Hybrid Printing of Conductive Traces from Bulk Metal for Digital Signals in Intelligent Devices

Abstract

1. Introduction

1.1. Deposition Dynamics of Microdroplets on Substrate

1.2. Signal Integrity in Digital Communication

2. Materials and Methods

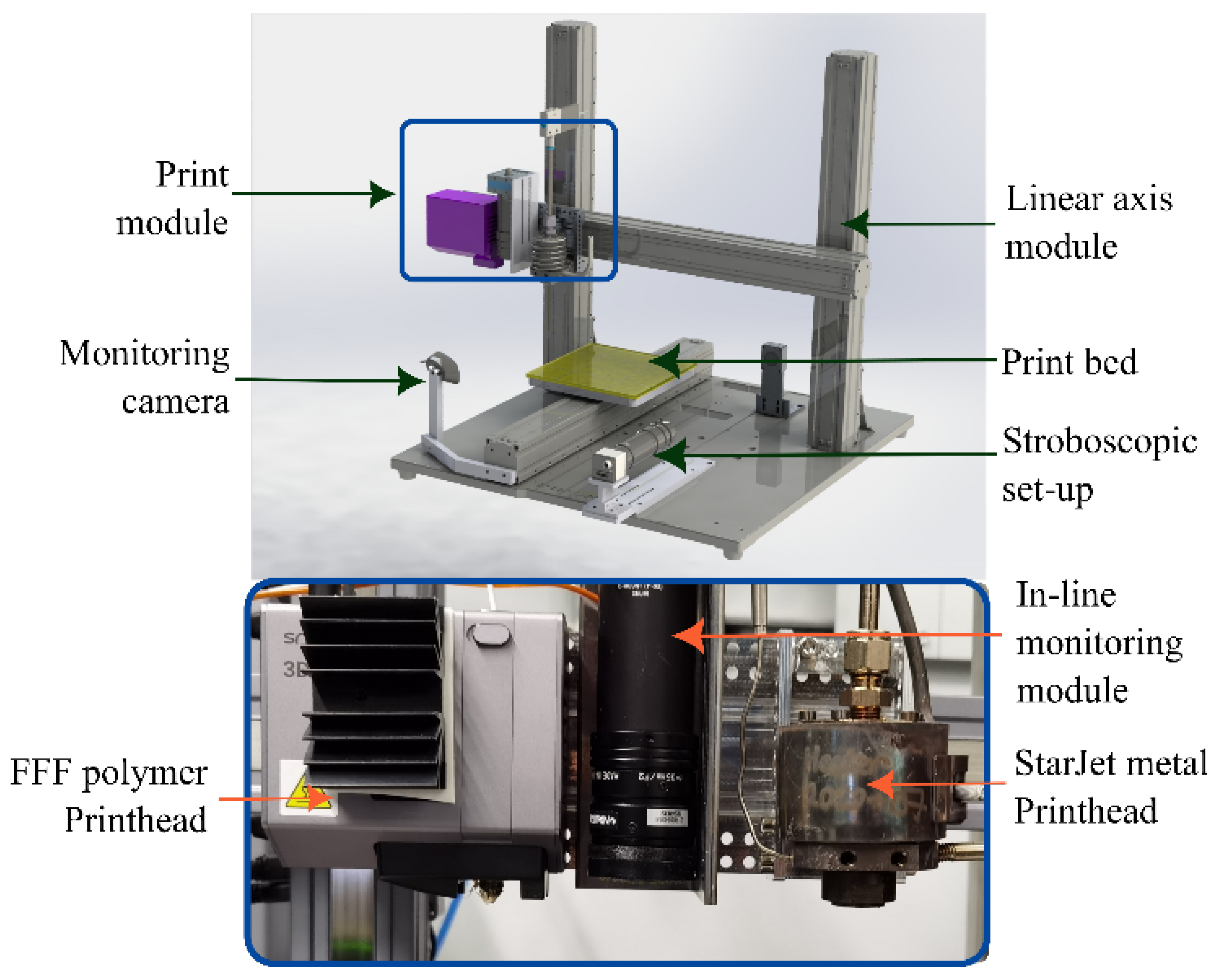

2.1. Hybrid Printing Platform

2.2. Materials and Print Parameters

2.3. Sample Preparation and Fabrication Methodology

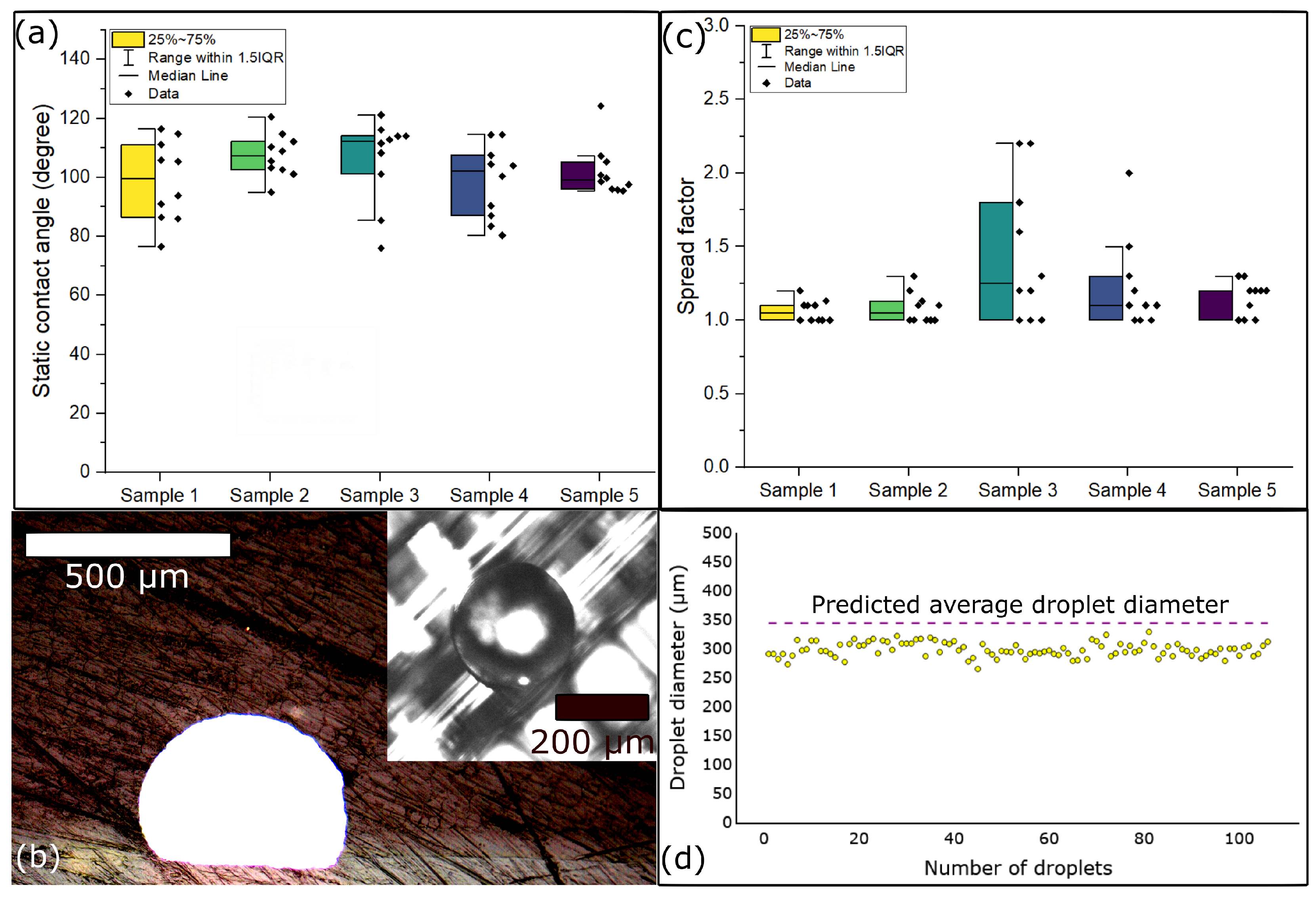

2.3.1. Metal Microdroplets on Polymer Substrates

2.3.2. Minimum Trace Pitch

2.3.3. Crosstalk in Adjacent Traces

2.4. Data and Image Analysis

2.5. Thermal Cycling Test

2.6. Electrical Resistance Measurement

2.7. Statistics and Data Analysis

3. Results

3.1. Quantifying the Spread of Metal Microdroplets on Polymer Substrates

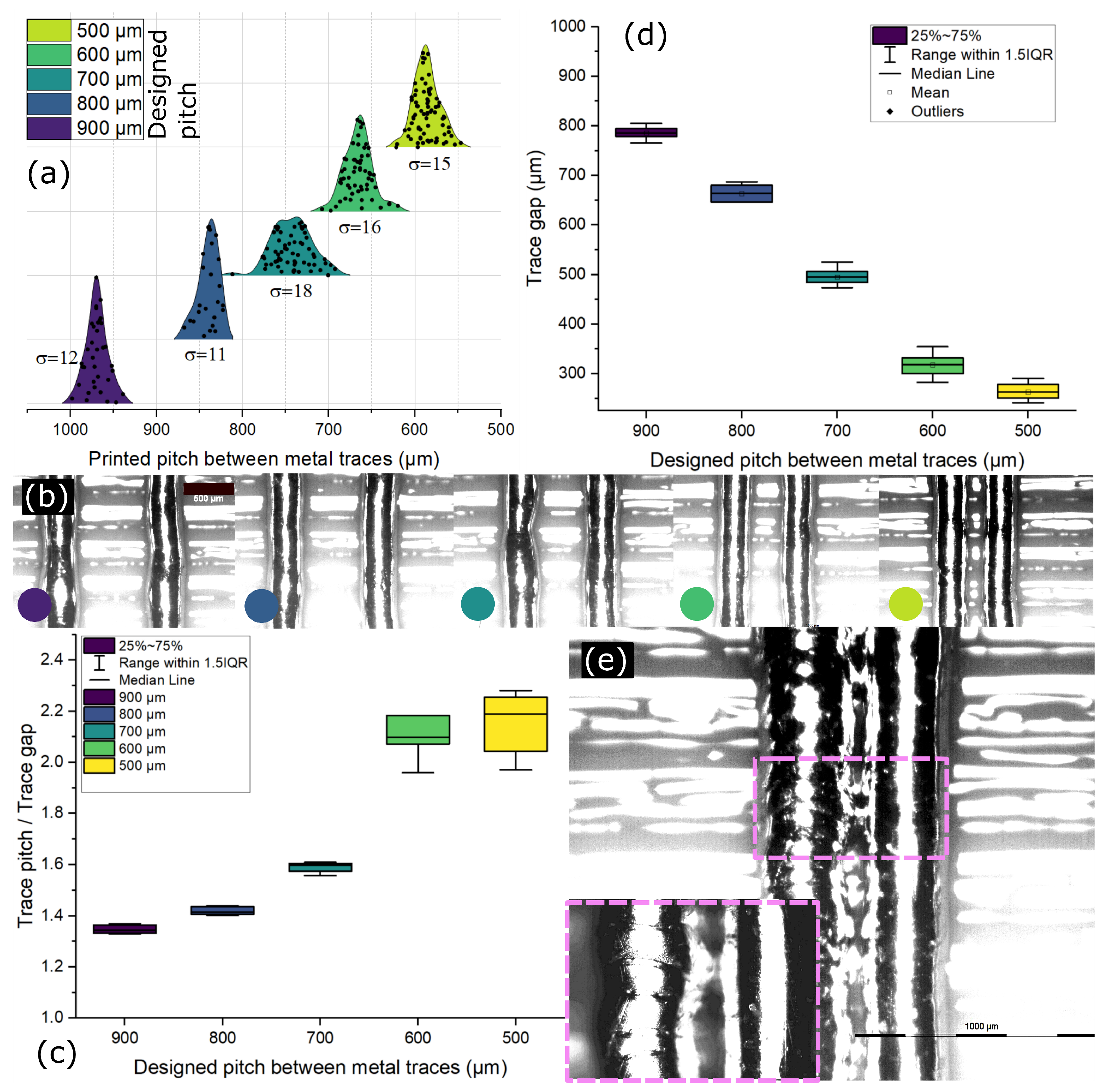

3.2. Characterization and Optimization of MTP Parameters in Hybrid Printing Methods

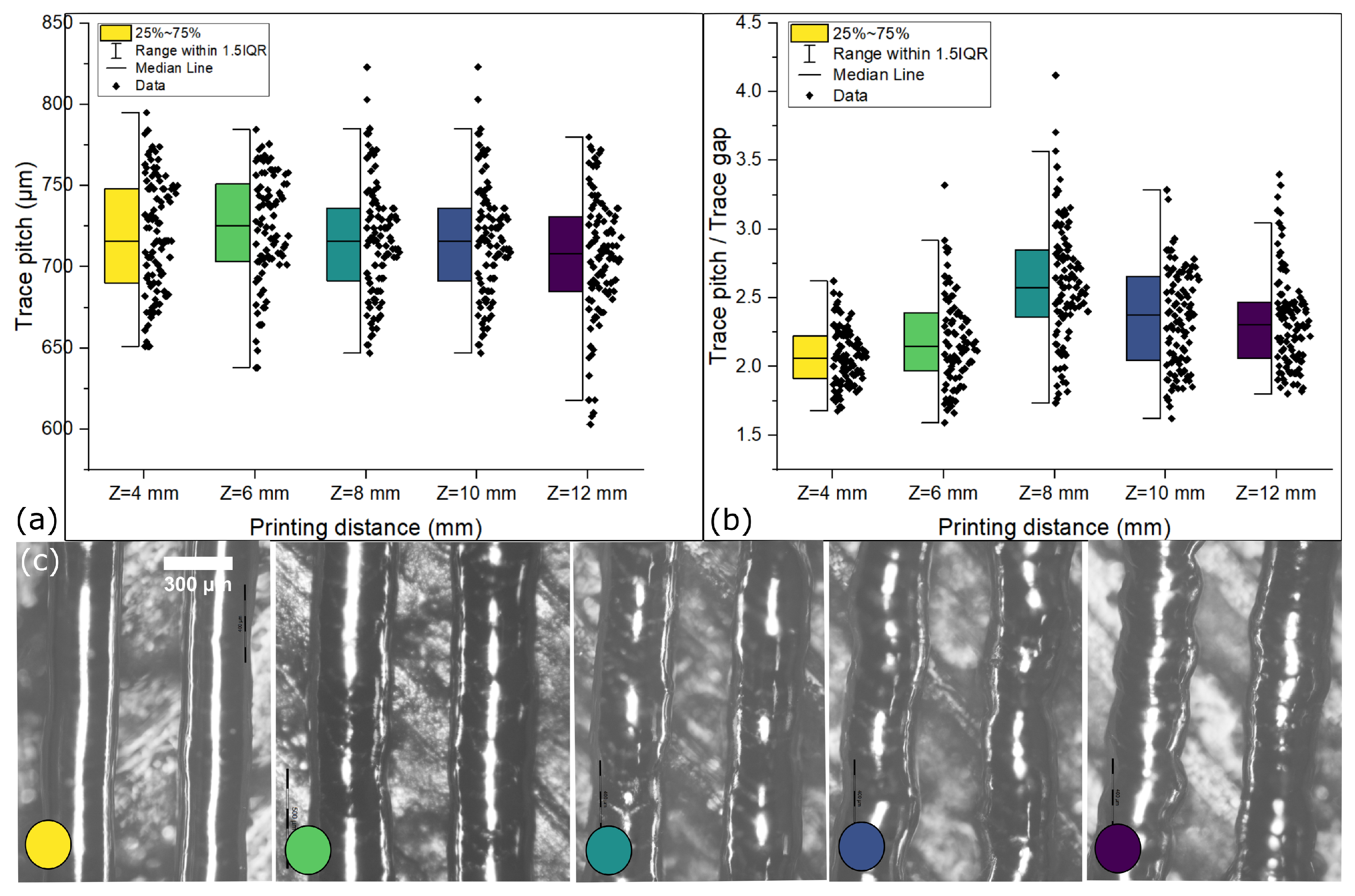

3.3. Effect of Printing Distance on Trace Pitch and Trace Gap

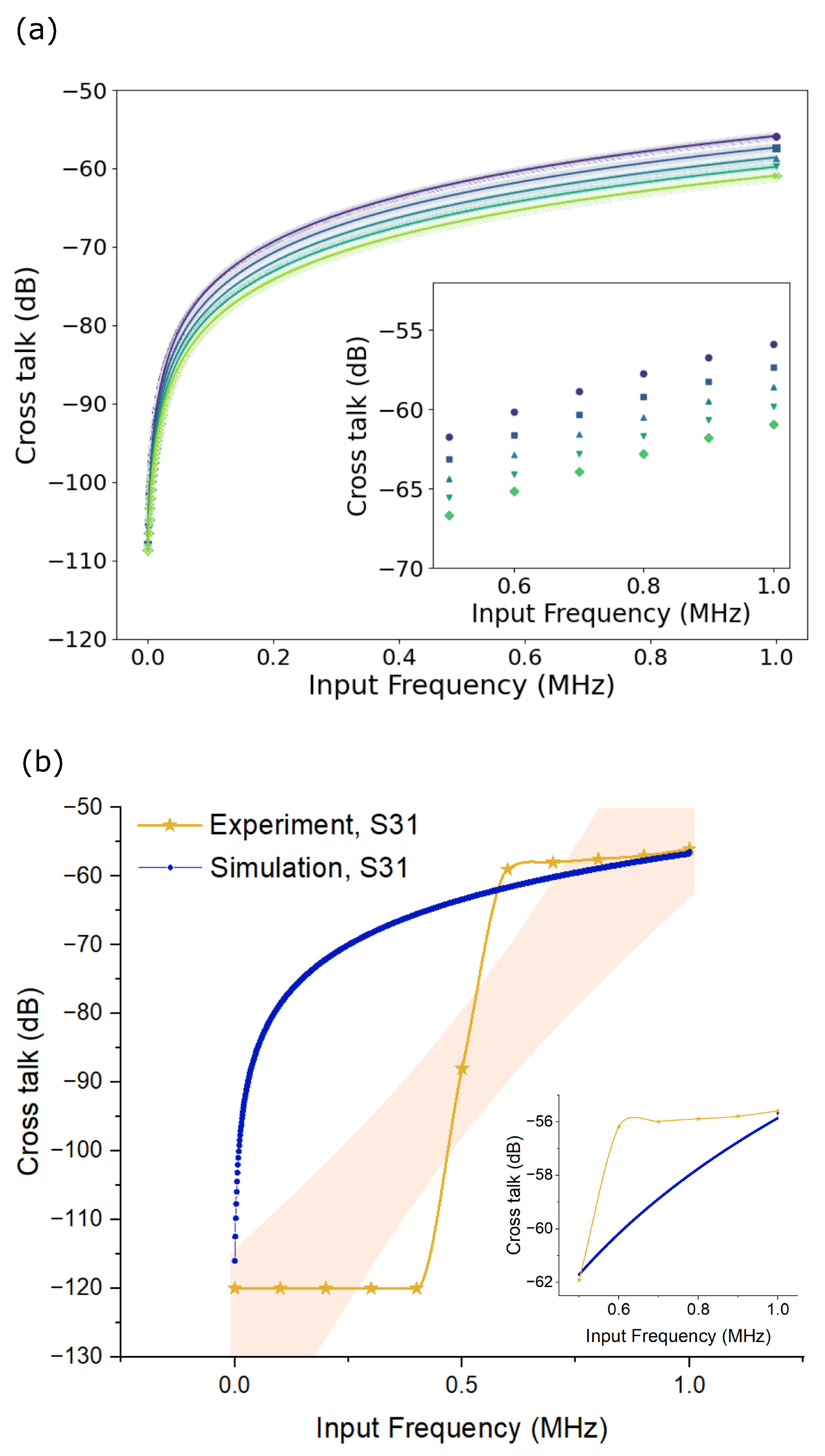

3.4. Crosstalk Characterization between Printed Electrical Traces at MTP

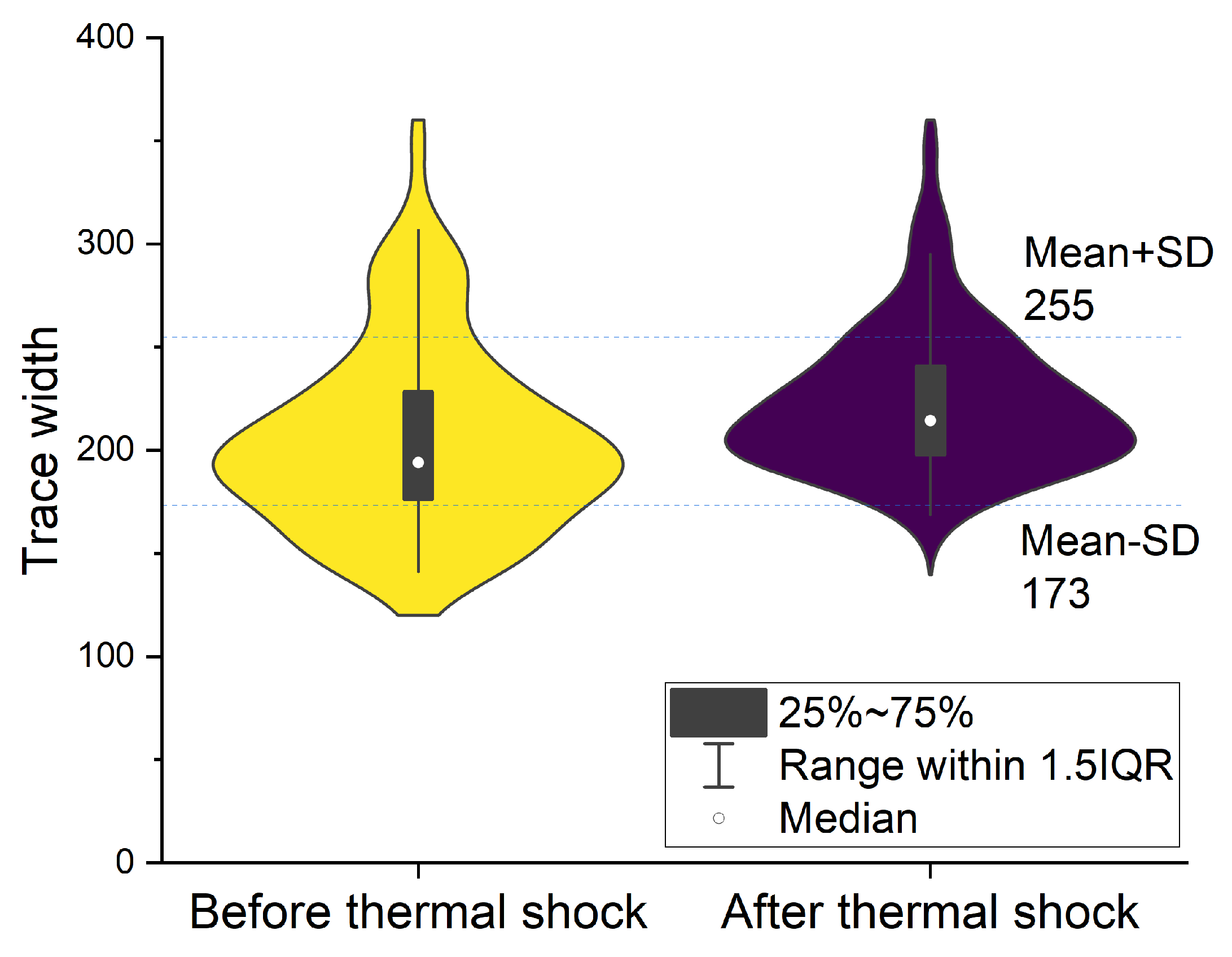

3.5. Thermal Characterization of the Printed Traces

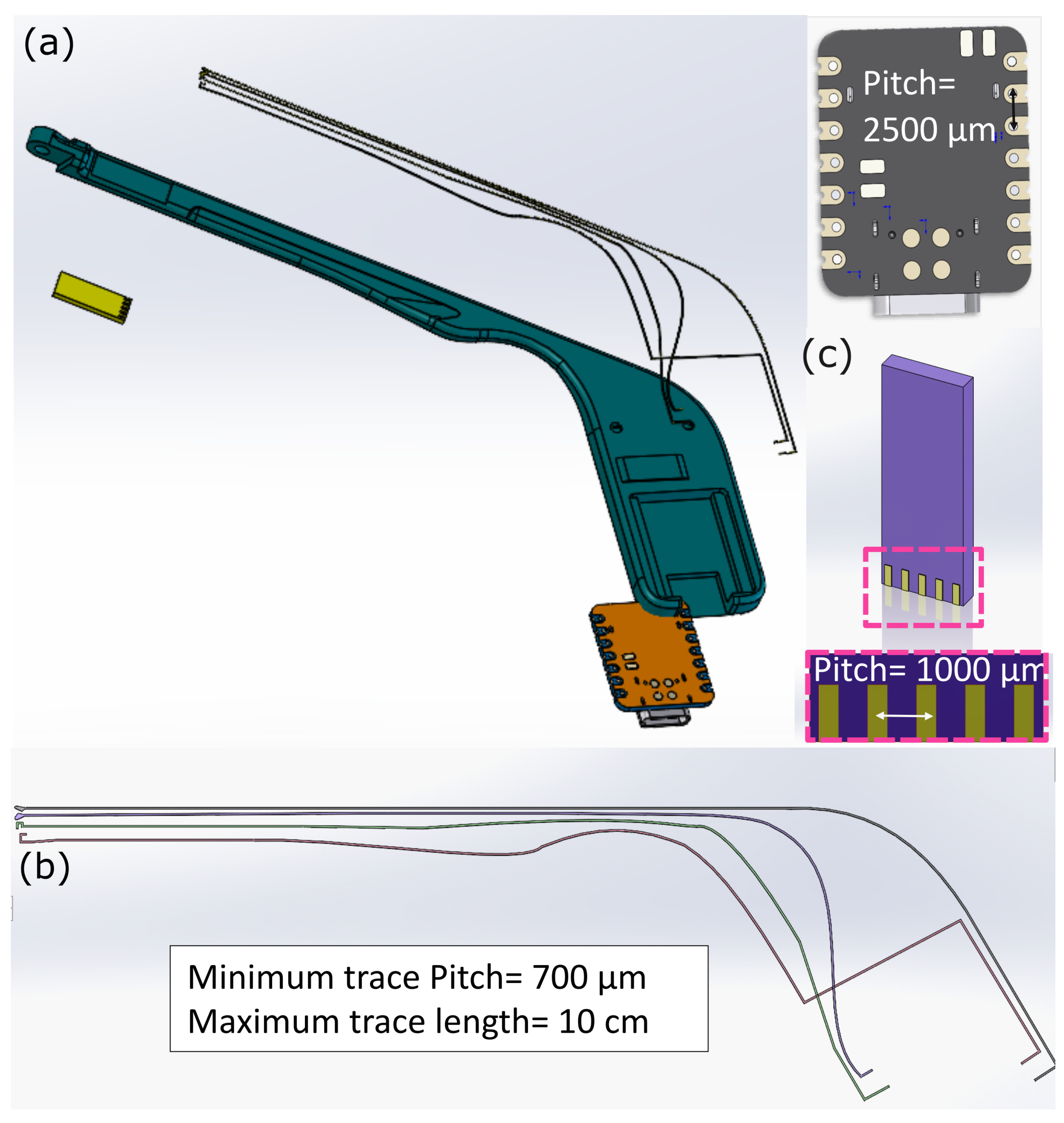

3.6. MMAM Printing of Customized Smart Eyeglasses Using Metal Microdroplets and Polymer

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MMAM | multi-material additive manufacturing |

| MTP | minimum trace pitch |

| PETG | polyethylene terephthalate glycol copolymer |

| SAC305 | Sn96.5Ag3Cu0.5 |

| FFF | Fused filament fabrication |

| CAD | computer-aided design |

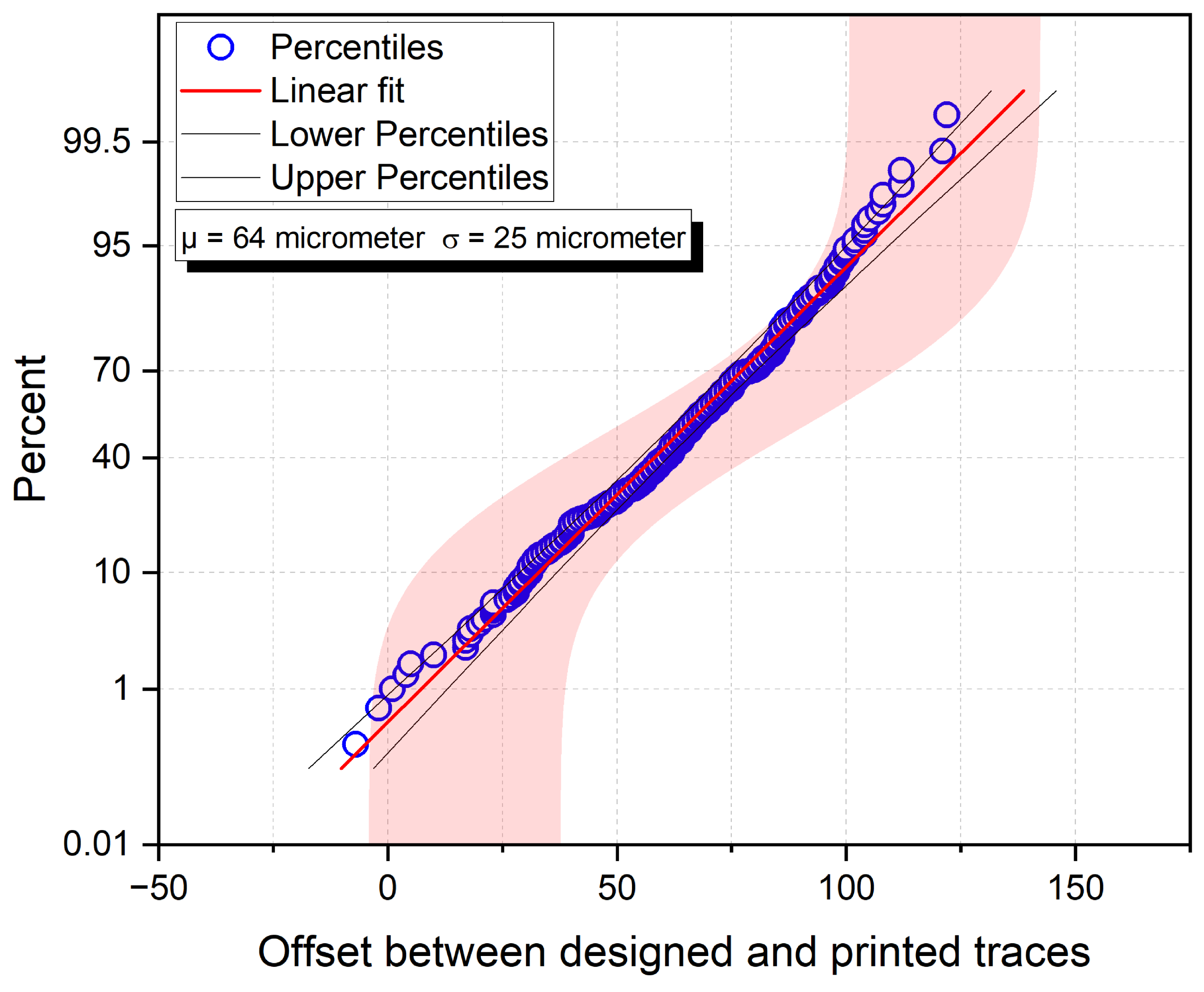

Appendix A. Prediction Curve for Offset in Printing MTP

Appendix B. Model for Smart Eyeglass Arm

References

- Nassar, H.; Dahiya, R. Fused Deposition Modeling–Based 3D–Printed Electrical Interconnects and Circuits. Adv. Intell. Syst. 2021, 3, 2100102. [Google Scholar] [CrossRef]

- Rayna, T.; Striukova, L. The Impact of 3D Printing Technologies on Business Model Innovation. In Digital Enterprise Design & Management; Benghozi, P.J., Krob, D., Lonjon, A., Panetto, H., Eds.; Springer International Publishing: Cham, Switzerland, 2014; Volume 261, pp. 119–132. [Google Scholar] [CrossRef]

- Dahiya, R.; Yogeswaran, N.; Liu, F.; Manjakkal, L.; Burdet, E.; Hayward, V.; Jorntell, H. Large-Area Soft e-Skin: The Challenges Beyond Sensor Designs. Proc. IEEE 2019, 107, 2016–2033. [Google Scholar] [CrossRef]

- Fried, S. 3D Printing Technologies for Electronics. J. Imaging Soc. Jpn. (Nihon Gazo Gakkaishi) 2017, 56, 617–620. [Google Scholar] [CrossRef]

- Farooqui, M.F.; Karimi, M.A.; Salama, K.N.; Shamim, A. 3D–Printed Disposable Wireless Sensors with Integrated Microelectronics for Large Area Environmental Monitoring. Adv. Mater. Technol. 2017, 2, 1700051. [Google Scholar] [CrossRef]

- Ghosh, U.; Ning, S.; Wang, Y.; Kong, Y.L. Addressing Unmet Clinical Needs with 3D Printing Technologies. Adv. Healthc. Mater. 2018, 7, e1800417. [Google Scholar] [CrossRef]

- Han, D.; Lee, H. Recent advances in multi-material additive manufacturing: Methods and applications. Curr. Opin. Chem. Eng. 2020, 28, 158–166. [Google Scholar] [CrossRef]

- Weisgrab, G.; Ovsianikov, A.; Costa, P.F. Functional 3D Printing for Microfluidic Chips. Adv. Mater. Technol. 2019, 4, 1900275. [Google Scholar] [CrossRef]

- Castrovilla, J.A. The printed circuit board industry and innovations for the 1990s. JOM 1989, 41, 25–27. [Google Scholar] [CrossRef]

- Zhang, Y.; Shi, G.; Qin, J.; Lowe, S.E.; Zhang, S.; Zhao, H.; Zhong, Y.L. Recent Progress of Direct Ink Writing of Electronic Components for Advanced Wearable Devices. ACS Appl. Electron. Mater. 2019, 1, 1718–1734. [Google Scholar] [CrossRef]

- Roshanghias, A.; Krivec, M.; Baumgart, M. Sintering strategies for inkjet printed metallic traces in 3D printed electronics. Flex. Print. Electron. 2017, 2, 045002. [Google Scholar] [CrossRef]

- Alhendi, M.; Sivasubramony, R.S.; Weerawarne, D.L.; Iannotti, J.; Borgesen, P.; Poliks, M.D. Assessing Current–Carrying Capacity of Aerosol Jet Printed Conductors. Adv. Eng. Mater. 2020, 22, 2000520. [Google Scholar] [CrossRef]

- Lall, P.; Sarwar, M.G.; Narangaparambil, J.; Miller, S. Print Process Development for Ag-Ink Thermoformable Conductive Traces Utilizing Direct Write technique for In-Mold Printed Electronics. In Proceedings of the 2023 22nd IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 30 May–2 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–10. [Google Scholar] [CrossRef]

- Mohan, N.; Ahuir-Torres, J.I.; Bhogaraju, S.K.; Kotadia, H.; Elger, G. Rapid Sintering of Inkjet Printed Cu Complex Inks Using Laser in Air. In Proceedings of the 2023 24th European Microelectronics and Packaging Conference & Exhibition (EMPC), Cambridge, UK, 11–14 September 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Mahajan, A.; Frisbie, C.D.; Francis, L.F. Optimization of aerosol jet printing for high-resolution, high-aspect ratio silver lines. ACS Appl. Mater. Interfaces 2013, 5, 4856–4864. [Google Scholar] [CrossRef]

- Agarwala, S.; Goh, G.L.; Yeong, W.Y. Optimizing aerosol jet printing process of silver ink for printed electronics. IOP Conf. Ser. Mater. Sci. Eng. 2017, 191, 012027. [Google Scholar] [CrossRef]

- Tao, Y.; Tao, Y.; Wang, B.; Wang, L.; Tai, Y. A facile approach to a silver conductive ink with high performance for macroelectronics. Nanoscale Res. Lett. 2013, 8, 296. [Google Scholar] [CrossRef]

- Wiklund, J.; Karakoç, A.; Palko, T.; Yiğitler, H.; Ruttik, K.; Jäntti, R.; Paltakari, J. A Review on Printed Electronics: Fabrication Methods, Inks, Substrates, Applications and Environmental Impacts. J. Manuf. Mater. Process. 2021, 5, 89. [Google Scholar] [CrossRef]

- Aga, R.S.; Kreit, E.B.; Dooley, S.R.; Bartsch, C.M.; Heckman, E.M.; Aga, R.S. Considerations in printing conductive traces for high pulsed power applications. Microelectron. Reliab. 2018, 81, 342–351. [Google Scholar] [CrossRef]

- Valayil Varghese, T.; Eixenberger, J.; Rajabi-Kouchi, F.; Lazouskaya, M.; Francis, C.; Burgoyne, H.; Wada, K.; Subbaraman, H.; Estrada, D. Multijet Gold Nanoparticle Inks for Additive Manufacturing of Printed and Wearable Electronics. ACS Mater. Au 2024, 4, 65–73. [Google Scholar] [CrossRef]

- Ghalamboran, M.; Nazeri, M.; Grau, G. Pattern-dependent resistivity variations in inkjet-printed conductors due to non-uniform ink drying. Flex. Print. Electron. 2024, 9, 015011. [Google Scholar] [CrossRef]

- Roach, D.J.; Hamel, C.M.; Dunn, C.K.; Johnson, M.V.; Kuang, X.; Qi, H.J. The m4 3D printer: A multi-material multi-method additive manufacturing platform for future 3D printed structures. Addit. Manuf. 2019, 29, 100819. [Google Scholar] [CrossRef]

- Khan, Z.; Koltay, P.; Zengerle, R.; Kartmann, S.; Shu, Z. One–Stop Hybrid Printing of Bulk Metal and Polymer for 3D Electronics. Adv. Eng. Mater. 2023, 26, 2300922. [Google Scholar] [CrossRef]

- Eastman, N.L. Considerations for mixed analog/digital PCB design. In Proceedings of the Wescon/96, Anaheim, CA, USA, 22–24 October 1996; IEEE: Piscataway, NJ, USA, 1996; pp. 297–301. [Google Scholar] [CrossRef]

- Catt, I. Crosstalk (Noise) in Digital Systems. IEEE Trans. Electron. Comput. 1967, EC-16, 743–763. [Google Scholar] [CrossRef]

- Rioboo, R.; Marengo, M.; Tropea, C. Time evolution of liquid drop impact onto solid, dry surfaces. Exp. Fluids 2002, 33, 112–124. [Google Scholar] [CrossRef]

- Yarin, A.L. DROP IMPACT DYNAMICS: Splashing, Spreading, Receding, Bouncing…. Annu. Rev. Fluid Mech. 2006, 38, 159–192. [Google Scholar] [CrossRef]

- Shin, D.Y.; Grassia, P.; Derby, B. Numerical and experimental comparisons of mass transport rate in a piezoelectric drop-on-demand inkjet print head. Int. J. Mech. Sci. 2004, 46, 181–199. [Google Scholar] [CrossRef]

- Le Bot, C.; Vincent, S.; Arquis, E. Impact and solidification of indium droplets on a cold substrate. Int. J. Therm. Sci. 2005, 44, 219–233. [Google Scholar] [CrossRef]

- Stringer, J.; Derby, B. Formation and stability of lines produced by inkjet printing. Langmuir ACS J. Surfaces Colloids 2010, 26, 10365–10372. [Google Scholar] [CrossRef]

- Fuquan, G.; Ain A., S. Precise deposition of molten microdrops: The physics of digital microfabrication. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1994, 444, 533–554. [Google Scholar] [CrossRef]

- Vaseghi, S.V. Advanced Digital Signal Processing and Noise Reduction, 2nd ed.; Wiley: Chichester, UK, 2001. [Google Scholar]

- Altair PollEx. Signal Integrity: Introduction. Available online: https://help.altair.com/Pollex/topics/pollex/solver/si_introduction_r.htm (accessed on 25 April 2024).

- Wang, J.; Ma, M. Crosstalk analysis in Signal Integrity. In Proceedings of the 2011 International Conference on Multimedia Technology, Washington, DC, USA, 14–15 May 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 261–264. [Google Scholar] [CrossRef]

- Anish, D.; Kumar, G.K.; Jagdale, R. Minimization of crosstalk in high speed PCB. In Proceedings of the 12th International Conference on Networking, VLSI and Signal Proceeding (ICNVS’10), Cambridge, UK, 20–22 February 2010; University of Cambridge: Cambridge, UK, 2010. [Google Scholar]

- Gravelle, L.B.; Wilson, P.F. EMI/EMC in printed circuit boards-a literature review. IEEE Trans. Electromagn. Compat. 1992, 34, 109–116. [Google Scholar] [CrossRef]

- Halligan, M.S.; Beetner, D.G. Maximum Crosstalk Estimation in Weakly Coupled Transmission Lines. IEEE Trans. Electromagn. Compat. 2014, 56, 736–744. [Google Scholar] [CrossRef]

- Palit, A.K.; Meyer, V.; Anheier, W.; Schloeffel, J. Analysis of crosstalk coupling effects between aggressor and victim interconnect using two-port network model. In Proceedings of the 45th Annual IEEE Symposium on Foundations of Computer Science, Rome, Italy, 17–19 October 2004; IEEE: Piscataway, NJ, USA, 2004; pp. 81–84. [Google Scholar] [CrossRef]

- Li, M.P. Jitter, Noise, and Signal Integrity at High-Speed; Prentice Hall Modern Semiconductor Design Series; Prentice Hall Signal Integrity Library, Prentice Hall: Hoboken, NJ, USA, 2008. [Google Scholar]

- Zhang, X.j.; Jiang, W.; Gao, L.; Li, H.z. Impack of crosstalk on signal integrity of high density ceramic package for IC. In Proceedings of the 2016 17th International Conference on Electronic Packaging Technology (ICEPT), Wuhan, China, 16–19 August 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 429–433. [Google Scholar] [CrossRef]

- Khan, Z.; Gururajan, D.; Koltay, P.; Kartmann, S.; Zengerle, R.; Shu, Z. Hybrid 3D Printing of Molten Metal Microdroplets and Polymers for Prototyping of Printed Circuit Boards Featuring Interdigitated 3D Capacitors. IEEJ Trans. Electr. Electron. Eng. 2024, 19, 894–899. [Google Scholar] [CrossRef]

- Shu, Z.; Fechtig, M.; Lombeck, F.; Breitwieser, M.; Zengerle, R.; Koltay, P. Direct Drop-on-Demand Printing of Molten Solder Bumps on ENIG Finishing at Ambient Conditions Through StarJet Technology. IEEE Access 2020, 8, 210225–210233. [Google Scholar] [CrossRef]

- Gerdes, B.; Jehle, M.; Lass, N.; Riegger, L.; Spribille, A.; Linse, M.; Clement, F.; Zengerle, R.; Koltay, P. Front side metallization of silicon solar cells by direct printing of molten metal. Sol. Energy Mater. Sol. Cells 2018, 180, 83–90. [Google Scholar] [CrossRef]

- Tan, H.W.; An, J.; Chua, C.K.; Tran, T. Metallic Nanoparticle Inks for 3D Printing of Electronics. Adv. Electron. Mater. 2019, 5, 1800831. [Google Scholar] [CrossRef]

- Ko, S.H. Low temperature thermal engineering of nanoparticle ink for flexible electronics applications. Semicond. Sci. Technol. 2016, 31, 073003. [Google Scholar] [CrossRef]

- Prusa Polymers. Available online: https://www.prusa3d.com/de/file/1566977/prusament-petg-technisches-datenblatt.pdf (accessed on 16 February 2022).

- Merrow, H.; Beroz, J.D.; Zhang, K.; Muecke, U.P.; Hart, A.J. Digital metal printing by electrohydrodynamic ejection and in-flight melting of microparticles. Addit. Manuf. 2021, 37, 101703. [Google Scholar] [CrossRef]

- Saphala, A.; Zhang, R.; Amft, O. Proximity-based Eating Event Detection in Smart Eyeglasses with Expert and Data Models. In Proceedings of the 2022 ACM International Symposium on Wearable Computers, New York, NY, USA, 11–15 September 2022; pp. 59–63. [Google Scholar] [CrossRef]

- Saphala, A.; Khan, Z.; Kartmann, S.; Zengerle, R.; Shu, Z.; Amft, O. Towards personalised wearable electronics: Leveraging printed bulk metal conductor technology for customisable 3D printed smart eyeglasses. In Proceedings of the LOPEC Conference 2024, Munich, Germany, 5–7 March 2024. [Google Scholar]

| StarJet Parameters | Value | FFF Parameters | Value |

|---|---|---|---|

| Reservoir temperature | 320 °C | Polymer road width | 450 μm |

| Orifice diameter | 183 μm | Nozzle diameter | 400 μm |

| Printing frequency | 18 HZ | Substrate thickness | 600 μm |

| Droplet spacing | 2800 μm | Extruder nozzle temperature | 240 °C |

| Printing distance | 4 mm | Print bed temperature | 85 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, Z.; Saphala, A.; Kartmann, S.; Koltay, P.; Zengerle, R.; Amft, O.; Shu, Z. Hybrid Printing of Conductive Traces from Bulk Metal for Digital Signals in Intelligent Devices. Micromachines 2024, 15, 750. https://doi.org/10.3390/mi15060750

Khan Z, Saphala A, Kartmann S, Koltay P, Zengerle R, Amft O, Shu Z. Hybrid Printing of Conductive Traces from Bulk Metal for Digital Signals in Intelligent Devices. Micromachines. 2024; 15(6):750. https://doi.org/10.3390/mi15060750

Chicago/Turabian StyleKhan, Zeba, Addythia Saphala, Sabrina Kartmann, Peter Koltay, Roland Zengerle, Oliver Amft, and Zhe Shu. 2024. "Hybrid Printing of Conductive Traces from Bulk Metal for Digital Signals in Intelligent Devices" Micromachines 15, no. 6: 750. https://doi.org/10.3390/mi15060750

APA StyleKhan, Z., Saphala, A., Kartmann, S., Koltay, P., Zengerle, R., Amft, O., & Shu, Z. (2024). Hybrid Printing of Conductive Traces from Bulk Metal for Digital Signals in Intelligent Devices. Micromachines, 15(6), 750. https://doi.org/10.3390/mi15060750