1. Introduction

Microfluidics is a rapidly developing and widely applied discipline. In the fast-evolving landscape of Lab-on-a-Chip (LOC) technology, microfluidic systems have found applications in various fields, including biomedical diagnostics, drug delivery, chemical synthesis, and enzyme reactions [

1]. LOC devices integrate multiple functionalities within a chip, encompassing tasks such as mixing, reactions, separation, and analysis [

2]. Micromixers, as crucial components of microfluidic systems, serve the purpose of blending two or more samples for subsequent processes [

3]. The efficiency of mixing can directly impact the overall performance of the system [

4]. However, achieving rapid mixing in microfluidics presents challenges due to the predominantly laminar flow at low Reynolds numbers within microchannels. Weak convective flow and high surface tension within the fluids limit convective mixing [

5], relying predominantly on molecular diffusion [

6], which is an inefficient mode of mixing [

7]. This necessitates longer channels to achieve uniform mixing [

8]. Based on existing research on micromixers, they can be categorized as active mixers and passive mixers, depending on whether external energy input is required [

9].

Over the past three decades, microfluidic mixing has evolved through landmark designs, including active mixers (e.g., acoustic [

10], magnetic [

11], etc.) and passive mixers (e.g., lamination [

12], chaotic convection [

13], and droplet-based [

14] methods). Active mixers, while effective, face limitations such as complex fabrication, external energy dependence, and potential damage to sensitive biomolecules [

9]. Recent innovations in active mixing have demonstrated remarkable capabilities, particularly surface acoustic wave (SAW) technologies coupled with bubble-induced streaming. These hybrid approaches achieve mixing times under 100 ms through bubble oscillation and acoustic streaming synergies. However, they require complex transducer arrays and precise bubble size control [

15], limiting their scalability compared to passive systems. Passive mixers, though simpler, often struggle to achieve rapid mixing at low Reynolds numbers (Re < 10) due to weak convective flows and reliance on molecular diffusion [

5,

6,

7]. For instance, serial lamination mixers [

16] perform well at moderate Re (10–70) but fail in low-Re regimes [

17], while chaotic convection mixers [

13] require intricate geometries prone to clogging [

18]. Modern chaotic mixers have evolved beyond traditional geometries, incorporating 3D fractal structures that achieve 90% mixing within 5 mm at Re = 0.5 [

19]. While effective, these designs often require advanced fabrication techniques like multi-layer lithography, presenting manufacturing challenges our planar design avoids. Droplet-based mixers [

14,

20,

21] leverage Taylor flow vortices and chaotic advection, yet systematic studies on optimizing inlet conditions (e.g., flow rates, gas pressure) for low-Re applications remain scarce [

22,

23].

Despite these advances, key challenges persist: (1) achieving high mixing efficiency (>90%) at ultra-low Re (<5) without complex geometries or external energy inputs; (2) minimizing mixing length (<5 cm) and time (<1 s) for portable LOC devices; and (3) bridging the gap between theoretical models and practical, scalable designs. Recent work by Pinho et al. [

24] highlights the potential of Dean-Taylor flows, but their focus on bi-phasic systems leaves room for optimizing single-phase-like droplet mixing. These challenges are particularly critical for three emerging applications: (1) point-of-care blood testing requiring gentle mixing of viscous whole blood (Re ≈ 1) in compact devices; (2) microfluidic protein synthesis where faster mixing prevents protein misfolding; (3) portable environmental monitoring needing <1 s mixing for rapid pollutant detection.

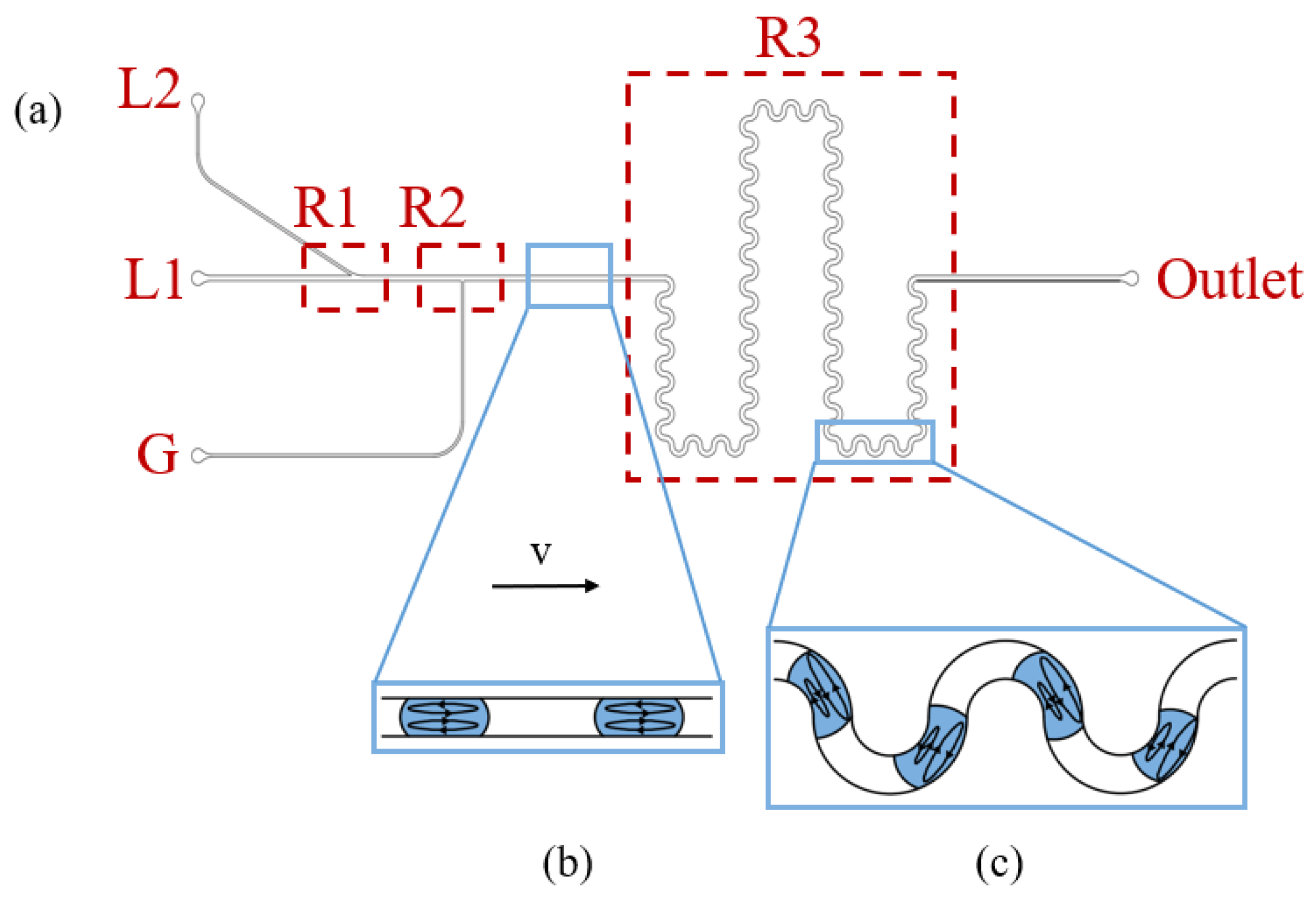

Here, we address these gaps by integrating Taylor flow vortices with chaotic convection in serpentine channels, enabling rapid mixing (≥95% efficiency) within 2 cm and 0.5–0.8 s at Re = 0.57–1.05. Our design departs from prior work as follows: (1) by systematically mapping inlet conditions (liquid flow rate, gas pressure) to droplet length and mixing efficiency; (2) combining T-junction and serpentine geometries in a monolithic, clog-resistant PMMA chip; and (3) demonstrating performance superior to classic designs [

22,

25] and recent alternatives [

24]. The mixer developed in this study, operating at low Reynolds numbers, is particularly suitable for applications requiring gentle fluid handling, such as point-of-care diagnostics (e.g., blood analysis), sensitive biochemical reactions, and microorganism cultivation. This Re range enables efficient mixing while minimizing shear stress, making it ideal for processing delicate biological samples and shear-sensitive fluids. The target performance thresholds (≥95% efficiency in 0.5–0.8 s) are derived from the following: (i) WHO ASSURED standards requiring <1 s mixing for point-of-care diagnostics [

26], (ii) nanoparticle synthesis needing >90% efficiency for PDI <0.2 [

27], and (iii) JIS K 0129 environmental protocols mandating 95% homogeneity [

24]. This approach balances simplicity, scalability, and performance, making it ideal for low-Re applications in diagnostics and chemical synthesis.

3. Results and Discussion

According to the research of Peng et al., the length of the droplets (

) and the total flow rate (

) jointly determine the mixing characteristics inside the droplet [

23]. Among these factors, the droplet length is influenced by the injection conditions, liquid viscosity, channel geometry, and surface properties [

32]. For this study, liquid viscosity, channel geometry, and surface properties were assumed to be fixed, so this paper primarily investigated the influence of gas–liquid injection conditions on droplet length and total flow rate. We initially determined the range of liquid flow rate and gas pressure for generating Taylor flow and compared the mixing efficiency between Taylor flow and single-phase flow in the mixer. Additionally, we conducted experimental studies to investigate the impact of liquid flow rate and gas pressure on droplet length, total flow rate, and mixing efficiency.

3.1. Define the Range of Liquid Flow Rate and Gas Pressure to Generate Taylor Flow

The ability to generate Taylor flow is a prerequisite for achieving efficient mixing in the mixer. Controlling the liquid and gas within the microchannel is critical for generating Taylor flow. Therefore, it is necessary to study the range of inlet liquid flow rate and gas pressure for generating Taylor flow.

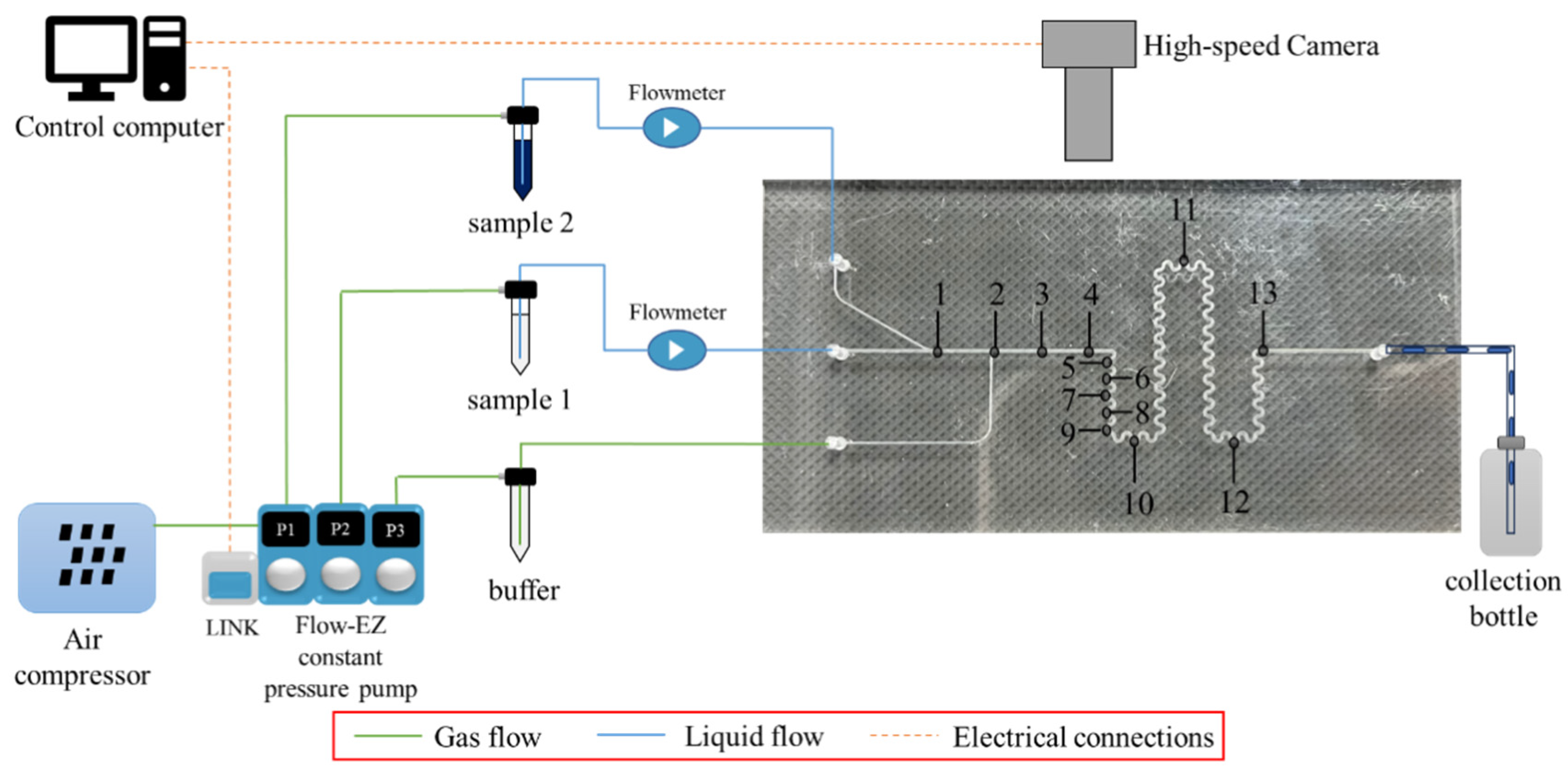

According to the research by Günther et al. [

33], when the apparent flow velocity of liquid (

) is 0.001~0.02 m/s, and the apparent flow velocity of gas (

) is 0.001~0.1 m/s, mixing occurs inside the droplet. Based on the cross-sectional area of the chip’s channels (

μm

2), the corresponding flow rates calculated from the equation

are

= 2.7–54

and

. The adjustment range of the total liquid inlet flow rate during the experiment was set to be 0–50 µL/min and the adjustment range of the gas pressure is 0–1000 mbar. Upon summarizing the preliminary experimental results, it was observed that as the total liquid flow rate and gas pressure changed, the flow pattern in the microchannel changed in four stages, as depicted in

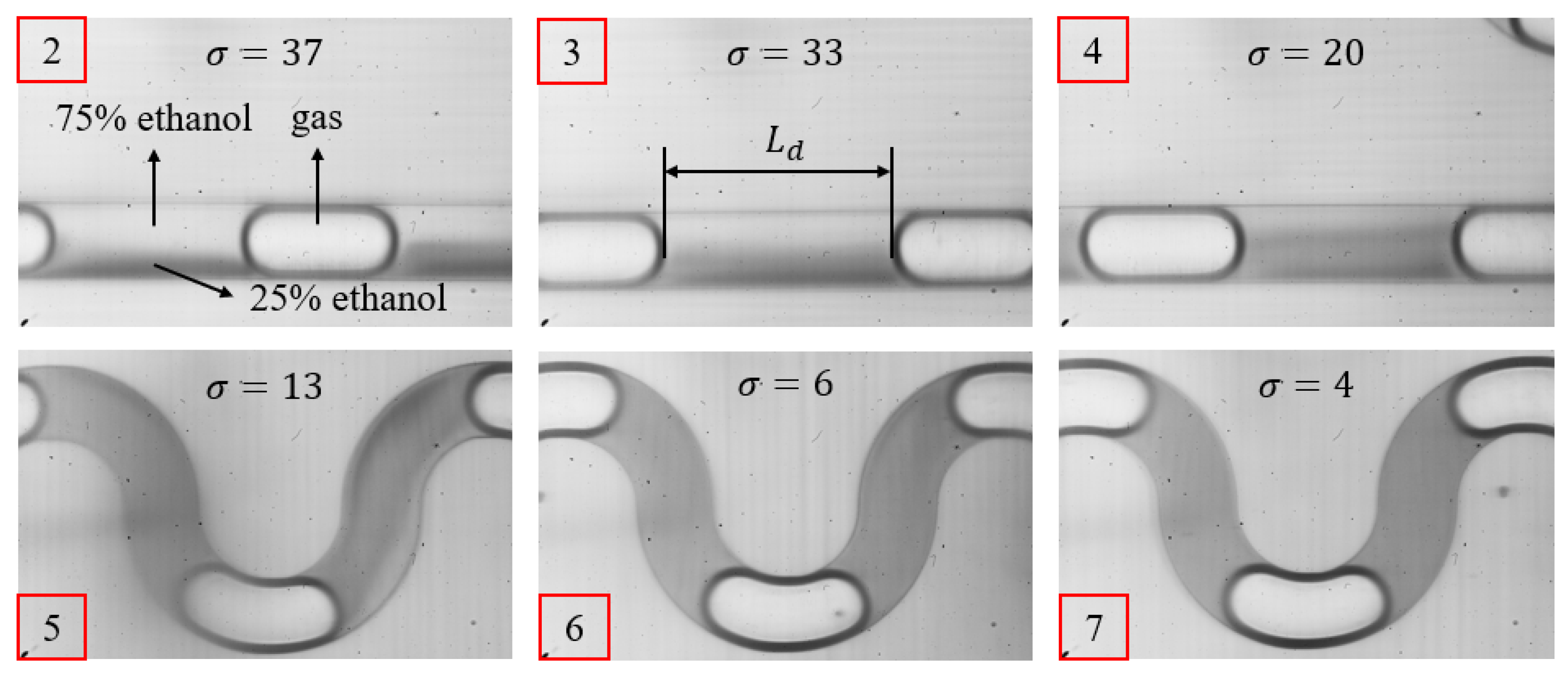

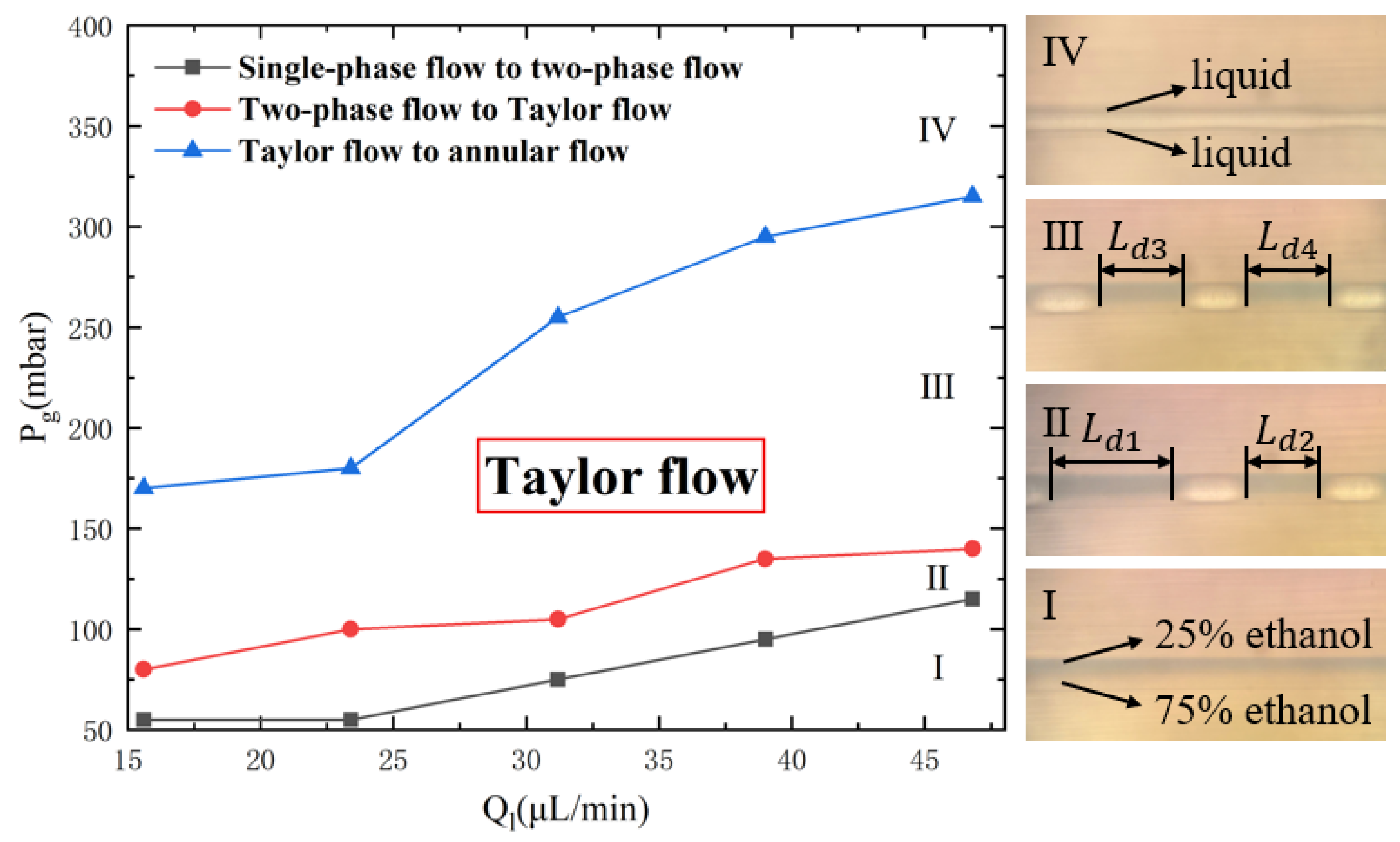

Figure 4.

Stage I: Single-phase Flow Stage. At this stage, the gas pressure is insufficient, and the liquid flows into the gas inlet channel. The input conditions can only generate single-phase flow and cannot generate Taylor flow. There are only liquids in the channel, as shown in

Figure 4, the upper blue liquid is a 25% ethanol solution, and the lower liquid is a 75% ethanol solution.

Stage II: Two-phase Flow Stage. At this stage, the gas pressure is insufficient to establish a stable Taylor flow, and it only restrains the liquid flow at the mouth of the T-shaped channel. The resulting flow pattern of stage II is like that of stage III, but the two-phase flow exhibits an unstable state, producing droplets of varying lengths, as can be clearly seen from

Figure 4,

.

Stage III: Taylor Flow Stage. At this stage, the gas pressure is approximately balanced with the liquid flow resistance. The Taylor flow is relatively stable, and the lengths of droplets are generally uniform, as can be clearly seen from

Figure 4,

. Effective control of droplet length can be achieved by adjusting the gas pressure and liquid flow rate.

Stage IV: Annular Flow Stage. At this stage, further increasing the gas pressure causes a transition from Taylor flow to annular flow, where the gas flows out from the center of the channel, and the liquid adheres to the wall of the channel.

The transition from unstable two-phase flow (Stage II) to the stable Taylor flow (Stage III) was determined by two quantitative metrics: the droplet length variation coefficient (Cv): Stage II: Cv > 15% (non-uniform droplets); Stage III: Cv ≤ 10% (stable Taylor flow) and pressure fluctuation amplitude: Stage II: ΔP/Pavg > 8%; Stage III: ΔP/Pavg ≤ 5%. During the generation of the Taylor flow, both the liquid flow rate and gas pressure have an impact on the length of the droplet, affecting the mixing efficiency. Therefore, experiments were designed to investigate the influence of liquid flow rate and gas pressure on mixing efficiency.

3.2. The Comparison of Mixing Efficiency Between Taylor Flow and Single-Phase Flow

While the low Re suggests laminar flow, established mechanisms enable chaotic convection: (1) curvature-induced Dean vortices, (2) periodic perturbation from serpentine turns, and (3) droplet-internal vortex asymmetry [

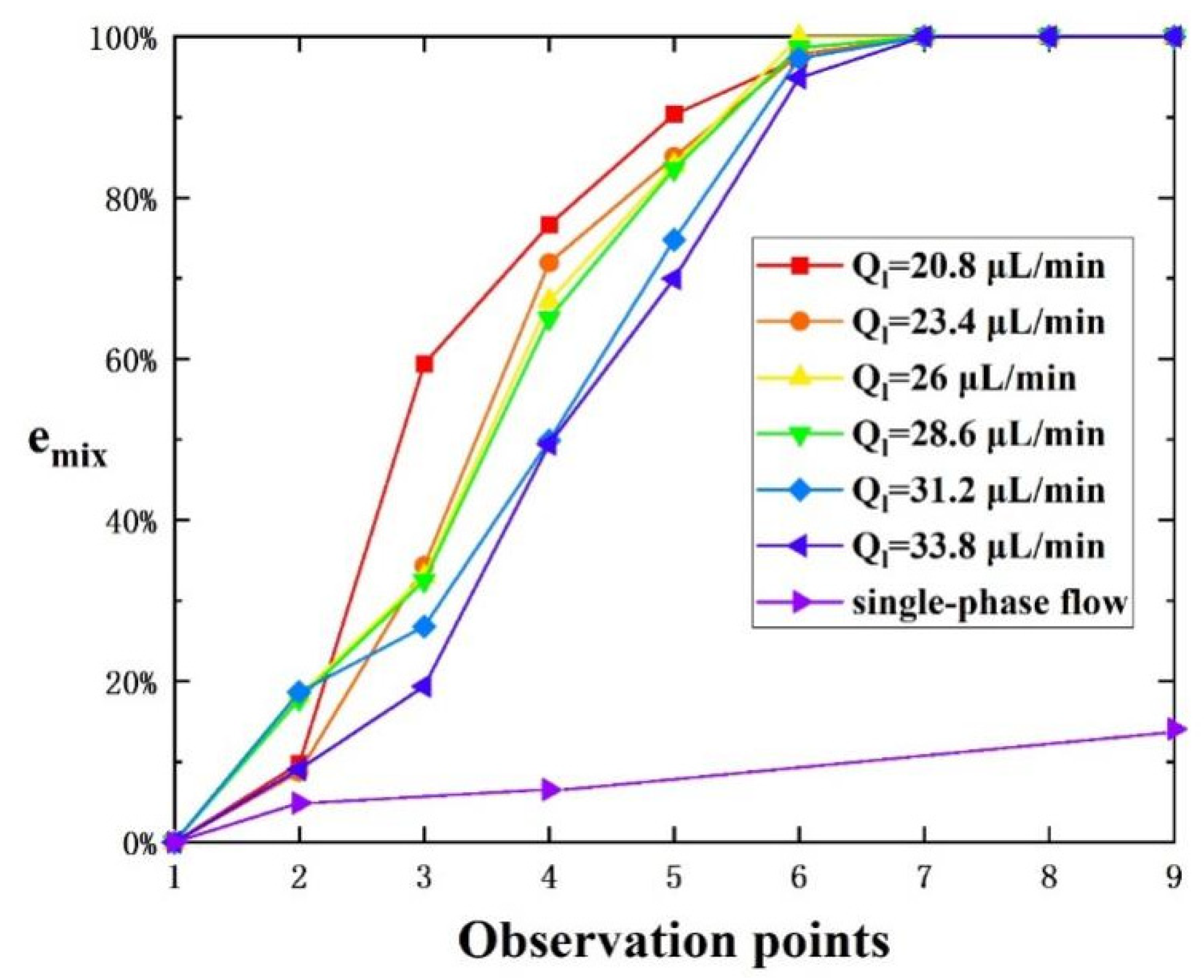

34]. These collectively produce Lagrangian chaos as evidenced by our mixing efficiency (9× straight channel), matching theoretical predictions for chaotic advection. As shown in

Figure 4, when the flow pattern in the microchannel was in Stage I, the gas pressure was relatively low, and the gas could not enter the main channel of the mixer, resulting in single-phase flow inside the microchannel. With the continuous increase in gas pressure, when the gas–liquid injection conditions were in Stage III, the Taylor flow was generated within the microchannel. At an inlet gas pressure of 110 mbar, the Taylor flow was generated at various inlet total liquid flow rates of 20.8 µL/min, 23.4 µL/min, 26 µL/min, 28.6 µL/min, 31.2 µL/min, and 33.8 µL/min. The corresponding Reynolds number Re, ranged from 0.57 to 1.05, calculated from

, where

is density,

is the average velocity,

is the hydraulic diameter,

is dynamic viscosity. The mixing efficiency of the Taylor flow and single-phase flow at

at observation points 1–9 is shown in

Figure 5. It was evident that the droplet generated by the Taylor flow at any inlet liquid flow rate achieved complete mixing at observation point 7, that is, the distance required for the droplet to achieve complete mixing from the generation of the Taylor flow at observation point 2 was not more than 2 cm. While the mixing efficiency of single-phase flow at observation point 7 was less than 20% and the single-phase flow was not fully mixed at observation point 13 (i.e., the end of the channel). The observation point 4 is located at the end of the straight channel, where the mixing efficiency of the Taylor flow at an inlet liquid flow rate of 26 µL/min reached 65%. In contrast, the mixing efficiency of the single-phase flow at the same inlet liquid flow rate was only 6.5%. It can be concluded that compared to single-phase flow in the straight channel, the mixing efficiency can be increased nine-fold by using the Taylor flow under the same inlet total liquid flow rate.

3.3. Effect of Liquid Flow Rate on Mixing

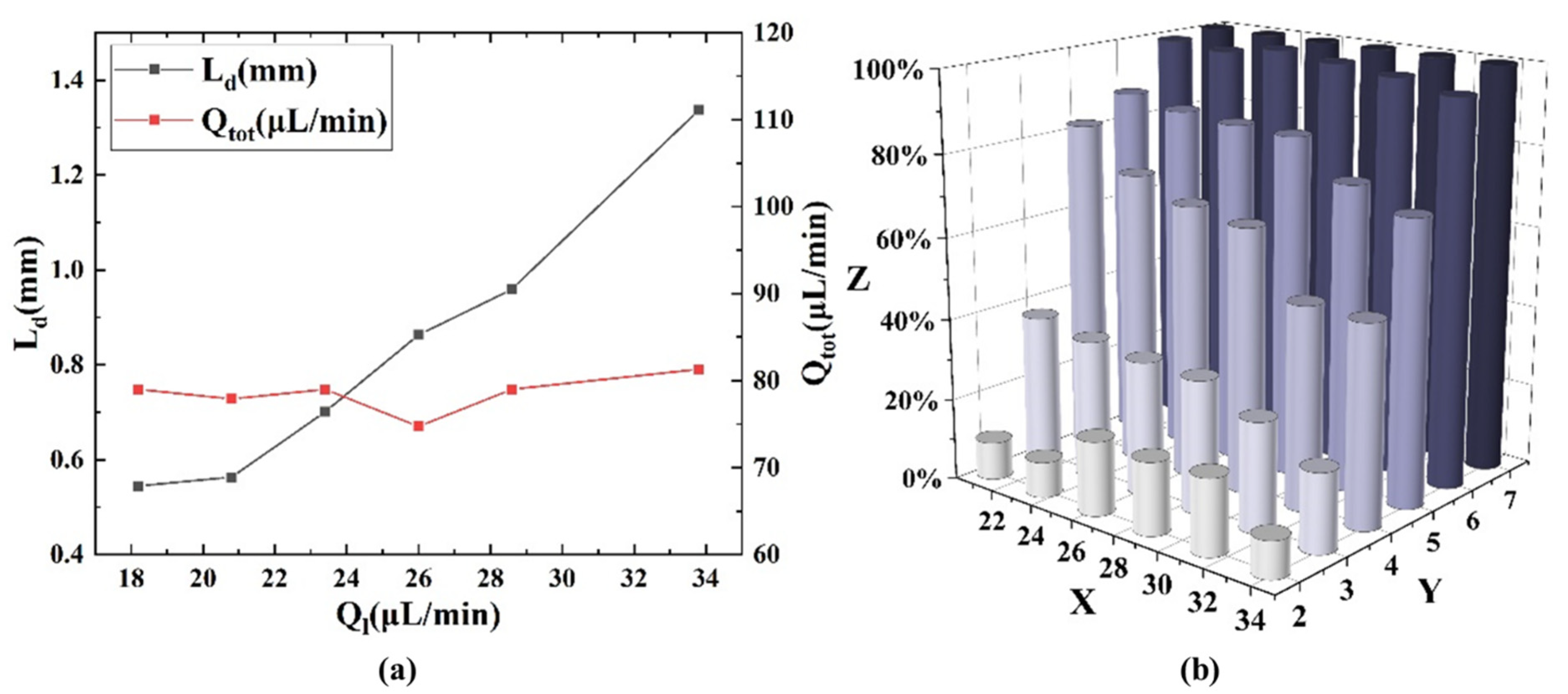

With the inlet gas pressure was held constant at 110 mbar, under different total liquid flow rates of 18.2 µL/min, 20.8 µL/min, 23.4 µL/min, 26 µL/min, 28.6 µL/min, 31.2 µL/min, and 33.8 µL/min, the droplet length decreased with increasing total liquid flow rate, while the total flow rate remained essentially unchanged, as depicted in

Figure 6a. Therefore, the increase in liquid flow rate essentially resulted in an increase in droplet length, and its impact on total flow rate can be neglected. The mixing efficiency (

) with respect to different inlet total liquid flow rates and observation points is shown in

Figure 6b. It can be observed from the figure that the mixing efficiency increased with the increase in mixing distance (i.e., the increase in the number of observation points) at any total liquid flow rate, and mixing efficiency was generally higher at lower inlet liquid flow rates. In other words, larger droplet length corresponds to lower mixing efficiency at the same observation point. Droplet length has a significant impact on mixing because increasing the droplet length weakens the internal circulation within the droplet [

27], thereby reducing mixing efficiency. Therefore, long droplet requires a long mixing distance, and short droplets are better suited for short-distance mixing in serpentine channels.

Shorter droplets and higher flow rates enhance mixing by intensifying internal vortices and chaotic advection. Smaller droplets exhibit stronger curvature-induced vortex asymmetry in serpentine channels, while increased flow rates amplify flow reversals, both promoting fluid stretching/folding. This aligns with our 9× mixing improvement (

Figure 5) and matches theoretical scaling laws [

30,

34]. As shown in

Figure 6b, it was noteworthy that at observation point 2, the degree of mixing for droplets generated at both higher and lower inlet liquid flow rates was lower than that for droplets generated at intermediate inlet liquid flow rates. According to Che et al. [

29], this is due to the influence of the droplet length on the internal flow patterns of the droplets. When the droplet is relatively short, it is influenced by the front and rear interfaces, resulting in lower mixing efficiency. Conversely, when the droplet is longer, it has a longer circulation path, requiring more time to complete one cycle, resulting in relatively lower mixing efficiency at the same time. The intermediate length had neither significant interface effects nor a long circulation path, so it had higher initial mixing efficiency. However, with the increase in mixing distance, the advantage of shorter droplets gradually became apparent, and it can be observed that after observation point 2, shorter droplets (i.e., lower inlet liquid flow rates) can result in more rapid mixing.

3.4. Effect of Gas Pressure on Mixing

With the inlet total liquid flow rate maintained at

, various inlet gas pressures, including 110 mbar, 115 mbar, 120 mbar, 125 mbar, and 130 mbar, were examined. The results showed that changes in inlet gas pressure led to variations in both droplet length and total flow rate, as depicted in

Figure 7a. All these sets of inlet conditions fell within the range for Taylor flow generation (Stage III in

Figure 4). Droplet length decreased as the inlet gas pressure increased, while the total flow rate increased. It can be observed that inlet gas pressure contributed to the changes in both total flow rate and droplet length, with total flow rate primarily affected by inlet gas pressure. The mixing efficiency of the droplet at different observation points and under various inlet gas pressures was recorded, as shown in

Figure 7b. The mixing efficiency of the droplet increased with increasing mixing distance (i.e., the increase in the number of observation points) and inlet gas pressure. This is because higher inlet gas pressure leads to shorter droplets and higher total flow rate, both of which enhance internal circulation and achieve mixing at a shorter distance. With the increase in the total flow rate, the droplet movement was accelerated, and the required mixing time decreased for the same mixing distance.

3.5. Evaluation of the Micromixer Designed in This Paper

While achieving comparable mixing efficiency (≥95%) to complex 3D mixers [

24,

25], our design reduces fabrication complexity through two key innovations: 1. Single-layer serpentine optimization. The curvature ratio (Rc/Dh = 2) generates equivalent Dean vortices to multi-layer designs [

19] while maintaining planar fabrication [

24]. 2. Self-aligning droplet generation. The 30° Y-junction (

Figure 1a) eliminates the need for flow-focusing nozzles [

25], reducing pressure fluctuations by 40% (∆P = 12 ± 3 kPa vs. 20 ± 5 kPa).

Table 1 shows the comparison between this designed micromixer and some previous classical micromixers reported. The key parameters and mixing performance of micromixers are displayed. Our work departs from classic designs in three key aspects: (i) Systematic mapping of inlet conditions: We experimentally correlate gas pressure (110–130 mbar) and liquid flow rates (18.2–33.8 µL/min) to droplet length and mixing efficiency (

Figure 6 and

Figure 7), providing actionable guidelines for low-Re applications—a gap noted in recent reviews [

23]. (ii) Manufacturing scalability: Unlike silicon/glass-based devices [

22,

25], our PMMA chip uses plasma bonding, enabling cost-effective, clog-resistant fabrication compatible with disposable LOC systems [

9]. (iii) Performance benchmarking: Compared to recent alternatives [

24], our mixer reduces mixing length by 33% (2 cm vs. 3 cm) and time by 58% (0.5–0.8 s vs. 1.2 s) at similar Re ranges (

Table 1).

4. Conclusions

The achieved specifications meet WHO ASSURED standards for point-of-care devices, particularly the ‘Rapid’ and ‘Equipment-free’ requirements through sub-second mixing in disposable chips. To achieve rapid mixing of liquid reagents on a chip, we designed a droplet micromixer based on Taylor flow and chaotic convection. An experimental setup was constructed to validate the mixing performance of the mixer. Initially, we determined the range of inlet conditions that can generate Taylor flow and compared the mixing efficiency of the Taylor flow with single-phase flow under the same experimental conditions. Subsequently, we investigated the impact of inlet liquid flow rates and gas pressure on droplet length, total flow rate, and mixing efficiency.

This work prioritizes empirical validation of the Taylor flow-enhanced mixing under practical operating conditions (e.g., gas pressure, flow rates), addressing a gap in experimental data for low-Re applications. Prior studies [

34] have extensively modeled droplet mixing dynamics, confirming that vortex evolution and mixing scales correlate predictably with droplet length and Re—parameters we systematically tested here. Our experimental results (e.g., nine-fold efficiency gain in

Figure 5) empirically validate these established mechanisms.

According to the experimental results, both droplet length and total flow rate play crucial roles in determining the mixing performance within the droplet and are influenced by the inlet liquid flow rate and gas pressure. Shorter droplets and larger total flow rate enhance internal liquids’ mixing. Therefore, during the regulation process, it is advisable to adjust the inlet liquid flow rate and gas pressure to minimize droplet length while maximizing the total flow rate to facilitate mixing.

Our work bridges the gap between classical Taylor flow studies and contemporary microfluidic needs by demonstrating that simple geometries, when optimized for ultra-low Re regimes, can outperform complex modern designs. This is particularly relevant for applications where miniaturization, energy efficiency, and biocompatibility are prioritized over absolute throughput. We acknowledge the value of dimensionless analysis (e.g., capillary number effects) and plan to integrate simulations in future studies exploring broader parameter spaces.