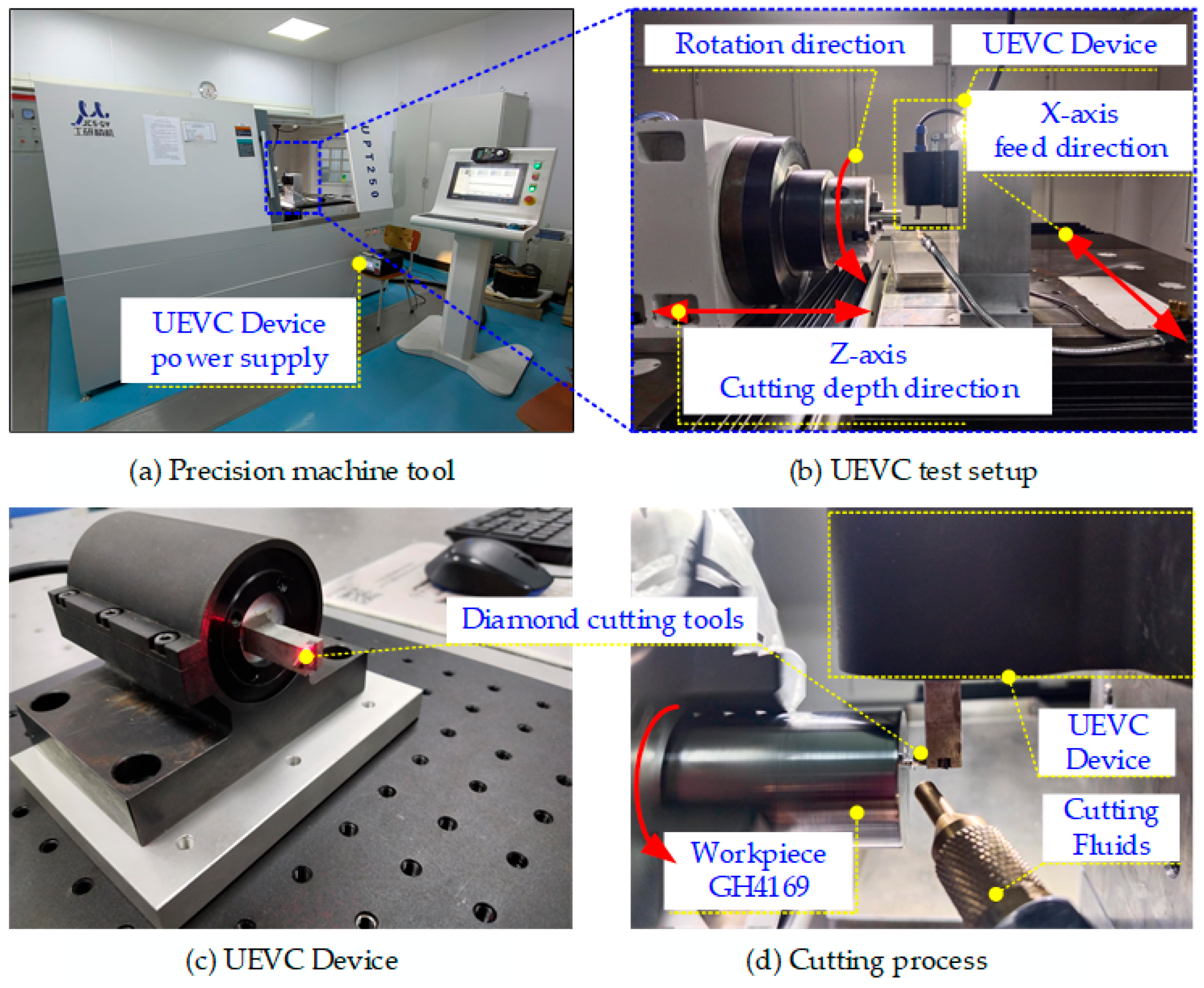

3.1. Experimental Equipment

3.2. Experimental Materials

3.3. Experimental Plan

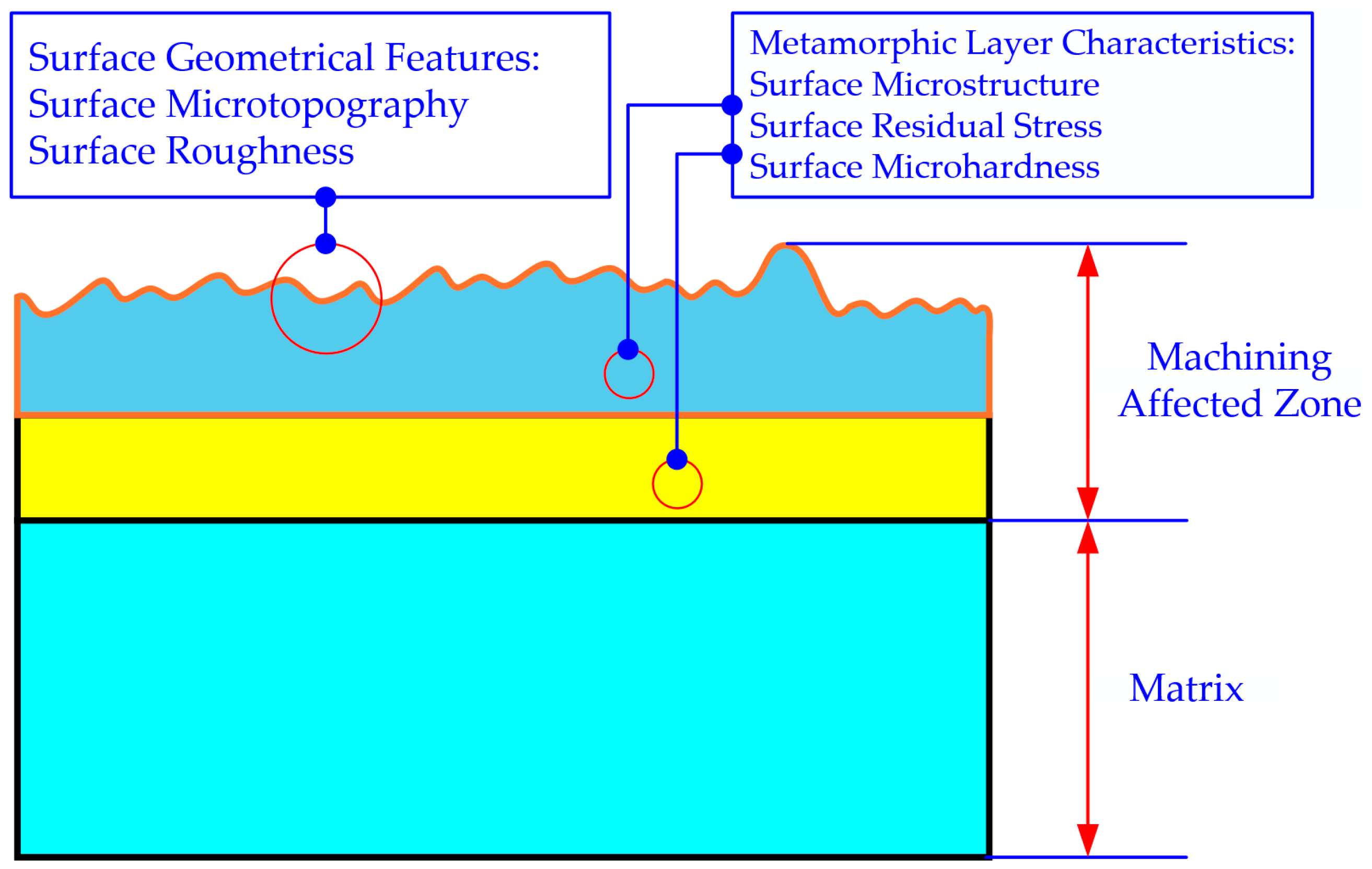

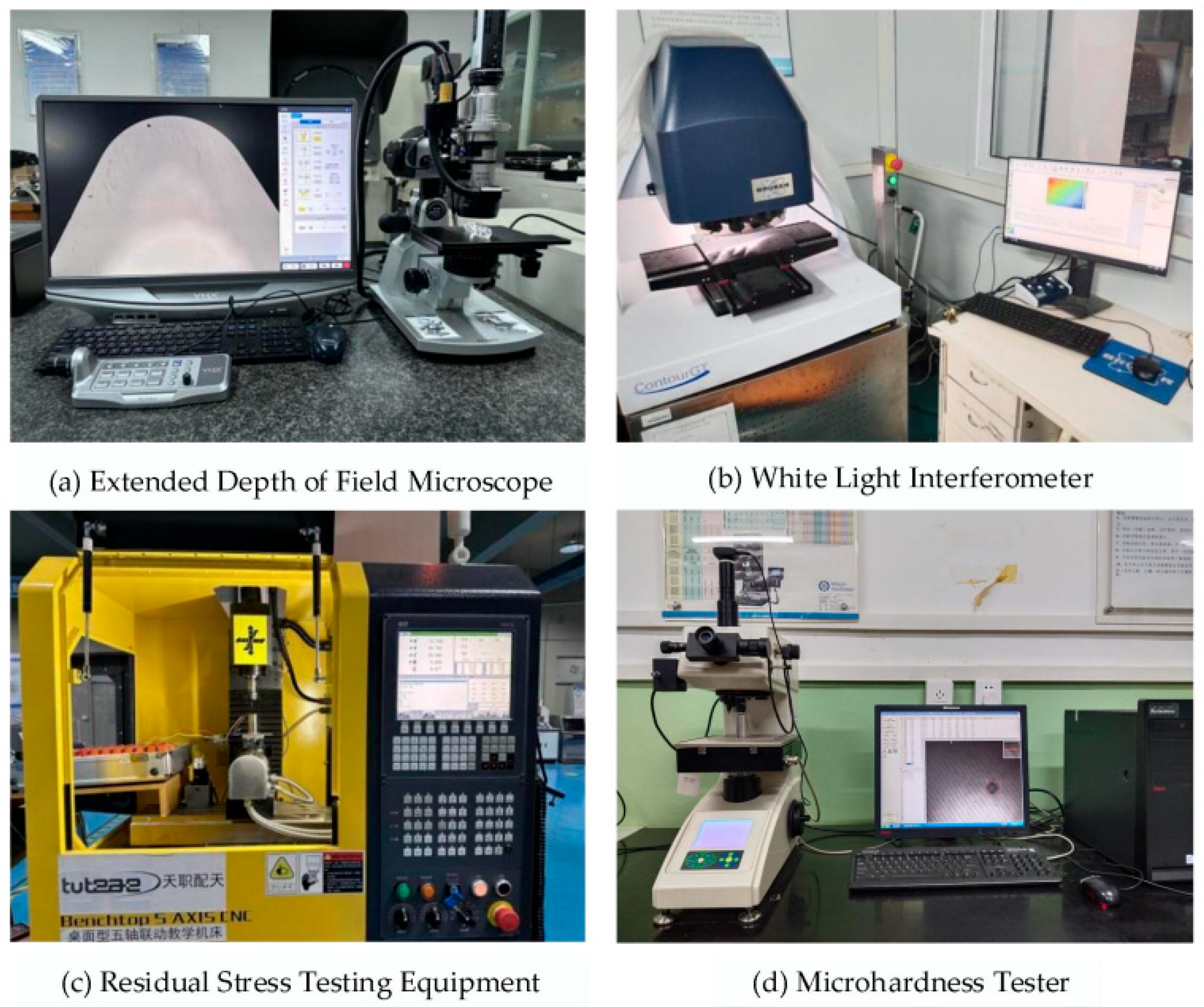

3.4. Surface Integrity Testing Methods

3.5. Analysis of Surface Roughness in Ultrasonic Elliptical Vibration Cutting

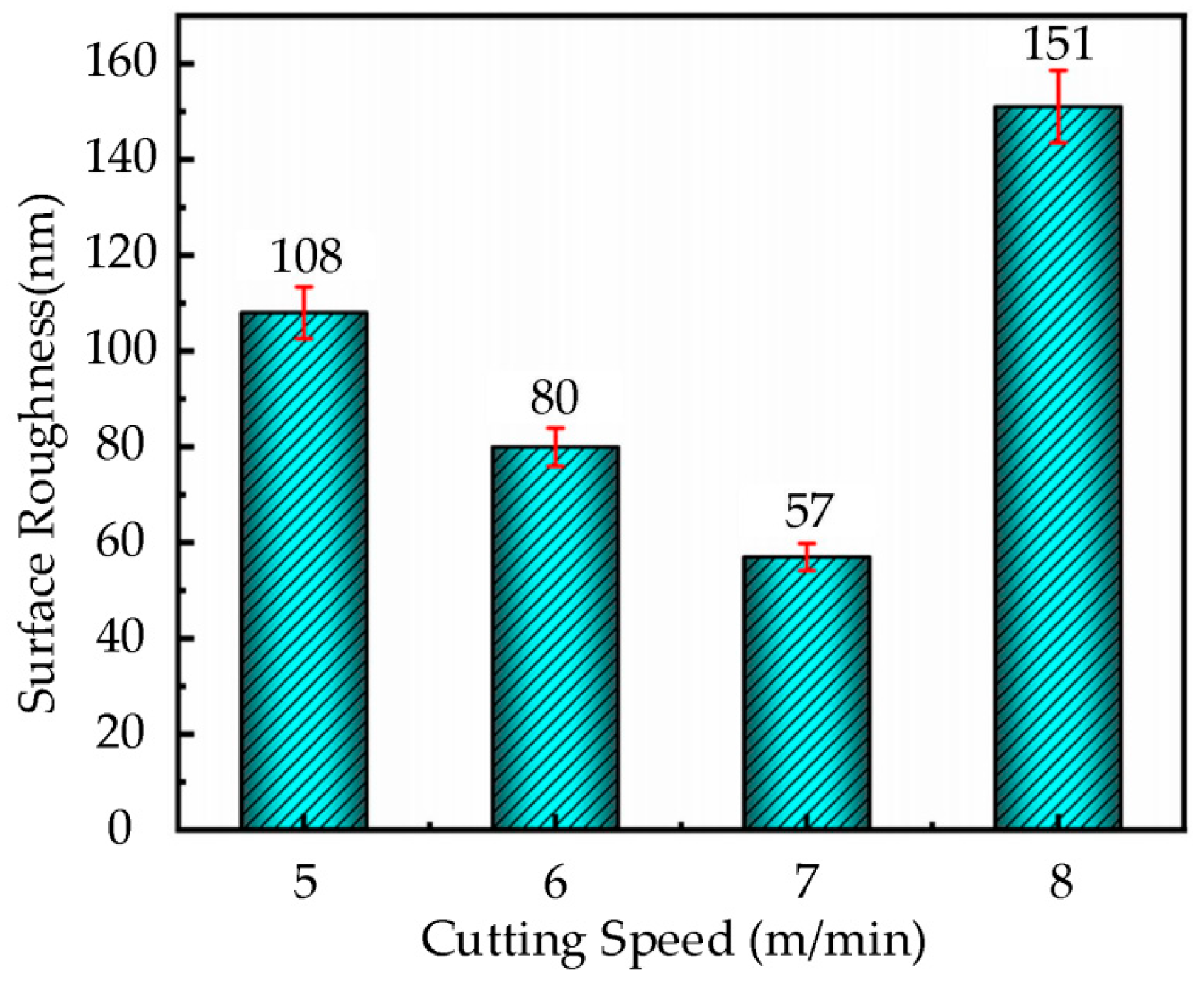

3.5.1. The Effect of Cutting Speed on Surface Roughness

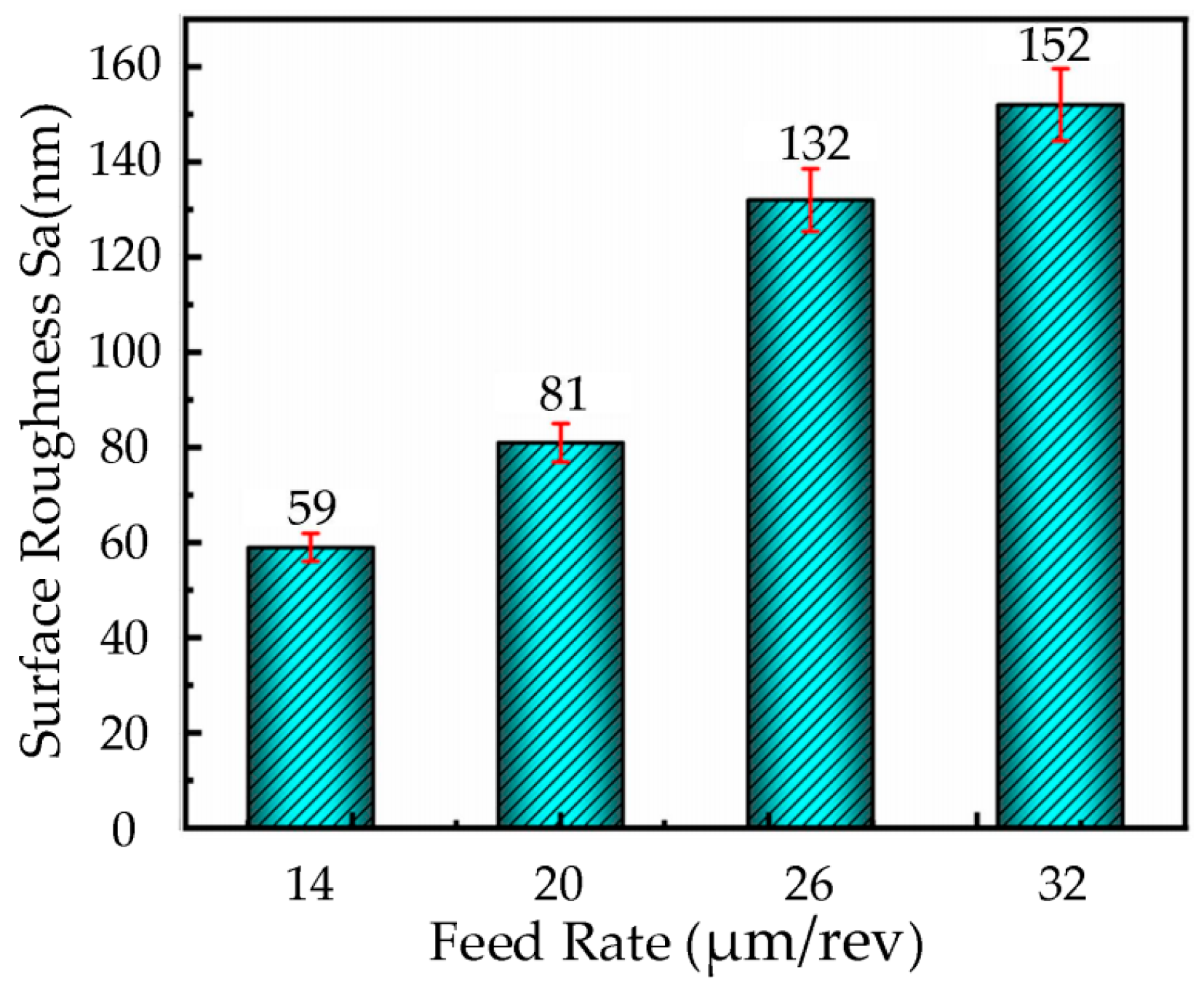

3.5.2. The Effect of Feed Rate on Surface Roughness

3.5.3. The Effect of Cutting Depth on Surface Roughness

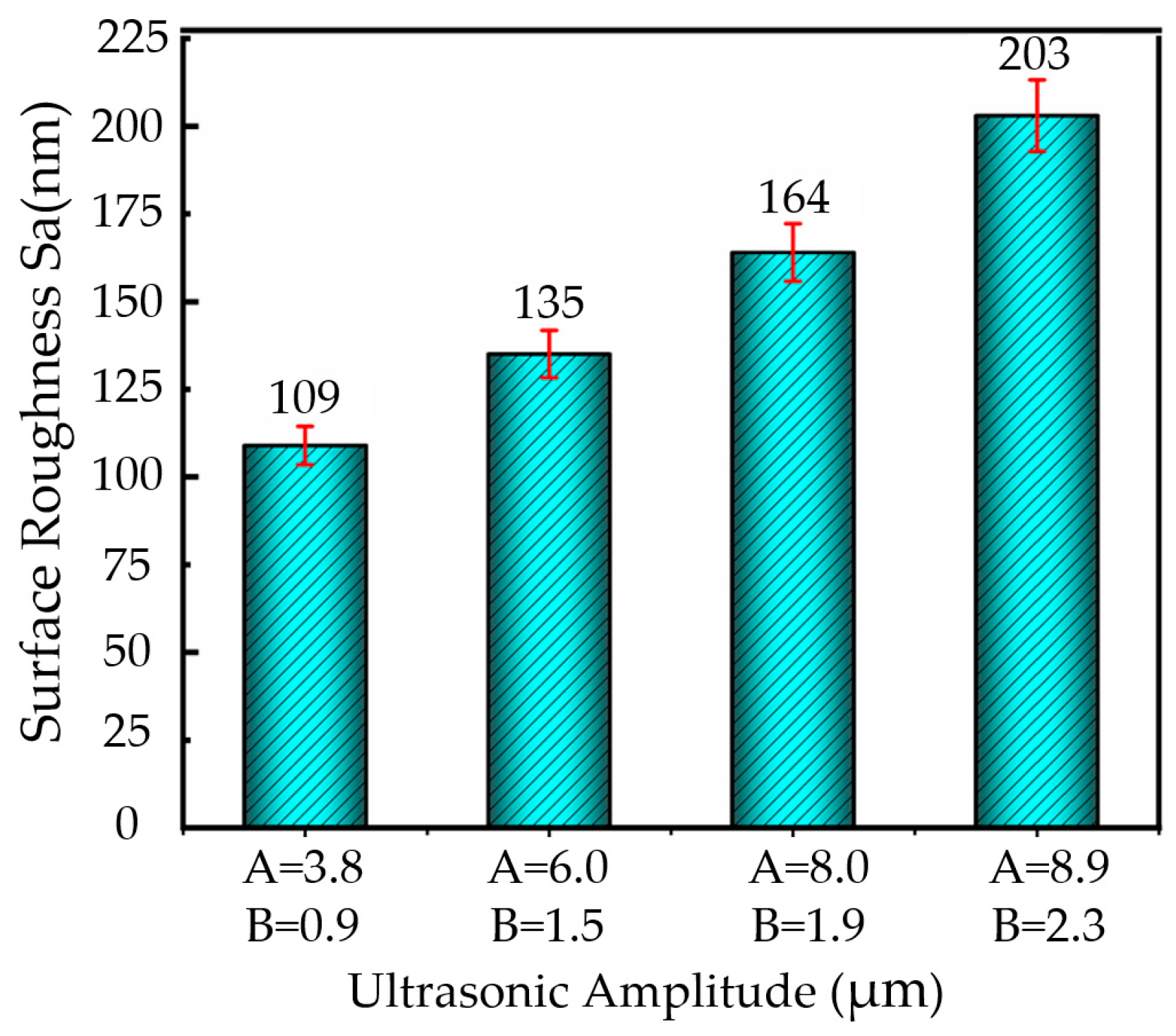

3.5.4. Effect of Ultrasonic Amplitude on Surface Roughness

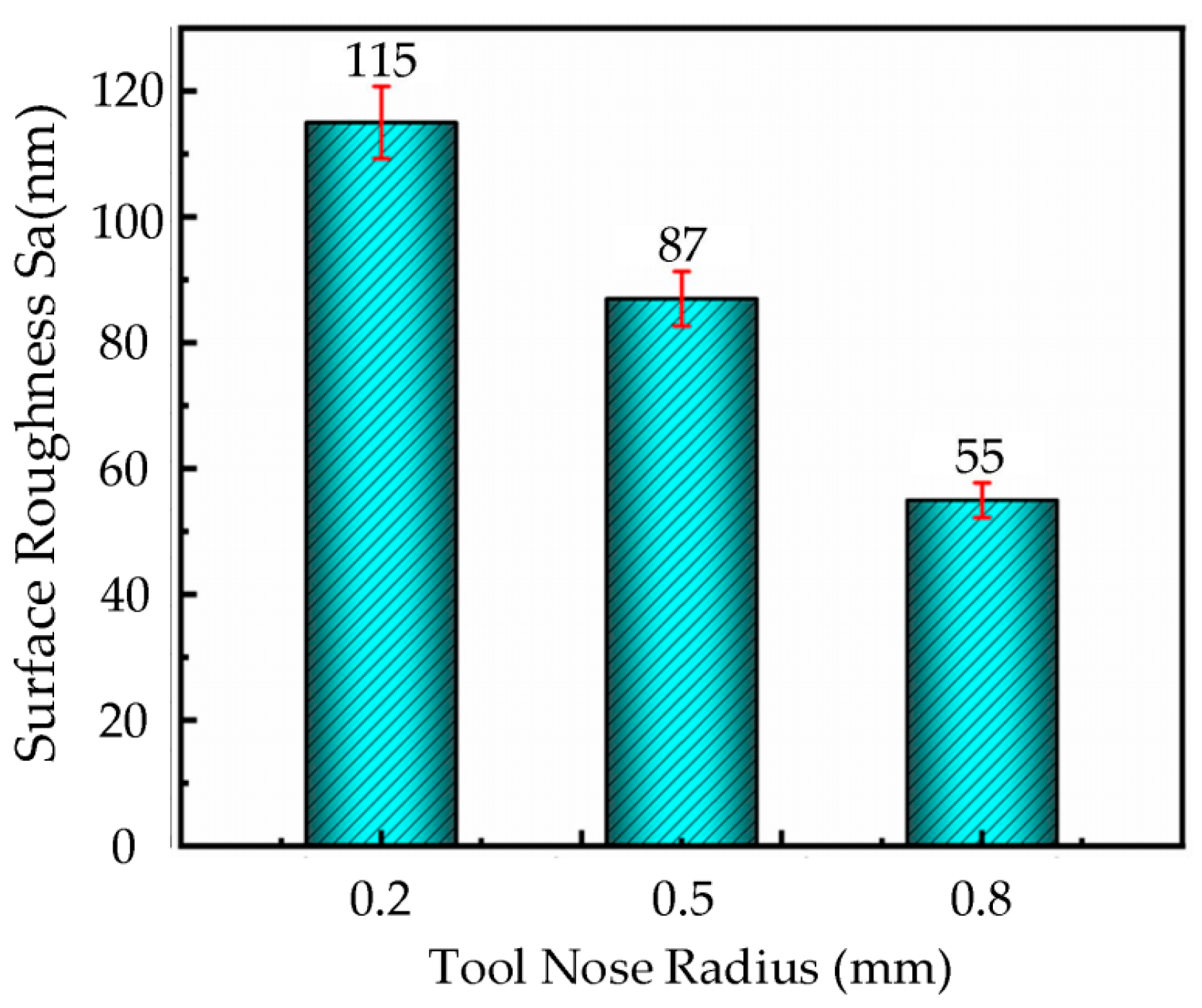

3.5.5. The Effect of Tool Nose Radius on Surface Roughness

3.6. Analysis of Surface Residual Stress in Ultrasonic Elliptical Vibration Cutting

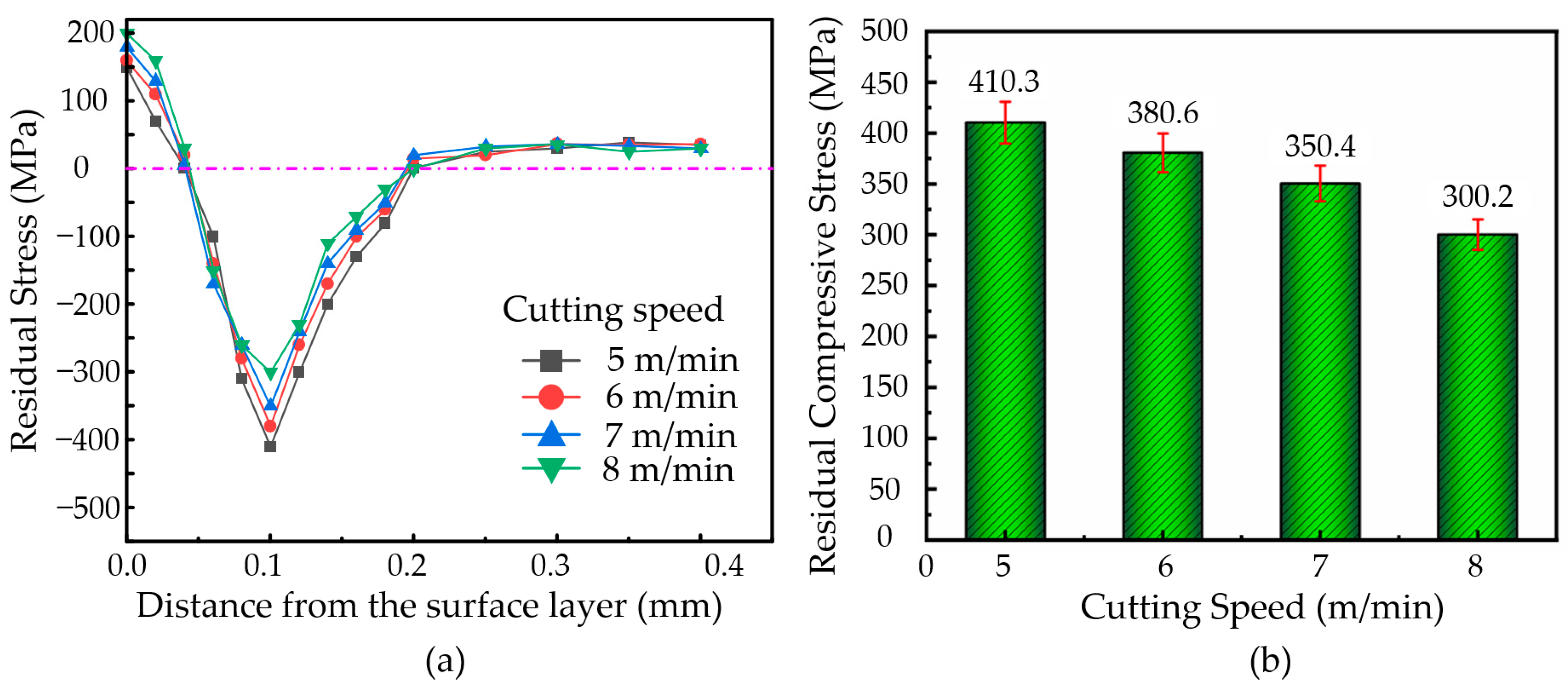

3.6.1. Effect of Cutting Speed on Residual Stress

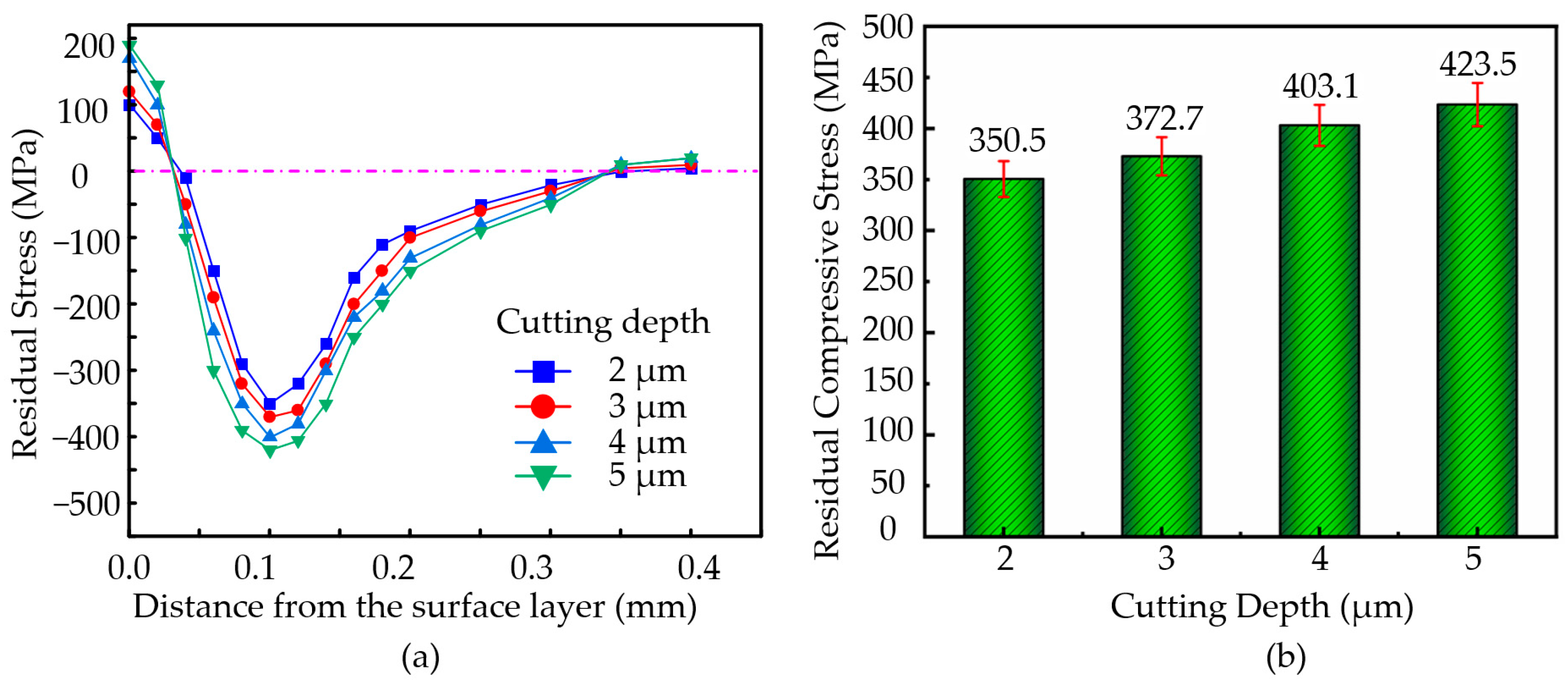

3.6.2. The Effect of Cutting Depth on Residual Stress

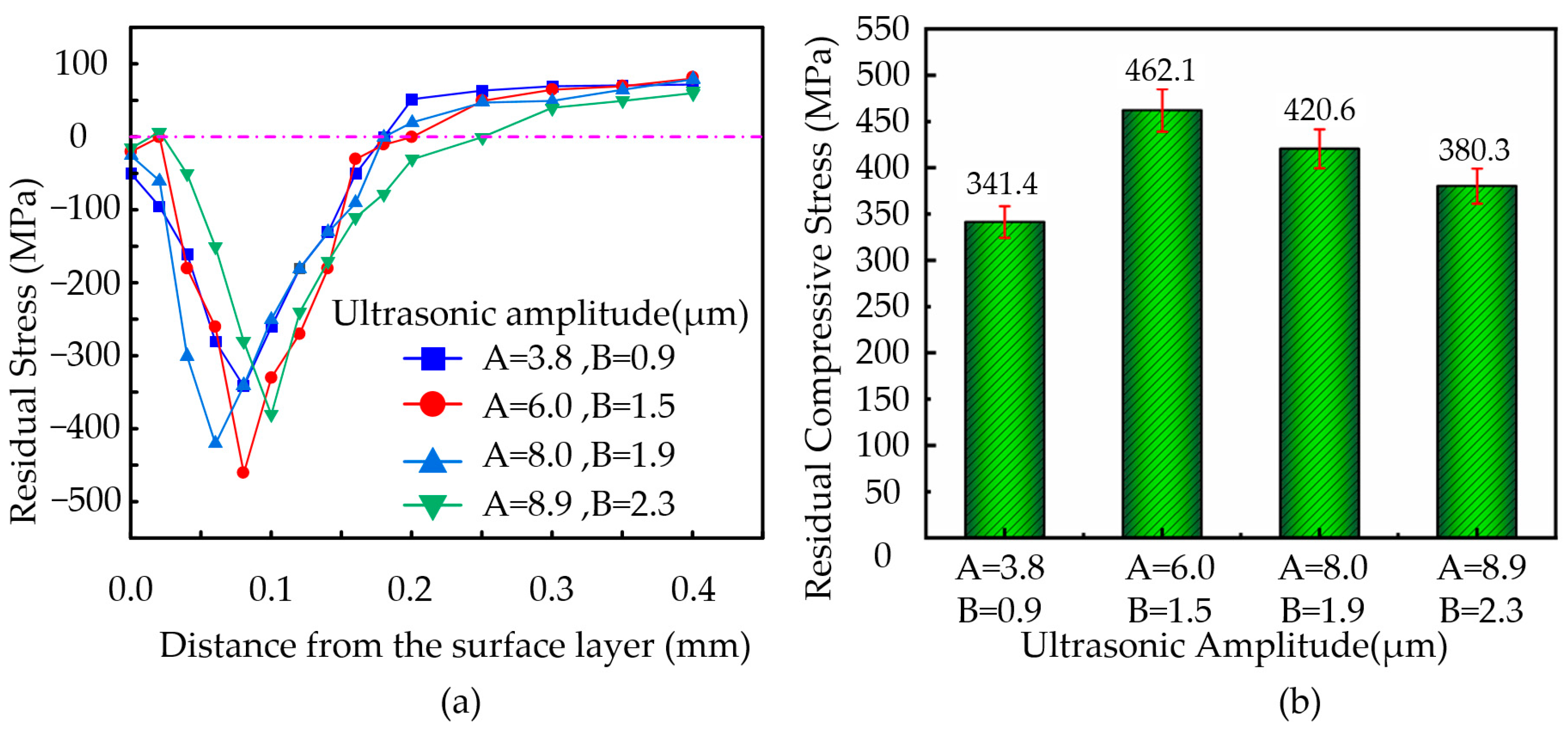

3.6.3. The Effect of Ultrasonic Amplitude on Residual Stress

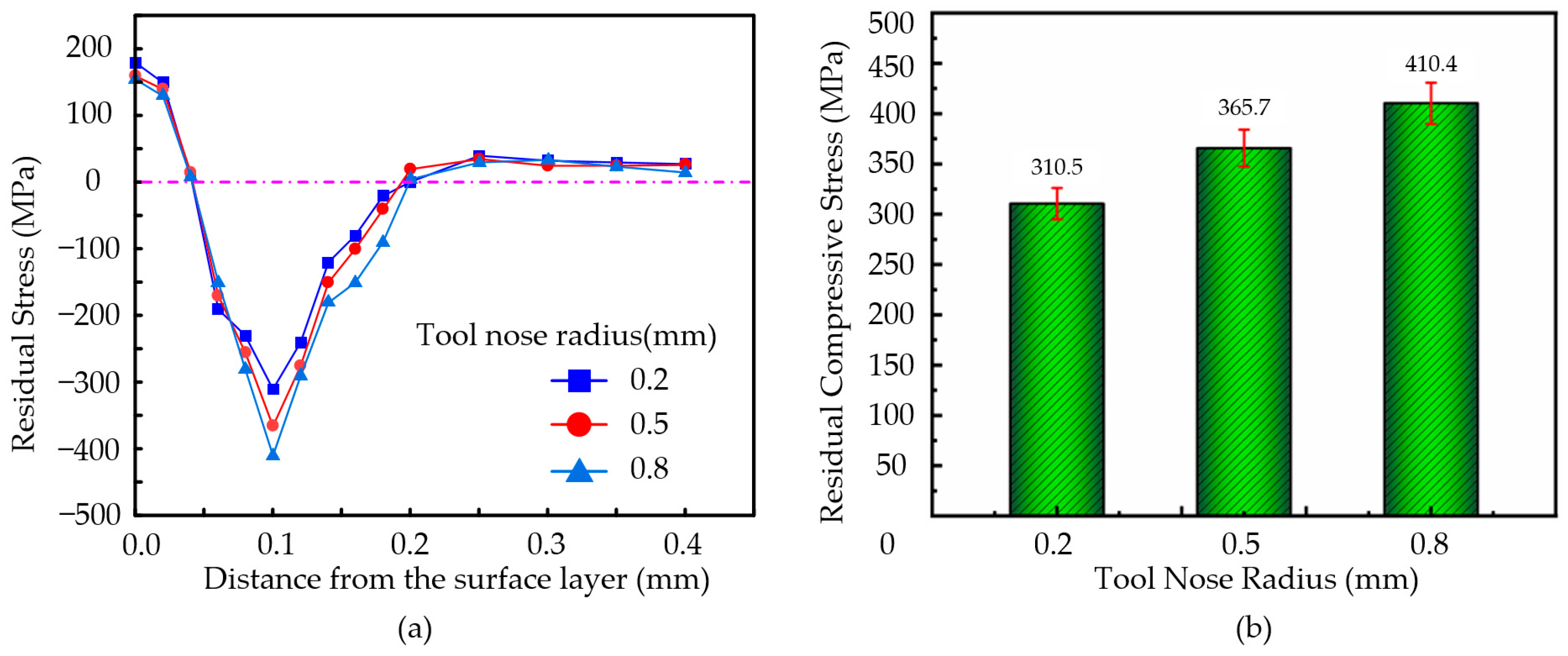

3.6.4. The Effect of Tool Tip Radius on Residual Stress

3.7. Analysis of Microhardness on the Surface of Ultrasonic Elliptical Vibration Cutting

3.7.1. Effect of Cutting Speed on Microhardness

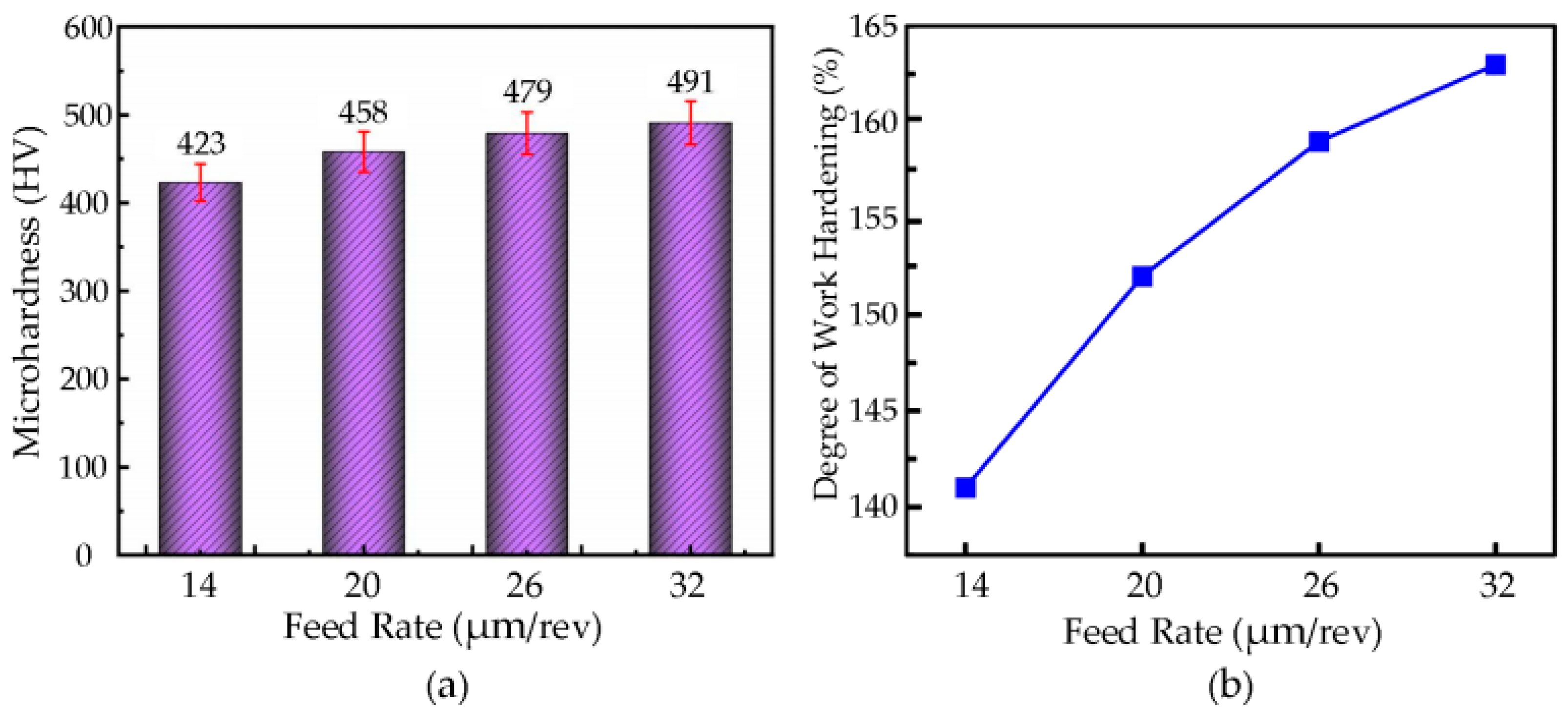

3.7.2. The Effect of Feed Rate on Microhardness

3.7.3. The Effect of Cutting Depth on Microhardness

3.7.4. The Effect of Ultrasonic Amplitude on Microhardness

4. Experiment on Surface Integrity of Ultrasonic Elliptical Vibration Cutting and Conventional Cutting

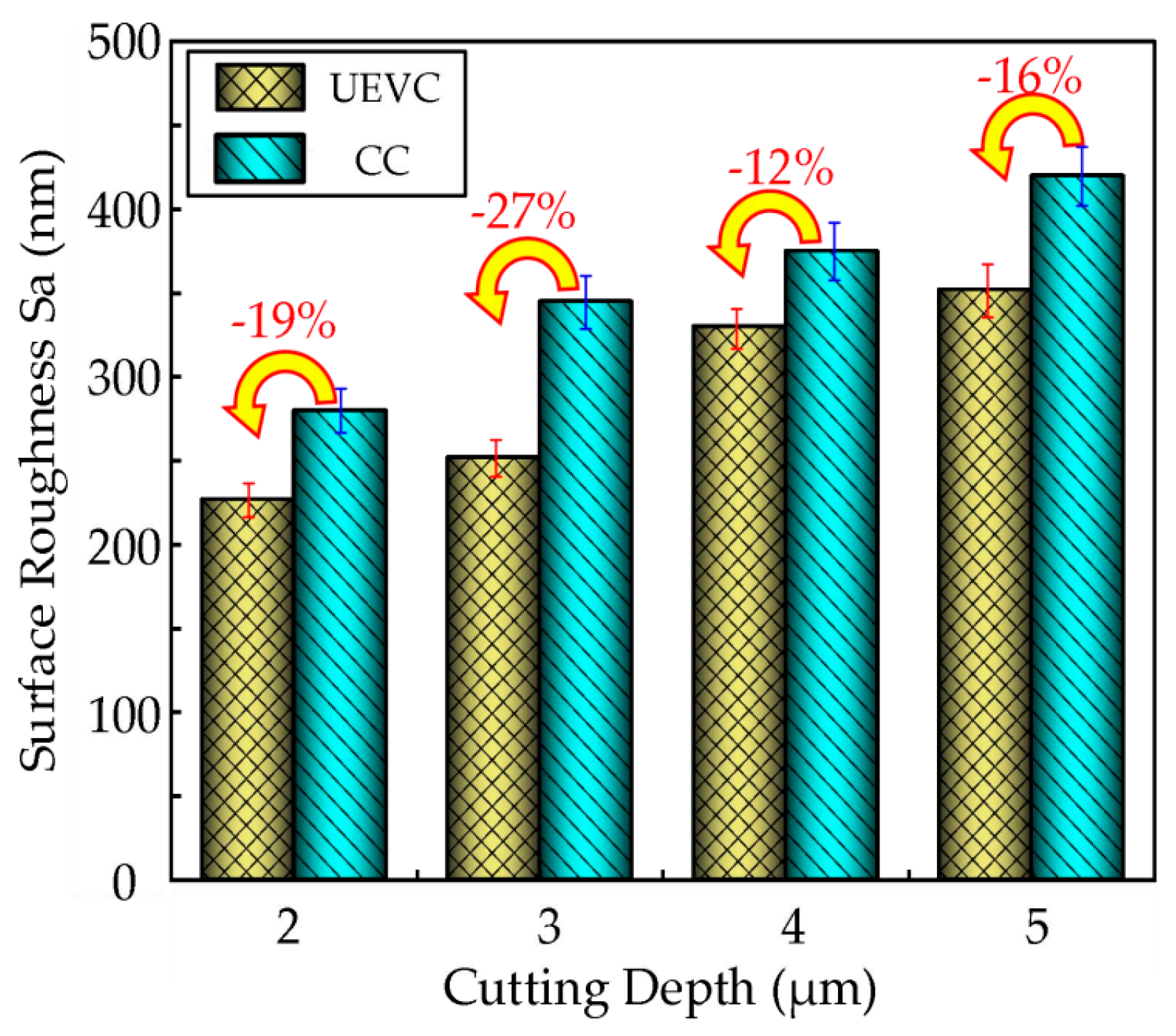

4.1. Comparison of Surface Roughness Between UEVC and CC

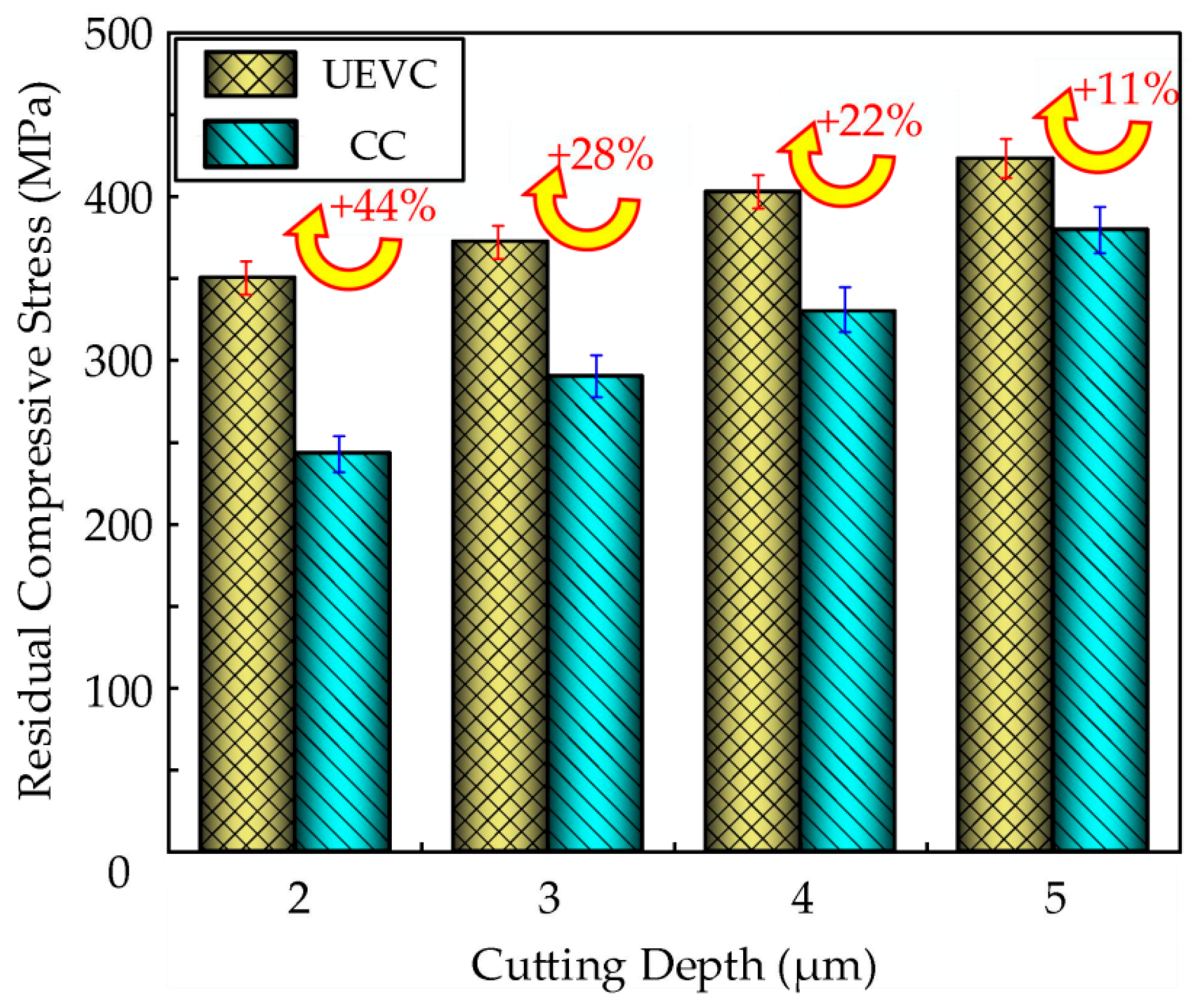

4.2. Comparison of Residual Stress on Surfaces Between UEVC and CC

4.3. Comparison of Surface Microhardness Between UEVC and CC

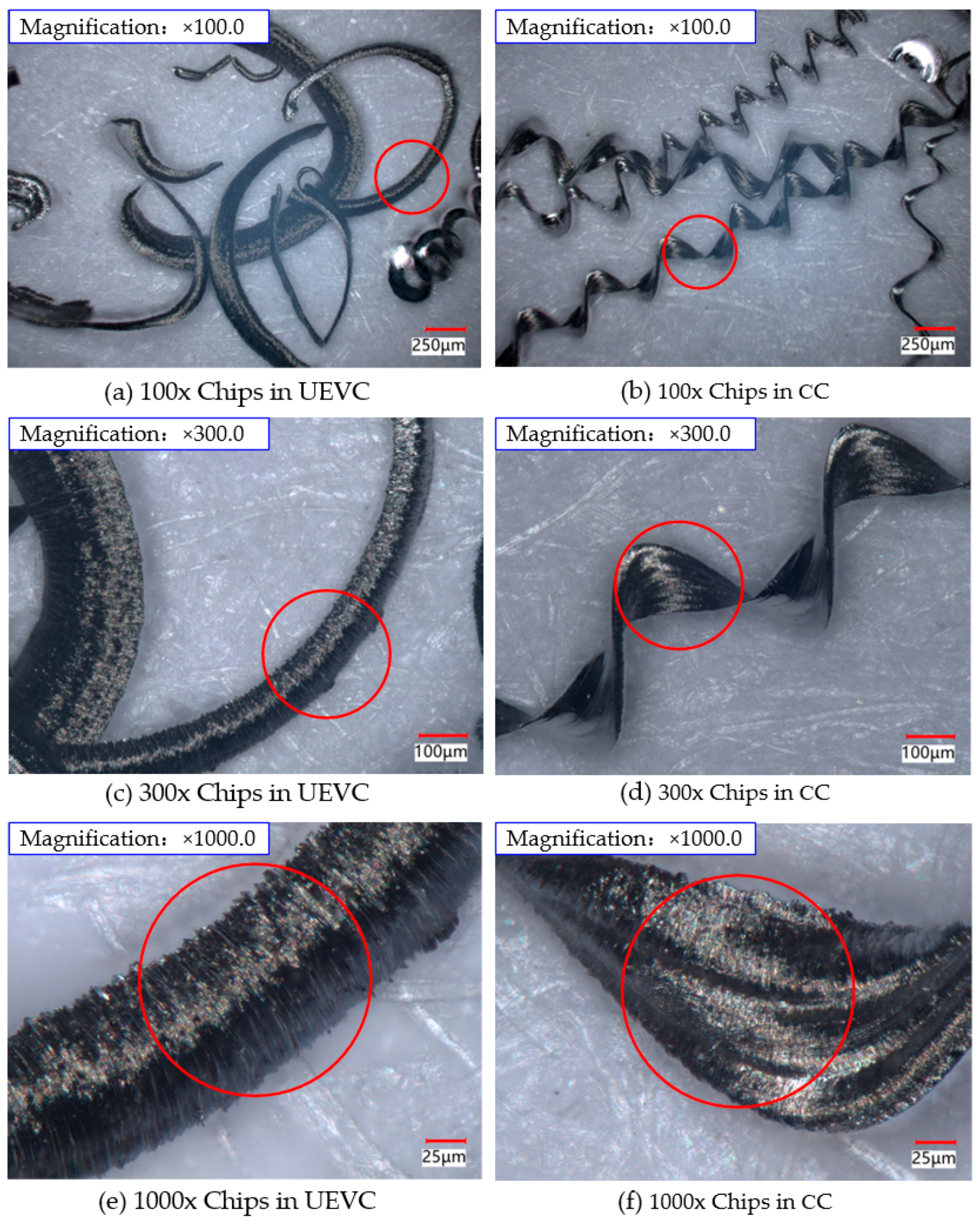

4.4. Comparison of Chip Morphology Between UEVC and CC

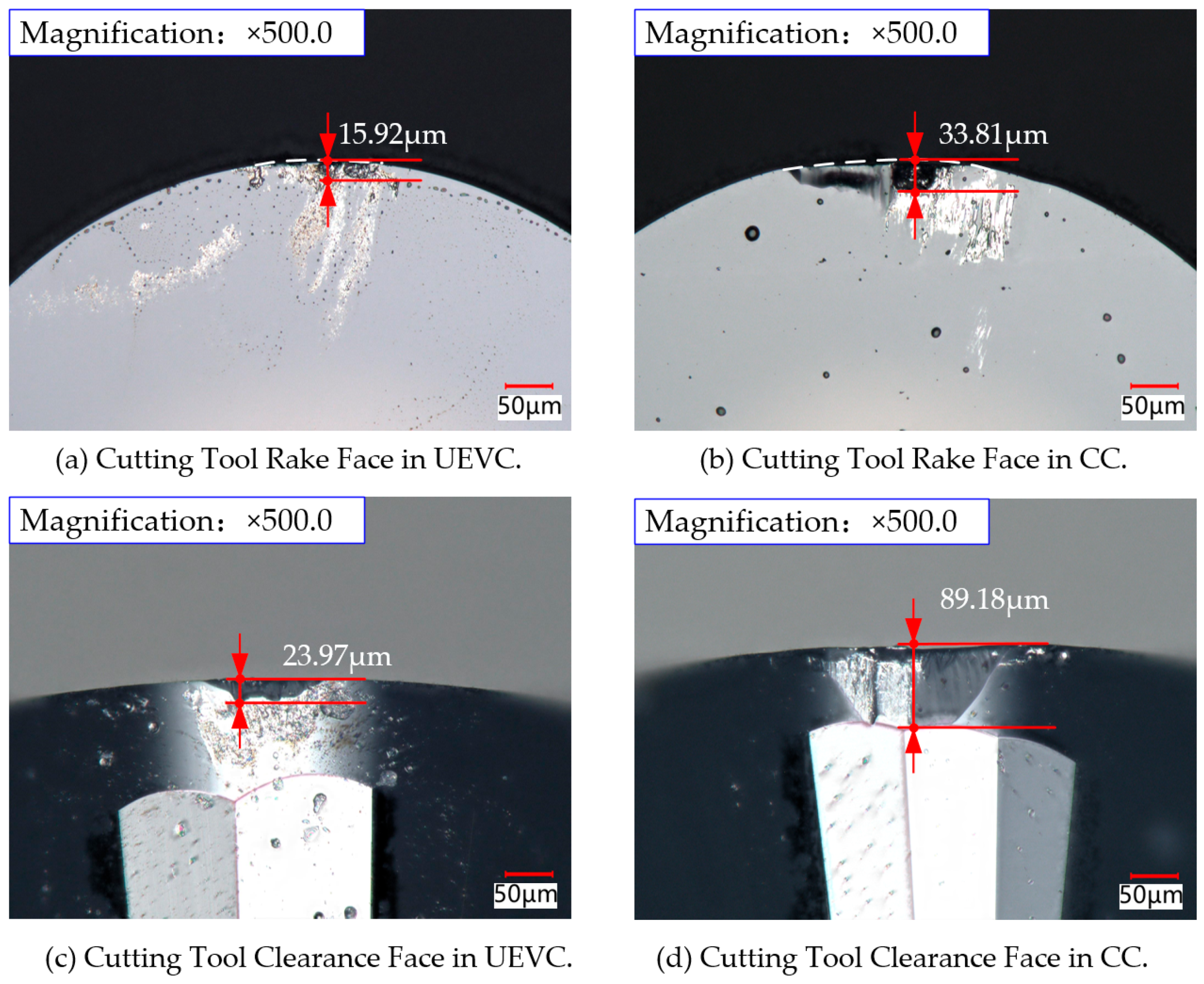

4.5. Comparison of Tool Wear Between UEVC and CC

5. Conclusions

- (1)

- The surface roughness of nickel-based superalloys under ultrasonic elliptical vibration cutting increases with the increase in the ultrasonic amplitude, cutting depth, and feed rate. It shows a trend of first decreasing and then increasing with the increase in the cutting speed, and decreases with the increase in the tool tip radius. Choosing an appropriate cutting speed, feed rate, cutting depth, ultrasonic amplitude, and tool tip radius can reduce the surface roughness by 62%, 61%, 36%, 46%, and 52%, respectively.

- (2)

- The residual compressive stress of the nickel-based superalloys under ultrasonic elliptical vibration cutting decreases with the increase in the cutting speed, while it increases with increased cutting depth and tool tip radius. It shows a trend of first increasing and then decreasing with the increase in ultrasonic amplitude. Choosing an appropriate cutting speed, cutting depth, ultrasonic amplitude, and tool tip radius can increase the residual compressive stress by 37%, 17%, 35%, and 32%, respectively.

- (3)

- The microhardness of the nickel-based superalloys under ultrasonic elliptical vibration cutting increases with the increase in feed rate, cutting depth, and ultrasonic amplitude, and it first decreases and then increases with the increase in cutting speed. Choosing an appropriate cutting speed, feed rate, cutting depth, and ultrasonic amplitude during precision machining can increase the microhardness by 32%, 16%, 35%, and 35%, respectively.

- (4)

- Compared with conventional cutting, ultrasonic elliptical vibration cutting has significant advantages in optimizing machining performance. At cutting depths of 2 µm, 3 µm, 4 µm, and 5 µm, the surface roughness decreased by about 19%, 27%, 12%, and 16%; the residual compressive stress increased by about 44%, 28%, 22%, and 11%; and the microhardness increased by 21%, 16%, 14%, and 10%, respectively. Meanwhile, the cutting tool wear reduced by approximately 53% under ultrasonic elliptical vibration cutting.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, S.J.; To, S.; Wang, S.J.; Zhu, Z.W. A review of surface roughness generation in ultra-precision machining. Int. J. Mach. Tools. Manuf. 2015, 91, 76–95. [Google Scholar] [CrossRef]

- Xiang, Y.; Xu, L.; Liao, P.F.; Shu, R.; Li, W.S.; Lu, D. Current status and development trends of ultrasonic vibration-assisted cutting technology for difficult-to-machine materials in aerospace. Tool Technol. 2018, 52, 8–11. [Google Scholar]

- Arunachalam, R.M.; Mannan, M.A.; Spowage, A.C. Residual stress and surface roughness when facing age hardened Inconel 718 with CBN and ceramic cutting tools. Int. J. Mach. Tools. Manuf. 2004, 44, 879–887. [Google Scholar] [CrossRef]

- Lv, S. Study on Surface Integrity in High-Speed Milling of Nickel-Based Superalloys. Master’s Thesis, Shandong University, Jinan, China, 2013. [Google Scholar]

- Huang, X.Q.; Liao, H.K. High-Temperature Alloys; Metallurgical Industry Press: Beijing, China, 2000; pp. 1–6. [Google Scholar]

- Tang, L.H.; Ma, F.R.; Hu, Y.J.; Zhang, J.H.; Sun, Y.J.; Li, B.D. Study on the surface quality of machined nickel-based superalloy steel using wide temperature range oil-based tri-phase mist cutting. Mod. Manuf. Eng. 2023, 1–9. [Google Scholar] [CrossRef]

- Zhang, X.F.; Yang, L.; Wang, Y.; Lin, B.; Dong, Y.H.; Shi, C. Mechanism study on ultrasonic vibration assisted face grinding of hard and brittle materials. J. Manuf. Process. 2020, 50, 520–527. [Google Scholar] [CrossRef]

- Pan, Y.A.; Bao, Y.; Feng, J.J.; Yin, S.; Dong, Z.G.; Kang, R.K. Study on the removal mechanism of high-density tungsten alloy in ultrasonic elliptical vibration cutting. J. Mech. Eng. 2023, 59, 65–74. [Google Scholar]

- Zhou, H. Design and Process Research of Ultrasonic Elliptical Vibration Turning System. Doctoral Dissertation, Guangdong University of Technology, Guangdong, China, 2022. [Google Scholar]

- Su, Q.; Su, G.S.; Shen, X.H.; Wang, B.L.; Du, J.; Zhang, P.R. Design of an ultrasonic elliptical vibration cutting tool based on an eccentric cone. Int. J. Adv. Manuf. Technol. 2023, 124, 1003–1016. [Google Scholar] [CrossRef]

- Wu, D.X.; Yao, C.F.; Zhao, L.; Hu, C.G. Study on surface roughness of GH4169 turned with ceramic tools. Aerosp. Manuf. Technol. 2012, 33–38. [Google Scholar] [CrossRef]

- Liu, T. Study on the Optimization of Internal Cooling Tool Micro-Lubrication Cutting Process for GH4169. Master’s Thesis, Xiangtan University, Xiangtan, China, 2017. [Google Scholar]

- Ning, P.X.; Zhao, J.; Ji, S.S.; Li, J.J.; Dai, H.D. Simulation and experiment on surface topography of complex surface in single point diamond turning based on determined tool path. Int. J. Adv. Manuf. Technol. 2021, 113, 2555–2562. [Google Scholar] [CrossRef]

- Yao, C.F.; Chen, G.C.; Wu, N.N.; Li, X.C. Study on the thermo-mechanical coupling and residual stress field in the turning process of GH4169. Aerosp. Manuf. Technol. 2017, 42–47. [Google Scholar] [CrossRef]

- Madariaga, A.; Esnaola, J.A.; Fernandez, E.; Arrazola, P.J.; Garay, A.; Morel, F.; Morel, F. Analysis of residual stress and work-hardened profiles on Inconel 718 when face turning with large-nose radius Tools. Int. J. Adv. Manuf. Technol. 2014, 71, 1587–1598. [Google Scholar] [CrossRef]

- Sharman, A.R.C.; Hughes, J.I.; Ridgway, K. The effect of tool nose radius on surface integrity and residual stresses when turning Inconel 718 TM. J. Mater. Process. Tech. 2015, 216, 123–132. [Google Scholar] [CrossRef]

- Du, H.; Yin, N.D. Residual stress simulation analysis of turning nickel-based alloy GH4169 based on AdvantEdge. J. Hubei Univ. Sci. Technol. 2014, 30, 11–15. [Google Scholar]

- Ni, C.B.; Zhu, J.J.; Zhang, B.G.; An, K.; Wang, Y.Q.; Liu, D.J.; Lu, W.; Zhu, L.D.; Liu, C.F. Recent advance in laser powder bed fusion of Ti–6Al–4V alloys: Microstructure, mechanical properties and machinability. Virtual Phys. Prototyp. 2025, 20, e2446952. [Google Scholar] [CrossRef]

- Pawade, R.S.; Joshi, S.S.; Brahmankar, P.K. Effect of machining parameters and cutting edge geometry on surface integrity of high-speed turned Inconel 718. Int. J. Mach. Tools. Manuf. 2008, 48, 15–28. [Google Scholar] [CrossRef]

- Sun, S.F.; Zhao, J.; Yuan, W.J.; Xi, W.; Zhao, C. Study on surface work hardening of GH4169 nickel-based superalloy. Tool. Technol. 2016, 50, 24–27. [Google Scholar]

- Nath, C.; Rahman, M.; Neo, K.S. Machinability study of tungsten carbide using PCD tools under ultrasonic elliptical vibration cutting. Int. J. Mach. Tools. Manuf. 2009, 49, 1089–1095. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Nb | Mo | Ti | Al | C | Si | Mn | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Wt (%) | 51.75 | 17 | 5.15 | 2.93 | 1.07 | 0.45 | 0.042 | 0.21 | 0.03 | surplus |

| Workpiece | Density ρ (kg/m3) | Hardness (HB) | Yield Strength σ0.2 (MPa) | Tensile Strength σb (MPa) | Elongation δs (%) | Shrinking Percentage ψ (%) |

|---|---|---|---|---|---|---|

| GH4169 | 8280 | 300 | 1260 | 1430 | 24 | 40 |

| No. | Cutting Speed v/(m/min) | Cutting Depth ap/(µm) | Feed Rate f/(µm/rev) | Ultrasonic Amplitude A, B/(µm) | Tool Nose Radius re/(mm) |

|---|---|---|---|---|---|

| 1 | 5 | 2 | 22 | A = 7.0, B = 1.7 | 0.5 |

| 2 | 6 | 2 | 22 | A = 7.0, B = 1.7 | 0.5 |

| 3 | 7 | 2 | 22 | A = 7.0, B = 1.7 | 0.5 |

| 4 | 8 | 2 | 22 | A = 7.0, B = 1.7 | 0.5 |

| 5 | 7 | 2 | 36 | A = 7.0, B = 1.7 | 0.5 |

| 6 | 7 | 3 | 36 | A = 7.0, B = 1.7 | 0.5 |

| 7 | 7 | 4 | 36 | A = 7.0, B = 1.7 | 0.5 |

| 8 | 7 | 5 | 36 | A = 7.0, B = 1.7 | 0.5 |

| 9 | 6 | 3.5 | 14 | A = 7.0, B = 1.7 | 0.5 |

| 10 | 6 | 3.5 | 20 | A = 7.0, B = 1.7 | 0.5 |

| 11 | 6 | 3.5 | 26 | A = 7.0, B = 1.7 | 0.5 |

| 12 | 6 | 3.5 | 32 | A = 7.0, B = 1.7 | 0.5 |

| 13 | 8 | 2 | 36 | A = 3.9, B = 0.9 | 0.5 |

| 14 | 8 | 2 | 36 | A = 6.0, B = 1.5 | 0.5 |

| 15 | 8 | 2 | 36 | A = 8.0, B = 1.9 | 0.5 |

| 16 | 8 | 2 | 36 | A = 8.9, B = 2.3 | 0.5 |

| 17 | 6 | 2.5 | 18 | A = 7.0, B = 1.7 | 0.2 |

| 18 | 6 | 2.5 | 18 | A = 7.0, B = 1.7 | 0.5 |

| 19 | 6 | 2.5 | 18 | A = 7.0, B = 1.7 | 0.8 |

| No. | Experimental Parameters | ||||

|---|---|---|---|---|---|

| Cutting Speed v/(m/min) | Cutting Depth ap/(µm) | Feed Rate f/(µm/rev) | Ultrasonic Amplitudes A, B/(µm) | Tool Nose Radius re/(mm) | |

| UEVC | 5 | 2, 3, 4, 5 | 22 | A = 7.0, B = 1.7 | 0.5 |

| CC | 5 | 2, 3, 4, 5 | 22 | 0 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, G.; Lu, Y.; Zhou, S.; Zhang, M.; He, X.; Zhang, F.; Chen, G. Experimental Study on Surface Integrity of Nickel-Based Superalloy in Ultrasonic Elliptical Vibration Cutting. Micromachines 2025, 16, 728. https://doi.org/10.3390/mi16070728

Hu G, Lu Y, Zhou S, Zhang M, He X, Zhang F, Chen G. Experimental Study on Surface Integrity of Nickel-Based Superalloy in Ultrasonic Elliptical Vibration Cutting. Micromachines. 2025; 16(7):728. https://doi.org/10.3390/mi16070728

Chicago/Turabian StyleHu, Gaofeng, Yanjie Lu, Shengming Zhou, Min Zhang, Xin He, Fenghui Zhang, and Guangjun Chen. 2025. "Experimental Study on Surface Integrity of Nickel-Based Superalloy in Ultrasonic Elliptical Vibration Cutting" Micromachines 16, no. 7: 728. https://doi.org/10.3390/mi16070728

APA StyleHu, G., Lu, Y., Zhou, S., Zhang, M., He, X., Zhang, F., & Chen, G. (2025). Experimental Study on Surface Integrity of Nickel-Based Superalloy in Ultrasonic Elliptical Vibration Cutting. Micromachines, 16(7), 728. https://doi.org/10.3390/mi16070728