Effect of Grain Size on Polycrystalline Copper Finish Quality of Ultra-Precision Cutting

Abstract

1. Introduction

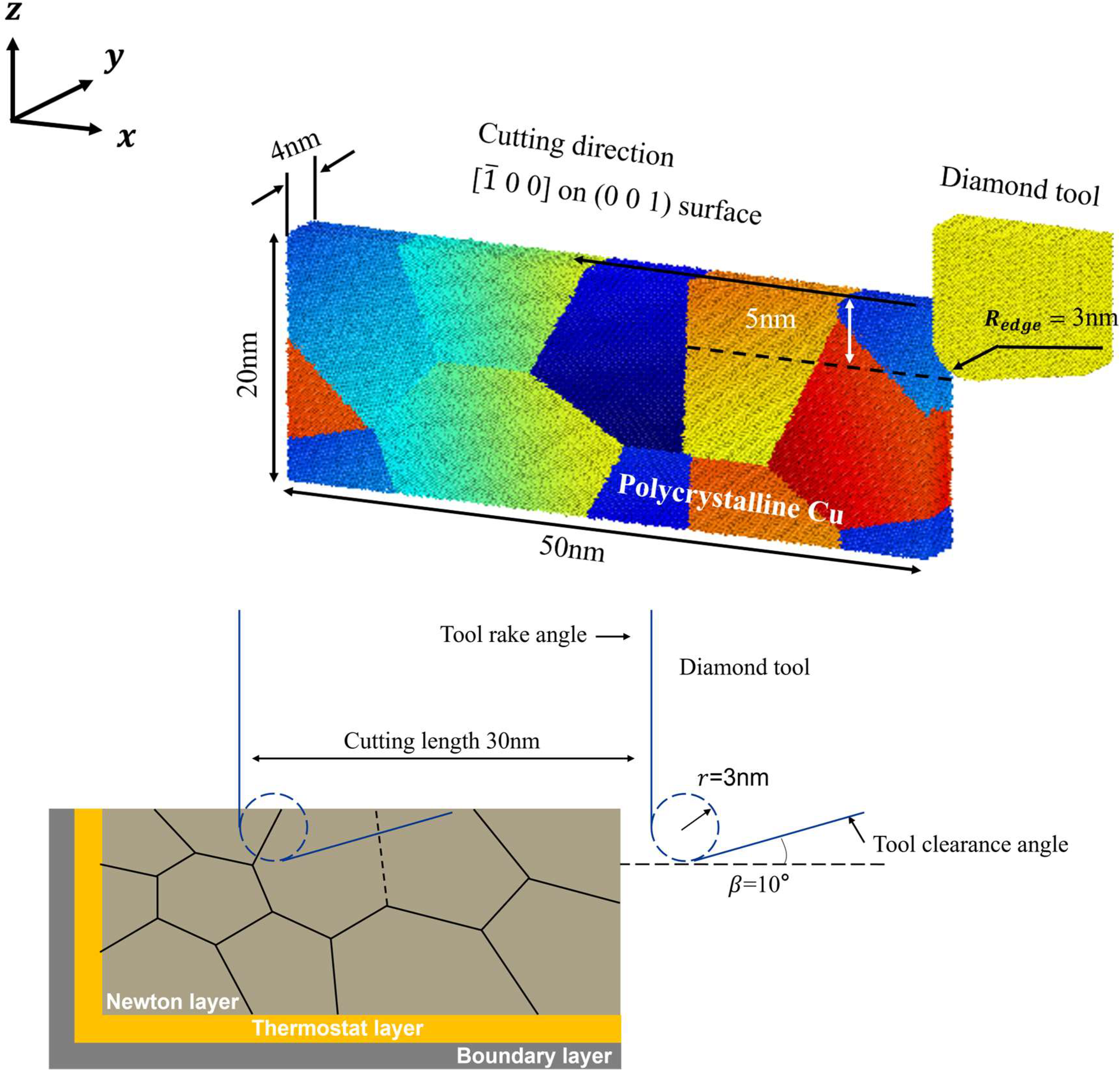

2. MD Simulation

2.1. Model Setup Configuration

2.2. Results and Analysis

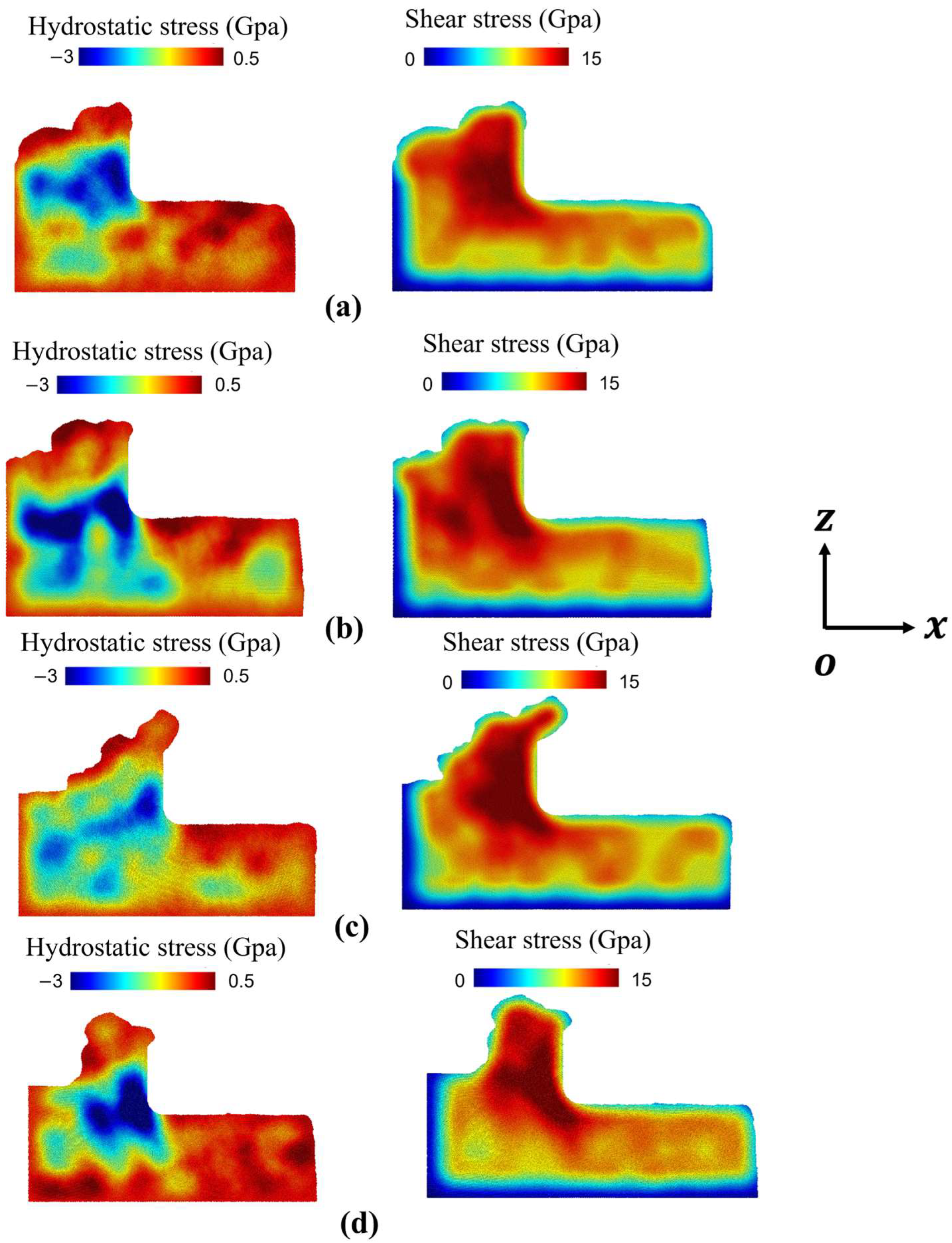

2.2.1. Stress Field Analysis

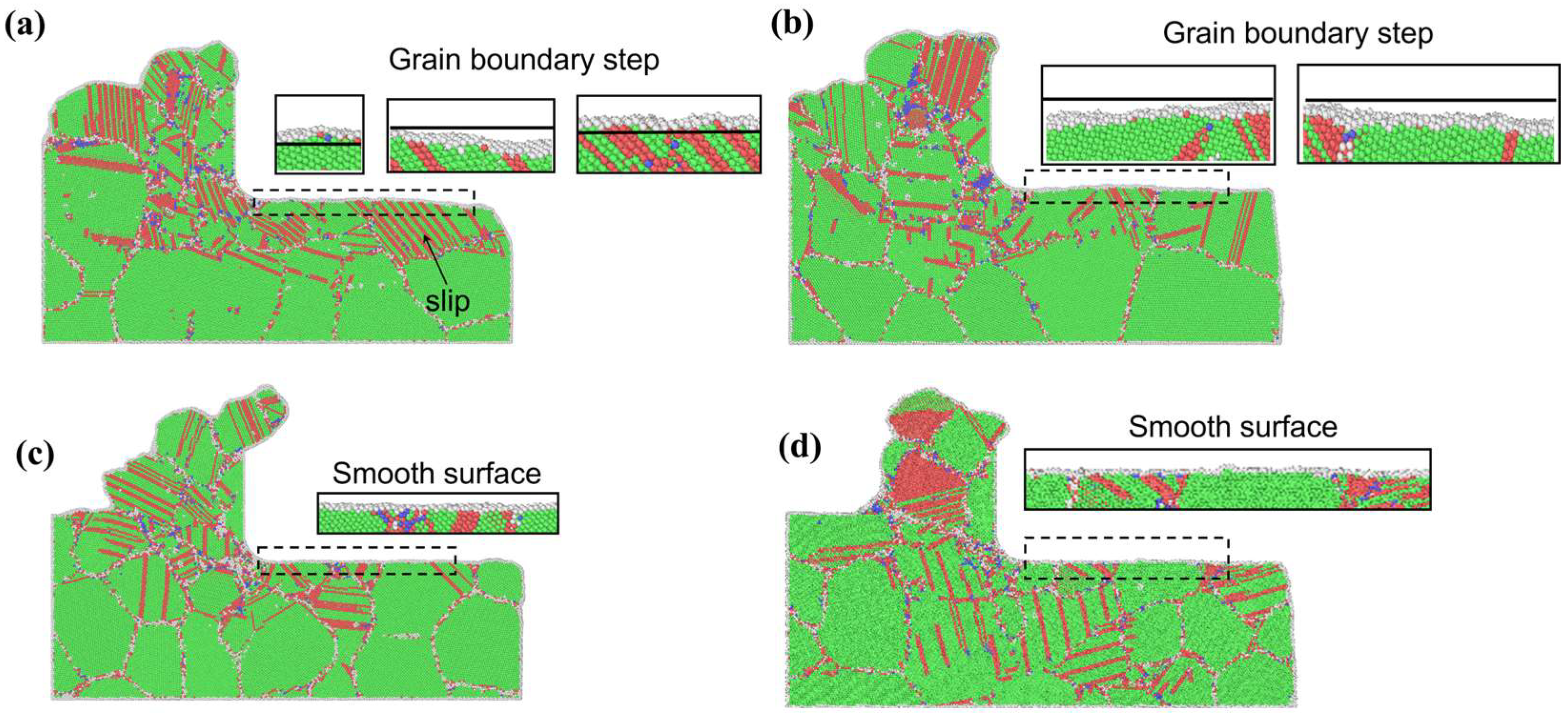

2.2.2. Analysis of Subsurface Defects in Machined Materials

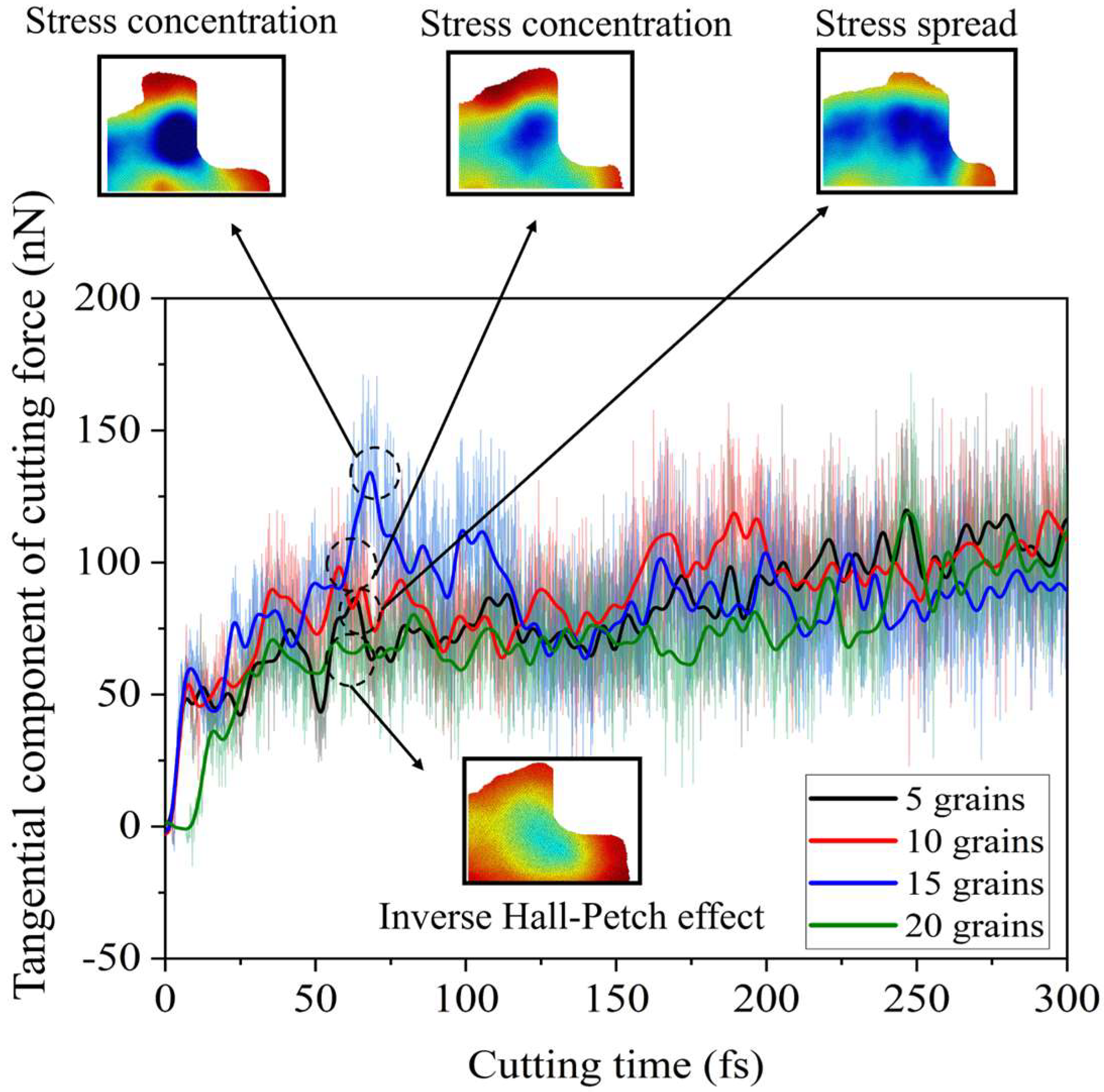

2.2.3. Cutting Force

3. Experimental Investigation on the Influence of Grain Size on Machined Surface Quality

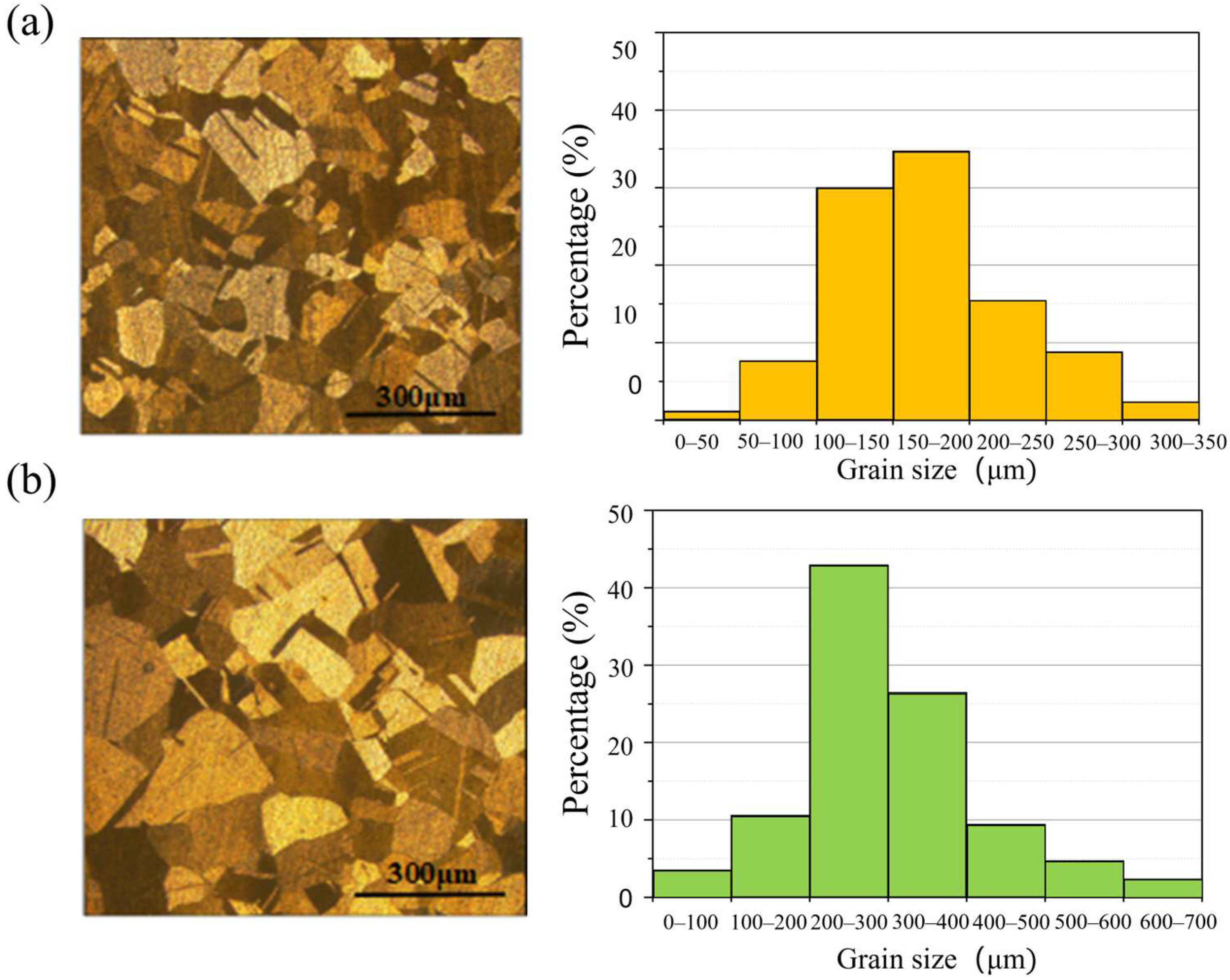

3.1. Grain Size Characterization

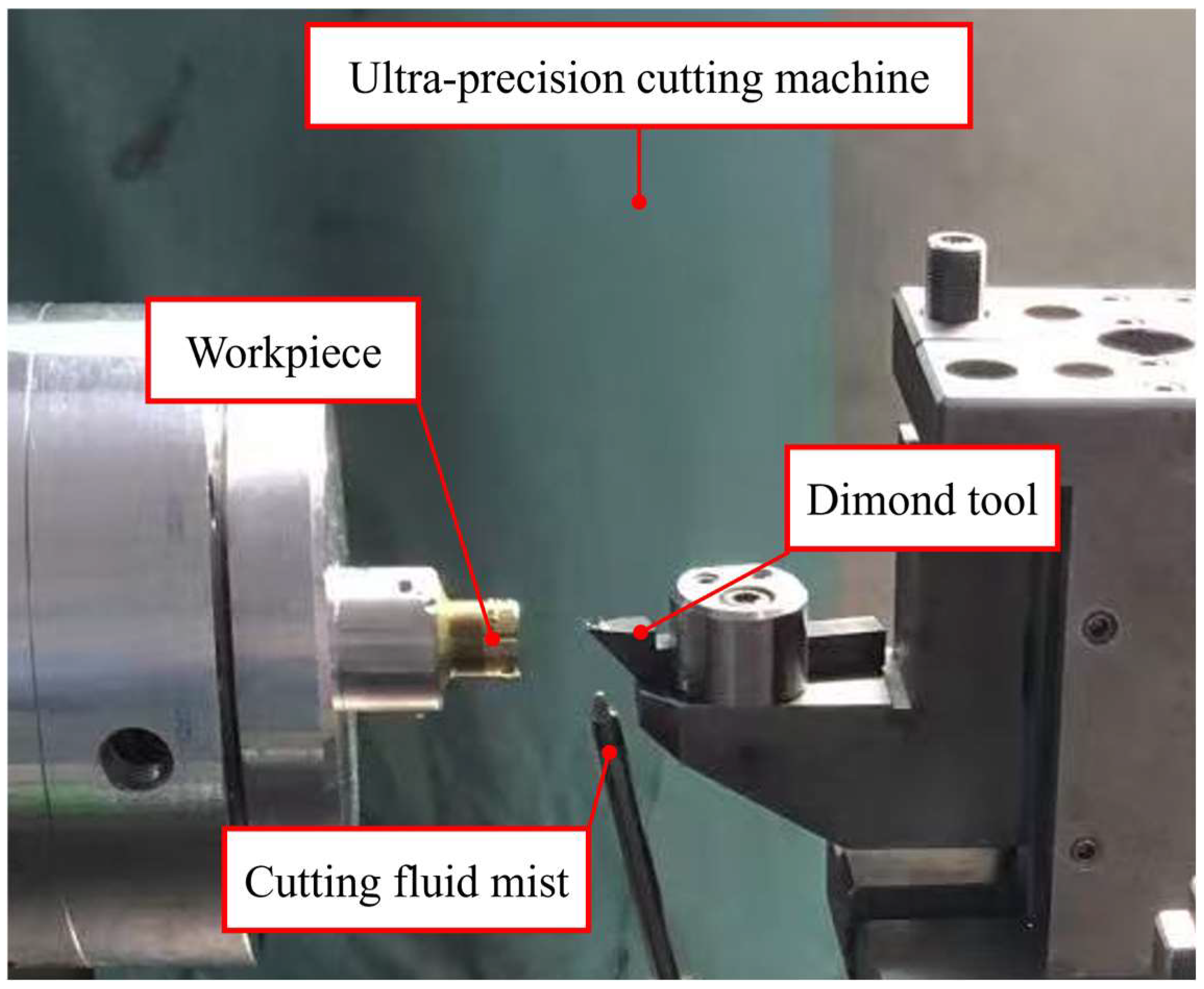

3.2. Experimental Design

3.3. Effect of Grain Size on Surface Quality

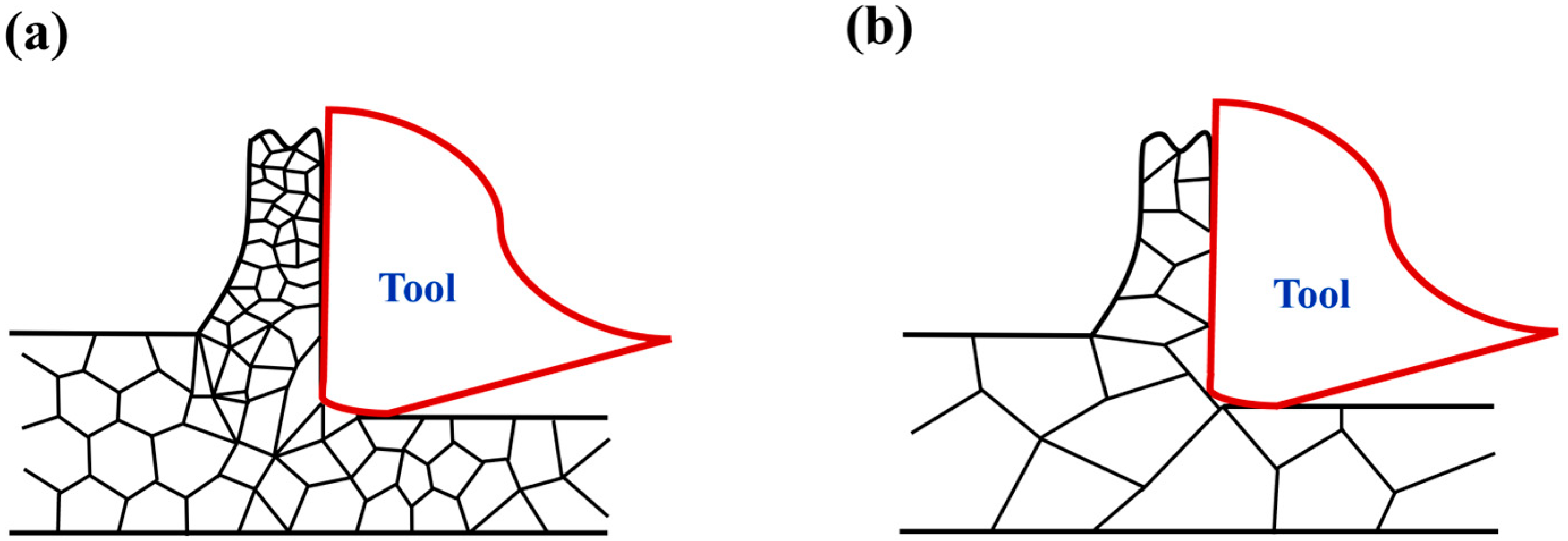

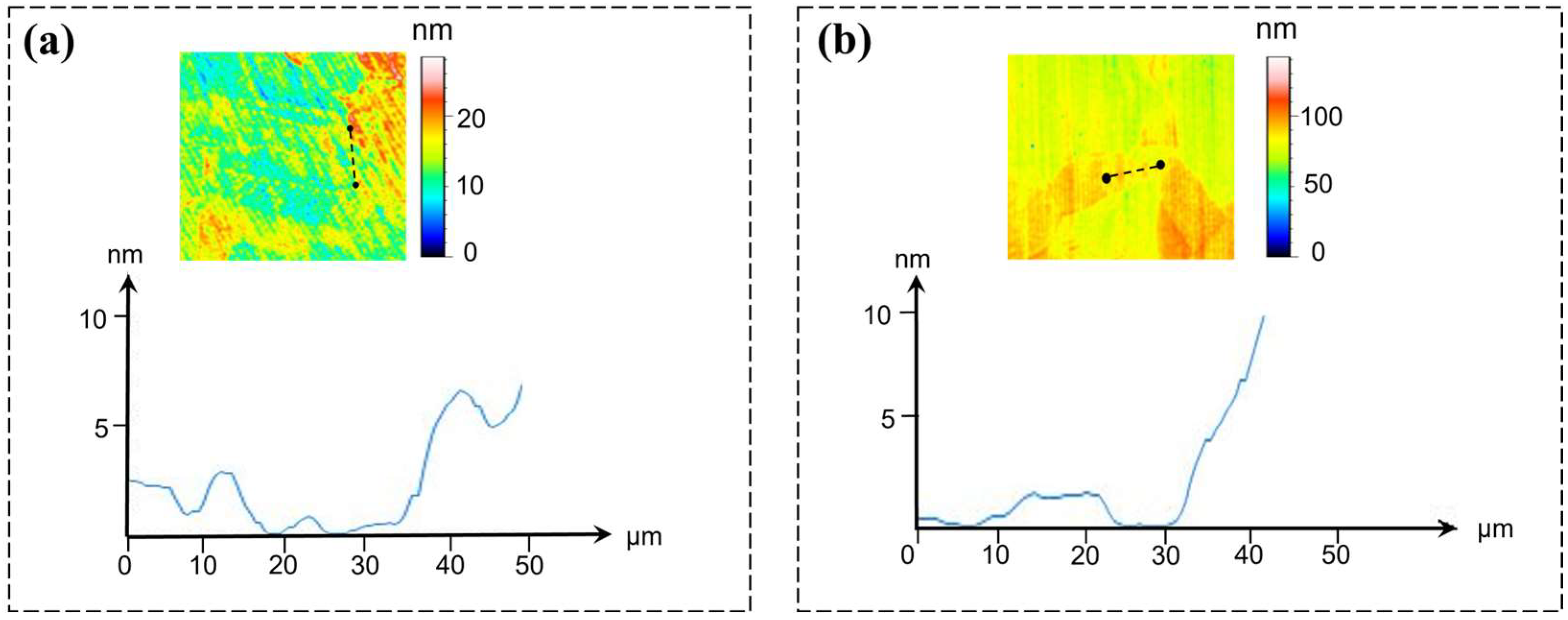

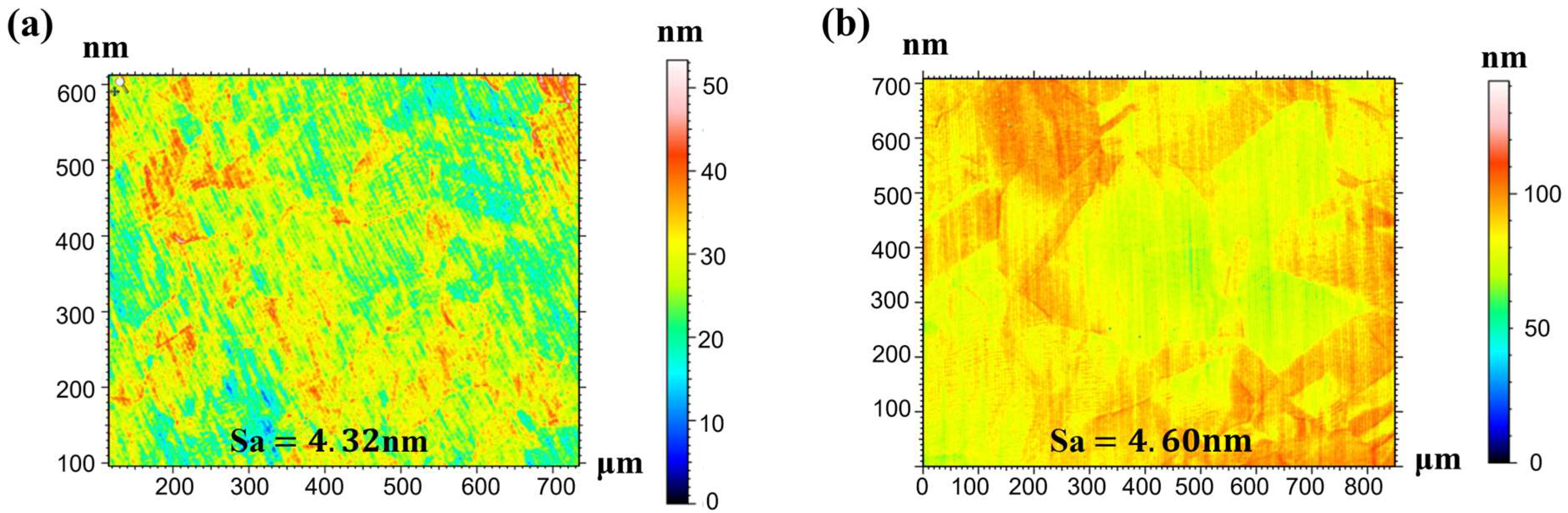

3.3.1. Effect of Grain Size on Micro-Scale Grain Boundary Step Height

3.3.2. Effect of Grain Size on Macroscopic Surface Quality

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cao, H.; Guo, Z.T.; Feng, R.C.; Li, H.Y.; Fu, R.; Zhou, Y.C.; Liu, J.H. Numerical simulation of nano-cutting behaviors for polycrystalline γ−TiAl alloy: The effect of grain sizes. J. Manuf. Process. 2023, 102, 169–181. [Google Scholar] [CrossRef]

- Li, R.; Cheng, C.M.; Dong, F.; Wu, G.; Shen, W.; Liang, K.; Wang, S.Z.; Liu, S. A study on the mechanical properties of polycrystalline aluminum nitride based on molecular dynamics simulation. Mater. Today Nano 2025, 29, 100581. [Google Scholar] [CrossRef]

- Xue, Z.F.; Lai, M.; Xu, F.F.; Fang, F.Z. Material deformation mechanism of polycrystalline tin in nanometric cutting. J. Manuf. Process. 2024, 132, 735–743. [Google Scholar] [CrossRef]

- Yao, X.X.; Hafiz, H.; Chen, L.; Cai, W.; Mao, Z.R.; Hu, S.Y. Coarse-grained molecular dynamics modelling of lithium-ion battery electrode drying: A sensitivity analysis. J. Manuf. Process. 2025, 144, 54–59. [Google Scholar] [CrossRef]

- Liu, H.J.; Zhang, Q.L.; Zhou, J. Residual stress distribution of silicon wafers machined by rotational grinding based on molecular dynamics. J. Manuf. Process. 2024, 119, 565–573. [Google Scholar] [CrossRef]

- Papanikolaou, M.; Salonitis, K. Grain size effects on nanocutting behaviour modelling based on molecular dynamics simulations. Appl. Surf. Sci. 2021, 540, 148291. [Google Scholar] [CrossRef]

- Hirel, P. Atomsk: A tool for manipulating and converting atomic data files. Comput. Phys. Commun. 2015, 197, 212–219. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—The open visualization tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Yang, X.X.; Zhang, B.; Bai, Q.; Kang, R.K.; Tang, J.G. Effect of grain size on subsurface characterization of pure iron subjected to orthogonal cutting. Int. J. Adv. Manuf. Technol. 2022, 120, 5793–5806. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Y.; Yang, X. Nano-scale machining of polycrystalline coppers—Effects of grain size and machining parameters. Nanoscale Res. Let. 2013, 8, 500. [Google Scholar] [CrossRef]

- Jia, H.L.; Liu, X.J.; Li, Z.X. The effect of grain size on the deformation mechanisms and mechanical properties of polycrystalline TiN: A molecular dynamics study. Comput. Mater. Sci. 2018, 143, 189–194. [Google Scholar] [CrossRef]

- Li, M.; Reece, M.J. Influence of grain size on the indentation-fatigue behavior of alumina. J. Am. Ceram. Soc. 2000, 83, 967–970. [Google Scholar] [CrossRef]

- Daw, M.S.; Baskes, M.I. Embedded-atom method: Derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 1984, 2, 6443. [Google Scholar] [CrossRef]

- Liu, D.H.; Wang, G.; Yu, J.C. Molecular dynamics simulation on formation mechanism of grain boundary steps in micro-cutting of polycrystalline copper. Comput. Mater. Sci. 2017, 126, 418–425. [Google Scholar] [CrossRef]

- Jang, H.; Farkas, D. Interaction of lattice dislocations with a grain boundary during nanoindentation simulation. Mater. Let. 2007, 6, 868–871. [Google Scholar] [CrossRef]

- Narayan, J. Size and interface control of novel nanocrystalline materials using pulsed laser deposition. J. Nanopart. Res. 2004, 2, 91–96. [Google Scholar] [CrossRef]

- Shi, J.; Liu, C.R. The influence of material models on finite element simulation of machining. J. Manuf. Sci. Eng. 2004, 126, 849–857. [Google Scholar] [CrossRef]

- Van Swygenhoven, H.; Derlet, P.M. Grain-boundary sliding in nanocrystalline fcc metals. Phys. Rev. B 2001, 64, 224105. [Google Scholar] [CrossRef]

- Schiøtz, J. Atomic-scale modeling of plastic deformation of nanocrystalline copper. Scr. Mater. 2004, 51, 837–841. [Google Scholar] [CrossRef]

- Heino, P.; Häkkinen, H.; Kaski, K. Molecular-dynamics study of mechanical properties of copper. Europhys. Let. 1998, 41, 273. [Google Scholar] [CrossRef]

- Ji, C.; Shi, J.; Wang, Y.; Liu, Z. A numeric investigation of friction behaviors along tool/chip interface in nanometric machining of a single crystal copper structure. Int. J. Adv. Manuf. Technol. 2013, 68, 365–374. [Google Scholar] [CrossRef]

- Fang, T.; Weng, C. Three-dimensional molecular dynamics analysis of processing using a pin tool on the atomic scale. Nanotechnology 2000, 11, 148–153. [Google Scholar] [CrossRef]

| Model Parameters | Parameters |

|---|---|

| Grain Count | 5, 10, 15, 20 |

| Material | Polycrystalline copper |

| Material Dimensions | |

| Timestep | 1 fs |

| Tool Material | Diamond |

| Tool Edge Radius | 3 nm |

| Tool Rake Angle | 0° |

| Tool Clearance Angle | 10° |

| Cutting Depth | 5 nm |

| Cutting Velocity | 0.1 nm/fs |

| Cutting Direction | on (0 0 1) |

| Potential Function | Tersoff, Morse |

| Cutting Length | 30 nm |

| Ensemble | NVT, NVE |

| Process Parameters | Parameters |

|---|---|

| Cutting Depth | 5 μm |

| Feed Rate | 5 μm/r |

| Rotational Speed | 1200 r/min |

| Coolant-Lubrication | Ethanol spray |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Yue, X.; You, K.; Wang, W. Effect of Grain Size on Polycrystalline Copper Finish Quality of Ultra-Precision Cutting. Micromachines 2025, 16, 1133. https://doi.org/10.3390/mi16101133

Zhang C, Yue X, You K, Wang W. Effect of Grain Size on Polycrystalline Copper Finish Quality of Ultra-Precision Cutting. Micromachines. 2025; 16(10):1133. https://doi.org/10.3390/mi16101133

Chicago/Turabian StyleZhang, Chuandong, Xinlei Yue, Kaiyuan You, and Wei Wang. 2025. "Effect of Grain Size on Polycrystalline Copper Finish Quality of Ultra-Precision Cutting" Micromachines 16, no. 10: 1133. https://doi.org/10.3390/mi16101133

APA StyleZhang, C., Yue, X., You, K., & Wang, W. (2025). Effect of Grain Size on Polycrystalline Copper Finish Quality of Ultra-Precision Cutting. Micromachines, 16(10), 1133. https://doi.org/10.3390/mi16101133