Optimization Design of High-Performance Powder-Spreading Arm for Metal 3D Printers

Abstract

1. Introduction

2. Materials and Methods

2.1. Design Methods

2.2. Material and Molding Method

2.3. Analysis Methods

3. Results and Discussion

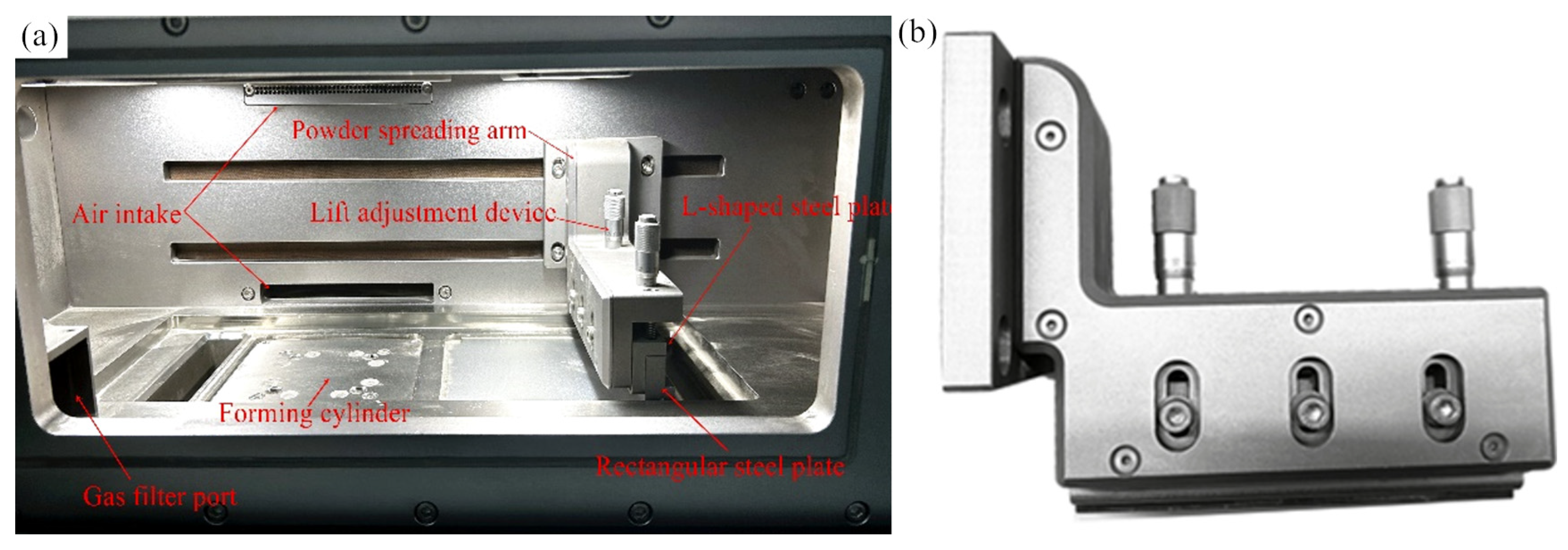

3.1. Reconstruction Effect of Metal 3D Printer Powder Arm

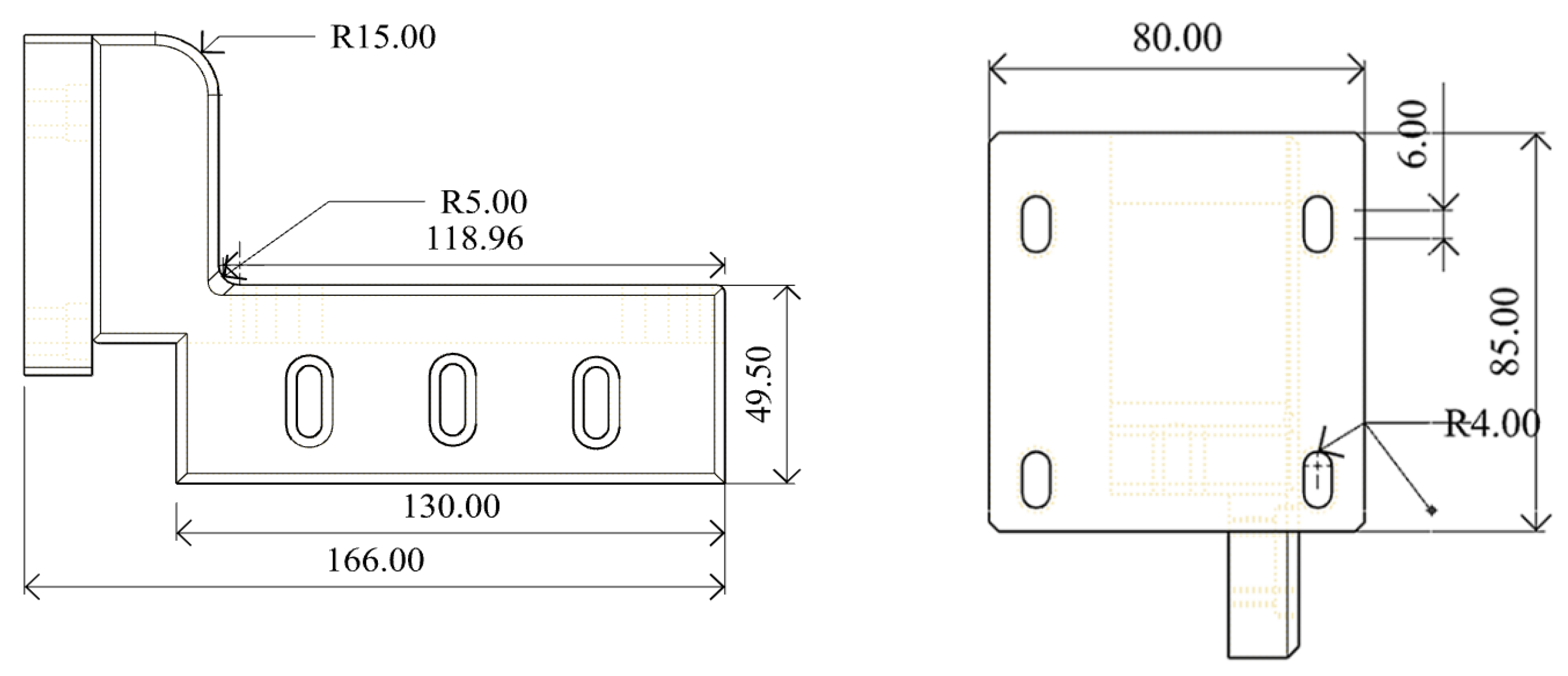

3.2. Finite Element Analysis of the Reconstructed Metal 3D Printer Powder-Laying Arm

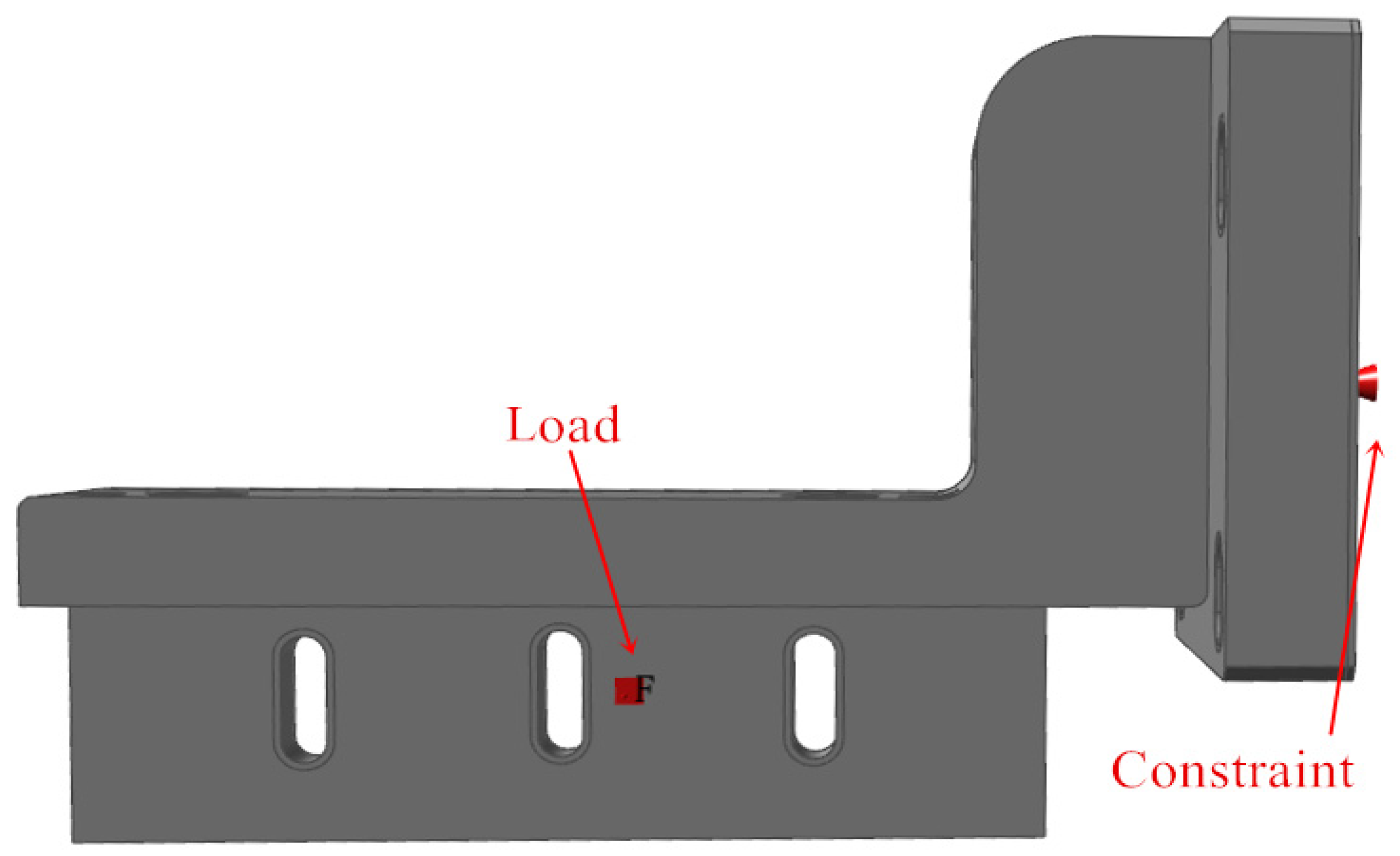

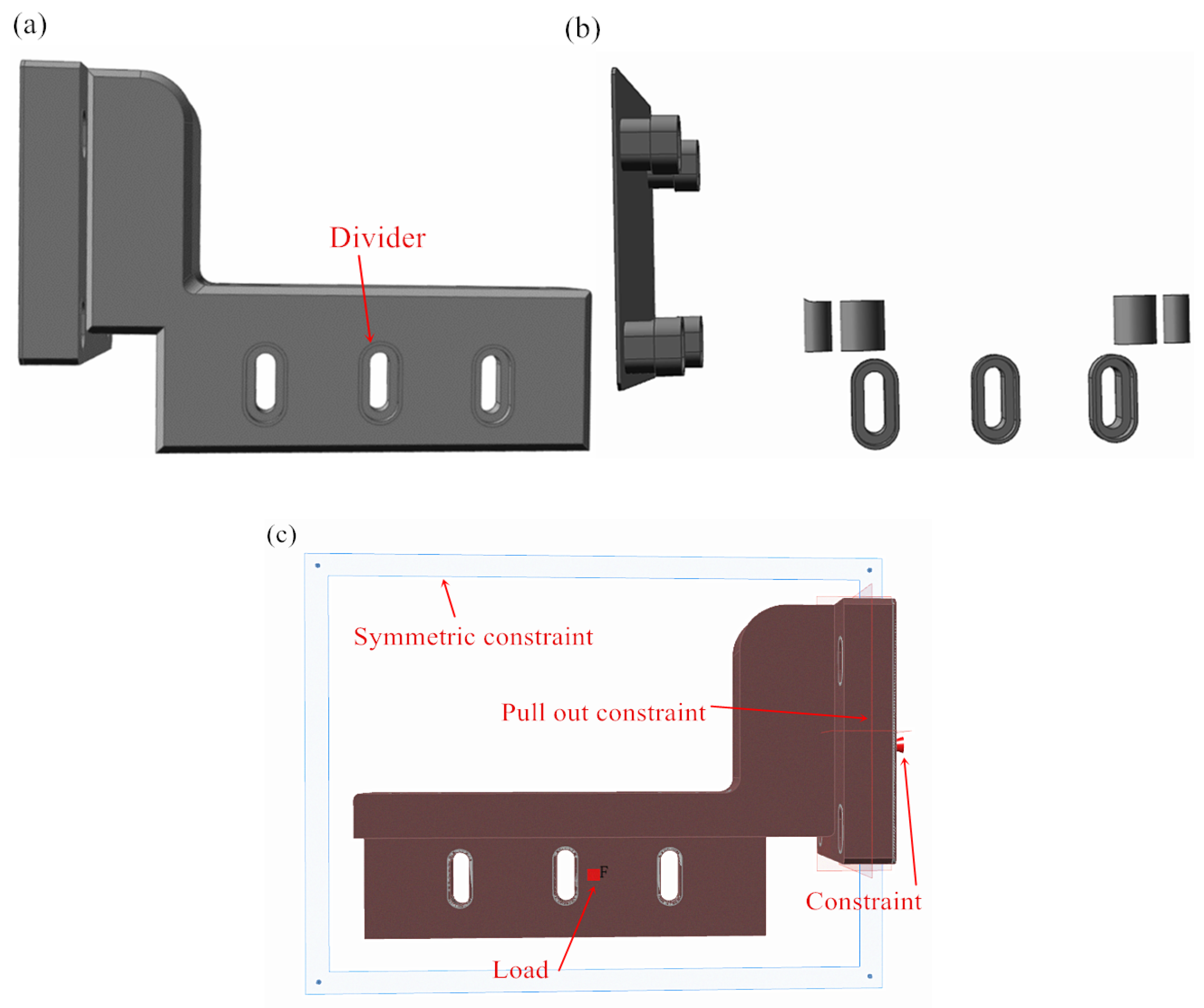

3.2.1. Load and Constraint Application of the Powder-Spreading Arm

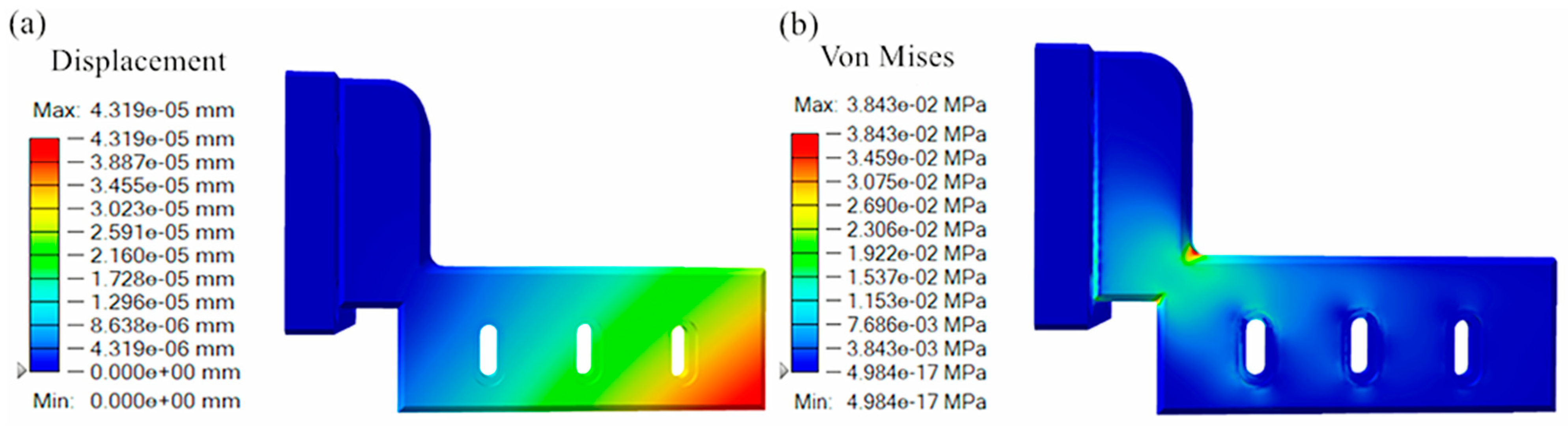

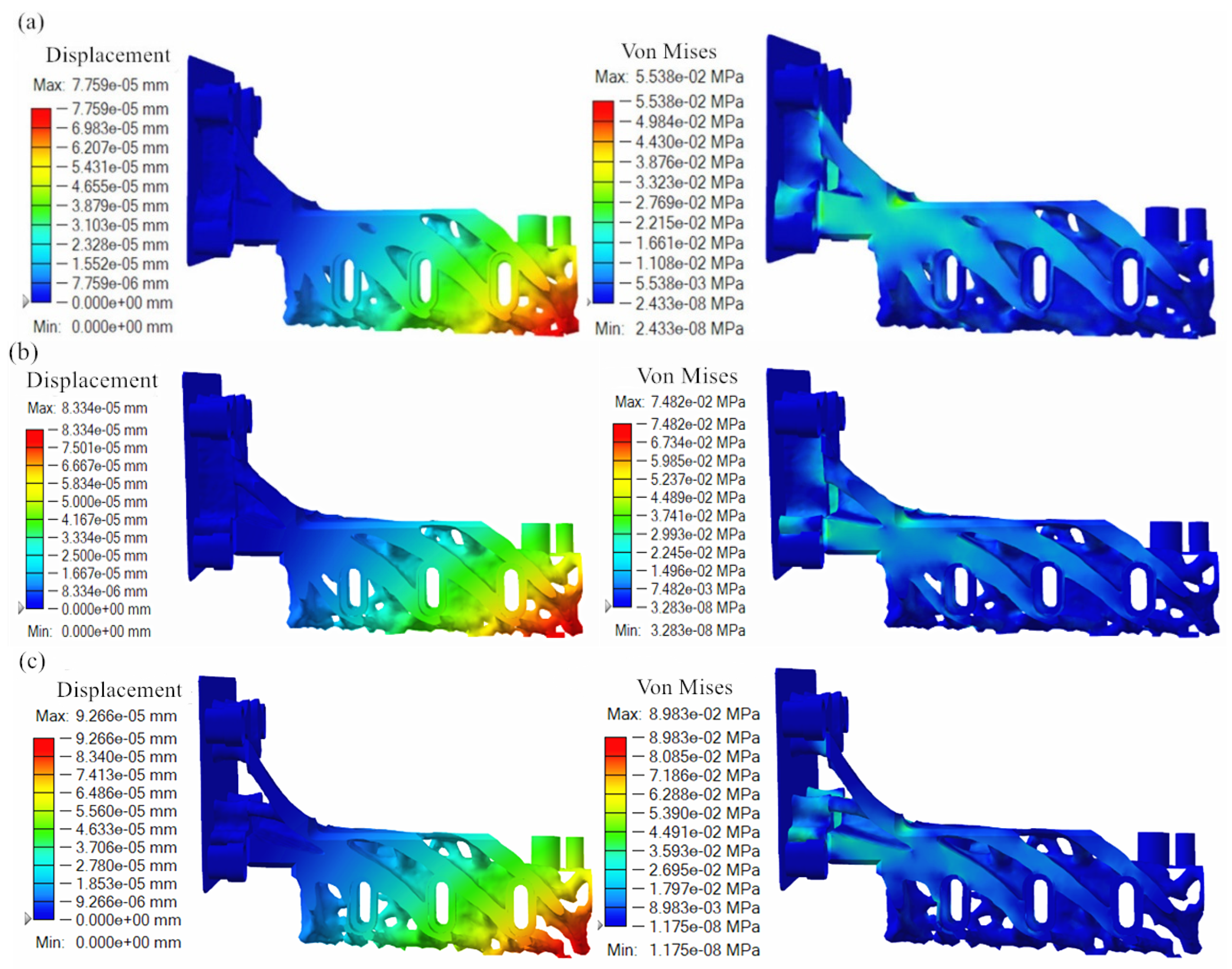

3.2.2. Finite Element Analysis Results of Powder-Spreading Arm

3.3. Topology Optimization Design of Powder-Spreading Arm for 3D Printer

3.3.1. Topology Optimization Analysis Parameter Settings for Powder-Spreading Arm

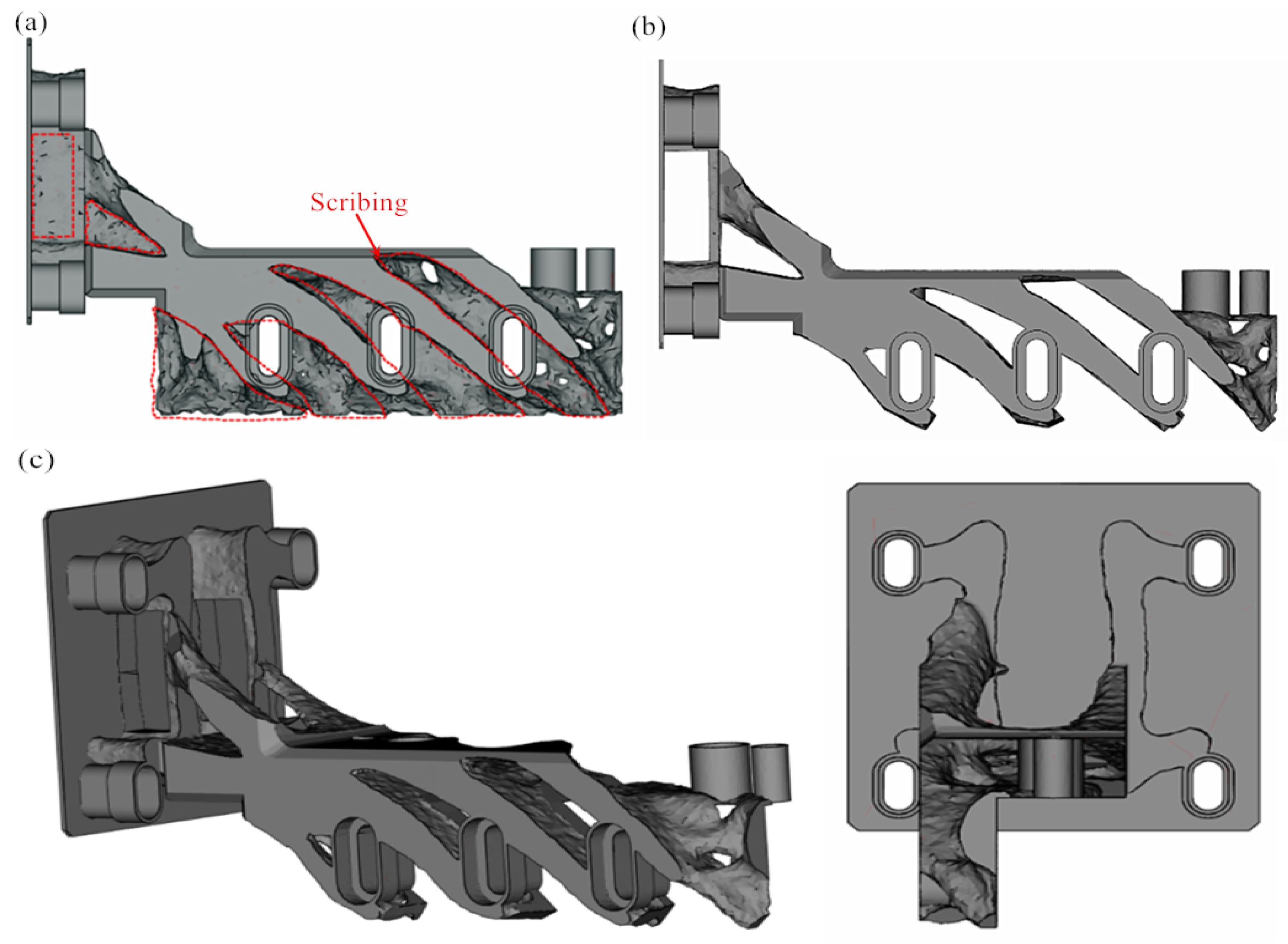

3.3.2. Topology Optimization Analysis of the Powder-Spreading Arm

3.4. Redesign of Powder Arm After Topology Optimization

3.5. Three-Dimensional Printing of the Powder-Spreading Arm After Topology Optimization

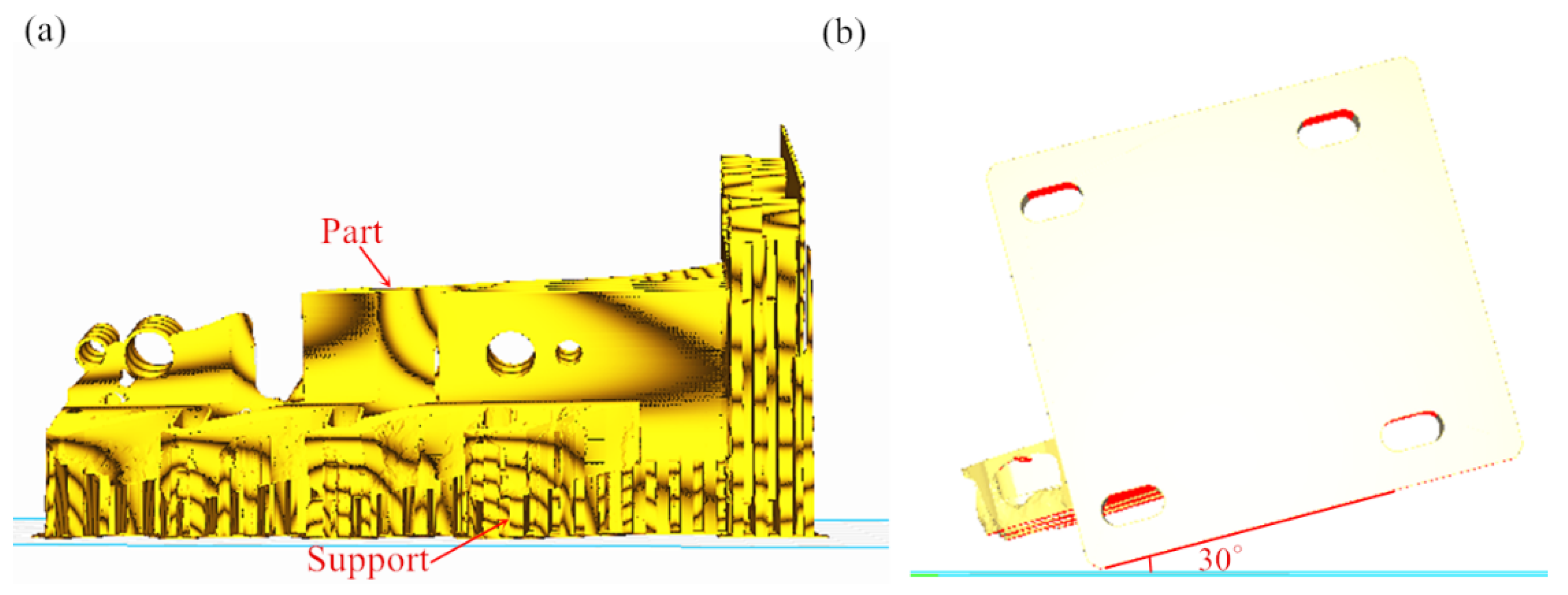

3.5.1. Data Processing of the 3D-Printed Powder-Spreading Arm

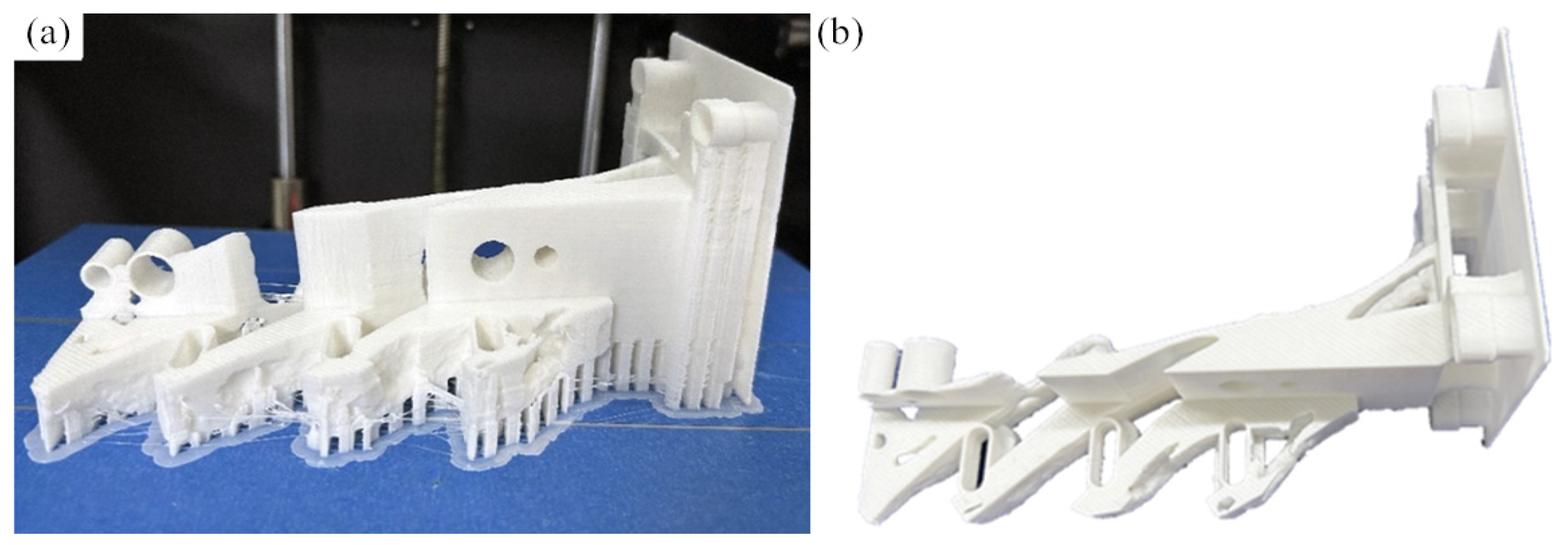

3.5.2. Analysis of the Powder Arm Effect Completed by 3D Printing

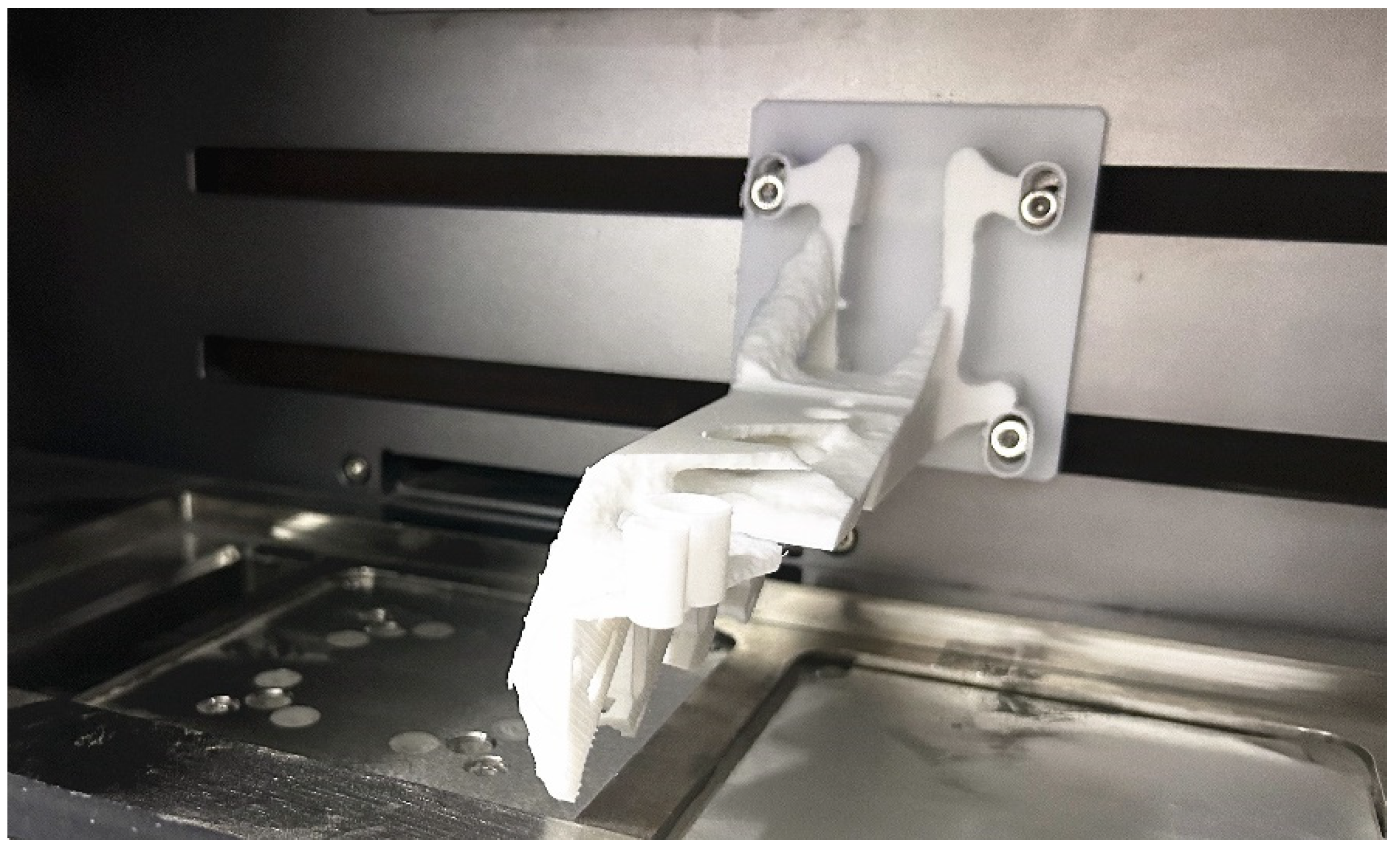

3.5.3. Matching Inspection of Powder-Spreading Arm Completed by 3D Printing

4. Conclusions

- (1)

- The displacement of the powder-spreading arm gradually decreases from the lower right corner to the upper left corner, with the maximum displacement concentrated at the lower right corner measuring 4.319 × 10−5 mm. The displacement amount is very small. The maximum stress is concentrated in the middle transition section, decreasing toward both ends, with the maximum stress being 3.843 × 10−2 MPa. The stress concentration and deformation during powder-spreading operations carried out by the arm are relatively small, providing ample optimization space.

- (2)

- The topological optimization’s displacement and maximum stress of the powder-spreading arm under different quality targets are relatively small, which can meet mechanical performance requirements. Based on the shape of the part after topological optimization, the powder-spreading arm under the 25% quality target maintains integrity at the fixed hole while achieving a significant reduction in mass.

- (3)

- The 3D-printed powder arm parts have a smooth surface, low roughness, no obvious slag hanging on the overhanging surface, and no obvious warping or deformation. The parts have a high surface finish after post-processing and good structural connections, and they can be used in actual assembly inspections. The fit between the 3D-printed powder arm and the assembly wall is tight, the screw hole positions are appropriate, and there are no apparent assembly conflicts between the components.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramesh, M.; Niranjana, K.; Bhoopathi, R.; Rajeshkumar, L. Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters. e-Polymers 2024, 24, 1430–1450. [Google Scholar] [CrossRef]

- Wu, J.; Heng, M.; Bai, Y. A novel dice-inspired multifunctional 3D printing guided splint for minimally invasive access cavity preparation and canal orifice identification. Technol. Health Care 2023, 31, 2381–2387. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Sawant, M.S.; Jain, N.K.; Kumari, A.; Gupta, S. Development of co-cr-mo-x Ti alloys by micro-plasma-based 3D printing for knee implant applications and its biocompatibility assessment. Int. J. Adv. Manuf. Technol. 2023, 126, 2445–2459. [Google Scholar] [CrossRef]

- Lubimyi, N.S.; Chepchurov, M.; Polshin, A.A.; Gerasimov, M.D.; Chetverikov, B.S.; Chetverikova, A.; Tikhonov, A.A.; Maltsev, A. Reducing the cost of 3d metal printing using selective laser melting (SLM) technology in the manufacture of a drill body by reinforcing thin-walled shell forms with metal-polymers. J. Manuf. Mater. Process. 2024, 8, 44. [Google Scholar] [CrossRef]

- Murat, F.; Kaymaz, I.; Şensoy, A.T.; Korkmaz, I.H. Determining the optimum process parameters of selective laser melting via particle swarm optimization based on the response surface method. Met. Mater. Int. 2023, 29, 59–70. [Google Scholar] [CrossRef]

- Jin, X.; Tipan, W. Design and implementation of control system for slm powder laying 3d printing equipment. Autom. Technol. Appl. 2018, 37, 151–154+167. [Google Scholar]

- Feng, C.; Xingang, M.; Jianqiang, X. Research on powder laying system of aluminum alloy selective laser melting 3d printing equipment. Robot. Technol. Appl. 2019, 3, 40–42. [Google Scholar]

- Zhenwei, S.; Minjie, W.; Wenjun, Q.; Liuhui, N.; Jianye, L.; Jiaqi, Z.; Yu, L.; Jinhai, W. Powder thickness of AlSi10Mg alloy printed by laser selective melting 3d printing. China Mech. Eng. 2022, 33, 959–964. [Google Scholar]

- Yinghua, A. 3d Printing Powder Spreading Device; Chongqing Anderuiyuan Technology Co., Ltd.: Chongqing, China, 2020. [Google Scholar]

- Tianguang, Z. Research on the Structural Design of Selective Laser Melting 3d Printing Equipment. Master’s Thesis, Shenyang University of Technology, Shenyang, China, 2019. [Google Scholar]

- Xiaolong, Q. Scalable Design and Optimization of Key Structures for Metal 3d Printers. Master’s Thesis, Guangzhou University, Guangzhou, China, 2020. [Google Scholar]

- Hao, L.; Dadbakhsh, S.; Seaman, O.; Felstead, M. Selective laser melting of a stainless steel and hydroxyapatite composite for load-bearing implant development. J. Mater. Process. Technol. 2009, 209, 5793–5801. [Google Scholar] [CrossRef]

- Poprawe, R.; Hinke, C.; Meiners, W.; Schrage, J.; Bremen, S.; Merkt, S. SLM production systems: Recent developments in process development, machine concepts and component design. In Advances in Production Technology; Springer International Publishing: Cham, Switzerland, 2015; pp. 49–65. [Google Scholar]

- Habiba, U.; Hebert, R.J. Powder spreading mechanism in laser powder bed fusion additive manufacturing: Experiments and computational approach using discrete element method. Materials 2023, 16, 2824. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Li, J.; Li, J.; Zhou, X.; Wang, A. 3D metal printer dust filter structural optimal design and key performance research. Mater. Des. 2019, 183, 108114. [Google Scholar] [CrossRef]

- Zhang, G.; Li, J.; Zhou, X.; Zhou, Y.; Wang, A. Optimized design and key performance factors of a gas circulation filtration system in a metal 3D printer. Sci. Rep. 2022, 12, 14267. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Li, J.; Zhou, X.; Zhou, Y.; Xie, J.; Bai, Y. Optimization Design of High-Performance Powder-Spreading Arm for Metal 3D Printers. Micromachines 2025, 16, 1194. https://doi.org/10.3390/mi16111194

Zhang G, Li J, Zhou X, Zhou Y, Xie J, Bai Y. Optimization Design of High-Performance Powder-Spreading Arm for Metal 3D Printers. Micromachines. 2025; 16(11):1194. https://doi.org/10.3390/mi16111194

Chicago/Turabian StyleZhang, Guoqing, Junxin Li, Xiaoyu Zhou, Yongsheng Zhou, Juanjuan Xie, and Yuchao Bai. 2025. "Optimization Design of High-Performance Powder-Spreading Arm for Metal 3D Printers" Micromachines 16, no. 11: 1194. https://doi.org/10.3390/mi16111194

APA StyleZhang, G., Li, J., Zhou, X., Zhou, Y., Xie, J., & Bai, Y. (2025). Optimization Design of High-Performance Powder-Spreading Arm for Metal 3D Printers. Micromachines, 16(11), 1194. https://doi.org/10.3390/mi16111194