Development of Vacuum-Chamber-Type Capacitive Micro-Pressure Sensors

Abstract

1. Introduction

2. Materials and Methods

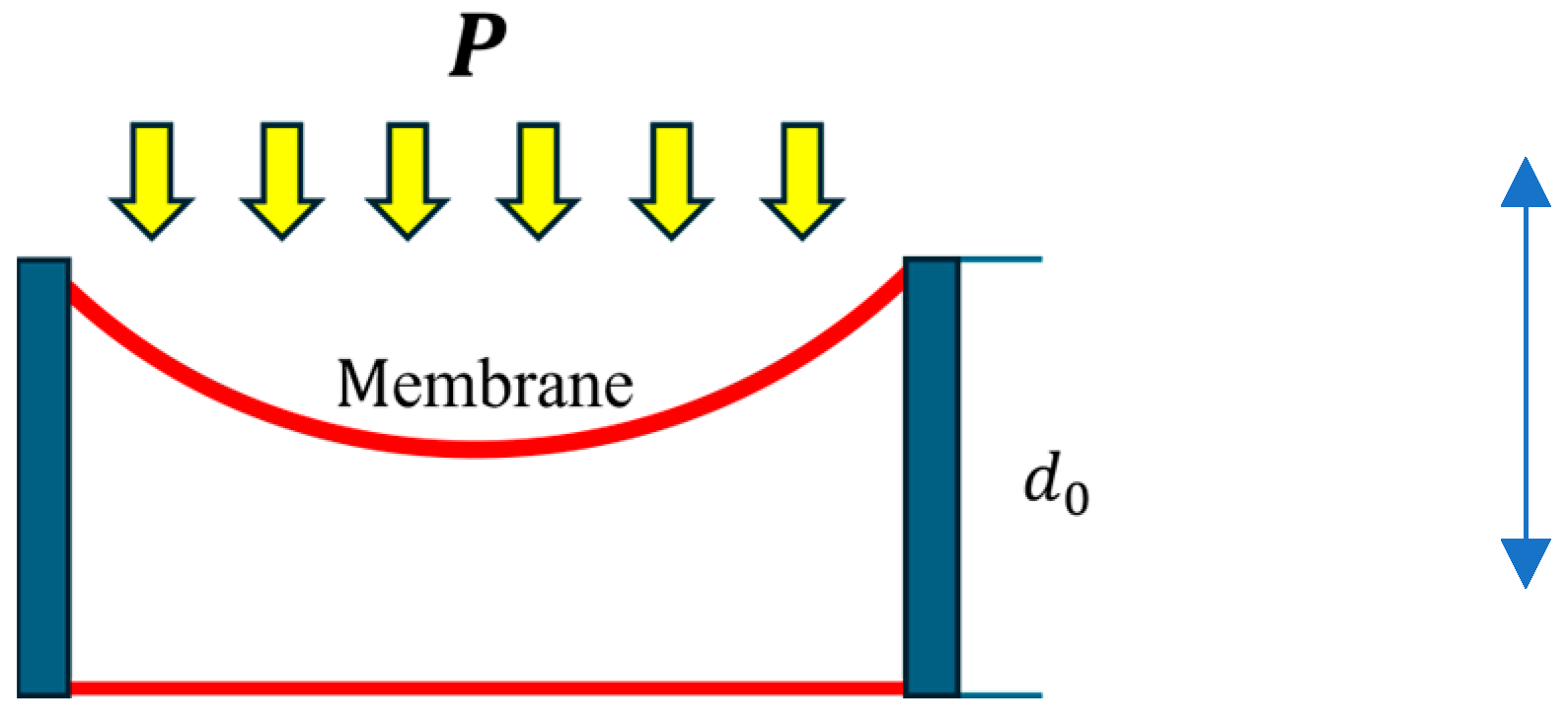

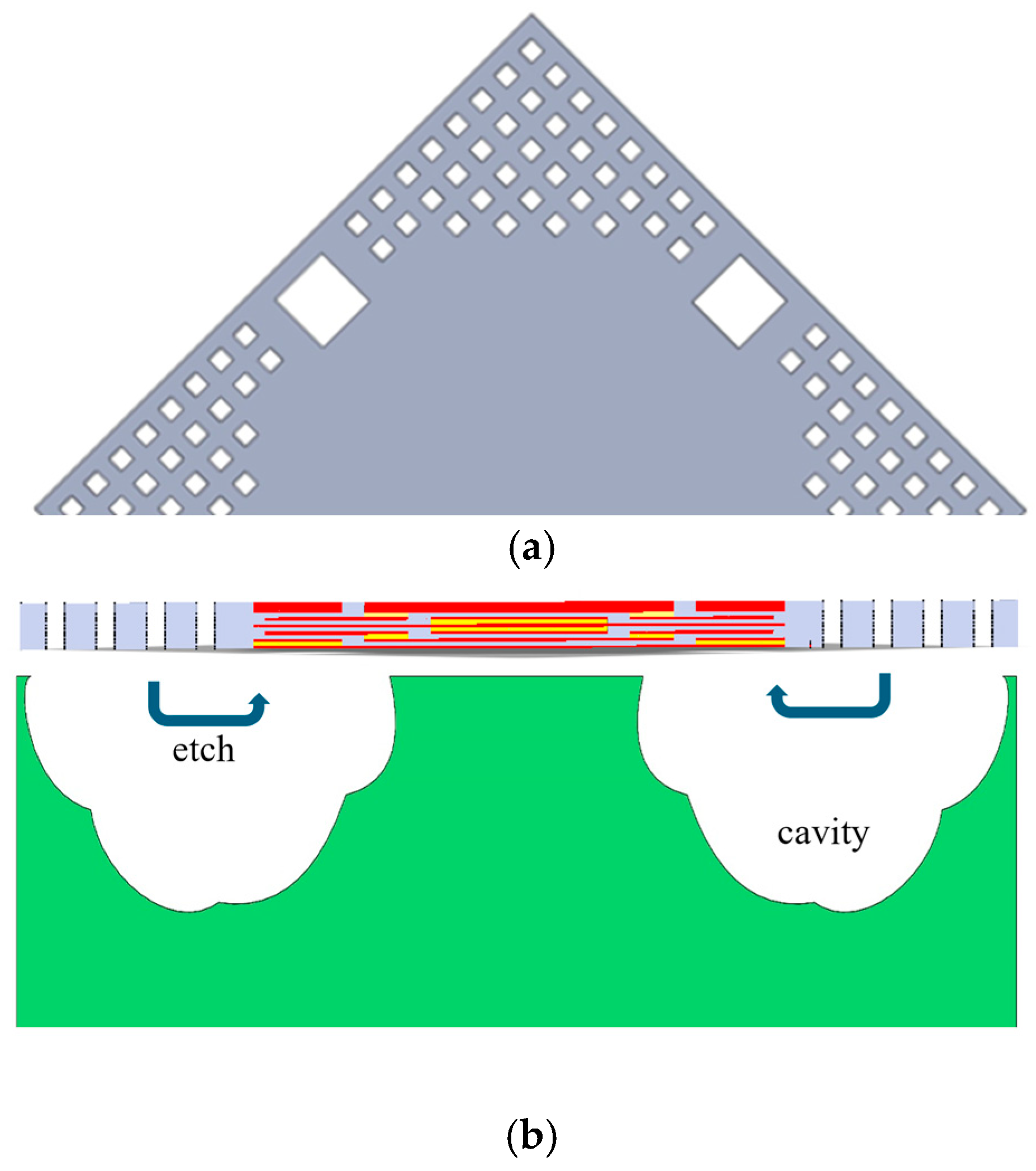

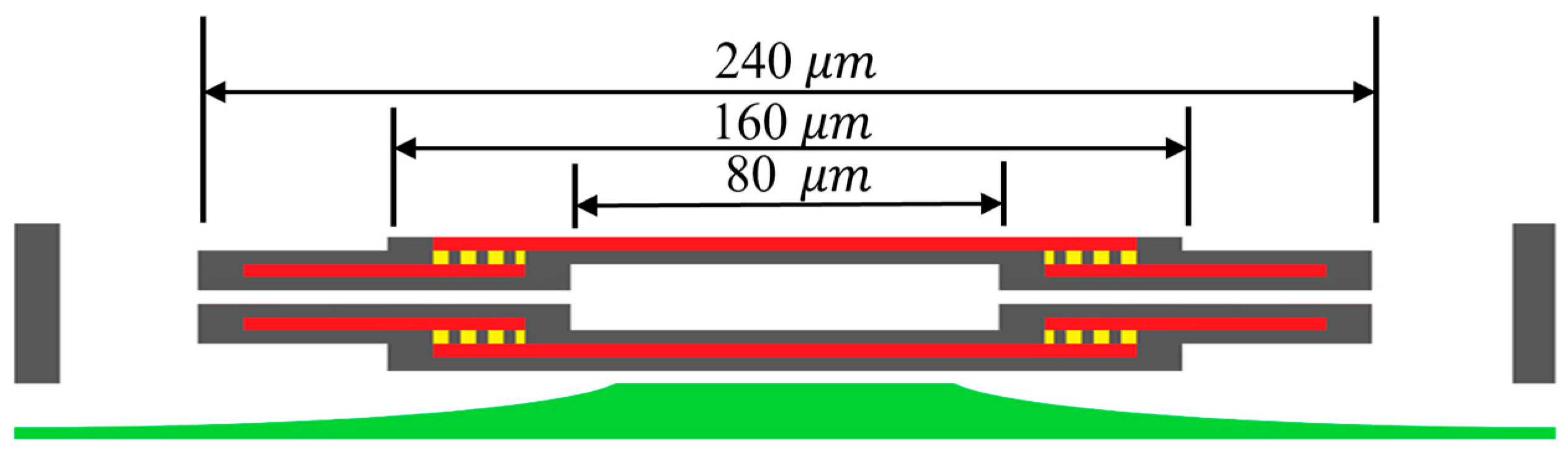

2.1. Conception Design

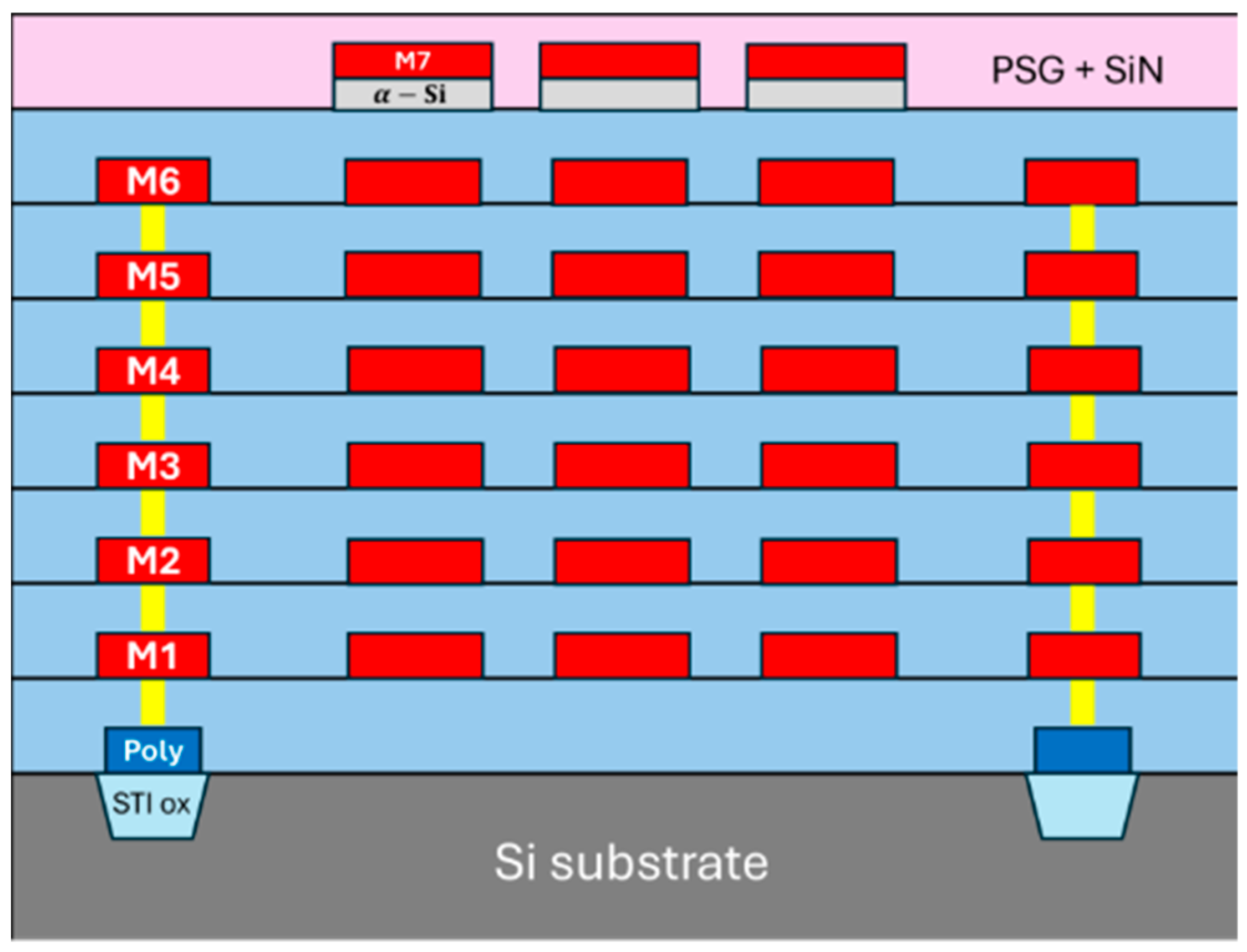

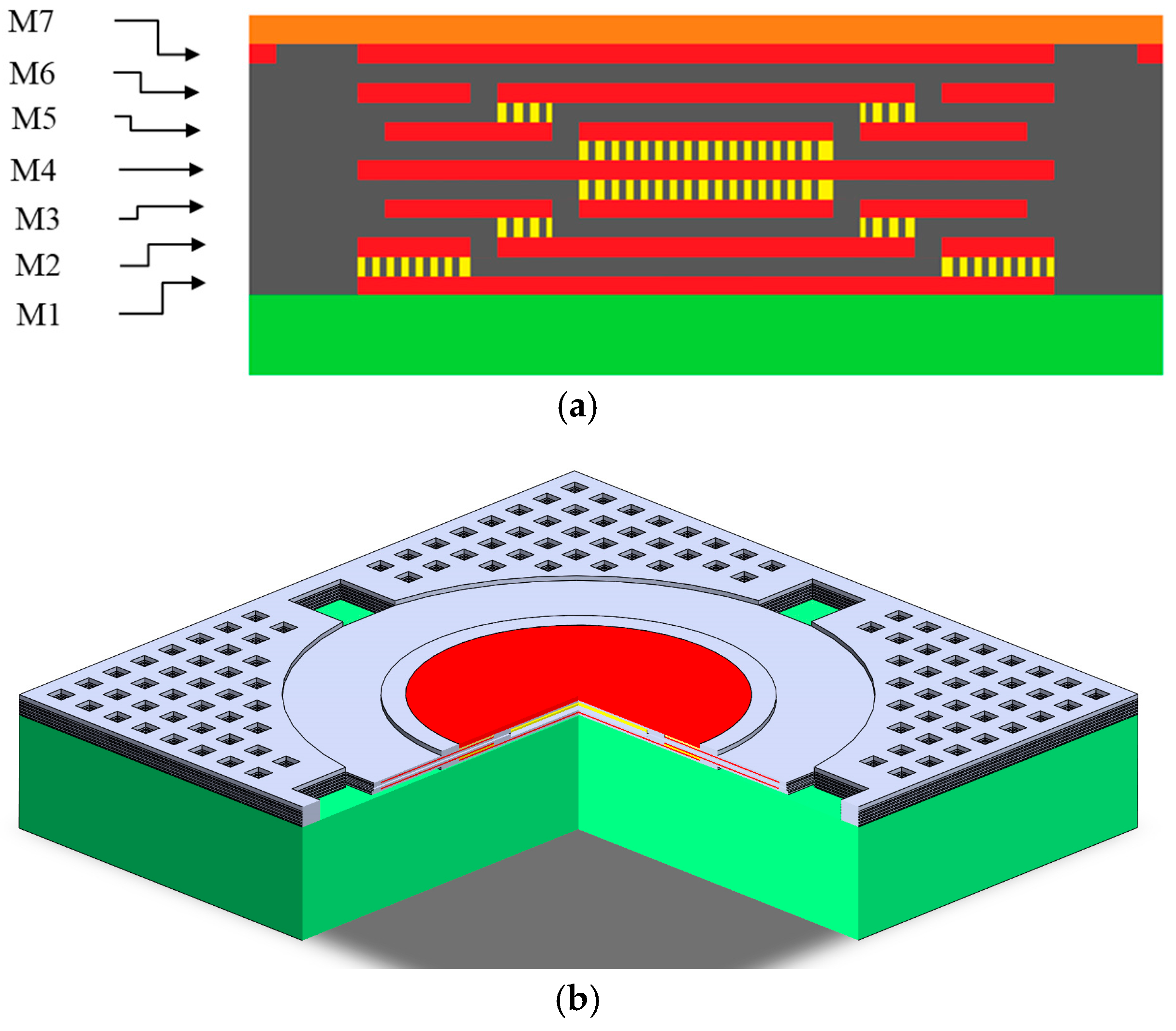

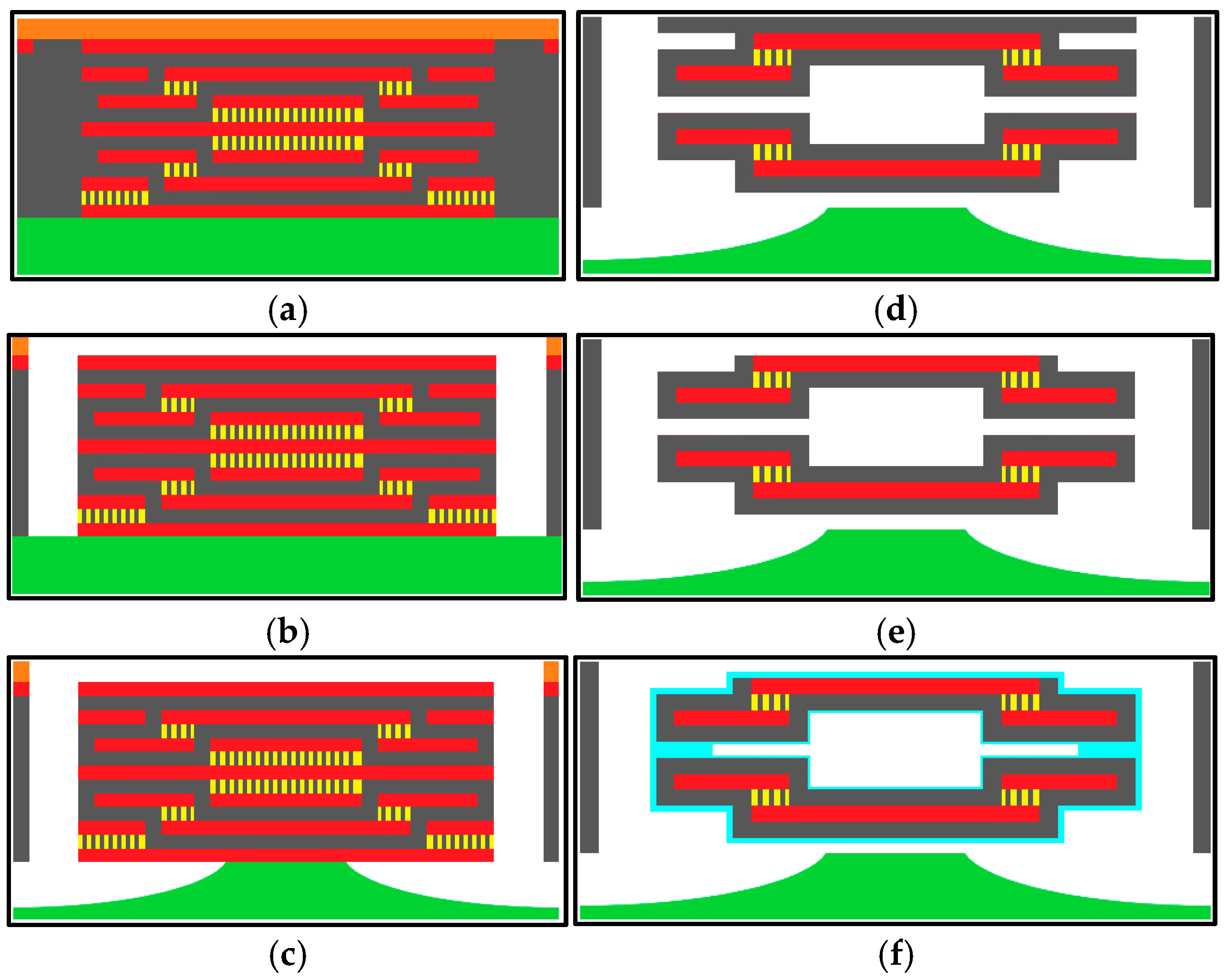

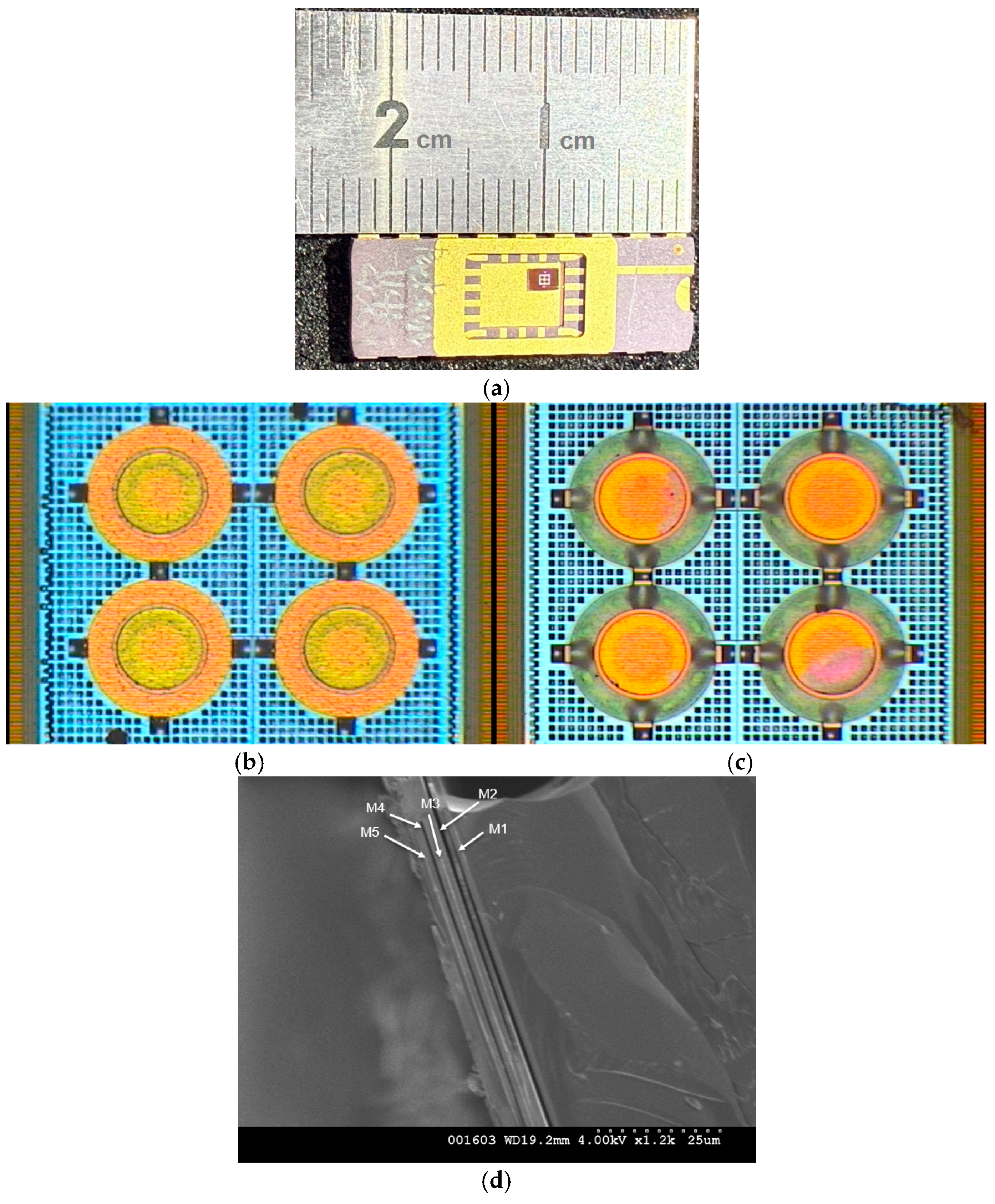

2.2. CMOS MEMS Sensor Fabrication

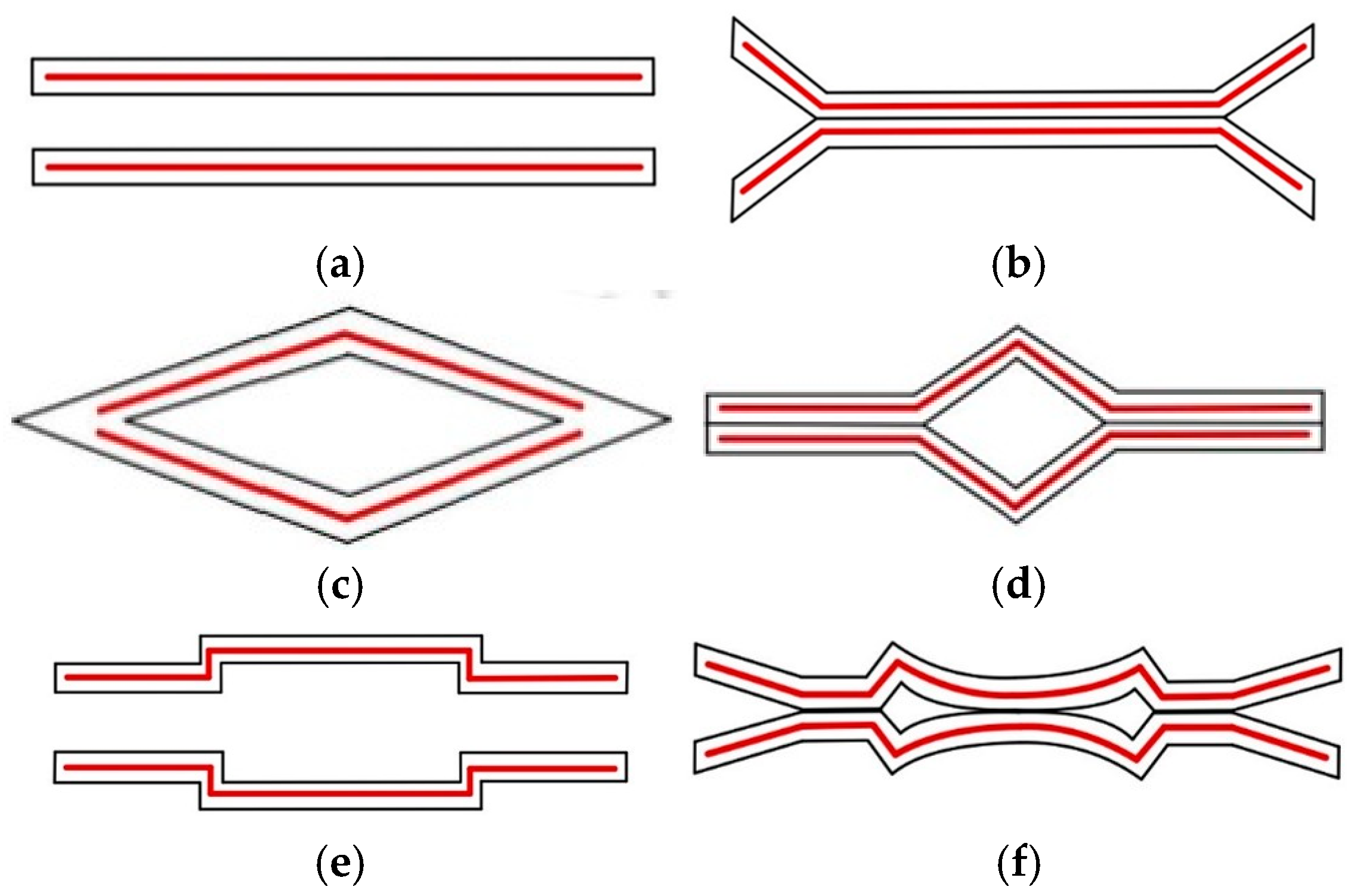

2.3. Layout Design

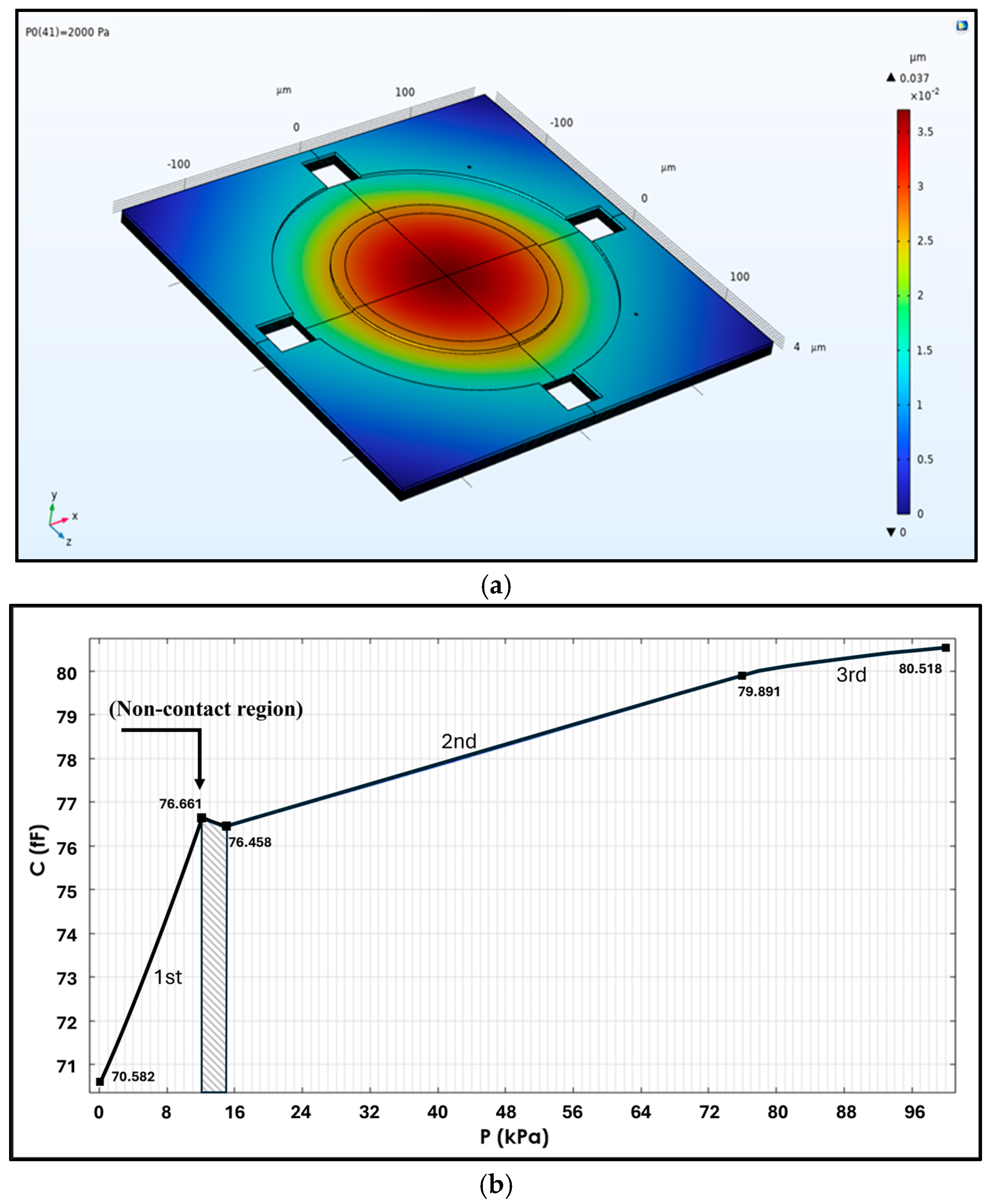

2.4. COMSOL Simulation

2.5. Surface Stiction Issue

3. Results

3.1. The Post-Etching Process

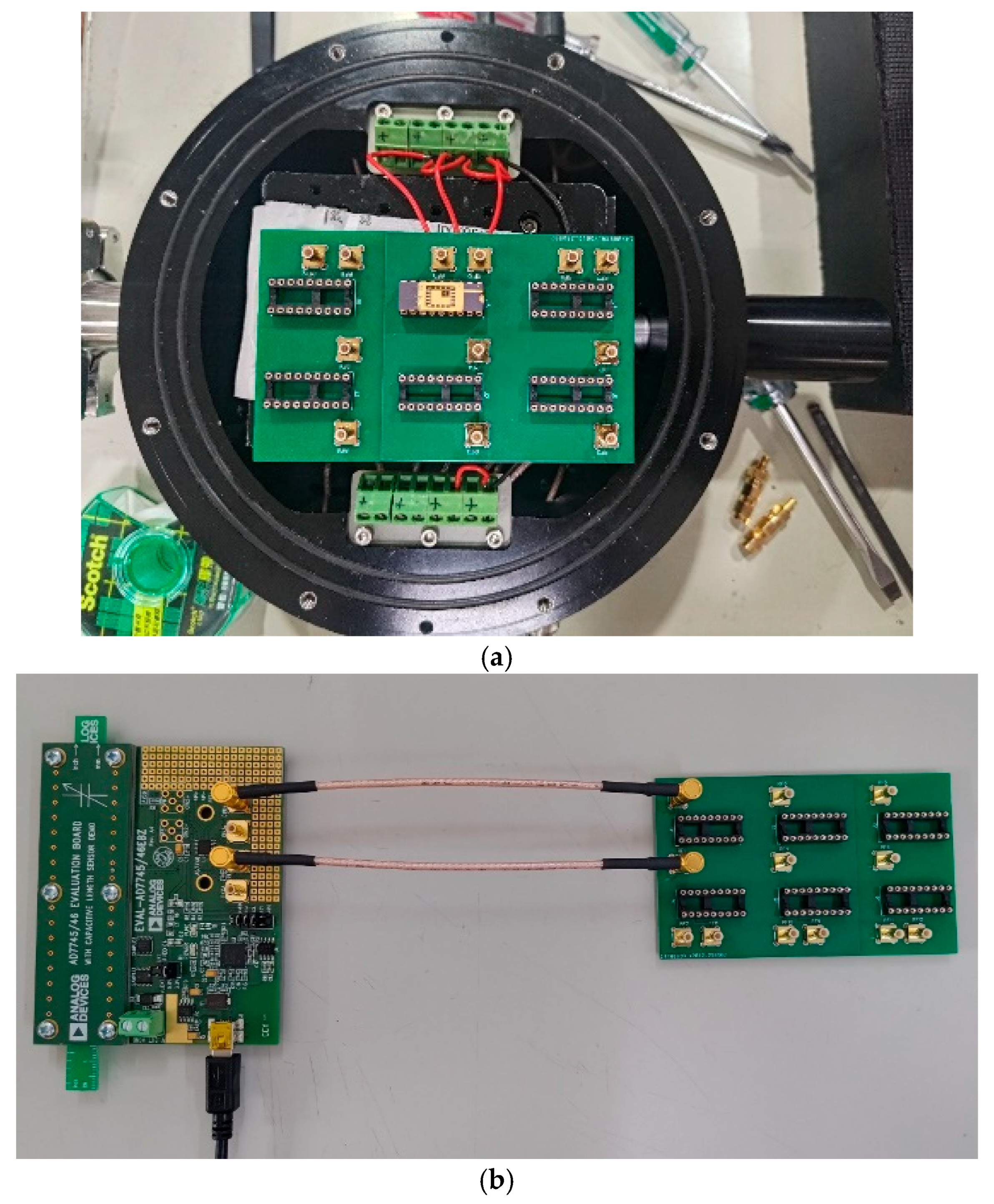

3.2. Small Capacitance Detection

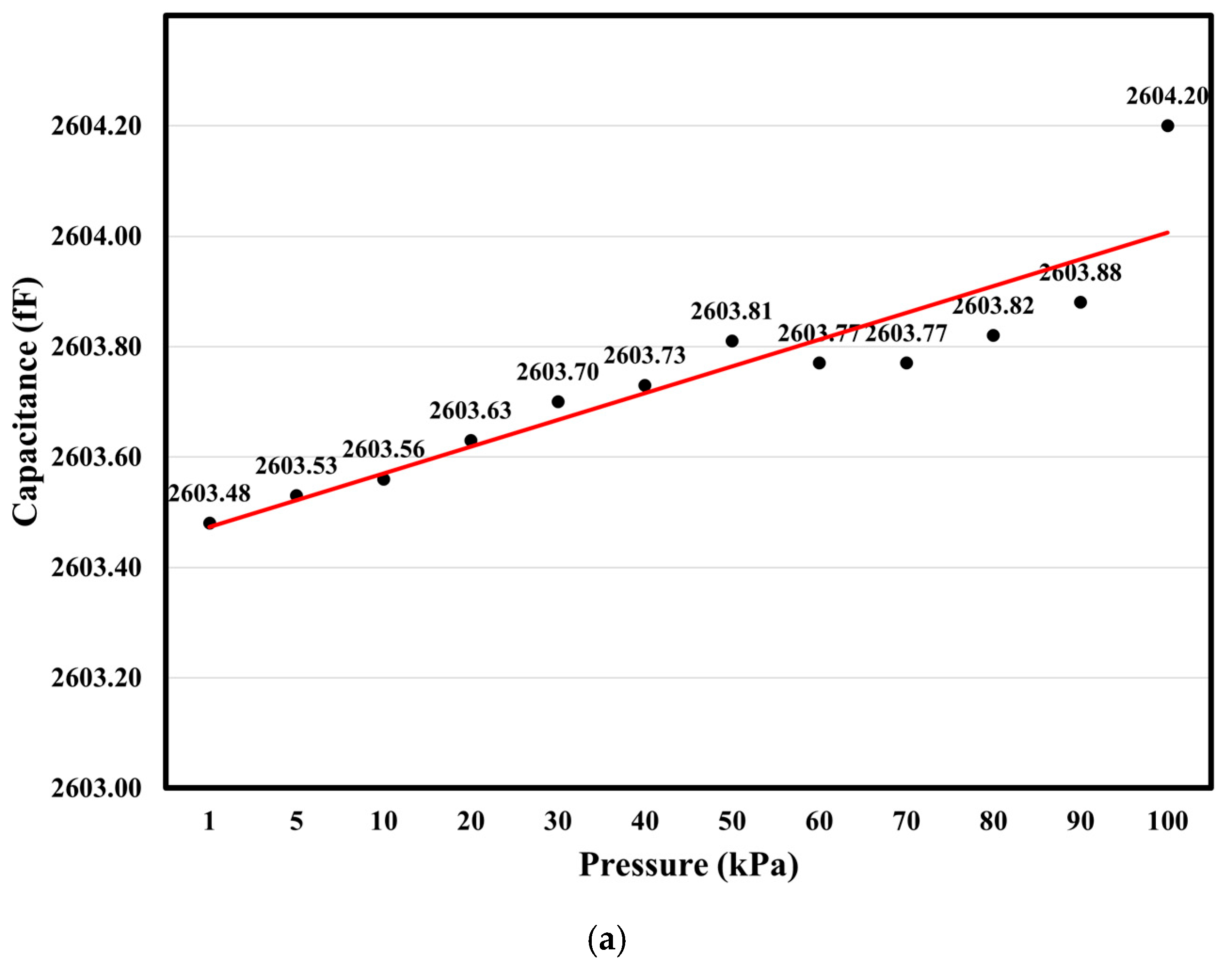

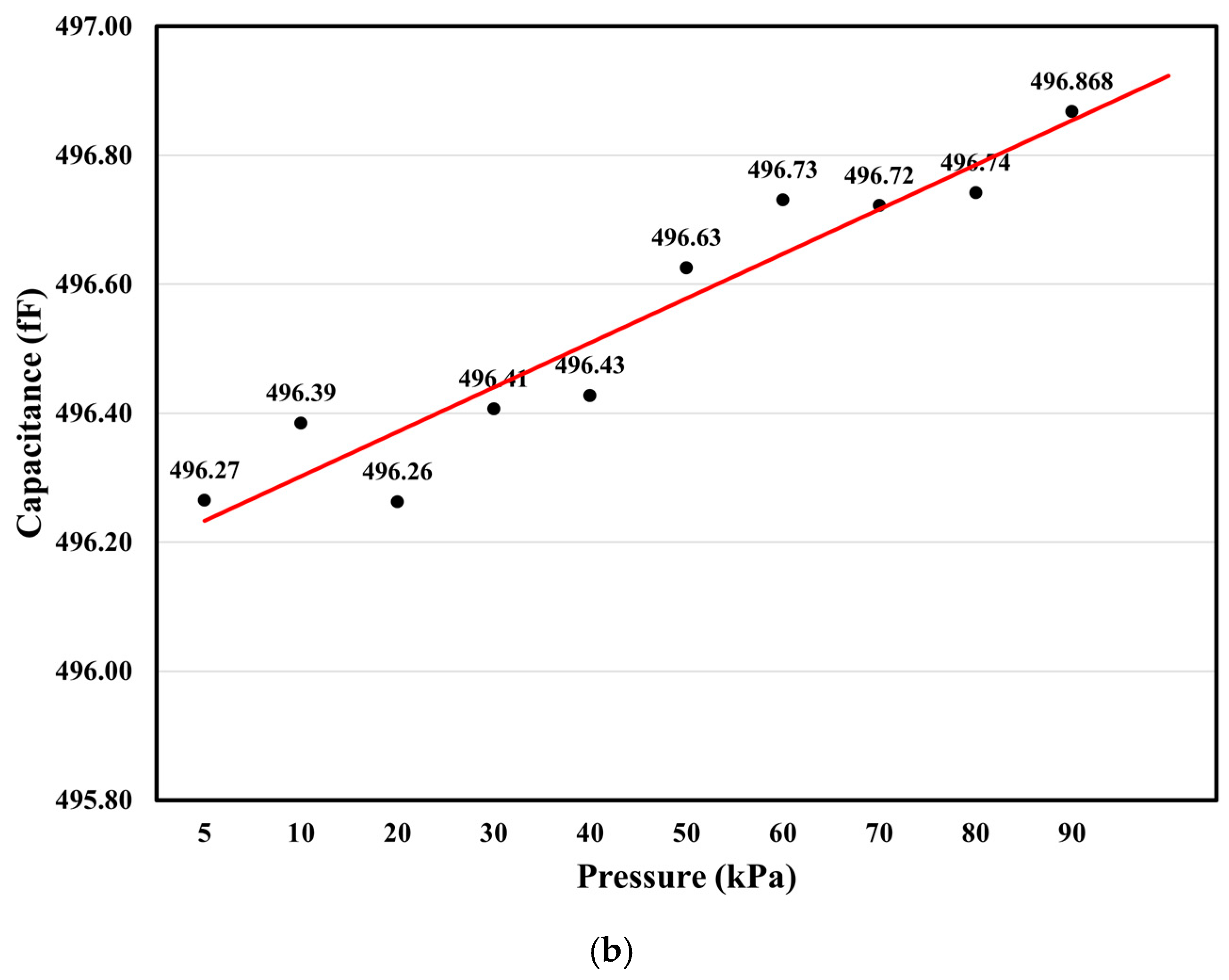

3.3. Pressure Testing in a Vacuum Chamber

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.; Liu, Q.; Ma, H.; Ke, N.; Ding, J.; Zhang, W.; Fan, X. Recent advances in graphene-based pressure sensors: A review. IEEE Sens. J. 2024, 24, 25227–25248. [Google Scholar] [CrossRef]

- Beeby, S. MEMS Mechanical Sensors; Artech House: Norwood, MA, USA, 2004. [Google Scholar]

- Zhang, D.; Subramanian, S.; Hampson, R.; Jackson, W.; Kontis, K.; Dobie, G.; Macleod, C. Automotive aerodynamics sensing using low-profile pressure sensor strip. IEEE Trans. Instrum. Meas. 2023, 72, 2005809. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, F.; Newbern, S.; Huang, A.; Ho, C.M.; Tai, Y.C. Flexible shear-stress sensor skin and its application to unmanned aerial vehicles. Sens. Actuators A Phys. 2003, 105, 321–329. [Google Scholar] [CrossRef]

- Yang, L.J.; Tasupalli, C.; Wang, W.C.; Lee, C.Y.; Lee, C.Y.; Athikary, K.G.; Wu, J.X. Initial study of the onsite measurement of flow sensors on turbine blades (SOTB). Micromachines 2024, 15, 877. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.J.; Wang, W.C.; Tasupalli, C.; Esakki, B.; Shaik, M.I. Sensors on Flapping Wings (SOFWs) Using Complementary Metal–Oxide–Semiconductor (CMOS) MEMS Technology. Eng 2025, 6, 15. [Google Scholar] [CrossRef]

- Kong, H.; Li, W.; Song, Z.; Niu, L. Recent advances in multimodal sensing integration and decoupling strategies for tactile perception. Mater. Futures 2024, 3, 022501. [Google Scholar] [CrossRef]

- Eaton, W.P.; Smith, J.H. Micromachined pressure sensors: Review and recent developments. Smart Mater. Struct. 1997, 6, 530. [Google Scholar] [CrossRef]

- Balavalad, K.B.; Sheeparmatti, B.G. A review on evolution, current trends and future scope of MEMS piezoresistive pressure sensor. Int. J. Eng. Res. Technol. 2015, 4, 321–325. [Google Scholar]

- Zhang, J.X.; Xiao, C.X.; Pan, K.H.; Chen, L.G.; Wang, B.; Li, G.Z. Temperature compensation and selection optimization of MEMS pressure sensor based on PSO-RBF. J. Funct. Mater. Devices 2025, 31, 130–136. (In Chinese) [Google Scholar]

- Baney, W.; Chilcott, D.; Huang, X.; Long, S.; Siekkinen, J.; Sparks, D.; Staller, S. A comparison between micromachined piezoresistive and capacitive pressure sensors. SAE Trans. 1997, 106, 562–565. [Google Scholar]

- Kubba, A.E.; Hasson, A.; Kubba, A.I.; Hall, G. A micro-capacitive pressure sensor design and modelling. J. Sens. Sens. Syst. 2016, 5, 95–112. [Google Scholar] [CrossRef]

- Qu, H. CMOS MEMS fabrication technologies and devices. Micromachines 2016, 7, 14. [Google Scholar] [CrossRef]

- Han, X.; Huang, M.; Wu, Z.; Gao, Y.; Xia, Y.; Yang, P.; Fan, S.; Lu, X.; Yang, X.; Liang, L.; et al. Advances in high-performance MEMS pressure sensors: Design, fabrication, and packaging. Microsyst. Nanoeng. 2023, 9, 156. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.W.; Oh, G.Y.; Lee, K.I.; Yang, Y.J.; Ko, J.B.; Kim, Y.W.; Hong, Y.S. A highly sensitive and flexible capacitive pressure sensor based on alignment airgap dielectric. Sensors 2022, 22, 7390. [Google Scholar] [CrossRef]

- Ghanam, M.; Goldschmidtboeing, F.; Bilger, T.; Bucherer, A.; Woias, P. MEMS shielded capacitive pressure and force sensors with excellent thermal stability and high operating temperature. Sensors 2023, 23, 4248. [Google Scholar] [CrossRef]

- Lin, W.C.; Cheng, C.L.; Wu, C.L.; Fang, W. Sensitivity improvement for CMOS-MEMS capacitive pressure sensor using double deformarle diaphragms with trenches. In Proceedings of the IEEE 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017. [Google Scholar]

- Ko, W.H.; Wang, Q. Touch mode capacitive pressure sensors. Sens. Actuators A Phys. 1999, 75, 242–251. [Google Scholar] [CrossRef]

- Kang, M.; Ri, C.; Choe, J. Capacitance response of concave well substrate touch-mode capacitive pressure sensor: Mathematical analysis and simulation. Microelectron. J. 2021, 114, 105118. [Google Scholar] [CrossRef]

- Ghedira, W.; Souissi, M.; Boudokhane, C.; Dhaouadi, H. Sustainable hydrophobic modification of cotton with rosemary wax extracted by supercritical CO2 explored through DFT analysis. Sci. Rep. 2025, 15, 31628. [Google Scholar] [CrossRef]

- Allafi, F.A.S.; Hossain, M.S.; Ab Kadir, M.O.; Shaah, M.A.H.; Lalung, J.; Ahmad, M.I. Waterless processing of sheep wool fiber in textile industry with supercritical CO2: Potential and challenges. J. Clean. Prod. 2021, 285, 124819. [Google Scholar] [CrossRef]

- Smith, W.W.; Kuper, A.B. Phosphosilicate glass passivation against sodium impurity in thermal oxide on silicon. In Proceedings of the 6th Annual Reliability Physics Symposium (IEEE), Los Angeles, CA, USA, 6–8 November 1967. [Google Scholar]

- Xu, W.; Wang, X.; Mousa, B.; Paszkiewicz, M.; Lee, Y.K. A CMOS MEMS thermal flow sensor for gas and liquid with parylene-C coating. IEEE Trans. Electron Devices 2020, 68, 919–922. [Google Scholar] [CrossRef]

- Tsai, M.H.; Sun, C.M.; Liu, Y.C.; Wang, C.; Fang, W. Design and application of a metal wet-etching post-process for the improvement of CMOS-MEMS capacitive sensors. J. Micromech. Microeng. 2009, 19, 105017. [Google Scholar] [CrossRef]

- Yapu, Z. Stiction and anti-stiction in MEMS and NEMS. Acta Mech. Sin. 2003, 19, 1–10. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, Y. Theoretical and experimental study of annular-plate self-sealing structures. J. Microelectromech. Syst. 2008, 17, 185–192. [Google Scholar] [CrossRef]

- Chang, P.Z.; Yang, L.J. A method using V-grooves to monitor the thickness of silicon membrane with m resolution. J. Micromech. Microeng. 1998, 8, 182. [Google Scholar] [CrossRef]

- Yang, L.J.; Chang, P.Z.; Chiang, C.C. The Application of V-groove slot-array method to the piezoresistive pressure sensors. J. Chin. Inst. Eng. 1997, 20, 335–341. [Google Scholar] [CrossRef]

- Yao, T.J.; Walsh, K.; Tai, Y.C. Dielectric charging effects on parylene electrostatic actuators. In Proceedings of the Technical Digest. MEMS 2002 IEEE International Conference—Fifteenth IEEE International Conference on Micro Electro Mechanical Systems (Cat. No. 02CH37266), Las Vegas, NV, USA, 24 January 2002. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.-J.; Jiang, D.-Y.; Wang, W.-C.; Tasupalli, C.; Shih, H.-Y.; Wang, Y.-J. Development of Vacuum-Chamber-Type Capacitive Micro-Pressure Sensors. Micromachines 2025, 16, 1290. https://doi.org/10.3390/mi16111290

Yang L-J, Jiang D-Y, Wang W-C, Tasupalli C, Shih H-Y, Wang Y-J. Development of Vacuum-Chamber-Type Capacitive Micro-Pressure Sensors. Micromachines. 2025; 16(11):1290. https://doi.org/10.3390/mi16111290

Chicago/Turabian StyleYang, Lung-Jieh, De-Yu Jiang, Wei-Chen Wang, Chandrashekhar Tasupalli, Horng-Yuan Shih, and Yi-Jen Wang. 2025. "Development of Vacuum-Chamber-Type Capacitive Micro-Pressure Sensors" Micromachines 16, no. 11: 1290. https://doi.org/10.3390/mi16111290

APA StyleYang, L.-J., Jiang, D.-Y., Wang, W.-C., Tasupalli, C., Shih, H.-Y., & Wang, Y.-J. (2025). Development of Vacuum-Chamber-Type Capacitive Micro-Pressure Sensors. Micromachines, 16(11), 1290. https://doi.org/10.3390/mi16111290