Dimension Prediction and Microstructure Study of Wire Arc Additive Manufactured 316L Stainless Steel Based on Artificial Neural Network and Finite Element Simulation

Abstract

1. Introduction

2. Experiment

3. Numerical Model

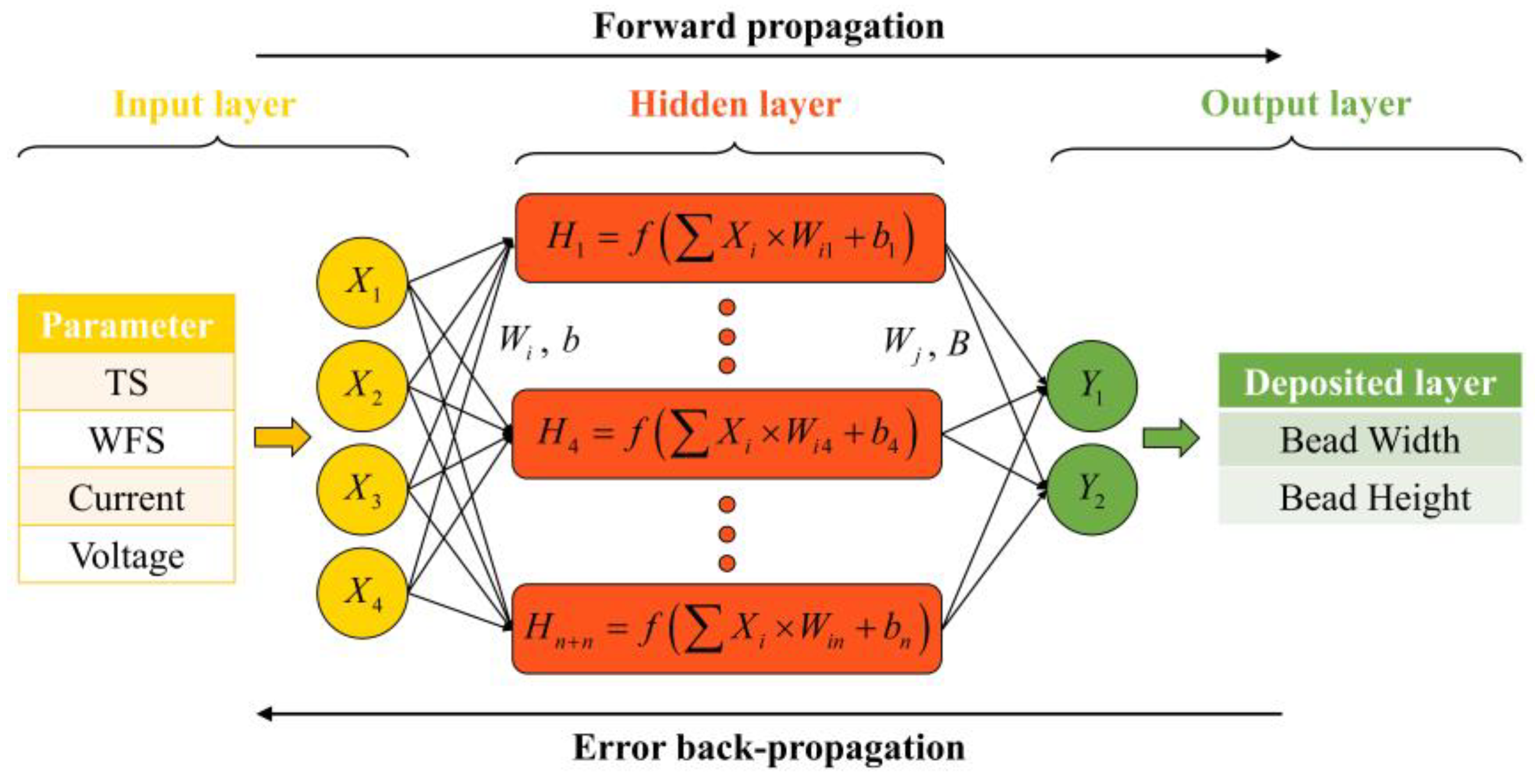

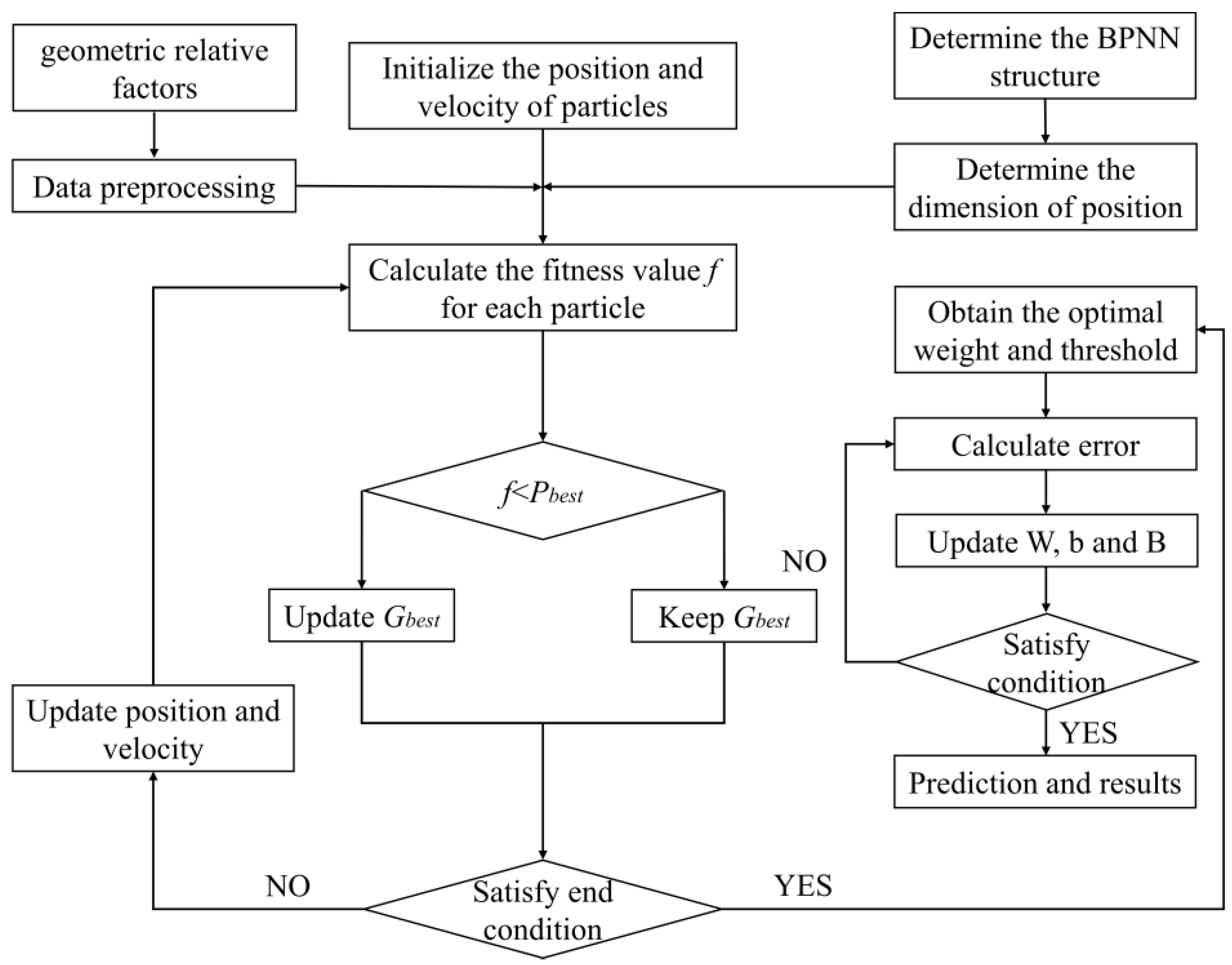

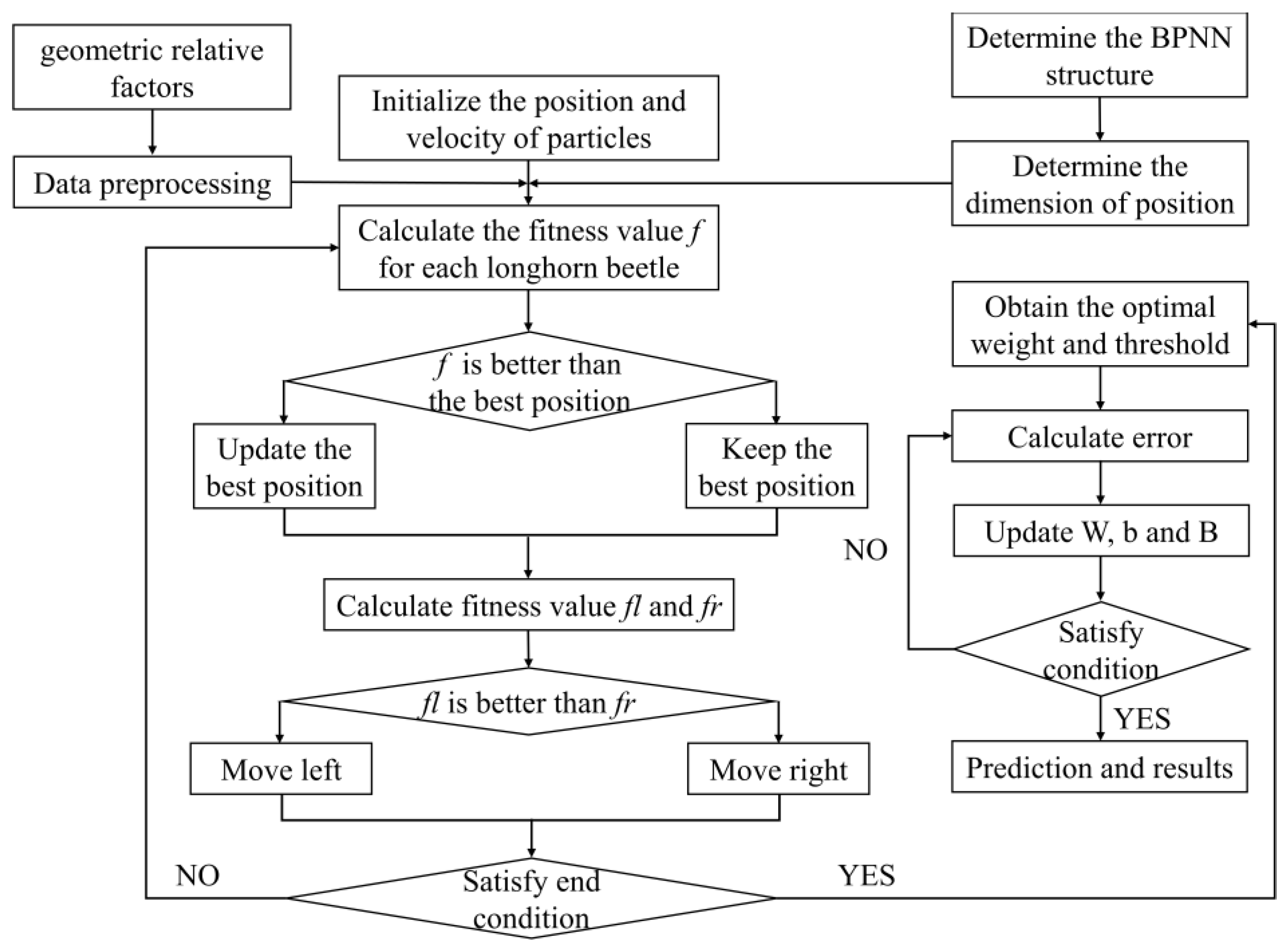

3.1. Dimension Prediction Model

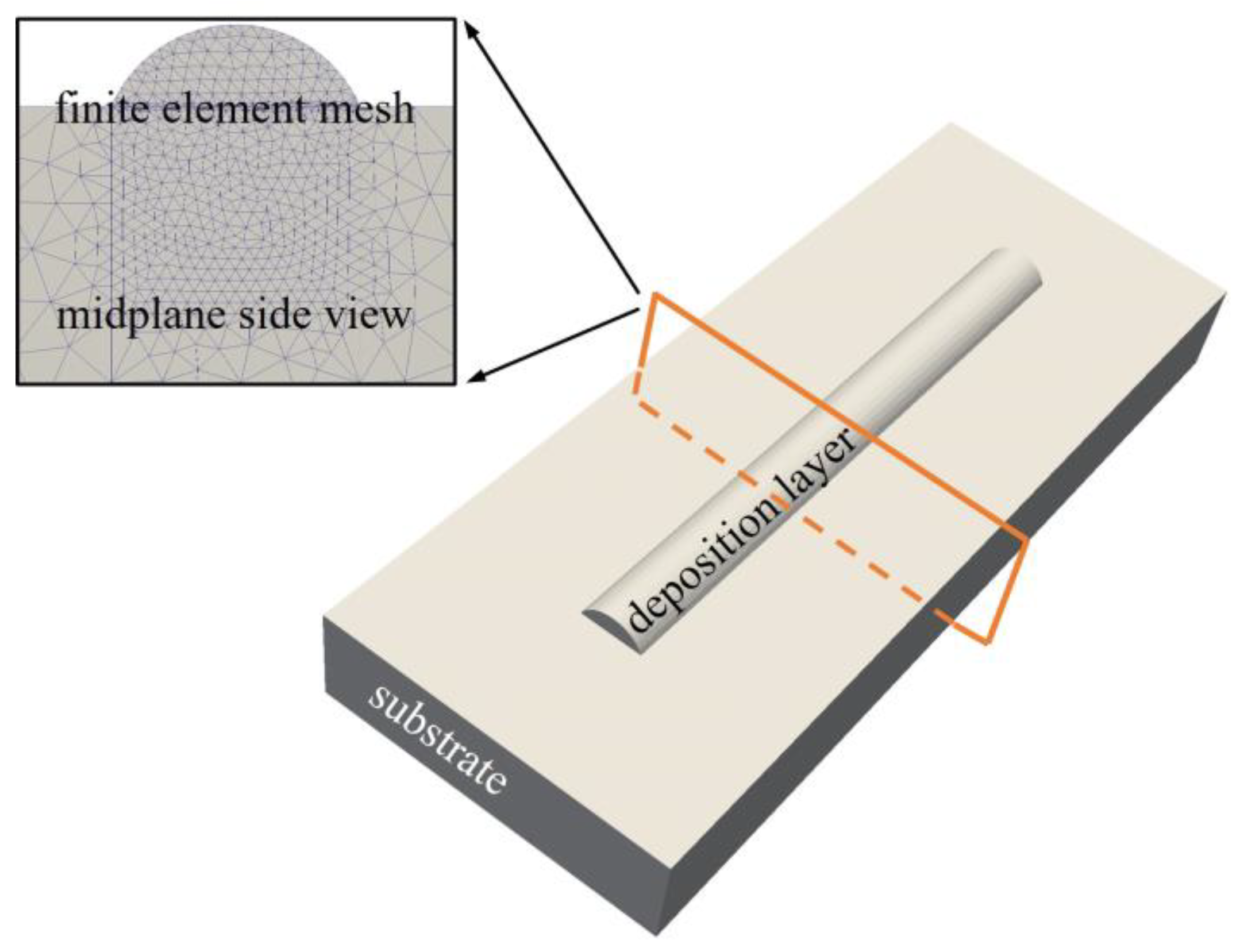

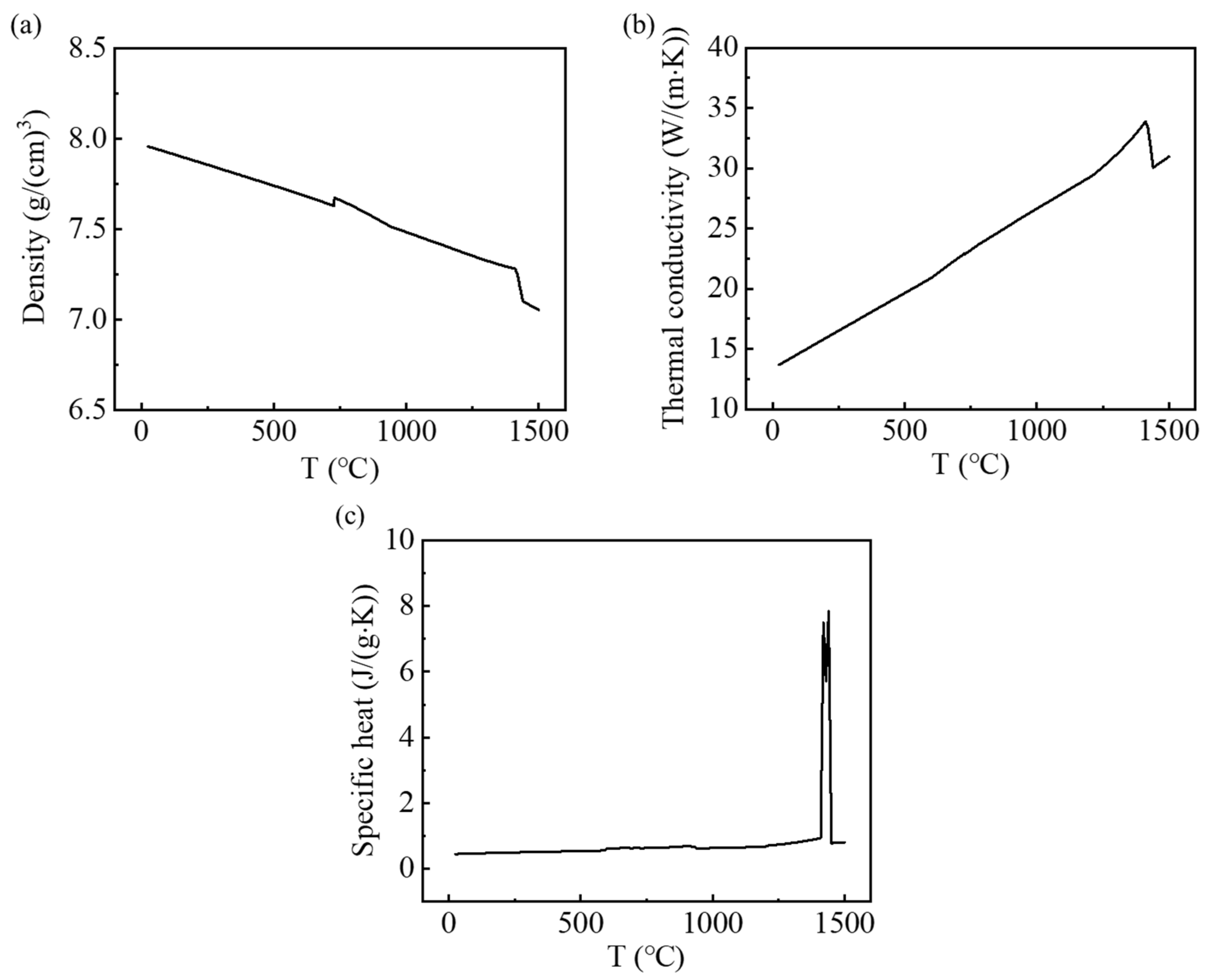

3.2. FE Heat Transfer Model

3.2.1. 3D Geometric Model

3.2.2. Heat Transfer Control Equation

4. Results and Discussion

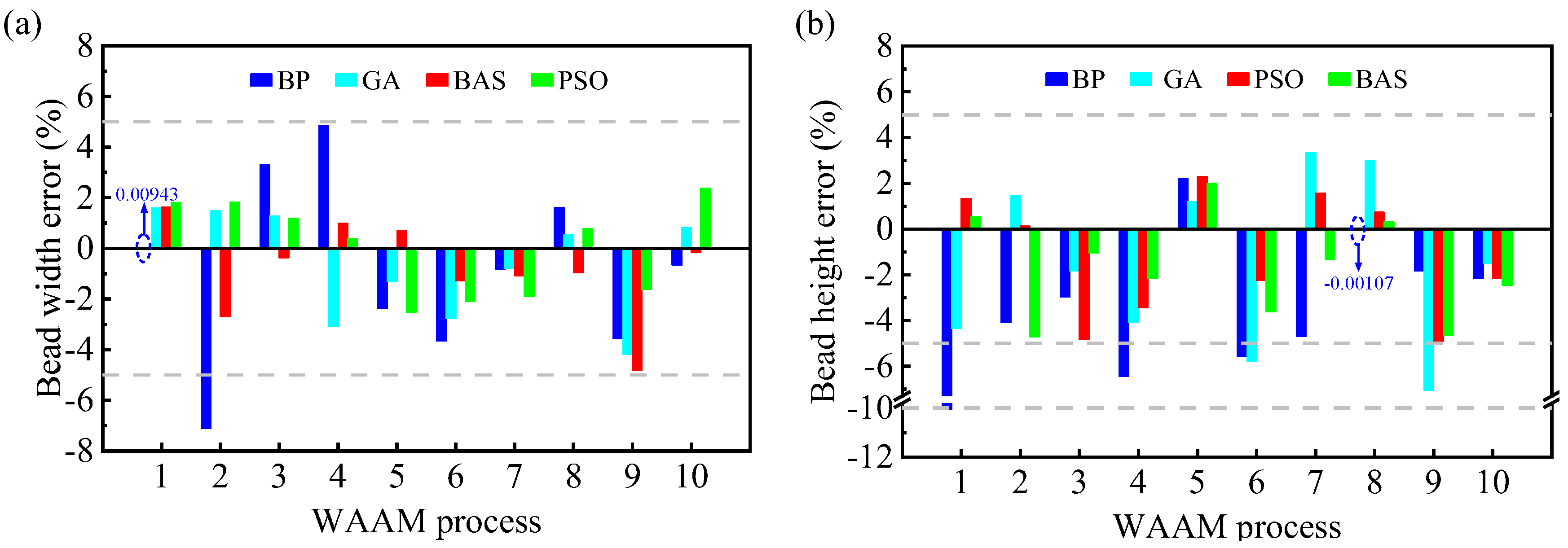

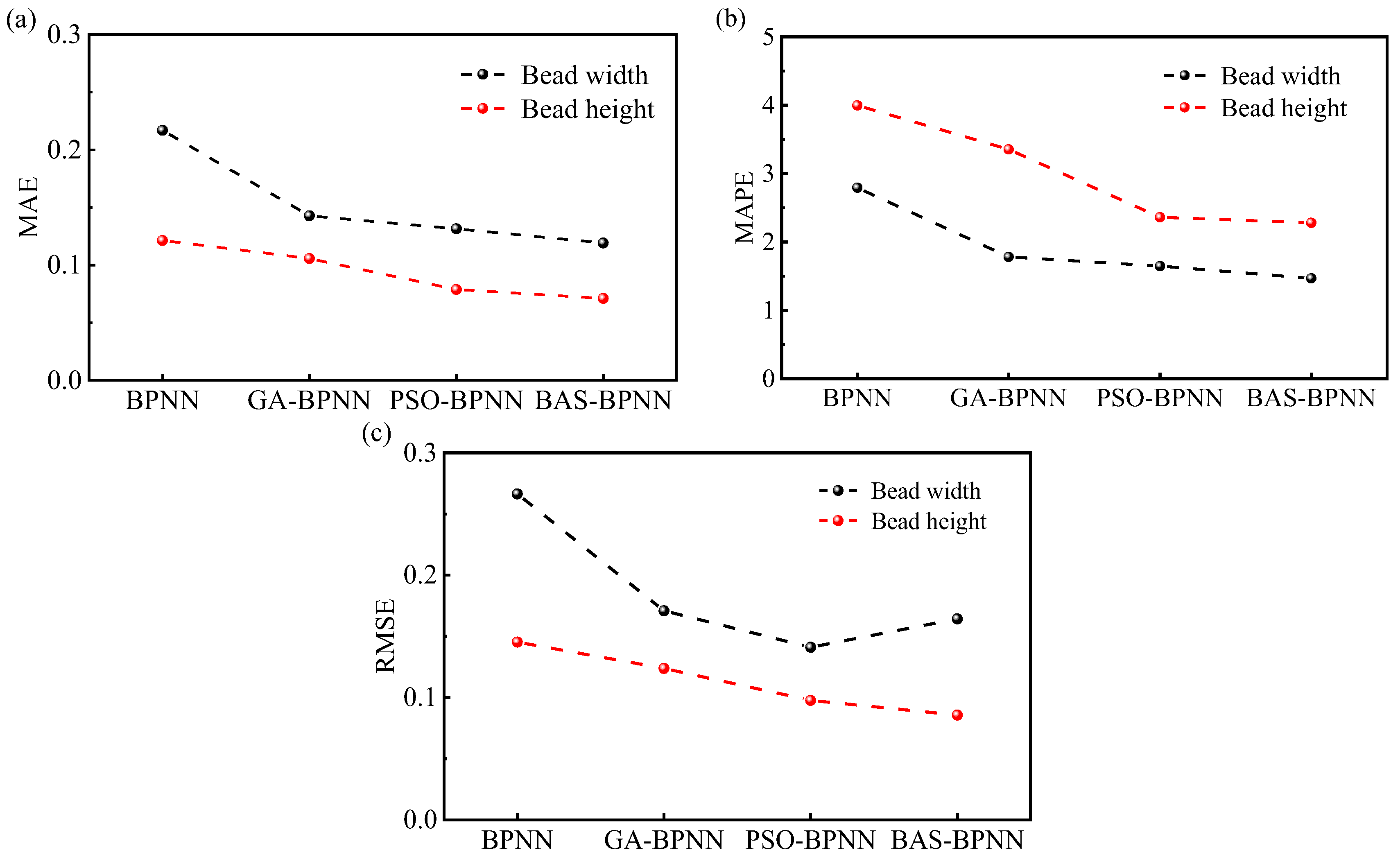

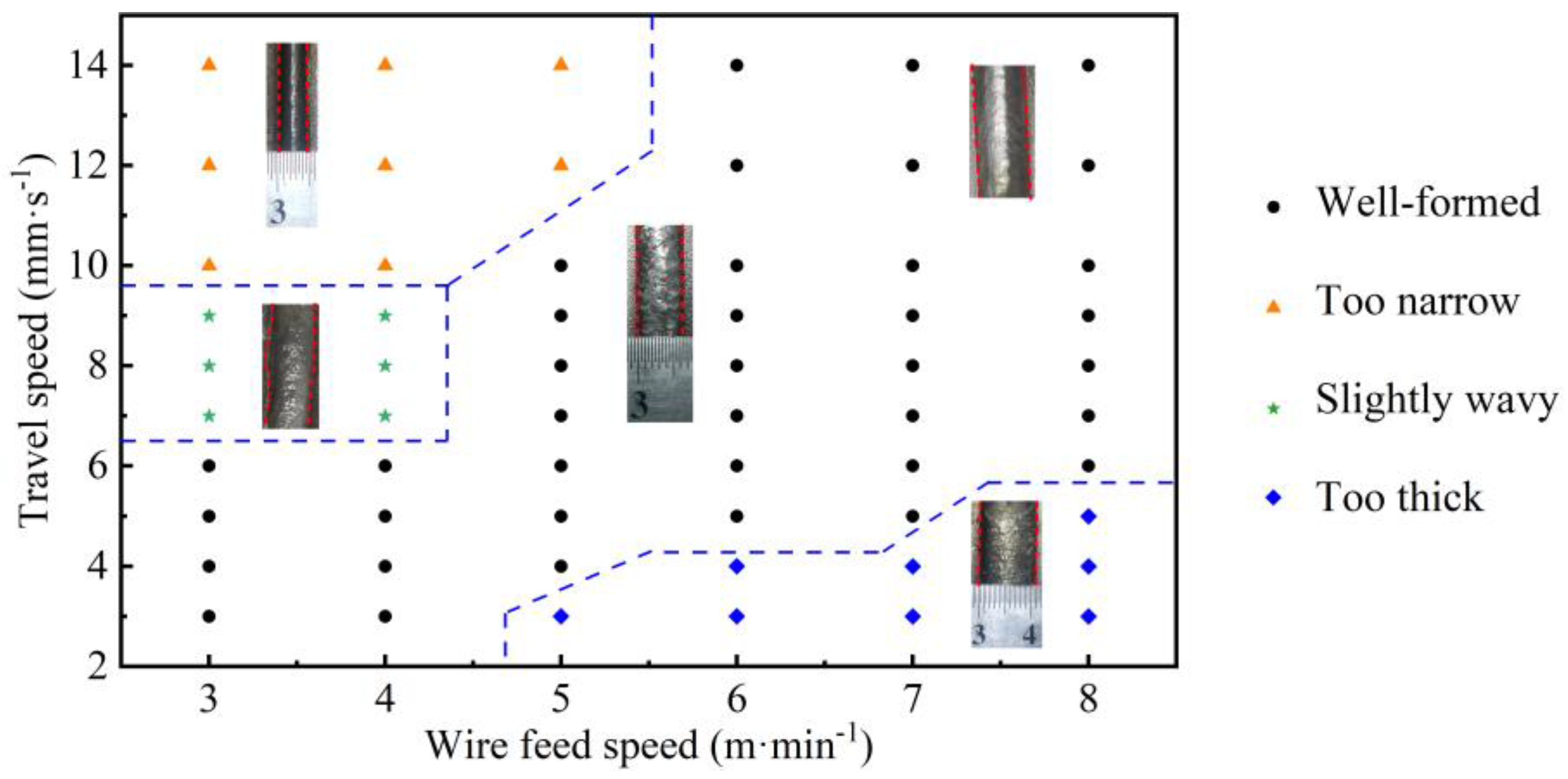

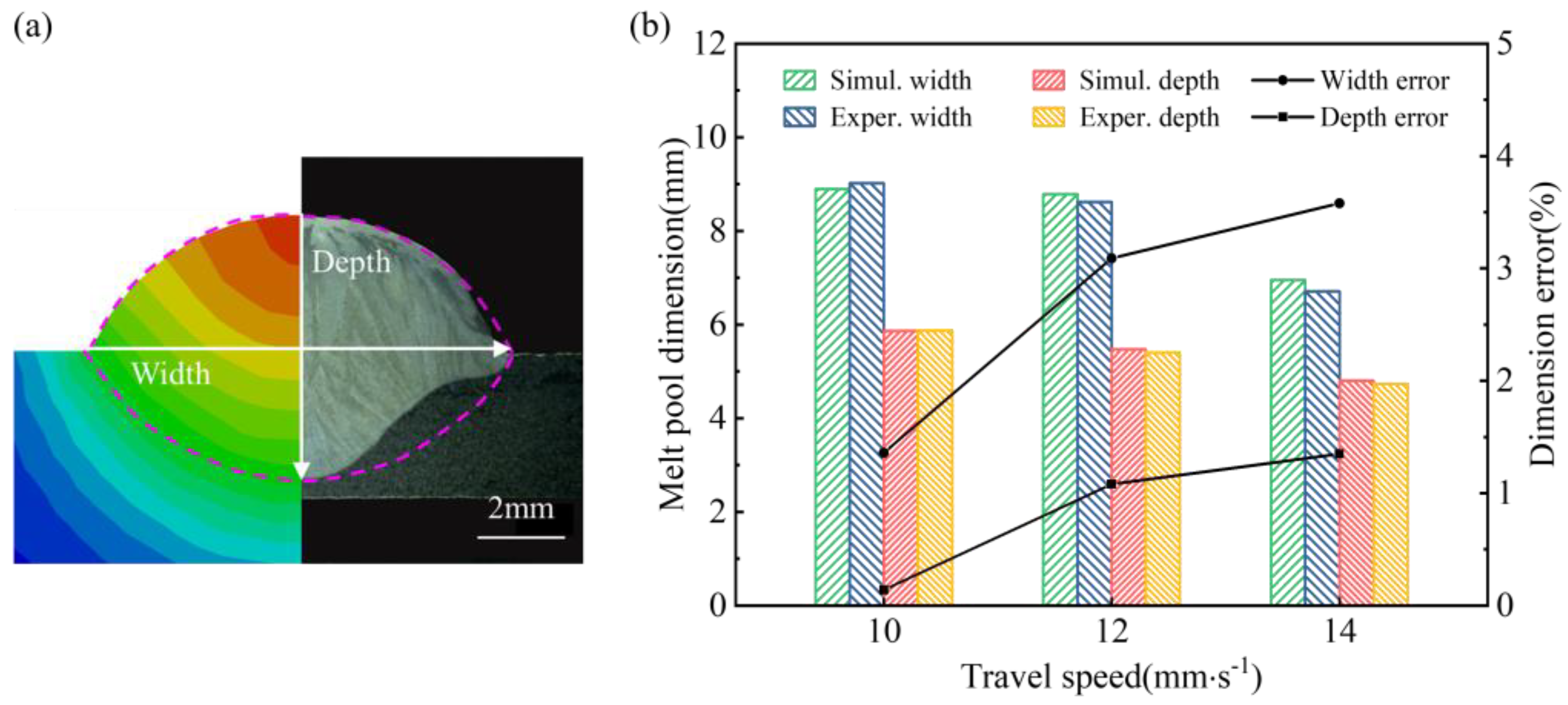

4.1. Geometry Dimension

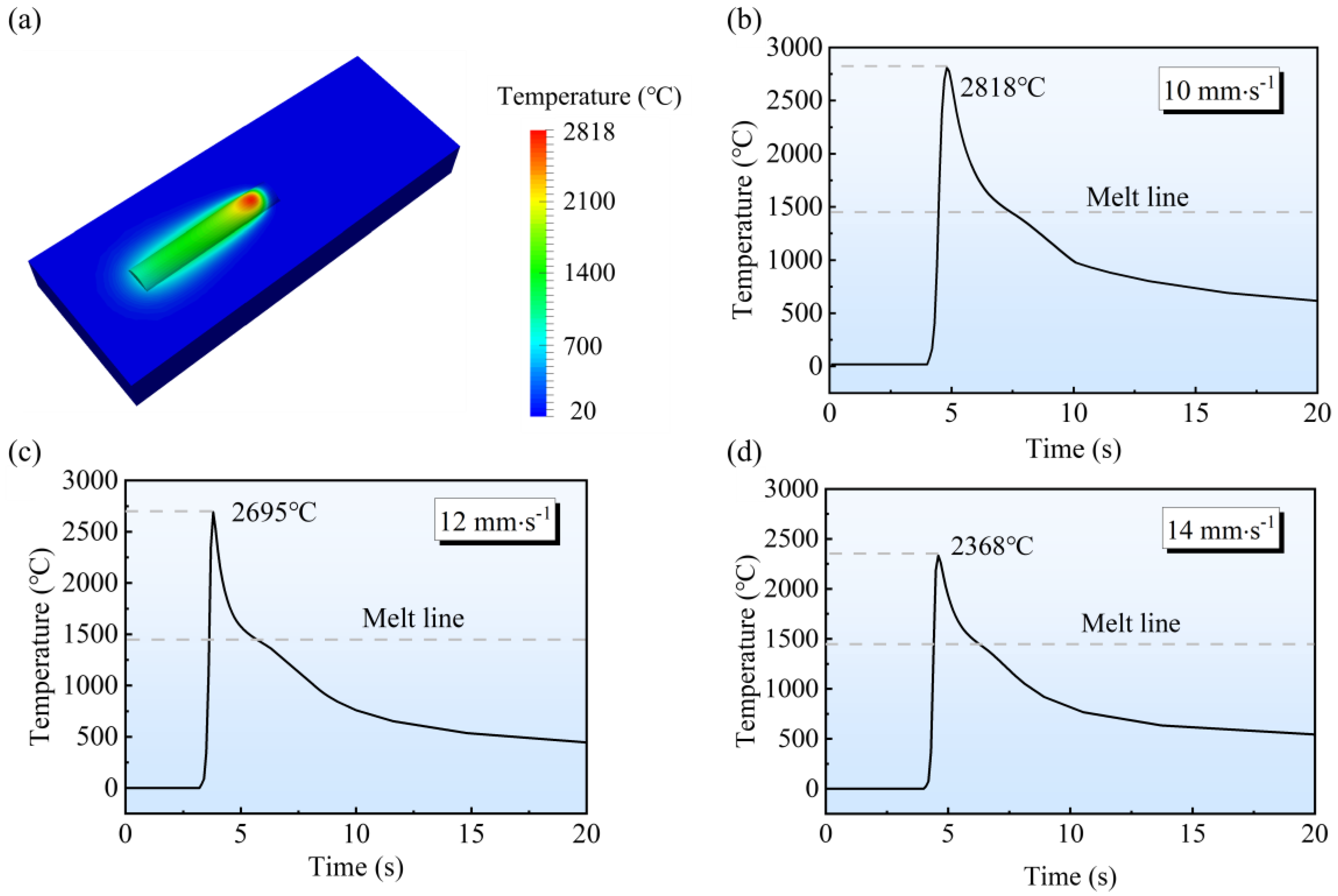

4.2. Thermal Evolution

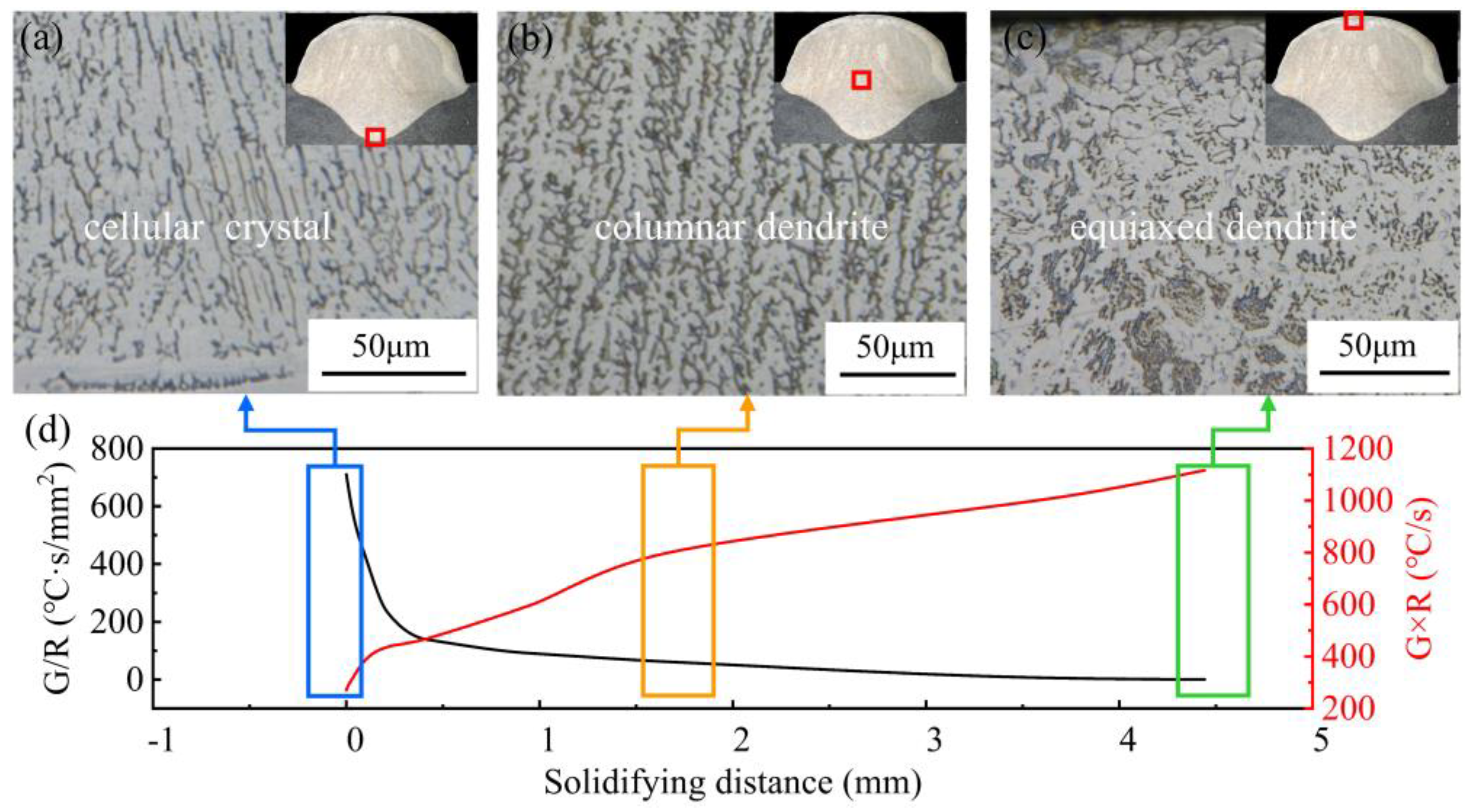

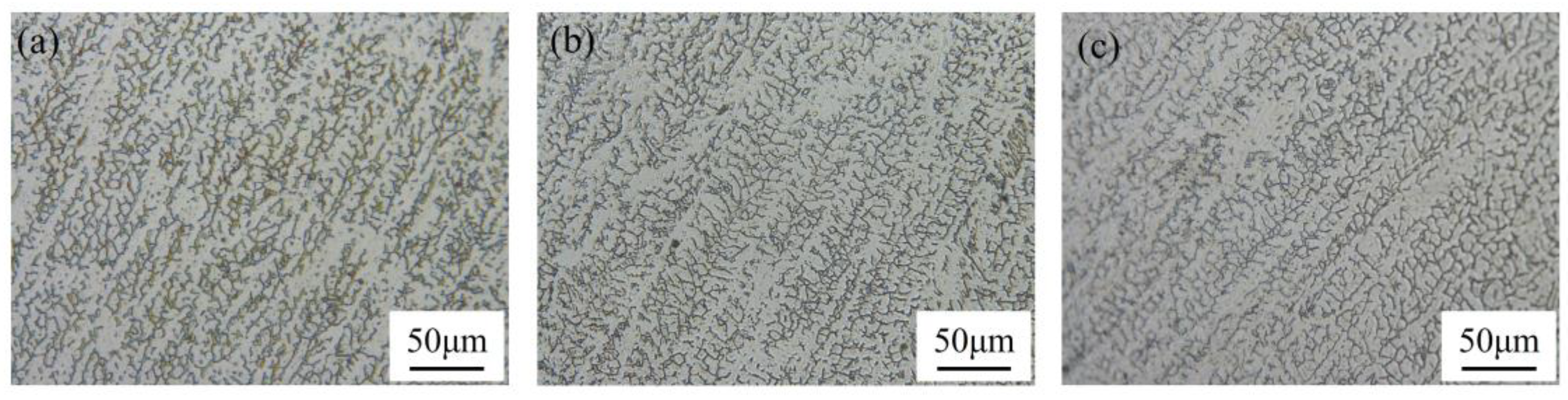

4.3. Microstructure Characteristic

5. Conclusions

- (1)

- The predicted width and height of the deposited layer under different processes were in good agreement with the experimental data. The errors of the width and height predicted by the models (GA-BPNN, PSO-BPNN, BAS-BPNN model) were all less than 6%. Besides this, the MAE, MAPE, and RMSE of the BAS-BPNN model were always smaller compared to other models, which means that the BAS-BPNN model had a better prediction capacity in the geometry dimension.

- (2)

- Process windows were established based on predictions and experiments. Continuous, stable, good melt tracks could be formed over a wide range of parameters (WFS (3–4 m·min−1) and TS (3–6 ); WFS (5 m·min−1) and TS (4–10 mm·s−1); WFS (6–7 m·min−1) and TS (5–14 mm·s−1); WFS (8 m·min−1) and TS (6–14 mm·s−1)). The width and height of the single track showed a decreasing trend when the TS was increased and an increasing trend when the WFS was decreased.

- (3)

- The melt pool obtained from the temperature simulation agreed well with the experimental results, and the coupled model was able to simulate effectively. When the TS was 14 mm·s−1, 12 mm·s−1, and 10 mm·s−1, the molten pool width errors were 1.36%, 3.09%, and 3.58%, and the molten pool depth errors were 0.14%, 1.08%, and 1.35%, respectively. The highest temperature in the molten pool increased as the TS decreased.

- (4)

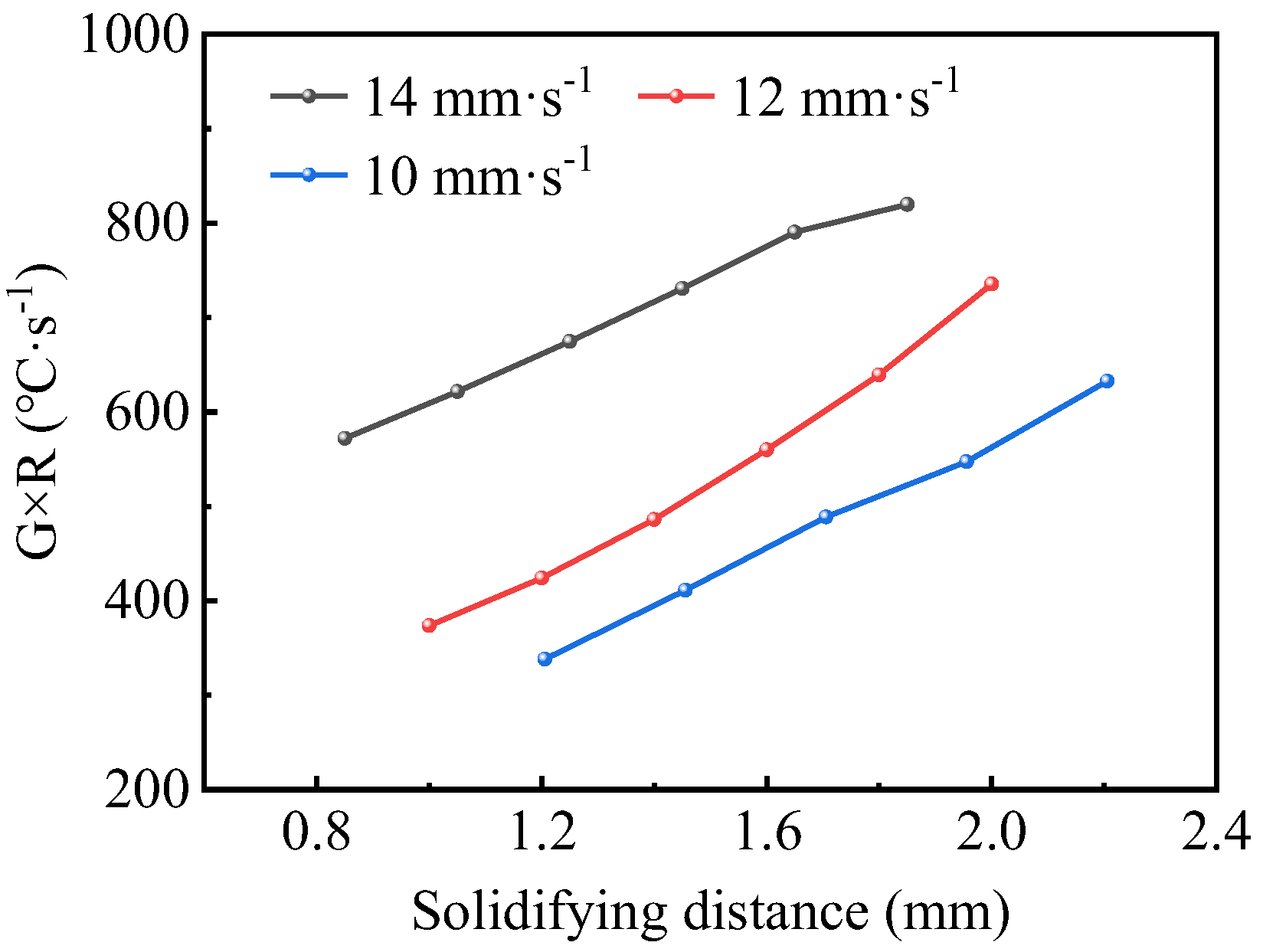

- The microstructural evolution during rapid solidification in the SS316L WAAM was related to its thermal behaviour. Decreases in induced a change in the crystal structure from columnar dendritic crystals to equiaxed dendritic crystals. Due to the increase in cooling rate, the primary dendrite spacing became larger and the δ-ferrite content increased.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Num. | WFS (m·min−1) | TS (mm·s−1) | TI (A) | TU (V) | BW (mm) | BH (mm) |

|---|---|---|---|---|---|---|

| 1 | 4 | 3 | 135 | 15.8 | 9.133 ± 0.292 | 4.253 ± 0.045 |

| 2 | 7 | 6 | 203 | 19.7 | 9.420 ± 0.253 | 3.567 ± 0.088 |

| 3 | 3.5 | 6 | 140 | 16 | 6.793 ± 0.069 | 2.590 ± 0.083 |

| 4 | 8 | 7 | 222 | 21.2 | 9.643 ± 0.845 | 3.295 ± 0.080 |

| 5 | 4 | 9 | 156 | 18.2 | 6.453 ± 0.059 | 2.730 ± 0.045 |

| 6 | 3.5 | 5 | 139 | 15.8 | 7.273 ± 0.049 | 2.680 ± 0.136 |

| 7 | 4.5 | 3 | 159 | 17.1 | 9.210 ± 0.151 | 4.280 ± 0.054 |

| 8 | 5 | 14 | 165 | 18.2 | 5.477 ± 0.541 | 1.930 ± 0.093 |

| 9 | 8.3 | 12 | 247 | 22.9 | 7.520 ± 0.233 | 2.690 ± 0.037 |

| 10 | 7 | 9 | 203 | 19.7 | 7.193 ± 0.117 | 2.947 ± 0.040 |

| 11 | 3 | 5 | 122 | 14.6 | 6.824 ± 0.409 | 2.853 ± 0.115 |

| 12 | 4.5 | 6 | 163 | 16.8 | 7.796 ± 0.031 | 3.050 ± 0.065 |

| 13 | 8.3 | 11 | 247 | 23.9 | 8.077 ± 0.268 | 2.737 ± 0.090 |

| 14 | 6 | 8 | 184 | 19.6 | 7.640 ± 0.320 | 3.180 ± 0.225 |

| 15 | 5 | 7 | 161 | 19.2 | 7.453 ± 0.293 | 3.167 ± 0.203 |

| 16 | 4 | 6 | 156 | 18.2 | 7.470 ± 0.199 | 3.070 ± 0.229 |

| 17 | 3.5 | 4 | 134 | 15.4 | 7.577 ± 0.276 | 2.870 ± 0.087 |

| 18 | 4.5 | 5 | 163 | 16.8 | 8.183 ± 0.073 | 3.118 ± 0.223 |

| 19 | 5 | 8 | 166 | 19.4 | 7.100 ± 0.216 | 3.040 ± 0.266 |

| 20 | 7 | 10 | 206 | 19.2 | 6.787 ± 0.115 | 2.487 ± 0.231 |

| 21 | 4 | 7 | 155 | 18.1 | 7.060 ± 0.196 | 2.830 ± 0.109 |

| 22 | 8.3 | 10 | 246 | 23.3 | 8.620 ± 0.236 | 2.790 ± 0.062 |

| 23 | 6 | 10 | 178 | 20.8 | 6.567 ± 0.236 | 2.320 ± 0.132 |

| 24 | 5 | 10 | 165 | 19.7 | 6.523 ± 0.528 | 2.640 ± 0.193 |

| 25 | 4 | 4 | 156 | 18.2 | 7.804 ± 0.046 | 3.410 ± 0.277 |

| 26 | 7 | 12 | 206 | 19.2 | 6.393 ± 0.120 | 2.323 ± 0.106 |

| 27 | 4 | 8 | 150 | 16.8 | 6.640 ± 0.190 | 2.846 ± 0.110 |

| 28 | 4 | 10 | 148 | 18.3 | 6.227 ± 0.143 | 2.467 ± 0.196 |

| 29 | 5.5 | 4 | 226 | 17.6 | 8.900 ± 0.102 | 3.960 ± 0.218 |

| 30 | 8 | 8 | 240 | 19 | 9.220 ± 0.985 | 3.187 ± 0.107 |

| 31 | 5 | 12 | 155 | 20.2 | 6.060 ± 0.091 | 2.300 ± 0.216 |

| 32 | 3 | 7 | 121 | 14.5 | 5.967 ± 0.256 | 2.287 ± 0.162 |

| 33 | 7.5 | 5 | 221 | 19.2 | 11.123 ± 0.202 | 3.506 ± 0.247 |

| 34 | 3 | 8 | 122 | 14.4 | 5.740 ± 0.117 | 1.940 ± 0.102 |

| 35 | 4 | 12 | 148 | 17.8 | 5.727 ± 0.086 | 2.053 ± 0.066 |

| 36 | 5 | 6 | 171 | 19 | 8.123 ± 0.054 | 3.290 ± 0.194 |

| 37 | 3 | 10 | 123 | 15 | 5.640 ± 0.071 | 1.850 ± 0.067 |

| 38 | 8 | 9 | 214 | 23.7 | 8.917 ± 0.293 | 3.015 ± 0.184 |

| 39 | 7 | 7 | 214 | 16.2 | 9.243 ± 0.526 | 3.226 ± 0.051 |

| 40 | 5 | 9 | 168 | 19.4 | 6.777 ± 0.111 | 2.890 ± 0.263 |

| 41 | 4 | 14 | 155 | 18.1 | 5.177 ± 0.833 | 1.870 ± 0.034 |

| 42 | 8.3 | 14 | 243 | 24.5 | 6.727 ± 0.060 | 2.440 ± 0.205 |

| 43 | 5.5 | 6 | 181 | 18.1 | 8.307 ± 0.090 | 3.489 ± 0.206 |

| 44 | 3.5 | 7 | 145 | 16.2 | 6.407 ± 0.052 | 2.590 ± 0.051 |

| 45 | 6 | 7 | 195 | 15.5 | 8.457 ± 0.292 | 3.170 ± 0.121 |

| 46 | 8 | 14 | 223 | 21.5 | 6.407 ± 0.168 | 2.207 ± 0.188 |

| 47 | 7.5 | 8 | 217 | 19.9 | 7.970 ± 0.218 | 3.260 ± 0.177 |

| 48 | 4 | 8 | 150 | 16.8 | 6.640 ± 0.140 | 2.980 ± 0.161 |

| 49 | 6 | 8 | 184 | 19.6 | 7.720 ± 0.305 | 3.070 ± 0.085 |

| 50 | 3 | 5 | 128 | 14.7 | 6.573 ± 0.090 | 2.720 ± 0.218 |

| 51 | 7 | 9 | 218 | 18.8 | 7.260 ± 0.241 | 2.924 ± 0.062 |

| 52 | 8 | 8 | 222 | 21.9 | 9.300 ± 0.205 | 3.500 ± 0.199 |

| 53 | 5 | 14 | 165 | 15.2 | 5.050 ± 0.236 | 2.010 ± 0.167 |

| 54 | 3 | 8 | 127 | 14.6 | 5.806 ± 0.172 | 1.927 ± 0.230 |

| 55 | 8.3 | 14 | 243 | 24.5 | 6.727 ± 0.048 | 2.370 ± 0.139 |

| 56 | 5 | 9 | 168 | 19.4 | 6.777 ± 0.040 | 2.877 ± 0.156 |

| 57 | 4 | 6 | 156 | 18.1 | 7.400 ± 0.065 | 3.020 ± 0.136 |

| 58 | 5 | 6 | 171 | 19 | 8.010 ± 0.119 | 2.976 ± 0.073 |

| 59 | 8 | 14 | 236 | 19 | 6.587 ± 0.333 | 2.260 ± 0.065 |

| 60 | 5 | 8 | 166 | 19.4 | 7.350 ± 0.150 | 2.860 ± 0.240 |

| 61 | 4 | 4 | 155 | 18.2 | 7.796 ± 0.068 | 3.440 ± 0.227 |

| 62 | 8.3 | 10 | 246 | 23.5 | 8.620 ± 0.111 | 2.817 ± 0.037 |

| 63 | 4 | 9 | 158 | 18.1 | 6.370 ± 0.108 | 2.667 ± 0.222 |

| 64 | 5 | 10 | 164 | 19.7 | 6.260 ± 0.096 | 2.377 ± 0.078 |

| 65 | 5.5 | 4 | 185 | 18.1 | 8.964 ± 0.057 | 3.943 ± 0.176 |

| 66 | 4 | 14 | 155 | 18.2 | 5.177 ± 0.205 | 1.667 ± 0.191 |

| 67 | 7 | 9 | 203 | 20.1 | 7.183 ± 0.055 | 2.910 ± 0.214 |

| 68 | 8.3 | 11 | 245 | 24.1 | 7.967 ± 0.095 | 2.638 ± 0.172 |

| 69 | 7.5 | 5 | 219 | 19.4 | 11.123 ± 0.223 | 3.337 ± 0.230 |

| 70 | 5.5 | 6 | 181 | 18.2 | 8.307 ± 0.198 | 3.516 ± 0.250 |

| 71 | 4 | 7 | 155 | 18.1 | 6.820 ± 0.073 | 2.790 ± 0.130 |

| 72 | 7.5 | 8 | 219 | 19.4 | 7.940 ± 0.107 | 3.250 ± 0.258 |

| 73 | 8.3 | 12 | 245 | 24.1 | 7.580 ± 0.271 | 2.650 ± 0.091 |

| 74 | 5 | 8 | 167 | 19.5 | 7.430 ± 0.297 | 2.800 ± 0.148 |

| 75 | 5 | 6 | 171 | 19 | 7.860 ± 0.253 | 2.950 ± 0.102 |

| 76 | 6 | 7 | 195 | 15.5 | 8.195 ± 0.213 | 3.145 ± 0.107 |

| 77 | 8 | 7 | 222 | 21.2 | 9.677 ± 0.166 | 3.237 ± 0.087 |

| 78 | 5 | 7 | 161 | 19.2 | 7.206 ± 0.083 | 3.005 ± 0.042 |

| 79 | 7 | 7 | 214 | 16.2 | 8.885 ± 0.115 | 3.262 ± 0.085 |

| 80 | 6 | 10 | 178 | 20.8 | 6.660 ± 0.061 | 2.240 ± 0.060 |

| 81 | 7 | 12 | 206 | 19.2 | 6.280 ± 0.167 | 2.260 ± 0.024 |

| 82 | 7 | 6 | 203 | 19.7 | 9.180 ± 0.130 | 3.620 ± 0.195 |

| 83 | 8 | 9 | 214 | 23.7 | 9.010 ± 0.100 | 2.976 ± 0.105 |

| 84 | 5 | 12 | 155 | 20.2 | 6.190 ± 0.199 | 2.260 ± 0.103 |

| 85 | 7 | 10 | 206 | 19.2 | 7.220 ± 0.103 | 2.780 ± 0.079 |

References

- Sun, L.B.; Jiang, F.C.; Huang, R.S.; Yuan, D.; Su, Y.; Guo, C.H.; Wang, J.D. Investigation on the process window with liner energy density for single-layer parts fabricated by wire and arc additive manufacturing. J. Manuf. Process. 2020, 56, 898–907. [Google Scholar] [CrossRef]

- Long, P.; Wen, D.X.; Min, J.; Zheng, Z.Z.; Li, J.J.; Liu, Y.X. Microstructure Evolution and Mechanical Properties of a Wire-Arc Additive Manufactured Austenitic Stainless Steel: Effect of Processing Parameter. Materials 2021, 14, 1681. [Google Scholar] [CrossRef]

- Xiong, Y.B.; Wen, D.X.; Zheng, Z.Z.; Li, J.J. Effect of interlayer temperature on microstructure evolution and mechanical performance of wire arc additive manufactured 300M steel. Mater. Sci. Eng. A 2022, 831, 13. [Google Scholar] [CrossRef]

- Li, Y.J.; Yu, S.F.; Chen, Y.; Yu, R.Z.; Shi, Y.S. Wire and arc additive manufacturing of aluminum alloy lattice structure. J. Manuf. Process. 2020, 50, 510–519. [Google Scholar] [CrossRef]

- Zhong, Y.; Zheng, Z.Z.; Li, J.J.; Wang, C. Fabrication of 316L nuclear nozzles on the main pipeline with large curvature by CMT wire arc additive manufacturing and self-developed slicing algorithm. Mater. Sci. Eng. A 2021, 820, 14. [Google Scholar] [CrossRef]

- Ge, J.G.; Ma, T.J.; Chen, Y.; Jin, T.N.; Fu, H.G.; Xiao, R.S.; Lei, Y.P.; Lin, J. Wire-arc additive manufacturing H13 part: 3D pore distribution, microstructural evolution, and mechanical performances. J. Alloys Compd. 2019, 783, 145–155. [Google Scholar] [CrossRef]

- Jing, C.C.; Chen, Z.; Liu, B.; Xu, T.Q.; Wang, J.; Lu, T.; Lu, J.P.; Guo, Y.L.; Liu, C.M. Improving mechanical strength and isotropy for wire-arc additive manufactured 304L stainless steels via controlling arc heat input. Mater. Sci. Eng. A 2022, 845, 11. [Google Scholar] [CrossRef]

- Ding, D.H.; Pan, Z.X.; Cuiuri, D.; Li, H.J. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Yuan, T.; Yu, Z.L.; Chen, S.J.; Xu, M.; Jiang, X.Q. Loss of elemental Mg during wire plus arc additive manufacturing of Al-Mg alloy and its effect on mechanical properties. J. Manuf. Process. 2020, 49, 456–462. [Google Scholar] [CrossRef]

- Wu, B.T.; Pan, Z.X.; Ding, D.H.; Cuiuri, D.; Li, H.J.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Shen, C.; Pan, Z.X.; Cuiuri, D.; Ding, D.H.; Li, H.J. Influences of deposition current and interpass temperature to the Fe3Al-based iron aluminide fabricated using wire-arc additive manufacturing process. Int. J. Adv. Manuf. Technol. 2017, 88, 2009–2018. [Google Scholar] [CrossRef]

- Wang, C.; Liu, T.G.; Zhu, P.; Lu, Y.H.; Shoji, T. Study on microstructure and tensile properties of 316L stainless steel fabricated by CMT wire and arc additive manufacturing. Mater. Sci. Eng. A 2020, 796, 12. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Miranda, R.M.; Santos, T.G.; Oliveira, J.P. Current Status and Perspectives on Wire and Arc Additive Manufacturing (WAAM). Materials 2019, 12, 1121. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.Y.; Pan, H.H.; Ren, L.B.; Quan, G.F. Microstructure and mechanical properties of wire arc additively manufactured AZ80M magnesium alloy. Mater. Lett. 2019, 247, 4–6. [Google Scholar] [CrossRef]

- Qi, Z.W.; Qi, B.J.; Cong, B.Q.; Sun, H.Y.; Zhao, G.; Ding, J.L. Microstructure and mechanical properties of wire plus arc additively manufactured 2024 aluminum alloy components: As-deposited and post heat-treated. J. Manuf. Process. 2019, 40, 27–36. [Google Scholar] [CrossRef]

- Cho, J.S.; Lee, D.H.; Seo, G.J.; Kim, D.B.; Shin, S.J. Optimizing the mean and variance of bead geometry in the wire + arc additive manufacturing using a desirability function method. Int. J. Adv. Manuf. Technol. 2022, 120, 7771–7783. [Google Scholar] [CrossRef]

- Fu, Y.H.; Wang, G.L.; Zhang, H.O.; Liang, L.Y. Optimization of surface appearance for wire and arc additive manufacturing of Bainite steel. Int. J. Adv. Manuf. Technol. 2016, 91, 301–313. [Google Scholar]

- Mu, H.C.; Polden, J.; Li, Y.X.; He, F.Y.; Xia, C.Y.; Pan, Z.X. Layer-by-layer model-based adaptive control for wire arc additive manufacturing of thin-wall structures. J. Intell. Manuf. 2022, 33, 1165–1180. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.J.; Hu, J.W.; Li, Y.Z. Forecasting process parameters for GMAW-based rapid manufacturing using closed-loop iteration based on neural network. Int. J. Adv. Manuf. Technol. 2013, 69, 743–751. [Google Scholar] [CrossRef]

- Ikeuchi, D.; Vargas-Uscategui, A.; Wu, X.; King, P.C. Neural Network Modelling of Track Profile in Cold Spray Additive Manufacturing. Materials 2019, 12, 2827. [Google Scholar] [CrossRef]

- Xian, G.; Oh, J.M.; Lee, J.; Cho, S.M.; Yeom, J.-T.; Choi, Y.; Kang, N. Effect of heat input on microstructure and mechanical property of wire-arc additive manufactured Ti-6Al-4V alloy. Weld. World 2022, 66, 847–861. [Google Scholar] [CrossRef]

- Hejripour, F.; Binesh, F.; Hebel, M.; Aidun, D.K. Thermal modeling and characterization of wire arc additive manufactured duplex stainless steel. J. Mater. Process. Technol. 2019, 272, 58–71. [Google Scholar] [CrossRef]

- Mishra, V.; Babu, A.; Schreurs, R.; Wu, K.; Hermans, M.J.M.; Ayas, C. Microstructure estimation and validation of ER110S-G steel structures produced by wire and arc additive manufacturing. J. Mater. Res. Technol. 2023, 23, 3579–3601. [Google Scholar] [CrossRef]

- Xiong, F.; Lian, Y.; Li, M.-J.; Ouyang, J.; Liu, Y. An extended cellular automaton finite volume method for grain nucleation–growth–coarsening during the wire-based additive manufacturing process. Addit. Manuf. 2023, 76, 103782. [Google Scholar] [CrossRef]

- Staroselsky, A.; Voytovych, D.; Acharya, R. Prediction of Ni-based alloy microstructure in wire arc additive manufacturing from cellular automata model. Comput. Mater. Sci. 2024, 233, 112721. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Integrated 2D cellular automata-phase field modeling of solidification and microstructure evolution during additive manufacturing of Ti6Al4V. Comput. Mater. Sci. 2020, 183, 109889. [Google Scholar] [CrossRef]

- Geng, R.; Du, J.; Wei, Z.; Ma, N. Multiscale modelling of microstructure, micro-segregation, and local mechanical properties of Al-Cu alloys in wire and arc additive manufacturing. Addit. Manuf. 2020, 36, 101735. [Google Scholar] [CrossRef]

- Ding, D.H.; Zhang, S.M.; Lu, Q.H.; Pan, Z.X.; Li, H.J.; Wang, K. The well-distributed volumetric heat source model for numerical simulation of wire arc additive manufacturing process. Mater. Today Commun. 2021, 27, 11. [Google Scholar] [CrossRef]

- Le, V.T.; Nguyen, H.D.; Bui, M.C.; Pham, T.Q.D.; Le, H.T.; Tran, V.X.; Tran, H.S. Rapid and accurate prediction of temperature evolution in wire plus arc additive manufacturing using feedforward neural network. Manuf. Lett. 2022, 32, 28–31. [Google Scholar] [CrossRef]

- Zhang, W.H.; Ding, C.S.; Wang, H.R.; Meng, W.; Xu, Z.L.; Wang, J.J. The Forming Profile Model for Cold Metal Transfer and Plasma Wire-Arc Deposition of Nickel-Based Alloy. J. Mater. Eng. Perform. 2021, 30, 4872–4881. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1986, 323, 533–536. [Google Scholar] [CrossRef]

- Holland, J.H. Genetic Algorithms and Adaptation. In Adaptive Control of Ill-Defined Systems; Selfridge, O.G., Rissland, E.L., Arbib, M.A., Eds.; Springer: Boston, MA, USA, 1984; pp. 317–333. [Google Scholar]

- Kemda, B.V.F.; Barka, N.; Jahazi, M.; Osmani, D. Multi-Objective Optimization of Process Parameters in Resistance Spot Welding of A36 Mild Steel and Hot Dipped Galvanized Steel Sheets Using Non-dominated Sorting Genetic Algorithm. Met. Mater.-Int. 2022, 28, 487–502. [Google Scholar] [CrossRef]

- Murat, F.; Kaymaz, I.; Sensoy, A.T.; Korkmaz, I.H. Determining the Optimum Process Parameters of Selective Laser Melting via Particle Swarm Optimization Based on the Response Surface Method. Met. Mater.-Int. 2023, 29, 59–70. [Google Scholar] [CrossRef]

- Zhang, X.Q.; Jiang, S.Q. Study on the application of BP neural network optimized based on various optimization algorithms in storm surge prediction. Proc. Inst. Mech. Eng. Part M-J. Eng. Marit. Environ. 2022, 236, 539–552. [Google Scholar] [CrossRef]

- Li, R.; Xiong, J. Influence of interlayer dwell time on stress field of thin-walled components in WAAM via numerical simulation and experimental tests. Rapid Prototyp. J. 2019, 25, 1433–1441. [Google Scholar] [CrossRef]

- Li, J.D.; Wang, X.C.; Yang, Q.; Zhao, J.W.; Wu, Z.D.; Wang, Z.H. Modeling and validation of bending force for 6-high tandem cold rolling mill based on machine learning models. Int. J. Adv. Manuf. Technol. 2022, 123, 389–405. [Google Scholar] [CrossRef]

- Li, C.; Yu, Z.B.; Gao, J.X.; Zhao, J.Y.; Han, X. Numerical simulation and experimental study of cladding Fe60 on an ASTM 1045 substrate by laser cladding. Surf. Coat. Technol. 2019, 357, 965–977. [Google Scholar] [CrossRef]

- Kurz, W.; Fisher, D. Fundamentals of Solidification, 4th ed.; Trans Tech Publication Ltd.: Wollerau, Switzerland, 1998; pp. 1–292. [Google Scholar]

- Tiller, W.A.; Jackson, K.A.; Rutter, J.W.; Chalmers, B. The redistribution of solute atoms during the solidification of metals. Acta Metall. 1953, 1, 428–437. [Google Scholar] [CrossRef]

- Di Schino, A.; Mecozzi, M.G.; Barteri, M.; Kenny, J.M. Solidification mode and residual ferrite in low-Ni austenitic stainless steels. J. Mater. Sci. 2000, 35, 375–380. [Google Scholar] [CrossRef]

- Fu, J.W.; Yang, Y.S.; Guo, J.J.; Tong, W.H. Effect of cooling rate on solidification microstructures in AISI 304 stainless steel. Mater. Sci. Technol. 2008, 24, 941–944. [Google Scholar] [CrossRef]

| Element | Cr | Ni | Mo | Mn | Si | C | S | P | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Content | 18.39 | 12.5 | 2.25 | 1.69 | 0.81 | 0.02 | 0.015 | 0.015 | 0.013 | balance |

| Parameter | Units | Value |

|---|---|---|

| Transient voltage (TU) | V | 14.4–24.5 |

| Transient current (TI) | A | 122–243 |

| Travel speed (TS) | mm·s−1 | 3–14 |

| Wire feed speed (WFS) | m·min−1 | 3–8.3 |

| Gas flow rate | L·min−1 | 20 |

| WAAM Parameter | Value (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Num. | WFS | TS | BPNN | GA-BPNN | PSO-BPNN | BAS-BPNN | Exper. |

| 1 | 8.3 | 9 | 8.9909 | 9.1334 | 9.1522 | 9.1359 | 8.99 |

| 2 | 8 | 12 | 6.8121 | 7.4419 | 7.4676 | 7.1362 | 7.3333 |

| 3 | 6 | 6 | 8.8909 | 8.7163 | 8.7083 | 8.5752 | 8.6067 |

| 4 | 7 | 8 | 8.3067 | 7.6802 | 7.9547 | 8.0022 | 7.9233 |

| 5 | 4 | 5 | 7.4564 | 7.5365 | 7.4448 | 7.6908 | 7.6367 |

| 6 | 3 | 6 | 6.2372 | 6.2942 | 6.3382 | 6.3904 | 6.4733 |

| 7 | 8 | 10 | 8.1115 | 8.1146 | 8.0252 | 8.091 | 8.18 |

| 8 | 5.5 | 7 | 7.8946 | 7.8108 | 7.8308 | 7.6952 | 7.77 |

| 9 | 5 | 5 | 8.4923 | 8.4383 | 8.6645 | 8.3837 | 8.8067 |

| 10 | 4.5 | 4 | 8.3912 | 8.5153 | 8.6473 | 6.193 | 8.4467 |

| WAAM Parameter | Value (mm) | ||||||

|---|---|---|---|---|---|---|---|

| Num. | WFS | TS | BPNN | GA-BPNN | PSO-BPNN | BAS-BPNN | Exper. |

| 1 | 8.3 | 9 | 2.7372 | 2.9113 | 3.084 | 3.0598 | 3.0433 |

| 2 | 8 | 12 | 2.4654 | 2.6072 | 2.5732 | 2.4488 | 2.57 |

| 3 | 6 | 6 | 3.5065 | 3.5476 | 3.439 | 3.5756 | 3.6133 |

| 4 | 7 | 8 | 2.9845 | 3.0601 | 3.0807 | 3.1213 | 3.19 |

| 5 | 4 | 5 | 3.1987 | 3.1669 | 3.2012 | 3.192 | 3.1292 |

| 6 | 3 | 6 | 2.3171 | 2.3118 | 2.3983 | 2.3647 | 2.4533 |

| 7 | 8 | 10 | 2.7386 | 2.9693 | 2.9183 | 2.8347 | 2.8733 |

| 8 | 5.5 | 7 | 3.137 | 3.2306 | 3.16 | 3.1468 | 3.137 |

| 9 | 5 | 5 | 3.6982 | 3.5011 | 3.5817 | 3.5923 | 3.7667 |

| 10 | 4.5 | 4 | 3.669 | 3.693 | 3.6699 | 3.6582 | 3.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di, Y.; Zheng, Z.; Pang, S.; Li, J.; Zhong, Y. Dimension Prediction and Microstructure Study of Wire Arc Additive Manufactured 316L Stainless Steel Based on Artificial Neural Network and Finite Element Simulation. Micromachines 2024, 15, 615. https://doi.org/10.3390/mi15050615

Di Y, Zheng Z, Pang S, Li J, Zhong Y. Dimension Prediction and Microstructure Study of Wire Arc Additive Manufactured 316L Stainless Steel Based on Artificial Neural Network and Finite Element Simulation. Micromachines. 2024; 15(5):615. https://doi.org/10.3390/mi15050615

Chicago/Turabian StyleDi, Yanyan, Zhizhen Zheng, Shengyong Pang, Jianjun Li, and Yang Zhong. 2024. "Dimension Prediction and Microstructure Study of Wire Arc Additive Manufactured 316L Stainless Steel Based on Artificial Neural Network and Finite Element Simulation" Micromachines 15, no. 5: 615. https://doi.org/10.3390/mi15050615

APA StyleDi, Y., Zheng, Z., Pang, S., Li, J., & Zhong, Y. (2024). Dimension Prediction and Microstructure Study of Wire Arc Additive Manufactured 316L Stainless Steel Based on Artificial Neural Network and Finite Element Simulation. Micromachines, 15(5), 615. https://doi.org/10.3390/mi15050615