A Back-to-Back Gap Waveguide-Based Packaging Structure for E-Band Radio Frequency Front-End

Abstract

1. Introduction

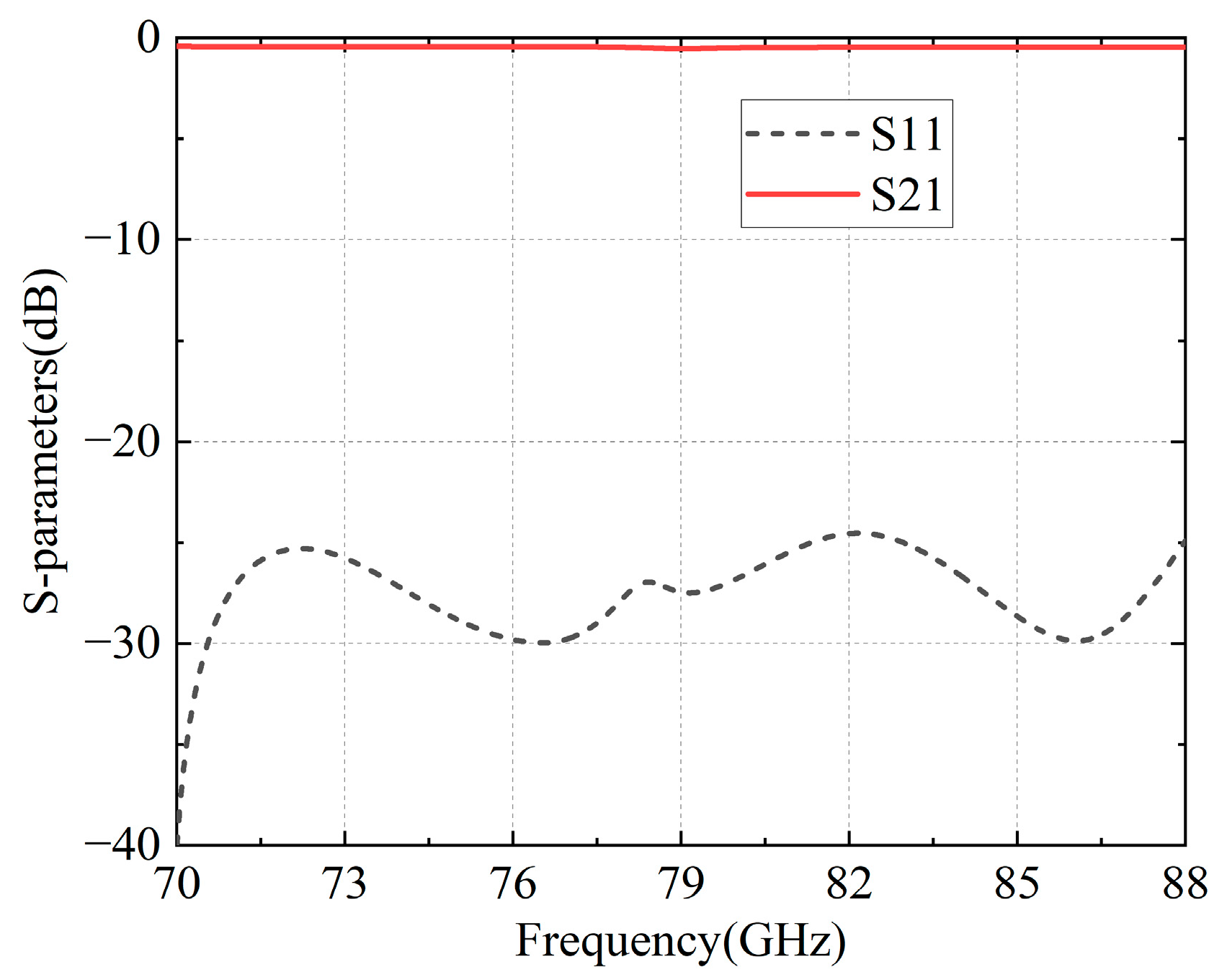

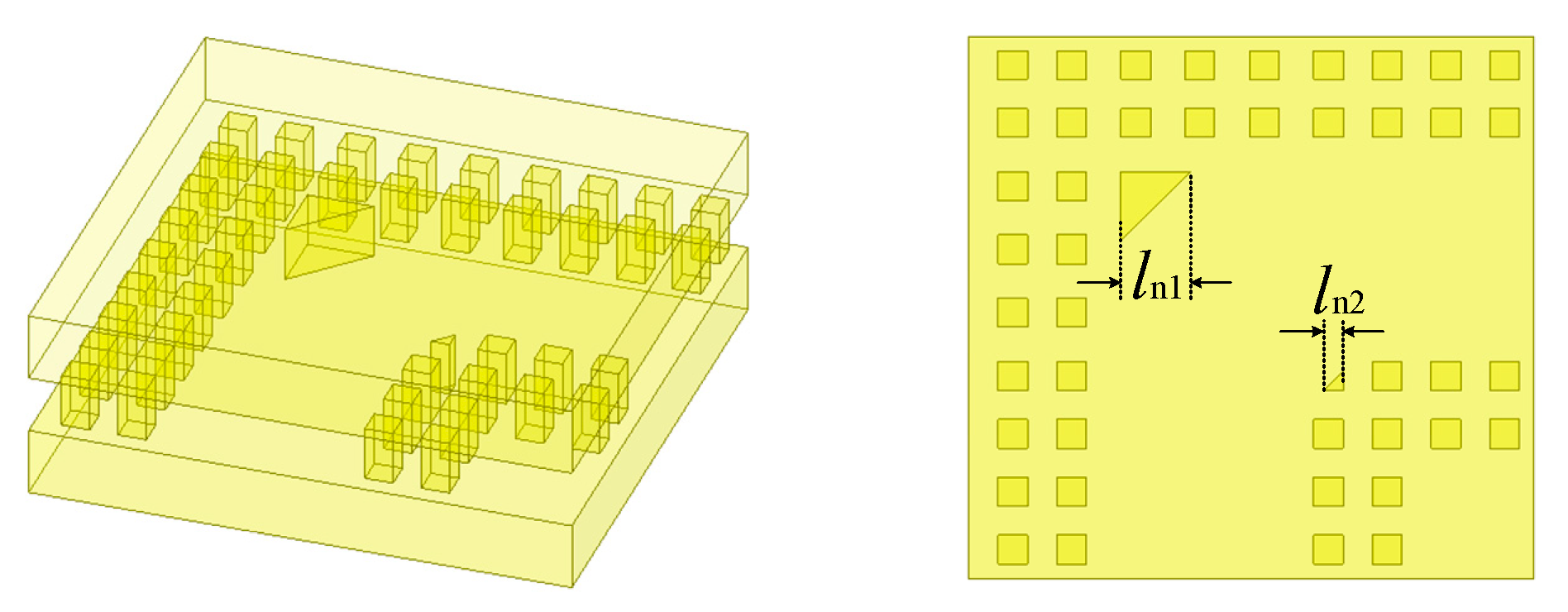

2. Unit Design of the Packaging Structure

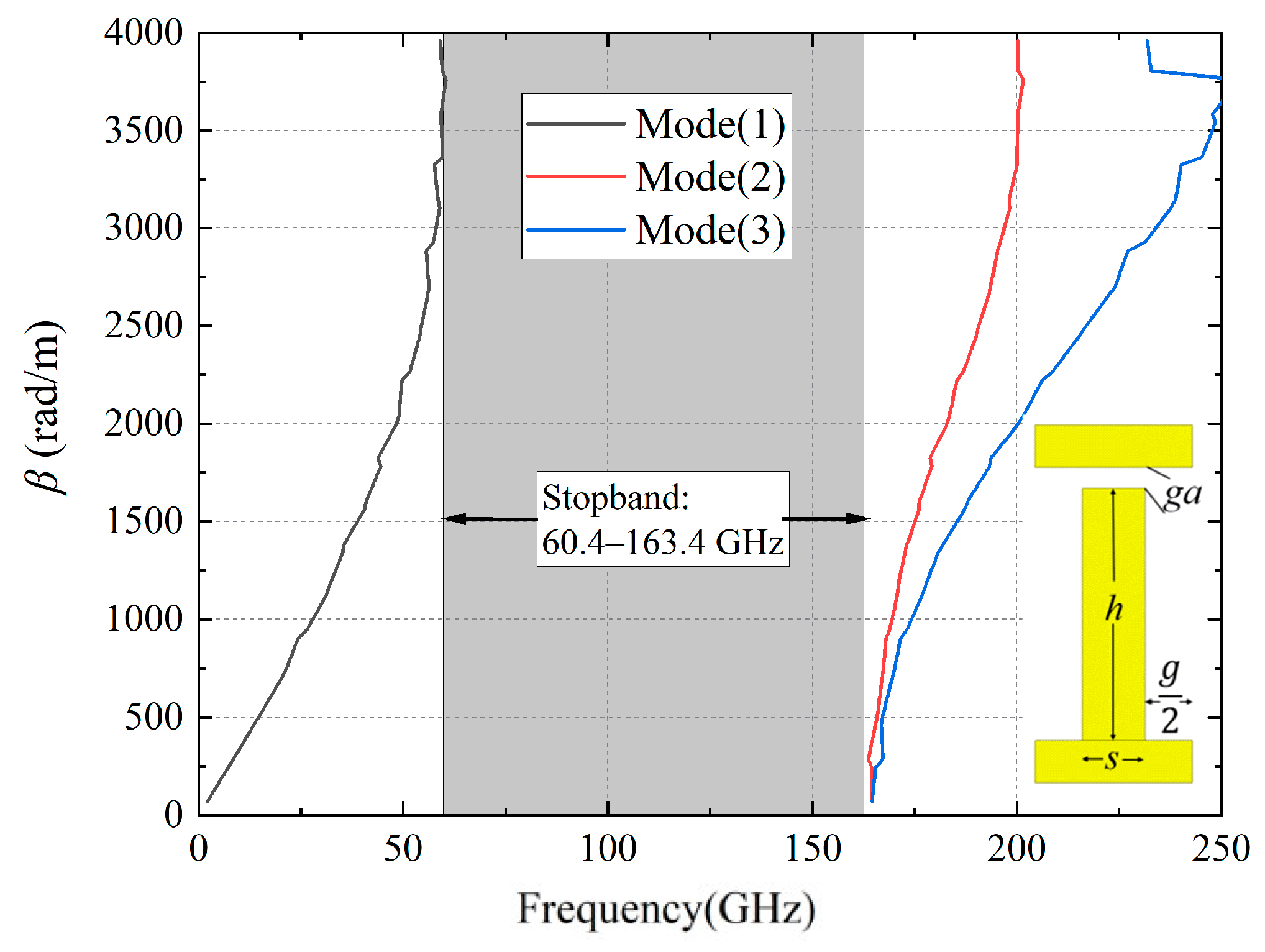

2.1. Back-to-Back GW Design

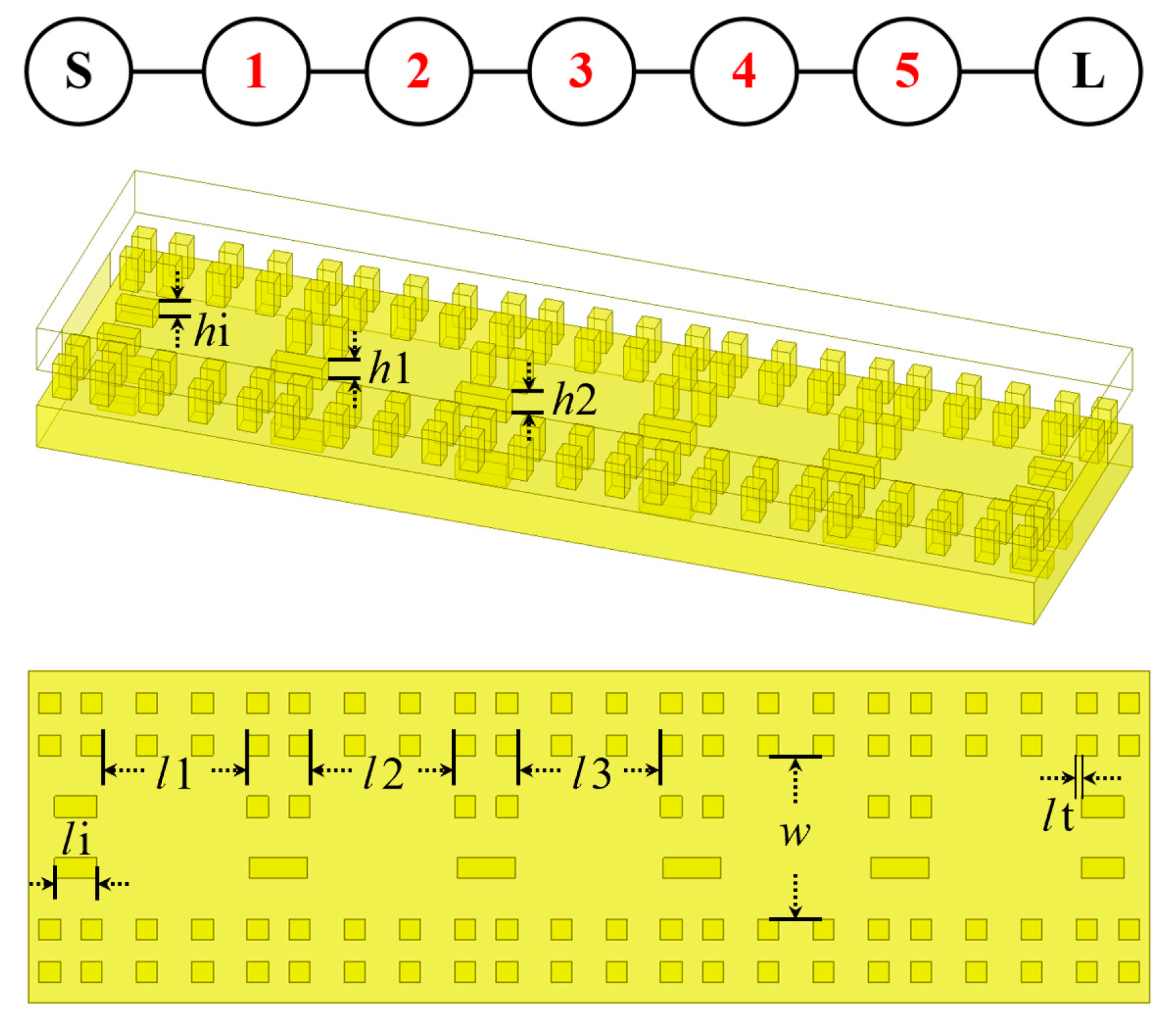

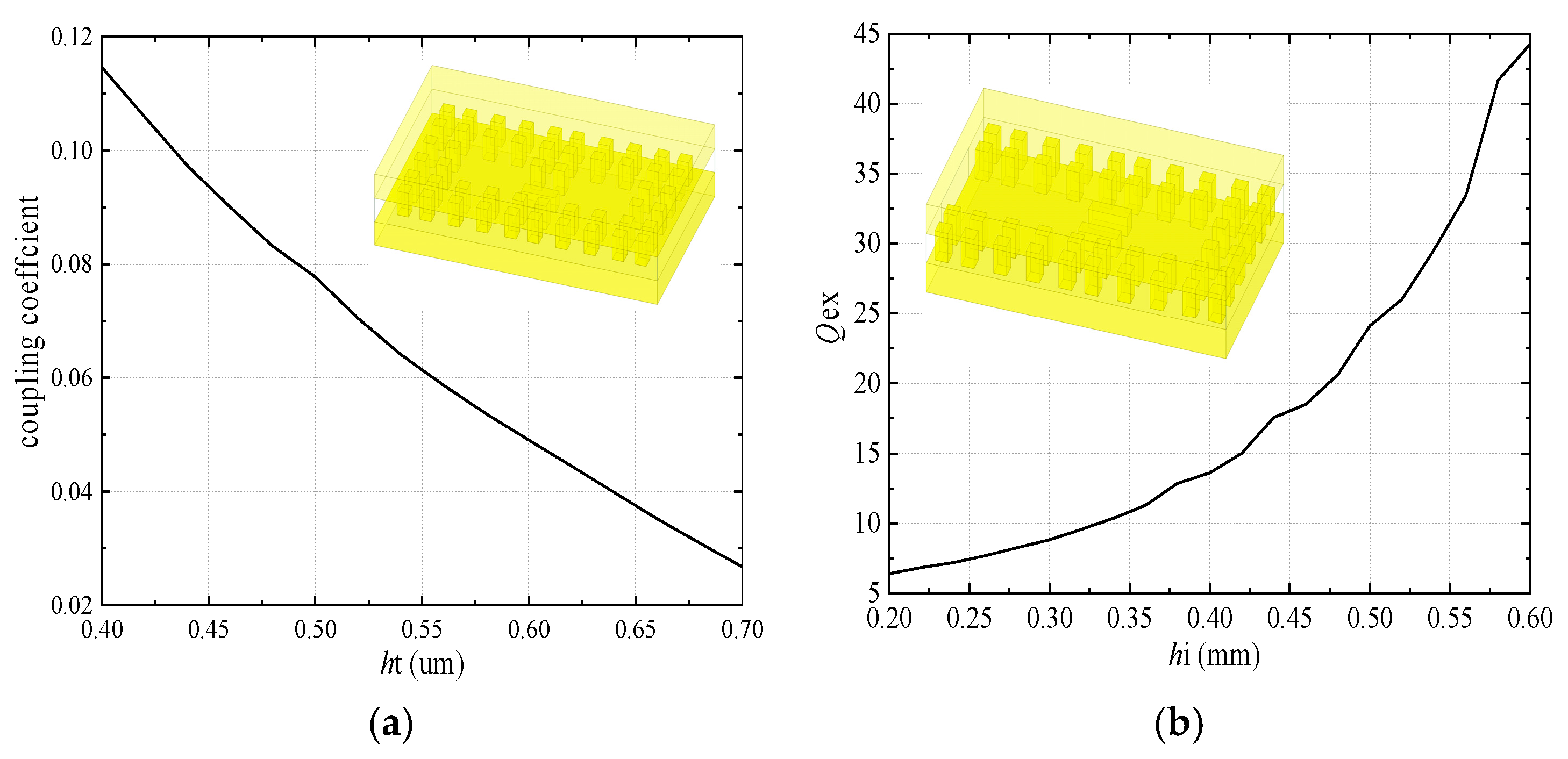

2.2. Hybrid Coupler and Bandpass Filter Design

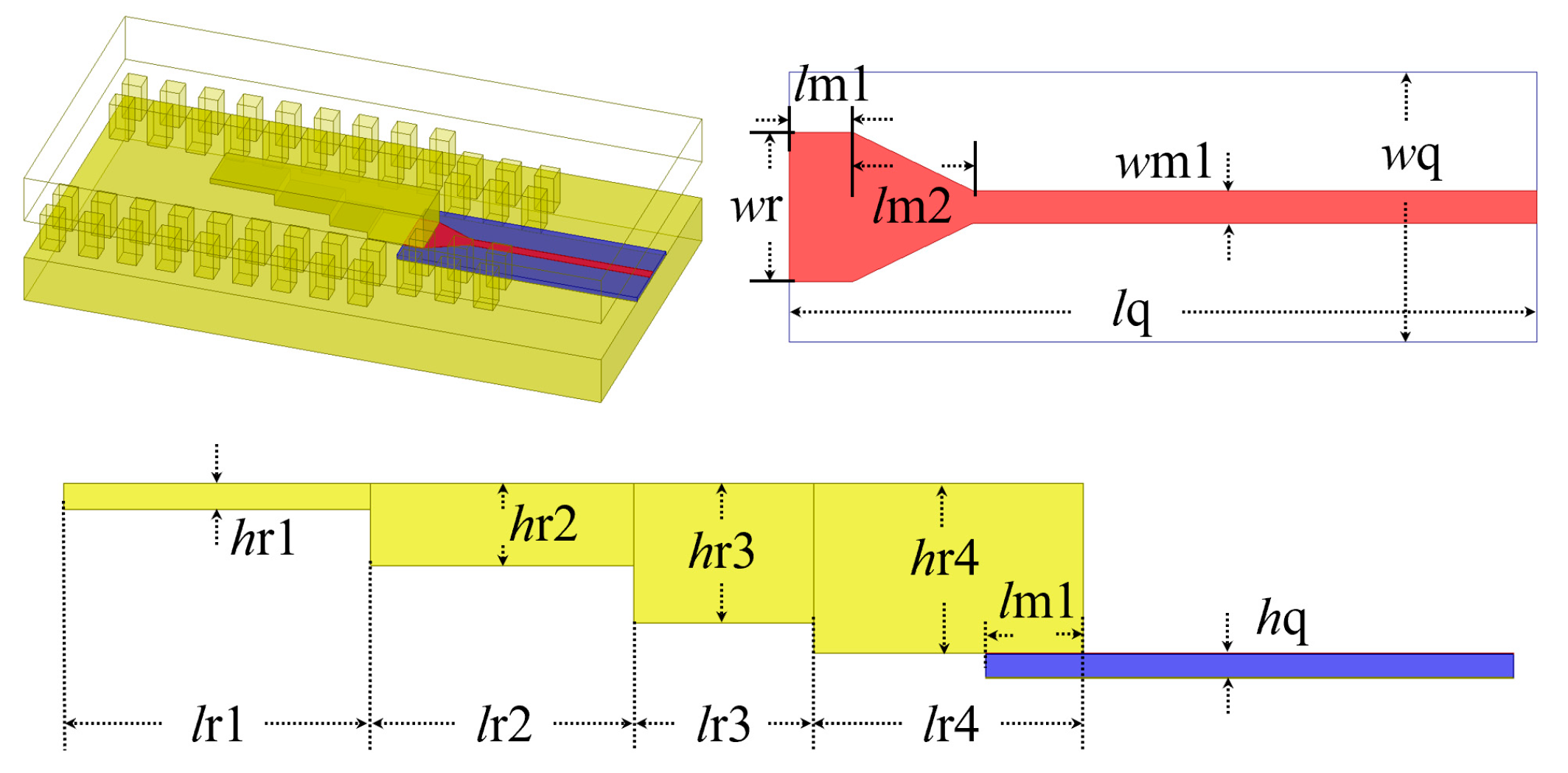

2.3. MS-GW Transition and Connecting Structure Design

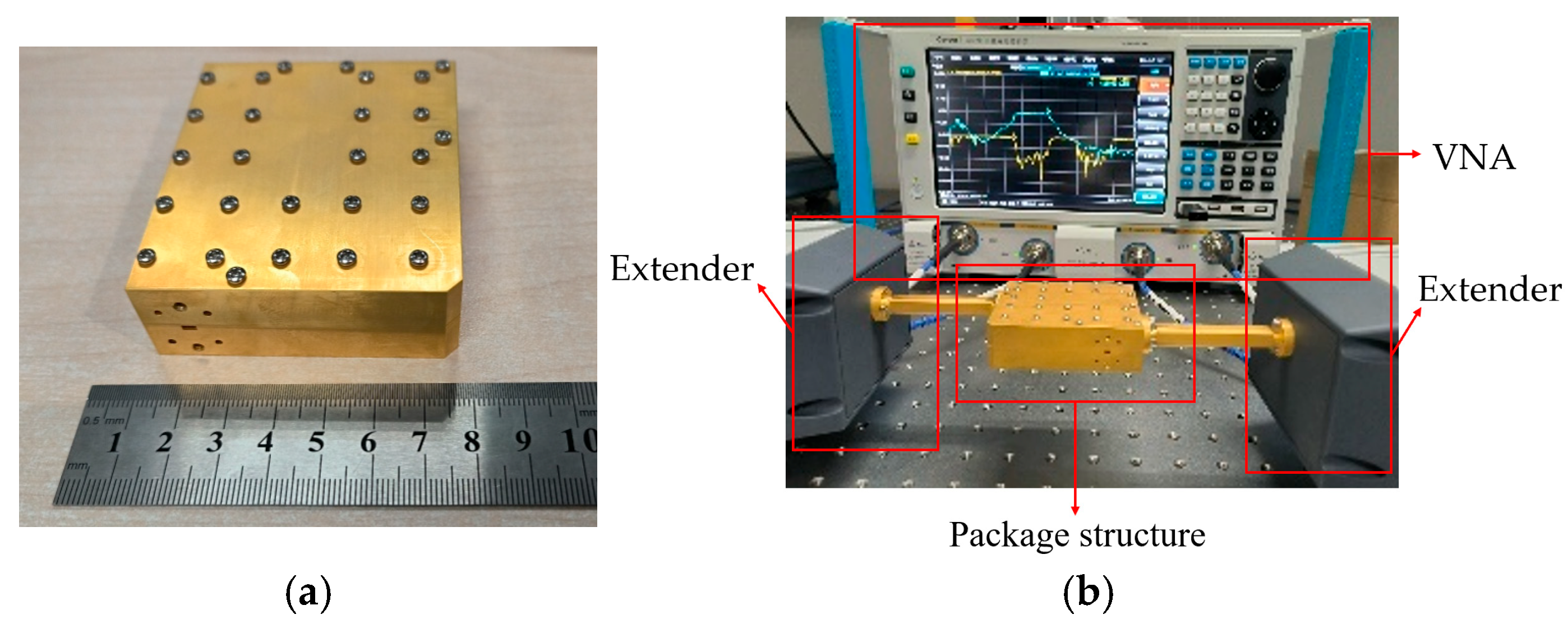

3. The Fabrication and Measurement of the Packaging Structure

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Harati, P.; Schoch, B.; Tessmann, A.; Schwantuschke, D.; Henneberger, R.; Czekala, H.; Zwick, T.; Kallfass, I. Is E-Band Satellite Communication Viable?: Advances in Modern Solid-State Technology Open Up the Next Frequency Band for SatCom. IEEE Microw. Mag. 2017, 18, 64–76. [Google Scholar] [CrossRef]

- Harati, P.; Rosello, E.; Dan, I.; Bammidi, E.; Eisenbeis, J.; Tessmann, A.; Schwantuschke, D.; Henneberger, R.; Kallfass, I. E-band downlink wireless data transmission for future satellite communication. In Proceedings of the 2017 Topical Workshop on Internet of Space (TWIOS), Phoenix, AZ, USA, 15–18 January 2017. [Google Scholar] [CrossRef]

- Rong, Y.; Yao, H.; Zaki, K.; Dolan, T. Millimeter-wave Ka-band H-plane diplexers and multiplexers. IEEE Trans. Microw. Theory Tech. 1999, 47, 2325–2330. [Google Scholar] [CrossRef]

- Teberio, F.; Arregui, I.; Soto, P.; Laso, M.; Boria, V.; Guglielmi, M. High-Performance Compact Diplexers for Ku/K-Band Satellite Applications. IEEE Trans. Microw. Theory Tech. 2017, 65, 3866–3876. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, Y.; Guo, C.; Cheng, Q.; Yu, M. Resonant Manifold Multiplexers. IEEE Trans. Microw. Theory Tech. 2022, 70, 1059–1071. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, B.; Liu, Y.; Niu, Z.; Dai, B.; Fan, Y.; Chen, X. A 200–225 GHz Manifold-Coupled Multiplexer Utilizing Metal Waveguides. IEEE Trans. Microw. Theory Tech. 2021, 69, 5327–5333. [Google Scholar] [CrossRef]

- Holloway, J.; Dogiamis, G.; Shin, S.; Han, R. 220-to-330 GHz Manifold Triplexer with Wide Stopband Utilizing Ridged Substrate Integrated Waveguides. IEEE Trans. Microw. Theory Tech. 2020, 68, 3428–3438. [Google Scholar] [CrossRef]

- Kojima, T.; Gonzalez, A.; Asayama, S.; Uzawa, Y. Design and Development of a Hybrid-Coupled Waveguide Multiplexer for a Multiband Receiver. IEEE Trans. THz Sci. Tech. 2017, 7, 10–19. [Google Scholar] [CrossRef]

- Uemichi, Y.; Nukaga, O.; Nakamura, K.; Han, X.; Hasegawa, Y.; Hosono, R.; Kobayashi, K.; Guan, N.; Amakawa, S. An E-band hybrid-coupled diplexer built of silica-based post-wall waveguide. In Proceedings of the 2017 47th European Microwave Conference (EuMC), Nuremberg, Germany, 10–12 October 2017. [Google Scholar] [CrossRef]

- Park, J.; Choi, E.; Baek, D.; Lee, P. A Circulator Coupled 8-Channel Ka-Band Input Multiplexer design of Communication Satellites. In Proceedings of the 2018 International Symposium on Antennas and Propagation (ISAP), Busan, Republic of Korea, 23–26 October 2018. [Google Scholar]

- Cameron, R.; Yu, M. Design of manifold-coupled multiplexers. IEEE Microw. Mag. 2007, 8, 46–59. [Google Scholar] [CrossRef]

- Marco, S.; Alessandro, F.; Giuseppe, V.; Giorgio, M.; Riccardo, G.; Giuseppe, M. A Compact In-Line Waveguide-to-Microstrip Transition in the Q-Band for Radio Astronomy Applications. Electronics 2018, 7, 24. [Google Scholar] [CrossRef]

- Piekarz, I.; Sorocki, J.; Delmonte, N.; Silvestri, L.; Marconi, S.; Alaimo, G.; Auricchio, F.; Bozzi, M. Wideband Microstrip to 3-D Printed Air-Filled Waveguide Transition Using a Radiation Probe. IEEE Microw. and Wireless Compon. Lett. 2022, 32, 1179–1182. [Google Scholar] [CrossRef]

- Zhang, Y.; Ruiz-Cruz, J.; Zaki, K.; Piloto, A. A Waveguide to Microstrip Inline Transition with Very Simple Modular Assembly. IEEE Microw. Wirel. Compon. Lett. 2010, 20, 480–482. [Google Scholar] [CrossRef]

- Zaman, A.; Vassilev, V.; Kildal, P.; Zirath, H. Millimeter Wave E-Plane Transition from Waveguide to Microstrip Line with Large Substrate Size Related to MMIC Integration. IEEE Microw. Wireless Compon. Lett. 2016, 26, 481–483. [Google Scholar] [CrossRef]

- Xu, Z.; Xu, J.; Qian, C. Novel In-Line Microstrip-to-Waveguide Transition Based on E-Plane Probe T-Junction Structure. IEEE Microw. Wireless Compon. Lett. 2021, 31, 1051–1054. [Google Scholar] [CrossRef]

- Kildal, P. Three metamaterial-based gap waveguides between parallel metal plates for mm/submm waves. In Proceedings of the 2009 3rd European Conference on Antennas and Propagation, Berlin, Germany, 23–27 March 2009. [Google Scholar]

- Raza, H.; Yang, J.; Kildal, P.; Alfonso, E. Resemblance between gap waveguides and hollow waveguides. IET Microw. Antennas and Propag. 2013, 7, 1221–1227. [Google Scholar] [CrossRef]

- Haddadi, A.; Alfonso, E.; Bencivenni, C.; Emanuelsson, T. E-Band High Gain Gap Waveguide Slot Array Antenna with ETSI Class-III Radiation Pattern Suitable for Mass Production. In Proceedings of the 2018 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting, Boston, MA, USA, 8–13 July 2018; pp. 1103–1104. [Google Scholar] [CrossRef]

- Feito, S.M.; Vaquero, Á.F.; Arrebola, M. Multibeam Metal-Only Groove Gap Waveguide-Based Array in E-Band. In Proceedings of the 2024 18th European Conference on Antennas and Propagation (EuCAP), Glasgow, UK, 17–22 March 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Li, S.; Yao, Y.; Cheng, X.; Yu, J. Design of a Dual-Band Filter Based on the Band Gap Waveguide. Electronics 2024, 13, 3982. [Google Scholar] [CrossRef]

- Reed, J. The Multiple Branch Waveguide Coupler. IEEE Trans. Microw. Theory Tech. 1958, 6, 398–403. [Google Scholar] [CrossRef]

- Cameron, R.; Kudsia, C.; Mansour, R. Microwave Filters for Communication Systems: Fundamentals, Design and Applications; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- Eshrah, I.; Kishk, A.; Yakovlev, A.; Glisson, A. Rectangular waveguide with dielectric-filled corrugations supporting backward waves. IEEE Trans. Microw. Theory Tech. 2005, 53, 3298–3304. [Google Scholar] [CrossRef]

| Parameters | w | l1 | l2 | l3 | lt | li | hi | h1 | h2 | |

|---|---|---|---|---|---|---|---|---|---|---|

| value | BPF_H | 2.8 | 2.225 | 2.235 | 2.226 | 0.1 | 0.8 | 0.45 | 0.563 | 0.646 |

| BPF_L | 3.1 | 2.759 | 2.746 | 2.724 | 0.1 | 0.8 | 0.42 | 0.502 | 0.549 | |

| Parameters | lm1 | lm2 | wm1 | wr | wq | lq | hr1 |

| Value | 0.385 | 0.825 | 0.22 | 1 | 1.8 | 10 | 0.113 |

| Parameters | hr2 | hr3 | hr4 | lr1 | lr2 | lr3 | lr4 |

| Value | 0.359 | 0.607 | 0.742 | 1.374 | 1.141 | 0.843 | 1.175 |

| Stage I | Stage II | Stage III | Stage IV | Stage V |

|---|---|---|---|---|

| Determine the overall performance indicators, such as passband, insertion loss, etc. | 1. Select the material of the substrate and the form of the transmission line 2. Design the hybrid coupler, filter and transition structure respectively | Design the signal ports and connect each component unit to simulate and optimize the model | 1. Metal structures are produced using CNC technology. 2. Fabricate dielectric substrates using the photolithography process. | 1. Assemble using conductive glue and screws 2. Measure the packaging structure |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiu, T.; Li, Z.; Wang, L.; Lin, P. A Back-to-Back Gap Waveguide-Based Packaging Structure for E-Band Radio Frequency Front-End. Micromachines 2025, 16, 644. https://doi.org/10.3390/mi16060644

Xiu T, Li Z, Wang L, Lin P. A Back-to-Back Gap Waveguide-Based Packaging Structure for E-Band Radio Frequency Front-End. Micromachines. 2025; 16(6):644. https://doi.org/10.3390/mi16060644

Chicago/Turabian StyleXiu, Tao, Zhi Li, Lei Wang, and Peng Lin. 2025. "A Back-to-Back Gap Waveguide-Based Packaging Structure for E-Band Radio Frequency Front-End" Micromachines 16, no. 6: 644. https://doi.org/10.3390/mi16060644

APA StyleXiu, T., Li, Z., Wang, L., & Lin, P. (2025). A Back-to-Back Gap Waveguide-Based Packaging Structure for E-Band Radio Frequency Front-End. Micromachines, 16(6), 644. https://doi.org/10.3390/mi16060644