Multilevel Multimodal Physical Unclonable Functions by Laser Writing of Silicon Carbide Color Centers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Manufacturing of MMPUF Labels

2.2. Information Acquisition of MMPUF Labels

2.3. Encoding of MMPUF Labels

2.4. Calculation of Encoding Performance of MMPUF

3. Results and Discussion

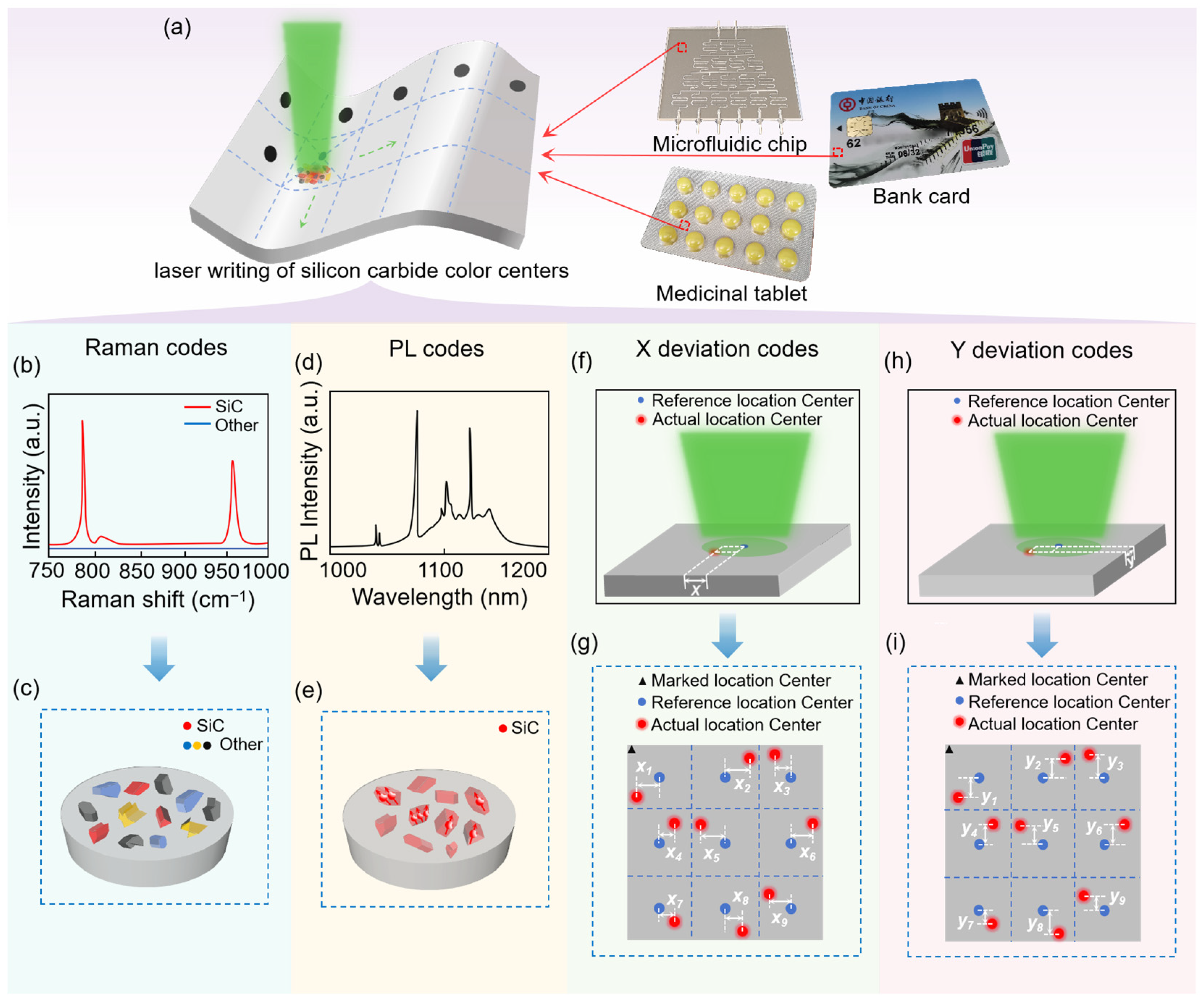

3.1. Construction of MMPUF

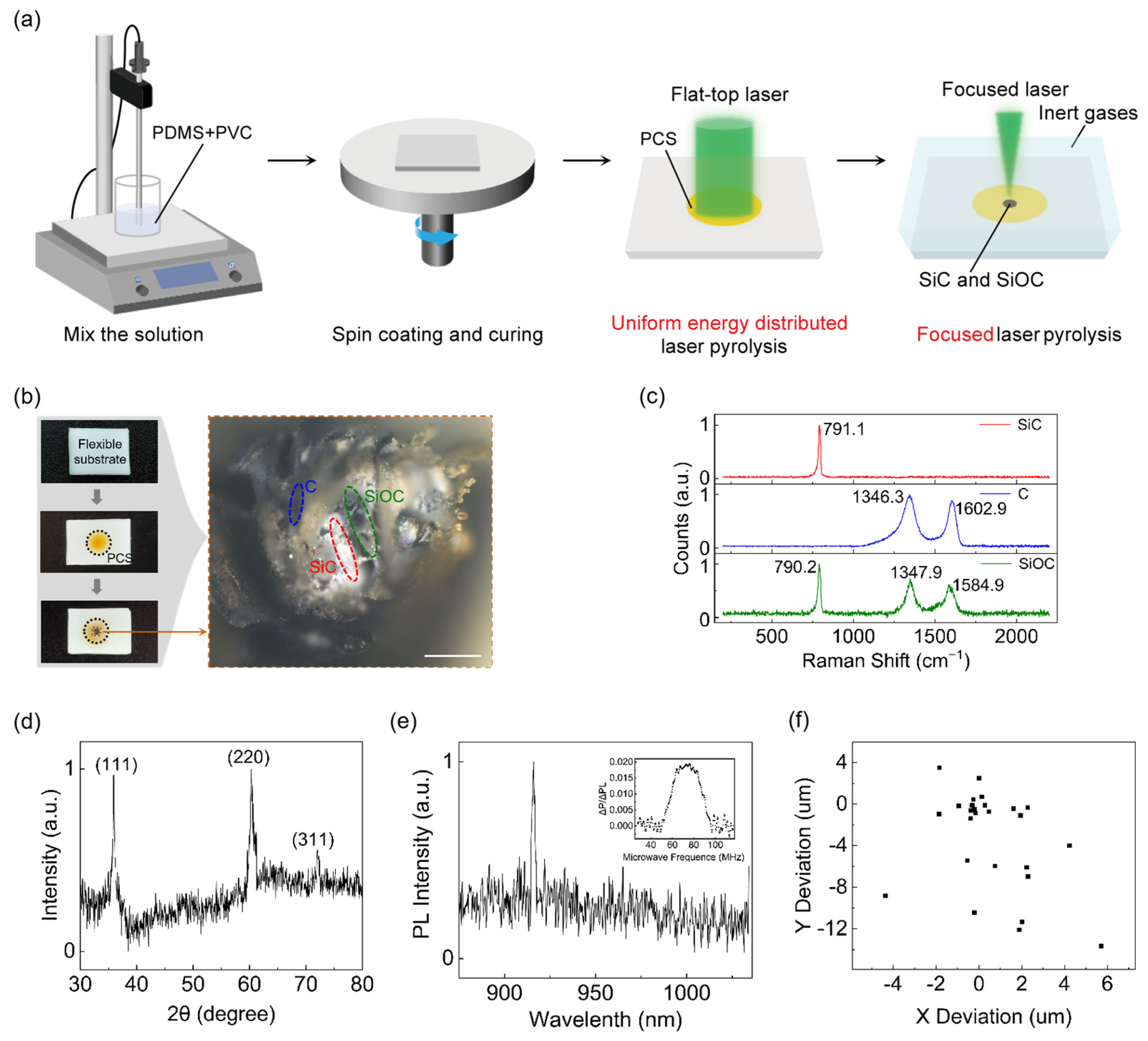

3.2. Fabrication and Characterization of MMPUF

3.3. Encoding of MMPUF

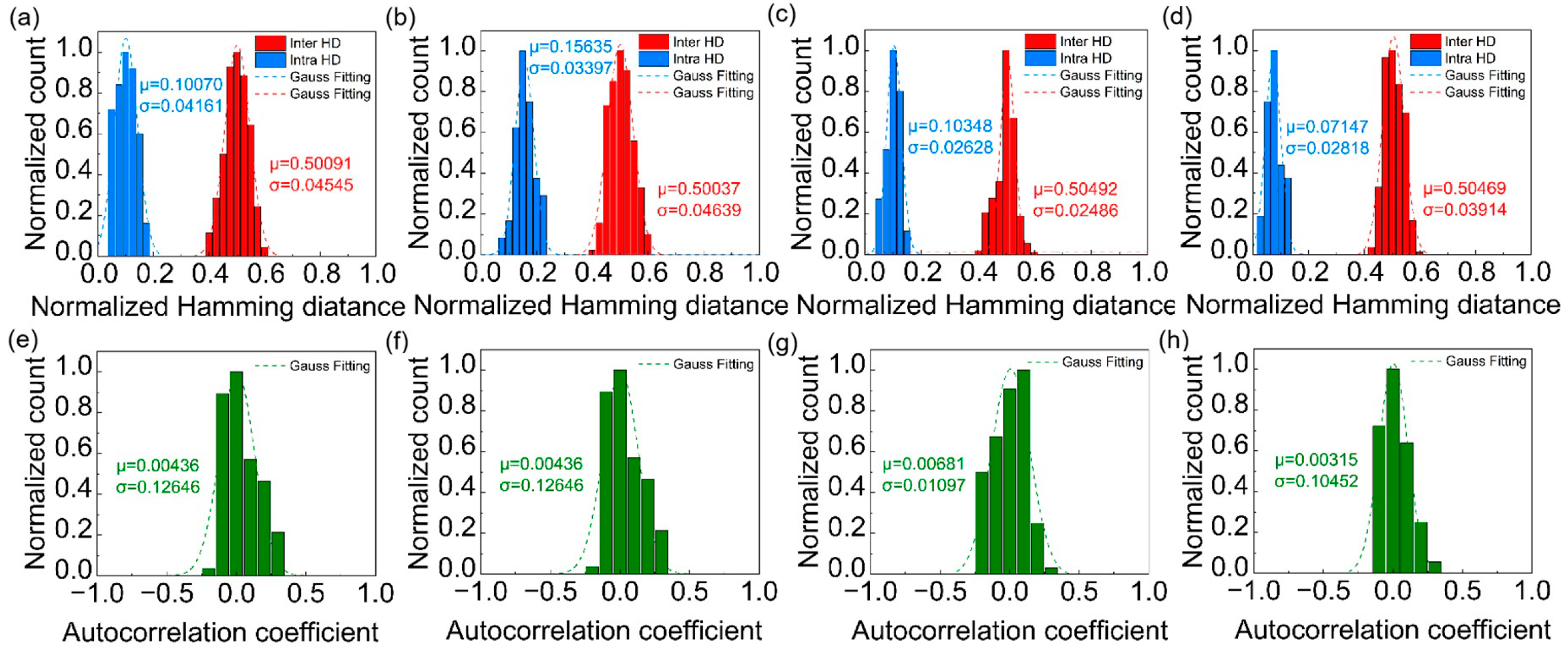

3.4. Performance of MMPUF

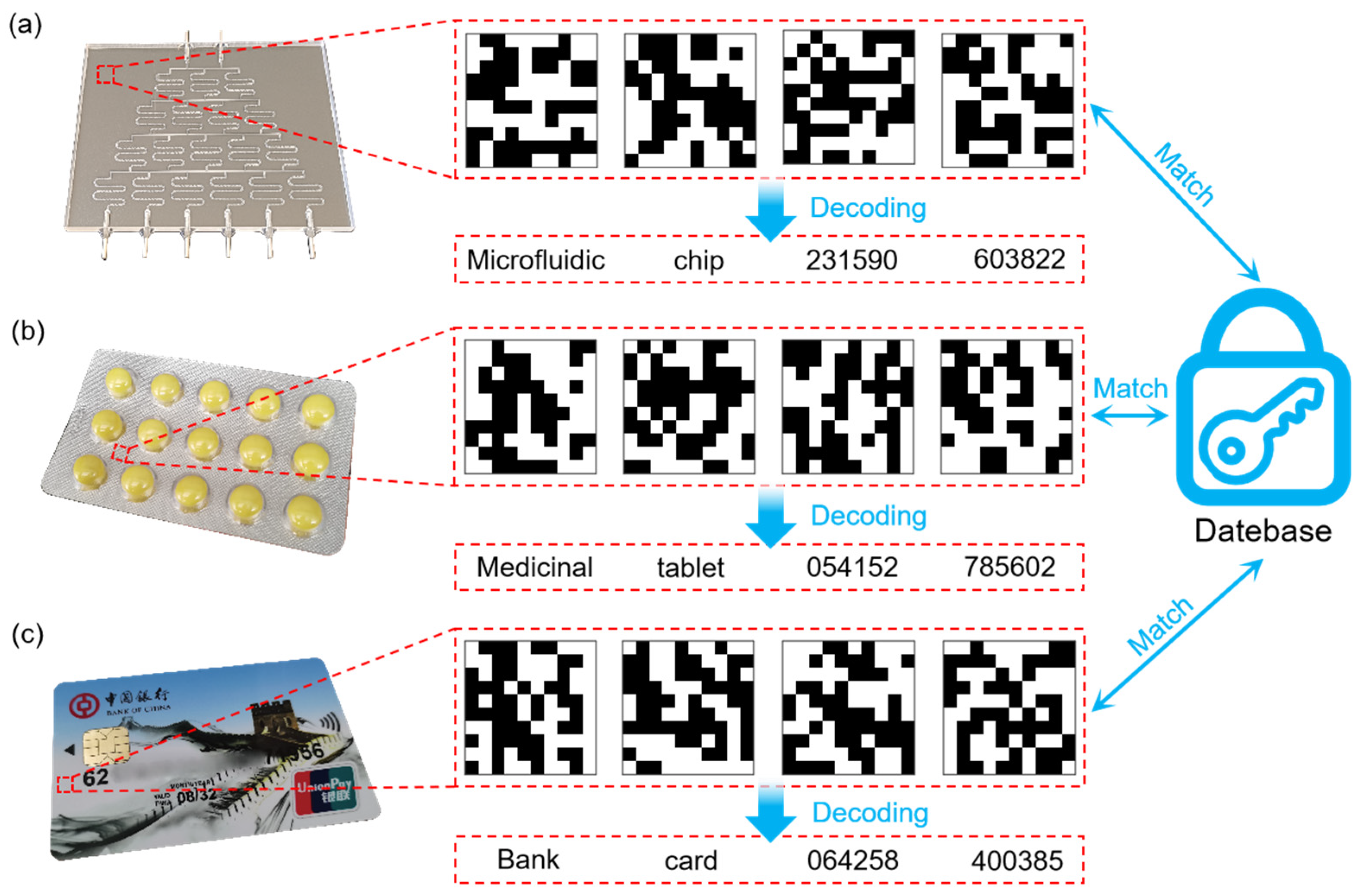

3.5. Applications of MMPUF

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hyka, D.; Hyra, A.; Basholli, F.; Mema, B.; Basholli, A. Data Security in Public and Private Administration: Challenges, Trends, and Effective Protection in the Era of Digitalization. Adv. Eng. Days (AED) 2023, 7, 125–127. [Google Scholar]

- Wali, A.; Dodda, A.; Wu, Y.; Pannone, A.; Reddy Usthili, L.K.; Ozdemir, S.K.; Ozbolat, I.T.; Das, S. Biological Physically Unclonable Function. Commun. Phys. 2019, 2, 39. [Google Scholar] [CrossRef]

- Li, Z.; Xu, H.; Zheng, Y.; Liu, L.; Li, L.; Lou, Z.; Wang, L. A Reconfigurable Heterostructure Transistor Array for Monocular 3D Parallax Reconstruction. Nat. Electron. 2025, 8, 46–55. [Google Scholar] [CrossRef]

- Shamsoshoara, A.; Korenda, A.; Afghah, F.; Zeadally, S. A Survey on Physical Unclonable Function (PUF)-Based Security Solutions for Internet of Things. Comput. Netw. 2020, 183, 107593. [Google Scholar] [CrossRef]

- Shepherd, M. Beef up International Cooperation on Counterfeits. Nat. Med. 2010, 16, 366. [Google Scholar] [CrossRef]

- Sun, L.; Rao, Y.; Wu, L.; Zhang, X.; Lan, Y.; Nazir, A. Fighting False Information from Propagation Process: A Survey. ACM Comput. Surv. 2023, 55, 207:1–207:38. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, L.; Wang, J.; Wang, Z.; Gupta, M.; Guo, X.; Zhu, Y.; Yiu, Y.C.; Hui, T.K.C.; Zhou, Y.; et al. Multimodal Dynamic and Unclonable Anti-Counterfeiting Using Robust Diamond Microparticles on Heterogeneous Substrate. Nat. Commun. 2023, 14, 2507. [Google Scholar] [CrossRef]

- Abdollahi, A.; Roghani-Mamaqani, H.; Razavi, B.; Salami-Kalajahi, M. Photoluminescent and Chromic Nanomaterials for Anticounterfeiting Technologies: Recent Advances and Future Challenges. ACS Nano 2020, 14, 14417–14492. [Google Scholar] [CrossRef]

- Al-Meer, A.; Al-Kuwari, S. Physical Unclonable Functions (PUF) for IoT Devices. ACM Comput. Surv. 2023, 55, 1–31. [Google Scholar] [CrossRef]

- Pappu, R.; Recht, B.; Taylor, J.; Gershenfeld, N. Physical One-Way Functions. Science 2002, 297, 2026–2030. [Google Scholar] [CrossRef]

- Nadimi Goki, P.; Civelli, S.; Parente, E.; Caldelli, R.; Teferi Mulugeta, T.; Sambo, N.; Secondini, M.; Potì, L. Optical Identification Using Physical Unclonable Functions. J. Opt. Commun. Netw. 2023, 15, E63. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, X.; Jeloka, S.; Cline, B.; Lu, W.D. Physical Unclonable Function Systems Based on Pattern Transfer of Fingerprint-Like Patterns. IEEE Electron. Device Lett. 2022, 43, 655–658. [Google Scholar] [CrossRef]

- Gao, Y.; Al-Sarawi, S.F.; Abbott, D. Physical Unclonable Functions. Nat. Electron. 2020, 3, 81–91. [Google Scholar] [CrossRef]

- Arppe, R.; Sørensen, T.J. Physical Unclonable Functions Generated through Chemical Methods for Anti-Counterfeiting. Nat. Rev. Chem. 2017, 1, 0031. [Google Scholar] [CrossRef]

- Li, Q.; Chen, F.; Su, J.; Yao, Y.; Kang, J.; Xie, F.; Li, M.; Zhang, J. Quantum Physical Unclonable Function Based on Multidimensional Fingerprint Features of Single Photon Emitters in Random AlN Nanocrystals. Adv. Funct. Mater. 2024, 35, 2416216. [Google Scholar] [CrossRef]

- Zheng, Y.; Cao, Y.; Chang, C.-H. UDhashing: Physical Unclonable Function-Based User-Device Hash for Endpoint Authentication. IEEE Trans. Ind. Electron. 2019, 66, 9559–9570. [Google Scholar] [CrossRef]

- Alharbi, A.; Armstrong, D.; Alharbi, S.; Shahrjerdi, D. Physically Unclonable Cryptographic Primitives by Chemical Vapor Deposition of Layered MoS2. ACS Nano 2017, 11, 12772–12779. [Google Scholar] [CrossRef]

- Maes, R.; Verbauwhede, I. Physically Unclonable Functions: A Study on the State of the Art and Future Research Directions. In Towards Hardware-Intrinsic Security; Sadeghi, A.-R., Naccache, D., Eds.; Information Security and Cryptography; Springer: Berlin/Heidelberg, Germany, 2010; pp. 3–37. ISBN 978-3-642-14451-6. [Google Scholar]

- Holcomb, D.E.; Fu, K. Power-Up SRAM State as an Identifying Fingerprint and Source of True Random Numbers. IEEE Trans. Comput. 2008, 58, 1198–1210. [Google Scholar] [CrossRef]

- Lai, X.; Ren, Q.; Vogelbacher, F.; Sha, W.E.I.; Hou, X.; Yao, X.; Song, Y.; Li, M. Bioinspired Quasi-3D Multiplexed Anti-Counterfeit Imaging via Self-Assembled and Nanoimprinted Photonic Architectures. Adv. Mater. 2022, 34, 2107243. [Google Scholar] [CrossRef]

- Hwang, K.; Kim, W.; Jin, I.K.; Lee, S.; Choi, Y. Multilevel States of Nano-Electromechanical Switch for a PUF-Based Security Device. Small 2019, 15, 1803825. [Google Scholar] [CrossRef]

- Jiao, F.; Lin, C.; Dong, L.; Mao, X.; Wu, Y.; Dong, F.; Zhang, Z.; Sun, J.; Li, S.; Yang, X.; et al. Silicon Vacancies Diamond/Silk/PVA Hierarchical Physical Unclonable Functions for Multi-Level Encryption. Adv. Sci. 2024, 11, 2308337. [Google Scholar] [CrossRef] [PubMed]

- Nocentini, S.; Rührmair, U.; Barni, M.; Wiersma, D.S.; Riboli, F. All-Optical Multilevel Physical Unclonable Functions. Nat. Mater. 2024, 23, 369–376. [Google Scholar] [CrossRef]

- Wang, C.; Yan, Z.; Gong, C.; Xie, H.; Qiao, Z.; Yuan, Z.; Chen, Y.-C. Multicolor Light Mixing in Optofluidic Concave Interfaces for Anticounterfeiting with Deep Learning Authentication. ACS Appl. Mater. Interfaces 2022, 14, 10927–10935. [Google Scholar] [CrossRef] [PubMed]

- Lyu, B.; Ouyang, Y.; Gao, D.; Wan, X.; Bao, X. Multilevel and Flexible Physical Unclonable Functions for High-End Leather Products or Packaging. Small 2025, 21, 2408574. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Li, Y.; Zhao, Z.; Li, Y.; Song, F.; Huang, W. Multilevel Stimuli–Responsive Smart “Sandwich” Label with Physical Unclonable Functions Bionic Wrinkles and Space-Selective Fluorescence Patterns. Small 2024, 20, 2405110. [Google Scholar] [CrossRef]

- Kim, J.H.; Jeon, S.; In, J.H.; Nam, S.; Jin, H.M.; Han, K.H.; Yang, G.G.; Choi, H.J.; Kim, K.M.; Shin, J.; et al. Nanoscale Physical Unclonable Function Labels Based on Block Copolymer Self-Assembly. Nat. Electron. 2022, 5, 433–442. [Google Scholar] [CrossRef]

- Minh, D.N.; Nguyen, L.A.T.; Nguyen, Q.H.; Vu, T.V.; Choi, J.; Eom, S.; Kwon, S.J.; Kang, Y. Synthesis of MAPbBr3-Polymer Composite Films by Photolysis of DMF: Toward Transparent and Flexible Optical Physical Unclonable Functions (PUFs) with Hierarchical Multilevel Complexity. Adv. Mater. 2023, 35, 2208151. [Google Scholar] [CrossRef]

- Scholz, A.; Zimmermann, L.; Gengenbach, U.; Koker, L.; Chen, Z.; Hahn, H.; Sikora, A.; Tahoori, M.B.; Aghassi-Hagmann, J. Hybrid Low-Voltage Physical Unclonable Function Based on Inkjet-Printed Metal-Oxide Transistors. Nat. Commun. 2020, 11, 5543. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.; Qin, Y.; Wang, Z.; Ma, Y.; Wen, H.; Li, Z.; Ma, Z.; Li, X.; Tang, J.; Liu, J. Multilevel Encoding Physically Unclonable Functions Based on The Multispecies Structure in Diamonds. Adv. Funct. Mater. 2024, 34, 2304648. [Google Scholar] [CrossRef]

- Pinheiro, T.; Morais, M.; Silvestre, S.; Carlos, E.; Coelho, J.; Almeida, H.V.; Barquinha, P.; Fortunato, E.; Martins, R. Direct Laser Writing: From Materials Synthesis and Conversion to Electronic Device Processing. Adv. Mater. 2024, 36, 2402014. [Google Scholar] [CrossRef]

- Chen, Y.-C.; Salter, P.S.; Niethammer, M.; Widmann, M.; Kaiser, F.; Nagy, R.; Morioka, N.; Babin, C.; Erlekampf, J.; Berwian, P.; et al. Laser Writing of Scalable Single Color Centers in Silicon Carbide. Nano Lett. 2019, 19, 2377–2383. [Google Scholar] [CrossRef] [PubMed]

- Nakashima, S.; Harima, H. Raman Investigation of SiC Polytypes. Phys. Stat. Sol. (a) 1997, 162, 39–64. [Google Scholar] [CrossRef]

- Niethammer, M.; Widmann, M.; Lee, S.-Y.; Stenberg, P.; Kordina, O.; Ohshima, T.; Son, N.T.; Janzén, E.; Wrachtrup, J. Vector Magnetometry Using Silicon Vacancies in 4 H -SiC Under Ambient Conditions. Phys. Rev. Appl. 2016, 6, 034001. [Google Scholar] [CrossRef]

- Leem, J.W.; Kim, M.S.; Choi, S.H.; Kim, S.-R.; Kim, S.-W.; Song, Y.M.; Young, R.J.; Kim, Y.L. Edible Unclonable Functions. Nat. Commun. 2020, 11, 328. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Qin, Y.; Guo, H.; Tian, Y.; Liu, L. Multilevel Multimodal Physical Unclonable Functions by Laser Writing of Silicon Carbide Color Centers. Micromachines 2025, 16, 329. https://doi.org/10.3390/mi16030329

Ma Y, Qin Y, Guo H, Tian Y, Liu L. Multilevel Multimodal Physical Unclonable Functions by Laser Writing of Silicon Carbide Color Centers. Micromachines. 2025; 16(3):329. https://doi.org/10.3390/mi16030329

Chicago/Turabian StyleMa, Yuxing, Yue Qin, Hao Guo, Ye Tian, and Lishuang Liu. 2025. "Multilevel Multimodal Physical Unclonable Functions by Laser Writing of Silicon Carbide Color Centers" Micromachines 16, no. 3: 329. https://doi.org/10.3390/mi16030329

APA StyleMa, Y., Qin, Y., Guo, H., Tian, Y., & Liu, L. (2025). Multilevel Multimodal Physical Unclonable Functions by Laser Writing of Silicon Carbide Color Centers. Micromachines, 16(3), 329. https://doi.org/10.3390/mi16030329