Abstract

In the rapidly advancing digital era, the demand for miniaturized and high-performance electronic devices is increasing, particularly in applications such as wireless communication, unmanned aerial vehicles, and healthcare devices. Radio-frequency microelectromechanical systems (RF MEMS), particularly RF MEMS switches, play a crucial role in enhancing RF performance by providing low-loss, high-isolation switching and precise signal path control in reconfigurable RF front-end systems. Among different configurations, electrothermally actuated bistable lateral RF MEMS switches are preferred for their energy efficiency, requiring power only during transitions. This paper presents a novel approach to improve the RF performance of such a switch through structural modifications and machine learning (ML)-driven optimization. To enable efficient high-frequency operation, the H-clamp structure was re-engineered into various lateral configurations, among which the I-clamp exhibited superior RF characteristics. The proposed I-clamp switch was optimized using an eXtreme Gradient Boost (XGBoost) ML model to predict optimal design parameters while significantly reducing the computational overhead of conventional EM simulations. Activation functions were employed within the ML model to improve the accuracy of predicting optimal design parameters by capturing complex nonlinear relationships. The proposed methodology reduced design time by 87.7%, with the optimized I-clamp switch achieving −0.8 dB insertion loss and −70 dB isolation at 10 GHz.

1. Introduction

The digital era of rapid technological progress and communication advancements undeniably demands miniaturized electronic devices with enhanced performance [1,2]. This demand is prominently evident in applications such as wireless communication systems [3], unmanned aerial vehicles [4], and healthcare devices [5], where compact, high-performance solutions are indispensable. Microelectromechanical systems (MEMS) have emerged as a transformative technology in modern electronics, revolutionizing various industries with their miniature size, low power consumption, and exceptional performance characteristics [6,7]. The integration of MEMS devices such as switches [8], variable capacitors [9], resonators [10], filters [11], phase shifters [12], antennas [13], tunable inductors [14], voltage-controlled oscillators (VCOs) [15], and power amplifiers [16], especially within radio-frequency (RF) systems, has significantly advanced wireless communication technologies, offering enhanced functionality and efficiency.

RF MEMS switches transformed wireless communication by offering dynamic and efficient RF path selection, essential for adaptable circuits, spectrum management, and advanced signal processing [17]. Their rapid switching capability enhances performance in cellular networks, satellite communications, radars, and IoT devices, marking a significant leap in the wireless technology evolution [18,19,20]. RF MEMS switches play a vital role in advanced systems such as reconfigurable systems by enabling real-time switching between multiple RF paths, facilitating dynamic reconfiguration of antennas, filters, and matching networks with minimal signal loss and high isolation [13,21].

Recent advancements in RF MEMS switches have led to the development of various configurations categorized by actuation mechanisms (electrothermal, electrostatic, magnetostatic, electromagnetic, piezoelectric), structural designs (cantilever and fixed–fixed beams), and circuit topologies (series and shunt), operating through capacitive or ohmic contact interfaces with either vertical or lateral mechanical deflection [22,23]. In [24,25,26,27,28,29,30,31,32,33], a significant breakthrough was the development of electrothermally actuated bistable lateral RF MEMS switches. Such bistable switches combine the efficiency of electrothermal actuation with the stability of a bistable mechanism, resulting in a device that can maintain its state without the need for a constant power supply [29]. The lateral deflection of a bistable switch allows for a compact design and reduces the overall footprint on chips, making it highly suitable for integrated circuits where space efficiency is a paramount goal [32]. The bistability characteristics greatly enhance power efficiency, as they eliminate the need for continuous input power to maintain the switch state, thereby saving energy and prolonging battery life in portable devices [25]. The reliability of such a bistable switch is significantly improved due to the reduced wear and tear from constant switching, offering a longer operational lifespan.

In our previous work [34], the development of a bistable RF MEMS switch demonstrating robust performance at lower frequencies was reported. However, the challenge now lies in optimizing these switches for higher-frequency applications, where the requirements for insertion loss and isolation become more stringent. Addressing these challenges necessitates innovative approaches to design and optimize the switch, aiming to enhance operational efficacy while meeting the rigorous demands of high-frequency applications. To overcome these limitations, this paper adopts a novel approach by implementing structural modifications tailored to enhance the RF performance of bistable RF MEMS switches. The conventional H-clamp is replaced with various lateral clamp designs, among which the I-clamp exhibits improved RF characteristics, including lower insertion loss and higher isolation. However, further optimization of the bistable switch structure is essential to achieve enhanced performance across a broader frequency range. The optimization of such complex RF MEMS switches is time-consuming using 3D electromagnetic (EM) simulations [35]. In the past decade, machine learning (ML) algorithms were utilized to expedite the optimization process and achieve superior RF performance [36,37,38,39,40]. Recently, a pulse-driven MEMS gas sensor integrated with machine learning models such as linear discriminant analysis (LDA), k-nearest neighbors (KNN), and support vector machine (SVM) achieved high accuracy in selective gas identification, offering a compact, low-power solution for IoT applications [41]. Similarly, a multiband THz MIMO antenna employed gradient boosting regression for isolation prediction, attaining an over 98% accuracy and validating performance through both CST and ADS simulations [42]. In [43], Bayesian regularization-based ML models were used to validate optimal process parameters in RF MEMS glass via drilling, enhancing quality characteristics through metaheuristic algorithms, such as genetic algorithm (GA) and particle swarm optimization (PSO). A cognitive computing framework was proposed to predict the flow status of a flexible rectifier using machine learning models such as Multilayer Perceptron (MLP) and CatBoost, demonstrating superior fluidic prediction accuracy compared to traditional methods [44]. A multimodal strain-sensing system was developed for tensegrity structures, where deep learning-assisted shape recognition using long short-term memory (LSTM) networks enabled real-time structural deformation tracking [45]. These studies illustrate the increasing utilization of ML techniques to enhance functional predictability and structural adaptability in microstructured systems. Based on these concepts, the present work explores ML-driven optimization specifically tailored for bistable RF MEMS switches, focusing on RF performance enhancement through structural modifications and regression-based modeling. Through iterative learning and data-driven modeling, the ML approach facilitates the exploration of a vast design space, leading to the identification of optimal switch configurations that maximize RF efficiency. To capture complex relationships and patterns in the dataset, activation functions play a critical role in shaping the learning dynamics of the ML model [46,47,48]. A distinguishing aspect of our work lies in the comprehensive comparative analysis of activation functions within the context of ML-based optimization for RF MEMS switch applications. The objective of this work was to present a systematic framework for improving the RF performance of bistable RF MEMS switches through a synergistic combination of structural modification and ML-based optimization.

The major contributions of this paper include the following:

- Proposal of a novel I-clamp bistable RF MEMS switch to obtain better performance at higher frequencies;

- Development of an ML-based optimization model for the I-clamp bistable RF MEMS switch structure to minimize RF losses and improve isolation, enabling faster design convergence compared to traditional EM simulation-driven methods;

- Implementation of activation functions to model nonlinear relationships between structural parameters and RF performance in ML-based optimization of the proposed RF MEMS switch.

This paper is organized as follows. Section 2 describes the electrothermally actuated bistable lateral RF MEMS switch structure, its operation, and the need for structural modification. Section 3 deals with direct and inverse modeling of ML to predict the optimal geometrical parameters of a bistable RF MEMS switch. Section 4 presents the results and the discussion of the proposed ML model, followed by the conclusions in Section 5.

2. Modeled Device—Electrothermally Actuated Bistable RF MEMS Switch

2.1. Structural Description

Figure 1 illustrates the structure of an electrothermally actuated bistable RF MEMS switch on a silicon substrate [29,34]. This structure comprises three main elements: two curved beams labeled as cosine arches, a retracting actuator, and a V-beam actuator. The upper cosine arch amplifies displacement, while the lower one is utilized as the bistable component. Coplanar waveguide (CPW) lines which perform RF signal transmission are strategically placed at the lower section of the device. They are seamlessly integrated with an intricate ladder structure of the arch and along with an extended structure called the H-clamp to establish lateral connections across the CPW lines on both sides.

Figure 1.

Structure of an electrothermally actuated H-Clamp bistable RF MEMS switch.

2.2. Working Mechanism

The operation of a bistable RF MEMS switch begins in its initial OFF state, which is STABLE STATE 1. The transition mechanism from STABLE STATE 1 to STABLE STATE 2 depends on the application of pulse voltage across specific terminals. This triggers electrothermal actuation, simultaneously activating both the initially retracting actuator and the V-beam actuators. As a result, the bistable arch undergoes a lateral movement, transitioning into its STABLE STATE 2 [29].

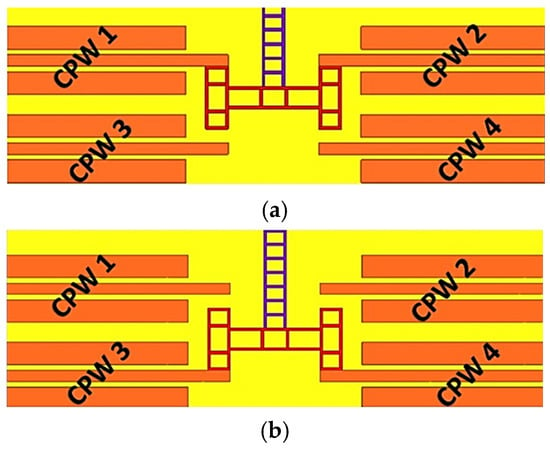

In STABLE STATE 1, the lateral displacement of the H-clamp results in contact with CPW lines 1 and 2, as shown in Figure 2a. Transitioning to STABLE STATE 2 involves the lateral movement of the H-clamp to establish contact with CPW lines 3 and 4, as in Figure 2b. This movement is facilitated by the coordinated operation of the actuators. To revert the switch to its default configuration of STABLE STATE 1, the device employs its bimodal switching capability, which enables the switch to alternate between its two stable states efficiently. This bimodal switching plays a vital role in the device operation, allowing for controlled lateral movements of the H-clamp between distinct pairs of CPW lines, thereby determining the operational state of the switch. The S-parameters of a bistable lateral RF MEMS switch in both stable states are shown in Table 1.

Figure 2.

(a) STABLE STATE 1; (b) STABLE STATE 2.

Table 1.

S-parameters of a bistable lateral RF MEMS switch in both stable states.

2.3. Need for Structure Modification

The RF performance analysis of an H-clamp-based bistable RF MEMS switch was carried out in [34], and it was observed that the switch operates efficiently only up to 6 GHz. As wireless technologies advance, the operational frequencies increase, necessitating devices that can perform efficiently at higher frequencies. The H-clamp directly impacts the electromagnetic performance of the switch, influencing RF losses that are critical in high-frequency applications. Hence, structural change of the H-clamp solves the problem of achieving the stringent RF performance metrics required at high frequencies.

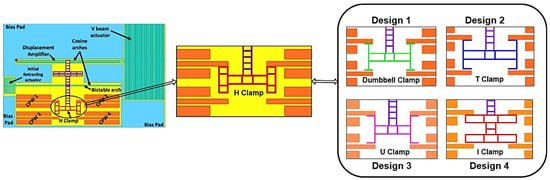

The H-clamp in a bistable switch is replaced with various reliable and mechanically stable lateral structures, such as dumbbell, T-shaped, U-shaped, and I-shaped clamps, as shown in Figure 3. Such lateral structures are designed and simulated in HFSS to analyze their RF performance. Among these structures, design 4 with an I-shaped clamp gives better RF performance when compared to the H-clamp structure.

Figure 3.

Structure modification of an H-clamp bistable RF MEMS switch with various lateral designs.

Optimization of dimensional parameters of the proposed I-clamp bistable switch efficiently minimizes RF losses and ensures better signal transmission at higher frequencies. Conventionally, such optimization is performed in EM simulation tools, which is a complex, time-consuming process. Hence, a machine learning (ML) model was proposed to optimize the bistable switch to obtain better RF performance.

3. Optimization of an I-Clamp Bistable Lateral RF MEMS Switch Using a Machine Learning Model

Machine learning (ML) has transformed various domains to solve complex optimization problems. An ML model learns from previous data, constructs prediction models, and predicts the response whenever new data are processed. It employs various ML algorithms such as linear regression, logistic regression, support vector machines (SVMs), decision trees, random forest, gradient boosting machines (eXtreme Gradient Boost, LightGBM, CatBoost), k-nearest neighbors (KNN), naive Bayes, neural networks, and ensemble methods to identify relationships in data, enabling ML model development [34]. One major advantage of ML is that once a model is trained and achieves acceptable prediction accuracy, it can be used for future predictions without the need for retraining or additional adjustments. In [49,50,51,52,53], evolutionary algorithms, namely genetic algorithms and particle swarm optimization, were used to optimize MEMS switches by evaluating outputs and generating new search directions to find global maxima or minima. In contrast, ML focuses on predicting outputs based on the established input–output relationships, making it effective for future predictions without seeking global optima.

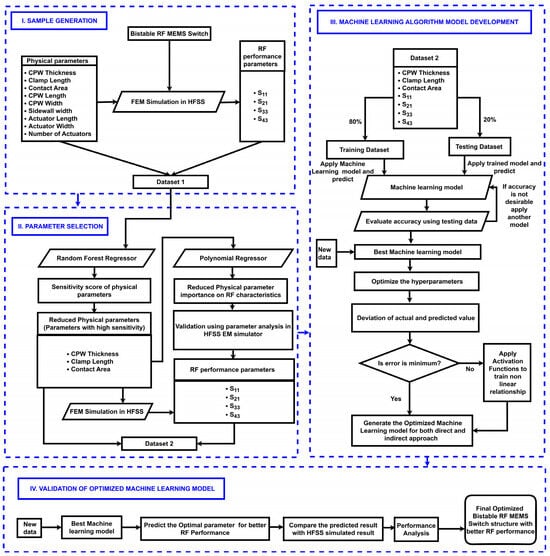

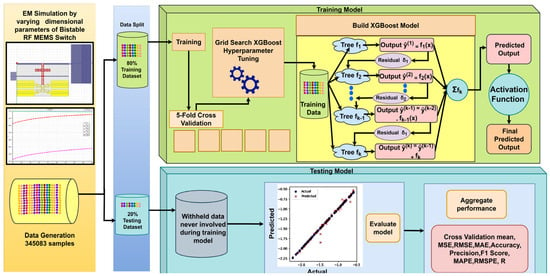

Implementing such ML algorithms to optimize the physical parameters of the proposed I-clamp-based RF MEMS switch significantly speeds up the design process. By predicting optimal configurations, ML provides a data-driven approach to designing a switch that is both efficient and innovative. The workflow of the proposed methodology for optimizing the I-clamp RF MEMS switch using an ML model is shown in Figure 4.

Figure 4.

Proposed methodology for optimizing an I-clamp RF MEMS switch.

The proposed method consisted of the generation of data samples, design parameter selection for design space reduction, development of an ML model to optimize design parameters for achieving the required RF performance, and validation of the developed ML model.

3.1. Sample Generation

The proposed I-clamp RF MEMS switch was designed and simulated using a high-frequency structure simulator (HFSS), and the resulting datasets were extracted for ML-based optimization. These datasets were used to train ML models and evaluate them through testing and prediction. To generate a dataset, the nine physical parameters of the switch (Dataset 1), such as CPW thickness, length, and width, clamp length, contact area, sidewall width, actuator length and width, and number of actuators, were varied to a certain range of values, as shown in Table 2.

Table 2.

Boundary conditions of the physical parameters for dataset generation.

The S-parameter responses, including S11, S21, S33, and S43, were obtained from 1 to 10 GHz, generating 5000 data samples for Dataset 1.

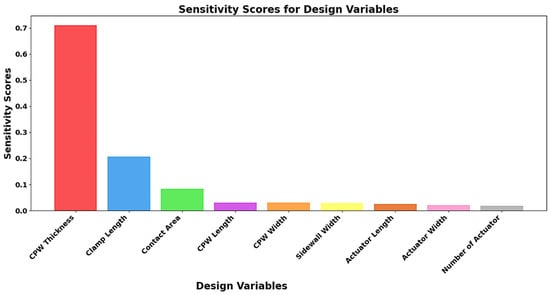

3.2. Parameter Selection

The RF performance of the proposed I-clamp bistable RF MEMS switch is influenced by multiple physical design parameters. Exhaustively simulating all possible physical parameter combinations using full-wave EM solvers such as HFSS is computationally expensive. Although ML methods offer a faster alternative for design optimization, their effectiveness depends on identifying the most influential input parameters to reduce dimensionality and training overhead. To address this, a sensitivity score analysis was conducted to determine the influence of each physical parameter on the RF performance of the switch. Dataset 1, consisting of nine physical parameters, such as CPW thickness, length, and width, clamp length, contact area, sidewall width, actuator length, actuator width, and number of actuators, was considered as input and S-parameters as the output. A random forest regressor was employed due to its ability to model complex nonlinear relationships and its resistance to overfitting in high-dimensional data. Sensitivity scores were computed by varying one parameter at a time while keeping others constant, generating 2004 unique combinations of samples. The influence of each variable was evaluated based on its contribution to reducing prediction error across the ensemble of decision trees. This analysis reveals that CPW thickness, clamp length, and contact area have the highest impact on the RF performance. These parameters were selected for optimization, effectively reducing computational complexity and improving the efficiency of the design process.

The accuracy of the predicted output is directly proportional to the amount of data, as a larger number of data samples helps to develop a more precise predictive model. Hence, Dataset 2 was generated by varying the most influential parameters such as CPW thickness, clamp length, and contact area across a wide range of values. A large number of samples was obtained through full-wave EM simulations in HFSS to train the machine learning model effectively using diverse combinations of these critical parameters.

To evaluate the impact of the key physical parameters such as CPW thickness, clamp length, and contact area on each output S-parameter (S11, S21, S33, and S43), a polynomial regression model was employed. This method captures nonlinear relationships using a polynomial function of the form:

where denotes the S-parameter, represents the input physical parameters, coefficients are learned during training, is the polynomial degree, and is the error term. This approach enables a detailed understanding of how variations in physical dimensions influence specific RF responses, offering valuable insights for targeted optimization of the switch.

3.3. Machine Learning Model Development

To optimize the I-clamp bistable RF MEMS switch, Dataset 2 containing CPW thickness (CT), clamp length (CL), and contact area (CA) as the input physical parameters and S11, S21, S33, and S43 as the output RF parameters was split 80% for training and 20% for testing the ML models. Various ML models such as decision trees, random forests, artificial neural network (ANN), k-nearest neighbors (KNN), boosting algorithms such as adaptive boosting (ADABoost), categorical boosting (CATBoost), gradient boosting machine (GBM), eXtreme gradient boosting (XGBoost), and LightGBM were used to train Dataset 2. These algorithms were selected for their effectiveness in performing regression on nonlinear numerical datasets. Python 3 is the preferred programming language for implementing these algorithms due to its simplicity and the extensive availability of libraries that aid in data preprocessing, machine learning, and visualization.

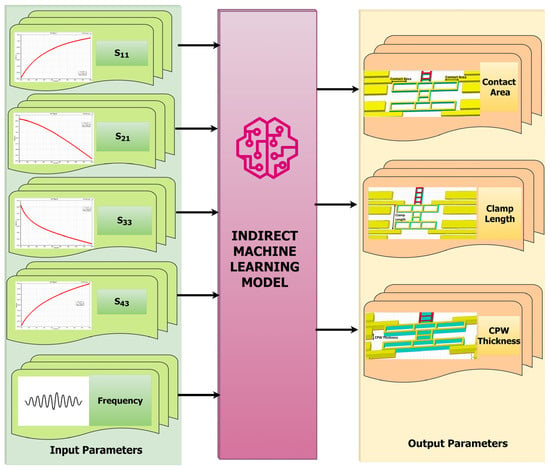

When these ML models were trained and tested, the eXtreme gradient boosting (XGBoost) ML model provided high modeling accuracy, fast calculation speed, and strong generalization ability among various models. Since it has a high parameter extraction ability, it is beneficial to extract the subtle characteristics of a given switch. Hence, it was chosen for predicting the scattering parameters for any random combinations of dimensions at the desired frequency using the direct method, as in Figure 5, and for predicting the dimensions for any random combinations of scattering parameters using the indirect method, as in Figure 6, within the boundary limits defined by the training dataset.

Figure 5.

Direct ML model.

Figure 6.

Indirect ML model.

Figure 7 describes the methodology for developing and evaluating an XGBoost-based ML model; 345,083 samples generated by the HFSS EM simulator were split into 276,067 samples and 69,016 samples for training and testing the XGBoost ML model, respectively.

Figure 7.

Methodology for developing an XGBoost-based ML model.

Prior to training the actual model, hyperparameter tuning was conducted using grid search, a method that exhaustively tests every combination of predefined sets of hyperparameter values such as column sampling by tree, minimum loss reduction (gamma), learning rate, maximum depth of a tree, minimum sum of instance weight needed in a child, number of trees or estimators, L1 regularization term on weights (alpha), L2 regularization term on weights (lambda), and subsample ratio of the training instances. Grid search systematically explores all possible combinations of hyperparameter values to identify the configuration that yields the best ML model performance.

To ensure model robustness and prevent overfitting, 5-fold cross-validation was employed. The training dataset was partitioned into five equal subsets, with each subset used once as a validation set while the remaining four were used for training. This process was repeated five times, ensuring each subset was used for validation exactly once. The performance metrics from all the folds were averaged to provide a reliable estimate of model generalization. This cross-validation strategy was combined with grid search to validate that the selected hyperparameters yielded consistent performance across different datasets. Table 3 gives the optimal values of hyperparameters for both the direct and indirect ML models using XGBoost.

Table 3.

Optimal hyperparameter values for the XGBoost models using direct and indirect methods.

Once the hyperparameters were determined, an XGBoost ML model was built by training a series of decision trees sequentially. Each tree f1, f2, …, fk tried to correct the errors such as residuals δ1, δ2, …, δk−1 made by the previous tree in the series. The predicted output for the given samples was the sum of the predictions from all the trees. Mathematically, an XGBoost model can be represented as follows.

The XGBoost algorithm is complex and involves a series of linear combinations and an objective function optimized through gradient boosting. The training data are represented as a set of tuples as in Equation (2), with the models in set consisting of .

Predictions are made through a linear combination of different models as in Equation (4).

Each instance and model produce an output , with the objective function measuring the discrepancy between actual and predicted outputs using a differentiable convex loss function .

where is the objective function, is a differentiable convex loss function used to measure the difference between the actual output, and predicted output, is the regularization form. The introduction of the regularization term mitigates overfitting by constraining model complexity, thereby promoting a simpler and more generalizable ML model. The objective function is expanded using Taylor series to approximate the loss, incorporating both the first- and second-order gradient statistics of the loss functions and , respectively. These gradients are crucial in guiding the optimization process, allowing the algorithm to adjust its parameters intelligently and converge toward the minimum loss.

where is the first-order gradient statistics of the loss function, is the second-order gradient statistics of the loss function. After introducing the training step, the complexity of the tree is defined as follows:

where P is the function assigned to each datapoint to leaf, T is the number of leaf nodes, and w is the vector of score for the leaves.

The regularization term is composed of two parts: term which controls the number of leaves and term , which controls the scores on the leaves. The final objective then combines the predictions weighted by the gradient statistics with the regularization term to arrive at a value that the algorithm seeks to minimize the loss.

The capacitance of the switch when the I-clamp and CPW lines are decoupled are as follows:

where and are the permittivities of the dielectric and the vacuum, respectively, represents the area, and is the gap distance. The capacitance exhibits a hyperbolic dependency on , significantly influencing the insertion loss when the switch is in the open position. This relationship highlights the nonlinear characteristics of the RF performance of the switch as dimensions are varied slightly. The impedance of the switch when the I-clamp and CPW lines come in contact with each other is as follows:

where is the length, is the width, is the thickness of the conductive path, and is the conductivity of the material. Impedance plays a crucial role in minimizing reflections and optimizing transmission. Hence, the S11 and S21 parameters’ dependence on the physical dimensions of the switch demonstrates nonlinear characteristics, especially notable in high-frequency operations where skin and proximity effects are significant. Such intricate and nonlinear relationships between the physical dimensions of RF MEMS switches and their associated S-parameters make the prediction of physical parameters from the RF performance more sensitive. Since the inverse modeling of RF MEMS switches with nonlinear characteristics is quite complex to achieve more accuracy, activation functions introduce nonlinearity to the XGBoost ML model, enabling it to learn complex patterns beyond simple linear decision boundaries. They also play a critical role in the model by allowing gradients to be propagated through the decision trees, facilitating effective learning and updates to the regularization term as in Equation (16):

Thus, Equation (13) with the activation function becomes the following:

Various activation functions were applied to the sum of the trained outputs to obtain the final predicted output with more accuracy. The activation function that enhanced the prediction accuracy of both the direct and indirect modeling of the proposed XGBoost model was further used for the optimization of the I-clamp RF MEMS switch. While the developed machine learning model demonstrates strong predictive performance, the inclusion of physical knowledge can further enhance interpretability and generalization. The following section discusses how physics-informed and hybrid approaches can complement the data-driven methodology.

3.4. Augmenting Data-Driven Models with Physical Constraints

Physics-informed machine learning (PIML) integrates known physical relationships into the training process to ensure the model adheres to established device behavior. For MEMS devices, this means incorporating expressions such as capacitance versus gap and impedance versus geometry directly into the loss function. This constrains the model to produce outputs that satisfy physical laws throughout training, not just fit the data. Enhanced versions, such as gradient-informed physics-informed neural networks (PINNs), also include derivative information—for example, penalizing violations in or to improve performance in regions with steep physical changes, such as during contact in MEMS switches. Hybrid (grey-box) learning methods combine fast physics-based estimates with machine learning to capture effects not covered by simplified models. A typical workflow computes a baseline prediction using reduced-order models or closed-form approximations. A learning algorithm, such as XGBoost, is then trained on the residual error , where is the output from a high-frequency structure (HFSS). The final prediction is constructed as follows:

This approach blends first-principles and data-driven modeling, improving extrapolation to new geometries and accounting for parasitic and layout-level non-idealities that analytical models might miss. Such methods not only enhance physical consistency, but also reduce overfitting and improve robustness—addressing the need for models that go beyond purely statistical “black-box” approaches. Building on these physics-aware strategies, we can also explore data-efficient sampling methods to further reduce our simulation burden.

3.5. Active Learning and Surrogate Modeling

Active learning and surrogate modeling naturally extend hybrid frameworks by focusing computational effort where it yields the greatest insight. To reduce reliance on exhaustive HFSS simulations, one can adopt an active learning-driven surrogate workflow. Starting from a small set of HFSS runs, a fast surrogate—such as a Gaussian process or neural network—predicts S-parameters across the design space. The surrogate’s uncertainty estimates then guide the selection of the next HFSS simulation points, concentrating efforts where they add the most value and drastically reducing the total number of runs. Surrogate-based optimization methods—such as expected improvement infill criteria—have long been used in electromagnetic design to approximate expensive black-box functions and drive sequential sampling. Recent studies have shown that active learning can achieve relative errors below 0.1% with fewer than fifty full-wave simulations, demonstrating its suitability for RF MEMS switch optimization. Integrating this strategy into our workflow would enable efficient dataset expansion by steering HFSS runs toward the most informative geometries. With this efficient data-generation scheme in place, we now turn to validate the predictive performance of our models.

3.6. Validation of the Machine Learning Model

Once both the direct and indirect ML models had been trained, they were tested using the withheld testing dataset that had never been involved in the training process. The performance of the model was evaluated by comparing the actual values from HFSS simulations with the predicted values from the ML model. A scatter plot comparing the actual values versus predicted values was used to evaluate prediction accuracy, with data closely aligned along the diagonal line indicating the ideal prediction accuracy.

The performance of various regression models is evaluated quantitatively using metrics such as mean square error (MSE), root mean square error (RMSE), mean absolute error (MAE), accuracy, training time, mean absolute percentage error (MAPE), root mean square percentage error (RMSPE), and the correlation coefficient (R). Each metric provides distinct insights into the predictive capabilities of the ML models. MSE and RMSE were used to evaluate the average magnitude of the ML model errors, with lower values indicating closer adherence of predictions to actual values.

MAE aided in quantifying the average prediction error, offering a direct measure of the average error magnitude. MAPE and RMSPE were used to assess errors in a relative sense, which is crucial for datasets with varying ranges. R was calculated to gauge the strength of the linear relationship between the predicted and actual values. Accuracy shows the proportion of predictions falling within a predefined acceptable range of the actual values. Training time was monitored to evaluate the computational efficiency of the model, an important factor in practical applications.

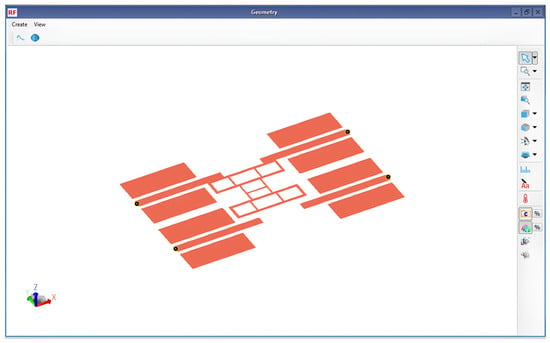

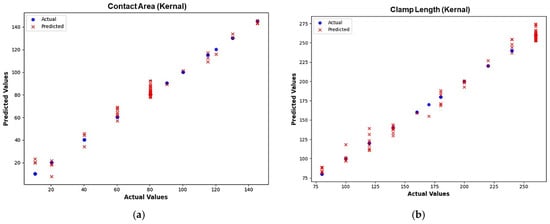

To validate the accuracy of the proposed I-clamp RF MEMS switch, post-layout parasitic extraction-based modeling was conducted to observe the performance closer to the fabricated prototype. The layout of the I-clamp switch was simulated in the RFPro platform of Advanced Design System (ADS), as shown in Figure 8.

Figure 8.

Layout of the proposed I-clamp RF MEMS switch in RFPro of ADS.

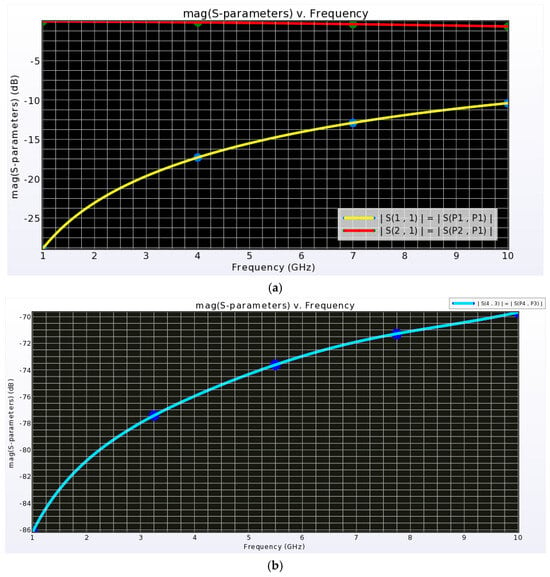

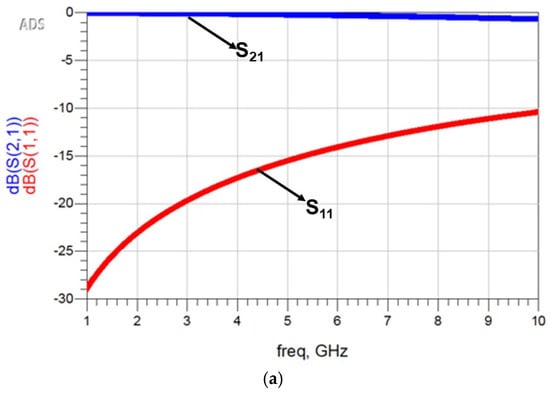

The simulation was carried out at an ambient temperature of 25 °C, with the operating frequency sweep from 1 GHz to 10 GHz. This setup was used to extract return loss, insertion loss, and isolation of the proposed switch, as shown in Figure 9.

Figure 9.

Post-layout extracted S-parameters of the I-clamp RF MEMS switch. (a) Return loss (S11) and insertion loss (S21). (b) Isolation loss (S43).

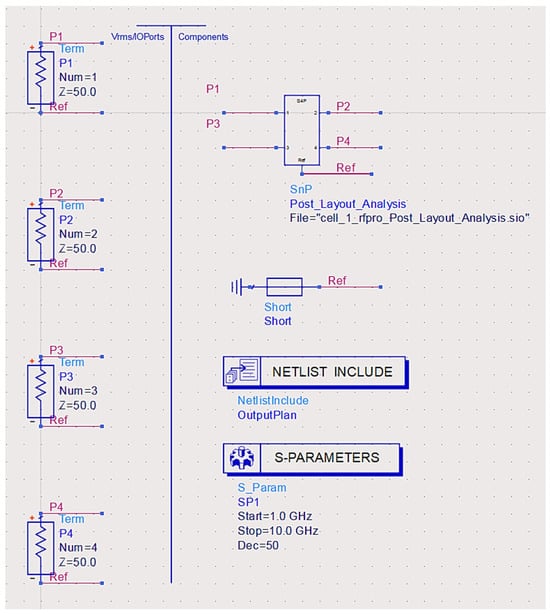

A test bench was created for the post-layout I-clamp RF MEMS switch in ADS to simulate the parasitic-extracted netlist using boundary conditions and excitation ports, as shown in Figure 10, to evaluate the S-parameter performance.

Figure 10.

Post-layout extraction simulation setup with a netlist-based test bench.

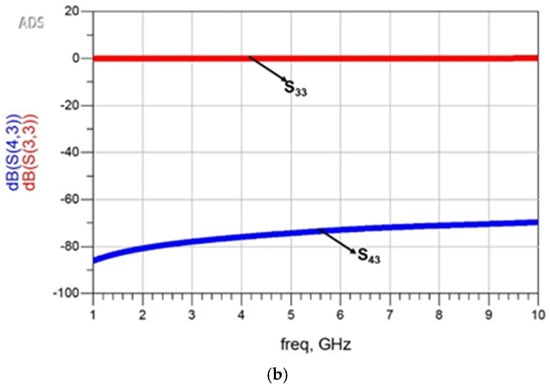

The test bench simulation results of the parasitic-extracted netlist are shown in Figure 11. These results closely align with the full-wave EM simulation.

Figure 11.

S-parameters of the proposed I-clamp RF MEMS switch from the ADS netlist-based test bench simulation. (a) S11 and S21. (b) S33 and S43.

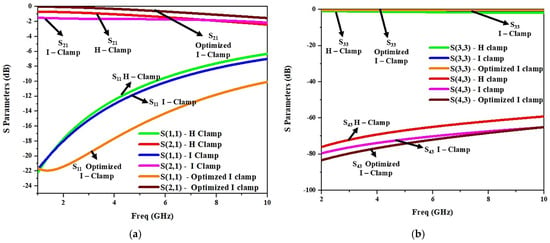

4. Results and Discussion

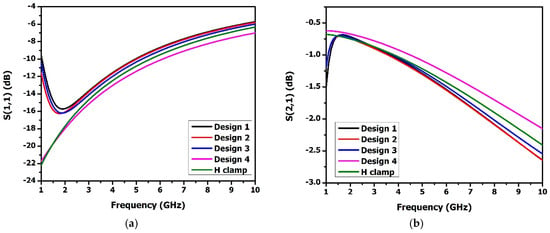

The electrothermally actuated bistable lateral RF MEMS switch structure used for low-frequency wireless applications was modified to improve its RF performance at a higher frequency. Structural modifications to the H-clamp enhanced its electromagnetic performance, reducing RF losses essential for high-frequency applications, thus meeting stringent RF performance requirements. Thus, the H-clamp structure of the switch was replaced by various lateral switch structures, and it was observed that the I-clamp structure showed better insertion loss and isolation. As shown in Figure 12, the I-clamp (design 4) bistable RF MEMS switch’s S11 was −10.5 dB, S21—−1.5 dB, S33—−0.3 dB, and S43—−74 dB at 7 GHz.

Figure 12.

S-parameter comparison of various lateral designs of the bistable RF MEMS switch. (a) S11, (b) S21, (c) S33, (d) S43.

To further improve the RF performance of the proposed I-clamp bistable RF MEMS switch, optimization of the design parameters was carried out. The optimization of the I-clamp bistable switch through ML models streamlined the traditionally complex and time-consuming EM simulation process, minimizing RF losses and enhancing signal transmission at higher frequencies. To train the ML model, Dataset 1 consisting of 2004 data samples with RF performance of the switch was obtained from the HFSS EM simulator by varying the physical parameters such as CPW thickness (CT), length (L), and width (W), clamp length (CL), contact area (CA), sidewall width (SW), actuator length (AL) and width (AW), and number of actuators (AN), as shown in Table 4.

Table 4.

Sample Dataset 1 containing physical parameters and the corresponding RF performance.

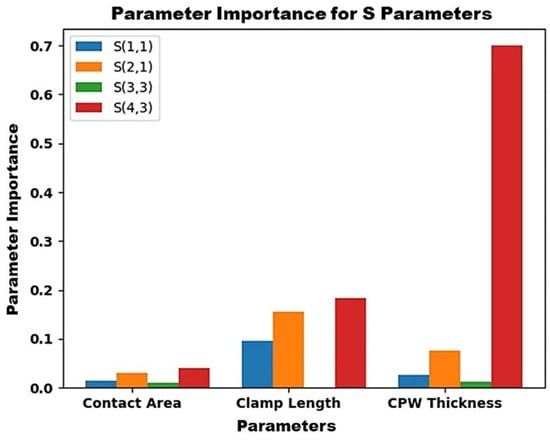

The design space for optimizing the proposed RF MEMS switch was reduced using sensitivity score analysis, which identified the parameters that significantly impacted RF performance. Dataset 1, containing physical parameters as inputs and S-parameters as outputs, was analyzed with a random forest regressor. This model streamlined the optimization process by identifying less significant design variables that could be excluded with minimal impact on RF performance, as shown in Figure 13.

Figure 13.

Sensitivity scores of the bistable RF MEMS switch design variables.

From Figure 13, it is observed that CPW thickness, clamp length, and contact area had high sensitivity scores, indicating a significant impact on the performance of the I-clamp RF MEMS switch. Therefore, these input parameters were selected for the optimization of the switch. Dataset 2, with a large number of samples, was generated by varying these selected input parameters, as shown in Table 5, for training both direct and indirect ML models.

Table 5.

Input and output parameters to train the direct and indirect ML models.

The influence of each input physical parameter on the individual output S-parameters was analyzed using a polynomial regressor, and it was observed that isolation was greatly influenced by input parameters, as shown in Figure 14.

Figure 14.

Bistable RF MEMS switch parameter importance for the S-parameters.

Dataset 2 with 345,083 samples was split 80% for training and 20% for testing. The direct and indirect ML models were trained using various machine learning algorithms such as decision tree, random forest, ANN, KNN, ADABoost, CATBoost, GBM, XGBoost, and LightGBM. The ML algorithm that provided the better performance was selected for optimization. Table 6 compares the performance metrics of the various ML algorithms for both direct and indirect methods.

Table 6.

Performance metrics of the various ML algorithms for the direct and indirect methods.

Table 6 shows that the XGBoost-based ML model performed efficiently compared to the other algorithms since it consistently demonstrated superior performance metrics, such as lower MSE, RMSE, MAE, MAPE, RMSPE values, and higher accuracy percentages and R2 values for both direct and indirect methods. This advantage was due to the ability of XGBoost to handle missing data, prevent overfitting with regularization, and utilize parallel processing for faster computation.

The prediction accuracy of the indirect model, which aimed to predict dimensions from S-parameters using an ML model, was lower than that of the direct model due to the complexity and inherent challenges in capturing the inverse relationship. Since it was highly nonlinear and sensitive, this complexity increased the potential for errors and inaccuracies, leading to lower accuracy in predictions. To address this issue, we proposed a model in which activation functions were used in conjunction with the XGBoost model. Various activation functions introduced nonlinearity into the model, enabling it to capture more complex patterns and relationships within the data.

Selecting an appropriate activation function is key for effective training and performance in ML model-based regressor problems. In regression models, activation functions must be nonlinear to capture complex patterns, differentiable for gradient-based optimization, zero-centered for balanced weight updates, and resistant to vanishing and exploding gradients to maintain effective learning and numerical stability. The trade-off between these characteristics is observed for different activation functions to choose the efficient activation function, which has such advantages as smooth gradients, efficient computation, and robustness against common training pitfalls. Table 7 provides a comparison of activation functions and evaluates their performance based on these key characteristics, which are essential in determining the effectiveness of each activation function in the regression problem.

Table 7.

Comparative evaluation of activation functions based on the regression model performance characteristics.

Based on the comparative analysis of activation function characteristics, as shown in Table 7, functions lacking key features such as differentiability, zero-centered output, or resistance to vanishing and exploding gradients were excluded from further optimization. These included Binary Step, Sigmoid, Softmax, Hard Sigmoid, Squared ReLU, and Log Softplus Error. This analysis focused on a subset of activation functions demonstrating strong theoretical and empirical suitability for regression modeling in RF MEMS switch optimization. The proposed XGBoost ML model was trained with different activation functions, and MSE values were obtained, as shown in Table 8.

Table 8.

Mean square error of the various activation functions.

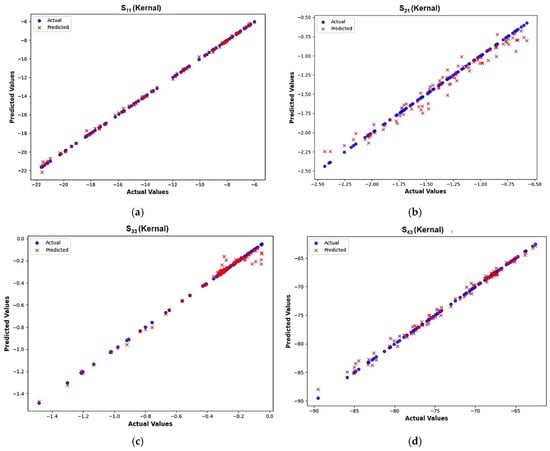

In Table 8, the integration of the kernel function with the XGBoost ML model gives a minimum prediction error of 0.127, and hence it was chosen for optimizing the I-clamp bistable RF MEMS switch. This ensured that the kernel activation function optimally improved the XGBoost model performance, effectively capturing the complex dependencies and reducing prediction errors in the indirect model. The proposed kernel-based XGBoost ML regressor model efficiently handled the intricate and nonlinear relationship between S-parameters and physical dimensions, enhancing its ability to make more accurate predictions despite the complexity of the indirect model. The XGBoost-based ML model with the kernel activation function was selected for prediction in both direct and indirect ML models. It was found that XGBoost converged well with the HFSS-simulated values, as shown in Figure 15 and Figure 16.

Figure 15.

Actual vs. predicted values obtained from the kernel-based XGBoost direct ML model. (a) S11. (b) S21. (c) S33. (d) S43.

Figure 16.

Actual vs. predicted values obtained from the kernel-based XGBoost direct ML model. (a) Contact area. (b) Clamp length. (c) CPW thickness. (d) Frequency.

The proposed kernel-based XGBoost machine learning model achieved rapid prediction of RF performance metrics within 8 min, even for large datasets, whereas conventional HFSS simulations required multiple iterations, each taking approximately 65 min on a system with 8 GB RAM and a 2.90 GHz Intel Core processor. This approach resulted in an 87.7% reduction in design time for the I-clamp bistable RF MEMS switch compared to traditional full-wave EM simulations. The proposed I-clamp bistable RF MEMS switch that had better RF performance was predicted using the proposed kernel-based XGBoost ML model, and it was predicted that it performed well with the CPW thickness of 0.5 µm, contact area of 145 µm, and clamp length of 260 µm. It was observed that the proposed structure ensured better RF performance, as shown in Figure 17. Table 9 gives a state-of-the-art comparison of bistable RF MEMS switches with the proposed switch.

Figure 17.

S-parameter results of the optimized bistable RF MEMS switch. (a) S11 and S21. (b) S33 and S43.

Table 9.

State-of-the-art comparison of bistable RF MEMS switches with the proposed I-clamp design.

From Table 9, it is observed that the RF performance of the proposed I-clamp switch was comparable to certain existing designs, demonstrating significantly higher isolation (−70 dB) and improved return loss (−11 dB) at 10 GHz. Unlike most existing studies, our work utilized artificial neural network (ANN) and machine learning (ML) models to predict the optimal dimensions of the switch by reducing design time, as highlighted in Table 9. In [34], although the ANN model achieved 99.5% accuracy in predicting one physical parameter, it could not handle the simultaneous prediction of multiple design parameters. Our proposed work leverages an XGBoost ML-based optimization strategy with a kernel activation function, which reduced the design time by 87.7% and enabled accurate prediction of optimal multidimensional structural parameters at the same time. To validate the simulation accuracy, post-layout parasitic extraction-based modeling was performed. Table 10 shows the comparison of EM simulation and post-layout S-parameters at 10 GHz, confirming the robustness of the proposed design through better RF performance.

Table 10.

EM simulation and post-layout S-parameter comparison at 10 GHz for the proposed I-clamp RF MEMS switch.

The fabrication and experimental characterization of the proposed I-clamp bistable RF MEMS switch will be carried out to validate the simulation-based findings in the future. The ML models developed in this work and trained on HFSS simulation data can be extended to incorporate experimental S-parameter measurements. This will enable the refinement of the model by capturing real-world variations arising from fabrication tolerances, material imperfections, and environmental influences. With sufficient measured data, the ML model can be retrained to enhance its predictive accuracy, thereby supporting more reliable and practically optimized switch designs.

5. Conclusions

This paper proposes an I-clamp bistable RF MEMS switch that significantly enhances RF performance in wireless communication systems, particularly by reducing insertion loss and increasing isolation. Optimization of the I-clamp structure by identifying the critical physical parameters that affect switch performance enabled us to efficiently explore a vast design space and identify optimal configurations that enhance RF efficiency. This work addresses the limitations of conventional optimization methods, which are often time-consuming and computationally intensive. The XGBoost ML model with the kernel activation function proved to be highly effective in predicting and optimizing these parameters. The ability of the ML model with an activation function to learn the complex, nonlinear relationships between physical dimensions and RF characteristics was instrumental in achieving superior performance metrics. The results from HFSS simulations and XGBoost predictions converged well with errors less than 0.5, proving the efficiency of the developed ML optimization approach. The optimized I-clamp bistable lateral RF MEMS switch showed better RF performance up to 10 GHz, making it reliable for high-frequency wireless communication. This ML approach saves time and computational resources while achieving better RF performance, leading to more efficient and reliable high-frequency applications.

Author Contributions

Conceptualization, J.J.P., S.K. and S.M.M.R.; methodology, J.J.P.; software, J.J.P.; validation, J.J.P. and S.K.; formal analysis, J.J.P.; investigation, J.J.P.; data curation, J.J.P.; writing—original draft preparation, J.J.P.; writing—review and editing, S.K. and S.M.M.R.; supervision, S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Department of Science and Technology (DST) of the Government of India, grant number DST/INSPIRE Fellowship/2021/IF210192.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Atherton, W.A. Miniaturization of Electronics. In From Compass to Computer; Palgrave: London, UK, 1984; pp. 237–267. [Google Scholar] [CrossRef]

- CTN Editorial. Predicting the Future of Communications Technologies|IEEE Communications Society. IEEE Communication Society. 2025. Available online: https://www.comsoc.org/publications/ctn/predicting-future-communications-technologies (accessed on 21 April 2025).

- Akyildiz, I.F.; Kak, A.; Nie, S. 6G and Beyond: The Future of Wireless Communications Systems. IEEE Access 2020, 8, 133995–134030. [Google Scholar] [CrossRef]

- Dai, M.; Huang, N.; Wu, Y.; Gao, J.; Su, Z. Unmanned-Aerial-Vehicle-Assisted Wireless Networks: Advancements, Challenges, and Solutions. IEEE Internet Things J. 2023, 10, 4117–4147. [Google Scholar] [CrossRef]

- Zhang, H.; Dai, J.; Zhang, W.; Fernandez, R.E.; Sobahi, N.; Chircov, C.; Grumezescu, A.M. Microelectromechanical Systems (MEMS) for Biomedical Applications. Micromachines 2022, 13, 164. [Google Scholar] [CrossRef] [PubMed]

- Frazier, A.B.; Warrington, R.O.; Friedrich, C. The Miniaturization Technologies: Past, Present, and Future. IEEE Trans. Ind. Electron. 1995, 42, 423–430. [Google Scholar] [CrossRef]

- Iannacci, J. RF-MEMS Technology for High-Performance Passives, 2nd ed.; IOP Publishing: Bristol, UK, 2022. [Google Scholar] [CrossRef]

- Cao, T.; Hu, T.; Zhao, Y. Research Status and Development Trend of MEMS Switches: A Review. Micromachines 2020, 11, 694. [Google Scholar] [CrossRef]

- Ferrari, V.; Comini, E.; Baù, M.; Zappa, D.; Shaheen, S.; Arslan, T.; Lomax, P. The Design, Simulation, and Parametric Optimization of an RF MEMS Variable Capacitor with an S-Shaped Beam. Micro 2024, 4, 474–489. [Google Scholar] [CrossRef]

- Wu, G.; Xu, J.; Ng, E.J.; Chen, W. MEMS Resonators for Frequency Reference and Timing Applications. J. Microelectromech. Syst. 2020, 29, 1137–1166. [Google Scholar] [CrossRef]

- Mirebrahimi, S.M.; Dousti, M.; Afrang, S. MEMS tunable filters based on DGS and waveguide structures: A literature review. Analog Integr. Circuits Signal Process. 2021, 108, 141–164. [Google Scholar] [CrossRef]

- Rahiminejad, S.; Alonso-Delpino, M.; Reck, T.; Peralta, A.; Lin, R.; Jung-Kubiak, C.; Chattopadhyay, G. A Low-Loss Silicon MEMS Phase Shifter Operating in the 550-GHz Band. IEEE Trans. Terahertz Sci. Technol. 2021, 11, 477–485. [Google Scholar] [CrossRef]

- Goel, S.; Gupta, N. Design, optimization and analysis of reconfigurable antenna using RF MEMS switch. Microsyst. Technol. 2020, 26, 2829–2837. [Google Scholar] [CrossRef]

- Le, H.T.; Haque, R.I.; Ouyang, Z.; Lee, S.W.; Fried, S.I.; Zhao, D.; Qiu, M.; Han, A. MEMS inductor fabrication and emerging applications in power electronics and neurotechnologies. Microsyst. Nanoeng. 2021, 7, 59. [Google Scholar] [CrossRef] [PubMed]

- Perez, C.; Garvi, R.; Lopez, G.; Quintero, A.; Leger, F.; Amaral, P.; Wiesbauer, A.; Hernandez, L. A VCO-Based ADC with Direct Connection to a Microphone MEMS, 80-dB Peak SNDR and 438-μW Power Consumption. IEEE Sens. J. 2023, 23, 8466–8477. [Google Scholar] [CrossRef]

- Gilasgar, M.; Barlabe, A.; Pradell, L. High-Efficiency Reconfigurable Dual-Band Class-F Power Amplifier with Harmonic Control Network Using MEMS. IEEE Microw. Wirel. Components Lett. 2020, 30, 677–680. [Google Scholar] [CrossRef]

- Rebeiz, G.M.; Muldavin, J.B. RF MEMS switches and switch circuits. IEEE Microw. Mag. 2001, 2, 59–71. [Google Scholar] [CrossRef]

- Shao, B.; Lu, C.; Xiang, Y.; Li, F.; Song, M. Comprehensive Review of RF MEMS Switches in Satellite Communications. Sensors 2024, 24, 3135. [Google Scholar] [CrossRef]

- Iannacci, J.; Tagliapietra, G. Prospects of Micro/Nanotechnologies (MEMS/NEMS) in the Emerging Scenario of 6G with Focus on RF-MEMS. In Proceedings of the 2023 16th International Conference on Advanced Technologies, Systems and Services in Telecommunications (TELSIKS), Nis, Serbia, 25–27 October 2023; pp. 13–20. [Google Scholar] [CrossRef]

- Iannacci, J.; Poor, H.V. Review and Perspectives of Micro/Nano Technologies as Key-Enablers of 6G. IEEE Access 2022, 10, 55428–55458. [Google Scholar] [CrossRef]

- Xu, Y.; Tian, Y.; Zhang, B.; Duan, J.; Yan, L. A novel RF MEMS switch on frequency reconfigurable antenna application. Microsyst. Technol. 2018, 24, 3833–3841. [Google Scholar] [CrossRef]

- Percy, J.J.; Kanthamani, S. Revolutionizing wireless communication: A review perspective on design and optimization of RF MEMS switches. Microelectron. J. 2023, 139, 105891. [Google Scholar] [CrossRef]

- Kurmendra; Kumar, R. A review on RF micro-electro-mechanical-systems (MEMS) switch for radio frequency applications. Microsyst. Technol. 2021, 27, 2525–2542. [Google Scholar] [CrossRef]

- Qiu, J.; Lang, J.H.; Slocum, A.H.; Weber, A.C. A bulk-micromachined bistable relay with U-shaped thermal actuators. J. Microelectromech. Syst. 2005, 14, 1099–1109. [Google Scholar] [CrossRef]

- Huang, H.W.; Yang, Y.J. A MEMS bistable device with push-on-push-off capability. J. Microelectromech. Syst. 2013, 22, 7–9. [Google Scholar] [CrossRef]

- Steiner, H.; Hortschitz, W.; Stifter, M.; Keplinger, F. Thermal actuated passive bistable MEMS switch. In Proceedings of the 2014 Microelectronic Systems Symposium (MESS), Vienna, Austria, 8–9 May 2014; pp. 4–8. [Google Scholar] [CrossRef]

- Yang, Y.J.; Liao, B.T.; Kuo, W.C. A novel 2 × 2 MEMS optical switch using the split cross-bar design. J. Micromech. Microeng. 2007, 17, 875–882. [Google Scholar] [CrossRef]

- Nathan, D.; Howell, L.L. A Self-Retracting Fully Compliant Bistable Micromechanism. J. Microelectromech. Syst. 2003, 12, 273–280. [Google Scholar]

- Yadav, D.; Murthy, N.S.; Palathingal, S.; Shekhar, S.; Giridhar, M.S.; Ananthasuresh, G.K. A two-terminal bistable electrothermally actuated microswitch. J. Microelectromech. Syst. 2019, 28, 540–549. [Google Scholar] [CrossRef]

- Dellaert, D.; Doutreloigne, J. Compact thermally actuated latching MEMS switch with large contact force. Electron. Lett. 2015, 51, 80–81. [Google Scholar] [CrossRef]

- Hu, T.; Zhao, Y.; Li, X.; Zhao, Y.; Bai, Y. Design and characterization of a microelectromechanical system electro-thermal linear motor with interlock mechanism for micro manipulators. Rev. Sci. Instrum. 2016, 87, 035001. [Google Scholar] [CrossRef]

- Pirmoradi, E.; Mirzajani, H.; Badri Ghavifekr, H. Design and simulation of a novel electro-thermally actuated lateral RF MEMS latching switch for low power applications. Microsyst. Technol. 2015, 21, 465–475. [Google Scholar] [CrossRef]

- Baker, M.S.; Howell, L.L. On-chip actuation of an in-plane compliant bistable micromechanism. J. Microelectromech. Syst. 2002, 11, 566–573. [Google Scholar] [CrossRef]

- Percy, J.J.; Kanthamani, S.; Sethuraman, S.; Roomi, S.M.M.; Maheswari, P.U. Artificial Neural Network Approach to Model Sidewall Metallization of Silicon-based Bistable Lateral RF MEMS Switch for Redundancy Applications. Silicon 2022, 14, 9175–9185. [Google Scholar] [CrossRef]

- Marinković, Z.; Marković, V.; Ćirić, T.; Vietzorreck, L.; Pronić-Rančić, O. Artifical neural networks in RF MEMS switch modelling. Facta Univ.-Ser. Electron. Energ. 2016, 29, 177–191. [Google Scholar] [CrossRef]

- Sarker, N.; Podder, P.; Mondal, M.R.H.; Shafin, S.S.; Kamruzzaman, J. Applications of Machine Learning and Deep Learning in Antenna Design, Optimization, and Selection: A Review. IEEE Access 2023, 11, 103890–103915. [Google Scholar] [CrossRef]

- Dahrouj, H.; Alghamdi, R.; Alwazani, H.; Bahanshal, S.; Ahmad, A.A.; Faisal, A.; Shalabi, R.; Alhadrami, R.; Subasi, A.; Al-Nory, M.T.; et al. An Overview of Machine Learning-Based Techniques for Solving Optimization Problems in Communications and Signal Processing. IEEE Access 2021, 9, 74908–74938. [Google Scholar] [CrossRef]

- El Misilmani, H.M.; Naous, T.; Al Khatib, S.K. A review on the design and optimization of antennas using machine learning algorithms and techniques. Int. J. RF Microw. Comput. Eng. 2020, 30, e22356. [Google Scholar] [CrossRef]

- Mahmood, M.R.; Matin, M.A.; Sarigiannidis, P.; Goudos, S.K. A Comprehensive Review on Artificial Intelligence/Machine Learning Algorithms for Empowering the Future IoT Toward 6G Era. IEEE Access 2022, 10, 87535–87562. [Google Scholar] [CrossRef]

- Liu, B.; Deferm, N.; Zhao, D.; Reynaert, P.; Gielen, G.G.E. An efficient high-frequency linear RF amplifier synthesis method based on evolutionary computation and machine learning techniques. IEEE Trans. Comput. Des. Integr. Circuits Syst. 2012, 31, 981–993. [Google Scholar] [CrossRef]

- Luo, W.; Dai, F.; Liu, Y.; Wang, X.; Li, M. Pulse-driven MEMS gas sensor combined with machine learning for selective gas identification. Microsyst. Nanoeng. 2025, 11, 72. [Google Scholar] [CrossRef]

- Haque, M.A.; Nahin, K.H.; Nirob, J.H.; Ahmed, M.K.; Sawaran Singh, N.S.; Paul, L.C.; Algarni, A.D.; ElAffendi, M.; El-Latif, A.A.A.; Ateya, A.A. Multiband THz MIMO antenna with regression machine learning techniques for isolation prediction in IoT applications. Sci. Rep. 2025, 15, 7701. [Google Scholar] [CrossRef]

- Bahar, D.; Dvivedi, A.; Kumar, P. Optimizing the quality characteristics of glass composite vias for RF-MEMS using central composite design, metaheuristics, and bayesian regularization-based machine learning. Meas. J. Int. Meas. Confed. 2025, 243, 116323. [Google Scholar] [CrossRef]

- Peng, Y.; Yang, X.; Li, D.; Ma, Z.; Liu, Z.; Bai, X.; Mao, Z. Predicting flow status of a flexible rectifier using cognitive computing. Expert Syst. Appl. 2025, 264, 125878. [Google Scholar] [CrossRef]

- Mao, Z.; Kobayashi, R.; Nabae, H.; Suzumori, K. Multimodal Strain Sensing System for Shape Recognition of Tensegrity Structures by Combining Traditional Regression and Deep Learning Approaches. IEEE Robot. Autom. Lett. 2024, 9, 10050–10056. [Google Scholar] [CrossRef]

- Dubey, S.R.; Singh, S.K.; Chaudhuri, B.B. Activation functions in deep learning: A comprehensive survey and benchmark. Neurocomputing 2022, 503, 92–108. [Google Scholar] [CrossRef]

- Jagtap, A.D.; Karniadakis, G.E. How important are activation functions in regression and classification? A survey, performance comparison, and future directions. J. Mach. Learn. Model. Comput. 2023, 4, 21–75. [Google Scholar] [CrossRef]

- Enyinna Nwankpa, C.; Ijomah, W.; Gachagan, A.; Marshall, S. Activation Functions: Comparison of Trends in Practice and Research for Deep Learning. November 2018. Available online: https://arxiv.org/abs/1811.03378v1 (accessed on 21 April 2025).

- Bajwa, R.; Yapici, M.K. Machine Learning-Based Modeling and Generic Design Optimization Methodology for Radio-Frequency Microelectromechanical Devices. Sensors 2023, 23, 4001. [Google Scholar] [CrossRef] [PubMed]

- Ardehshiri, A.; Karimi, G.; Dehdasht-Heydari, R. Design and optimization of a low voltage RF switch MEMS capacitance using genetic algorithm and Taguchi method. Circuit World 2019, 45, 53–64. [Google Scholar] [CrossRef]

- Thalluri, L.N.; Bommu, S.; Rao, S.M.; Rao, K.S.; Guha, K.; Kiran, S.S. Target Application Based Design Approach for RF MEMS Switches using Artificial Neural Networks. Trans. Electr. Electron. Mater. 2022, 23, 509–521. [Google Scholar] [CrossRef]

- Ardehshiri, A.; Soltanian, F.; Moradkhani, M.; Nosrati, M. Enhancing Micro-Pump Efficiency: Multi-Objective Optimization of Low Voltage MEMS Switches for Drug Delivery Applications. Digit. Technol. Res. Appl. 2024, 3, 73–88. [Google Scholar] [CrossRef]

- Liang, J.; Liu, J.; Yang, Y.; Wang, F. The design of RF MEMS switch based on adaptive chaotic perturbation particle swarm optimization algorithm. In Proceedings of the 2014 10th International Conference on Natural Computation (ICNC), Xiamen, China, 19–21 August 2014; pp. 291–296. [Google Scholar] [CrossRef]

- Zhang, Y.; Ding, G.; Shun, X.; Gu, D.; Cai, B.; Lai, Z. Preparing of a high speed bistable electromagnetic RF MEMS switch. Sens. Actuators A Phys. 2007, 134, 532–537. [Google Scholar] [CrossRef]

- Sun, Z.; Bian, W.; Zhao, J. A zero static power consumption bi-stable RF MEMS switch based on inertial generated timing sequence method. Microsyst. Technol. 2022, 28, 973–984. [Google Scholar] [CrossRef]

- Daneshmand, M.; Fouladi, S.; Mansour, R.R.; Lisi, M.; Stajcer, T. Thermally actuated latching RF MEMS switch and its characteristics. IEEE Trans. Microw. Theory Tech. 2009, 57, 3229–3238. [Google Scholar] [CrossRef]

- Naito, Y.; Nakamura, K.; Uenishi, K. Laterally movable triple electrodes actuator toward low voltage and fast response RF-MEMS switches. Sensors 2019, 19, 864. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).