1. Introduction

Cardiovascular diseases are the leading cause of death worldwide, with mortality rates increasing year by year in China. This rise is attributed to changes in lifestyle and an increase in the incidence of acute coronary syndromes [

1,

2,

3]. For certain critically ill patients, surgical intervention and medical devices remain the only viable options, with stents becoming a primary method for treating cardiovascular diseases [

4,

5,

6]. Currently, most metallic vascular stents on the market are manufactured from stent tubes created through laser cutting. These tubes are primarily formed by extruding and continuously drawing metal billets, which involves complex processing parameters. As a result, the inner walls of the formed tubes are prone to various surface defects, including pits, folds, cracks, scratches, and pitting, as well as the presence of a degraded layer of hard particle oxides. These defects hinder the subsequent processing of the vascular stents and complicate the materials’ post-treatment, thereby affecting their therapeutic efficacy in the human body.

Cobalt–chromium alloys are widely used in dental and orthopedic implants due to their superior mechanical properties, biocompatibility, and corrosion resistance [

7,

8,

9]. Their high elastic modulus enables cobalt–chromium alloy vascular stents to be thinner and more flexible while maintaining high radial strength [

9]. Furthermore, the high density of cobalt–chromium alloys enhances their compatibility with MRI and improves visibility under X-ray imaging. These characteristics make cobalt–chromium alloys an ideal choice for fabricating vascular stents, thereby enhancing patient safety and treatment outcomes. Consequently, eliminating surface defects on the inner walls of cobalt–chromium alloy tubes during the manufacturing process is crucial for achieving high-quality inner surfaces, particularly in the field of medical vascular stent fabrication.

Currently, electrochemical polishing is a commonly used method for polishing the inner walls of metal vascular stent tubes [

10,

11,

12]. The principle involves using a vascular stent tube as the anode and applying a direct current in an electrolytic cell, which induces an oxidation reaction on its surface to remove defects and reduce surface roughness. However, this method has several issues, such as uneven surface oxide layers and the tendency to generate new defects, including impurities and blisters. As noted by Simka et al. [

13], in their experimental study utilizing a concentrated sulfuric acid–alcohol system as the primary polishing solution, they compared the appearance of samples treated with three different electrochemical polishing solution formulations: concentrated sulfuric acid–nitric acid–hydrofluoric acid, concentrated sulfuric acid–hydrofluoric acid–methanol, and concentrated sulfuric acid–hydrofluoric acid–ethylene glycol. The study found that the concentrated sulfuric acid–nitric acid–hydrofluoric acid system exhibited excessive acidity, leading to uneven corrosion on the sample surface, resulting in significant and highly variable surface roughness. Babilas et al. [

14] similarly proposed the use of this dual-acid system for sample polishing, achieving relatively uniform surfaces with good corrosion resistance. However, due to the strong corrosiveness of concentrated sulfuric acid and concentrated phosphoric acid, the surface condition of the alloy is susceptible to the effects of strong acid corrosion, leading to unstable polishing results. Improper control of polishing time may also result in over-polishing, while the presence of phosphorus (P) and sulfur (S) elements could cause environmental pollution. Furthermore, Fushimi et al. [

12] discovered that adding a small amount of deionized water to a concentrated sulfuric acid and methanol solution while polishing at −10 °C could yield samples with higher surface gloss. However, methanol is highly toxic, and prolonged exposure to a methanol environment poses health risks. All these factors hinder subsequent coating and drug incorporation processes and may pose health hazards. Additionally, electrochemical polishing equipment is complex, requiring precise control of parameters such as the composition, concentration, and current density of the electrolyte, and involves the use of corrosive electrolytes that can cause environmental pollution. Due to equipment limitations, achieving efficient polishing for longer vascular stent tubes presents significant challenges. Therefore, for small-diameter seamless metal tubes, the search for more efficient, environmentally friendly, and safe methods and processes for inner wall finishing has become an important focus of current research.

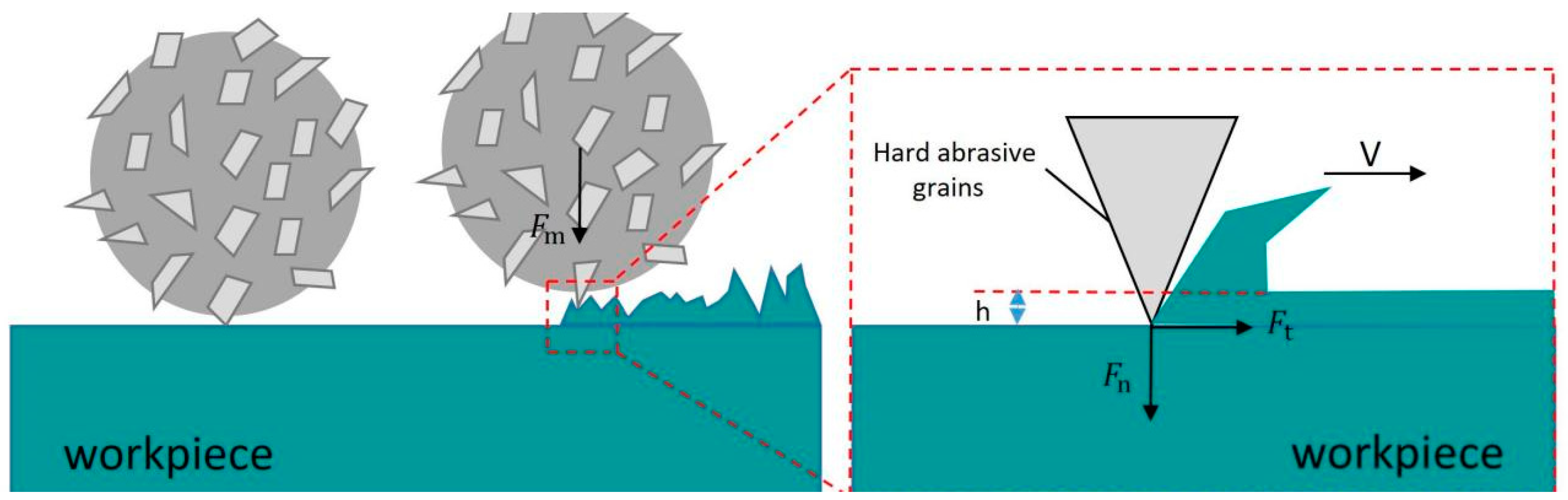

Magnetic Abrasive Finishing (MAF) is an advanced processing technique that integrates the effects of magnetic fields with traditional grinding methods. This technology enables the enhancement of nanometer-level surface roughness with minimal damage to the workpiece surface. By harnessing the magnetic field’s influence, magnetic abrasives can penetrate non-magnetic materials like magnetic field lines. Specifically, when a magnetic field is applied externally to the workpiece, the internally filled magnetic abrasives become magnetized, forming numerous elastic magnetic abrasive brushes aligned along the magnetic field lines. These brushes press against the surface of the workpiece to be processed and move relative to it. During this interaction, the magnetic abrasives continually engage with the surface through processes such as pressing, scratching, sliding, and micro-cutting, effectively removing material from the surface. As a result, the workpiece surface is treated uniformly and smoothly, achieving a high-quality polishing effect [

15].

The MAF (Magnetically Assisted Finishing) technology offers numerous advantages over traditional machining methods, which are particularly evident when handling complex shapes and workpieces with narrow internal walls. It not only enhances processing efficiency but also effectively controls surface quality during machining, achieving precision requirements at the micro and even nano levels [

16]. Many scholars, both domestic and international, have conducted extensive research on MAF technology. Misrad [

17] combined ultrasonic vibration with a magnetic abrasive finishing process, which significantly improved the surface finishing efficiency of workpieces. Misrad identified two distinct types of forces present during the machining process: a normal force (i.e., indentation force) and a tangential force (cutting force), which directly affect the surface roughness and material removal rate of a workpiece. Through finite element simulations, Misrad analyzed an electromagnet to calculate the magnetic flux density in a working area and assessed the normal force on a workpiece’s surface. The wear theory, combined with ultrasonic vibration effects, was utilized to compute torque during the finishing process. The study predicted the normal force and torque in ultrasonic-assisted magnetic abrasive finishing, relating these forces to the power supply voltage, working gap, and concentration of abrasive particles in flexible magnetic brushes. Ultimately, Misrad validated the accuracy of the theoretical model by comparing it with experimental results.

XinJian Zhang et al. [

18] developed a uniquely designed core-shell structure magnetic abrasive particle (MAP) that features an enhanced magnetic saturation rate and improved morphology. By determining the number of active abrasive particles within the MAP, they established a roughness model based on indentation theory. They elaborated on the evolution of the MAF (Magnetically Assisted Forming) mechanism during the elastic–plastic deformation of processed materials, aiming for high efficiency and precision in the MAF processing of slender tube surfaces. XinJian Zhang noted that the grooves on the magnetic pole drive the maximum magnetic force on the MAP. Their theoretical model of magnetic force and the number of active abrasive particles aligned with experimental parameters, effectively predicting and explaining MAF phenomena and mechanisms. For example, the experiments on zirconium alloy tubes demonstrated that after five MAF treatments using the designed MAP, the surface roughness, Ra, improved by a maximum of 63.38%, achieving a final roughness, Ra, of 0.119 μm.

Kala, Prateek, et al. [

19] proposed a mathematical model for the double-disk magnetic abrasive finishing (DDMAF) process, designed to effectively process flat paramagnetic workpieces, which are traditionally considered challenging to machines. In their study, surface roughness was modeled as a function of a workpiece’s material properties and various process parameters, including working gap, number of abrasive meshes, abrasive weight percentage, rotational speed, and feed rate. The process model employed Lorentz force and Ampère’s law to estimate the processing force acting on iron particles. These forces were used to calculate the finishing force transferred to the abrasive particles, achieved through the force balance between iron and abrasive particles. Prateek also accounted for the effects of abrasive particle size distribution and frictional force on the finishing force. To determine changes in surface roughness, the research team developed a MATLAB code encompassing all the aforementioned aspects. Their model has been validated against experimental results and applied to study the influence of various process parameters on machining outcomes. Xing, Baijun, and YanHua Zou [

20] introduced a method that combines magnetic abrasive finishing with electrolytic magneto rheological polishing (EMAF) to enhance the efficiency of traditional MAF processes. Given that EMAF involves electrochemical reactions, the machining mechanisms vary for different metals. They explored the feasibility of using composite machining tools for the precision surface finishing of aluminum alloy A5052 through a series of experiments and preliminarily investigated its machining mechanisms. Surface roughness and material removal rate were employed to evaluate the finishing effects and efficiency. The current curve of the EMAF process was utilized for assessing and analyzing its machining process. Through simulation analysis and experimental results, the feasibility of EMAF in precision surface finishing was confirmed. Finally, a series of exploratory experiments and parameter optimizations led to the following conclusions: (1) Under identical composite tool and experimental conditions (excluding electrolytic conditions), the EMAF process incorporating electrochemical reactions significantly enhances the finishing efficiency of aluminum alloy A5052 compared to traditional MAF methods. (2) With a working gap set at 1 mm and a NaNO

3 solution concentration of 15%, the recommended processing voltage is approximately 3.4 V. These findings underscore the effectiveness of the EMAF process in improving precision surface finishing efficiency, supported by both a theoretical analysis and experimental validation.

To solve the difficult problem of traditional processing methods struggling to finish the inner wall of ultra-slender vascular stent tubes, in this study, the plasma melting powder spraying method was used to prepare metal-based Al2O3 magnetic abrasives with excellent performance, and the magnetic finishing equipment for the inner wall of vascular stent tubes was designed and built. Through a response surface test with four factors and three levels, designed based on the response surface method (Box–Behnken), the influence of tube rotation speed, magnetic pole feed speed, abrasive filling amount, and machining clearance on the surface roughness and their interactions were analyzed. The process parameters were optimized by using the established model and multiple regression equations, and the optimal parameter combination was obtained. This study aims to reduce inner wall surface roughness and eliminate defects, thereby improving surface quality and preparing for the subsequent processes of bare-metal vascular stents.