Large Strain Extrusion Machining of 7075 Aluminum Alloy with Micro-Textured Tools and Analysis of Chip Morphology and Microstructure

Abstract

1. Introduction

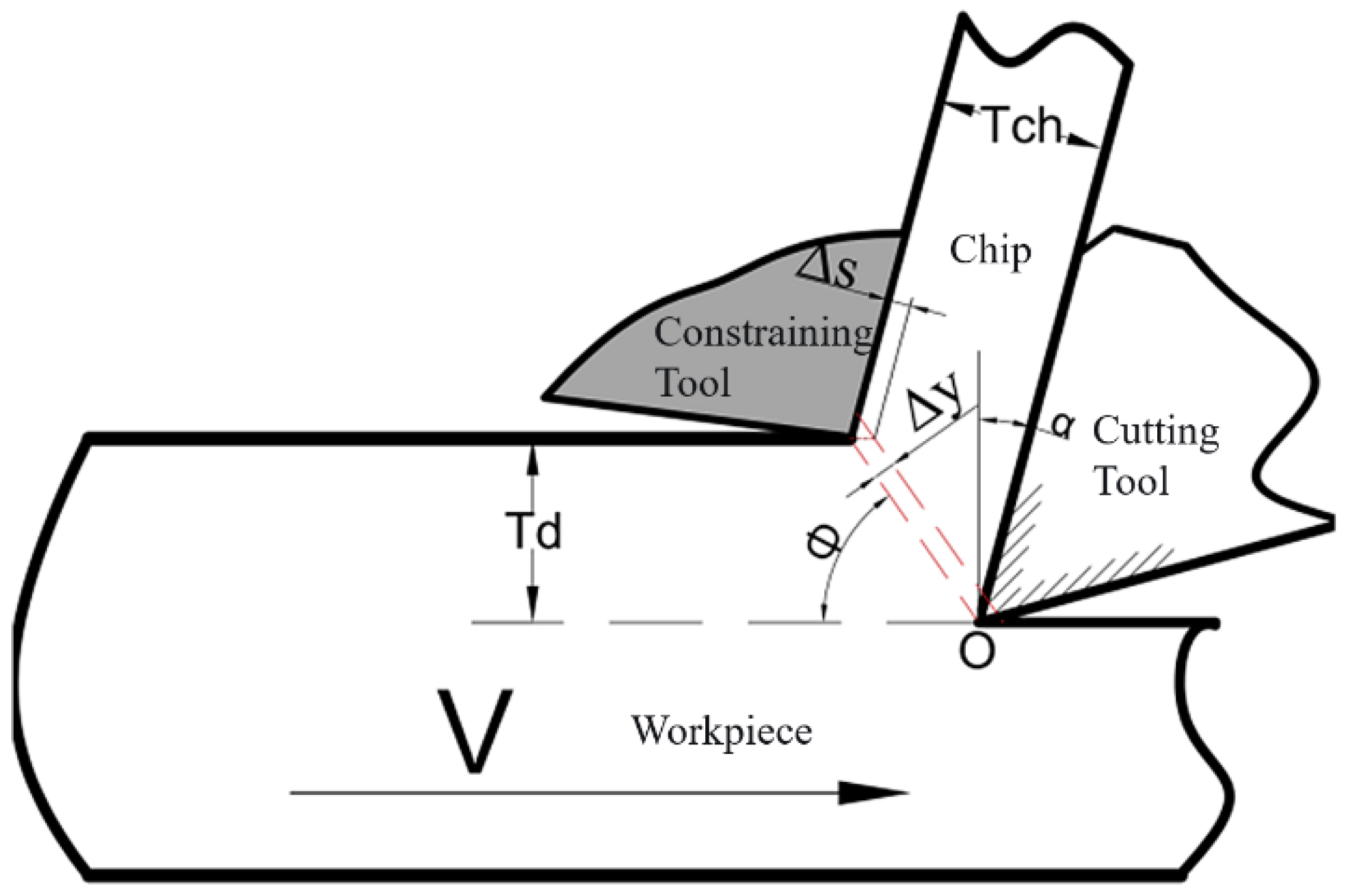

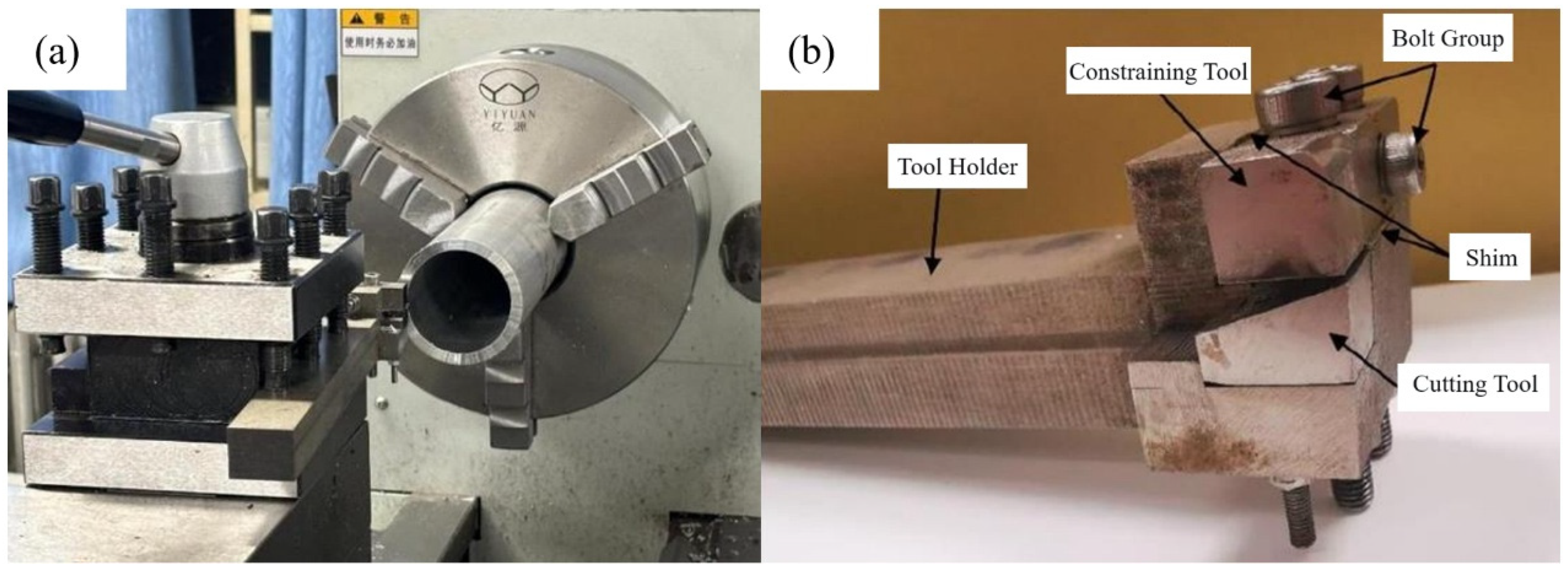

2. Principle of LSEM

3. Experiments and Methods

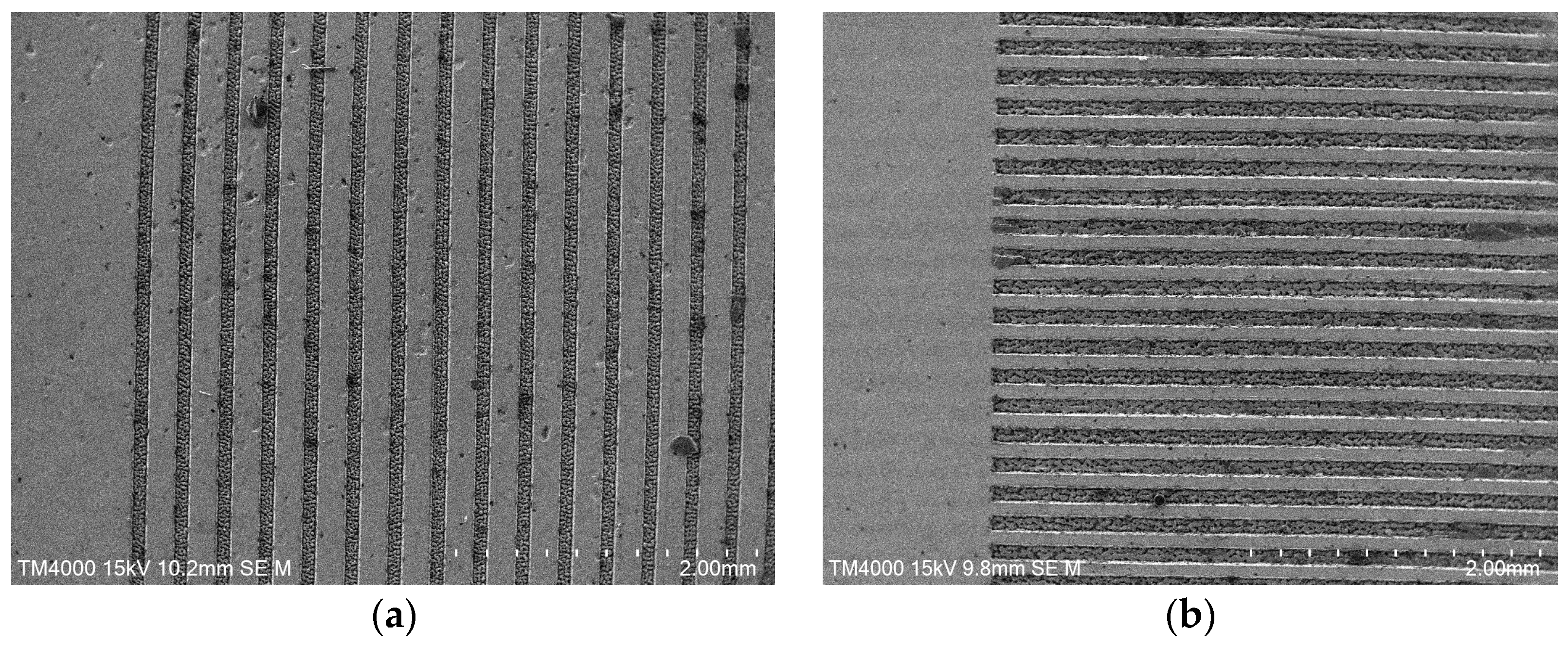

3.1. Preparation of Microtextured Tools

3.2. LSEM Experiment

4. Results and Analysis

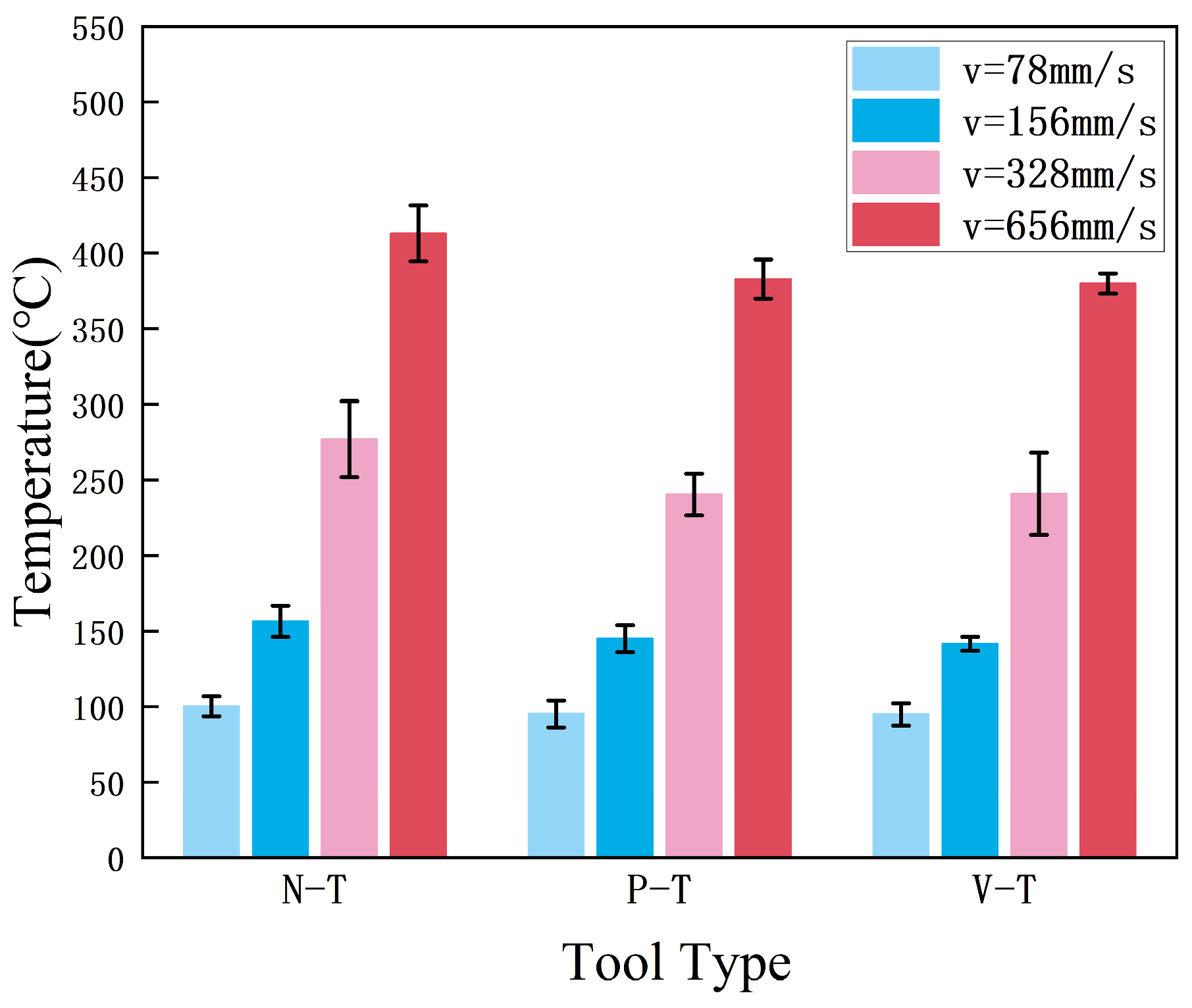

4.1. Cutting Temperature

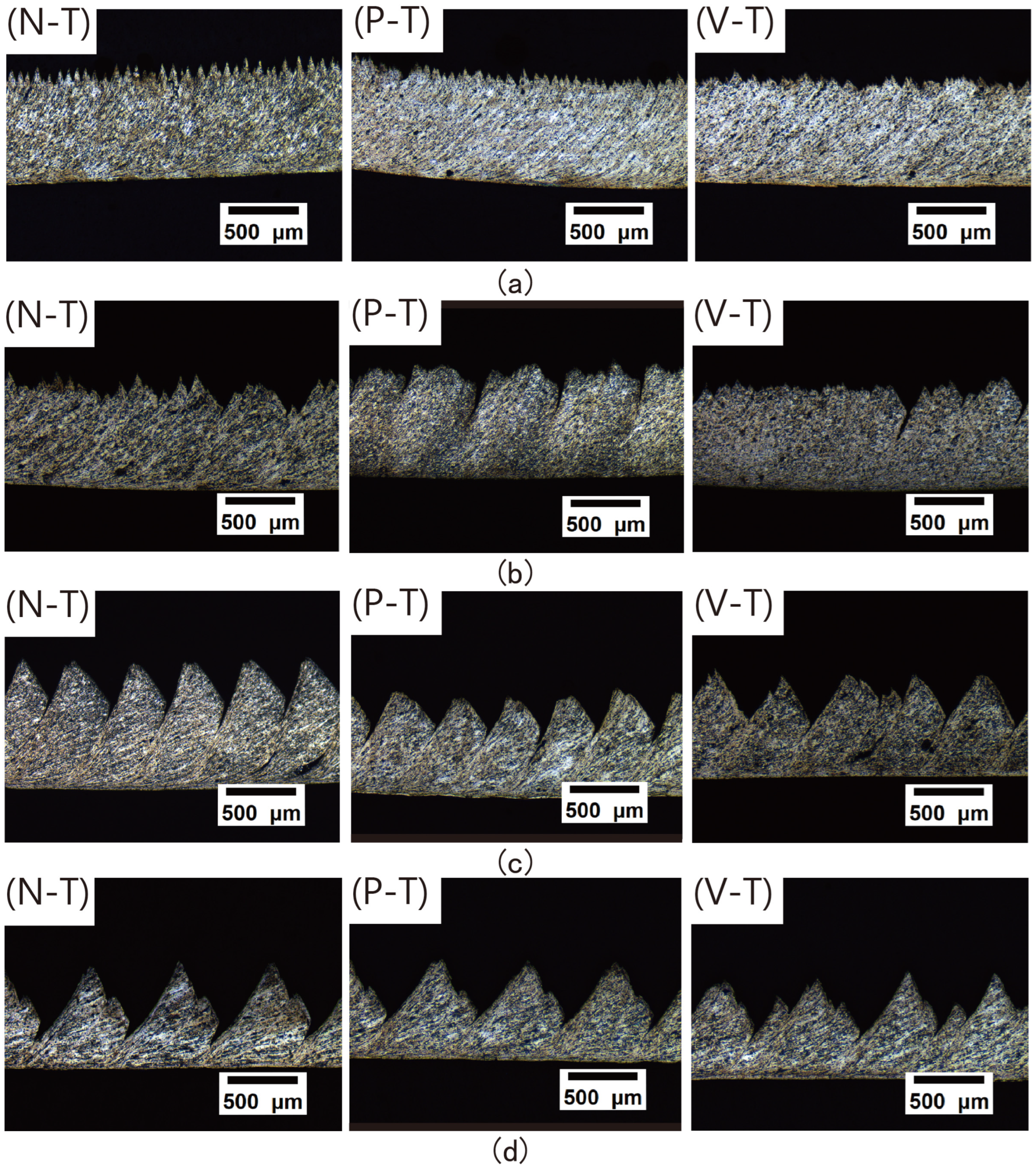

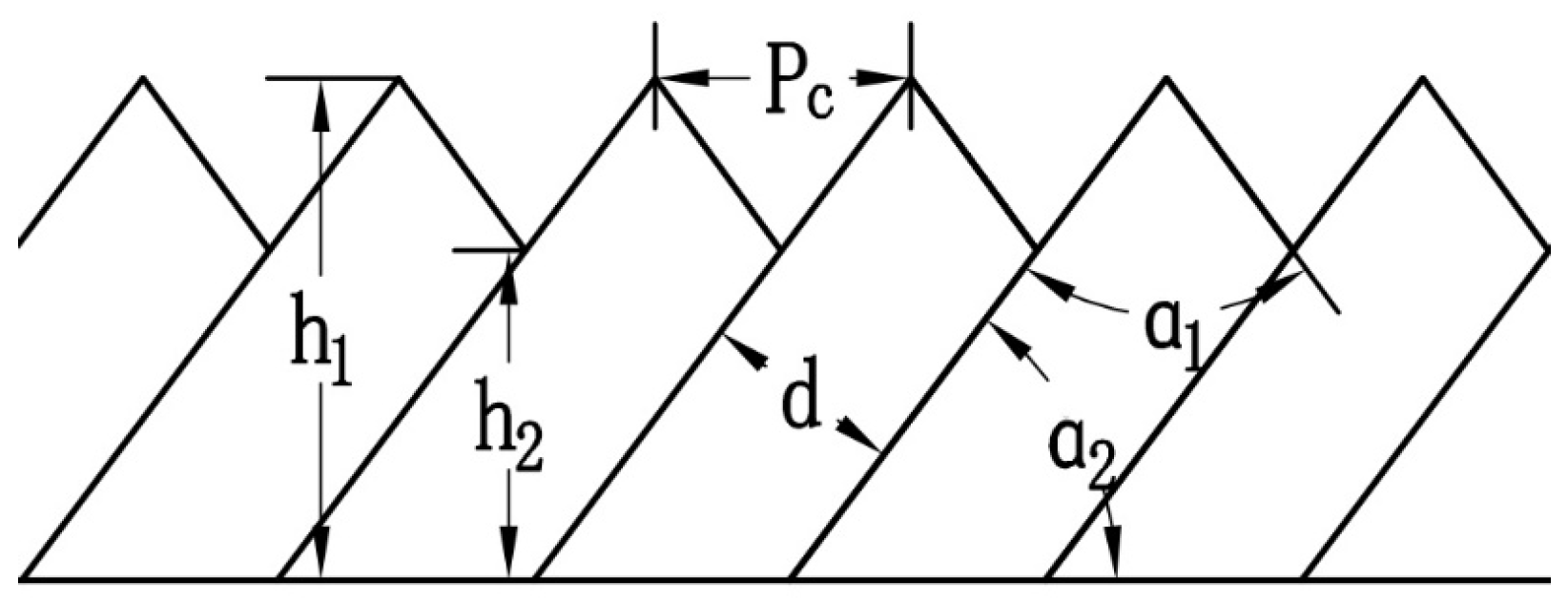

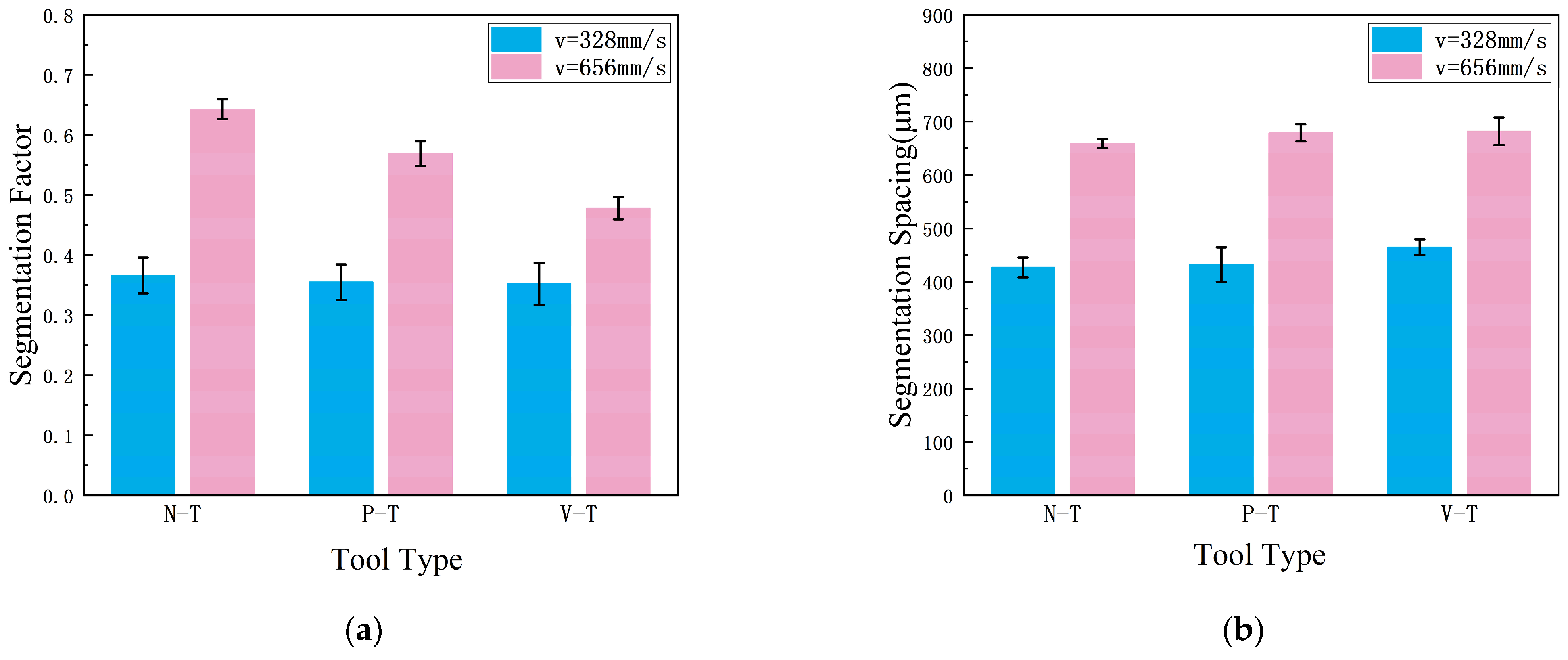

4.2. Chip Morphology

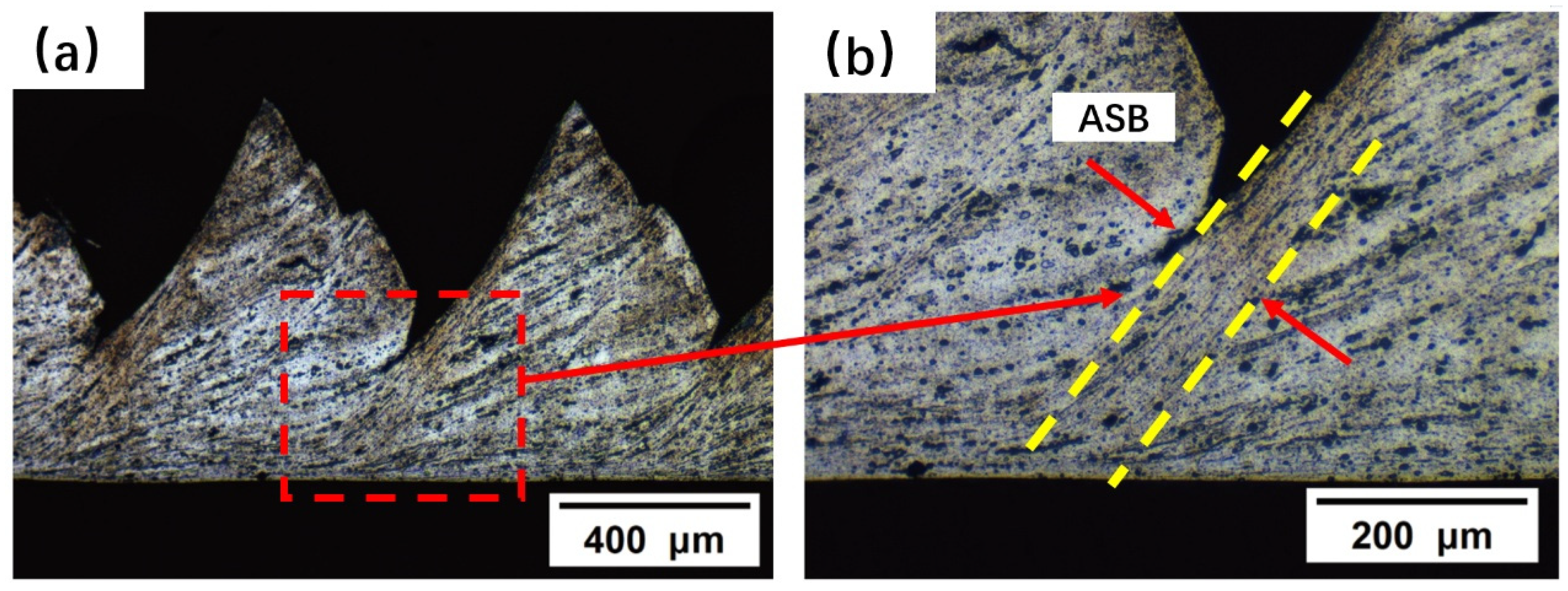

4.3. Microstructure of Chips

5. Conclusions

- Microtextured cutting tools effectively reduce cutting temperatures. Compared to N-T tools, P-T tools and V-T tools reduced maximum cutting temperatures by 8.22% (20.82 °C) and 8.97% (22.71 °C) on average, with maximum reductions of 13.20% (36.56 °C) and 13.02% (36.06 °C), respectively. Microtextures guide chip flow directionality, reducing adhesion time at the tool-chip interface while increasing the tool’s effective heat dissipation area. This enhances heat dissipation efficiency, thereby lowering cutting temperatures and reducing tool wear.

- Microtextured cutting tools suppress serrated chip formation. Under identical cutting conditions, chips produced by P-T and V-T tools exhibited lower serration ( ) than those from N-T tools (with maximum reductions of 11.51% and 25.66%, respectively). The increased serration spacing enhances chip formation stability, thereby improving machined surface quality.

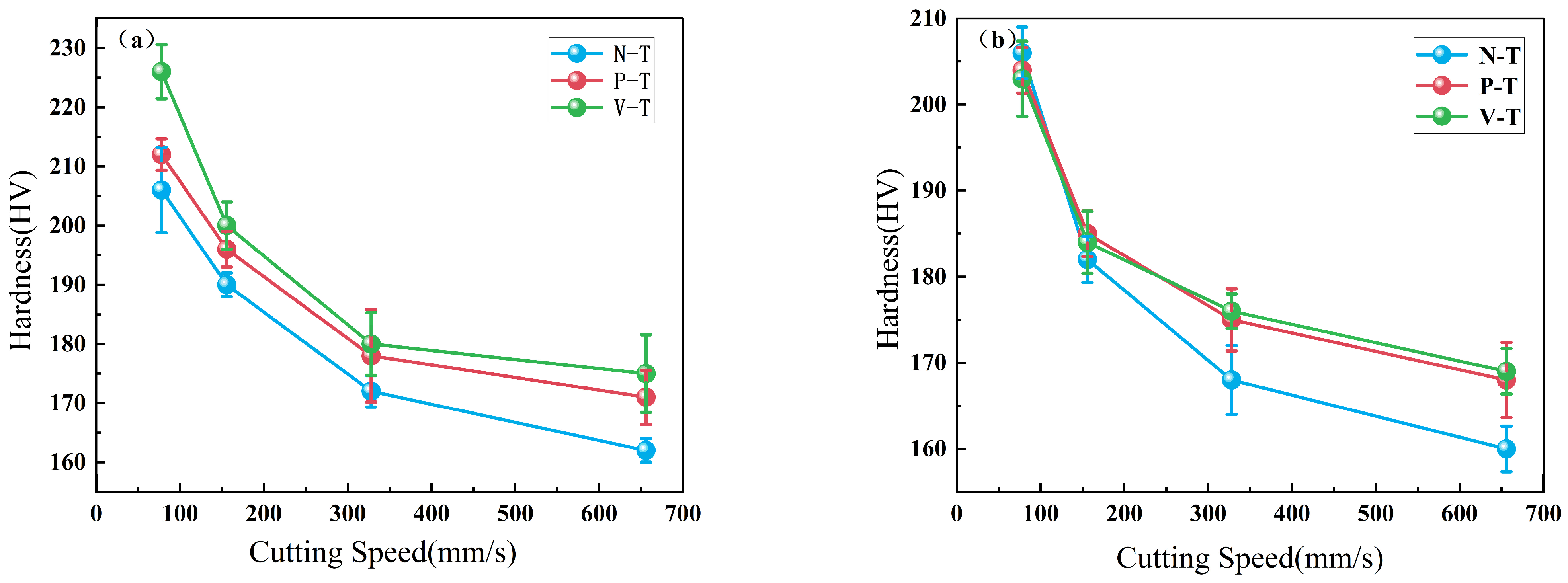

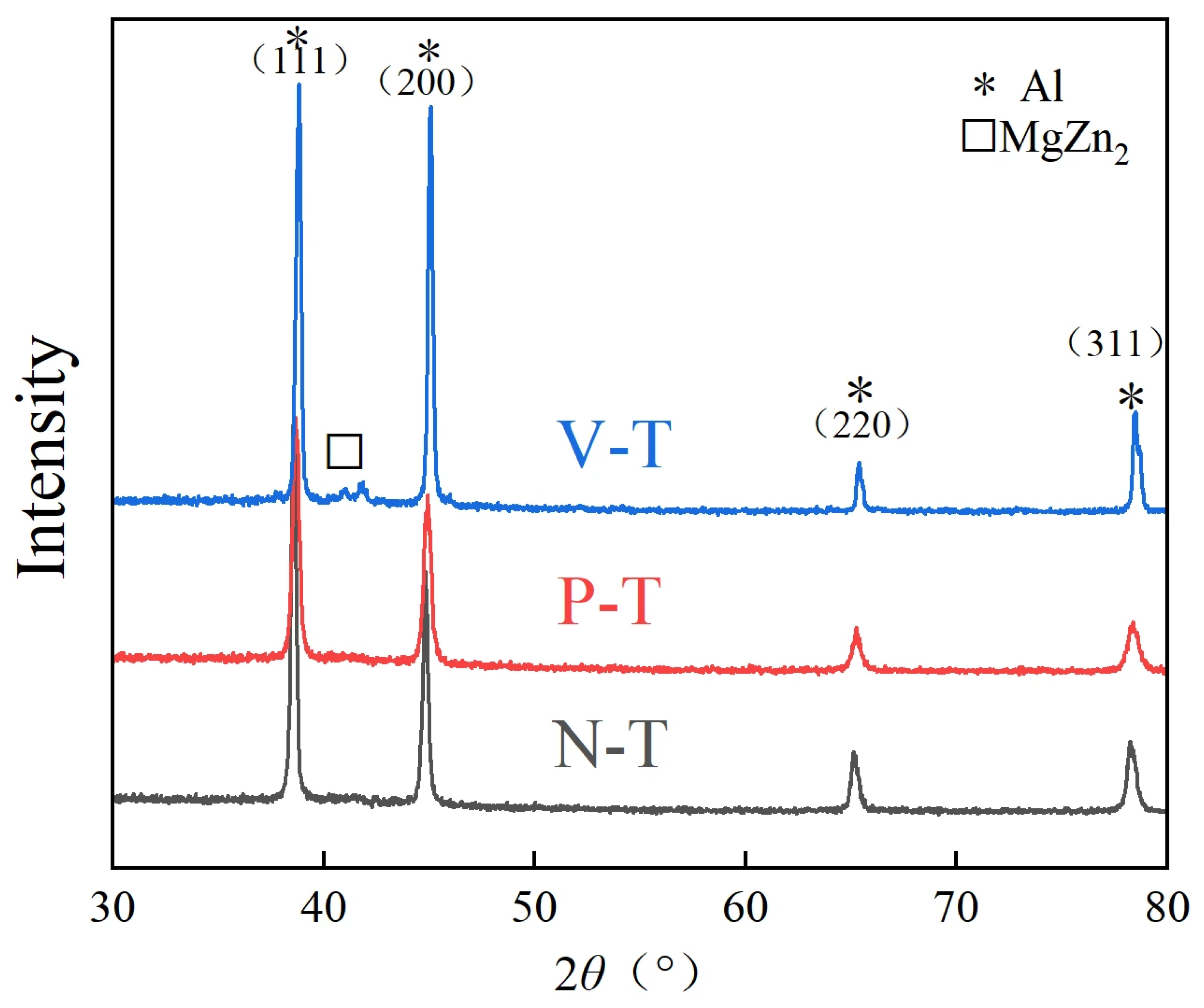

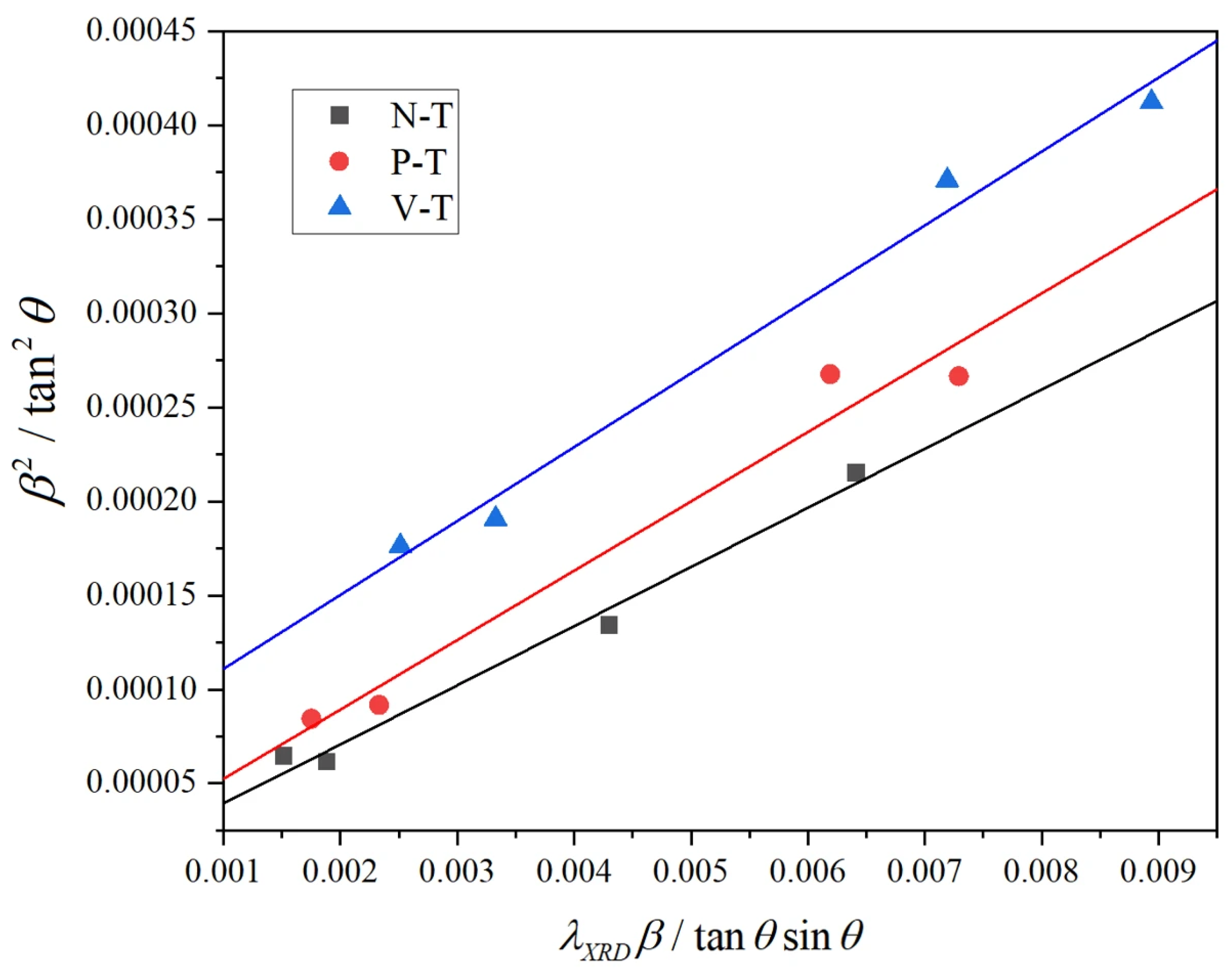

- Microtextured cutting tools can enhance the microstructural properties of materials. The microhardness of both shear slip zones and matrix regions in chips produced by the two microtextured tools is generally higher than that in chips produced by the N-T tool. The dislocation density in chips produced by V-T tools (1.01 × 1015 m−2) was significantly higher than that in chips from P-T tools (4.42 × 1014 m−2) and N-T tools (2.68 × 1014 m−2), indicating the potential of microtextured tools for optimizing cutting processes and enhancing material microstructural properties.

- Comparing the two microtexture tools, the V-T tool demonstrates superior performance, exhibiting more pronounced effects in reducing cutting temperatures, suppressing chip serration and enhancing material micro-strength.

- Microtextured tools can optimize the LSEM process. This study confirms that introducing microtextured tools into the LSEM process effectively overcomes challenges such as high cutting temperatures and significant tool-chip friction. Microtexturing optimizes the LSEM process of Al7075 across multiple levels—tribology, thermodynamics, and microstructural evolution—by reducing friction, promoting heat dissipation, guiding chip flow, suppressing serration formation, refining grain size, and increasing dislocation density. Provides technical support for the processing of high-strength aluminum alloys.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Description |

| Depth of cut | |

| ASB | Adiabatic Shear Band |

| b | The Burgers vector |

| d | Adiabatic shear band spacing |

| The grain size | |

| DRX | Dynamic recrystallization |

| f | Feed rate |

| Serration degree | |

| Tooth crest height | |

| Tooth root height | |

| LSEM | Large Strain Extrusion Machining |

| N-T | Non-textured tools |

| Serration pitch | |

| P-T | Parallel-to-cutting-edge microtextured tools |

| Chip thickness | |

| Cutting layer thickness | |

| V-T | Perpendicular-to-cutting-edge microtextured tools |

| V/v | Tool velocity |

| Clearance Angle | |

| Rake angle of serrated chip | |

| Clearance angle of serrated chip | |

| α/ | Tool rake angle |

| β | Half-width at half maximum of the diffraction peak |

| ∆y | Width of the Primary Shear Zone |

| ε | Effective strain |

| Strain rate | |

| λ | The chip thickness compression ratio |

| X-ray wavelength | |

| ρ | Dislocation density |

| φ | Shear angle |

| θ | Half-diffraction angle |

References

- Zhou, B.; Liu, B.; Zhang, S.G. The advancement of 7xxx series aluminum alloys for aircraft structures: A review. Metals 2021, 11, 718. [Google Scholar] [CrossRef]

- Gurusamy, M.; Rao, B.C. A Comprehensive Review of Large-Strain-Extrusion Machining Process for Production of Fine-Grained Materials. Crystals 2023, 13, 131. [Google Scholar] [CrossRef]

- Efe, M.; Moscoso, W.; Trumble, K.P.; Compton, W.D.; Chandrasekar, S. Mechanics of large strain extrusion machining and application to deformation processing of magnesium alloys. Acta Mater. 2012, 60, 2031–2042. [Google Scholar] [CrossRef]

- Sevier, M.; Yang, H.T.Y.; Moscoso, W.; Chandrasekar, S. Analysis of severe plastic deformation by large strain extrusion machining. Met. Mater. Trans. A 2008, 39, 2645–2655. [Google Scholar] [CrossRef]

- Deng, W.J.; Lin, P.; Xie, Z.C.; Li, Q. Analysis of Large-Strain Extrusion Machining with Different Chip Compression Ratios. J. Nanomater. 2012, 2012, 851753. [Google Scholar] [CrossRef]

- Pi, Y.Y.; Deng, W.J.; Zhang, J.Y.; Yin, X.L.; Xia, W. Towards understanding the microstructure and temperature rule in large strain extrusion machining. Adv. Manuf. 2021, 9, 262–272. [Google Scholar] [CrossRef]

- Cai, S.L.; Dai, L.H. Suppression of repeated adiabatic shear banding by dynamic large strain extrusion machining. J. Mech. Phys. Solids 2014, 73, 84–102. [Google Scholar] [CrossRef]

- Wang, P.H.; Yue, X.J.; Zong, C.G.; Zhang, P.; Zhang, Q.; Zhai, Y.C.; Yu, X.A. Research on the influence of tool geometric parameters on the LSEM mechanism of 7A04 aluminum alloy. Vacuum 2021, 192, 110396. [Google Scholar] [CrossRef]

- Wang, Q.W.; Yang, Y.; Yao, P.; Zhang, Z.Y.; Yu, S.M.; Zhu, H.T.; Huang, C.Z. Friction and cutting characteristics of micro-textured diamond tools fabricated with femtosecond laser. Tribol. Int. 2021, 154, 106720. [Google Scholar] [CrossRef]

- Jahaziel, R.B.; Krishnaraj, V.; Priyadarshini, B.G. Investigation on influence of micro-textured tool in machining of Ti-6Al-4V alloy. J. Mech. Sci. Technol. 2022, 36, 1987–1995. [Google Scholar] [CrossRef]

- Sun, X.Y.; Wang, X.Y.; Hu, Y.W.; Duan, J.A. The effect of micro-texture on wear resistance of WC/Co-based tools during cutting Ti-6Al-4V. Appl. Phys. A 2021, 127, 453. [Google Scholar] [CrossRef]

- Sugihara, T.; Kobayashi, R.; Enomoto, T. Direct observations of tribological behavior in cutting with textured cutting tools. Int. J. Mach. Tools Manuf. 2021, 168, 103726. [Google Scholar] [CrossRef]

- Wang, X.M.; Li, C.H.; Zhang, Y.B.; Said, Z.; Debnath, S.; Sharma, S.; Yang, M.; Gao, T. Influence of texture shape and arrangement on nanofluid minimum quantity lubrication turning. Int. J. Adv. Manuf. Technol. 2022, 119, 631–646. [Google Scholar] [CrossRef]

- Tong, X.; Han, P.; Yang, S.C. Coating and micro-texture techniques for cutting tools. J. Mater. Sci. 2022, 57, 17052–17104. [Google Scholar] [CrossRef]

- Cai, S.L.; Chen, Y.; Ye, G.G.; Jiang, M.Q.; Wang, H.Y.; Dai, L.H. Characterization of the deformation field in large-strain extrusion machining. J. Mater. Process. Technol. 2015, 216, 48–58. [Google Scholar] [CrossRef]

- Yin, X.L.; Deng, W.J.; Zou, Y.H.; Zhang, J.Y. Ultrafine grained Al 7075 alloy fabricated by cryogenic temperature large strain extrusion machining combined with aging treatment. Mater. Sci. Eng. A 2019, 762, 138106. [Google Scholar] [CrossRef]

- Wang, Z.F.; Niu, Y.; Sun, H.M.; Jiao, F. Preparation and mechanism of copper ultra-fine grain strip by ultrasonic vibration extrusion cutting-model, FEM and experiment. J. Mater. Res. Technol. 2023, 24, 4919–4934. [Google Scholar] [CrossRef]

- Shankar, M.R.; Chandrasekar, S.; King, A.H.; Compton, W.D. Microstructure and stability of nanocrystalline aluminum 6061 created by large strain machining. Acta Mater. 2005, 53, 4781–4793. [Google Scholar] [CrossRef]

- Yin, X.L.; Wang, W.; Wang, Z.L.; Guo, R.Y.; Yu, H.C.; Pi, Y.Y.; Yan, W.J.; Wang, H.B.; Zhou, H.B. Thermal stability, microstructure evolution and grain growth kinetics of ultrafine grained Al 7075 alloy processed by cryogenic temperature extrusion machining. J. Alloys Compd. 2023, 950, 169900. [Google Scholar] [CrossRef]

- Ye, G.G.; Jiang, M.Q.; Xue, S.F.; Ma, W.; Dai, L.H. On the instability of chip flow in high-speed machining. Mech. Mater. 2018, 116, 104–119. [Google Scholar] [CrossRef]

- Yin, X.; Ma, S.; Wu, Y.; Wang, W.; Cui, L.; Chen, Y. Study on Textured Tool Cutting of 7050 Aluminum Alloy and Formation Mechanism of Serrated Chips. J. Mater. Eng. Perform. 2025, 1–10. [Google Scholar] [CrossRef]

- Yin, X.L.; Wang, Z.L.; Yu, H.C.; Wang, W.B. Microstructure, aging behavior, and friction and wear properties of ultrafine-grained 7050 aluminum alloy produced by cryogenic temperature extrusion machining. Mater. Today Commun. 2024, 39, 109344. [Google Scholar] [CrossRef]

- Rosas, J.; Lopes, H.; Guimaraes, B.; Piloto, P.A.G.; Miranda, G.; Silva, F.S.; Paiva, O.C. Influence of Micro-Textures on Cutting Insert Heat Dissipation. Appl. Sci. 2022, 12, 6583. [Google Scholar] [CrossRef]

- Ye, G.G.; Chen, Y.; Xue, S.F.; Dai, L.H. Critical cutting speed for onset of serrated chip flow in high speed machining. Int. J. Mach. Tools Manuf. 2014, 86, 18–33. [Google Scholar] [CrossRef]

- Ding, F.; Zhang, T.; Wang, C.Y.; Sui, J.B.; Zhu, X.G.; Gao, K. Mechanism of chip segmentation transition from shear slip to shear fracture of Zirconium-based bulk metallic glass in mechanical machining. J. Mater. Res. Technol. 2024, 30, 7398–7412. [Google Scholar] [CrossRef]

- Le, K.C.; Tran, T.M.; Langer, J.S. Thermodynamic dislocation theory of adiabatic shear banding in steel. Scr. Mater. 2018, 149, 62–65. [Google Scholar] [CrossRef]

- Rowe, R.A.; Allison, P.G.; Palazotto, A.N.; Davami, K. Adiabatic Shear Banding in Nickel and Nickel-Based Superalloys: A Review. Metals 2022, 12, 1879. [Google Scholar] [CrossRef]

- Schulz, H.; Abele, E.; Sahm, A. Material aspects of chip formation in HSC machining. Cirp Ann. 2001, 50, 45–48. [Google Scholar] [CrossRef]

- Fan, L.; Deng, Z.L.; He, Y.; Zhu, X.L.; Gao, X.J.; Jin, Z. The effects of micro-texture shape on serrated chip geometry in the hardened steel AISI D2 cutting process. Surf. Topogr.-Metrol. Prop. 2022, 10, 015031. [Google Scholar] [CrossRef]

- Wu, R.R.; Jing, Q.Q.; Zhang, Z.X.; Gao, B.; Hou, J.; Shuang, Y.H.; Chen, H.Q.; Wang, F. Hot Deformation and Dynamic Recrystallization of 7075 Al Alloy in the Extruded State. J. Mater. Eng. Perform. 2025, 34, 17392–17409. [Google Scholar] [CrossRef]

- Yang, H.B.; Qian, Z.; Sun, P.; Yang, H.M.; Zheng, S.J.; Li, M.N. Flow Behavior and Activation Energy Evolution of 7075-T6 Al Alloy During Hot Deformation. JOM 2024, 76, 3679–3693. [Google Scholar] [CrossRef]

- Duan, C.Z.; Wang, M.J. Characteristics of adiabatic shear bands in the orthogonal, cutting of 30CrNi3MOV steel. J. Mater. Process. Technol. 2005, 168, 102–106. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, P.C.; Lu, T.W.; Feng, K.; Tong, Y.G.; Sun, B.H.; Yao, N.; Xie, Y.; Han, B.L.; Zhang, X.C.; et al. Effects of post annealing on the microstructure, precipitation behavior, and mechanical property of a (CoCrNi)94Al3Ti3 medium-entropy alloy fabricated by laser powder bed fusion. J. Mater. Sci. Technol. 2023, 135, 142–155. [Google Scholar] [CrossRef]

- Zhang, B.B.; Yan, F.K.; Zhao, M.J.; Tao, N.R.; Lu, K. Combined strengthening from nanotwins and nanoprecipitates in an iron-based superalloy. Acta Mater. 2018, 151, 310–320. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Liao, X.Z.; Cheng, S.; Ma, E.; Zhu, Y.T. Simultaneously increasing the ductility and strength of nanostructured alloys. Adv. Mater. 2006, 18, 2280–2283. [Google Scholar] [CrossRef]

- Arvapalli, S.S.; Miryala, M.; Sakai, N.; Murakami, M.; Jirsa, M. Novel ultra-sonic boron refinement in distilled water for cost-efficient fabrication of MgB2 bulk ceramic superconductors. Ceram. Int. 2022, 48, 28102–28111. [Google Scholar] [CrossRef]

- Pang, J.J.; Liu, F.C.; Liu, J.; Tan, M.J.; Blackwood, D.J. Friction stir processing of aluminium alloy AA7075: Microstructure, surface chemistry and corrosion resistance. Corros. Sci. 2016, 106, 217–228. [Google Scholar] [CrossRef]

- Roushan, A. Effect of discrete and continuous texture geometries on tool wear and derivative cutting effect during the machining. Wear 2025, 568, 205964. [Google Scholar] [CrossRef]

| Machining Parameter | Value |

|---|---|

| v/(m/min) | 4.68, 9.36, 19.68, 39.36 |

| /(mm) | 0.5 |

| f/(mm/r) | 0.69 |

| λ | 1.4 |

| /(°) | 10° |

| /(°) | 5° |

| Group | 2θ (Deg) | Full Width at Half Maximum (FWHM) (Deg) | Microstress Deformation (%) | Grain Size Dimension (nm) | Dislocation Density (m−2) |

|---|---|---|---|---|---|

| N-T | 38.81581 | 0.29614 | 0.202 | 37.3 | 2.68 × 1014 |

| 45.06850 | 0.27525 | ||||

| 65.40259 | 0.28876 | ||||

| 78.51829 | 0.37652 | ||||

| P-T | 38.81581 | 0.32271 | 0.258 | 27.8 | 4.42 × 1014 |

| 45.06850 | 0.38166 | ||||

| 65.40259 | 0.34757 | ||||

| 78.51829 | 0.42503 | ||||

| V-T | 38.58053 | 0.40723 | 0.168 | 25.6 | 1.01 × 1015 |

| 44.83276 | 0.45517 | ||||

| 65.17355 | 0.50584 | ||||

| 78.29915 | 0.61913 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, X.; Yang, M.; Wang, W.; Li, Y.; Li, Y. Large Strain Extrusion Machining of 7075 Aluminum Alloy with Micro-Textured Tools and Analysis of Chip Morphology and Microstructure. Micromachines 2025, 16, 1327. https://doi.org/10.3390/mi16121327

Yin X, Yang M, Wang W, Li Y, Li Y. Large Strain Extrusion Machining of 7075 Aluminum Alloy with Micro-Textured Tools and Analysis of Chip Morphology and Microstructure. Micromachines. 2025; 16(12):1327. https://doi.org/10.3390/mi16121327

Chicago/Turabian StyleYin, Xiaolong, Minghui Yang, Wan Wang, Youhua Li, and Yuying Li. 2025. "Large Strain Extrusion Machining of 7075 Aluminum Alloy with Micro-Textured Tools and Analysis of Chip Morphology and Microstructure" Micromachines 16, no. 12: 1327. https://doi.org/10.3390/mi16121327

APA StyleYin, X., Yang, M., Wang, W., Li, Y., & Li, Y. (2025). Large Strain Extrusion Machining of 7075 Aluminum Alloy with Micro-Textured Tools and Analysis of Chip Morphology and Microstructure. Micromachines, 16(12), 1327. https://doi.org/10.3390/mi16121327