Pipeline Elbow Corrosion Simulation for Strain Monitoring with Fiber Bragg Gratings

Abstract

1. Introduction

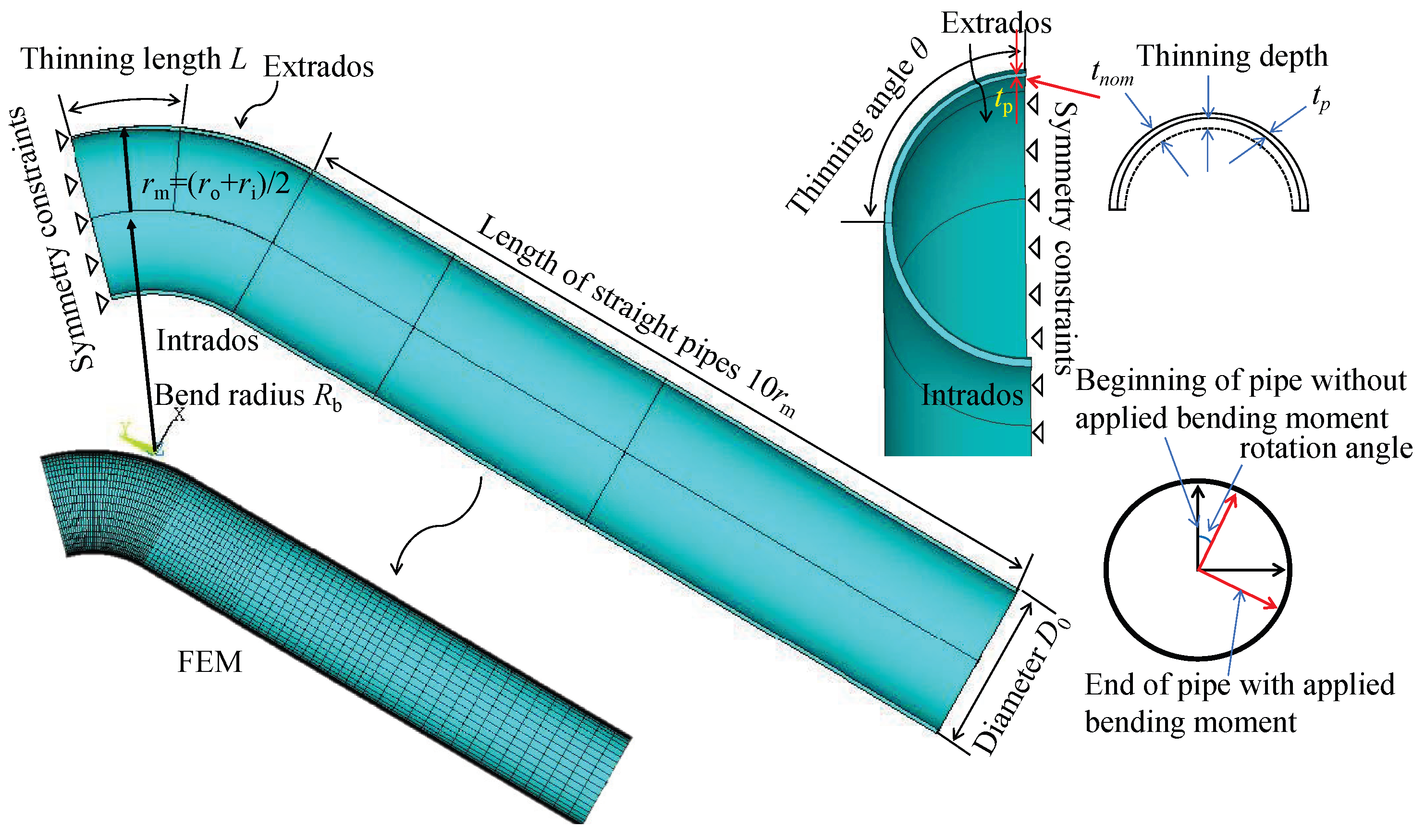

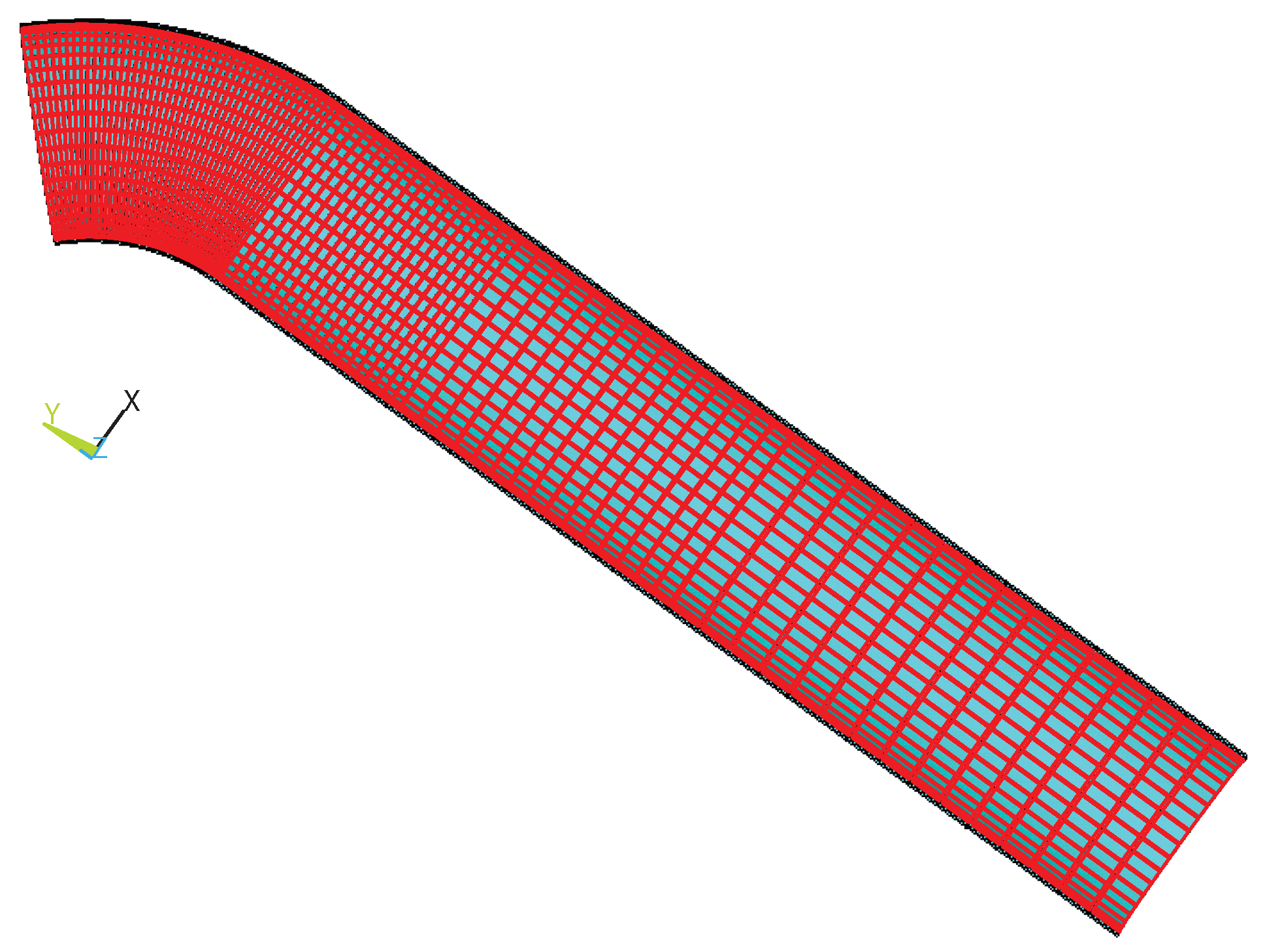

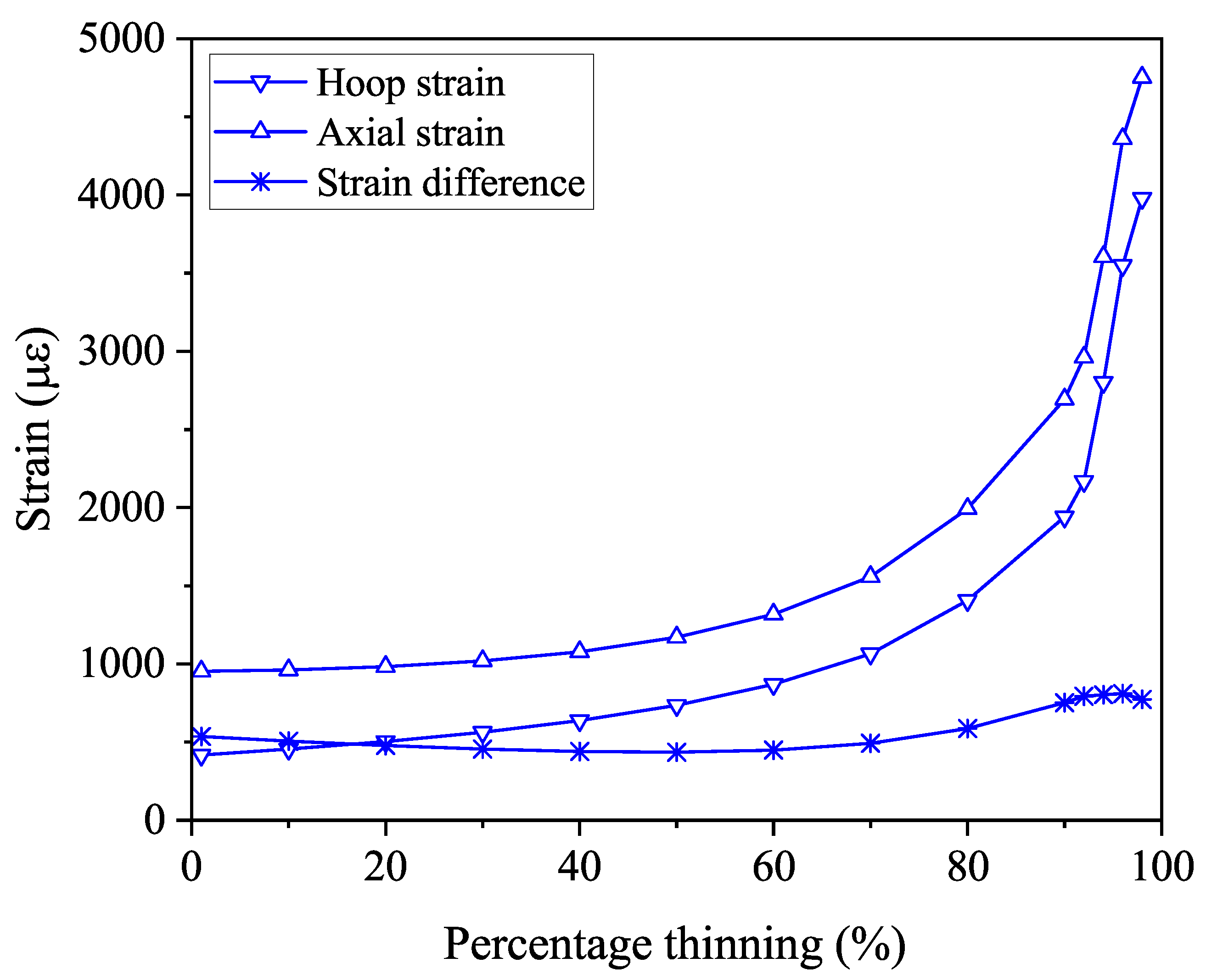

2. Principle of Measuring the Wall Thickness by FBG Corrosion Sensor

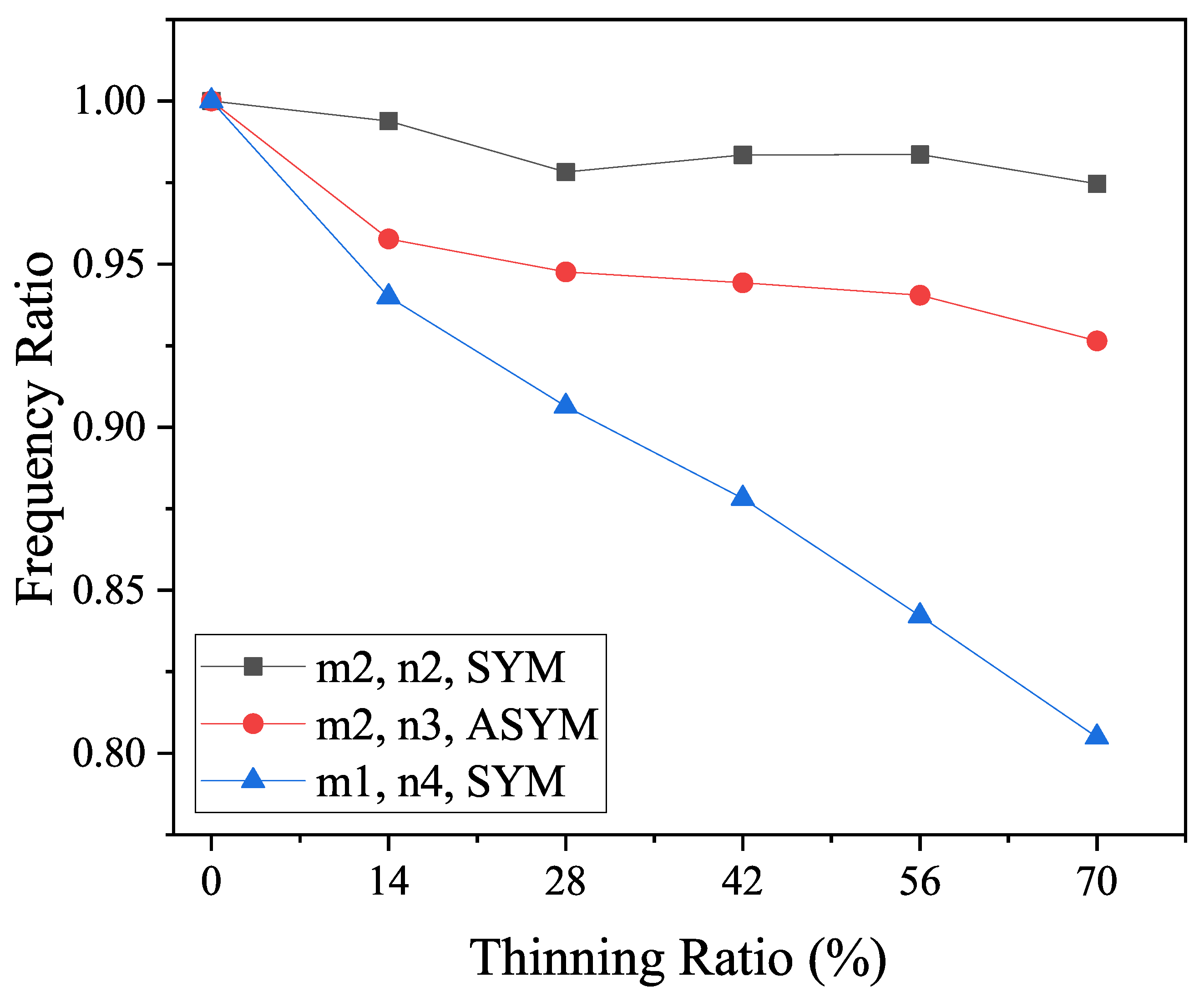

3. Simulation of a Pipe Elbow with Wall Thickness Reduction under Various Loads

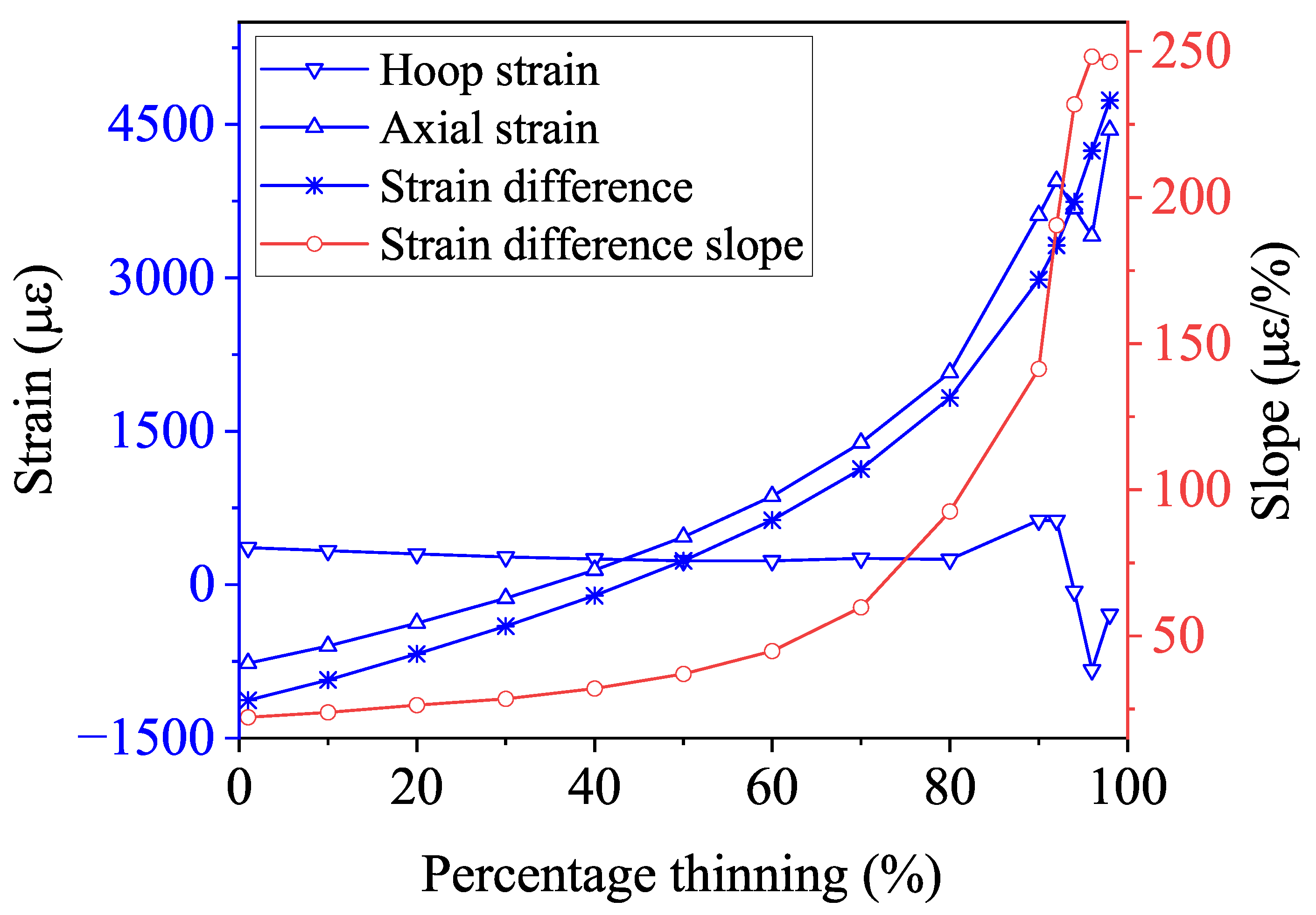

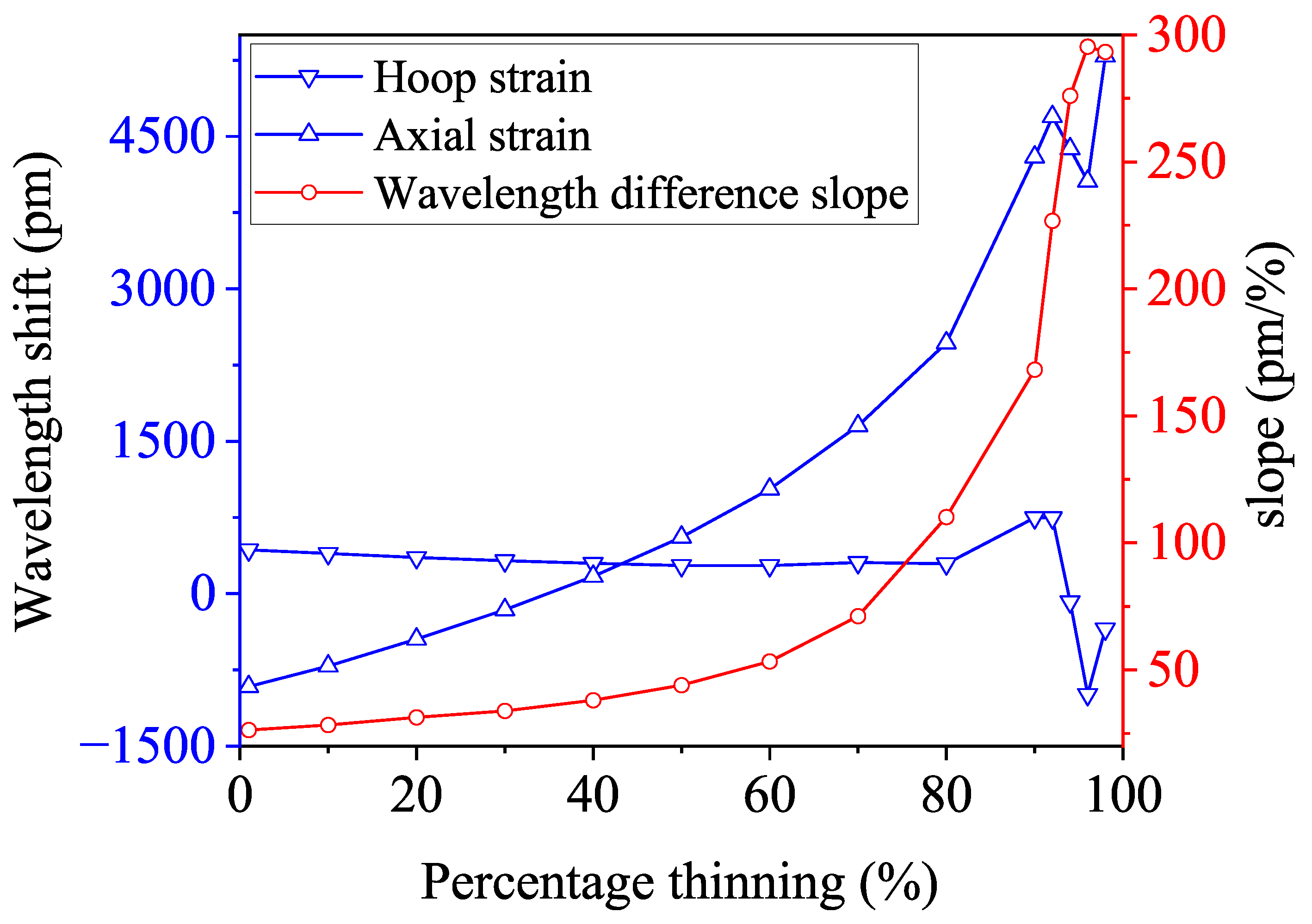

3.1. Internal Pressure on the Inner Wall of the Pipe Elbow

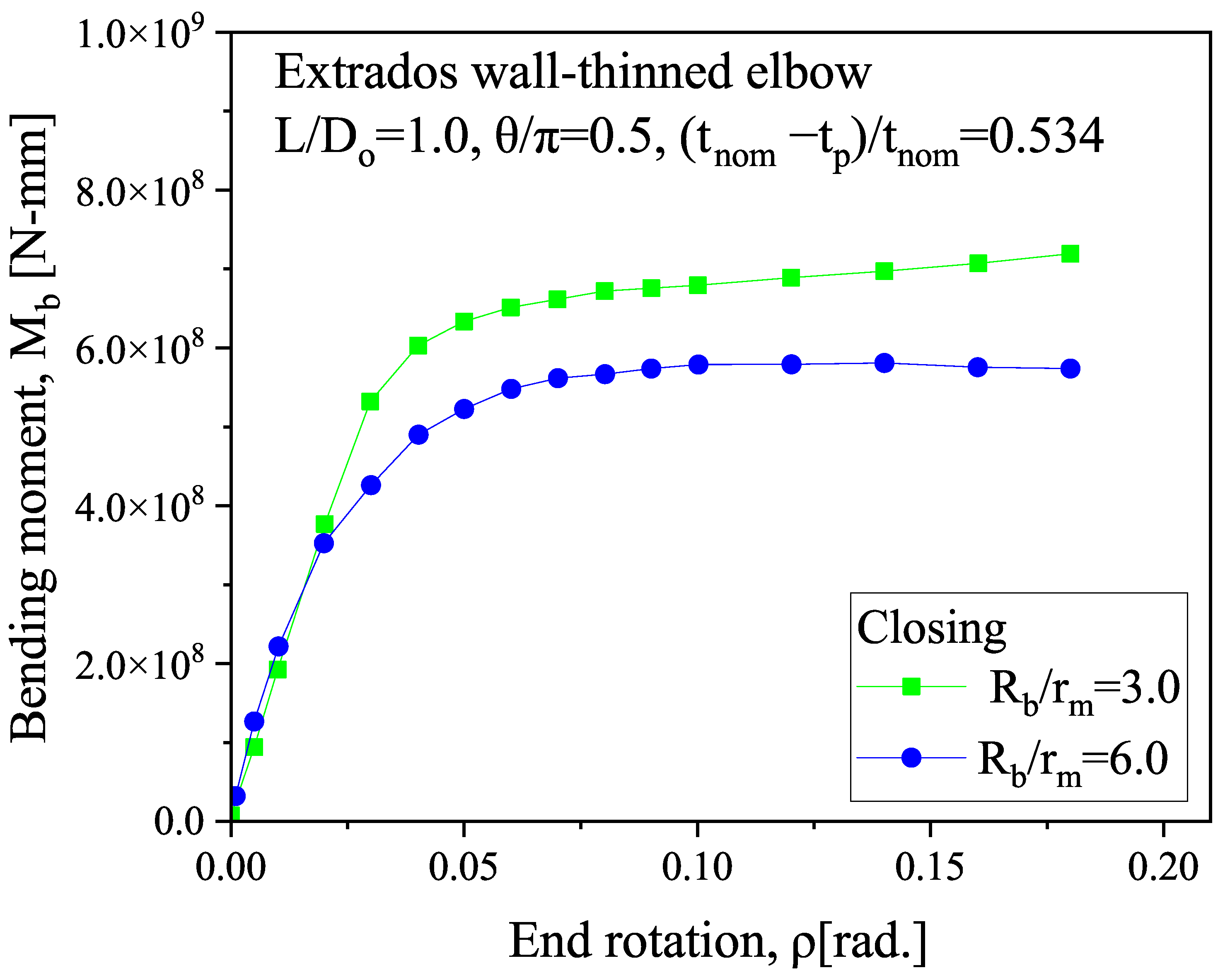

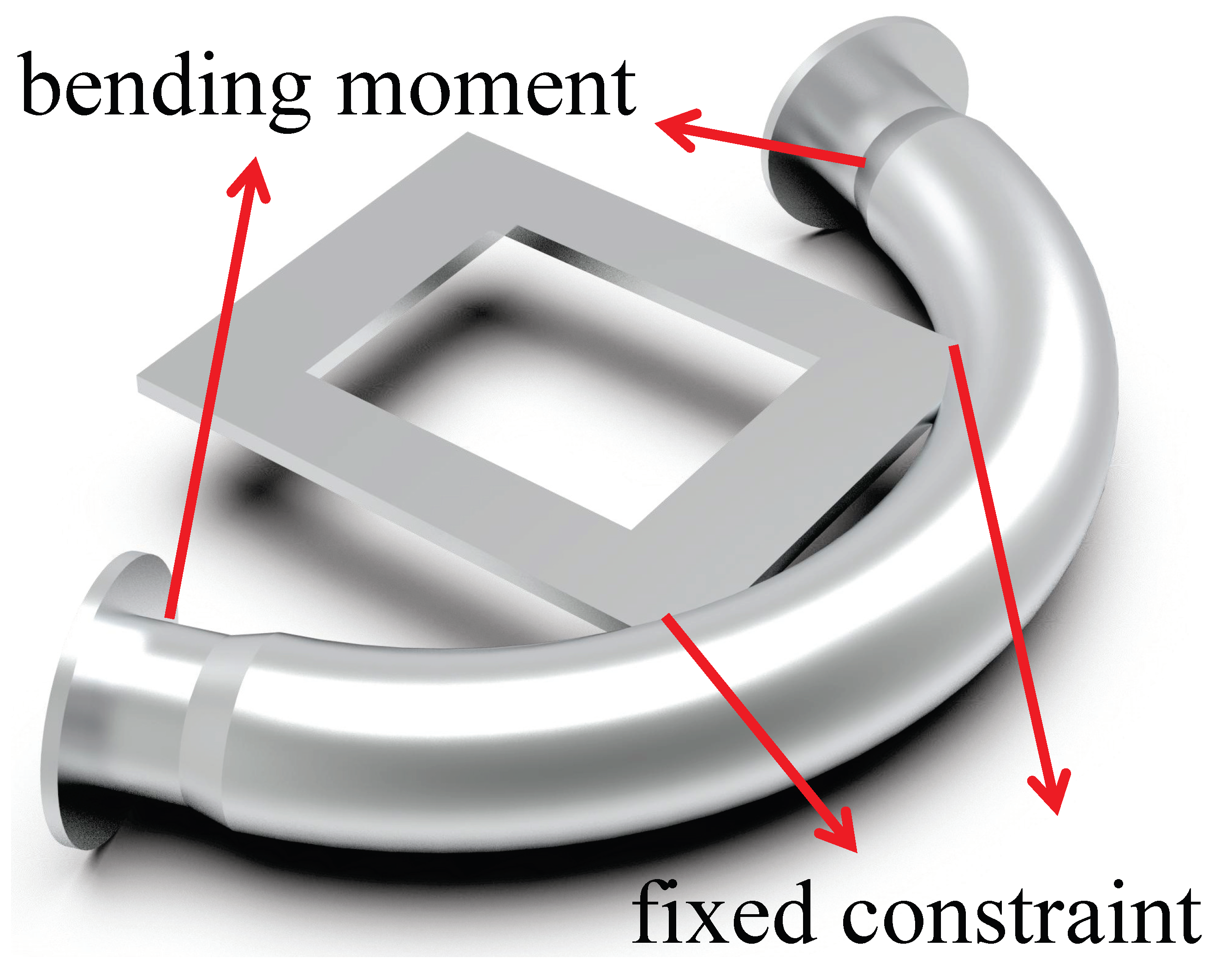

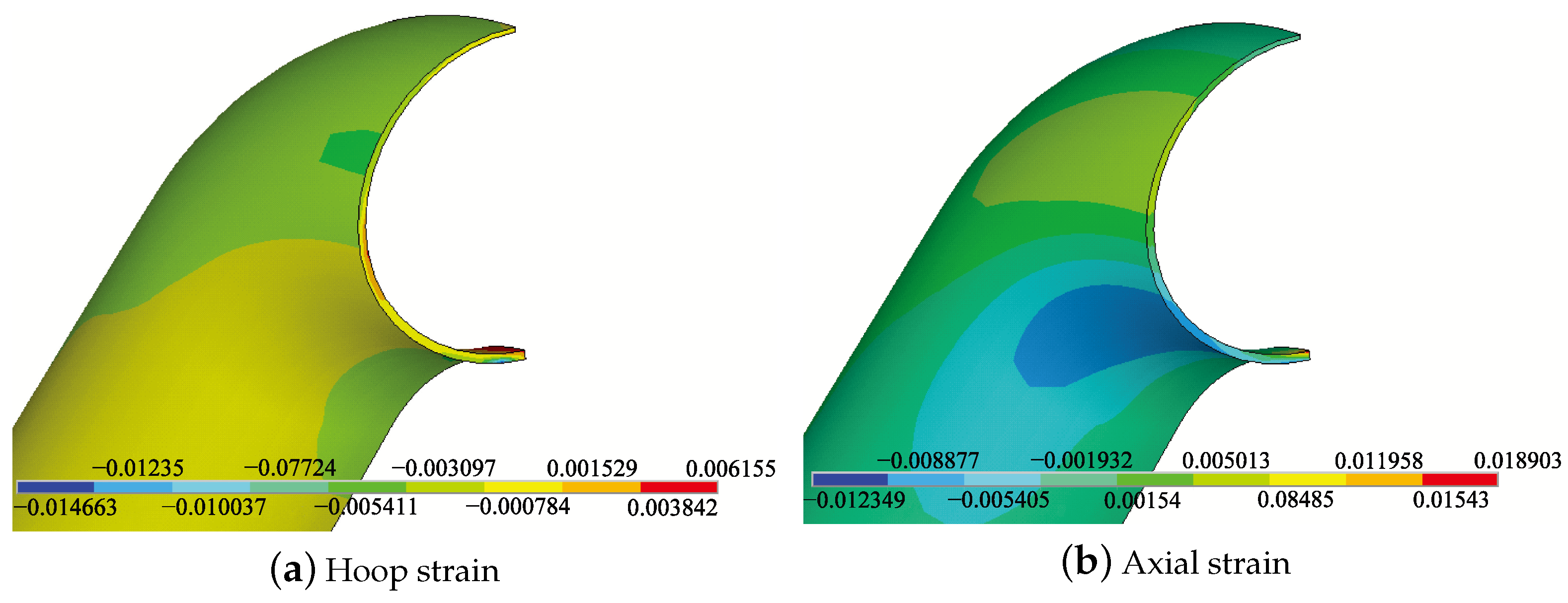

3.2. Bending Moment on the Ending of the Pipe Elbow

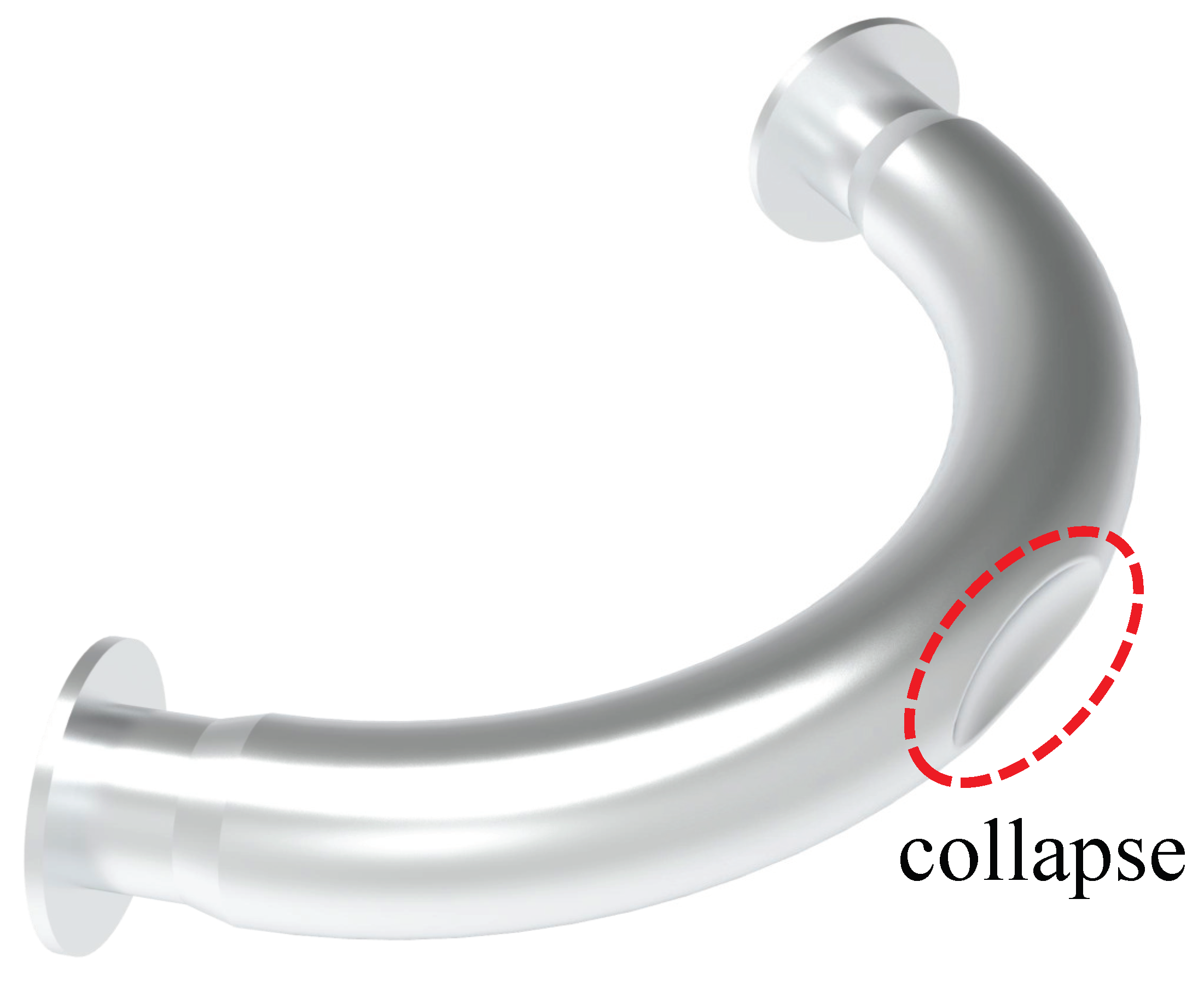

3.3. Combined Internal Pressure and Bending Moment

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Outer radius of the pipe elbow | |

| Inner radius of the pipe elbow | |

| Average of outer and inner radii | |

| Thickness of the pipe elbow | |

| Radius of curvature of the pipe elbow | |

| h | Half of thickness of the pipe elbow |

| Center angle of curvature of the pipe elbow | |

| Bending radius of the pipe elbow | |

| Diameter of the pipe elbow | |

| L | Thinning length of the pipe elbow |

| Hoop strain of the pipe elbow ( ) | |

| Axial strain of the pipe elbow ( ) | |

| E | Young’s modulus of the pipe elbow |

| Poisson’s ratio of the pipe elbow | |

| Initial Bragg wavelength of FBG | |

| Change in Bragg wavelength of FBG | |

| k | Strain coefficient of FBG |

| Thermal expansion coefficient | |

| Thermo-optic coefficient | |

| Temperature change of the pipe elbow (°C) |

References

- Hong, B.; Li, Y.; Li, X.; Li, G.; Huang, A.; Ji, S.; Li, W.; Gong, J.; Guo, J. Experimental investigation of erosion rate for Gas-Solid two-phase flow in 304 stainless/L245 carbon steel. Pet. Sci. 2022, 19, 1347–1360. [Google Scholar] [CrossRef]

- He, X.; Gao, P.; Wang, J.; Zhang, Z. Experimental investigation on hot water rapid depressurization process characteristics inside and outside of the ruptured pipeline. Nucl. Eng. Des. 2024, 425, 113341. [Google Scholar] [CrossRef]

- Nash, C.; Karve, P.; Adams, D. Diagnosing nuclear power plant pipe wall thinning due to flow accelerated corrosion using a passive, thermal non-destructive evaluation method: Feasibility assessment via numerical experiments. Nucl. Eng. Des. 2022, 386, 111542. [Google Scholar] [CrossRef]

- Bukharin, N.; Farrokhzad, M.A.; El Hassan, M. A comprehensive analysis of the erosion in a Carbon Steel boiler tube elbow through the use of 3D mapping of the corroded surface and CFD modeling. Mech. Adv. Mater. Struct. 2023, 31, 1–9. [Google Scholar] [CrossRef]

- Zhang, X.; Cho, S.W. Composition engineering of indium zinc oxide semiconductors for damage-free back-channel wet etching metallization of oxide thin-film transistors. Micromachines 2023, 14, 1839. [Google Scholar] [CrossRef]

- Shin, D.H.; Hwang, H.K.; Kim, H.H.; Lee, J.H. Evaluation of commercial corrosion sensors for real-time monitoring of pipe wall thickness under various operational conditions. Sensors 2022, 22, 7562. [Google Scholar] [CrossRef] [PubMed]

- Komary, M.; Komarizadehasl, S.; Tošić, N.; Segura, I.; Lozano-Galant, J.A.; Turmo, J. Low-cost technologies used in corrosion monitoring. Sensors 2023, 23, 1309. [Google Scholar] [CrossRef] [PubMed]

- Dong, B.; Liu, W.; Chen, L.; Zhang, T.; Fan, Y.; Zhao, Y.; Li, S.; Yang, W.; Banthukul, W. Optimize Ni, Cu, Mo element of low Cr-steel rebars in tropical marine atmosphere environment through two years of corrosion monitoring. Cem. Concr. Compos. 2022, 125, 104317. [Google Scholar] [CrossRef]

- Liu, M. Corrosion and mechanical behavior of metal materials. Materials 2023, 16, 973. [Google Scholar] [CrossRef]

- Sharma, S.; Kumar, A. Recent advances in metallic corrosion inhibition: A review. J. Mol. Liq. 2021, 322, 114862. [Google Scholar] [CrossRef]

- Hou, B.; Li, X.; Ma, X.; Du, C.; Zhang, D.; Zheng, M.; Xu, W.; Lu, D.; Ma, F. The cost of corrosion in China. NPJ Mater. Degrad. 2017, 1, 4. [Google Scholar] [CrossRef]

- Farh, H.M.H.; Ben Seghier, M.E.A.; Zayed, T. A comprehensive review of corrosion protection and control techniques for metallic pipelines. Eng. Fail. Anal. 2023, 143, 106885. [Google Scholar] [CrossRef]

- Kokilaramani, S.; Al-Ansari, M.M.; Rajasekar, A.; Al-Khattaf, F.S.; Hussain, A.; Govarthanan, M. Microbial influenced corrosion of processing industry by re-circulating waste water and its control measures—A review. Chemosphere 2021, 265, 129075. [Google Scholar] [CrossRef]

- Al-Moubaraki, A.H.; Obot, I.B. Corrosion challenges in petroleum refinery operations: Sources, mechanisms, mitigation, and future outlook. J. Saudi Chem. Soc. 2021, 25, 101370. [Google Scholar] [CrossRef]

- Li, K.; Zeng, Y.; Luo, J.-L. Corrosion of SS310 and Alloy 740 in High Temperature Supercritical CO2 with Impurities H2O and O2. Corros. Sci. 2021, 184, 109350. [Google Scholar] [CrossRef]

- Ren, Y.; Wu, H.; Du, J.; Liu, B.; Wang, X.; Jiao, Z.; Tian, Y.; Baker, I. Effect of laser scanning speeds on microstructure, tribological and corrosion behavior of Ti-23Nb alloys produced by laser metal deposition. Mater. Charact. 2023, 197, 112647. [Google Scholar] [CrossRef]

- Calabrese, L.; Proverbio, E. A Review on the applications of acoustic emission technique in the study of stress corrosion cracking. Corros. Mater. Degrad. 2021, 2, 1–30. [Google Scholar] [CrossRef]

- Vasagar, V.; Hassan, M.K.; Abdullah, A.M.; Karre, A.V.; Chen, B.; Kim, K.; Al-Qahtani, N.; Cai, T. Non-destructive techniques for corrosion detection: A review. Corros. Eng. Sci. Technol. Int. J. Corros. Process. Corros. Control 2024, 59, 56–85. [Google Scholar] [CrossRef]

- Taheri, H.; Jones, C.; Taheri, M. Assessment and detection of stress corrosion cracking by advanced eddy current array nondestructive testing and material characterization. J. Nat. Gas Sci. Eng. 2022, 102, 104568. [Google Scholar] [CrossRef]

- Wasif, R.; Tokhi, M.O.; Shirkoohi, G.; Marks, R.; Rudlin, J. Development of permanently installed magnetic eddy current sensor for corrosion monitoring of ferromagnetic pipelines. Appl. Sci. 2022, 12, 1037. [Google Scholar] [CrossRef]

- Hren, M.; Kosec, T.; Legat, A. Characterization of stainless steel corrosion processes in mortar using various monitoring techniques. Constr. Build. Mater. 2019, 221, 604–613. [Google Scholar] [CrossRef]

- Khalaf, A.H.; Xiao, Y.; Xu, N.; Wu, B.; Li, H.; Lin, B.; Nie, Z.; Tang, J. Emerging AI technologies for corrosion monitoring in oil and gas industry: A comprehensive review. Eng. Fail. Anal. 2024, 155, 107735. [Google Scholar] [CrossRef]

- Wang, X.; Yang, L.; Sun, T.; Rasool, G.; Sun, M.; Hu, N.; Guo, Z. A review of development and application of out-of-pipe detection technology without removing cladding. Measurement 2023, 219, 113249. [Google Scholar] [CrossRef]

- Rao, D.; Kuang, B.; Zhang, X.; Zhang, S. Study of CAP1400 Secondary Pipe Wall Thinning Rate under Flow Accelerated Corrosion. Ann. Nucl. Energy 2021, 155, 108170. [Google Scholar] [CrossRef]

- Esu, O.E.; Wang, Y.; Chryssanthopoulos, M.K. A baseline-free method for damage identification in pipes from local vibration mode pair frequencies. Struct. Health Monit. 2022, 21, 2152–2189. [Google Scholar] [CrossRef]

- Esu, O.E.; Wang, Y.; Chryssanthopoulos, M.K. Local vibration mode pairs for damage identification in axisymmetric tubular structures. J. Sound Vib. 2021, 494, 115845. [Google Scholar] [CrossRef]

- Chung, B.; Kim, J.; Jang, D.; Kim, S.; Choi, Y. Experimental investigation of a method for diagnosing wall thinning in an artificially thinned carbon steel elbow based on changes in modal characteristics. Nucl. Eng. Technol. 2023, 55, 947–957. [Google Scholar] [CrossRef]

- Liu, X.; Gong, C.; Zhang, L.; Jin, H.; Wang, C. Numerical study of the hydrodynamic parameters influencing internal corrosion in pipelines for different elbow flow configurations. Eng. Appl. Comput. Fluid Mech. 2020, 14, 122–135. [Google Scholar] [CrossRef]

- Fan, L.; Le, K.; Guo, C.; Sun, C.; Chen, G. Magnet-assisted hybrid EFPI/FBG sensor for internal corrosion monitoring of steel pipelines. Opt. Fiber Technol. 2022, 73, 103064. [Google Scholar] [CrossRef]

- Jiang, W.; Yao, K.; Lin, Q.; Zhao, Y.; Lu, D. Optical fiber sensing-aided 3D-printed replacement parts for enhancing the sensing ability of architectural heritage. Micromachines 2023, 14, 2135. [Google Scholar] [CrossRef]

- Yu, K.; Chen, W.; Deng, D.; Wu, Q.; Hao, J. Advancements in battery monitoring: Harnessing fiber grating sensors for enhanced performance and reliability. Sensors 2024, 24, 2057. [Google Scholar] [CrossRef] [PubMed]

- Sousa, I.; Pereira, L.; Mesquita, E.; Souza, V.L.; Araújo, W.S.; Cabral, A.; Alberto, N.; Varum, H.; Antunes, P. Sensing system based on FBG for corrosion monitoring in metallic structures. Sensors 2022, 22, 5947. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.; Bao, Y. Review of fiber optic sensors for corrosion monitoring in reinforced concrete. Cem. Concr. Compos. 2021, 120, 104029. [Google Scholar] [CrossRef]

- Luo, D.; Li, Y.; Lim, K.-S.; Yang, H.; Ahmad, H. Development of Fe-C film coated polymer optical fiber sensor for steel bar corrosion monitoring. Measurement 2023, 210, 112561. [Google Scholar] [CrossRef]

- Tan, X.; Fan, L.; Huang, Y.; Bao, Y. Detection, visualization, quantification, and warning of pipe corrosion using distributed fiber optic sensors. Autom. Constr. 2021, 132, 103953. [Google Scholar] [CrossRef]

- Sweeney, D.C.; Schrell, A.M.; Petrie, C.M. Pressure-driven fiber-optic sensor for online corrosion monitoring. IEEE Trans. Instrum. Meas. 2021, 70, 9510310. [Google Scholar] [CrossRef]

- Tang, F.; Li, Z.; Li, C.; Chen, Y.; Li, H.-N. Monitoring passivation, pitting corrosion initiation, and propagation of steel bar with Iron–Carbon electroplated long period fiber-grating sensor. J. Mater. Civ. Eng. 2020, 32, 04020373. [Google Scholar] [CrossRef]

- Guo, C.; Fan, L.; Chen, G. Corrosion-induced mass loss measurement under strain conditions through Gr/AgNW-based, Fe-C coated LPFG sensors. Sensors 2020, 20, 1598. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhou, H.; Zhou, Z.; Ma, C. Steel corrosion process in ultra-high performance concrete monitored by fiber Bragg grating sensor. Constr. Build. Mater. 2024, 431, 136442. [Google Scholar] [CrossRef]

- Tang, F.; Zhou, G.; Li, H.-N.; Verstrynge, E. A review on fiber optic sensors for rebar corrosion monitoring in RC structures. Constr. Build. Mater. 2021, 313, 125578. [Google Scholar] [CrossRef]

- Li, J.; Zhao, Y.; Wang, J. A spiral distributed monitoring method for steel rebar corrosion. Micromachines 2021, 12, 1451. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wang, C.; Zhao, Y. A long-term monitoring method of corrosion damage of prestressed anchor cable. Micromachines 2023, 14, 799. [Google Scholar] [CrossRef]

- Vahdati, N.; Wang, X.; Shiryayev, O.; Rostron, P.; Yap, F.F. External corrosion detection of oil pipelines using fiber optics. Sensors 2020, 20, 684. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Deng, F.; Xu, L.; Azarmi, F. Two-dimensional pitted corrosion localization on coated steel based on fiber Bragg grating sensors. J. Civ. Struct. Health Monit. 2020, 10, 927–945. [Google Scholar] [CrossRef]

- Shen, W.; Pang, Q.; Fan, L.; Li, P.; Zhao, X. Monitoring and quantification of non-uniform corrosion induced mass loss of steel piles with distributed optical fiber sensors. Autom. Constr. 2023, 148, 104769. [Google Scholar] [CrossRef]

- Budinski, V.; Njegovec, M.; Pevec, S.; Macuh, B.; Donlagic, D. High-order fiber Bragg grating corrosion sensor based on the detection of a local surface expansion. Struct. Control Health Monit. 2023, 2023, 1–14. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, D.; Huang, Y.; Shi, S.; Pan, H.; Bao, Y. Monitoring epoxy coated steel under combined mechanical loads and corrosion using fiber Bragg grating sensors. Sensors 2022, 22, 8034. [Google Scholar] [CrossRef]

- Xu, L.; Shi, S.; Yan, F.; Huang, Y.; Bao, Y. Experimental study on combined effect of mechanical loads and corrosion using tube-packaged long-gauge fiber Bragg grating sensors. Struct. Health Monit. 2023, 22, 3985–4004. [Google Scholar] [CrossRef]

- Wang, J.; Ren, L.; Jia, Z.; Jiang, T.; Wang, G. A novel pipeline leak detection and localization method based on the FBG pipe-fixture sensor array and compressed sensing theory. Mech. Syst. Signal Process. 2022, 169, 108669. [Google Scholar] [CrossRef]

- Altabey, W.A.; Wu, Z.; Noori, M.; Fathnejat, H. Structural health monitoring of composite pipelines utilizing fiber optic sensors and an AI-based algorithm—A comprehensive numerical study. Sensors 2023, 23, 3887. [Google Scholar] [CrossRef]

- Purwasih, N.; Shinozaki, H.; Okazaki, S.; Kihira, H.; Kuriyama, Y.; Kasai, S.; Nishiyama, Y.; Takahashi, H. Utilization of fiber Bragg grating sensors for high-temperature pipeline structural health monitoring. Mech. Syst. Signal Process. 2020, 138, 106544. [Google Scholar]

- Huang, X.; Davies, M.; Moseley, D.A.; Salazar, E.E.; Sanabria, C.; Duke, O.; Ludbrook, B.M.; Badcock, R.A. Temperature and strain sensitivities of a groove bonded fiber Bragg grating at room and cryogenic temperatures. Appl. Opt. 2022, 61, 8427. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-W.; Na, M.-G.; Park, C.-Y. Effect of Local Wall Thinning on the Collapse Behavior of Pipe Elbows Subjected to a Combined Internal Pressure and In-Plane Bending Load. Nucl. Eng. Des. 2008, 238, 1275–1285. [Google Scholar] [CrossRef]

| Illustration | Quantity |

|---|---|

| Elastic module | 206 GPa |

| Poisson ratio | 0.3 |

| Thickness of pipe | 20 mm |

| Bend radius, | 3 |

| Thinning length, | 1.0 |

| Thinning depth, | 0.534 |

| Thinning angle, | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, K.; Peng, Z.; Zhang, Y.; Zhu, P.; Chen, W.; Hao, J. Pipeline Elbow Corrosion Simulation for Strain Monitoring with Fiber Bragg Gratings. Micromachines 2024, 15, 1098. https://doi.org/10.3390/mi15091098

Yu K, Peng Z, Zhang Y, Zhu P, Chen W, Hao J. Pipeline Elbow Corrosion Simulation for Strain Monitoring with Fiber Bragg Gratings. Micromachines. 2024; 15(9):1098. https://doi.org/10.3390/mi15091098

Chicago/Turabian StyleYu, Kaimin, Zixuan Peng, Yuanfang Zhang, Peibin Zhu, Wen Chen, and Jianzhong Hao. 2024. "Pipeline Elbow Corrosion Simulation for Strain Monitoring with Fiber Bragg Gratings" Micromachines 15, no. 9: 1098. https://doi.org/10.3390/mi15091098

APA StyleYu, K., Peng, Z., Zhang, Y., Zhu, P., Chen, W., & Hao, J. (2024). Pipeline Elbow Corrosion Simulation for Strain Monitoring with Fiber Bragg Gratings. Micromachines, 15(9), 1098. https://doi.org/10.3390/mi15091098