Thermal Gas Flow Sensor Using SiGe HBT Oscillators Based on GaN/Si SAW Resonators

Abstract

1. Introduction

2. Design and Experiment

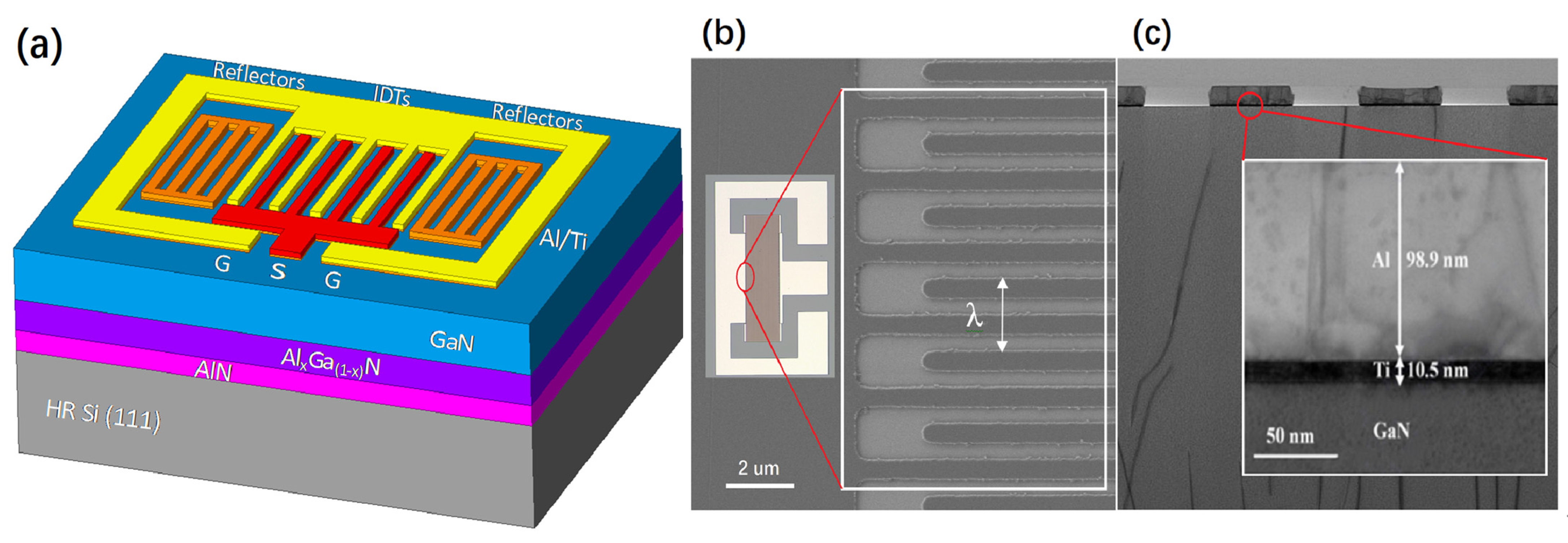

2.1. Process, Design and Characterization of GaN/Si SAW Sensors

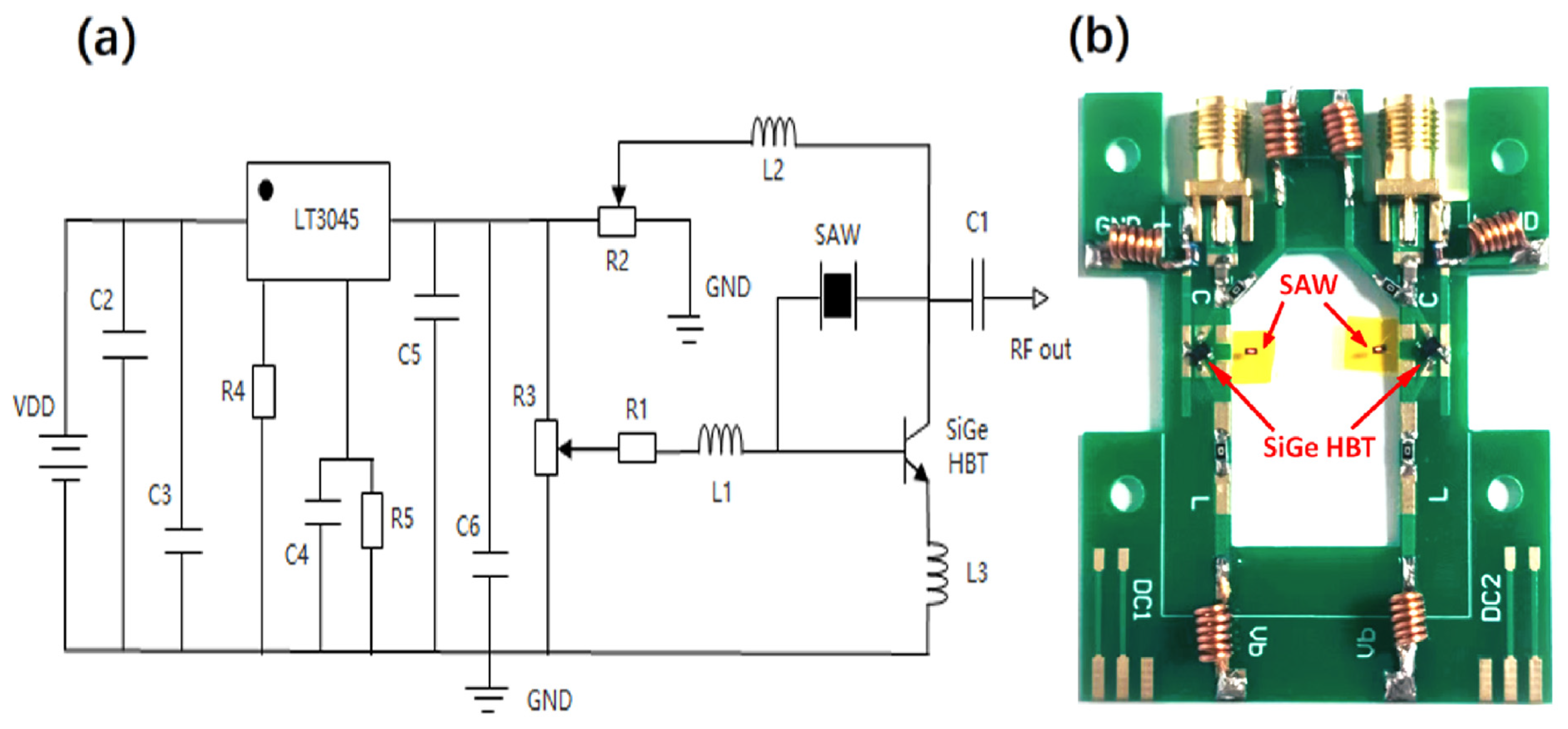

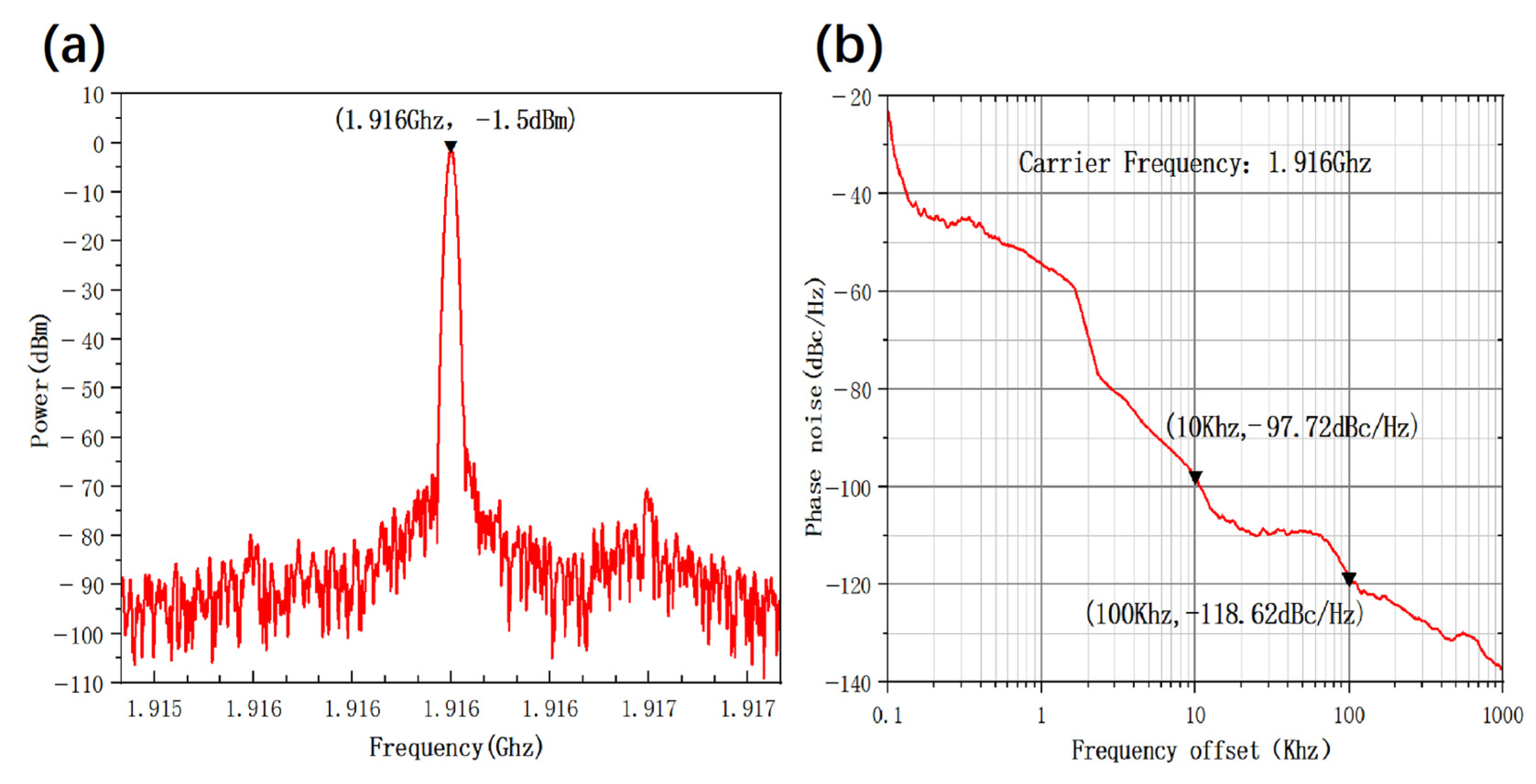

2.2. Design of SiGe HBT High-Frequency Oscillator Based on GaN/Si SAW Resonator

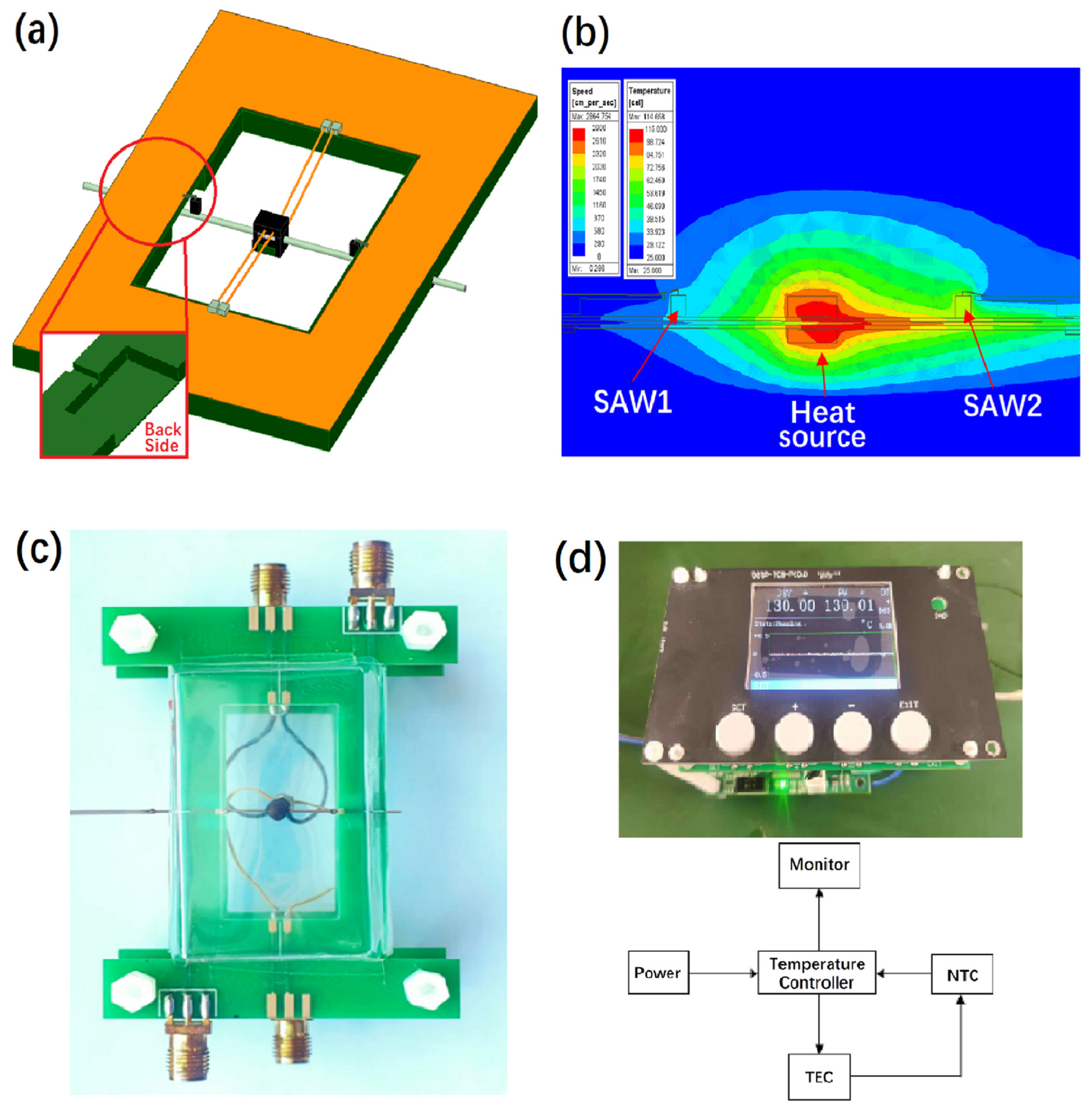

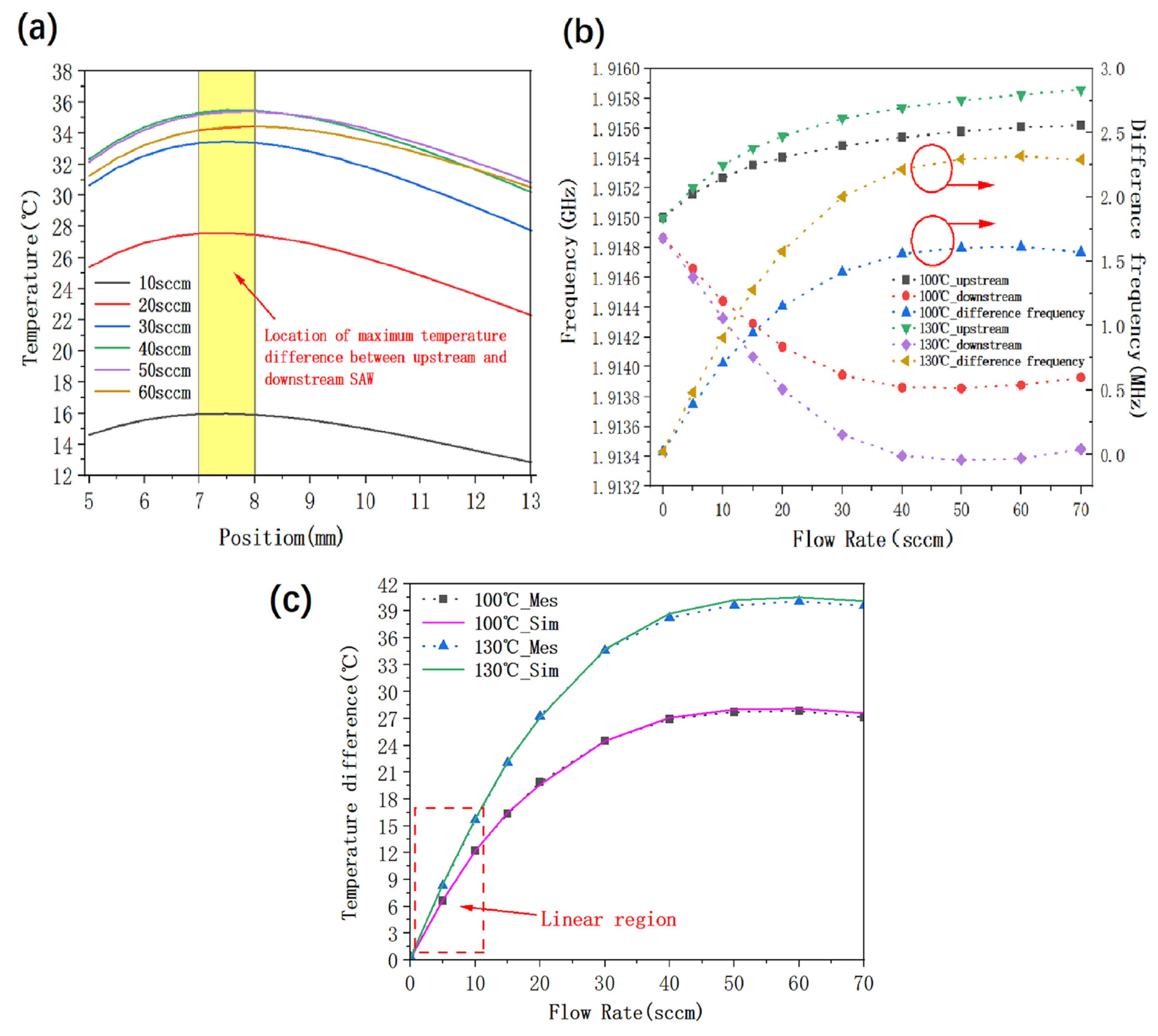

2.3. Thermal Simulation and Temperature Controller Design

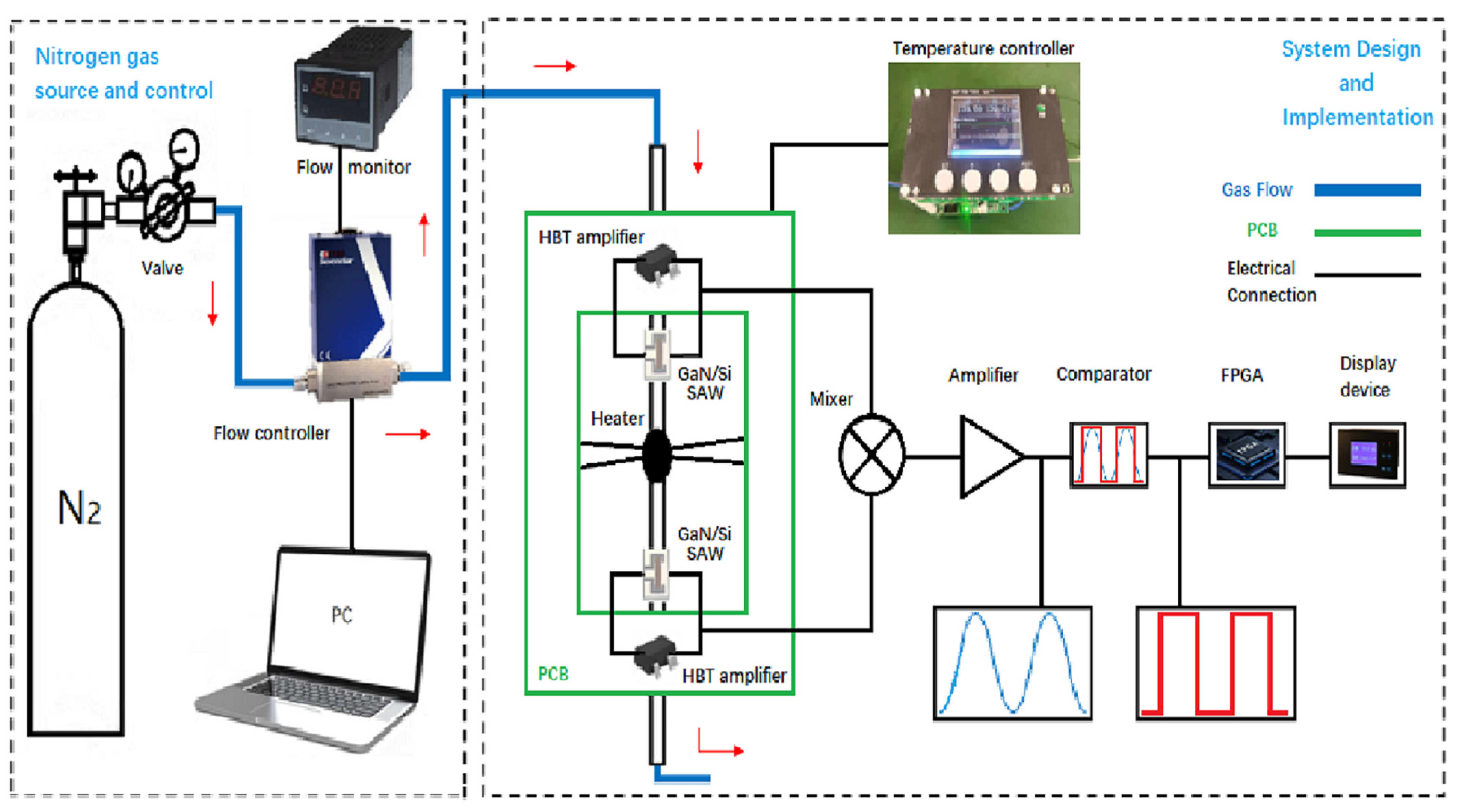

2.4. System Design

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ribeiro, L.; Saotome, O.; d’Amore, R.; de Oliveira Hansen, R. High-Speed and High-Temperature Calorimetric Solid-State Thermal Mass Flow Sensor for Aerospace Application: A Sensitivity Analysis. Sensors 2022, 22, 3484. [Google Scholar] [CrossRef]

- Qiao, J.; Jiao, B.; Liu, R.; Kong, Y.; Yun, S.; Ye, Y. MEMS Thermal Flow Sensor with Enhanced Sensitivity by Multi Channel Data Acquisition. In Proceedings of the 2025 Symposium on Design, Test, Integration and Packaging of MEMS/MOEMS (DTIP), Split, Croatia, 1–4 June 2025; pp. 1–5. [Google Scholar] [CrossRef]

- Qiao, J.; Chen, J.; Jiao, B.; Liu, R.; Kong, Y.; Ye, Y.; Yu, L.; Du, X.; Yun, S.; Hao, Q.; et al. A Highly Sensitive Dual-Mode Thermal Flow Sensor Based on Calorimetric Mode. IEEE Sensors J. 2024, 24, 1245–1254. [Google Scholar] [CrossRef]

- Yan, X.; Zhao, L.; Tang, C.; Zou, J.; Gao, W.; Jian, J.; Jin, Q.; Zhang, X. Intelligent MEMS Thermal Mass Flowmeter Based on Modified Sage-Husa Adaptive Robust-Strong Tracking Kalman Filtering. IEEE Sens. J. 2025, 25, 283–290. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Liu, C.; Lin, Y.; Zhang, L.; Zhao, H. A high-accuracy ultrasonic gas flow meter based on scandium-doped aluminum nitride piezoelectric micromachined ultrasonic transducers. IEEE Trans. Instrum. Meas. 2024. early access. [Google Scholar] [CrossRef]

- Wu, C.; Liu, G.; Zhai, Y.; Xiang, Y.; Bai, J.; Shi, J.; Wu, Y.; Zheng, F. Development of gas meter based on MEMS thermal flow sensor. In Proceedings of the 2019 IEEE 14th International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Bangkok, Thailand, 11–14 April 2019. [Google Scholar]

- Crabtree, M.A. Industrial Flow Measurement. Ph.D. Thesis, University of Huddersfield, Huddersfield, UK, 2009. [Google Scholar]

- Kato, M.; Pugh, J.; McGlinchey, D. Development of a particulate solids thermal mass flowmeter. KONA Powder Part. J. 2014, 31, 163–170. [Google Scholar] [CrossRef]

- Fu, Y.-Q.; Pang, H.-F.; Torun, H.; Tao, R.; McHale, G.; Reboud, J.; Tao, K.; Zhou, J.; Luo, J.-T.; Gibson, D.; et al. Engineering inclined orientations of piezoelectric films for integrated acoustofluidics and lab-on-a-chip operated in liquid environments. Lab Chip 2021, 21, 254–271. [Google Scholar] [CrossRef]

- Takai, T.; Iwamoto, H.; Takamine, Y.; Yamazaki, H.; Fuyutsume, T.; Kyoya, H.; Nakao, T.; Kando, H.; Hiramoto, M.; Toi, T.; et al. High-performance SAW resonator on new multilayered substrate using LiTaO3 crystal. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2017, 64, 1382–1389. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Lu, R.; Zhou, H.; Link, S.; Yang, Y.; Li, Z.; Huang, K.; Ou, X.; Gong, S. Surface acoustic wave devices using lithium niobate on silicon carbide. IEEE Trans. Microw. Theory Tech. 2020, 68, 3653–3666. [Google Scholar] [CrossRef]

- Su, R.; Shen, J.; Lu, Z.; Xu, H.; Niu, Q.; Xu, Z.; Zeng, F.; Song, C.; Wang, W.; Fu, S.; et al. Wideband and low-loss surface acoustic wave filter based on 15° YX-LiNbO3/SiO2/Si structure. IEEE Electron Device Lett. 2021, 42, 438–441. [Google Scholar] [CrossRef]

- Zeng, F.; An, J.X.; Zhou, G.; Li, W.; Wang, H.; Duan, T.; Jiang, L.; Yu, H. A comprehensive review of recent progress on GaN high electron mobility transistors: Devices, fabrication and reliability. Electronics 2018, 7, 377. [Google Scholar] [CrossRef]

- Zhao, D.; Wu, Z.; Duan, C.; Mei, B.; Li, Z.; Wang, Z.; Tang, Q.; Yang, Q.; Wu, Y.; Zhang, W.; et al. Design and simulation of reverse-blocking Schottky-drain AlN/AlGaN HEMTs with drain field plate. Sci. China Inf. Sci. 2022, 65, 122401. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, L.; Jiang, J.; Lu, X.; Yang, L.; Hou, B.; Liao, M.; Zhou, Y.; Ma, X.; Hao, Y. Ferroelectric gate AlGaN/GaN E-mode HEMTs with high transport and sub-threshold performance. IEEE Electron Device Lett. 2017, 39, 79–82. [Google Scholar] [CrossRef]

- Rais Zadeh, M.; Gokhale, V.J.; Ansari, A.; Faucher, M.; Theron, D.; Cordier, Y.; Buchaillot, L. Gallium nitride as an electromechanical material. J. Microelectromech. Syst. 2014, 23, 1252–1271. [Google Scholar] [CrossRef]

- Ansari, A. Gallium Nitride Integrated Microsystems for Radio Frequency Applications. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 2016. [Google Scholar]

- Ansari, A.; Gokhale, V.J.; Thakar, V.A.; Roberts, J.; Rais-Zadeh, M. Gallium nitride-on-silicon micromechanical overtone resonators and filters. In Proceedings of the 2011 International Electron Devices Meeting, Washington, DC, USA, 5–7 December 2011. [Google Scholar]

- Zhu, H.; Ansari, A.; Luo, W.; Rais-Zadeh, M. Observation of acoustoelectric effect in micromachined lamb wave delay lines with AlGaN/GaN heterostructure. In Proceedings of the 2016 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 3–7 December 2016. [Google Scholar]

- Ansari, A.; Rais Zadeh, M. A thickness-mode AlGaN/GaN resonant body high electron mobility transistor. IEEE Trans. Electron Devices. 2014, 61, 1006–1013. [Google Scholar] [CrossRef]

- Lalinský, T.; Rýger, I.; Vanko, G.; Tomáška, M.; Kostič, I.; Haščík, S.; Vallo, M. AlGaN/GaN based SAW-HEMT structures for chemical gas sensors. Procedia Eng. 2010, 5, 152–155. [Google Scholar] [CrossRef]

- Ji, X.; Dong, W.-X.; Zhang, Y.-M.; Wang, J.-F.; Xu, K. Fabrication and characterization of one-port surface acoustic wave resonators on semi-insulating GaN substrates. Chin. Phys. B 2019, 28, 067701. [Google Scholar] [CrossRef]

- Qamar, A.; Ghatge, M.; Tabrizian, R.; Rais-Zadeh, M. Thermo-acoustic engineering of GaN SAW resonators for stable clocks in extreme environments. In Proceedings of the 2020 IEEE 33rd International Conference on Micro Electro Mechanical Systems (MEMS), Vancouver, BC, Canada, 18–22 January 2020. [Google Scholar]

- Zhang, Q.; Wang, Y.; Tao, R.; Li, D.; Fu, Y.; Xie, J. Flexible ZnO thin film surface acoustic wave device for flow rate measurement. In Proceedings of the 2020 IEEE 33rd International Conference on Micro Electro Mechanical Systems (MEMS), Vancouver, BC, Canada, 18–22 January 2020. [Google Scholar]

- Talbi, F.A.; Talbi, A.; Sarry, F.; Moreira, F.; Elhakiki, M.; Elmazria, O.; Le Brizoual, L.; Alnot, P. Zero TCF ZnO/Quartz SAW structure for gas sensing applications. In Proceedings of the 2004 IEEE International Frequency Control Symposium and Exposition, Montreal, QC, Canada, 23–27 August 2004. [Google Scholar]

- Hefele, A.; Strobl, C.; Baigar, E.; Kurzmaier, G.; Reiner, A.; Horner, A.L.; Wixforth, A. Fluid independent flow determination by surface acoustic wave driven ultrasonic techniques. IEEE Open J. Ultrason. Ferroelectr. Freq. Control. 2021, 1, 11–20. [Google Scholar] [CrossRef]

- Nomura, T.; Saitoh, A.; Koyama, K. Mass flow sensor using dual SAW device. In Proceedings of the 2007 IEEE International Frequency Control Symposium Joint with the 21st European Frequency and Time Forum, Geneva, Switzerland, 29 May–1 June 2007. [Google Scholar]

- Yoo, B.-K.; Park, Y.-W.; Kang, C.-Y.; Yoon, S.-J.; Kim, J.-S. Surface acoustic wave sensors to detect volatile gases by measuring output phase shift. J. Electroceram. 2006, 17, 1013–1017. [Google Scholar] [CrossRef]

- Anisimkin, V.; Penza, M.; Maksimov, S.; Vasanelli, L. SAW delay lines for thermal detection of gases and gas flows. In Proceedings of the 1995 IEEE Ultrasonics Symposium, Seattle, WA, USA, 7–10 November 1995; Volume 1. [Google Scholar]

- Penza, M.; Anisimkin, V.; Maximov, S.; Vasanelli, L. Selective gas detection using uncoated SAW delay lines. Sens. Actuators B Chem. 1997, 42, 103–107. [Google Scholar] [CrossRef]

- Yu, G.; Liang, R.; Zhao, H.; Xiao, L.; Cui, J.; Zhao, Y.; Cui, W.; Wang, J.; Xu, J.; Fu, J.; et al. Geometry characteristics and wide temperature behavior of silicon-based GaN surface acoustic wave resonators with ultrahigh quality factor. Sci. China Inf. Sci. 2024, 67, 122402. [Google Scholar] [CrossRef]

- Frickey, D.A. Conversions between S, Z, Y, H, ABCD, and T parameters which are valid for complex source and load impedances. IEEE Trans. Microw. Theory Tech. 1994, 42, 205–211. [Google Scholar] [CrossRef]

- Lu, Z.; Fu, S.; Chen, Z.; Shen, J.; Su, R.; Wang, R.; Song, C.; Zeng, F.; Wang, W.; Pan, F. High-frequency and high-temperature stable surface acoustic wave devices on ZnO/SiO2/SiC structure. J. Phys. D Appl. Phys. 2020, 53, 305102. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, W.; Cui, J.; Zhang, W.; Yu, G.; Zhao, D.; Du, J.; Li, Z.; Fu, J.; Ren, T. Thermal Gas Flow Sensor Using SiGe HBT Oscillators Based on GaN/Si SAW Resonators. Micromachines 2025, 16, 1151. https://doi.org/10.3390/mi16101151

Cui W, Cui J, Zhang W, Yu G, Zhao D, Du J, Li Z, Fu J, Ren T. Thermal Gas Flow Sensor Using SiGe HBT Oscillators Based on GaN/Si SAW Resonators. Micromachines. 2025; 16(10):1151. https://doi.org/10.3390/mi16101151

Chicago/Turabian StyleCui, Wenpu, Jie Cui, Wenchao Zhang, Guofang Yu, Di Zhao, Jingqing Du, Zhen Li, Jun Fu, and Tianling Ren. 2025. "Thermal Gas Flow Sensor Using SiGe HBT Oscillators Based on GaN/Si SAW Resonators" Micromachines 16, no. 10: 1151. https://doi.org/10.3390/mi16101151

APA StyleCui, W., Cui, J., Zhang, W., Yu, G., Zhao, D., Du, J., Li, Z., Fu, J., & Ren, T. (2025). Thermal Gas Flow Sensor Using SiGe HBT Oscillators Based on GaN/Si SAW Resonators. Micromachines, 16(10), 1151. https://doi.org/10.3390/mi16101151