Applicability Analysis of High-Voltage Transmission and Substation Equipment Based on Silicon Carbide Devices

Abstract

1. Introduction

2. Power Electronics

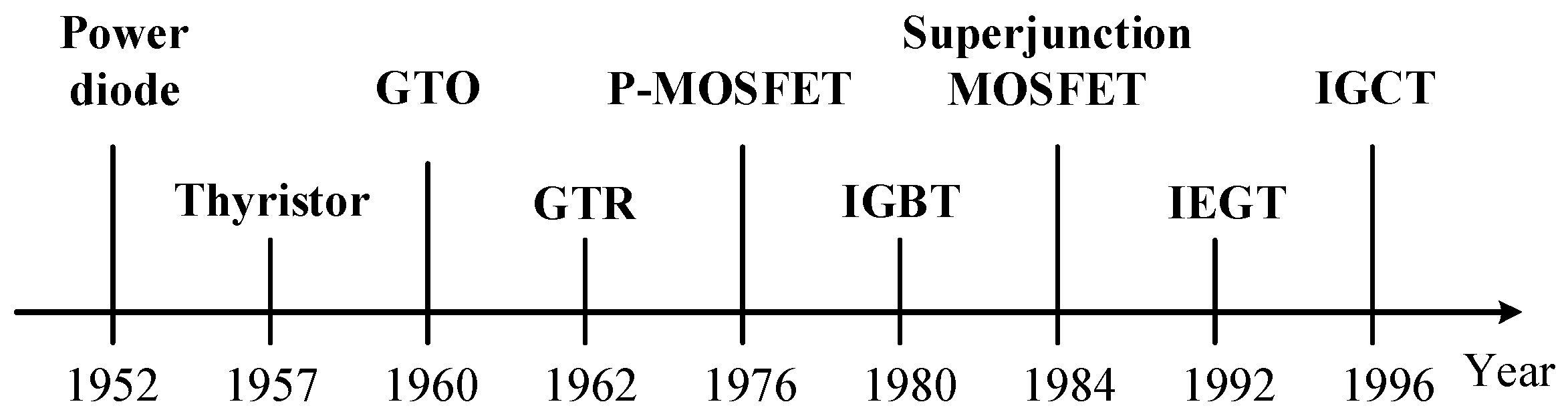

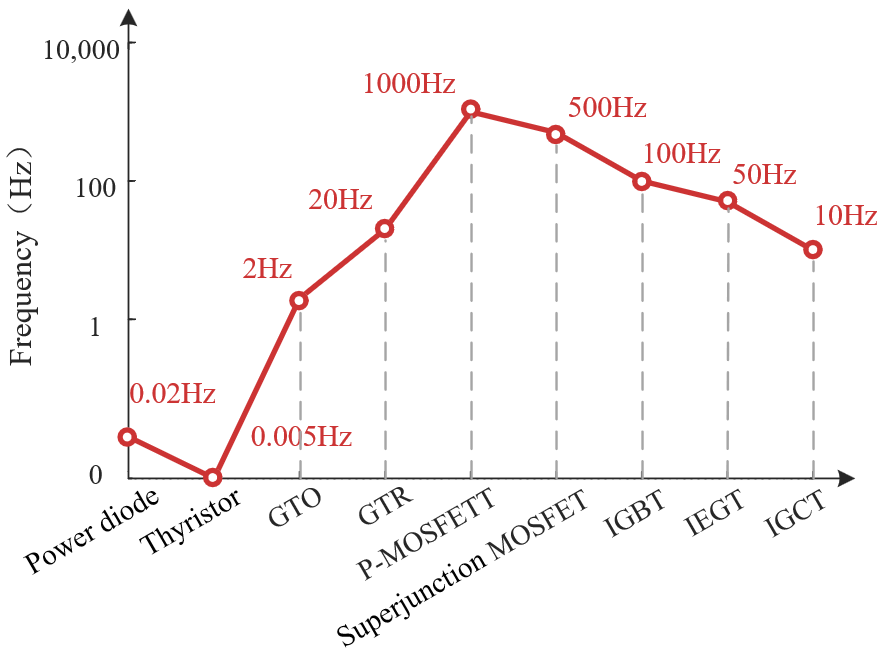

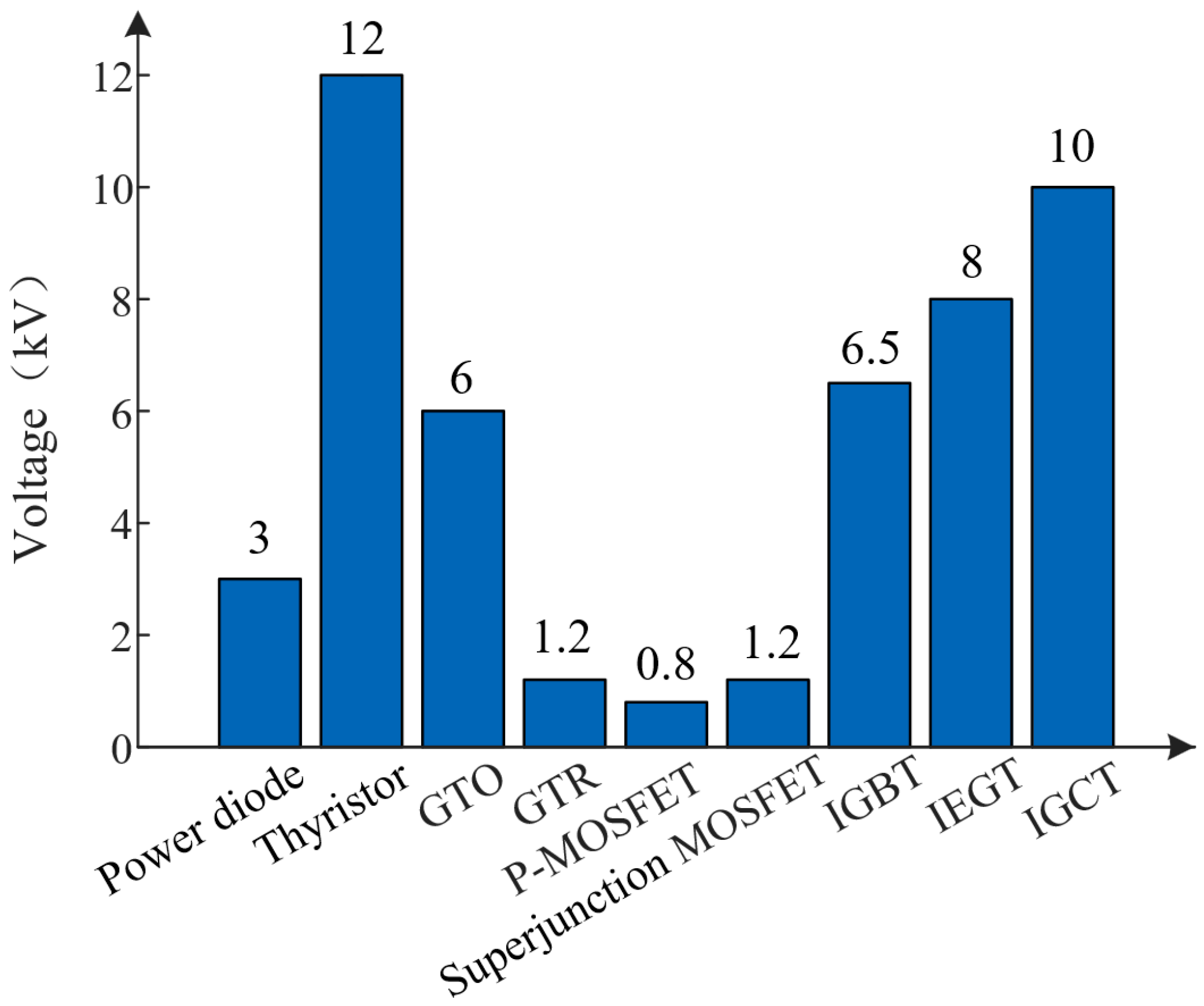

2.1. Power Electronics Development Process

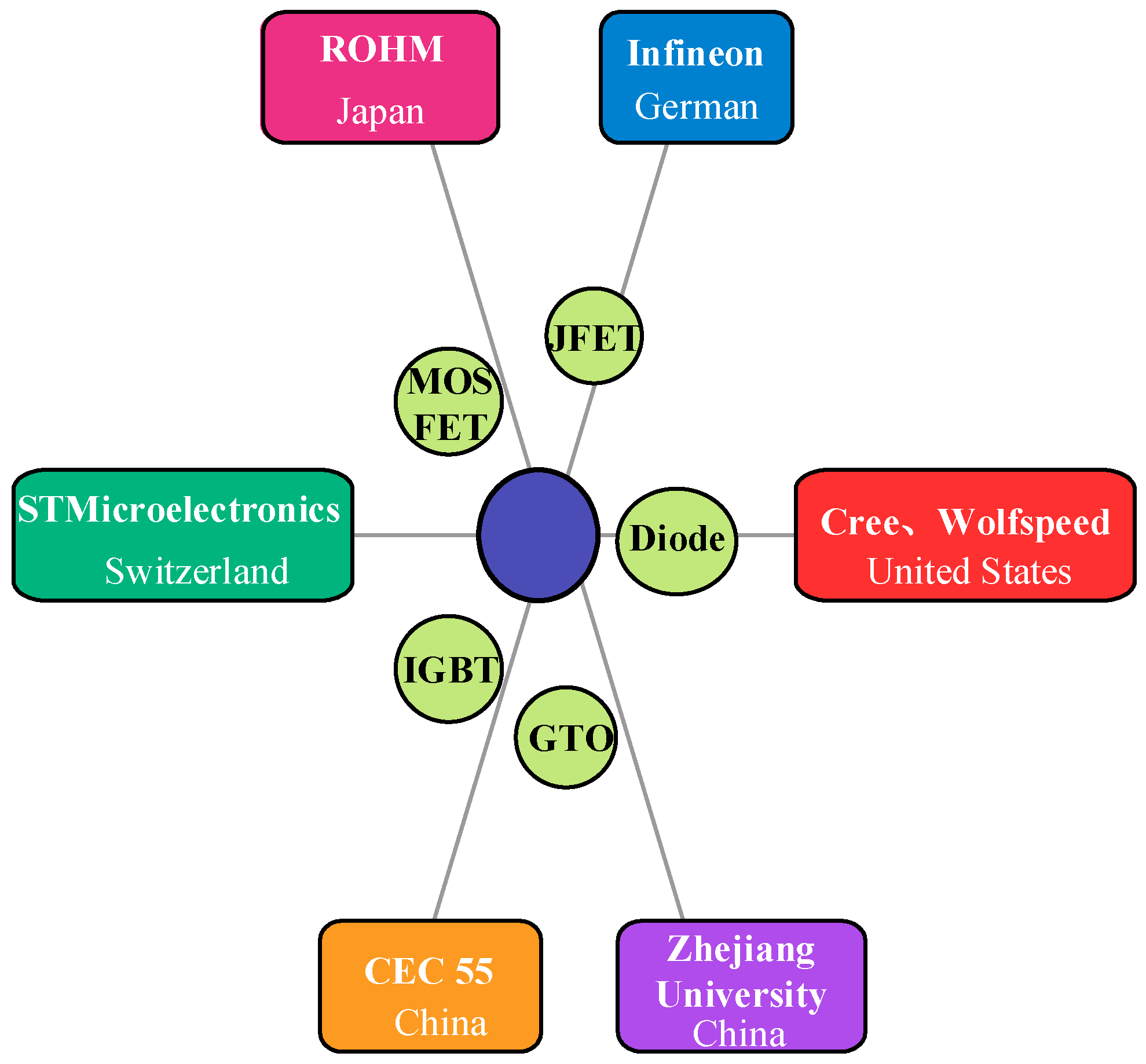

2.2. Classification of Power Electronic Devices

- (1)

- Power Diode

- (2)

- Thyristor

- (3)

- GTO

- (4)

- GTR

- (5)

- P-MOSFET

- (6)

- IGBT

- (7)

- JFET

- (8)

- IEGT

- (9)

- IGCT

3. Technical Characteristics and Advantages of SiC Devices

3.1. Material Characteristics of Silicon Carbide

- (1)

- In terms of forbidden bandwidth, SiC has a wide bandgap characteristic and 4H-SiC material has a forbidden bandwidth of 3.26 eV, which is about three times that of silicon material. According to the physical properties of semiconductors, the increase in forbidden bandwidth means that the energy threshold required for the valence band electrons to jump to the conduction band is significantly increased. In turn, the intrinsic breakdown voltage rises approximately to VB ∝ Eg^2. For 4H-SiC (Eg = 3.26 eV), the theoretical 1D limit is 180–200 kV, whereas Si (Eg = 1.12 eV) saturates at 11–12 kV under the same drift-length and doping conditions [36].

- (2)

- In terms of thermal conductivity, SiC has excellent thermal conductivity performance. The thermal conductivity is about three times that of silicon materials. It not only significantly improves the thermal efficiency of the device, but also enhances the through-current capability. It can operate stably in extreme high-temperature environments. The upper operating temperature limit exceeds 500 °C, breaking through the limitations of silicon-based power devices in terms of temperature (below 150 °C).

- (3)

- In terms of carrier transport properties, the 4H-SiC material has a high electron saturation drift speed and a low dielectric constant. Its electron saturation drift speed reaches two times that of silicon materials. This feature enables 4H-SiC devices to achieve faster switching speeds, which demonstrates excellent high-frequency operation. At the same time, the low dielectric constant can give 4H-SiC devices stronger chemical stability and radiation resistance. This ensures reliable operation in harsh environments.

- (4)

- In terms of critical breakdown field strength, SiC has a high critical breakdown electric field strength; 3C-SiC is about seven times higher than that of Si materials and can withstand high voltage stress. At the same time, the insulating breakdown field strength of 4H-SiC is up to 10 times that of Si material. This property allows a higher impurity doping concentration with a thinner drift layer structure in device fabrication. The critical electric field of 4H-SiC (Ec ≈ 2.5 MV/cm) is 7–10 times higher than that of silicon [37]. This allows its non-punch-through drift layer to be both thinner and more heavily doped for a given blocking voltage. Further, 4H-SiC-based high-voltage devices have very low on-resistance and a higher on-current density.

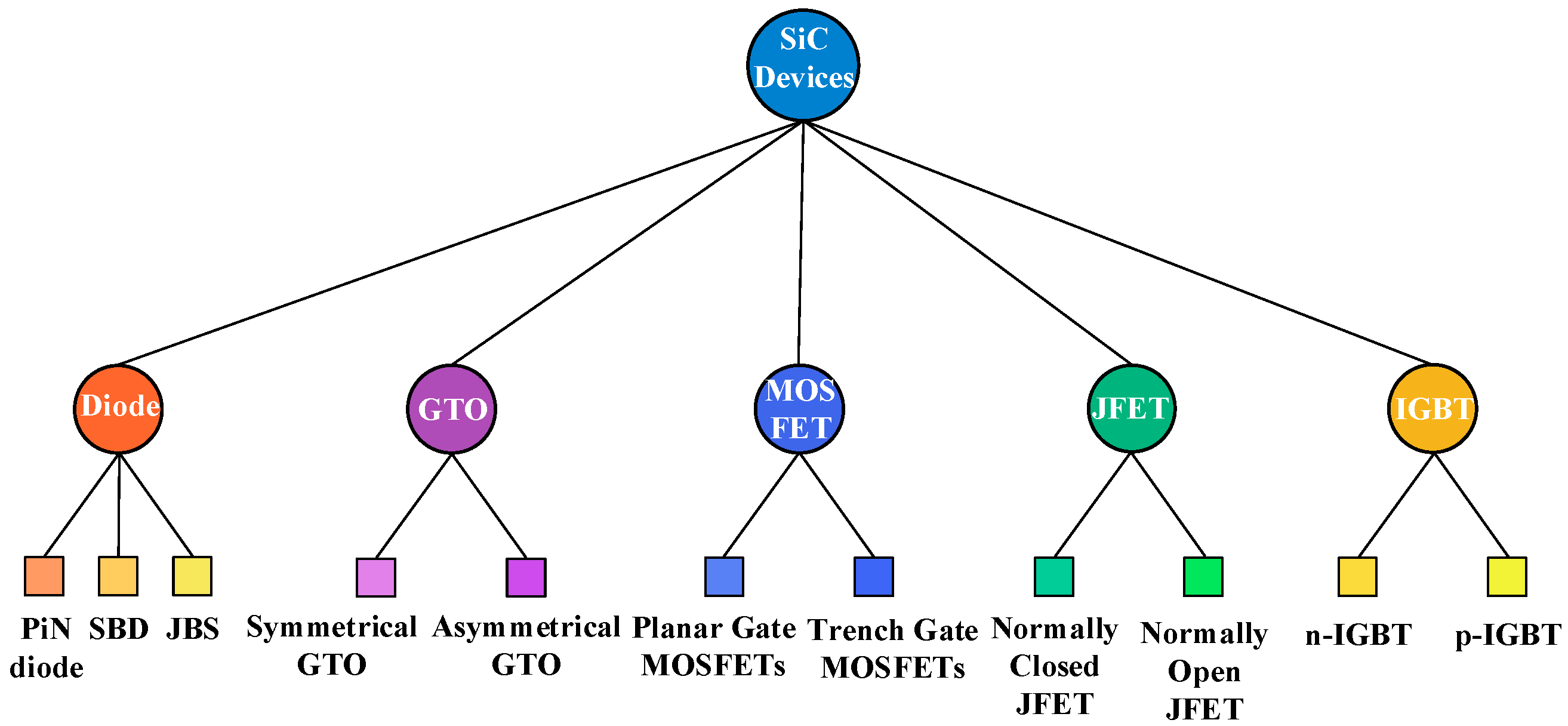

3.2. Classification of Silicon Carbide Device

- (1)

- SiC power diode

- (2)

- SiC junction field effect transistor (JFET)

- (3)

- SiC MOSFET

- (4)

- SiC-insulated gate bipolar transistor (IGBT)

- (5)

- SiC gate turn-off thyristor (GTO)

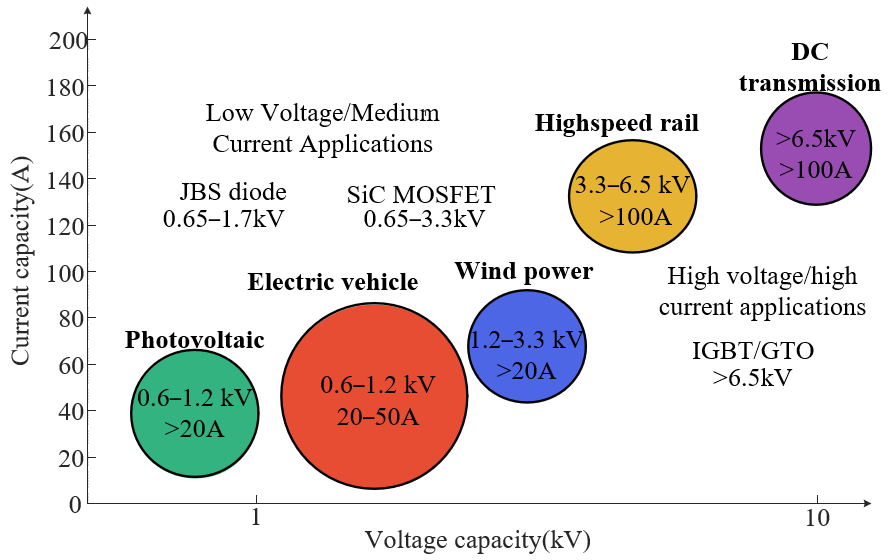

3.3. Applications of Silicon Carbide Device

4. Analysis of Applications for High-Voltage Transmission and Substation

4.1. Flexible DC Transmission System

4.2. High Voltage DC Circuit Breaker

4.3. Power Electronics Transformers

4.4. Flexible AC Transmission System

5. Technical Bottlenecks and Future Research Directions

- (1)

- Insufficient high-voltage and high-current dynamic testing capabilities.

- (2)

- Silicon carbide device packaging integration challenges.

- (3)

- Gate oxygen reliability and interface stability issues.

- (4)

- Preparation of SiC substrate and the epitaxial layer.

- (5)

- Research and development of high-voltage, high-current silicon carbide devices.

- (6)

- High-voltage series connection and multi-chip parallel connection technology.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tang, Z.; Yang, Y.; Blaabjerg, F. Power Electronics: The Enabling Technology for Renewable Energy Integration. CSEE J. Power Energy Syst. 2022, 8, 39–52. [Google Scholar]

- Chauhan, P.; Pant, S.; Bharti, B.K.; Kuntal, R.S.; Tiwari, V.K.; Dhami, J. Application of Wide Bandgap in Power Electronics: Next-Gen Smart Grids. In Proceedings of the 2025 First International Conference on Advances in Computer Science, Electrical, Electronics, and Communication Technologies (CE2CT), Nainital, India, 21–22 February 2025; pp. 1157–1161. [Google Scholar]

- Vivona, M. Electrical and Structural Properties of Surfaces and Interfaces in Ti/Al/Ni Ohmic Contacts to p-Type Implanted 4H-SiC. Appl. Surf. Sci. 2017, 420, 331–335. [Google Scholar]

- Zhengyou, M. Study on the Application of Advanced Power Electronics in Smart Grid. In Proceedings of the 2017 Sixth International Conference on Future Generation Communication Technologies (FGCT), Dublin, Ireland, 21–23 August 2017; pp. 1–4. [Google Scholar]

- Gayathri, N.M.; Kannbhiran, A. Power Electronics for Renewable Energy Systems. In Renewable Energy for Sustainable Growth Assessment; Scrivener Publishing: Beverly, MA, USA, 2022; pp. 327–362. [Google Scholar]

- Neeb, C.; Boettcher, L.; Conrad, M.; De Doncker, R.W. Innovative and Reliable Power Modules: A Future Trend and Evolution of Technologies. IEEE Ind. Electron. Mag. 2014, 8, 6–16. [Google Scholar] [CrossRef]

- Okumura, H. Power Electronics Innovation by Silicon Carbide Power Semiconductor Devices. In Proceedings of the 2014 IEEE International Meeting for Future of Electron Devices, Kansai (IMFEDK), Kyoto, Japan, 19–20 June 2014; pp. 1–2. [Google Scholar]

- Mantooth, H.A.; Ang, S.S. Packaging Architectures for Silicon Carbide Power Electronic Modules. In Proceedings of the 2018 International Power Electronics Conference (IPEC-Niigata 2018—ECCE Asia), Niigata, Japan, 20–24 May 2018; pp. 153–156. [Google Scholar]

- Östling, M. Silicon Carbide Power Devices: Evolution, Applications, and Future Opportunities. IEEE Electron Devices Mag. 2025, 2, 30–35. [Google Scholar] [CrossRef]

- Shigekane, H.; Fujihira, T.; Sasagawa, K.; Seki, Y.; Takahashi, Y.; Takai, A. Macro-Trend and a Future Expectation of Innovations in Power Electronics and Power Devices. In Proceedings of the 2009 IEEE 6th International Power Electronics and Motion Control Conference, Wuhan, China, 17–20 May 2009; pp. 35–39. [Google Scholar]

- Biczel, P.; Jasinski, A.; Lachecki, J. Power Electronic Devices in Modern Power Systems. In Proceedings of the EUROCON 2007—The International Conference on “Computer as a Tool”, Warsaw, Poland, 9–12 September 2007; p. 1586. [Google Scholar]

- Zhao, M.; Wang, Z.; Xue, Y. An Overview on Application Analysis of Power Electronic Technology in Smart Grid. In Proceedings of the 2018 Chinese Control And Decision Conference (CCDC), Shenyang, China, 9–11 June 2018; pp. 5186–5189. [Google Scholar]

- Qiu, Y.; Dai, C.; Jin, R. Impact of Power Electronic Device Development on Power Grids. In Proceedings of the 2016 28th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Prague, Czech Republic, 12–16 June 2016; pp. 9–14. [Google Scholar]

- Fan, Z.; Yang, Z.; Xie, K.; Yu, J. General Steady-State Modeling and Linearization of Power Electronic Devices in AC-DC Hybrid Grid. IEEE Trans. Power Syst. 2021, 36, 5746–5755. [Google Scholar] [CrossRef]

- Nakamura, K.; Tanaka, K.; Takeda, N.; Suzuki, M.; Kawase, Y. Lifetime Control Free Cathode Side Concept for Si-Based Power Diode Targeting High-Speed Operation and High Dynamic Ruggedness. In Proceedings of the 2022 IEEE 34th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Vancouver, BC, Canada, 22–25 May 2022; pp. 269–272. [Google Scholar]

- Huang, Y.; Chen, Q.; Chen, Z.; Zhu, L.; Wen, Z. Thyristor Lifetime Prediction Based on Thermal Resistance Update Strategy. In Proceedings of the 2025 6th International Conference on Electrical Technology and Automatic Control (ICETAC), Nanjing, China, 20–22 June 2025; pp. 800–804. [Google Scholar]

- Liu, H.; Wang, J.; Liang, S.; Yu, H.; Deng, G.; Wang, Y.; Shen, Z.J. Modeling and Analysis of SiC GTO Thyristor’s Dynamic Turn-On Transient. IEEE Trans. Electron Devices 2022, 69, 6241–6248. [Google Scholar] [CrossRef]

- Kumar, M.; Hsueh, K.-Y.; Hsu, S.-J.; Wu, C.-H. Design and Fabrication of Novel Darlington Transistor Using Light-Emitting Transistors for Smart Thermal Sensor Technology. IEEE Electron Device Lett. 2024, 45, 1365–1368. [Google Scholar] [CrossRef]

- Lee, M.-C.; Chung, N.-J.; Lin, H.-R.; Lee, W.-L.; Chung, Y.-Y.; Wang, S.-Y.; Luo, G.-L.; Chien, C.-H. Electrical Characteristics of Si0.8 Ge0.2 p-MOSFET with TMA Pre-Doping and NH3 Plasma IL Treatment. IEEE Trans. Electron Devices 2022, 69, 1776–1780. [Google Scholar]

- Wang, B.; Wang, L.; Mu, W.; Qin, M.; Yang, F.; Liu, J.; Tomoyuki, Y.; Tatsuhiko, F. Thermal Performances and Annual Damages Comparison of MMC Using Reverse Conducting IGBT and Conventional IGBT Module. IEEE Trans. Power Electron. 2021, 36, 9806–9825. [Google Scholar] [CrossRef]

- Iwamuro, N.; Laska, T. IGBT History, State-of-the-Art, and Future Prospects. IEEE Trans. Electron Devices 2017, 64, 741–752. [Google Scholar]

- Bischoff, R.; Himmelsbach, R. Investigations on a Semiconductor Switching Array Based on COTS SiC MOSFET Devices. IEEE Trans. Plasma Sci. 2023, 51, 2781–2787. [Google Scholar] [CrossRef]

- Dai, S.; Liu, Z.; Wang, Z.; Zhao, Y.; Li, G. Study of Electrical Contacts Fatigue and Degradation Evaluation for Press-Pack IEGT Under Power Cycling Tests. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 5168–5180. [Google Scholar] [CrossRef]

- Zhou, W.; Zhao, B.; Lou, Y.; Sun, X.; Liu, Q.; Bai, R.; Liu, J.; Chen, Z.; Yu, Z.; Zeng, R. Current Oscillation Phenomenon of MMC Based on IGCT and Fast Recovery Diode with High Surge Current Capability for HVDC Application. IEEE Trans. Power Electron. 2021, 36, 6218–6222. [Google Scholar] [CrossRef]

- Akbar, G.; Di Fatta, A.; Rizzo, G.; Ala, G.; Romano, P.; Imburgia, A. Comprehensive Review of Wide-Bandgap (WBG) Devices: SiC MOSFET and Its Failure Modes Affecting Reliability. Physchem 2025, 5, 10. [Google Scholar] [CrossRef]

- Biela, J.; Schweizer, M.; Waffler, S.; Kolar, J.W. SiC versus Si—Evaluation of Potentials for Performance Improvement of Inverter and DCDC Converter Systems by SiC Power Semiconductors. IEEE Trans. Ind. Electron. 2011, 58, 2872–2882. [Google Scholar] [CrossRef]

- Giannakis, A.; Peftitsis, D. Performance Evaluation of High Power Semiconductor Devices Employed in Solid-State Circuit Breakers for MVDC Grids. In Proceedings of the 2019 21st European Conference on Power Electronics and Applications (EPE ′19 ECCE Europe), Genova, Italy, 3–5 September 2019; pp. 1–10. [Google Scholar]

- Das, A.; Kanjilal, M.R.; Mukherjee, M.; Santra, A. Review on Wide Band Gap Semiconductor. In Proceedings of the 2022 IEEE International Conference of Electron Devices Society Kolkata Chapter (EDKCON), Kolkata, India, 26–27 November 2022; pp. 586–591. [Google Scholar]

- Kimoto, T. Updated Trade-off Relationship between Specific on-Resistance and Breakdown Voltage in 4H-SiC{0001} Unipolar Devices. Jpn. J. Appl. Phys. 2019, 58, 018002. [Google Scholar] [CrossRef]

- Huang, A.Q. Power Semiconductor Devices for Smart Grid and Renewable Energy Systems. Power Electron. Renew. Energy Syst. Smart Grid Technol. Appl. 2019, 105, 85–152. [Google Scholar]

- Rasul, A.; Teixeira, R.; Baptista, J. Silicon Carbide Converter Design: A Review. Energies 2025, 18, 2140. [Google Scholar] [CrossRef]

- Miao, X.; Zhang, J.; Yan, B. Preparation of SiC from Carbonaceous Vanadium-Bearing Stone Coal via Carbothermal Reduction Method. Ceram. Int. 2024, 50, 6324–6331. [Google Scholar] [CrossRef]

- Kimoto, T. Material Science and Device Physics in SiC Technology for High-Voltage Power Devices. Jpn. J. Appl. Phys. 2015, 54, 040103. [Google Scholar] [CrossRef]

- Liang, Z.; Ning, P.; Wang, F. Development of Advanced All-Sic Power Modules. IEEE Trans. Power Electron. 2014, 29, 2289–2295. [Google Scholar] [CrossRef]

- Liu, Y.; Bai, F.; Fang, J. A Trench Heterojunction Diode-Integrated 4H-SiC LDMOS with Enhanced Reverse Recovery Characteristics. Micromachines 2025, 16, 909. [Google Scholar]

- Nouketcha, F.; Lelis, A.; Green, R.; Cui, Y.; Darmody, C.; Goldsman, N. Detailed Study of Breakdown Voltage and Critical Field in Wide Bandgap Semiconductors. In Proceedings of the 2019 IEEE 7th Workshop on Wide Bandgap Power Devices and Applications (WiPDA), Raleigh, NC, USA, 29–31 October 2019; pp. 200–207. [Google Scholar]

- Yoo, D.; Kim, M.; Kang, I.; Lee, H.-J. 4H-SiC/SiO2 Interface Degradation in 1.2 kV 4H-SiC MOSFETs Due to Power Cycling Tests. Electron. 2024, 13, 1267. [Google Scholar] [CrossRef]

- Zhu, G.; Pahl, B. SiC-Based Wireless Power Transformation for Data Centers and Medium Voltage Applications. In Proceedings of the 2020 IEEE Industry Applications Society Annual Meeting, Detroit, MI, USA, 10–16 October 2020; pp. 1–6. [Google Scholar]

- She, X.; Huang, A.Q.; Lucia, O.; Ozpineci, B. Review of Silicon Carbide Power Devices and Their Applications. IEEE Trans. Ind. Electron. 2017, 64, 8193–8205. [Google Scholar] [CrossRef]

- Fukuda, K.; Okamoto, D.; Okamoto, M.; Deguchi, T.; Mizushima, T.; Takenaka, K.; Fujisawa, H.; Harada, S.; Tanaka, Y.; Yonezawa, Y.; et al. Development of Ultrahigh-Voltage Sic Devices. IEEE Trans. Electron Devices 2015, 62, 396–404. [Google Scholar] [CrossRef]

- Ma, Y.; Guan, Y. Recent Progress on Laser-Assisted Machining for Silicon Carbide Materials. J. Manuf. Process. 2025, 151, 623–654. [Google Scholar] [CrossRef]

- Zhu, M.; Pei, Y.; Yang, F.; Xue, Z.; Ma, D.; Wang, L. Investigation of Two High-Temperature Bipolar Phenomena and Characteristics of 1.2-kV SiC Power Diodes for High-Temperature Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2024, 12, 651–662. [Google Scholar]

- Wang, X.; Qi, J.; Yang, M.; Zhang, G. Analysis of 600 V/650 V SiC Schottky Diodes at Extremely High Temperatures. CPSS TPEA 2020, 5, 11–17. [Google Scholar] [CrossRef]

- Qi, J.; Yang, X.; Li, X.; Chen, W.; Tian, K.; Wang, M.; Guo, S.; Yang, M. Comparative Temperature Dependent Evaluation and Analysis of 1.2-kV SiC Power Diodes for Extreme Temperature Applications. IEEE Trans. Power Electron. 2020, 35, 13384–13399. [Google Scholar] [CrossRef]

- Chen, S.; Liu, A.; He, J.; Bai, S.; Sheng, K. Design and Application of High-Voltage SiC JFET and Its Power Modules. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 780–789. [Google Scholar] [CrossRef]

- Sheng, K.; Ren, N.; Xu, H. A Recent Review on Silicon Carbide Power Devices Technologies. Proc. CSEE 2020, 40, 1741–1752, (In Chinese with English abstract). [Google Scholar]

- Van Cuong, V.; Meguro, T.; Ishikawa, S.; Maeda, T.; Sezaki, H.; Kuroki, S.I. Thermal Stability of Gate Driver Circuits Based on 4H-SiC MOSFETs at 300 °C for High-Power Applications. IEEE J. Electron Devices Soc. 2025, 13, 161–167. [Google Scholar] [CrossRef]

- Wei, J.; Wei, Z.; Fu, H.; Cao, J.; Wu, T.; Sun, J.; Zhu, X.; Li, S.; Zhang, L.; Liu, S.; et al. Review on the Reliability Mechanisms of SiC Power MOSFETs: A Comparison Between Planar-Gate and Trench-Gate Structures. IEEE Trans. Power Electron. 2023, 38, 8990–9005. [Google Scholar] [CrossRef]

- Huang, R.; Tao, Y.; Bai, S.; Chen, G.; Wang, L.; Liu, A.; Wei, N.; Li, Y.; Zhao, Z. Design and Fabrication of a 3.3 KV 4H-SiC MOSFET. J. Semicond. 2015, 36, 094002. [Google Scholar] [CrossRef]

- Allen, S.; Pala, V.; VanBrunt, E.; Hull, B.; Cheng, L.; Ryu, S.; Richmond, J.; O’Loughlin, M.; Burk, A.; Palmour, J. Next-Generation Planar SiC MOSFETs from 900 V to 15 KV. Mater. Sci. Forum 2015, 821–823, 701–704. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, Q.; Yu, W.; Huang, A.Q. A Medium-Voltage Medium-Frequency Isolated DC-DC Converter Based on 15-KV SiC MOSFETs. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 5, 100–109. [Google Scholar] [CrossRef]

- Fei, C.; Bai, S.; Wang, Q.; Huang, R.; He, Z.; Liu, H.; Liu, Q. Influences of Pre-Oxidation Nitrogen Implantation and Post-Oxidation Annealing on Channel Mobility of 4H-SiC MOSFETs. J. Cryst. Growth 2020, 531, 125338. [Google Scholar] [CrossRef]

- Yu, L.C.; Dunne, G.T.; Matocha, K.S.; Cheung, K.P.; Suehle, J.S.; Sheng, K. Reliability Issues of SiC MOSFETs: A Technology for High-Temperature Environments. IEEE Trans. Device Mater. Reliab. 2010, 10, 418–426. [Google Scholar] [CrossRef]

- Karthika, K.; Archana, G.; Alais Mala, K.M.; Anand, I.V.; Kumar, M.S.; Samuel, T.S.A. Performance Analysis of Silicon Carbide Processing for Power MOSFET. In Proceedings of the 2024 9th International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 16–18 December 2024; pp. 72–78. [Google Scholar]

- Shi, B.; Ramones, A.I.; Liu, Y.; Wang, H.; Li, Y.; Pischinger, S.; Andert, J. A Review of Silicon Carbide MOSFETs in Electrified Vehicles: Application, Challenges, and Future Development. IET Power Electron. 2023, 16, 2103–2120. [Google Scholar] [CrossRef]

- Asllani, B.; Morel, H.; Bevilacqua, P.; Planson, D. Demonstration of the Short-Circuit Ruggedness of a 10 kV Silicon Carbide Bipolar Junction Transistor. In Proceedings of the 2020 22nd European Conference on Power Electronics and Applications (EPE’20 ECCE Europe), Lyon, France, 7–11 September 2020; pp. 1–10. [Google Scholar]

- Hinojosa, M.; Ogunniyi, A.; O’Brien, H.; Bayne, S.B.; Scozzie, C. Evaluation of High-Voltage, High-Power 4H-SiC Insulated-Gate Bipolar Transistors. In Proceedings of the 2014 IEEE International Power Modulator and High Voltage Conference (IPMHVC), Santa Fe, NM, USA, 1–5 June 2014; pp. 101–104. [Google Scholar]

- Xu, H.; Wang, L.; Li, C.; Li, W.; Zhao, M.; Shi, J.; Qu, B.; Mei, Y.; Xiang, L.; Deng, Y.; et al. SiC MOSFETs: The Inevitable Trend for 800V Electric Vehicle Air Conditioning Compressors. IEEE Trans. Veh. Technol. 2025, 74, 2620–2634. [Google Scholar] [CrossRef]

- Yang, X.; Tao, Y.; Yang, T.; Huang, R.; Song, B. Fabrication of 4H-SiC n-Channel IGBTs with Ultra High Blocking Voltage. J. Semicond. 2018, 39, 2–5. [Google Scholar] [CrossRef]

- Chowdhury, S.; Hitchcock, C.W.; Stum, Z.; Dahal, R.P.; Bhat, I.B.; Chow, T.P. Operating Principles, Design Considerations, and Experimental Characteristics of High-Voltage 4H-SiC Bidirectional IGBTs. IEEE Trans. Electron Devices 2017, 64, 888–896. [Google Scholar] [CrossRef]

- Friedrichs, P. Silicon Carbide Power Semiconductors—New Opportunities for High Efficiency. In Proceedings of the 2008 3rd IEEE Conference on Industrial Electronics and Applications, Singapore, 3–5 June 2008; pp. 1770–1774. [Google Scholar]

- Al-Bayati, A.M.S.; Alharbi, S.S.; Alharbi, S.S.; Matin, M. A Comparative Design and Performance Study of a Non-Isolated DC-DC Buck Converter Based on Si-MOSFET/Si-Diode, SiC-JFET/SiC-Schottky Diode, and GaN-Transistor/SiC-Schottky Diode Power Devices. In Proceedings of the 2017 North American Power Symposium (NAPS), Morgantown, WV, USA, 17–19 September 2017; pp. 1–6. [Google Scholar]

- Stracke, G.; Müller, C.R.; Ali, H. New 1400 V SiC MOSFET for Performance and Efficiency Boost in ETRUCK Inverters 2 Switching Characteristics. In Proceedings of the PCIM Conference 2025, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nürnberg, Germany, 6–8 May 2025; pp. 6–8. [Google Scholar]

- Hamada, K.; Nagao, M.; Ajioka, M.; Kawai, F. SiC—Emerging Power Device Technology for next-Generation Electrically Powered Environmentally Friendly Vehicles. IEEE Trans. Electron Devices 2015, 62, 278–285. [Google Scholar] [CrossRef]

- Do, T.V.; Li, K.; Trovao, J.P.; Boulon, L. Reviewing of Using Wide-Bandgap Power Semiconductor Devices in Electric Vehicle Systems: From Component to System. In Proceedings of the 2020 IEEE Vehicle Power and Propulsion Conference (VPPC), Gijon, Spain, 18 November–16 December 2020; pp. 1–6. [Google Scholar]

- Su, H.; Zhang, L.; Meng, D.; Li, Y.; Han, N.; Xia, Y. Modeling and Evaluation of SiC Inverters for EV Applications. Energies 2022, 15, 7025. [Google Scholar] [CrossRef]

- Asllani, B.; Morel, H.; Phung, L.V.; Planson, D. 10 kV Silicon Carbide PiN Diodes—From Design to Packaged Component Characterization. Energies 2019, 12, 4566. [Google Scholar] [CrossRef]

- Nitzsche, M.; Cheshire, C.; Fischer, M.; Ruthardt, J. Comprehensive Comparison of a SiC MOSFET and Si IGBT Based Inverter. In Proceedings of the 2019 International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management (PCIM), Nuremberg, Germany, 7–9 May 2019; pp. 1828–1834. [Google Scholar]

- Langpoklakpam, C.; Liu, A.-C.; Chu, K.-H.; Hsu, L.-H.; Lee, W.-C.; Chen, S.-C.; Sun, C.-W.; Shih, M.-H.; Lee, K.-Y.; Kuo, H.-C. Review of Silicon Carbide Processing for Power MOSFET. Crystals 2022, 12, 245. [Google Scholar] [CrossRef]

- Li, X.; Xu, Z.; Zhang, Z. Application of MMC with Embedded Energy Storage for Overvoltage Suppression and Fault Ride-through Improvement in Series LCC-MMC Hybrid HVDC System. J. Mod. Power Syst. Clean Energy 2023, 11, 1001–1013. [Google Scholar] [CrossRef]

- Shen, Z.J.; Sabui, G.; Miao, Z.; Shuai, Z. Wide-Bandgap Solid-State Circuit Breakers for DC Power Systems: Device and Circuit Considerations. IEEE Trans. Electron Devices 2015, 62, 294–300. [Google Scholar] [CrossRef]

- Sato, Y.; Tanaka, Y.; Fukui, A.; Yamasaki, M.; Ohashi, H. SiC-SIT Circuit Breakers with Controllable Interruption Voltage for 400-V DC Distribution Systems. IEEE Trans. Power Electron. 2014, 29, 2597–2605. [Google Scholar] [CrossRef]

- Khan, W.A.; Raza, A.; Usman, M.R.; Hamid, S.; Rehman, S.-U.-; Usman, M.A.; Politis, C. Fault Interruption Scheme for HVDC System Using SiC-MESFET and VCB Based Hybrid Circuit Breaker. IEEE Access 2021, 9, 157371–157383. [Google Scholar] [CrossRef]

- Ma, D.; Chen, W.; Shu, L.; Qu, X.; Zhan, X.; Liu, Z. A Multiport Power Electronic Transformer Based on Modular Multilevel Converter and Mixed-Frequency Modulation. IEEE Trans. Circuits Syst. II 2020, 67, 1284–1288. [Google Scholar] [CrossRef]

- Cheng, J.; Zhang, Y.; Cheng, X.; Guo, K.; Wang, Y.; Jiang, M.; Wang, Y.; Liu, Y. Thermal Behavior and Switching Losses of MOSFET in High-Frequency Transformer Circuits. Case Stud. Therm. Eng. 2025, 73, 106643. [Google Scholar] [CrossRef]

- Das, S.C. Experimental Study on the Influence of Junction Temperature on the Relationship between IGBT Switching Energy Loss and Device Current. Microelectron. Reliab. 2018, 80, 134–143. [Google Scholar] [CrossRef]

- Wei, Y.; Jia, J.; Wang, Z.; Wu, Y.; Wu, J. Temperature-Sensitive Electrical Parameters of SiC MOSFET Power Module and Its Application in Junction Temperature Evaluation. In Proceedings of the 2023 3rd International Conference on Electrical Engineering and Control Science (IC2ECS), Hangzhou, China, 29–31 December 2023; pp. 1614–1619. [Google Scholar]

- Li, Q.; Yuan, L.; Zhang, F.; Li, H.; Xiao, G.; Chen, Y.; Sun, T.; Liu, X.; Fu, T. Novel SiC/Si Heterojunction LDMOS with Electric Field Modulation Effect by Reversed L-Shaped Field Plate. Results Phys. 2020, 16, 102837. [Google Scholar]

- Daranagama, T.; Udrea, F.; Logan, T.; McMahon, R. A Performance Comparison of SiC and Si Devices in a Bi-Directional Converter for Distributed Energy Storage Systems. In Proceedings of the 2016 IEEE 7th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Vancouver, BC, Canada, 27–30 June 2016; pp. 1–8. [Google Scholar]

- Fuentes, C.D.; Müller, M.; Bernet, S.; Kouro, S. SiC-Mosfet or Si-IGBT: Comparison of Design and Key Characteristics of a 690 V Grid-Tied Industrial Two-Level Voltage Source Converter. Energies 2021, 14, 3054. [Google Scholar]

- Godignon, P.; Biscarrat, J.; Tranchesset, M.; Lavieville, R.; Tournier, D.; Brosselard, P.; Montserrat, J. Breakdown Voltage Capability of Vertical 4H–SiC Power Devices. Mater. Sci. Semicond. Process. 2024, 178, 108347. [Google Scholar] [CrossRef]

- Hein, L.; Heimler, P.; Lentzsch, T.; Lutz, J.; Basler, T. Advanced Power Cycling Test Strategies on Discrete SiC MOSFETs in Different Operating Modes and the Impact on Lifetime. Microelectron. Reliab. 2025, 170, 115786. [Google Scholar] [CrossRef]

- Chen, Y.; Lan, X.; Li, L.; Li, X.; Zhang, Z.; Xin, G. Failure Evolution Analysis of SiC Power Modules in Electric-Thermal-Mechanical Multi-Physical Fields. Microelectron. Reliab. 2025, 169, 115751. [Google Scholar] [CrossRef]

- Xu, J.; Wei, Y.; Zhang, D.; Yu, X.; Liang, X.; Guo, Q.; Xiang, Y.; Feng, J. Study on Gate Oxide Reliability of SiC Power MOSFETs under 300 MeV Proton Irradiation. Microelectron. Reliab. 2025, 169, 115750. [Google Scholar]

- Zhang, Z.; Guo, Y.; Robertson, J. Mobility Degradation in 4H-SiC MOSFETs and Interfacial Formation of Carbon Clusters. Solid. State. Electron. 2021, 183, 108051. [Google Scholar]

- Shao, S.; Cui, W.; Jiang, Y.; Pei, X.; Zhang, J. Adaptive Balancing of Series-Connected SiC MOSFETs Based on Active Clamping and Comparison Circuitry. IEEE Access 2025, 13, 3154–3164. [Google Scholar] [CrossRef]

- Cha, H.-R.; Kim, R.-Y. Voltage Balance Switching Scheme for Series-Connected SiC MOSFET LLC Resonant Converter. Energies 2019, 12, 4003. [Google Scholar] [CrossRef]

- Pei, Y.; Yuan, W.; Li, Y.; Guo, N.; Zhang, X.; Liu, X. Influence of Growth Process on Suppression of Surface Morphological Defects in 4H-SiC Homoepitaxial Layers. Micromachines 2024, 15, 665. [Google Scholar] [CrossRef]

- Capan, I. Electrically Active Defects in 3C, 4H, and 6H Silicon Carbide Polytypes: A Review. Crystals 2025, 15, 255. [Google Scholar] [CrossRef]

- Harada, S.; Murayama, K. Advances in Defect Characterization Techniques Using Polarized Light Observation in SiC Wafers for Power Devices. J. Cryst. Growth 2025, 650, 127982. [Google Scholar] [CrossRef]

- Sun, S.; Liu, J.; Chen, L.; Lu, Z.; Wang, Y.; Yang, W.; Sun, Y.; Guo, H. A Magnetic Integration Mismatch Suppression Strategy for Parallel SiC Power Devices Applications. Electronics 2024, 13, 954. [Google Scholar] [CrossRef]

| Material | Bandwidth Eg (eV) | Critical Breakdown Field EF (MV/cm) | Electron Mobility μ (cm2/V·s) | Electron Saturation Drift Rate v (107 cm/s) | Heat Conductivity λ (W/cm·K) | Dielectric Constant ε |

|---|---|---|---|---|---|---|

| Si | 1.1 | 0.3 | 1350 | 1 | 1.5 | 11.8 |

| 3C-SiC | 2.2 | 2.1 | 1000 | 2 | 4.5 | 9.6 |

| 4H-SiC | 3.26 | 3.2 | 950 | 2 | 4.5 | 9.7 |

| 6H-SiC | 3.0 | 3.0 | 500 | 2 | 4.5 | 9.7 |

| GaN | 3.39 | 3.3 | 900 | 2.5 | 1.3 | 9 |

| Ga2O3 | 4.7 | 8 | 300 | 2.42 | 0.13 | 10 |

| Diamond | 5.45 | 5.6 | 1900 | 2.7 | 20 | 5.5 |

| SiC Devices | Main Applications | Advantages |

|---|---|---|

| JBS Diode | Photovoltaics Electric vehicles Wind energy | No reverse recovery voltage |

| PiN Diode | DC transmission High voltage applications | High voltage and high current fields |

| MOSFET | Industrial power supplies Specialty applications | Gate drive weak regulation capability |

| JFET | Electric vehicles Wind power generation | High reliability |

| IGBT/GTO | High-speed rail traction DC power transmission | Ultra-high voltage and high current applications |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Nie, M.; Dong, Q.; Liu, H.; Jia, P.; Li, Z.; Fang, Y. Applicability Analysis of High-Voltage Transmission and Substation Equipment Based on Silicon Carbide Devices. Micromachines 2025, 16, 1192. https://doi.org/10.3390/mi16111192

Zhang H, Nie M, Dong Q, Liu H, Jia P, Li Z, Fang Y. Applicability Analysis of High-Voltage Transmission and Substation Equipment Based on Silicon Carbide Devices. Micromachines. 2025; 16(11):1192. https://doi.org/10.3390/mi16111192

Chicago/Turabian StyleZhang, Huiyuan, Ming Nie, Qinxiao Dong, He Liu, Pengfei Jia, Zhiyuan Li, and Yonghao Fang. 2025. "Applicability Analysis of High-Voltage Transmission and Substation Equipment Based on Silicon Carbide Devices" Micromachines 16, no. 11: 1192. https://doi.org/10.3390/mi16111192

APA StyleZhang, H., Nie, M., Dong, Q., Liu, H., Jia, P., Li, Z., & Fang, Y. (2025). Applicability Analysis of High-Voltage Transmission and Substation Equipment Based on Silicon Carbide Devices. Micromachines, 16(11), 1192. https://doi.org/10.3390/mi16111192