Research on Radiation-Hardened RCC Isolated Power Supply for High-Radiation-Field Applications

Abstract

1. Introduction

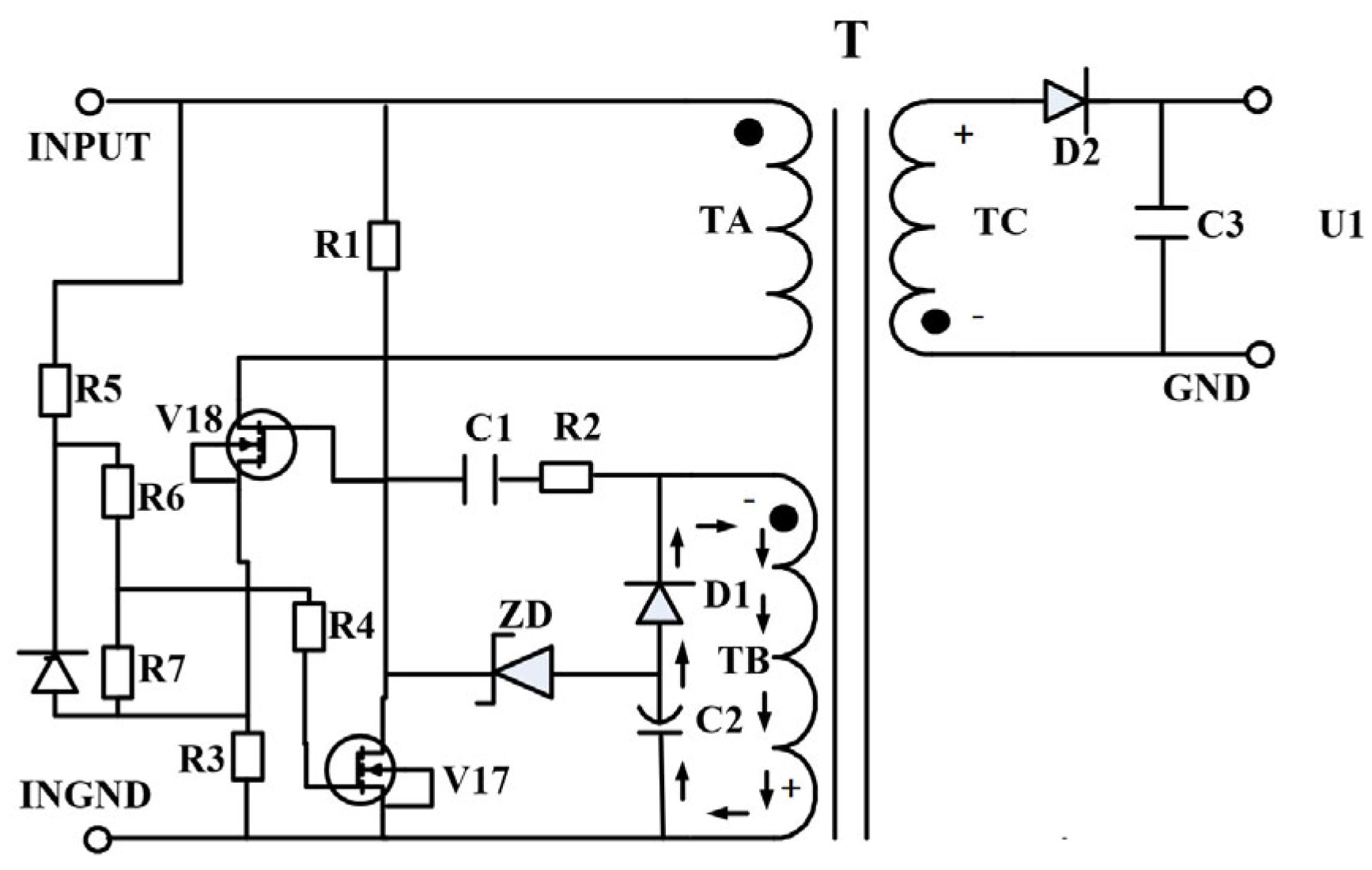

2. Circuit Schematic Block Diagram

3. Circuit Parameter Design

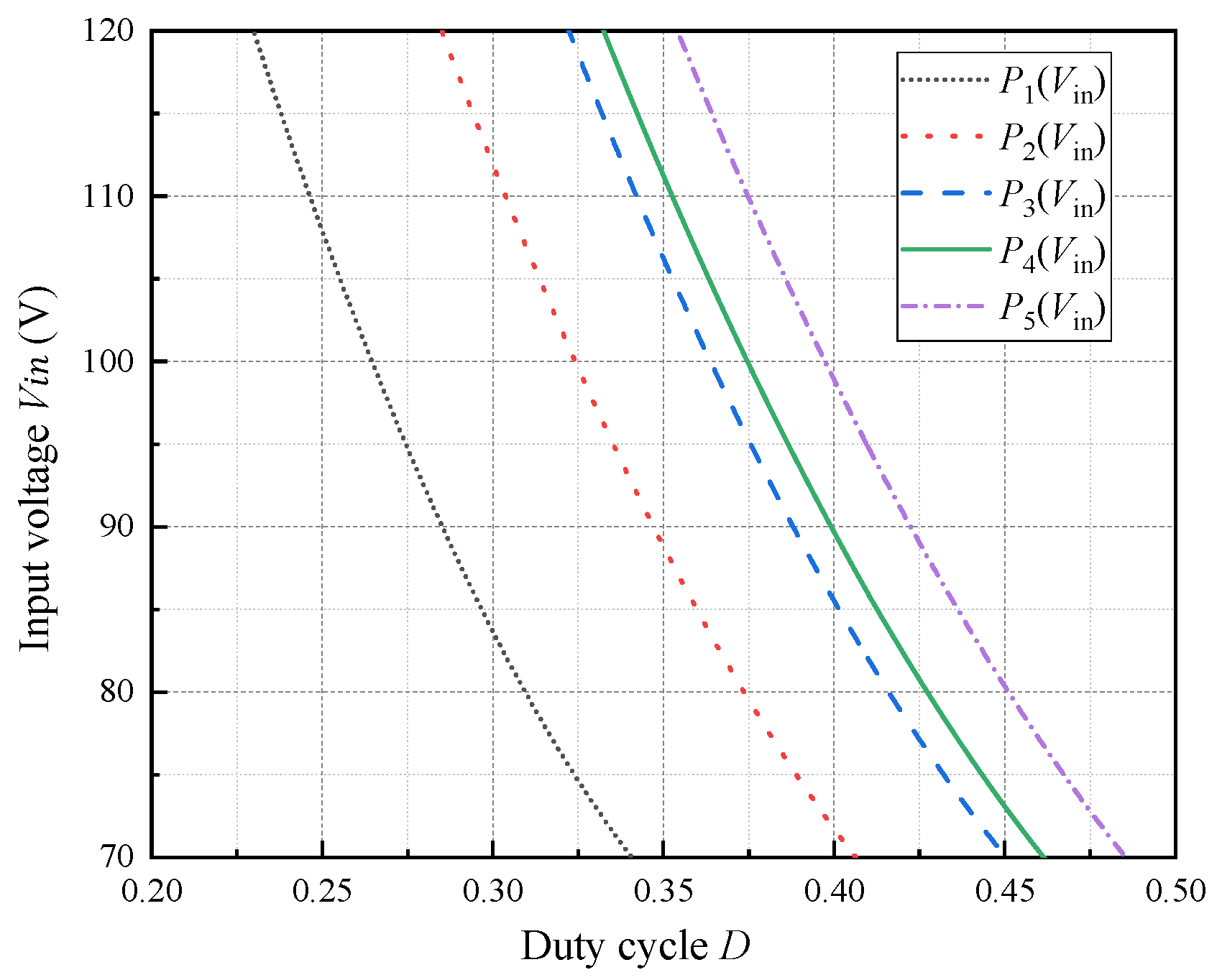

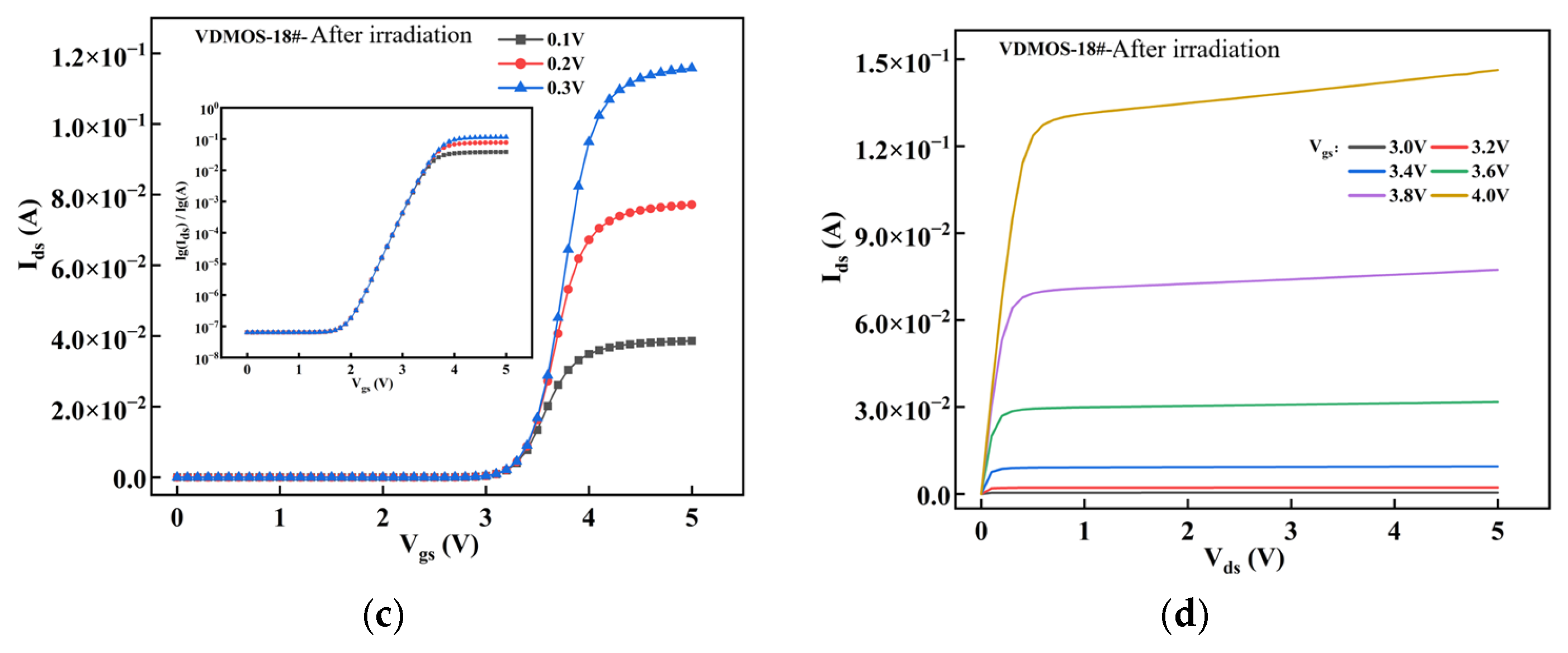

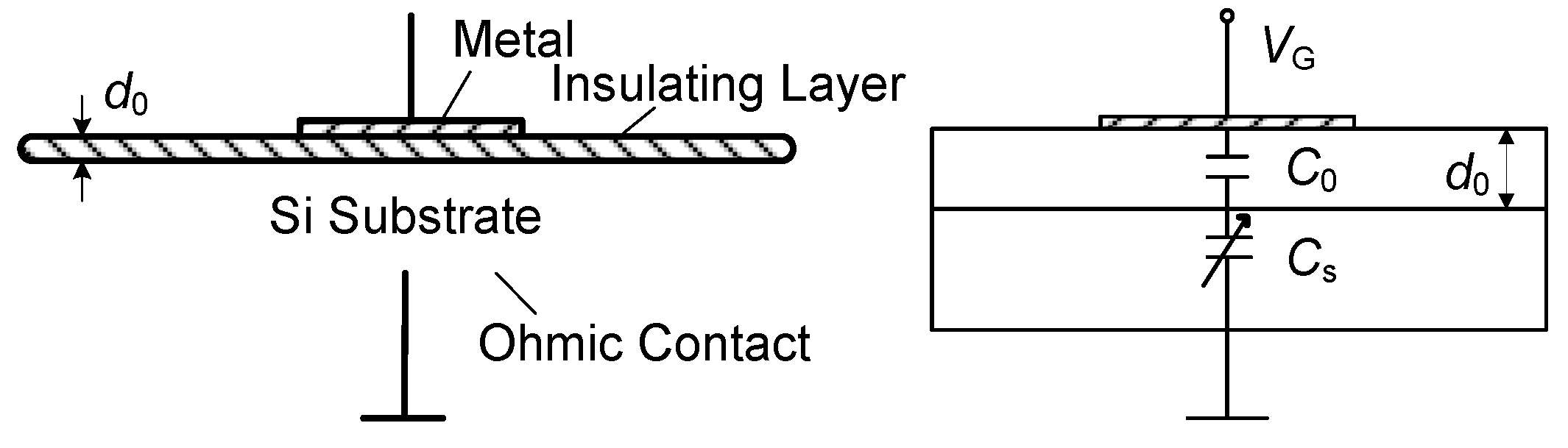

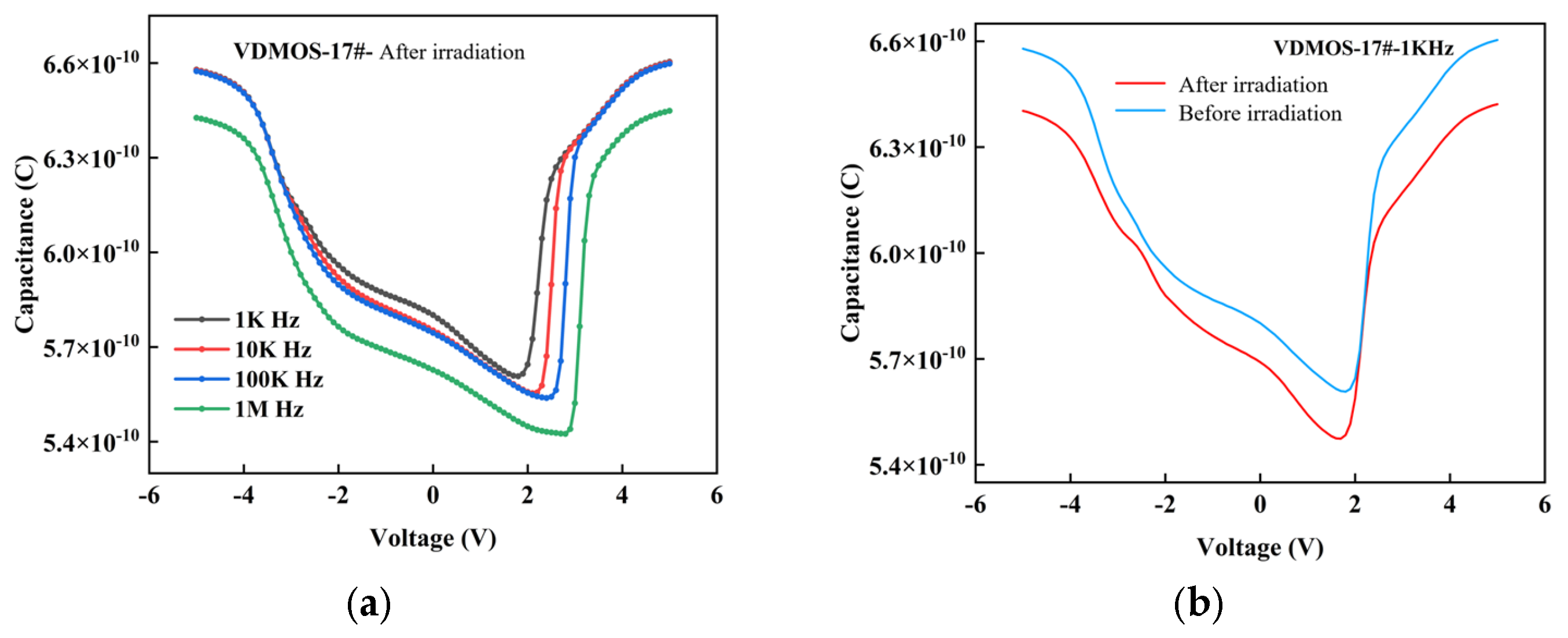

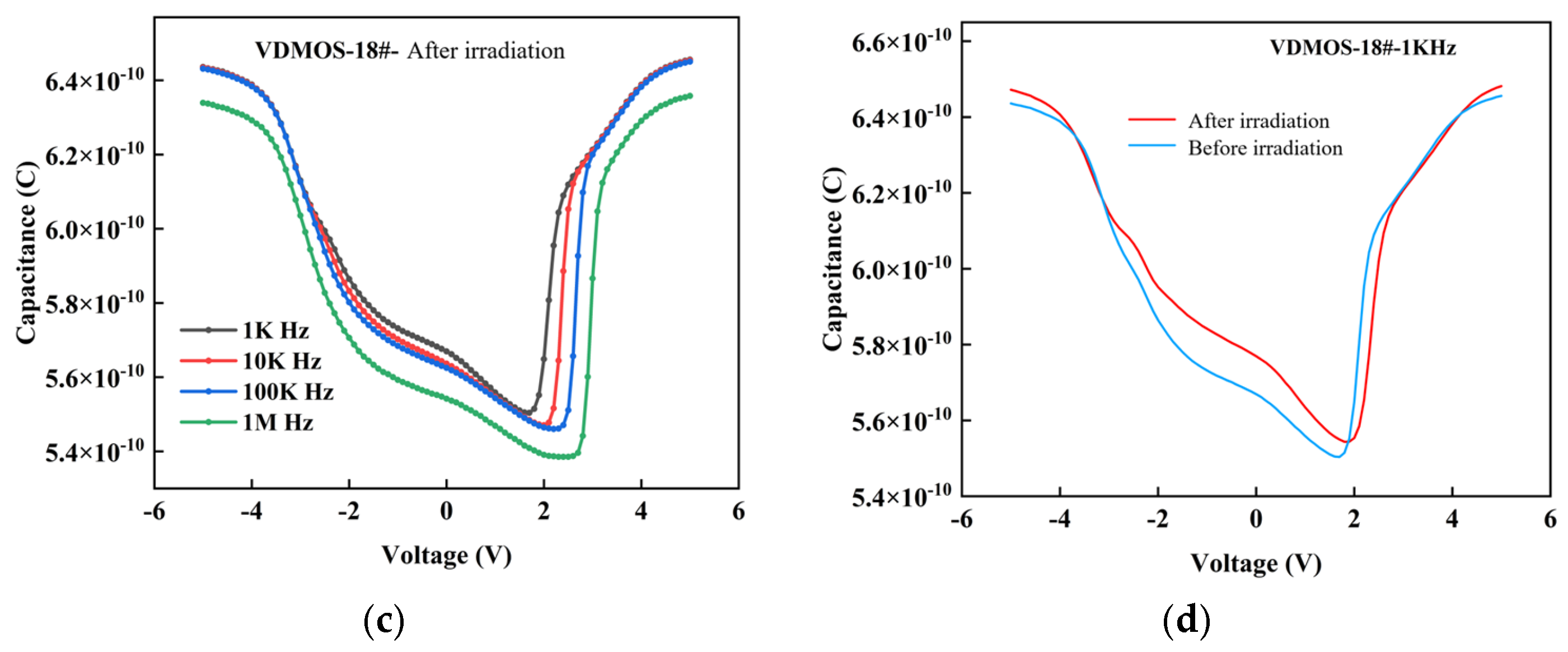

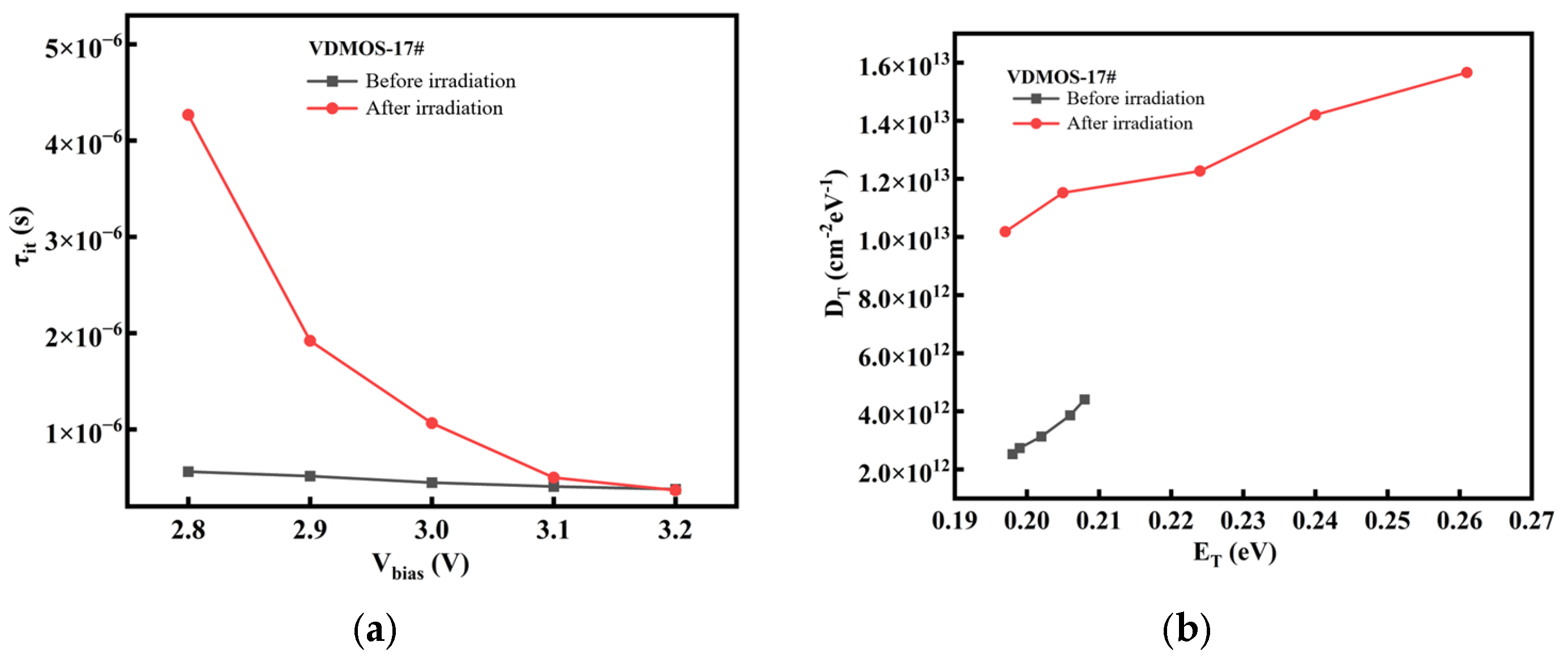

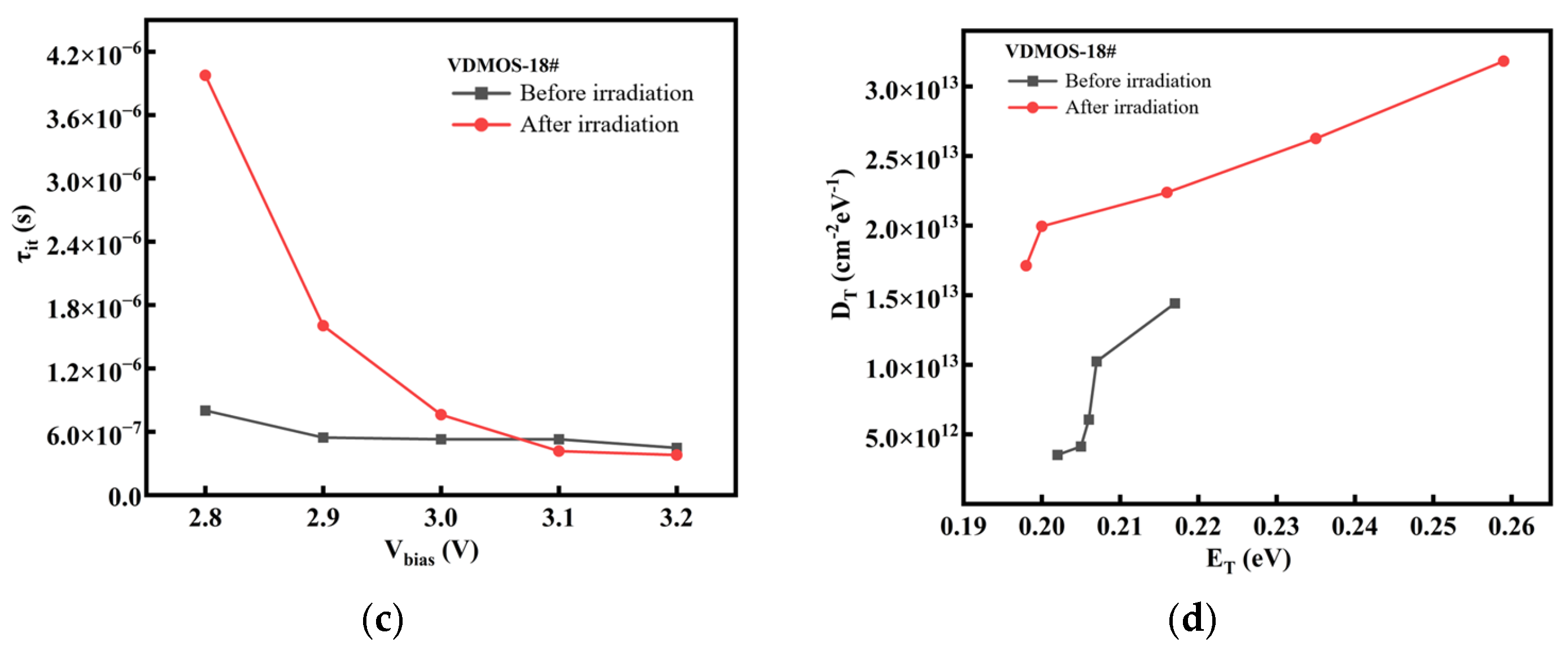

3.1. Selection of the Turns Ratio

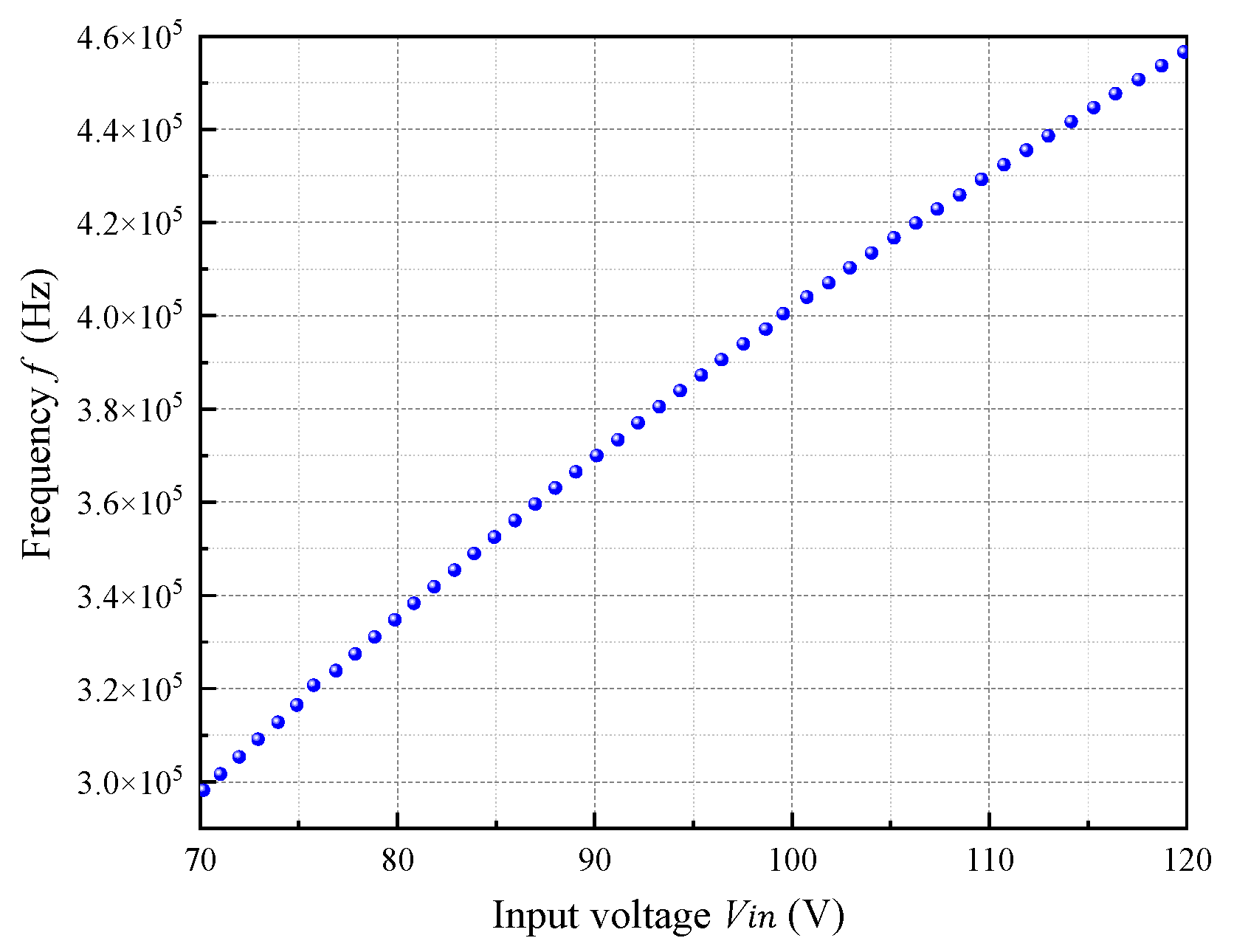

3.2. Frequency Selection

3.3. Peak Primary Current Ip

4. Transformer Design

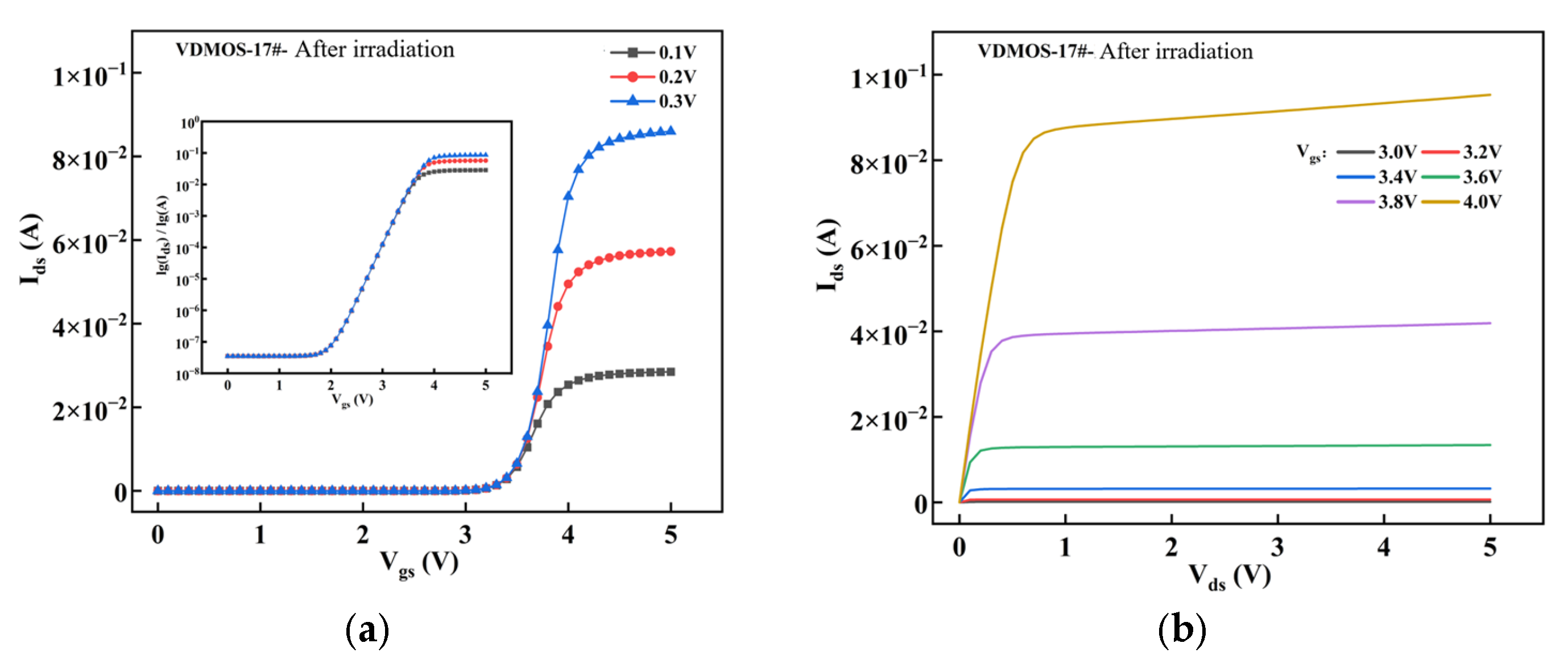

5. Irradiation Test Results and Discussion

6. Results and Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Talukder, A.; Ifty, M.R.; Al Fahad, A. Comprehensive review of GaN HEMTs: Architectures, recent developments, reliability concerns, challenges, and multifaceted applications. e-Prime—Adv. Electr. Eng. Electron. Energy 2025, 13, 101059. [Google Scholar] [CrossRef]

- Pan, S.; Feng, S.; Li, X.; Feng, Z.; Lu, X.; Bai, K.; Zhang, Y. Effects of 1 MeV electron radiation on the AlGaN/GaN high electron mobility transistors. J. Semicond. 2024, 45, 092503. [Google Scholar] [CrossRef]

- Yang, J.; Sun, X.; Yu, X.; Qin, Z.; Li, X. Characteristics of displacement defects in PNP transistors caused by heavy ion irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2020, 467, 86–90. [Google Scholar] [CrossRef]

- Ye, E.-L.; Lai, Y.-F.; Shen, C.-X.; Hou, Y.-J.; Nan, H.-J. Simulation of displacement damage in Si & SiO2 caused by protons. Radiat. Phys. Chem. 2025, 228, 112417. [Google Scholar] [CrossRef]

- Zimmaro, A.; Zoppo, V.; Ferraro, R.; Danzeca, S. Investigation of Radiation Effects on GaN HEMTs for Particle Accelerators. CERN Indico. 2025. Available online: https://indico.cern.ch/event/1500025/contributions/6323254/attachments/3004809/5296426/Investigation%20of%20Radiation%20Effects%20on%20GaN%20HEMTs%20for%20Particle%20Accelerators.pdf (accessed on 1 September 2025).

- Wang, C.; Bai, X.; Chen, W.; Yang, S.; Liu, Y.; Jin, X.; Ding, L. Simulation of synergistic effects on lateral PNP bipolar transistors induced by neutron and gamma irradiation. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2015, 796, 108–113. [Google Scholar] [CrossRef]

- Wu, K.; Lv, X.; Zou, D.; Lu, Y.; Li, J.; Zhao, Y. Neutron flux effect in silicon-based bipolar junction transistors exposed to californium-252. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2022, 1034, 166743. [Google Scholar] [CrossRef]

- Li, Q.; Lu, J.; Situ, Z.; Liu, X.; Zhang, Y.; Kong, X.; Li, C. Study of irradiation damage in silicon at different scales. Mater. Today Commun. 2024, 38, 108225. [Google Scholar] [CrossRef]

- Rasel, M.A.J.; Stepanoff, S.P.; Wetherington, M.; Haque, A.; Wolfe, D.E.; Ren, F.; Pearton, S. Thermo-mechanical aspects of gamma irradiation effects on GaN HEMTs. Appl. Phys. Lett. 2022, 120, 124101. [Google Scholar] [CrossRef]

- Hu, P.-P.; Xu, L.-J.; Zhang, S.-X.; Zhai, P.-F.; Lv, L.; Yan, X.-Y.; Li, Z.-Z.; Cao, Y.-R.; Zheng, X.-F.; Zeng, J.; et al. Failure mechanisms of AlGaN/GaN HEMTs irradiated by high-energy heavy ions with and without bias. Nucl. Sci. Technol. 2025, 36, 156–165. [Google Scholar] [CrossRef]

- Feng, Z.; Pan, S.; Feng, S.; Zheng, X.; Wang, Y.; Zhang, B.; Lu, X. γ-irradiation induced trapping effects on off-state and on-state p-GaN Gate high-electron-mobility transistors. Mater. Sci. Semicond. Process. 2025, 198, 109799. [Google Scholar] [CrossRef]

- Ravindran, R.; Massoud, A.M. An overview of wide and ultra wide bandgap semiconductors for next-generation power electronics applications. Microelectron. Eng. 2025, 299, 112348. [Google Scholar] [CrossRef]

- Zhang, G.; Dong, S.; Xin, Q.; Guo, L.; Wang, X.; Xin, G.; Qin, N.; Lan, X.; Guo, C.; Wang, W.; et al. Transistor-level thermal management in wide and ultra-wide bandgap power semiconductor transistors: A review. Int. J. Therm. Sci. 2026, 219, 110200. [Google Scholar] [CrossRef]

- Li, H.; Guo, H.; Cao, R.; Tu, H.; Huang, X.; Xue, Y.; Zeng, X. Study on electron and gamma irradiation effects and damage mechanism of GaN HEMT. Microelectron. Reliab. 2025, 167, 115616. [Google Scholar] [CrossRef]

- Baba, T.; Siddiqui, N.A.; Saidin, N.B.; Yusoff, S.H.M.; Sani, S.F.B.A.; Karim, J.A.; Hasbullah, N.F. Radiation-induced degradation of silicon carbide MOSFETs–A review. Mater. Sci. Eng. B 2024, 300, 117096. [Google Scholar] [CrossRef]

- Goud, R.S.P.; Akkanaboina, M.; Machiboyina, S.; Kumar, K.R.; Anjum, A.; Khan, S.A.; Prakash, A.P.G.; Pathak, A.P.; Rao, S.V.S.N. A study on the gamma and swift heavy ion irradiation-induced effects on the electrical properties of TaOx-based MOS capacitors. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2024, 554, 165455. [Google Scholar] [CrossRef]

- Neamen, D.A. Semiconductor Physics and Devices: Basic Principles, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2012. [Google Scholar]

- Streetman, B.G.; Banerjee, S.K. Solid State Electronic Devices, 7th ed.; Pearson: Boston, MA, USA, 2015. [Google Scholar]

| Input Voltage (V) | Input Current (A) | Output Voltage (V) | Voltage Variation (mV) | Load Variation (mV) | Efficiency |

|---|---|---|---|---|---|

| 70 | 0.275 | 12.031 | - | - | 77.80% |

| 120 | 0.163 | 12.043 | 12 | - | 76.50% |

| 100 (Typical value) | 0.191 | 12.038 | - | - | 78.20% |

| 100 | 0.03 (No load) | 12.036 | - | 2 | - |

| Input Voltage (V) | Input Current (A) | Output Voltage (V) | Voltage Variation (mV) | Load Variation (mV) | Efficiency |

|---|---|---|---|---|---|

| 70 | 0.277 | 12.015 | - | - | 77.30% |

| 120 | 0.164 | 12.031 | 16 | - | 76.10% |

| 100 (Typical value) | 0.194 | 12.017 | - | - | 77.50% |

| 100 | 0.04 (No load) | 12.005 | - | 12 | - |

| Input Voltage (V) | Input Current (A) | Output Voltage (V) | Voltage Variation (mV) | Load Variation (mV) | Efficiency |

|---|---|---|---|---|---|

| 70 | 0.049 | 12.142 | - | - | 58.3% |

| 120 | 0.026 | 12.186 | 44 | - | 63.1% |

| 100 (Typical value) | 0.032 | 12.163 | - | - | 61.8% |

| 100 | 0.005 (No load) | 12.231 | - | 68 | - |

| Input Voltage (V) | Input Current (A) | Output Voltage (V) | Voltage Variation (mV) | Load Variation (mV) | Efficiency |

|---|---|---|---|---|---|

| 70 | 0.053 | 8.805 | - | - | 53.1% |

| 120 | 0.028 | 9.151 | 346 | - | 58.3% |

| 100 (Typical value) | 0.036 | 8.981 | - | - | 56.3% |

| 100 | 0.10 (No load) | 9.183 | - | 202 | - |

| Parameters | Test Conditions | Minimum Value | Maximum Value |

|---|---|---|---|

| V(BR)DSS | VGs = 0 V, ID = 1 mA | 150 V | - |

| VGS(th) | VDs = VGs, ID = 1 mA | 1.5 V | 5 V |

| IGSSF | VGS = 20 V, VDS = 0 V | −200 nA | 200 nA |

| IGSSR | VGS = 20 V, VDS = 0 V | - | - |

| IDSS | VGs = 0 V, VDs = 80 V | 150 V | A |

| RDS(ON) | VGs = 12 V, ID = 5 A | 1.5 V |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, X.; Yin, H.; Wu, Y.; Zhu, L.; Hong, K.; He, Q.; Zhou, Z.; Dong, G. Research on Radiation-Hardened RCC Isolated Power Supply for High-Radiation-Field Applications. Micromachines 2025, 16, 1135. https://doi.org/10.3390/mi16101135

Lu X, Yin H, Wu Y, Zhu L, Hong K, He Q, Zhou Z, Dong G. Research on Radiation-Hardened RCC Isolated Power Supply for High-Radiation-Field Applications. Micromachines. 2025; 16(10):1135. https://doi.org/10.3390/mi16101135

Chicago/Turabian StyleLu, Xiaojin, Hong Yin, Youran Wu, Lihong Zhu, Ke Hong, Qifeng He, Ziyu Zhou, and Gang Dong. 2025. "Research on Radiation-Hardened RCC Isolated Power Supply for High-Radiation-Field Applications" Micromachines 16, no. 10: 1135. https://doi.org/10.3390/mi16101135

APA StyleLu, X., Yin, H., Wu, Y., Zhu, L., Hong, K., He, Q., Zhou, Z., & Dong, G. (2025). Research on Radiation-Hardened RCC Isolated Power Supply for High-Radiation-Field Applications. Micromachines, 16(10), 1135. https://doi.org/10.3390/mi16101135