Recent Developments in (K, Na)NbO3-Based Lead-Free Piezoceramics

Abstract

1. Introduction

2. KNN-Modified Ceramics with the O–T–PC Multistructure

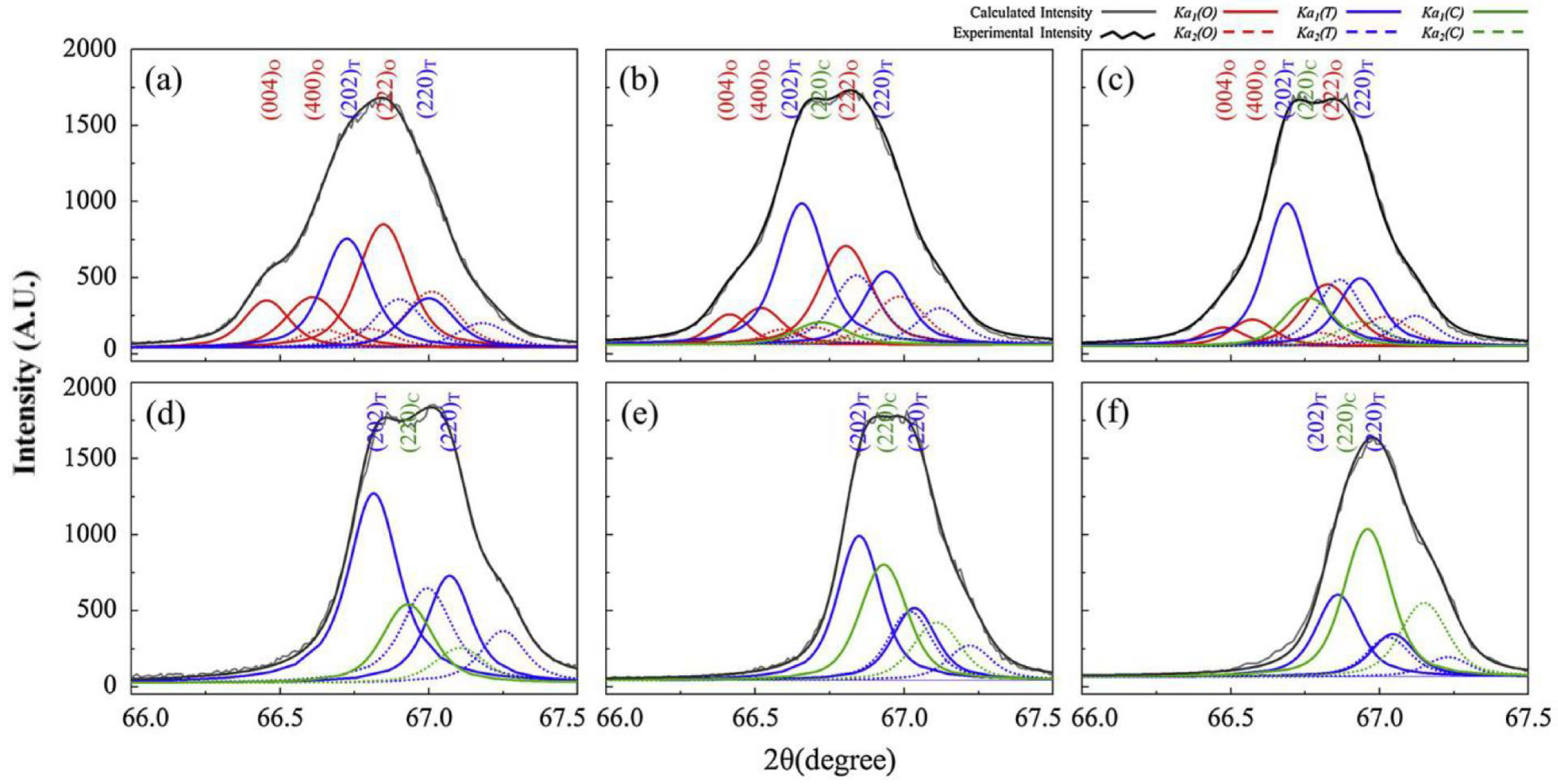

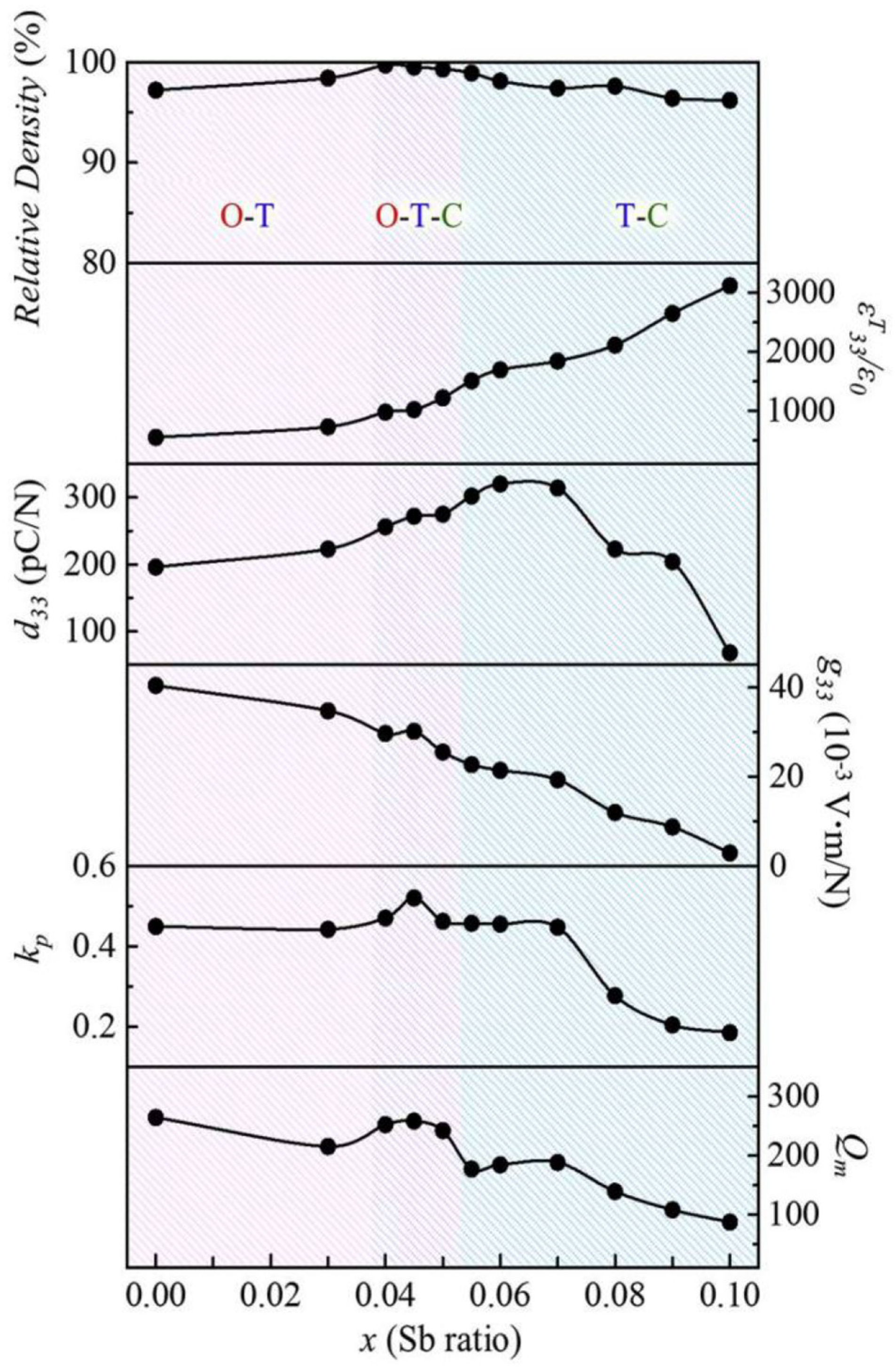

2.1. (Na, K)(Nb, Sb)-CaTiO3 Ceramics with the O–T–PC (or O–T–C) Multistructure

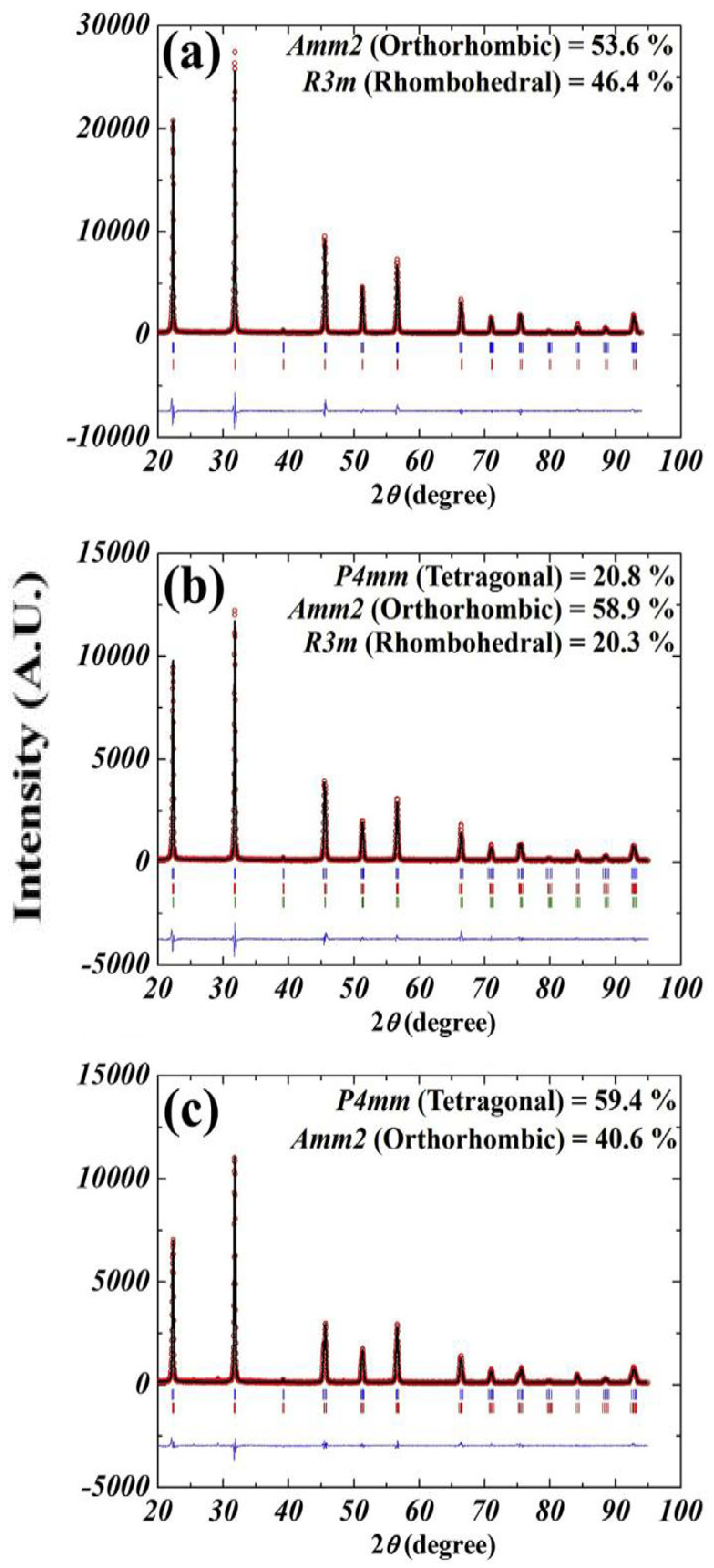

2.2. (Li, Na, K)(Nb, Sb)-SrZrO3 Ceramics with an O–T–PC (or O–T–R) Multistructure

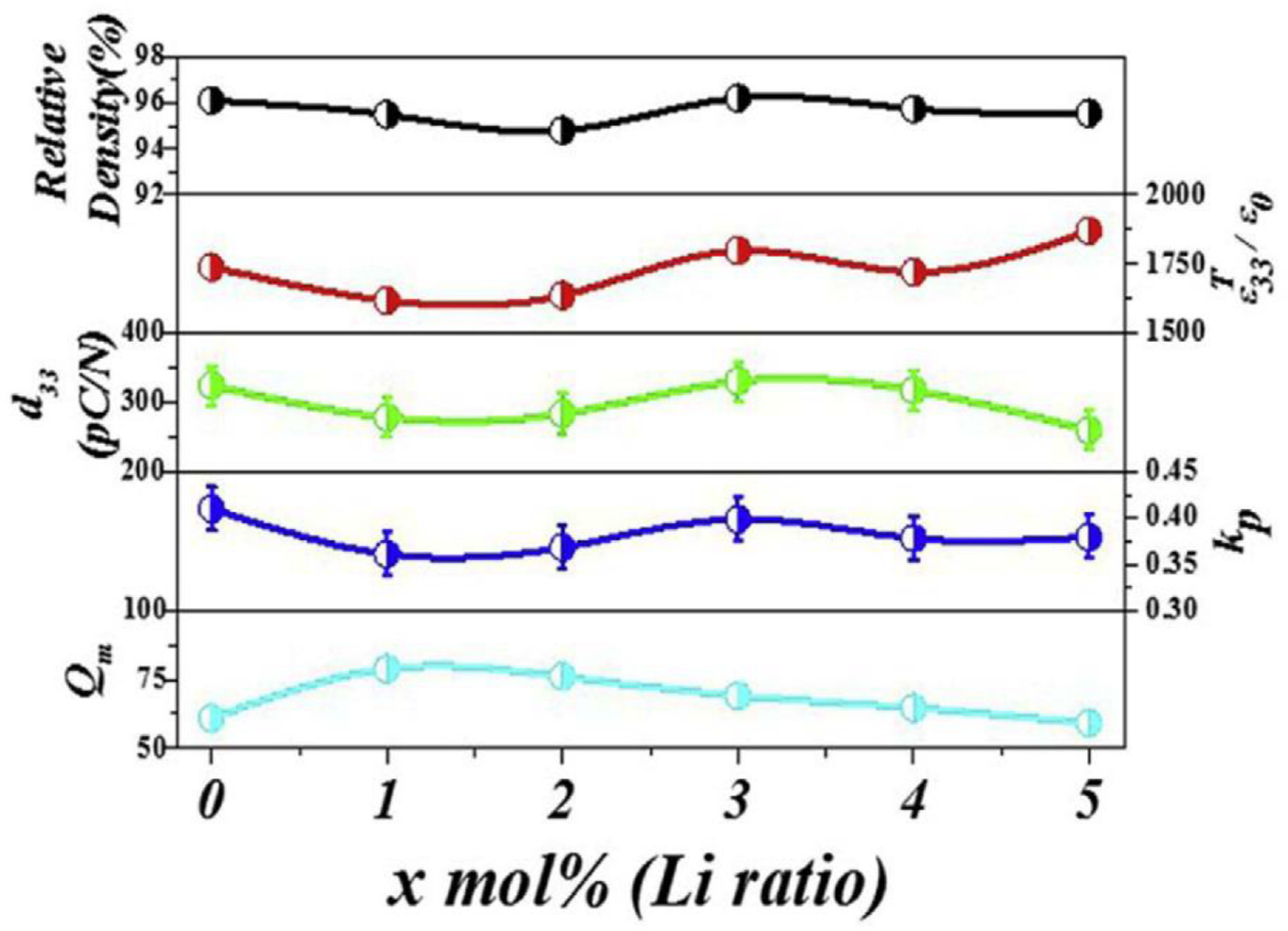

2.3. (K, Na, Li)(Nb, Sb)O3-(Ca, Sr)ZrO3 Ceramics with an O–T–PC (or O–T–R) Multistructure

3. KNN-Modified Piezoceramics with the R–O–T Multistructure

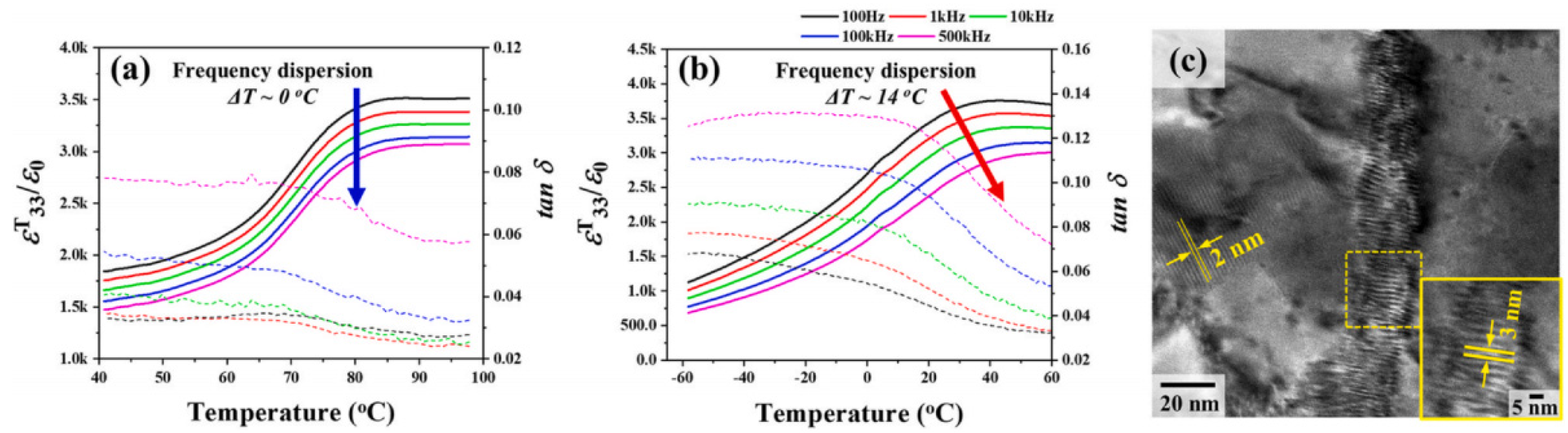

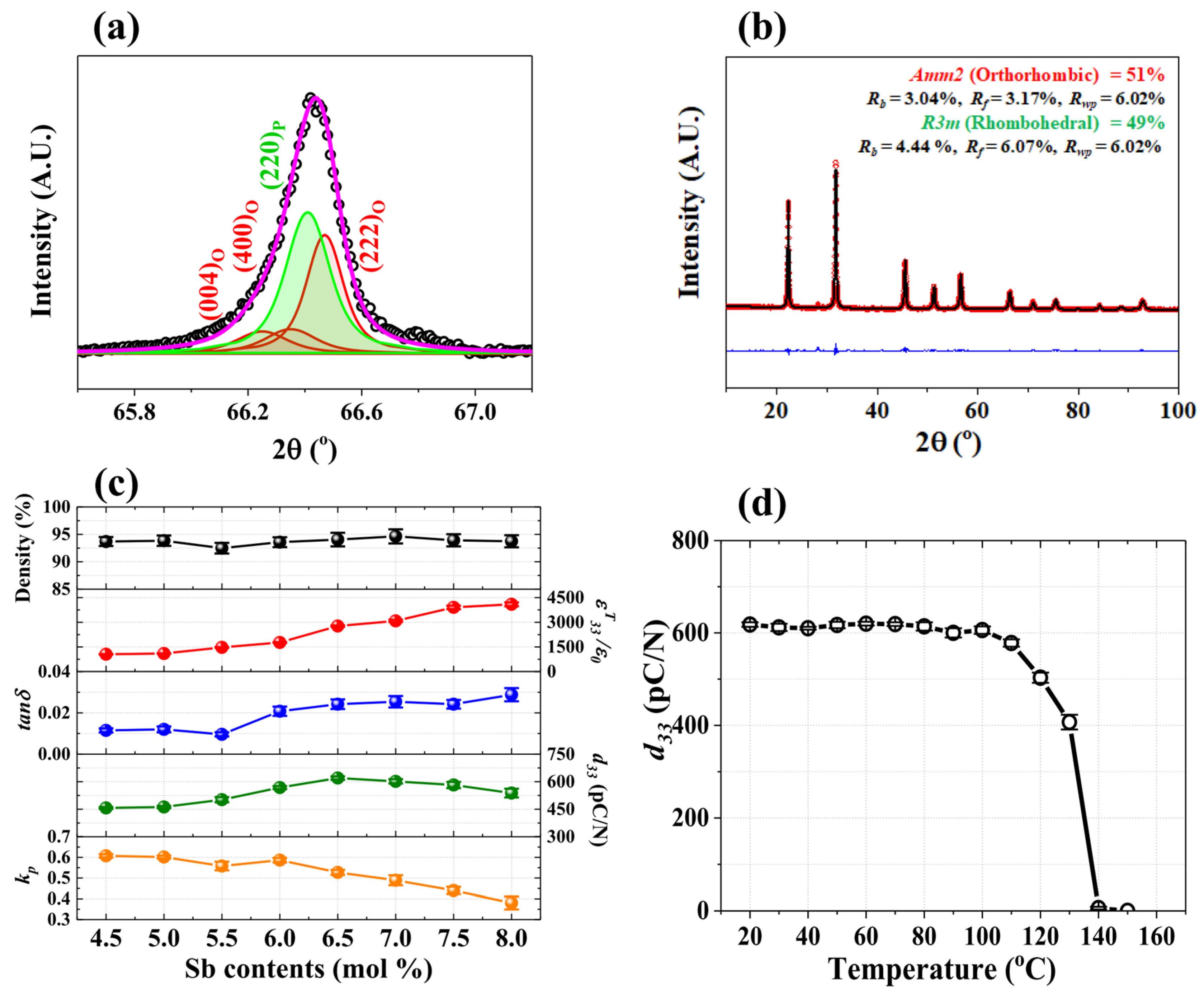

3.1. (1−x)(K, Na)(Nb, Sb)O3−x(Bi, Na)HfO3 Piezoceramics with the R–O–T Multistructure

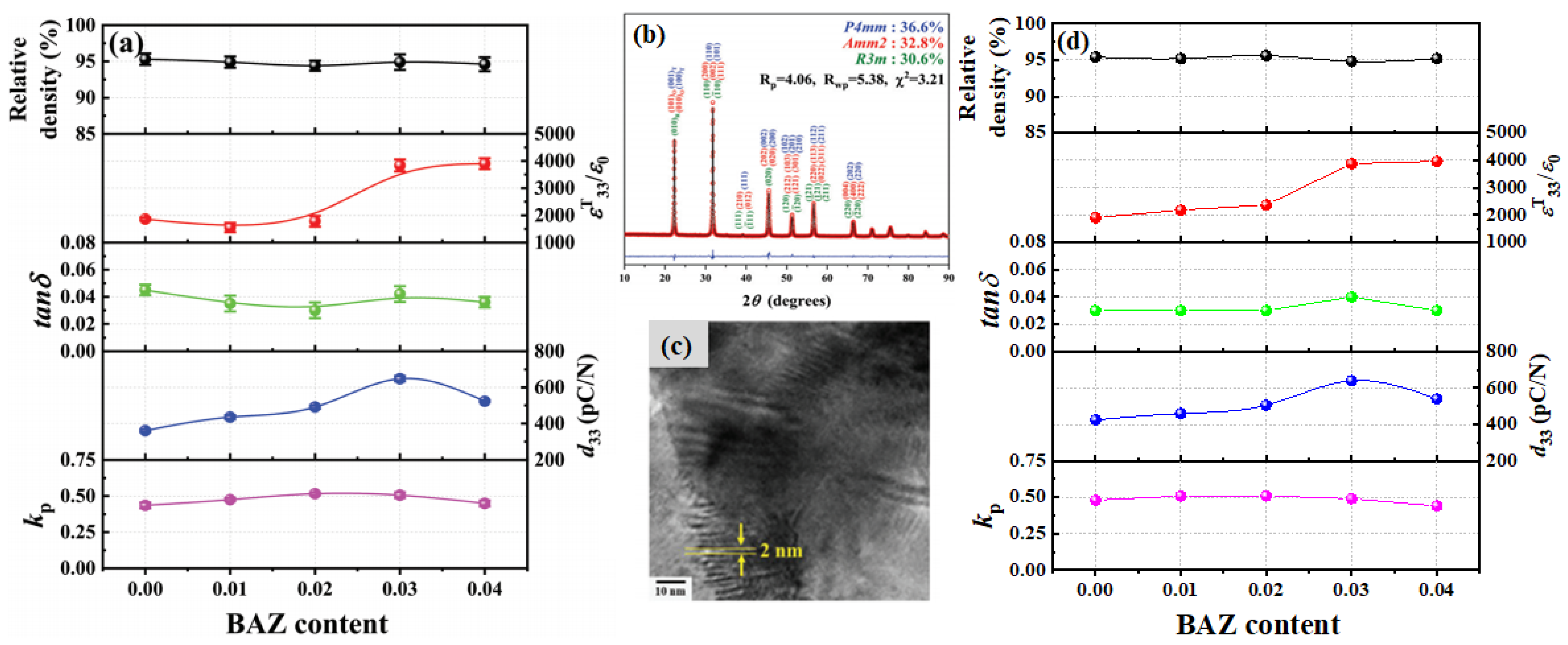

3.2. (K, Na)(Nb, Sb)O3-Bi(Na, K)ZrO3-Fe2O3-AgSbO3 Piezoceramics with an R–O–T Multistructure

3.3. (K, Na)(Nb, Sb)O3-MZrO3-(Bi, Ag)ZrO3 Ceramics (M = Ca, Sr, and Ba) with an R–O–T Multistructure

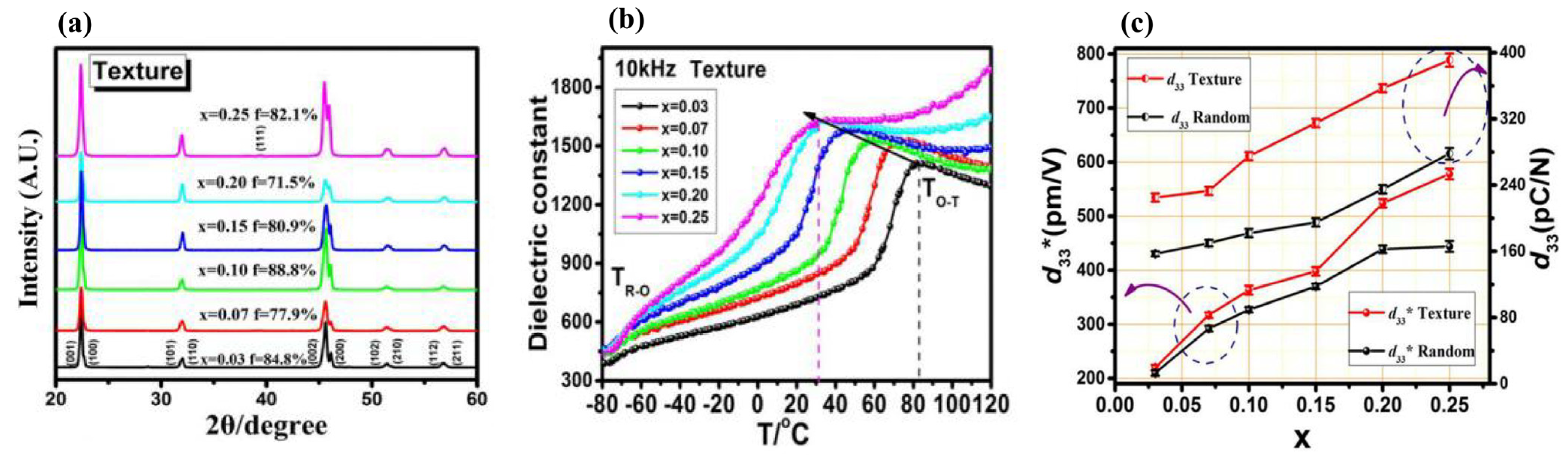

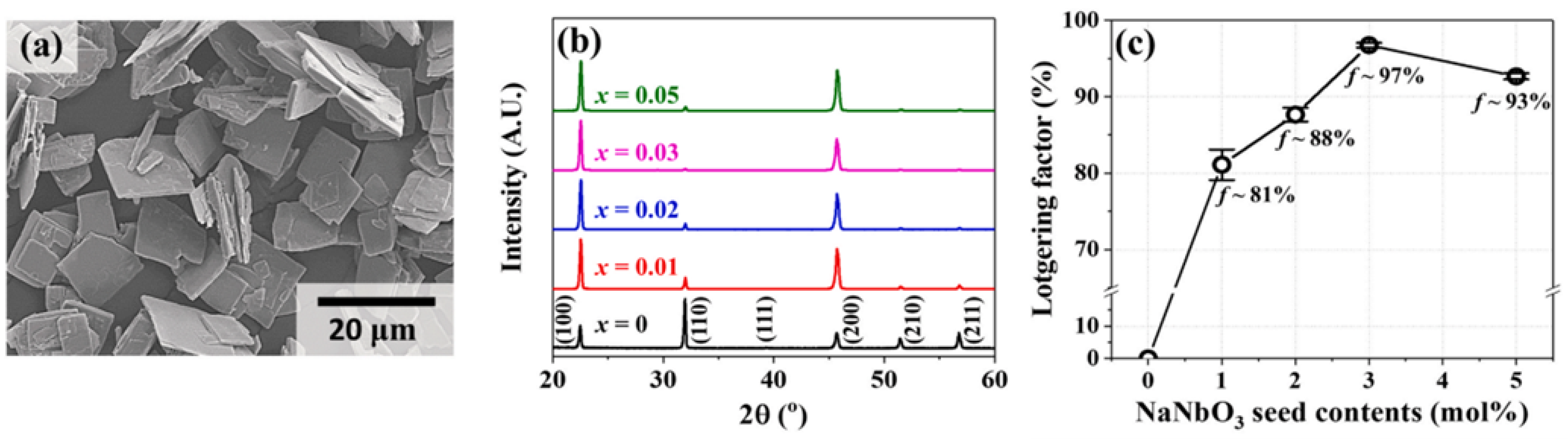

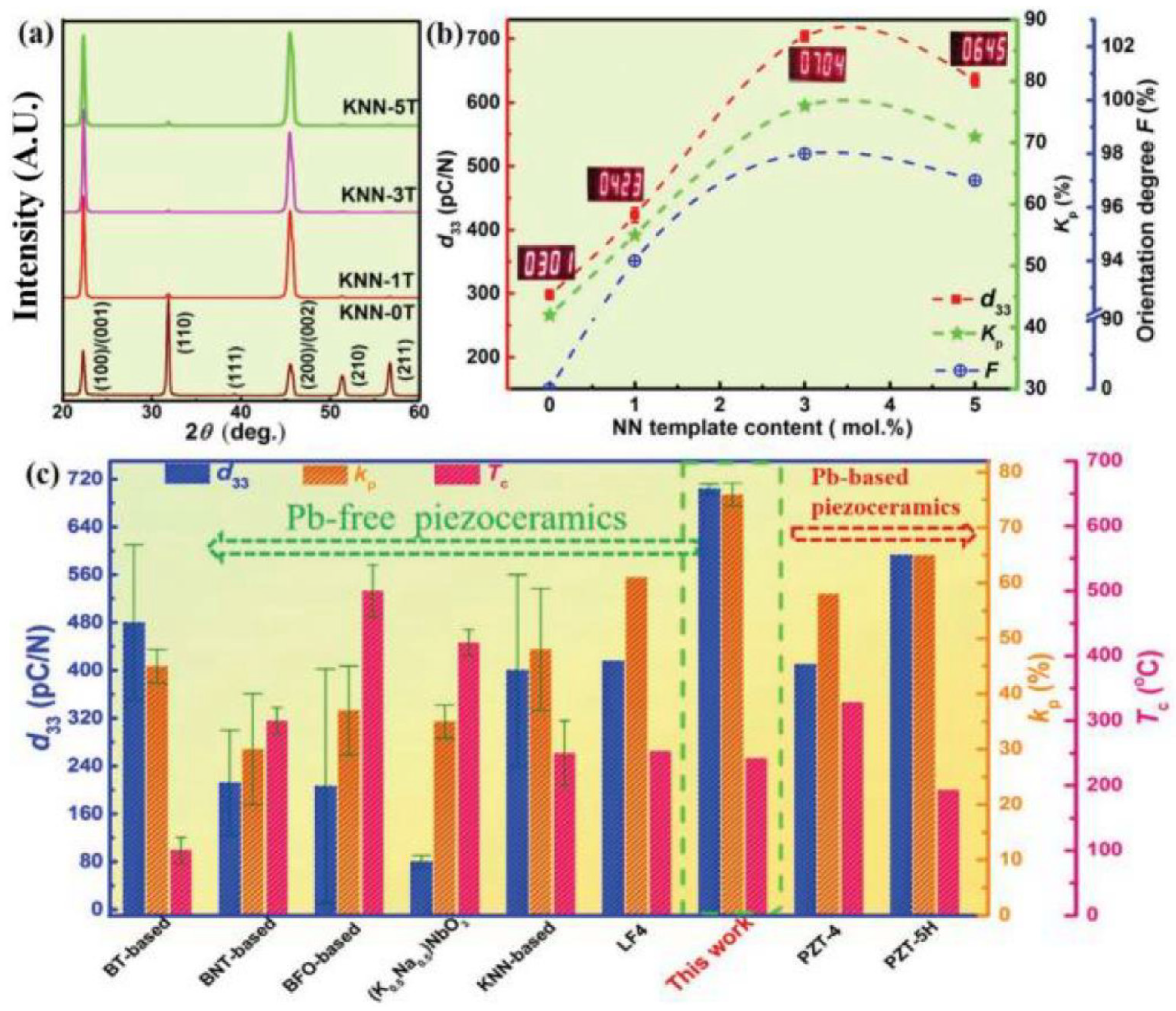

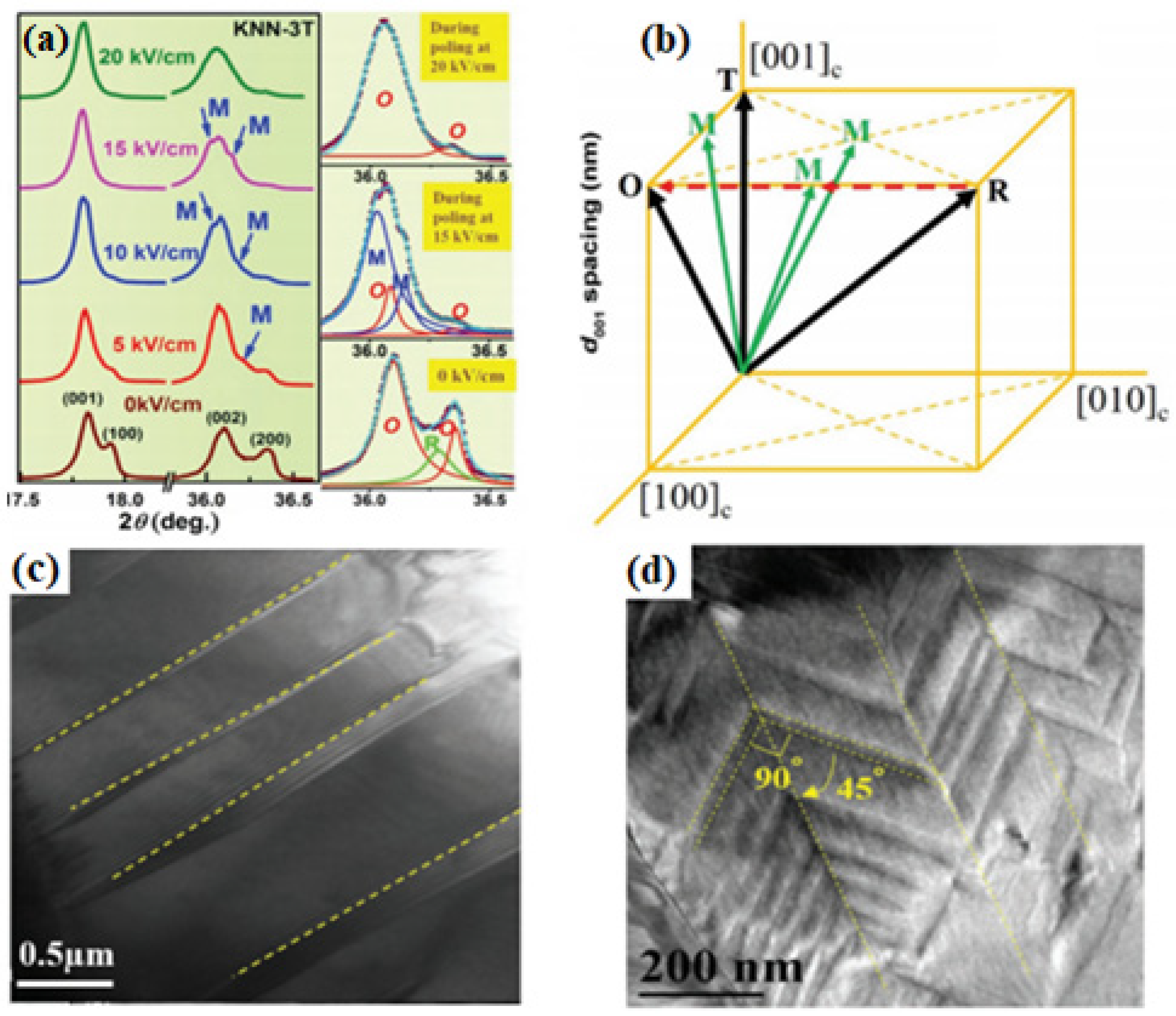

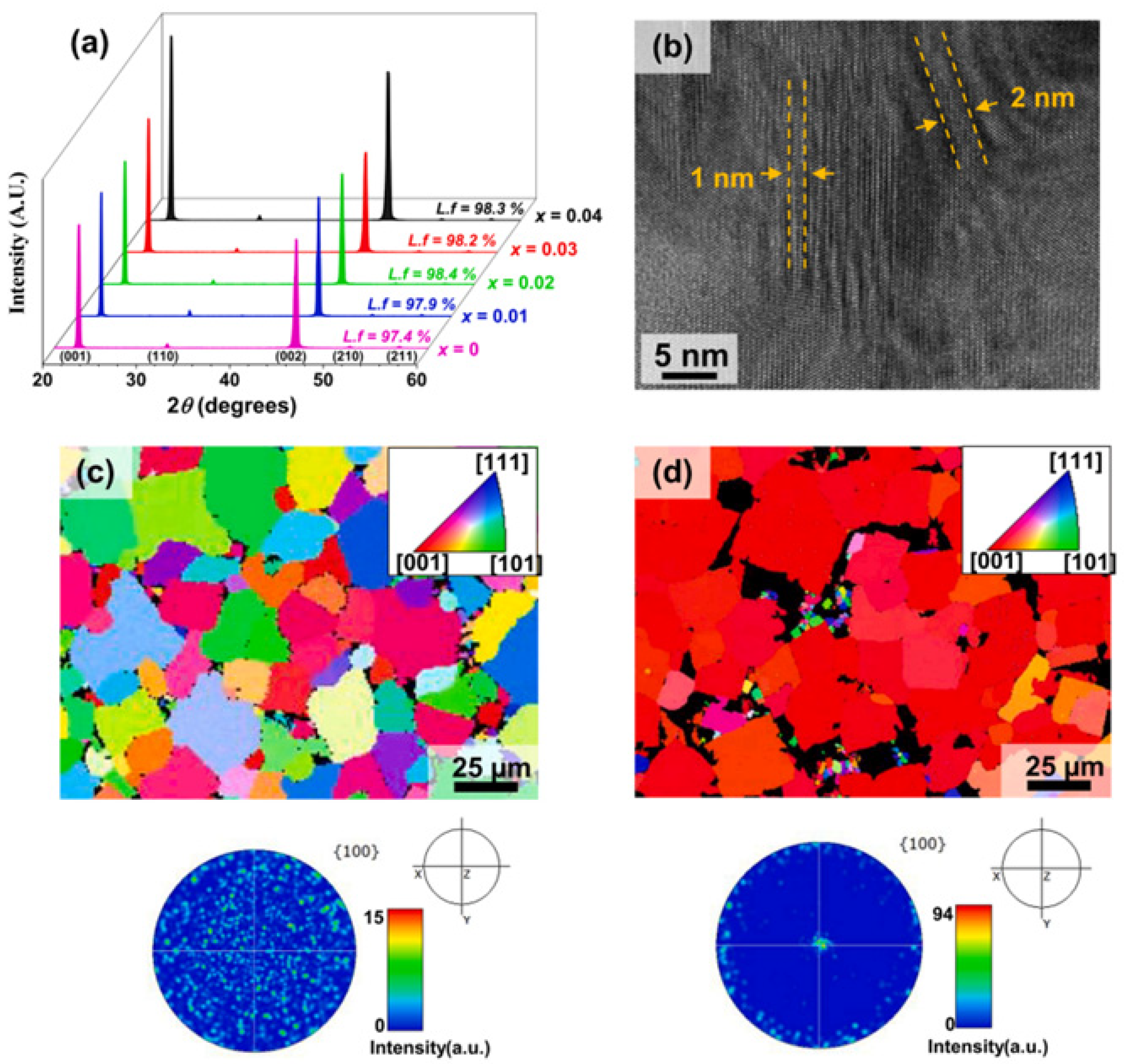

4. [001]-Textured KNN-Based Lead-Free Piezoceramics

4.1. [001]-Textured (K, Na, Li)(Nb, Sb, Ta)O3-CaZrO3 Ceramics with an O–T Multistructure

4.2. [001]-Textured (K, Na)(Nb, Sb)O3-MZrO3 (M = Sr and Ca) Piezoceramics with an O–PC (or O–R) Multistructure

4.3. [001]-Textured (K, Na)(Nb, Sb)O3-CaZrO3-(Bi, K)HfO3 Piezoceramics with an O–R Multistructure

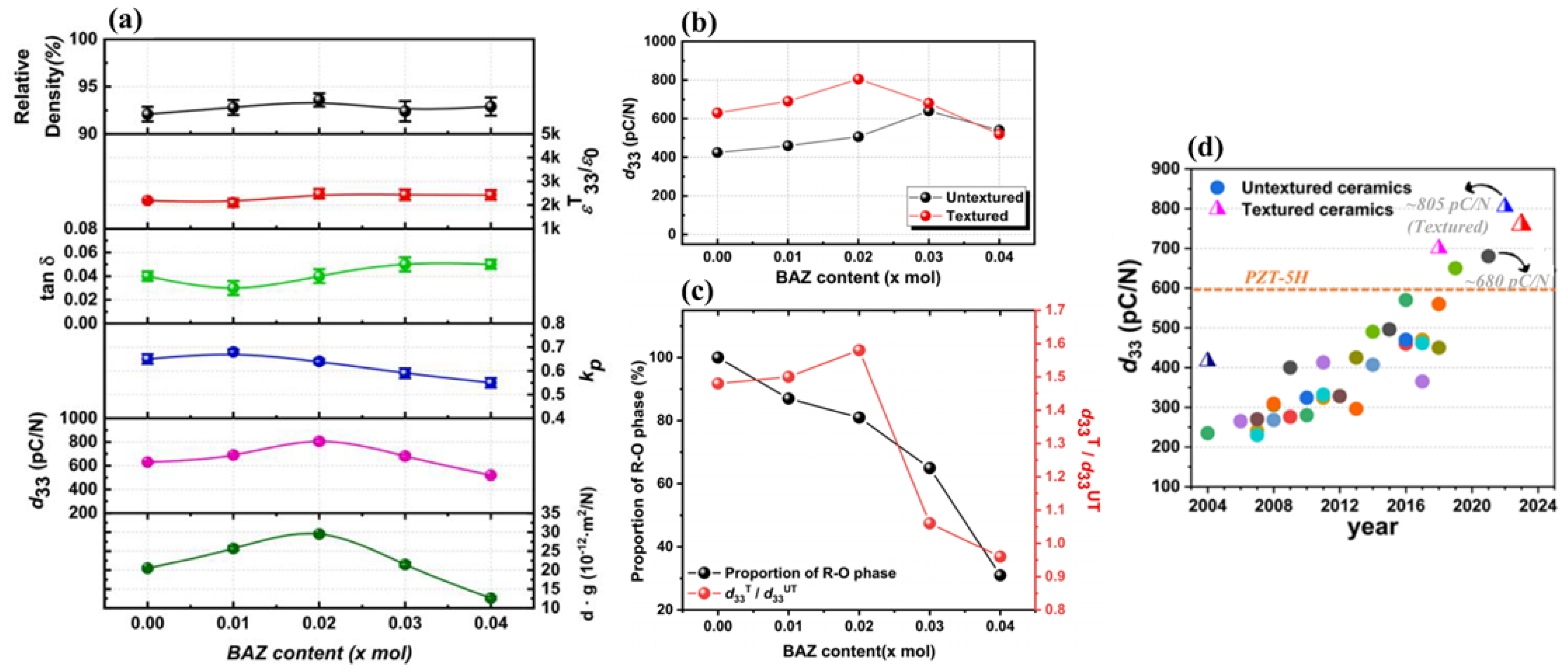

4.4. [001]-Textured (K, Na)(Nb, Sb)O3-MZrO3-(Bi, Ag)ZrO3 Piezoceramics (M = Ba, Sr, and Ca) with an R–O–T Multistructure Containing a Large Proportion of the R–O Phase

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sun, E.; Cao, W. Relaxor-based ferroelectric single crystals: Growth, domain engineering, characterization and applications. Prog. Mater. Sci. 2014, 65, 124–210. [Google Scholar] [CrossRef] [PubMed]

- Xiong, H.; Wang, L. Piezoelectric energy harvester for public roadway: On-site installation and evaluation. Appl. Energy 2016, 174, 101–107. [Google Scholar] [CrossRef]

- Fialka, J.; Benes, P.; Michlovska, L.; Klusacek, S.; Pikula, S.; Dohnal, P.; Havranek, Z. Measurement of thermal depolarization effects in piezoelectric coefficients of soft PZT ceramics via the frequency and direct methods. J. Eur. Ceram. Soc. 2016, 36, 2727–2738. [Google Scholar] [CrossRef]

- Yi, J.; Chang, S.; Shen, Y. Disturbance-observer-based hysteresis compensation for piezoelectric actuators. IEEE/ASME Trans. Mechatron. 2009, 14, 456–464. [Google Scholar]

- Li, J.; Zhou, X.; Zhao, H.; Shao, M.; Li, N.; Zhang, S.; Du, Y. Development of a novel parasitic-type piezoelectric actuator. IEEE/ASME Trans. Mechatron. 2017, 22, 541–550. [Google Scholar] [CrossRef]

- Johnson, M.J.; Boris, D.R.; Petrova, T.B.; Walton, S.G. Characterization of a compact, low-cost atmospheric-pressure plasma jet driven by a piezoelectric transformer. IEEE Trans. Plasma Sci. 2019, 47, 434–444. [Google Scholar] [CrossRef]

- Senousy, M.S.; Rajapakse, R.K.N.D.; Mumford, D.; Gadala, M.S. Self-heat generation in piezoelectric stack actuators used in fuel injectors. Smart Mater. Struct. 2009, 18, 045008. [Google Scholar] [CrossRef]

- Ramesh Kumar, K.; Narayanan, S. Active vibration control of beams with optimal placement of piezoelectric sensor/actuator pairs. Smart Mater. Struct. 2008, 17, 055008. [Google Scholar] [CrossRef]

- Lu, Y.; Tang, H.; Fung, S.; Wang, Q.; Tsai, J.M.; Daneman, M.; Boser, B.E.; Horsley, D.A. Ultrasonic fingerprint sensor using a piezoelectric micromachined ultrasonic transducer array integrated with complementary metal oxide semiconductor electronics. Appl. Phys. Lett. 2015, 106, 263503. [Google Scholar] [CrossRef]

- Seo, Y.; Corona, D.; Hall, N.A. On the theoretical maximum achievable signal-to-noise ratio (SNR) of piezoelectric microphones. Sens. Actuators A Phys. 2017, 264, 341–346. [Google Scholar] [CrossRef]

- Ramshani, Z.; Johnson, M.J.; Atashbar, M.Z.; Go, D.B. A broad area electrospray generated by a piezoelectric transformer. Appl. Phys. Lett. 2016, 109, 044103. [Google Scholar] [CrossRef]

- Kim, S.W.; Lee, T.G.; Kim, D.H.; Lee, K.T.; Jung, I.; Kang, C.Y.; Han, S.H.; Kang, H.W.; Nahm, S. Determination of the appropriate piezoelectric materials for various types of piezoelectric energy harvesters with high output power. Nano Energy 2019, 57, 581–591. [Google Scholar] [CrossRef]

- Kim, S.W.; Lee, T.G.; Kim, D.H.; Kim, E.J.; Kim, D.S.; Kang, W.S.; Jo, W.; Lee, S.J.; Han, S.H.; Kang, H.W. Thermally stable large strain in low-loss (Na0.2K0.8)NbO3-BaZrO3 for multilayer actuators. J. Am. Ceram. Soc. 2019, 102, 6837–6849. [Google Scholar] [CrossRef]

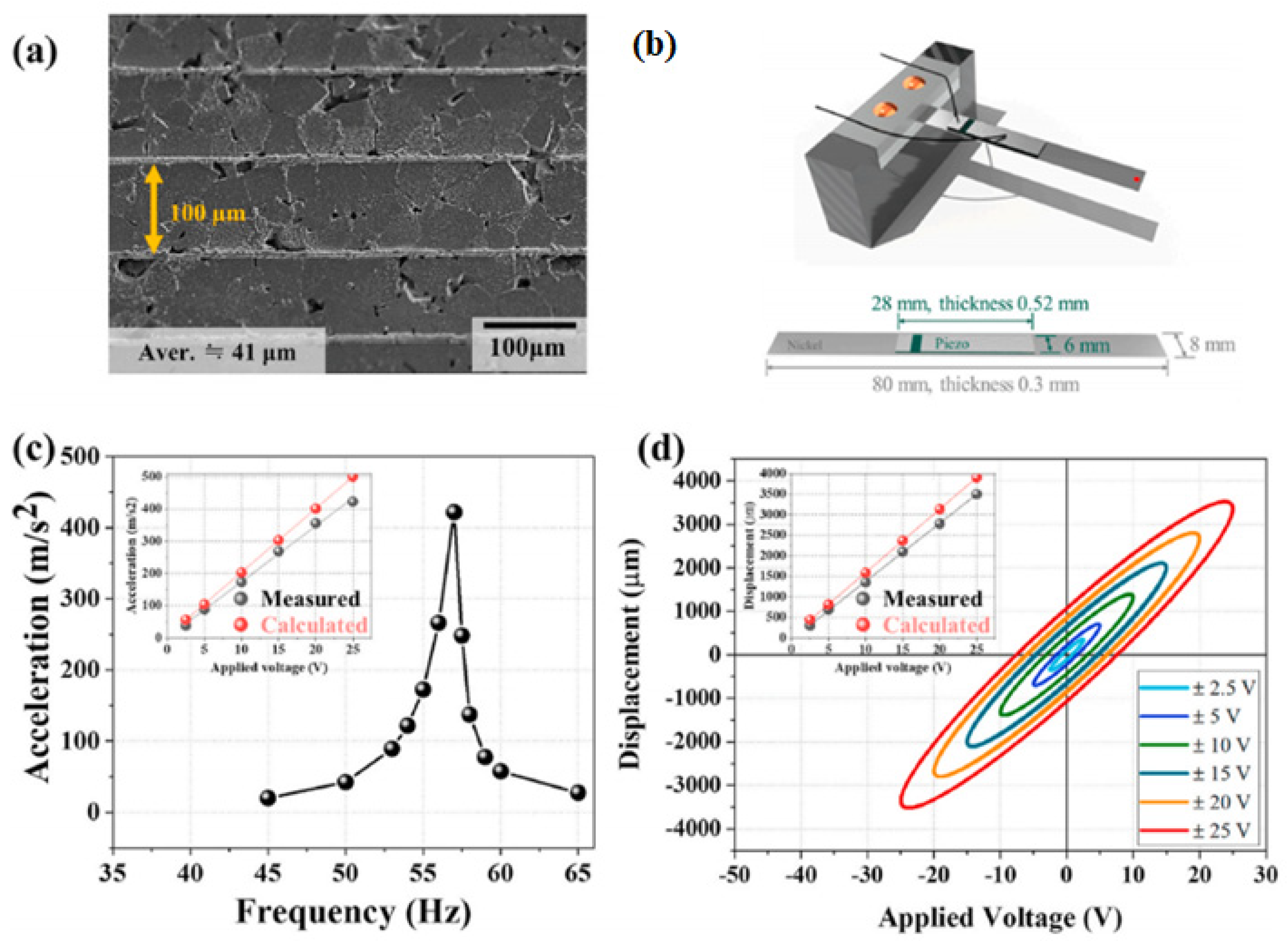

- Chae, S.J.; Lee, T.G.; Kim, D.S.; Kim, S.W.; Kim, E.J.; Park, S.M.; Kang, W.S.; Lee, S.J.; Kang, C.Y.; Nahm, S. Superior piezoelectric properties of lead-free thick-films and their application to alternative multilayer actuator. J. Alloys Compd. 2020, 834, 155079. [Google Scholar] [CrossRef]

- Lee, T.G.; Jo, S.H.; Seung, H.M.; Kim, S.W.; Kim, E.J.; Youn, B.D.; Nahm, S.; Kim, M. Enhanced energy transfer and conversion for high performance phononic crystal-assisted elastic wave energy harvesting. Nano Energy 2020, 78, 105226. [Google Scholar] [CrossRef]

- Kim, J.H.; Woo, J.U.; Yee, Y.J.; Kim, I.S.; Shin, H.S.; Hwang, H.G.; Kweon, S.H.; Choi, H.J.; Nahm, S. [001]-oriented crystalline potassium-sodium niobate thin film fabricated at low temperature for use in piezoelectric energy harvester. Appl. Surf. Sci. 2021, 537, 147871. [Google Scholar] [CrossRef]

- Kim, J.H.; Kweon, S.H.; Nahm, S. Low-temperature crystalline lead-free piezoelectric thin films grown on 2D perovskite nanosheet for flexible electronic device applications. Nano Res. 2019, 12, 2559–2567. [Google Scholar] [CrossRef]

- Woo, J.U.; Kim, I.S.; Kim, B.; Nahm, S. Physical properties of crystalline NaNbO3 thin film grown on Sr2Nb3O10 nanosheets at low temperatures for piezoelectric energy harvesters. Appl. Surf. Sci. 2022, 593, 153464. [Google Scholar] [CrossRef]

- Woo, J.U.; Kim, S.W.; Kim, D.S.; Kim, I.S.; Shin, H.S.; Nahm, S. Growth and piezoelectric properties of amorphous and crystalline (K1−xNax)NbO3−based thin films. J. Korean Cera Soc. 2021, 58, 249–268. [Google Scholar] [CrossRef]

- Im, M.; Lee, W.H.; Kweon, S.H.; Nahm, S. New lead-free piezoelectric thin film fabricated using metal-oxide nanosheets at low temperature. Ceram. Int. 2019, 45, 21773–21780. [Google Scholar] [CrossRef]

- Song, H.C.; Kim, S.W.; Kim, H.S.; Lee, D.G.; Kang, C.Y.; Nahm, S. Piezoelectric energy harvesting design principles for materials and structures: Material figure-of-merit and self-resonance tuning. Adv. Mater. 2020, 32, 2002208. [Google Scholar] [CrossRef]

- Kim, E.J.; Lee, T.G.; Kim, D.S.; Kim, S.W.; Yee, Y.J.; Han, S.H.; Kang, H.W.; Nahm, S. Textured Pb (Zr, Ti)O3-Pb [(Zn, Ni)1/3Nb2/3]O3 multilayer ceramics and their application to piezoelectric actuators. Appl. Mater. Today 2020, 20, 100695. [Google Scholar] [CrossRef]

- Lee, T.G.; Kim, S.W.; Kim, E.J.; Lee, S.J.; Hwang, H.G.; Hong, Y.W.; Kim, J.S.; Chae, K.H.; Choi, J.W.; Kang, C.Y. Crystal structure and piezoelectric characteristics of various phases near the triple-point composition in PZ-PT-PNN system. J. Eur. Ceram. Soc. 2020, 40, 1947–1956. [Google Scholar] [CrossRef]

- Seo, I.; Jo, S.; Kim, D.S.; Kang, H.W.; Nahm, S.; Han, S.H. Fabrication and characterization of low temperature sintered hard piezoelectric ceramics for multilayer piezoelectric energy harvesters. Ceram. Int. 2021, 47, 16688–16695. [Google Scholar] [CrossRef]

- Kim, E.J.; Kim, S.W.; Kim, D.S.; Go, S.H.; Chae, S.J.; Eum, J.M.; Yu, H.M.; Chae, Y.G.; Nahm, S. Piezoelectric properties of [001]-textured high-power PMnN-PZT piezoceramics sintered at a low temperature. J. Eur. Ceram. Soc. 2023, 43, 1912–1922. [Google Scholar] [CrossRef]

- Lee, D.G.; Go, S.H.; Yoo, I.R.; Choi, S.H.; Kim, Y.Y.; Kim, H.S.; Hur, S.; Kang, H.; Baik, J.M.; Park, Y.S. Mn-doped 0.15 Pb (Yb1/2Nb1/2)O3–0.48Pb(Mg1/3Nb2/3)O3–0.37 PbTiO3 piezoelectric ceramics for high performance high-power transducers. Ceram. Int. 2023, 49, 33480–33488. [Google Scholar] [CrossRef]

- Kang, M.G.; Jung, W.S.; Kang, C.Y.; Yoon, S.J. Recent progress on PZT based piezoelectric energy harvesting technologies. Actuators 2016, 5, 5. [Google Scholar] [CrossRef]

- Chu, S.Y.; Chen, T.Y.; Tsai, I.T.; Water, W. Doping effects of Nb additives on the piezoelectric and dielectric properties of PZT ceramics and its application on SAW device. Sens. Actuators A Phys. 2004, 113, 198–203. [Google Scholar] [CrossRef]

- Kara, H.; Ramesh, R.; Stevens, R.; Bowen, C.R. Porous PZT ceramics for receiving transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2003, 50, 289–296. [Google Scholar] [CrossRef]

- Bell, A.J.; Deubzer, O. Lead-free piezoelectrics—The environmental and regulatory issues. MRS Bull. 2018, 43, 581–587. [Google Scholar] [CrossRef]

- Ringgaard, E.; Wurlitzer, T. Lead-free piezoceramics based on alkali niobates. J. Eur. Ceram. Soc. 2005, 25, 2701–2706. [Google Scholar] [CrossRef]

- Koruza, J.; Bell, A.J.; Frömling, T.; Webber, K.G.; Wang, K.; Rödel, J. Requirements for the transfer of lead-free piezoceramics into application. J. Materiom 2018, 4, 13–26. [Google Scholar] [CrossRef]

- Zhou, M.; Liang, R.; Zhou, Z.; Yan, S.; Dong, X. Novel sodium niobate-based lead-free ceramics as new environment-friendly energy storage materials with high energy density, high power density, and excellent stability. ACS Sustain. Chem. Eng. 2018, 6, 12755–12765. [Google Scholar] [CrossRef]

- Panda, P.K. Review: Environmental friendly lead-free piezoelectric materials. J. Mater. Sci. 2009, 44, 5049–5062. [Google Scholar] [CrossRef]

- Panda, P.K.; Sahoo, B. PZT to lead free piezo ceramics: A review. Ferroelectrics 2015, 474, 128–143. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Koh, S.C.L.; Reaney, I.M.; Acquaye, A.; Wang, D.; Taylor, S.; Genovese, A. Integrated hybrid life cycle assessment and supply chain environmental profile evaluations of lead-based (lead zirconate titanate) versus lead-free (potassium sodium niobate) piezoelectric ceramics. Energy Environ. Sci. 2016, 9, 3495–3520. [Google Scholar] [CrossRef]

- Guo, Y.; Kakimoto, K.I.; Ohsato, H. Dielectric and piezoelectric properties of lead-free (Na0.5K0.5)NbO3–SrTiO3 ceramics. Solid. State Commun. 2004, 129, 279–284. [Google Scholar] [CrossRef]

- Li, F.; Jin, L.; Guo, R. High electrostrictive coefficient Q33 in lead-free Ba(Zr0.2Ti0.8)O3−x(Ba0.7Ca0.3)TiO3 piezoelectric ceramics. Appl. Phys. Lett. 2014, 105, 232903. [Google Scholar] [CrossRef]

- Wu, J.; Xiao, D.; Wu, W.; Chen, Q.; Zhu, J.; Yang, Z.; Wang, J. Role of room-temperature phase transition in the electrical properties of (Ba, Ca)(Ti, Zr)O3 ceramics. Scr. Mater. 2011, 65, 771–774. [Google Scholar] [CrossRef]

- Gao, J.; Hu, X.; Zhang, L.; Li, F.; Zhang, L.; Wang, Y.; Hao, Y.; Zhong, L.; Ren, X. Major contributor to the large piezoelectric response in (1−x)Ba(Zr0.2Ti0.8)O3−x(Ba0.7Ca0.3)TiO3 ceramics: Domain wall motion. Appl. Phys. Lett. 2014, 104, 252909. [Google Scholar] [CrossRef]

- Wang, C.M.; Zhang, S.; Wang, J.F.; Zhao, M.L.; Wang, C.L. Electromechanical properties of calcium bismuth niobate (CaBi2Nb2O9) ceramics at elevated temperature. Mater. Chem. Phys. 2009, 118, 21–24. [Google Scholar] [CrossRef]

- Aoyagi, R.; Takeda, H.; Okamura, S.; Shiosaki, T. Ferroelectric and piezoelectric properties of bismuth layered-structure ferroelectric (Sr, Na, Bi)Bi2Ta2O9 ceramics. Mater. Sci. Eng. B 2005, 116, 156–160. [Google Scholar] [CrossRef]

- Suzuki, M.; Nagata, H.; Ohara, J.; Funakubo, H.; Takenaka, T. Bi3−xMxTiTaO9(M = La or Nd) ceramics with high mechanical quality factor Qm. Jap J. Appl. Phys. 2003, 42, 6090. [Google Scholar] [CrossRef]

- Takenaka, T.; Nagata, H.; Hiruma, Y. Current developments and prospective of lead-free piezoelectric ceramics. Jpn. J. Appl. Phys. 2008, 47, 3787. [Google Scholar] [CrossRef]

- Wang, C.M.; Wang, J.F.; Gai, Z.G. Enhancement of dielectric and piezoelectric properties of M0.5Bi4.5Ti4O15 (M = Na, K, Li) ceramics by Ce doping. Scr. Mater. 2007, 57, 789–792. [Google Scholar] [CrossRef]

- Nagata, H.; Itagaki, M.; Takenaka, T. Piezoelectric properties of bismuth layer-structured ferroelectric SrBi2Ta2O9-Bi3TiTaO9 ceramics. Ferroelectrics 2003, 286, 85–92. [Google Scholar] [CrossRef]

- Lin, D.; Kwok, K.W.; Chan, H. Structure and electrical properties of Bi0.5Na0.5TiO3–BaTiO3–Bi0.5Li0.5TiO3 lead-free piezoelectric ceramics. Solid. State Ion. 2008, 178, 1930–1937. [Google Scholar] [CrossRef]

- Hussain, A.; Ahn, C.W.; Lee, J.S.; Ullah, A.; Kim, I.W. Large electric-field-induced strain in Zr-modified lead-free Bi0.5(Na0.78K0.22)0.5TiO3 piezoelectric ceramics. Sens. Actuators A Phys. 2010, 158, 84–89. [Google Scholar] [CrossRef]

- Wang, X.; Tang, X.; Chan, H. Electromechanical and ferroelectric properties of (Bi1/2Na1/2)TiO3–(Bi1/2K1/2)TiO3–BaTiO3 lead-free piezoelectric ceramics. Appl. Phys. Lett. 2004, 85, 91–93. [Google Scholar] [CrossRef]

- Wang, F.; Xu, M.; Tang, Y.; Wang, T.; Shi, W.; Leung, C.M. Large strain response in the ternary Bi0.5Na0.5TiO3–BaTiO3–SrTiO3 solid solutions. J. Am. Ceram. Soc. 2012, 95, 1955–1959. [Google Scholar] [CrossRef]

- Jo, W.; Dittmer, R.; Acosta, M.; Zang, J.; Groh, C.; Sapper, E.; Wang, K.; Rödel, J. Giant electric-field-induced strains in lead-free ceramics for actuator applications–status and perspective. J. Electroceram. 2012, 29, 71–93. [Google Scholar] [CrossRef]

- Li, L.; Hao, J.; Xu, Z.; Li, W.; Chu, R. 0.46% unipolar strain in lead-free BNT-BT system modified with Al and Sb. Mater. Lett. 2016, 184, 152–156. [Google Scholar] [CrossRef]

- Bai, W.; Li, P.; Li, L.; Zhang, J.; Shen, B.; Zhai, J. Structure evolution and large strain response in BNT–BT lead-free piezoceramics modified with Bi(Ni0.5Ti0.5)O3. J. Alloys Compd. 2015, 649, 772–781. [Google Scholar] [CrossRef]

- Malik, R.A.; Kang, J.K.; Hussain, A.; Ahn, C.W.; Han, H.S.; Lee, J.S. High strain in lead-free Nb-doped Bi1/2(Na0. 84K0.16)1/2TiO3–SrTiO3 incipient piezoelectric ceramics. Appl. Phys. Exp. 2014, 7, 061502. [Google Scholar] [CrossRef]

- Zhao, S.; Li, G.; Ding, A.; Wang, T.; Yin, Q. Ferroelectric and piezoelectric properties of (Na, K)0.5Bi0.5TiO3 lead free ceramics. J. Phys. D Appl. Phys. 2006, 39, 2277. [Google Scholar] [CrossRef]

- Hussain, A.; Rahman, J.U.; Zaman, A.; Malik, R.A.; Kim, J.S.; Song, T.K.; Kim, W.J.; Kim, M.H. Field-induced strain and polarization response in lead-free Bi1/2(Na0.80K0.20)1/2TiO3–SrZrO3 ceramics. Mater. Chem. Phys. 2014, 143, 1282–1288. [Google Scholar] [CrossRef]

- Pham, K.N.; Hussain, A.; Ahn, C.W.; Ill, W.K.; Jeong, S.J.; Lee, J.S. Giant strain in Nb-doped Bi0.5(Na0.82K0.18)0.5TiO3 lead-free electromechanical ceramics. Mater. Lett. 2010, 64, 2219–2222. [Google Scholar] [CrossRef]

- Panda, P.; Sahoo, B.; Thejas, T. High strain lead-free piezo ceramics for sensor and actuator applications: A review. Sens. Int. 2023, 4, 100226. [Google Scholar] [CrossRef]

- Kang, X.Y.; Zhao, Z.H.; Lv, Y.K.; Dai, Y. BNT-based multi-layer ceramic actuator with enhanced temperature stability. J. Alloys Compd. 2019, 771, 541–546. [Google Scholar] [CrossRef]

- Chandrasekhar, M.; Kumar, P. Synthesis and characterizations of BNT–BT and BNT–BT–KNN ceramics for actuator and energy storage applications. Ceram. Int. 2015, 41, 5574–5580. [Google Scholar] [CrossRef]

- Matthias, B.; Remeika, J. Dielectric properties of sodium and potassium niobates. Phys. Rev. 1951, 82, 727. [Google Scholar] [CrossRef]

- Shirane, G.; Newnham, R.; Pepinsky, R. Dielectric properties and phase transitions of NaNbO3 and (Na, K)NbO3. Phys. Rev. 1954, 96, 581. [Google Scholar] [CrossRef]

- Egerton, L.; Dillon, D.M. Piezoelectric and dielectric properties of ceramics in the system potassium—Sodium niobate. J. Am. Ceram. Soc. 1959, 42, 438–442. [Google Scholar] [CrossRef]

- Jaffe, B.; Cook, W.; Jaffee, H. Piezoelectric Ceramics; Academic Press: London, UK, 1971. [Google Scholar]

- Dungan, R.; Golding, R. Polarization of NaNbO3-KNbO3 ceramic solid solutions. J. Am. Ceram. Soc. 1965, 48, 601–601. [Google Scholar] [CrossRef]

- Zuo, R.; Rödel, J.; Chen, R.; Li, L. Sintering and electrical properties of lead-free Na0.5K0.5NbO3 piezoelectric ceramics. J. Am. Ceram. Soc. 2006, 89, 2010–2015. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, B.; Li, H.; Shang, P. Effects of Na/K ratio on the phase structure and electrical properties of NaxK1− xNbO3 lead-free piezoelectric ceramics. Rare Met. 2010, 29, 220–225. [Google Scholar] [CrossRef]

- Bernard, J.; Benčan, A.; Rojac, T.; Holc, J.; Malič, B.; Kosec, M. Low-temperature sintering of K0.5Na0.5NbO3 ceramics. J. Am. Ceram. Soc. 2008, 91, 2409–2411. [Google Scholar] [CrossRef]

- Park, H.Y.; Cho, K.H.; Paik, D.S.; Nahm, S.; Lee, H.G.; Kim, D.H. Microstructure and piezoelectric properties of lead-free (1 − x)(Na0.5K0.5)NbO3−xCaTiO3 ceramics. J. Appl. Phys. 2007, 102, 124101. [Google Scholar] [CrossRef]

- Park, H.Y.; Ahn, C.W.; Song, H.C.; Lee, J.H.; Nahm, S.; Uchino, K.; Lee, H.G.; Lee, H.J. Microstructure and piezoelectric properties of 0.95 (Na0.5K0.5)NbO3–0.05 BaTiO3 ceramics. Appl. Phys. Lett. 2006, 89, 062906. [Google Scholar] [CrossRef]

- Zuo, R.; Fu, J.; Lv, D.; Liu, Y. Antimony tuned rhombohedral-orthorhombic phase transition and enhanced piezoelectric properties in sodium potassium niobate. J. Am. Ceram. Soc. 2010, 93, 2783–2787. [Google Scholar] [CrossRef]

- Wu, B.; Wu, H.; Wu, J.; Xiao, D.; Zhu, J.; Pennycook, S.J. Giant piezoelectricity and high Curie temperature in nanostructured alkali niobate lead-free piezoceramics through phase coexistence. J. Am. Chem. Soc. 2016, 138, 15459–15464. [Google Scholar] [CrossRef] [PubMed]

- Pang, X.; Qiu, J.; Zhu, K.; Cao, Y. Effects of Sb content on electrical properties of lead-free piezoelectric (K0.4425Na0.52Li0.0375)(Nb0.9625−xSbxTa0.0375)O3 ceramics. Ceram. Int. 2012, 38, 1249–1254. [Google Scholar] [CrossRef]

- Wang, X.; Wu, J.; Xiao, D.; Zhu, J.; Cheng, X.; Zheng, T.; Zhang, B.; Lou, X.; Wang, X. Giant piezoelectricity in potassium–sodium niobate lead-free ceramics. J. Am. Chem. Soc. 2014, 136, 2905–2910. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Li, J.F. (K,Na)NbO3-based lead-free piezoceramics: Phase transition, sintering and property enhancement. J. Adv. Ceram. 2012, 1, 24–37. [Google Scholar] [CrossRef]

- Wang, K.; Li, J.F. Analysis of crystallographic evolution in (Na, K)NbO3-based lead-free piezoceramics by X-ray diffraction. Appl. Phys. Lett. 2007, 91, 262902. [Google Scholar] [CrossRef]

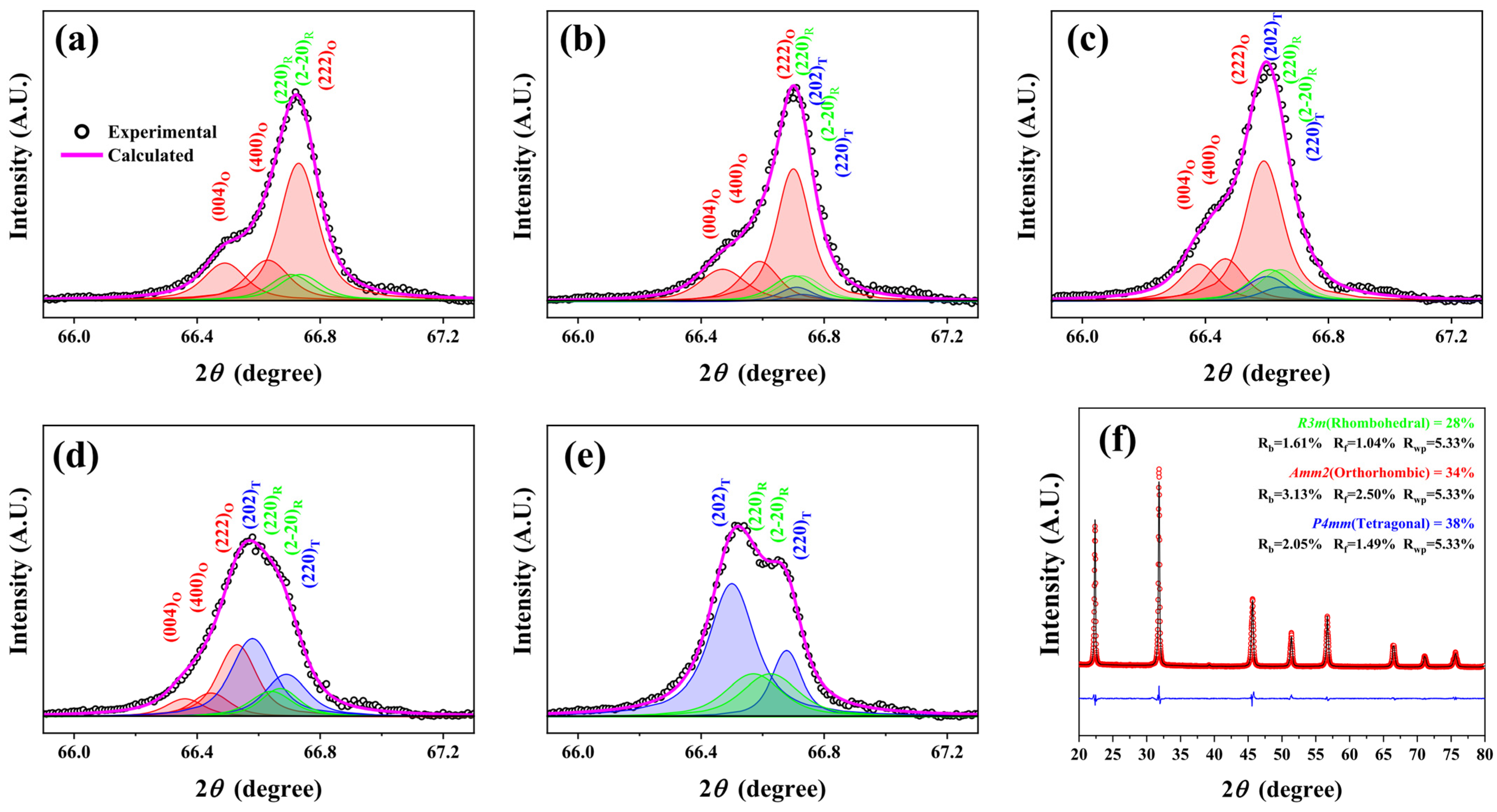

- Lee, K.T.; Kim, D.H.; Cho, S.H.; Kim, J.S.; Ryu, J.; Ahn, C.W.; Lee, T.H.; Kim, G.H.; Nahm, S. Pseudocubic-based polymorphic phase boundary structures and their effect on the piezoelectric properties of (Li, Na, K)(Nb, Sb)O3-SrZrO3 lead-free ceramics. J. Alloys Compd. 2019, 784, 1334–1343. [Google Scholar] [CrossRef]

- Lee, T.G.; Cho, S.H.; Kim, D.H.; Hwang, H.G.; Lee, K.T.; Hong, C.H.; Hong, Y.W.; Chae, K.H.; Choi, J.W.; Kim, J.S. Various cubic-based polymorphic phase boundary structures in (1 − y)(Na0.5K0.5)(Nb1−xSbx)-yCaTiO3 ceramics and their piezoelectric properties. J. Eur. Ceram. Soc. 2019, 39, 973–985. [Google Scholar] [CrossRef]

- Lee, K.T.; Lee, T.G.; Kim, S.W.; Chae, S.J.; Kim, E.J.; Kim, J.S.; Choi, J.W.; Nahm, S. Thermally stable high strain and piezoelectric characteristics of (Li, Na, K)(Nb, Sb)O3-CaZrO3 ceramics for piezo actuators. J. Am. Ceram. Soc. 2019, 102, 6115–6125. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, T.G.; Cho, S.H.; Lee, K.T.; Lee, T.H.; Hong, Y.W.; Hong, C.H.; Kim, J.S.; Nahm, S. Piezoelectric properties of (Na0.5K0.5)(Nb1-xSbx)O3-SrTiO3 ceramics with tetragonal-pseudocubic PPB structure. J. Am. Ceram. Soc. 2018, 101, 3997–4010. [Google Scholar] [CrossRef]

- Kim, D.S.; Eum, J.M.; Go, S.H.; Shin, H.S.; Kim, H.; Chae, S.J.; Kim, S.W.; Kim, E.J.; Woo, J.U.; Nahm, S. Remarkable piezoelectric performance and good thermal stability of <001>-textured 0.96(K0.5Na0.5)(Nb1−ySby)O3-0.04SrZrO3 lead-free piezoelectric ceramics. J. Alloys Compd. 2021, 882, 160662. [Google Scholar]

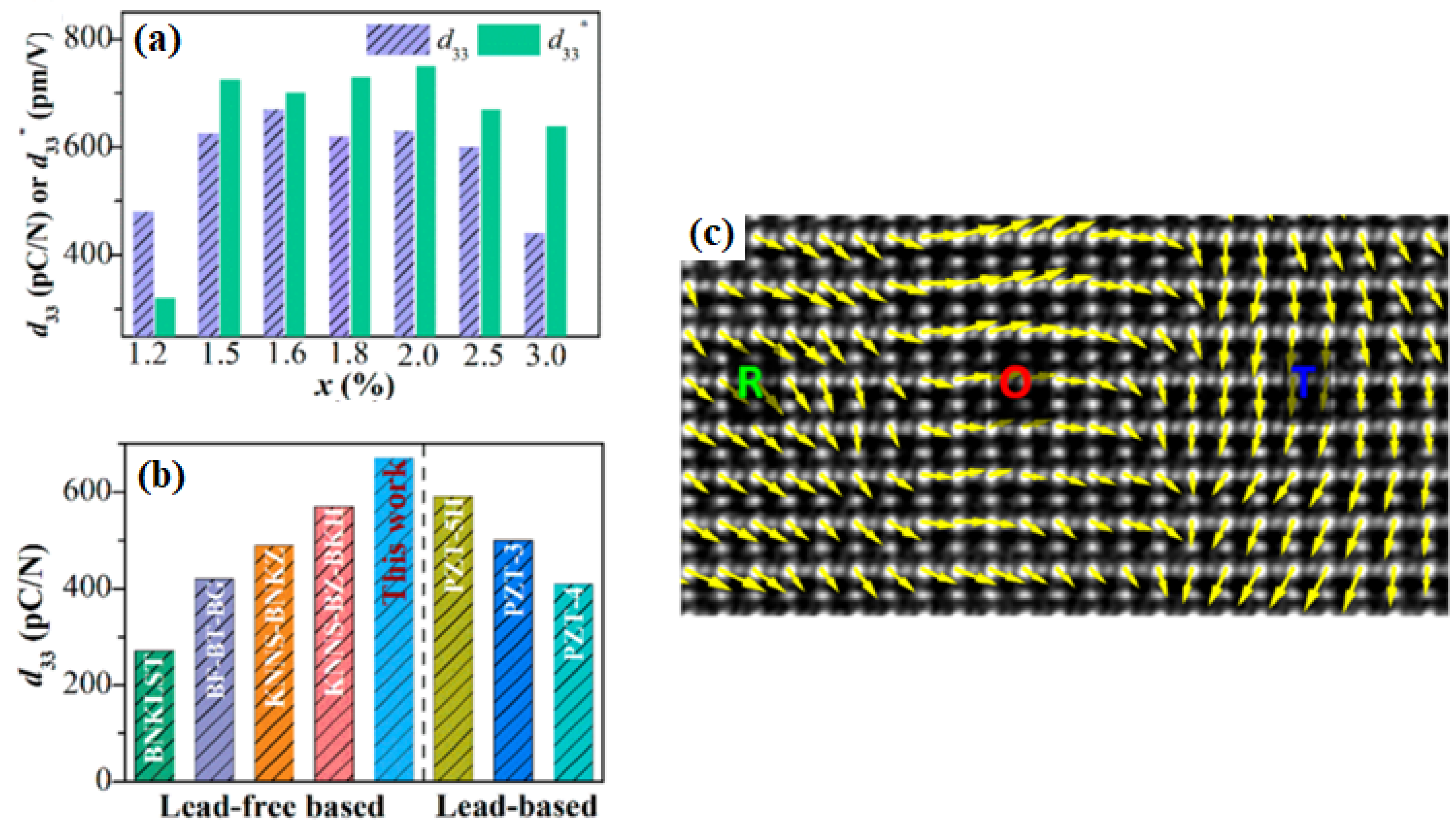

- Kim, H.; Kim, D.S.; Chae, S.J.; Go, S.H.; Kim, S.W.; Lee, D.G.; Song, H.C.; Kim, E.J.; Eum, J.M.; Nahm, S. Simultaneous realization of high d33 and large strain in (K,Na,Li)(Nb,Sb)O3-(Ca,Sr)ZrO3 materials and their application in piezoelectric actuators. Ceram. Int. 2021, 47, 34443–34454. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T.; Nonoyama, T.; Takatori, K.; Homma, T.; Nagaya, T.; Nakamura, M. Lead-free piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef] [PubMed]

- Lv, X.; Zhu, J.; Xiao, D.; Zhang, X.X.; Wu, J. Emerging new phase boundary in potassium sodium-niobate based ceramics. Chem. Soc. Rev. 2020, 49, 671–707. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Zhang, J.; Yao, W.; Wang, X.; Liu, D.; Sun, X. Piezoelectric performance, phase transitions, and domain structure of 0.96 (K0.48Na0.52)(Nb0.96Sb0.04)O3−0.04(Bi0.50Na0.50)ZrO3 ceramics. J. Appl. Phys. 2018, 124, 164101. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.F. Review of chemical modification on potassium sodium niobate lead-free piezoelectrics. J. Mater. Chem. C 2019, 7, 4284–4303. [Google Scholar] [CrossRef]

- Xing, J.; Tan, Z.; Jiang, L.; Chen, Q.; Wu, J.; Zhang, W.; Xiao, D.; Zhu, J. Phase structure and piezoelectric properties of (1 − x)K0.48Na0.52Nb0.95Sb0.05O3−x(Bi0.5Na0.5)0.9(Li0.5Ce0.5)0.1ZrO3 lead-free piezoelectric ceramics. J. Appl. Phys. 2016, 119, 034101. [Google Scholar] [CrossRef]

- Xing, J.; Zheng, T.; Wu, J.; Xiao, D.; Zhu, J. Progress on the doping and phase boundary design of potassium–sodium niobate lead-free ceramics. J. Adv. Dielectr. 2018, 8, 1830003. [Google Scholar] [CrossRef]

- Zhang, B.; Wu, J.; Cheng, X.; Wang, X.; Xiao, D.; Zhu, J.; Wang, X.; Lou, X. Lead-free piezoelectrics based on potassium–sodium niobate with giant d33. ACS Appl. Mater. Interfaces 2013, 5, 7718–7725. [Google Scholar] [CrossRef]

- Zang, G.Z.; Wang, J.F.; Chen, H.C.; Su, W.B.; Wang, C.M.; Qi, P.; Ming, B.Q.; Du, J.; Zheng, L.M.; Zhang, S. Perovskite(Na0.5K0.5)1−x(LiSb)xNb1−xO3 lead-free piezoceramics. Appl. Phys. Lett. 2006, 88, 212908. [Google Scholar] [CrossRef]

- Wu, J.; Xiao, D.; Wang, Y.; Zhu, J.; Wu, L.; Jiang, Y. Effects of K/Na ratio on the phase structure and electrical properties of (KxNa0.96−xLi0.04)(Nb0.91Ta0.05Sb0.04)O3 lead-free ceramics. Appl. Phys. Lett. 2007, 91, 252907. [Google Scholar] [CrossRef]

- Wu, J.; Tao, H.; Yuan, Y.; Lv, X.; Wang, X.; Lou, X. Role of antimony in the phase structure and electrical properties of potassium–sodium niobate lead-free ceramics. RSC Adv. 2015, 5, 14575–14583. [Google Scholar] [CrossRef]

- Zhang, J.; Zong, X.; Wu, L.; Gao, Y.; Zheng, P.; Shao, S. Polymorphic phase transition and excellent piezoelectric performance of (K0.55Na0.45)0.965Li0.035Nb0.80Ta0.20O3 lead-free ceramics. Appl. Phys. Lett. 2009, 95, 022909. [Google Scholar] [CrossRef]

- Xu, K.; Li, J.; Lv, X.; Wu, J.; Zhang, X.; Xiao, D.; Zhu, J. Superior piezoelectric properties in potassium–sodium niobate lead-free ceramics. Adv. Mater. 2016, 28, 8519–8523. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Tan, Z.; Xie, L.; Li, Y.; Xing, J.; Wu, J.; Chen, Q.; Xiao, D.; Zhu, J. Study of the relationships among the crystal structure, phase transition behavior and macroscopic properties of modified (K,Na)NbO3-based lead-free piezoceramics. J. Eur. Ceram. Soc. 2018, 38, 2335–2343. [Google Scholar] [CrossRef]

- Klein, N.; Hollenstein, E.; Damjanovic, D.; Trodahl, H.; Setter, N.; Kuball, M. A study of the phase diagram of (K,Na,Li)NbO3 determined by dielectric and piezoelectric measurements, and Raman spectroscopy. J. Appl. Phys. 2007, 102, 014112. [Google Scholar] [CrossRef]

- Wang, R.; Bando, H.; Katsumata, T.; Inaguma, Y.; Taniguchi, H.; Itoh, M. Tuning the orthorhombic–rhombohedral phase transition temperature in sodium potassium niobate by incorporating barium zirconate. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2009, 3, 142–144. [Google Scholar] [CrossRef]

- Zuo, R.; Ye, C.; Fang, X. Dielectric and piezoelectric properties of lead free Na0.5K0.5NbO3–BiScO3 ceramics. Jap J. Appl. Phys. 2007, 46, 6733. [Google Scholar] [CrossRef]

- Zuo, R.; Fu, J. Rhombohedral–tetragonal phase coexistence and piezoelectric properties of (NaK)(NbSb)O3–LiTaO3–BaZrO3 lead-free ceramics. J. Am. Ceram. Soc. 2011, 94, 1467–1470. [Google Scholar] [CrossRef]

- Zuo, R.; Fang, X.; Ye, C.; Li, L. Phase transitional behavior and piezoelectric properties of lead-free (Na0.5K0.5)NbO3–(Bi0.5K0.5)TiO3 ceramics. J. Am. Ceram. Soc. 2007, 90, 2424–2428. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J.; Cheng, X.; Wang, X.; Zhang, B.; Xiao, D.; Zhu, J.; Lou, X.; Wang, X. New potassium–sodium niobate material system: A giant-d33 and high-TC lead-free piezoelectric. Dalton Trans. 2014, 43, 11759–11766. [Google Scholar] [CrossRef]

- Liang, W.; Wu, W.; Xiao, D.; Zhu, J. Effect of the addition of CaZrO3 and LiNbO3 on the phase transitions and piezoelectric properties of K0.5Na0.5NbO3 lead-free ceramics. J. Am. Ceram. Soc. 2011, 94, 4317–4322. [Google Scholar] [CrossRef]

- Wang, X.; Wu, J.; Xiao, D.; Cheng, X.; Zheng, T.; Lou, X.; Zhang, B.; Zhu, J. New potassium–sodium niobate ceramics with a giant d33. ACS Appl. Mater. Interfaces 2014, 6, 6177–6180. [Google Scholar] [CrossRef] [PubMed]

- Go, S.H.; Park, S.J.; Kim, S.H.; Chae, S.J.; Kim, E.J.; Lee, G.S.; Nahm, S. [001]-texturing of (K,Na)NbO3-based piezoceramics with a pseudocubic structure and their application to piezoelectric devices. J. Materiom. 2023, in press. [CrossRef]

- Yan, Y.; Geng, L.D.; Zhu, L.F.; Leng, H.; Li, X.; Liu, H.; Lin, D.; Wang, K.; Wang, Y.U.; Priya, S. Ultrahigh piezoelectric performance through synergistic compositional and microstructural engineering. Adv. Sci. 2022, 9, 2105715. [Google Scholar] [CrossRef] [PubMed]

- Huan, Y.; Wei, T.; Wang, Z.; Lei, C.; Chen, F.; Wang, X. Polarization switching and rotation in KNN-based lead-free piezoelectric ceramics near the polymorphic phase boundary. J. Eur. Ceram. Soc. 2019, 39, 1002–1010. [Google Scholar] [CrossRef]

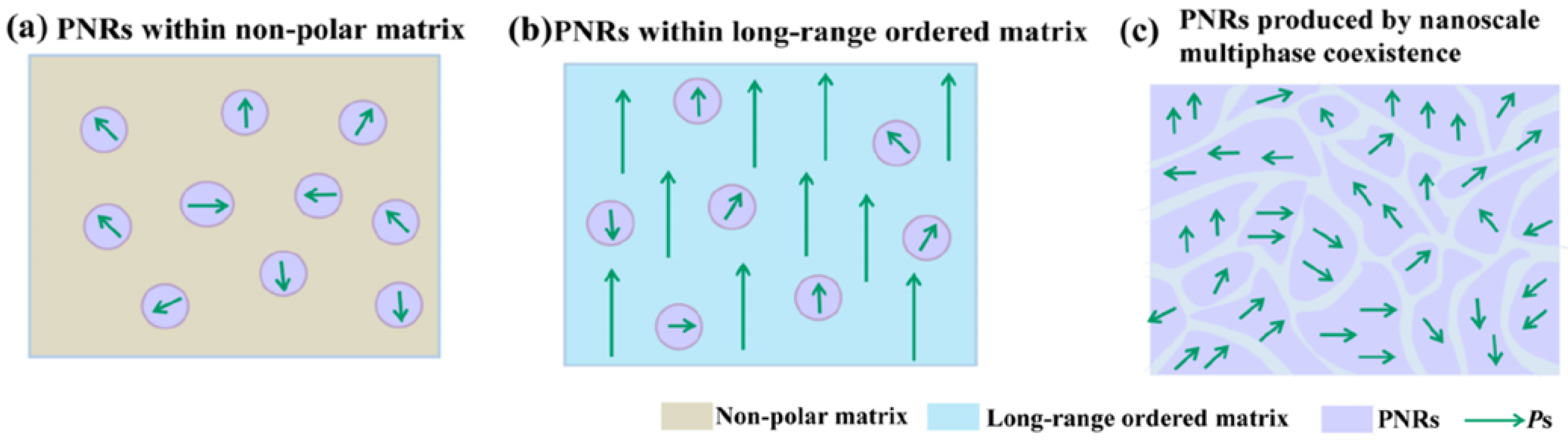

- Tao, H.; Wu, H.; Liu, Y.; Zhang, Y.; Wu, J.; Li, F.; Lyu, X.; Zhao, C.; Xiao, D.; Zhu, J.; et al. Ultrahigh performance in lead-free piezoceramics utilizing a relaxor slush polar state with multiphase coexistence. J. Am. Chem. Soc. 2019, 141, 13987–13994. [Google Scholar] [CrossRef] [PubMed]

- Lv, X.; Zhang, X.X.; Wu, J. Nano-domains in lead-free piezoceramics: A review. J. Mater. Chem. A 2020, 8, 10026–10073. [Google Scholar] [CrossRef]

- Torres-Matheus, O.A.; García, R.E.; Bishop, C.M. Microstructural phase coexistence kinetics near the polymorphic phase boundary. Acta Mater. 2021, 206, 116579. [Google Scholar] [CrossRef]

- Chae, S.J.; Kim, S.H.; Kim, I.S.; Lee, G.S.; Park, S.J.; Nahm, S. Optimized physical properties of [001]-textured (Na, K)NbO3-based lead-free piezoceramics for high power piezoelectric energy harvesters. J. Mater. Chem. C 2024. 12, 1268–1280. [CrossRef]

- Messing, G.L.; Trolier-McKinstry, S.; Sabolsky, E.M.; Duran, C.; Kwon, S.; Brahmaroutu, B.; Park, P.; Yilmaz, H.; Rehrig, P.W.; Eitel, K.B.; et al. Templated grain growth of textured piezoelectric ceramics. Crit. Rev. Solid. State Mater. Sci. 2004, 29, 45–96. [Google Scholar] [CrossRef]

- Li, L.; Bai, W.; Zhang, Y.; Shen, B.; Zhai, J. The preparation and piezoelectric property of textured KNN-based ceramics with plate-like NaNbO3 powders as template. J. Alloys Compd. 2015, 622, 137–142. [Google Scholar] [CrossRef]

- Liu, B.; Li, P.; Shen, B.; Zhai, J.; Zhang, Y.; Li, F.; Liu, X. Simultaneously enhanced piezoelectric response and piezoelectric voltage coefficient in textured KNN-based ceramics. J. Am. Ceram. Soc. 2018, 101, 265–273. [Google Scholar] [CrossRef]

- Chae, S.J.; Na, J.W.; Kim, D.S.; Kim, S.W.; Go, S.H.; Kim, H.; Kim, E.J.; Eum, J.M.; Nahm, S. Application of [001]-textured (K,Na)(Nb, Sb)O3-CaZrO3 thick films to piezoelectric energy harvesters. Ceram. Int. 2022, 48, 18401–18414. [Google Scholar] [CrossRef]

- Li, P.; Zhai, J.; Shen, B.; Zhang, S.; Li, X.; Zhu, F.; Zhang, X. Ultrahigh piezoelectric properties in textured (K,Na)NbO3-based lead-free ceramics. Adv. Mater. 2018, 30, 1705171. [Google Scholar] [CrossRef] [PubMed]

- Go, S.H.; Kim, D.S.; Chae, Y.G.; Chae, S.J.; Kim, E.J.; Yu, H.M.; Kim, B.J.; Park, S.J.; Lee, J.H.; Nahm, S. Effect of the crystal structure on the piezoelectricity of [001]-textured (Na, K)(Nb, Sb)O3-SrZrO3-(Bi, Ag)ZrO3 lead-free piezoelectric thick film. Actuators 2023, 12, 66. [Google Scholar] [CrossRef]

- Go, S.H.; Chae, Y.G.; Chae, S.J.; Kim, E.J.; Yu, H.M.; Cho, W.H.; Nahm, S. Piezoelectric properties of [001]-textured (K,Na)(Nb,Sb)O3-CaZrO3-(Ag,Bi)ZrO3 ceramics and their application in panel loudspeakers. J. Alloys Compd. 2023, 968, 171958. [Google Scholar] [CrossRef]

- Go, S.H.; Kim, H.; Kim, D.S.; Eum, J.M.; Chae, S.J.; Kim, E.J.; Nahm, S. Improvement of piezoelectricity of (Na, K)Nb-based lead-free piezoceramics using [001]-texturing for piezoelectric energy harvesters and actuators. J. Eur. Ceram. Soc. 2022, 42, 6478–6492. [Google Scholar] [CrossRef]

- Chae, Y.G.; Chae, S.J.; Go, S.H.; Kim, E.J.; Park, S.J.; Song, H.; Nahm, S. Ultrahigh performance piezoelectric energy harvester using lead-free piezoceramics with large electromechanical coupling factor. Int. J. Energy Res. 2023, 2023, 6177201. [Google Scholar] [CrossRef]

- Go, S.H.; Eum, J.M.; Kim, D.S.; Chae, S.J.; Kim, S.W.; Kim, E.J.; Chae, Y.G.; Woo, J.U.; Nahm, S. Piezoelectricity of (K,Na)(Nb,Sb)O3–SrZrO3(Bi,Ag)ZrO3 piezoceramics and their application in planar-type actuators. J. Mater. Chem. C 2021, 9, 16741–16750. [Google Scholar] [CrossRef]

- Go, S.H.; Kim, D.S.; Eum, J.M.; Shin, H.S.; Chae, S.J.; Kim, S.W.; Kim, E.J.; Woo, J.U.; Nahm, S. Excellent piezoelectric properties of (K,Na)(Nb, Sb)O3-CaZrO3-(Bi, Ag)ZrO3 lead-free piezoceramics. J. Alloys Compd. 2021, 889, 161817. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, X.; Su, W.; Yao, W.; Zhou, C. Superior piezoelectricity and rhombohedral-orthorhombic-tetragonal phase coexistence of (1−x)(K,Na)(Nb,Sb)O3−x(Bi,Na)HfO3 ceramics. Scr. Mater. 2020, 176, 108–111. [Google Scholar] [CrossRef]

| x = 0.035 | x = 0.040 | x = 0.042 | x = 0.045 | x = 0.047 | |

|---|---|---|---|---|---|

| ρ (g/cm3) | 4.49 | 4.56 | 4.62 | 4.62 | 4.61 |

| d33 (pC/N) | 350 | 450 | 480 | 540 | 475 |

| kp | 0.6 | 0.58 | 0.55 | 0.56 | 0.53 |

| ε’ | 1550 | 2150 | 2680 | 3350 | 3340 |

| tan δ | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, G.-S.; Kim, J.-S.; Kim, S.-H.; Kwak, S.; Kim, B.; Kim, I.-S.; Nahm, S. Recent Developments in (K, Na)NbO3-Based Lead-Free Piezoceramics. Micromachines 2024, 15, 325. https://doi.org/10.3390/mi15030325

Lee G-S, Kim J-S, Kim S-H, Kwak S, Kim B, Kim I-S, Nahm S. Recent Developments in (K, Na)NbO3-Based Lead-Free Piezoceramics. Micromachines. 2024; 15(3):325. https://doi.org/10.3390/mi15030325

Chicago/Turabian StyleLee, Geun-Soo, Jung-Soo Kim, Seung-Hyun Kim, San Kwak, Bumjoo Kim, In-Su Kim, and Sahn Nahm. 2024. "Recent Developments in (K, Na)NbO3-Based Lead-Free Piezoceramics" Micromachines 15, no. 3: 325. https://doi.org/10.3390/mi15030325

APA StyleLee, G.-S., Kim, J.-S., Kim, S.-H., Kwak, S., Kim, B., Kim, I.-S., & Nahm, S. (2024). Recent Developments in (K, Na)NbO3-Based Lead-Free Piezoceramics. Micromachines, 15(3), 325. https://doi.org/10.3390/mi15030325