1. Introduction

Landslide monitoring is crucial for mitigating the risk of landslide disasters, but existing rainfall sensors often rely on power supply methods that are impractical for remote, field-based deployment. These disasters cause significant casualties and economic losses worldwide annually, making landslide monitoring a vital tool for risk reduction. Key parameters for landslide monitoring include rainfall [

1,

2], soil pressure [

3], displacement [

4,

5], pore water pressure [

6], and groundwater level [

7]. Commonly used sensors and methods for monitoring these parameters include rainfall sensors [

8], satellite remote sensing [

9], inclinometers [

10], GPS [

11,

12], total stations [

13], and piezometers [

14]. Most landslides are directly related to rainfall. Rainfall increases soil weight, reduces its shear strength, and increases pore water pressure, all of which contribute to landslide initiation. Therefore, rainfall monitoring is a crucial component of landslide prediction and early warning systems.

However, rainfall sensors for landslide monitoring are often deployed in remote and unmanned field environments. Current power supply methods for these sensors primarily rely on cable power, solar power, and battery power. However, in field environments, laying cables and replacing batteries significantly increase costs and may pose safety risks to personnel. Solar power is heavily affected by cloudy and rainy weather. Especially during critical monitoring periods when continuous rainfall is likely to trigger landslides, solar panels may experience power outages due to prolonged lack of sunlight, resulting in the loss of crucial early warning data. Thus, if a rainfall sensor could generate electricity from the rainfall environment itself, this problem could be effectively solved.

The triboelectric nanogenerator (TENG), proposed by Wang Z.L. [

15] and others, has been widely utilized in the field of self-powered sensors. In the generator field, TENG can harvest energy from various sources, including wind [

16,

17,

18], water [

19], vibration [

20], tides [

21], and waves [

22,

23]. In the sensor field, TENG has been used to monitor various parameters in real time, including vibration frequency, tilt angle [

24], pressure [

25,

26,

27], velocity [

28], temperature [

29,

30,

31], and humidity [

32]. Furthermore, TENG has been widely applied in downhole monitoring in the geological field. Examples include deep learning-based downhole mechanical operation monitoring [

33], self-powered downhole vibration sensor research [

34], and downhole energy harvesting and vibration monitoring [

35].

This study proposes a hybrid TENG–electromagnetic rainfall sensor for landslide monitoring, offering dual functionality of rainfall measurement and power generation. The sensor utilizes rainfall-induced triboelectric generation to simultaneously achieve power generation and rainfall measurement. It also utilizes the impact of rainfall to drive an electromagnetic generator (EMG) to further enhance the overall power generation of the sensor.

2. Structure and Working Principle

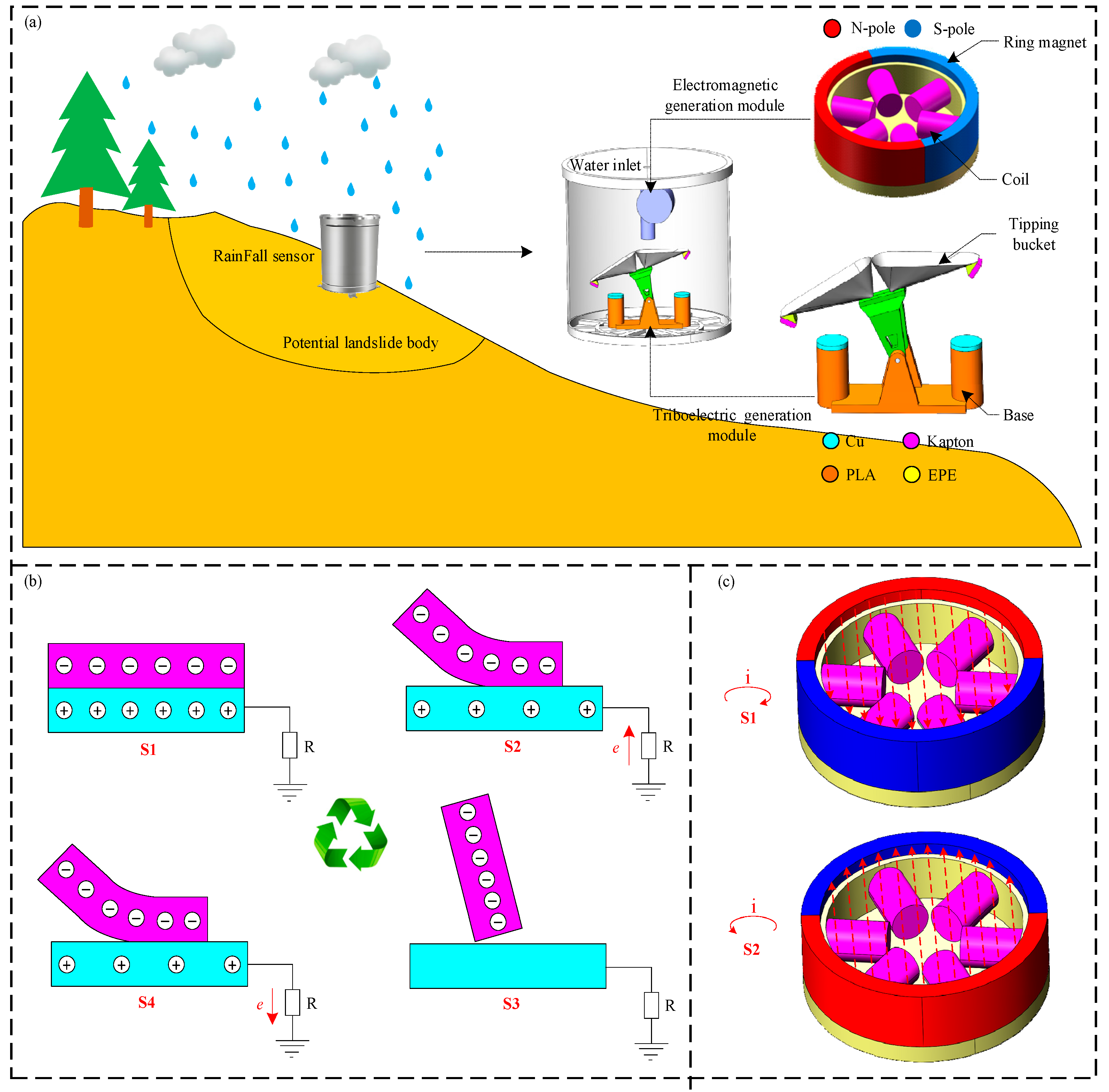

Figure 1 illustrates the structure and working principle of the sensor. As shown in

Figure 1a, the sensor is installed on a potential landslide body. Its basic structure consists of two module units: a triboelectric generator and an electromagnetic generator. Two module units work independently. The triboelectric generator, characterized by its high voltage and low current, is used as the sensing unit, while the electromagnetic generator, with its larger power output, serves as the power generation module. The electromagnetic generator module mainly comprises an annular magnet and six coils. Rainwater impacts the impeller of the electromagnetic generator, causing it to rotate, which in turn rotates the annular magnet. This rotation results in the cutting of magnetic field lines by the coils, generating an induced current, thus achieving power generation. The triboelectric generator module primarily consists of a tipping bucket and a base. The tipping bucket features a triangular chamber design with a capacity of 4 mL and is fixed to the base. The material of the base is PLA. This paper selects Kapton and Cu as friction materials based on the triboelectric series, also taking into account the ease of material acquisition and processing. A Kapton film with dimensions of 25 × 20 × 0.05 mm is attached to the back of the tipping bucket as a triboelectric layer. Correspondingly, a copper film with a diameter of 20 mm and a thickness of 0.1 mm is attached to the base at the friction location aligned with the tipping bucket, serving as the other triboelectric layer. These two triboelectric layers form a single-electrode triboelectric nanogenerator. An EPE foam is adhered to the back of the tipping bucket, providing excellent elastic–plastic deformation capability. This allows for deformation during contact and compression with the base, ensuring sufficient contact between the Kapton and copper triboelectric layers. When rainwater, having passed through the electromagnetic generator, further enters the tipping bucket of the triboelectric generator, the tipping bucket will rotate as the water volume increases. This rotation causes the Kapton and copper triboelectric layers to rub against each other, generating a triboelectric signal, which simultaneously achieves power generation and tipping bucket count measurement. Since the volume of the tipping bucket is fixed at 4 mL, each generated triboelectric signal signifies that the bucket has collected 4 mL of water. Therefore, the time interval between two consecutive triboelectric signals can be recorded by the subsequent circuit, and by combining this interval with the bucket volume, the average rainfall rate during this period can be calculated. Furthermore, the sensor does not include subsequent circuitry. Users can design specific signal processing and power management circuits based on their actual measurement and power generation functional requirements.

The detailed working principles of the triboelectric generator and the electromagnetic generator are further explained below concerning

Figure 1b,c. As shown in

Figure 1b-S1, in the initial state, the Kapton and Cu triboelectric layers are in full contact. Based on the electron-donating and accepting capabilities of the nanomaterials in the triboelectric series, the Kapton surface carries negative charges, while the Cu surface carries an equal amount of positive charges. As the device operates, progressing to the state shown in

Figure 1b-S2, the movement of the tipping bucket causes the Kapton triboelectric layer to gradually separate from the Cu triboelectric layer. At this time, due to the weakening attraction between the negative charges on the Kapton surface and the positive charges on the Cu surface, electrostatic induction occurs on the Cu triboelectric layer. Negative charges are transferred from the ground to the Cu triboelectric layer, generating an induced current in the circuit. When the Kapton is completely separated from the Cu, as shown in

Figure 1b-S3, the charge transfer in the Cu triboelectric layer is complete, and no induced current is generated in the circuit. As the Kapton moves in the reverse direction, reaching the state shown in

Figure 1b-S4, under the attraction of the negative charges on the Kapton, the charges in the Cu triboelectric layer are transferred back to the ground, generating a reverse transfer current in the circuit. Therefore, within one working cycle, a triboelectric pulse signal is generated in the circuit. The frequency of the triboelectric charge pulse signal corresponds one-to-one with the number of triboelectric contacts, enabling the dual functions of power generation and rainfall monitoring.

In the electromagnetic generator unit, the fan blades and the ring magnet are rigidly fixed together. When the rainwater flow drives the fan blades to rotate, the ring magnet also rotates coaxially. As shown in

Figure 1c, the relative motion between the coil and the ring magnet causes a change in the magnetic flux passing through the coil. According to Faraday’s law of electromagnetic induction, the change in magnetic flux induces an electromotive force (EMF) in the coil, thereby generating a current. The direction of the induced current can be determined using Lenz’s law and the right-hand screw rule. Specifically, since the direction of the induced current always attempts to oppose the change in magnetic flux, when the ring magnet rotates to the states shown in

Figure 1c-S1 and 1c-S2, the direction of the induced current in the coil is clockwise and counterclockwise, respectively. This results in a continuously changing alternating current (AC) being generated in the electromagnetic generator, thus achieving the function of power generation.

3. Experiments and Analysis

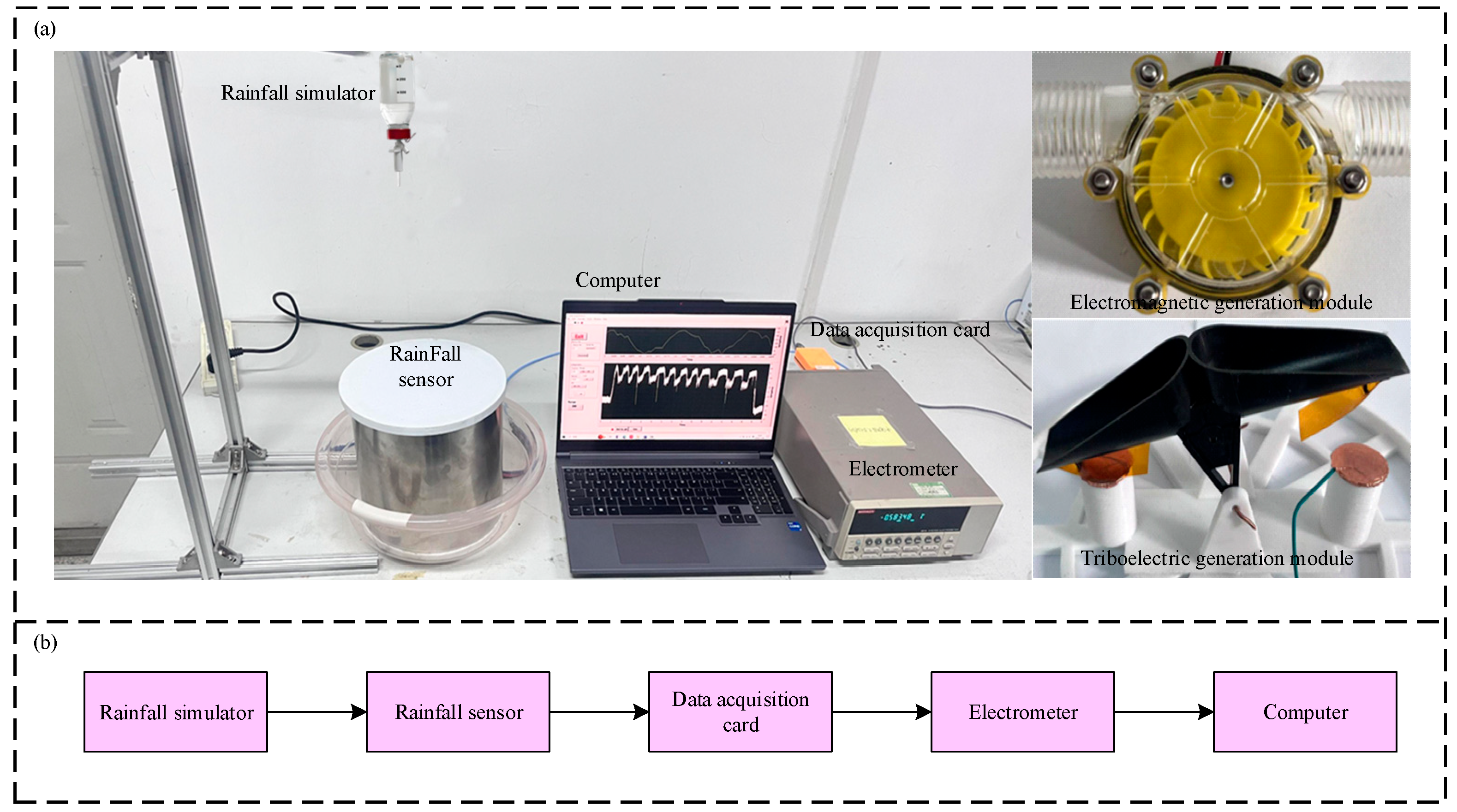

To investigate the sensing and power generation performance of the rainfall sensor under varying rainfall intensities, an indoor simulated experimental setup was constructed, as depicted in

Figure 2. This experimental setup primarily consists of a rainfall simulator, a rainfall sensor, a data acquisition card, an electrometer, and a computer. During the experiment, the rainfall simulator precisely controls the time interval between water droplet release and the water droplet size, thereby simulating different rainfall intensities. Water droplets, introduced through the water inlet, initially reach the electromagnetic generator module, inducing power generation. Subsequently, the water flows into the triboelectric generator module, inducing triboelectric generation. The electrical signals generated by the sensor are read by both the data acquisition card and the electrometer before being transmitted to the computer. A LabVIEW-basedsoftware program (version 13.0) installed on the computer enables real-time display of the measured data. The measurement function, power generation function, and environmental adaptability of the sensor were tested, as detailed below.

3.1. Measurement Function Tests and Analysis

Figure 3 shows the output voltage and current waveforms of the sensor’s triboelectric nanogenerator (TENG) module under different rainfall intensities. Rainfall intensity is classified according to the World Meteorological Organization’s precipitation intensity classification standards: rainfall less than 10 mm is defined as light rain, 20–25 mm as moderate rain, 25–50 mm as heavy rain, 50–100 mm as rainstorm, 100–200 mL as heavy rainstorm, and 200–250 mm as exceptionally heavy rainstorm. As shown in

Figure 3a, the frequency of the output voltage waveform gradually increases with increasing rainfall intensity, while the output voltage amplitude does not exhibit a significant change, remaining approximately at −5 V.

Figure 3b shows the output current variation. As rainfall intensity increases, the frequency of the output current waveform gradually increases, and the current amplitude also increases slightly, with a maximum output current of approximately 11.5 nA. This phenomenon occurs because the output voltage of the TENG is related to the contact area of the triboelectric materials. As the rainfall intensity increases, the triboelectric contact area of the sensor does not change significantly; therefore, the voltage amplitude remains relatively constant. However, the output current is related to the amount of charge transfer per unit time. As the rainfall intensity increases, the frequency of the sensor’s tipping bucket rotation increases, leading to an increase in the amount of charge transfer per unit time. Consequently, the output current increases slightly.

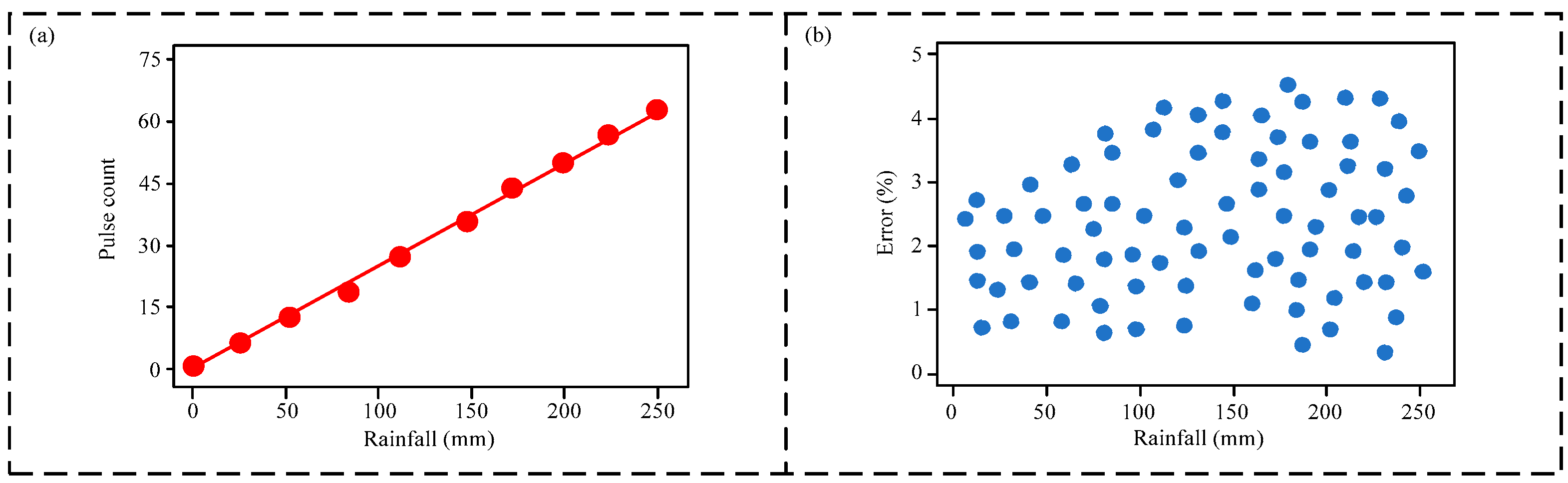

Figure 4 shows the calibration curve and measurement error scatter plot for the triboelectric nanogenerator (TENG) module. As shown in

Figure 4a, the number of output pulses from the TENG module increases gradually with increasing rainfall intensity, exhibiting a good linear relationship. This indicates that the sensor possesses a satisfactory measurement function. To further assess the sensor’s measurement error at different rainfall intensities, a total of 5000 experimental data points were collected. A representative measurement error scatter plot is shown in

Figure 4b. The measurement error exhibits a relatively wide range of fluctuation, but the maximum measurement error is less than 5%. Therefore, the sensor’s measurement error is defined as 5%.

3.2. Power Generation Performance Tests and Analysis

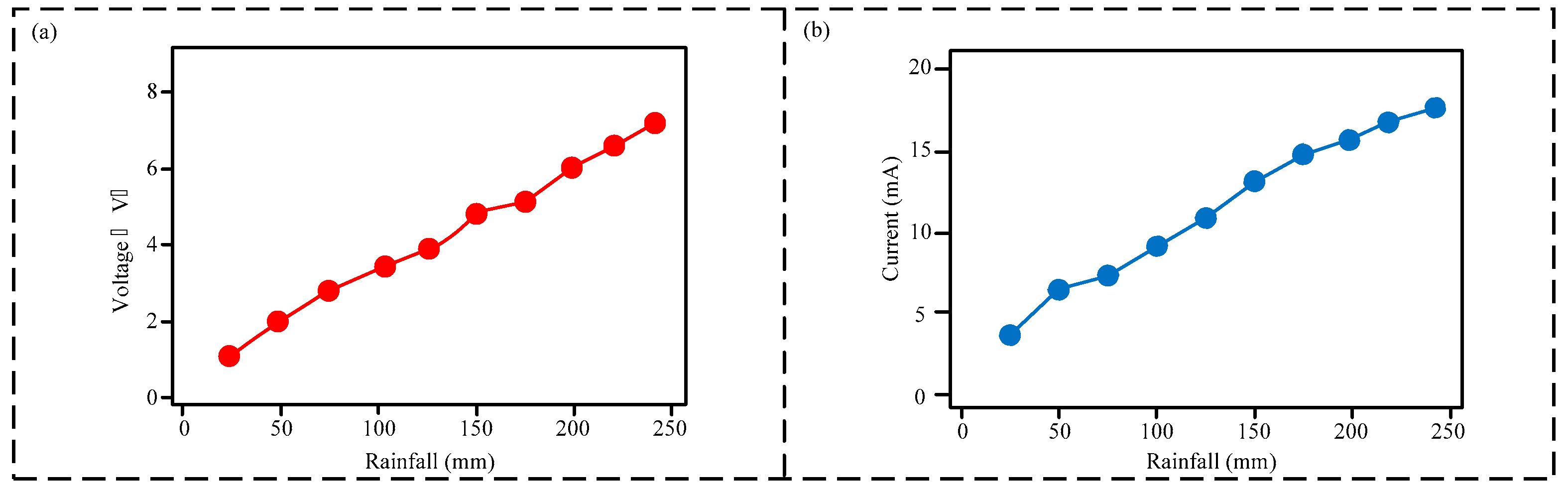

The primary function of the electromagnetic generator (EMG) module is power generation. Therefore, the output voltage and current of the EMG module were tested under varying rainfall intensities. As shown in

Figure 5a, the output voltage of the EMG module increases linearly with increasing rainfall intensity, rising from 0.5 V to 6.3 V. Similarly,

Figure 5b demonstrates that the output current of the EMG module also increases linearly with increasing rainfall intensity, increasing from 5 mA to 17.5 mA. This phenomenon is attributed to the increased rotational speed of the EMG module’s blades at higher rainfall intensities, resulting in a greater rate of magnetic flux cutting per unit time, thereby producing a higher output current and voltage.

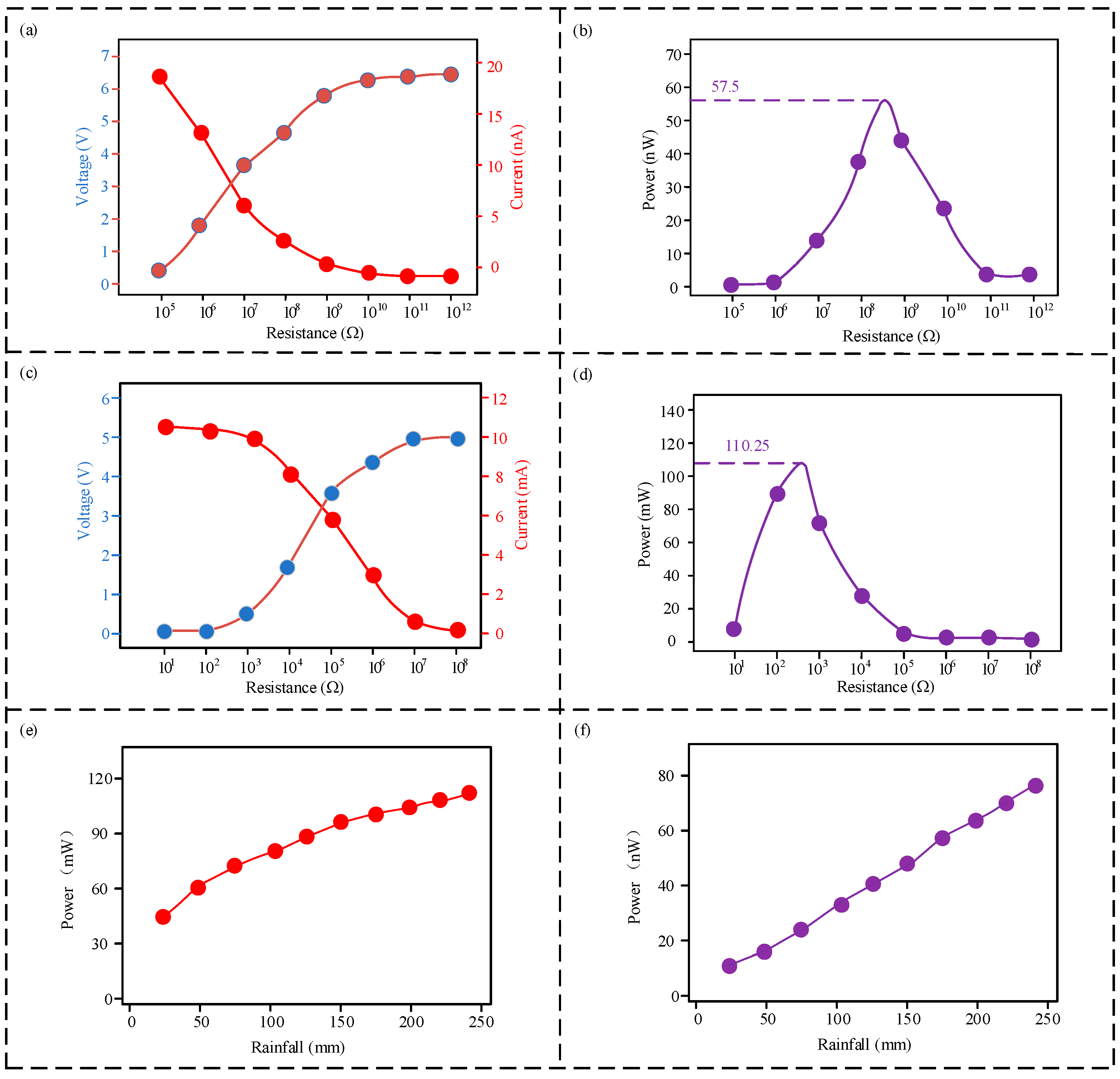

Both the triboelectric nanogenerator (TENG) and electromagnetic generator (EMG) modules of the sensor possess power generation capabilities. Consequently, the output characteristics of both modules were tested under varying external loads at a constant rainfall intensity of 180 mm. The results are presented in

Figure 6. As shown in

Figure 6a,b, the output voltage of the TENG module increases gradually with increasing external load while the output current decreases. The maximum output power of 57.5 nW is achieved at an external load of 4.3 × 10

8 Ω. Similarly, as shown in

Figure 6c,d, the output voltage of the EMG module increases gradually with increasing external load while the output current decreases. The maximum output power of 110.25 mW is achieved at an external load of 3.6 × 10

2 Ω. As shown in

Figure 6e,f, the output power of both the EMG and TENG modules increases with increasing rainfall.

3.3. Environmental Adaptability Tests and Analysis

Given that the rainfall sensor is intended for long-term outdoor deployment, it is essential to investigate the influence of environmental temperature and humidity variations on the output signals of each sensor module to ensure long-term stable and reliable operation. Temperature and humidity experiments were conducted using a controlled temperature chamber and humidifier, respectively. During the experiments, the sensor was placed inside the temperature chamber. For the temperature experiments, the humidity was maintained at ambient (room) humidity, and the temperature was varied manually by adjusting the temperature chamber settings. Similarly, for the humidity experiments, the temperature was maintained at room temperature, and the humidity was varied manually by adjusting the humidifier settings.

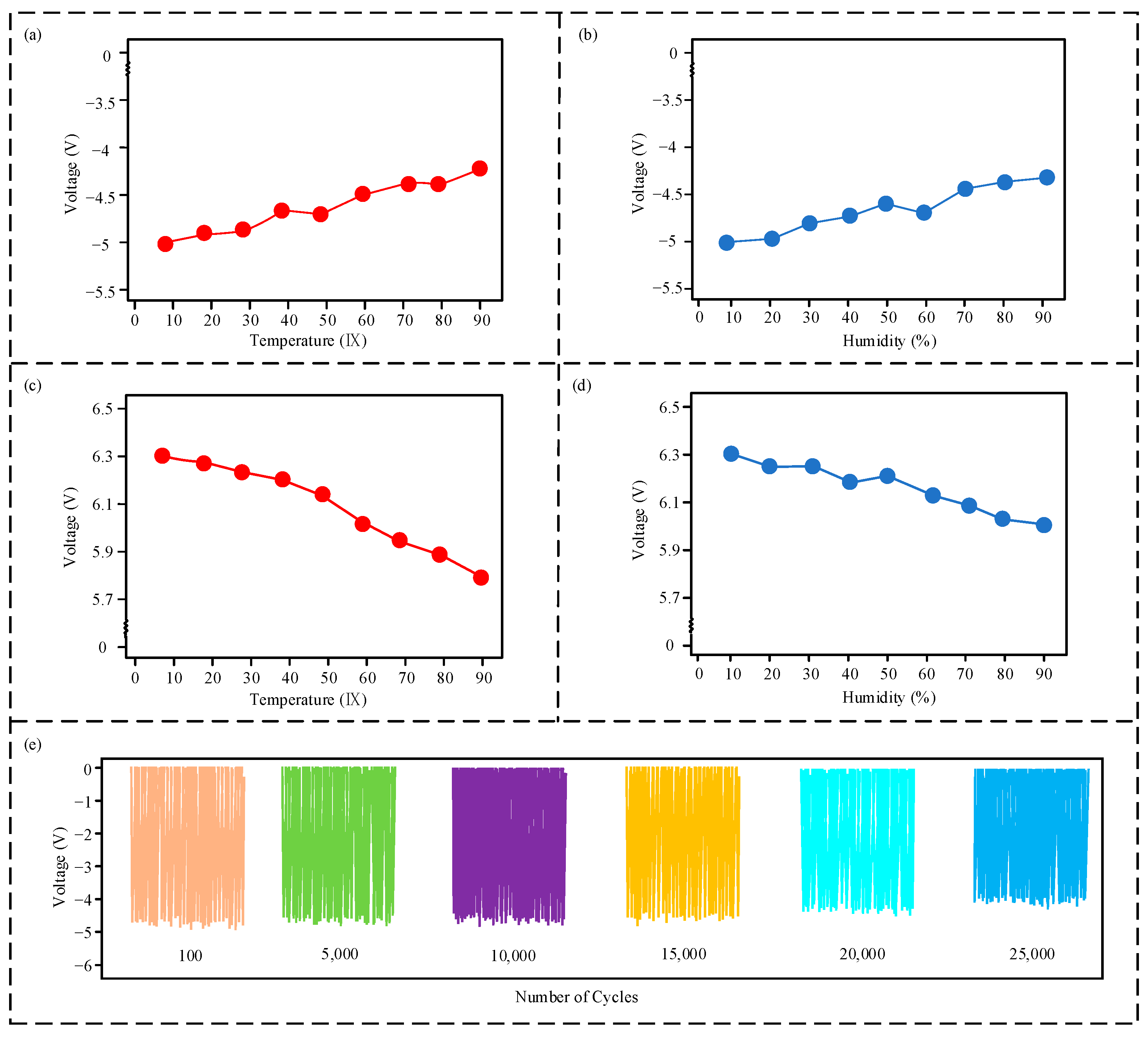

As shown in

Figure 7a, the output voltage of the triboelectric nanogenerator (TENG) module decreases from −5 V to −4.23 V as the temperature increases from 0 °C to 90 °C, representing a reduction of 15.5%. Similarly,

Figure 7b shows that the output voltage of the TENG module decreases from −5 V to −4.32 V as the humidity increases from 0% to 90%, corresponding to an attenuation rate of 13.7%. Correspondingly, as shown in

Figure 7c,d, the output voltage of the electromagnetic generator (EMG) module decreases by 7.7% and 5.1% within the temperature range of 0 °C to 90 °C and the humidity range of 0% to 90%, respectively. The resulting voltage amplitudes are 5.81 V and 5.98 V, respectively. These results indicate that the TENG module is more susceptible to the effects of temperature and humidity than the EMG module.

For the sensor, the output signal of the TENG module is used as the detection signal. Because the TENG output signal is pulsed, the subsequent microprocessor typically connects directly to the sensor output signal via a pulse input port. As the pulse input port adheres to the Transistor–Transistor Logic (TTL) logic level standard, signals with a voltage amplitude greater than 2 V are considered valid high-level signals. Therefore, even after temperature and humidity variations, the output signal voltage amplitude of the sensor remains significantly greater than the TTL high-level signal threshold, ensuring a valid signal and, thus, no impact on the sensor’s detection. Consequently, the operating temperature range of the sensor can be defined as 0 °C to 90 °C, and the operating humidity range can be defined as 0% to 90%.

Furthermore, the signal stability of the sensor during long-term operation was tested. Because the EMG module has no frictional contact components, while the frictional contact of the TENG module can degrade the signal output performance, only the TENG module was tested for long-term stability. As shown in

Figure 7e, after 25,000 cycles, the output voltage decreases to approximately −4 V, which remains above the TTL voltage threshold for effective signal recognition. This demonstrates that the sensor exhibits good long-term operational stability.

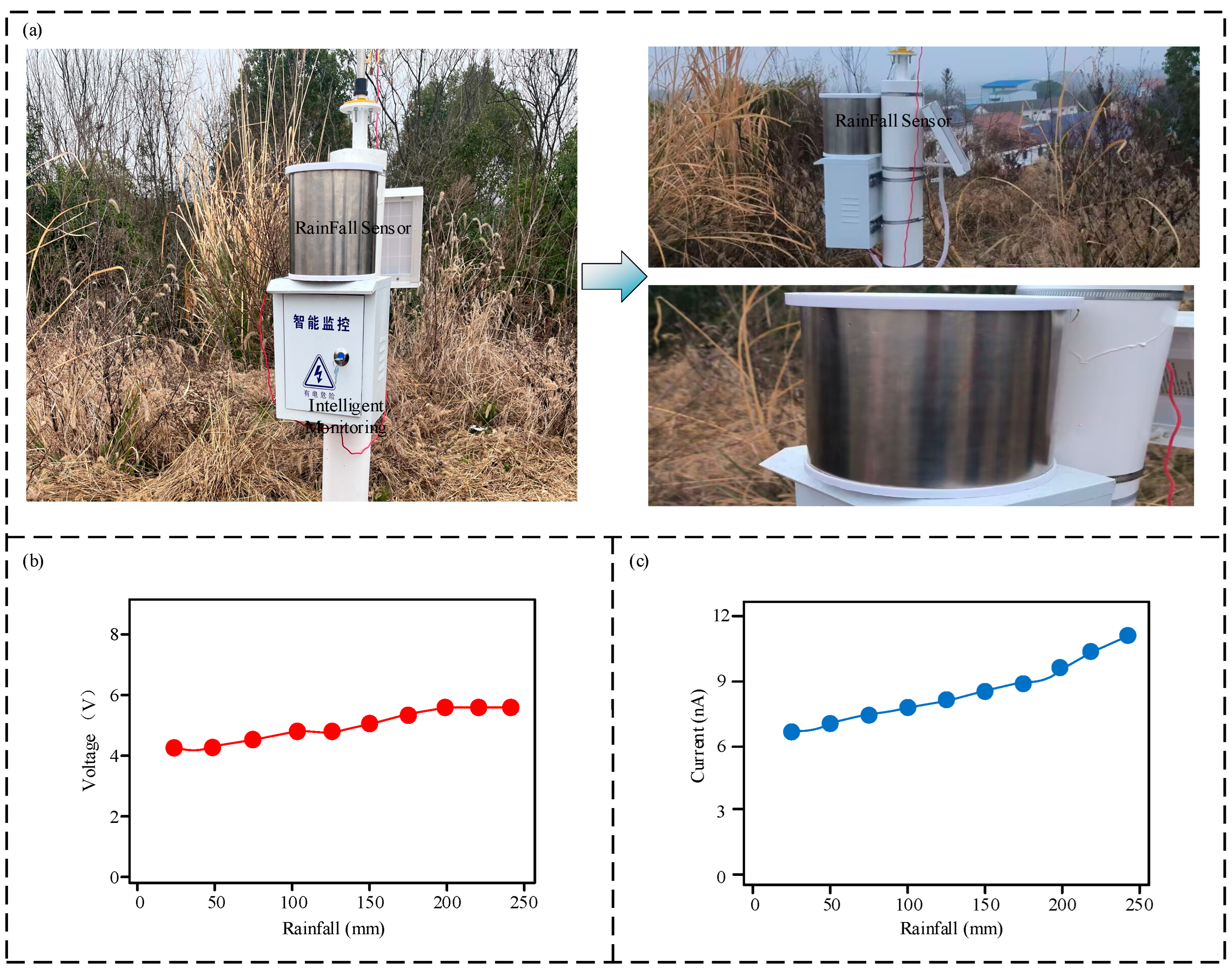

3.4. Field Experimentation, Testing, and Analysis

Figure 8 shows the on-site test setup. As shown in

Figure 8a, which is a photograph of the actual on-site setup, the rainfall sensor collects rainwater.

Figure 8b,c present the on-site data. It is evident that as the rainfall amount increases, both the voltage amplitude and current amplitude of the sensor’s output signal progressively increase. The increase in voltage amplitude is relatively small, while the increase in current amplitude is considerably larger. This is consistent with the experimental results.

4. Conclusions and Discussions

This study presents a hybrid landslide rainfall sensor based on triboelectric nanogenerator (TENG) and electromagnetic generator (EMG) technologies, capable of simultaneously measuring rainfall and providing real-time power generation. Experimental results indicate that the sensor exhibits a measurement error of less than 5% and can operate stably in environmental conditions with temperatures below 90 °C and humidity levels below 90%. Furthermore, the sensor demonstrates power generation capabilities, with the TENG module delivering a maximum power output of 57.5 nW when connected to a 4.3 × 108 Ω load resistor and the EMG module delivering a maximum power output of 110.25 mW when connected to a 3.6 × 102 Ω load resistor.

Compared to conventional rainfall sensors, this sensor integrates power generation functionality. The combined TENG and EMG architecture further enhances power generation capabilities, enabling self-powered operation, which is particularly advantageous for remote landslide monitoring applications. However, the detection accuracy of the sensor requires further improvement. Future work will focus on optimizing the sensor structure or exploring the use of high-performance nanomaterials to enhance the output voltage amplitude, thereby increasing the signal-to-noise ratio and reducing the occurrence of false positive detections, which will ultimately improve the measurement precision. Furthermore, designing a suitable data processing circuit to store the electrical energy generated by TENG is also expected to power subsequent circuit boards.

Author Contributions

Validation, Z.Z., S.M., B.C., and X.S.; data curation, H.Z.; writing—original draft, K.S.; methodology, Z.Z., and S.M.; writing—review and editing, H.Z., Z.Z., X.S., and K.S.; project administration, H.Z., S.M., B.C., and K.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Open Research Fund of the Hubei Key Laboratory of Disaster Prevention and Mitigation (China Three Gorges University), grant number 2023KJZ10, and Hubei Province Natural Science Foundation geological innovation and development joint fund, grant number 2023AFD221.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed at the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Qin, J.; Huang, T.; Wang, T.; Li, H.; Yu, Y.; Wang, Z.; Shen, P.; Chen, T. A Capillary Structured Droplet-Based Triboelectric Nanogenerator for High-Accuracy Rainfall Monitoring. IEEE Sens. J. 2024, 24, 11342–11353. [Google Scholar]

- Chen, X.; Letu, H.; Shang, H.; Ri, X.; Tang, C.; Ji, D.; Shi, C.; Teng, Y. Rainfall Area Identification Algorithm Based on Himawari-8 Satellite Data and Analysis of its Spatiotemporal Characteristics. Remote Sens. 2024, 16, 747. [Google Scholar] [CrossRef]

- Wang, C.; Yang, Y.; Zhang, X.; Wang, F.; Bi, X.; Li, H.; Wang, Z.; Cheng, T. Ultra-High Sensitivity Real-Time Monitoring of Landslide Surface Deformation via Triboelectric Nanogenerator. Adv. Mater. 2024, 36, 2410471. [Google Scholar]

- Chen, J.G.; Zou, H.; Pan, G.; Mao, S.; Chen, B.; Chuan, W. Self-Powered Sensor Based on Triboelectric Nanogenerator for Landslide Displacement Measurement. J. Sens. 2024, 2024, 6182699. [Google Scholar] [CrossRef]

- Zhou, Z.; Xu, Z.; Cao, L.N.Y.; Sheng, H.; Li, C.; Shang, Y.; Tang, W.; Wang, Z. Triboelectricity Based Self-Powered Digital Displacement Sensor for Aircraft Flight Actuation. Adv. Funct. Mater. 2024, 34, 2311839. [Google Scholar]

- Wang, W.; Zhao, C.; Wang, Z.; Mao, B.; Wang, H.; Zhang, Y.; Xi, Z.; Xiang, C.; Xu, M.; Qu, J. A Durable and Self-Powered Triboelectric Sensor for Hydraulic Pressure Monitoring and Underwater Disturbance Detection. IEEE Sens. J. 2024, 24, 18928–18936. [Google Scholar]

- Wei, Y.; Chen, Y.; Cao, X.; Xiang, M.; Hang, Y.; Li, H. A critical review of groundwater table fluctuation: Formation, effects on multifields, and contaminant behaviors in a soil and aquifer system. Environ. Sci. Technol. 2024, 58, 2185–2203. [Google Scholar] [CrossRef]

- Veloso, V.Q.; Reis, F.A.G.V.; Carvalho Cabral, V.; Sa, A.A.; Gramani, M.F.; Ogura, A.T.; Boesing, I.J.; Balbinot, G.; Tatizana, C. Brazil Proposal for real-time rainfall monitoring of gravitational mass movements in Serra do Mar, SP. Landslides 2025, 1–20. [Google Scholar] [CrossRef]

- Vecchi, E.; Tavasci, L.; Giorgini, E.; Gandolfi, S. A Priori Estimation of Radar Satellite Interferometry’s Sensitivity for Landslide Monitoring in the Italian Emilia-Romagna Region. Remote Sens. 2024, 16, 2562. [Google Scholar]

- Wei, Y.; Ma, Z.; Xu, H.; Xu, Y.; Chen, D.; Dong, Y. Real-time Pre-Warning System for Petroleum Pipeline Landslide Prediction Based on Imbalanced Machine Learning Methods with Finite Element Analysis. IEEE Trans. Instrum. Meas. 2025, 74, 2506008. [Google Scholar] [CrossRef]

- Gautam, R.; Gajurel, A.P.; Upadhyaya, B.R.; Pandey, K.; Pratt-Sitaula, B. Application of the differential GPS technique to monitor landslides: A case study of Dutti Landslide, Nepal. J. Nepal. Geol. Soc. 2024, 67, 139–148. [Google Scholar] [CrossRef]

- Li, B.; Wang, G.; Chen, L.C.; Sun, F.; Wang, R.; Liao, M.; Xu, H.; Li, S.; Kang, Y. Analysis of landslide deformation mechanisms and coupling effects under rainfall and reservoir water level effects. Eng. Geol. 2024, 343, 107803. [Google Scholar] [CrossRef]

- Tamimi, R.; Toth, C. Accuracy Assessment of UAV LiDAR Compared to Traditional Total Station for Geospatial Data Collection in Land Surveying Contexts. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2024, 48, 421–426. [Google Scholar] [CrossRef]

- Ma, S.Y.; Ye, X.W.; Liu, Z.X.; Ding, Y.; Zhang, D.; Sun, F. Mechanical Behavior Monitoring and Load Inversion Analysis of Large-Diameter Underwater Shield Tunnel during Construction. Sensors 2024, 24, 1310. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Wang, Z.L. Biopolymer and biomimetic techniques for triboelectric nanogenerators (TENGs). Adv. Mater. 2024, 2409440. [Google Scholar] [CrossRef]

- Liu, D.; Luo, J.; Huang, L.; Chen, M.; Ji, M.; Wang, Z.; Kang, J. Triboelectric Nanogenerators as a Practical Approach for Wind Energy Harvesting: Mechanisms, Designs, and Applications. Nano Energy 2025, 136, 110767. [Google Scholar] [CrossRef]

- Hasan, M.A.M.; Zhu, W.; Bowen, C.R.; Wang, Z.; Yang, Y. Triboelectric nanogenerators for wind energy harvesting. Nat. Rev. Electr. Eng. 2024, 1, 453–465. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, G.; Zhang, Z.; Ren, H.; Zhou, H.; Gui, Y.; Du, Z.; Cheng, G. Enhancing the output energy of triboelectric nanogenerator by adaptive arc discharge devices and its application in wireless weather sensing system. Nano Energy 2024, 129, 109987. [Google Scholar] [CrossRef]

- Wu, H.; Zheng, H.; Qin, X.; Jin, Y.; Li, Y.; Yang, S.; Yi, Z.; Gao, S.; Wang, S.; Wang, Z. Drinking-bird-enabled triboelectric hydrovoltaic generator. Device 2024, 2, 100318. [Google Scholar] [CrossRef]

- Wang, X.; Yin, G.; Sun, T.; Xu, X.; Rasool, G.; Abbas, K. Mechanical vibration energy harvesting and vibration monitoring based on triboelectric nanogenerators. Energy Technol. 2024, 12, 2300931. [Google Scholar] [CrossRef]

- Shan, B.; Ai, T.; Wang, K. Triboelectric nanogenerator for ocean energy harvesting: A review of technological advances and future perspectives. Int. J. Electrochem. Sci. 2024, 19, 100694. [Google Scholar] [CrossRef]

- Guo, D.; Chen, C.; Li, J.; Zhai, L.; Li, S.; He, S.; Feng, J.; Wan, L.; Liu, G.; Zhai, J. Structural Quality Factor of Flo-TENG under Stochastic Wave Excitation. Adv. Sci. 2024, 11, 2405165. [Google Scholar] [CrossRef]

- Yang, H.; Liang, X.; Kan, J.; Wang, Z.; Jiang, T.; Hong, Z. Triboelectric nanogenerator integrated with a simple controlled switch for regularized water wave energy harvesting. Nano Res. 2024, 17, 7585–7592. [Google Scholar] [CrossRef]

- Yuan, M.; Yao, W.; Ding, Z.; Li, J.; Dai, B.; Zhang, X.; Xie, Y. Integrated acoustic metamaterial triboelectric nanogenerator for joint low-frequency acoustic insulation and energy harvesting. Nano Energy 2024, 122, 109328. [Google Scholar] [CrossRef]

- Lakshakoti, B.; Sankar, P.R.; Supraja, P.; Navaneeth, M.; Mahesh, V.; Kumar, K.; Prakash, K.; Kumar, R. Innovative triboelectric nanogenerator (TENG) design utilizing a stress ball for energy harvesting, wellness, and safety applications. Eng. Res. Express 2024, 6, 015081. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, G.; Ren, H.; Zhang, Z.; Zhang, Z.; Qin, H.; Zheng, M.; Du, Z.; Cheng, G. A real-time self-powered wireless pressure sensing system based on capacitive triboelectric pressure sensor. Nano Energy 2025, 136, 110729. [Google Scholar] [CrossRef]

- Wang, T.; Wang, C.; Zeng, Q.; Gu, G.; Wang, X.; Cheng, G.; Du, Z. A real-time, self-powered wireless pressure sensing system with an efficient coupling energy harvester, sensing, and communication modules. Nano Energy 2024, 125, 109533. [Google Scholar] [CrossRef]

- Hu, Y.; Li, X.; Gao, Y.; Zhao, Z.; Liu, X.; He, L.; Zhang, B.; Zhou, L.; Wang, Z.; Wang, J. A Combined Wind Harvesting and Speed Sensing System Based on Constant-Voltage Triboelectric Nanogenerator. Adv. Energy Mater. 2024, 14, 2400672. [Google Scholar] [CrossRef]

- Cao, R.; Liu, Y.; Li, H.; Shen, Z.; Li, F.; Jia, X.; Chen, C.; Liu, R.; Luo, C.; Yang, W.; et al. Advances in high-temperature operatable triboelectric nanogenerator. SusMat 2024, 4, e196. [Google Scholar] [CrossRef]

- He, S.; Gui, Y.; Wang, Y.; Cao, L.; He, G.; Tang, C. CuO/TiO2/MXene-based sensor and SMS-TENG array integrated inspection robots for self-powered ethanol detection and alarm at room temperature. ACS Sens. 2024, 9, 1188–1198. [Google Scholar] [CrossRef]

- Zhang, Z.; Gu, G.; Zhang, W.; Du, Z.; Cheng, G. Triboelectric nanogenerator with enhanced charge density and limited open-circuit voltage for efficient power management and industrial environmental monitoring. Nano Energy 2024, 131, 110308. [Google Scholar] [CrossRef]

- Zhang, J.; Boyer, C.; Zhang, Y.X. Enhancing the humidity resistance of triboelectric nanogenerators: A review. Small 2024, 20, 2401846. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Kong, L.; Wang, Y.; Wang, H.; Hong, H. Monitoring Downhole Machinery Operations Using Noncontact Triboelectric Nanogenerators and Deep Learning. IEEE Sens. J. 2024, 24, 25414–25421. [Google Scholar] [CrossRef]

- Liu, J.; Huang, H.; Zhou, Q.; Chuan, W. Self-powered downhole drilling tools vibration sensor based on triboelectric nanogenerator. IEEE Sens. J. 2021, 22, 2250–2258. [Google Scholar] [CrossRef]

- Liu, J.; Pan, G.; Wu, C.; Feng, Y. Research on Hybrid Vibration Sensor for Measuring Downhole Drilling Tool Vibrational Frequencies. Appl. Sci. 2024, 14, 2076–3417. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).