1. Introduction

Accurate theoretical models of background–inclusion media are essential in the quantitative determination of mechanical properties of poroelastic materials such as biological tissues, hydrogels, micro-fibrous scaffolds and micro-porous polymers, in which inclusions such as tumours and structural anomalies are common [

1]. These theoretical models allow us to precisely evaluate mechanical features and compare them on an

elastography image (elastogram) in imaging techniques like ultrasound

elastography [

2]. A

number of mathematical models have been developed for the mechanical behaviour

of poroelastic materials with inclusions in recent years. Shin et al. [

3]

used Eshelby’s model of

elasticity, an analytical method of estimating the elastic properties of

inclusion–matrix media, in order to determine strain and stress components

inside breast tissues with ellipsoidal lesions as inclusions. In another study,

Goswami and his co-workers [

4]

developed a theoretical platform using the Caley–Hamilton theorem

and classical elasticity to analyse the shear induced nonlinear mechanics in

phantoms with undesirable inclusions under finite deformations. A poroelastic

model was also presented by Islam and Righetti [

5]

using the conventional

poroelasticity theory for investigating the mechanics of biological tissues

containing spherical tumours. Moreover, a numerical mathematical approach was

proposed to study large-scale elastic bodies with thin inclusions based on a

scale-free elasticity theory and finite element technique [

6]. Costa and Gentile [

7]

developed a discrete doublet

model of mechanics to simulate ultrasound wave propagation within biological

tissues as the poroelastic material, excluding any potential inclusions. In a

recent study conducted by Favata et al. [

8], it has been shown that the mechanical behaviour of biological

inclusions at microscale levels is different from those at large scales. The development

of microscale premalignant inclusions leads to stiffness softening, while the

presence of large-scale inclusions is associated with a hardening behaviour,

known as the soft-cell solid tumour paradox [

9]. More recently, mathematical models of poroelasticity

[

10]

and an artificial neural

network technique [

11] have been developed to capture Poisson’s ratio in abnormalities and estimate

mechanical stiffness in inhomogeneous materials.

However, at nano and microscales, the

dimensionless mechanical characteristics of a substance are highly sensitive to

its size [

12,

13,

14,

15]. This widely reported phenomenon is known as scale (size) dependency [

16,

17] and is associated with

several underlying factors including molecular interactions [

18]

and stiffness alteration [

19]. As classical local elasticity

and poroelasticity models are formulated on the basis of scale-free theories of

continuum mechanics, they lack the ability to capture size effects and, thus,

fail to accurately estimate the mechanical response at nano and microscales.

Peddieson et al. [

20] applied a version of nonlocal elasticity, which was first introduced by Eringen [

21], to develop scale-dependent beam models suitable for describing the mechanics of nanoscale devices such as small-scale actuators with nanocantilevers as building blocks.

Following this pioneering work, several researchers across the world have

extended the application of nonlocal theories to other small-scale structures

and devices such as nanobeams [

22], nanoscale sensors [

23], nanoplates [

24,

25,

26] and fluid-conveying microtubes [

27,

28].

In addition to fundamental small-scale

solid structures, modified nonlocal models have been utilised to assess and

predict the mechanical behaviour of poroelastic, viscoelastic and biological

materials of small sizes [

29,

30,

31]. These structures include, but are not limited to, microtubules [

32,

33], nanoporous materials with

surface effects [

34]

and lipid micro-tubules [

35]. In all of these valuable studies, it has been demonstrated that

scale effects have a vital role to play in mechanical deformation. Stress

nonlocality described by the Eringen nonlocal elasticity (nonlocal scale

effect) is associated with small-scale interactions, leading to substantial

stiffness reduction in the structure. Furthermore, it has been recently

demonstrated that nonlocal models hold great promise as highly accurate

mathematical tools for the description and design of microscale systems and phenomena,

especially in biology such as microscale migration of cells [

36], microelectromechanical

response [

37] and wave

propagation in biological tissues [

38].

To the best of our knowledge, to date,

no nonlocal scale-dependent poroelastic model has been developed for the

mechanical deformation of materials with small-scale inclusions. In imaging

technologies such as ultrasound and optical elastography that utilise the

mechanical properties of a given poroelastic material to detect abnormalities,

mathematical models play a crucial role in the accurate visualisation of

mechanical characteristics [

5,

39]. However, conventional mathematical models are formed based on

classical elasticity theories that fail to capture size effects and thus cannot

be employed at ultrasmall levels [

13]. In this paper, stress nonlocality-based size effects on the

mechanical response of poroelastic materials with small-scale inclusions are

studied for the first time. Furthermore, this research represents the first

integration of nonlocal elasticity and a light gradient boosting machine for

addressing inclusion problems. The proposed nonlocal scale-dependent model of

poroelasticity developed in this paper could be used in elastography imaging

techniques to accurately detect inclusions of ultrasmall sizes.

A case study of a potential

application of this model is investigated. The detection of small-scale tumours

in breast tissue (poroelastic medium) is considered as the undesirable

microscale inclusion. To include size dependency, nonlocal elasticity theory is

utilised. The influences of tissue fluid content, hydraulic conductivity and

microfiltration are captured by using a modified version of poroelasticity

theory. The governing differential equations are derived by decoupling the

scale-dependent constitutive relations and equilibrium equation in the

spherical coordinate system. To discretise the decoupled differential

equations, Galerkin method is employed. An accurate solution is presented with

the use of the precise integration method and Dormand–Prince technique. A light

gradient boosting machine learning model is also presented to extract and learn

the underlying patterns in the mechanical behaviour of spherical poroelastic

inclusions. To optimise the model, a grid search cross validation approach is

implemented. A detailed examination of the effects of nonlocal scale

coefficient and inclusion size on the time-dependent fluid pressure and radial

displacement is presented.

2. Nonlocal Poroelasticity Modelling

In this section, a nonlocal

scale-dependent model is developed for poroelastic materials including

small-scale spherical inclusions. In biomedical applications, small-scale

inclusions of interest to be detected by ultrasound imaging or other imaging

techniques are usually a clump of cancer cells with a stiffness lower than

healthy cells [

8,

9].

This softening behaviour can be effectively incorporated using nonlocal

continuum mechanics as stress nonlocality is associated with structural

stiffness softening. An appropriate model for this case is a refined

combination of Eringen’s nonlocal theory and poroelasticity to account for both

stiffness softening and fluid effects.

The conservation of mass for the fluid

content of a given poroelastic material can be written as [

40]

where

,

and

n are the fluid density,

fluid velocity and porosity, respectively. Moreover,

, “.” and

t indicate the

gradient operator, dot product and time,

respectively.

Similarly, the mass balance equation for the solid matrix is obtained as

Here

and

are the solid matrix density and

velocity, respectively. Assuming that the fluid part and solid components

(particles) are not compressible, and combining the mass balance Equations (1)

and (2), one obtains

where

is the

specific discharge that is associated with the relative velocity (

) as

where

It is assumed that the fundamental

solid particles and fluid part of the poroelastic material are individually

incompressible [

40]. However, the relative sliding, rotating and movement between these components

allow for the overall material and the solid phase as a whole to exhibit compressibility [

5]. The volumetric strain of the whole solid part (

) is related to the displacement

vector (

) by

Using Equations (3) and (6), the

following relation is obtained

According to Darcy’s

law, the specific discharge of a porous

material is proportionally dependent on the fluid pressure gradient (

) and the gravity vector (

) as [

40]

in which

,

and

represent the material permeability,

fluid viscosity and fluid pressure, respectively. Substituting Equation (8)

into Equation (7) and considering the effect of potential microfiltration [

41], the final version of the mass

balance equation (storage equation) is obtained as

where

and

denote the

hydraulic

conductivity and volumetric weight of the fluid, which are defined

by

and

, respectively.

is the Laplace operator. In the case

of biological inclusions such as solid tumours,

is the total microfiltration

coefficient, which is expressed by [

5,

41]

where

in which

and

indicate the tumour lymphatic and

vascular microfiltration coefficients, respectively.

,

and

stand for the vascular permeability, surface area and volume, respectively. Similarly,

,

and

are the lymphatic permeability,

surface area and volume, respectively. Equation (9) represents the storage equation of poroelastic

materials from biological tissues to porous micro-polymers. For applications in which there is no microfiltration effect,

is set to zero.

For spherical poroelastic inclusions,

the components of the total stress tensor (

) are related to the effective stress (

) and fluid pressure (

p) as

Effective stress components can be

interpreted

as the parts of the total stress

tensor that are responsible for porous material deformation. To detect an

inclusion in a given poroelastic medium, in many practical cases, it is assumed

that the average size of the inclusion is very small compared to the medium

size as the whole size [

5,

42].

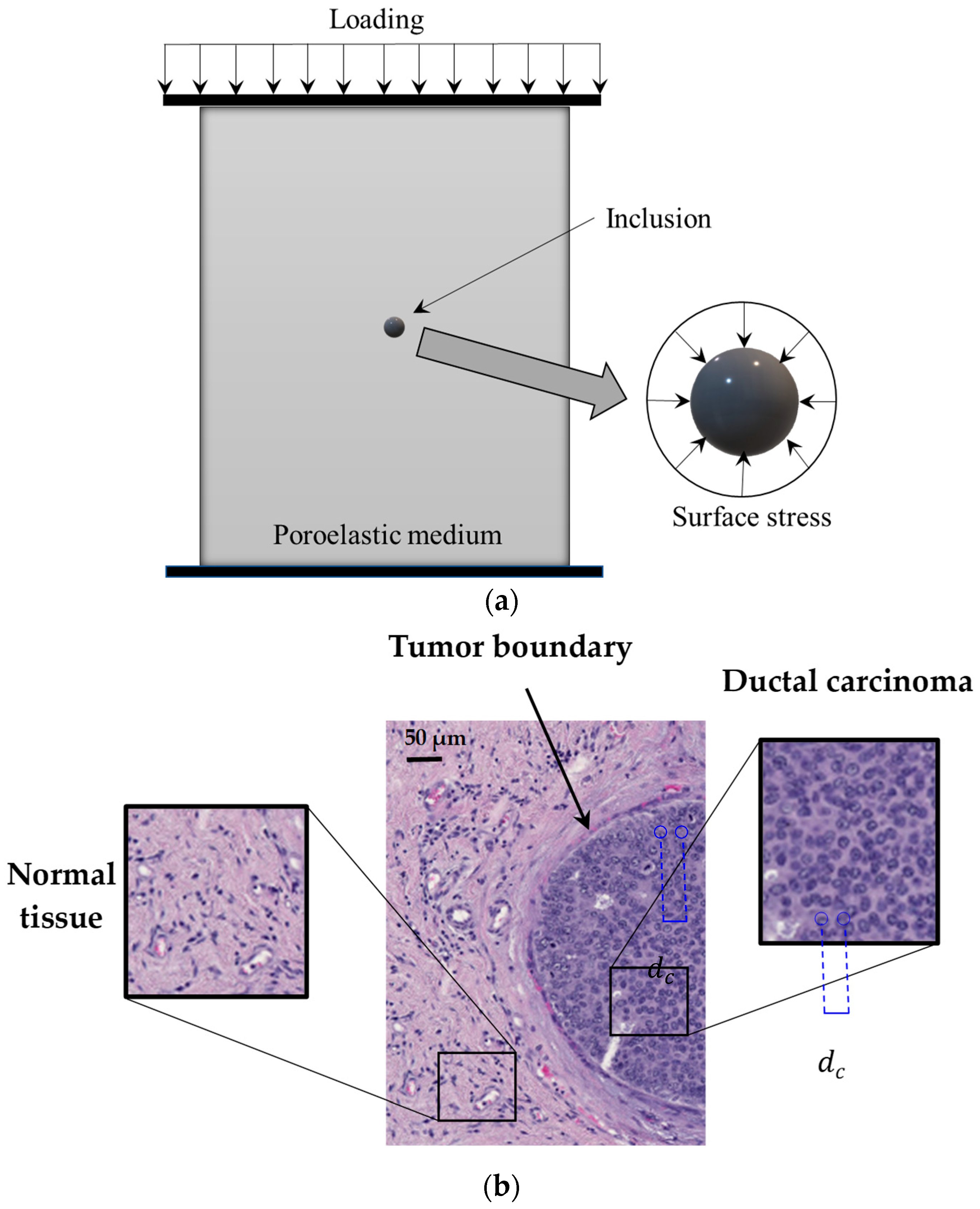

Figure 1 shows the schematic representation of a poroelastic medium

including a small-scale inclusion of a spherical shape. A slight compressive

load is applied on the top surface of the medium. A compressor plate is used to

make sure that the compressive load is uniformly distributed on the medium

surface. In practical applications, the compressive force is commonly applied

by utilising an ultrasound transducer, and a number of force sensors can be

used to measure the magnitude of the loading. Since the inclusion size is very

small compared to the distance from the inclusion centre to the loading

location, it is reasonable to assume that the spherical inclusion is subject to

a symmetric uniform radial load, as indicated in

Figure 1. Therefore, the

normal stress along the

direction is the same as that of the

direction (

). The equilibrium differential

equation is given by

where

r denotes the

radial

distance from the inclusion centre.

Substituting Equation (12) into the above equilibrium equation leads to

The average size of the inclusion is

very small compared to the background medium, and thus we can assume that the loading

condition is spherically symmetric on the inclusion surface [

5]; this assumption is made as

this study deals with the scale-dependent mechanics of ultrasmall inclusions.

Furthermore, it is assumed that the deflection caused by external loading is

small, leading to geometrical linearity assumption for strain-displacement

relations. In practical applications, especially in biomedical scenarios,

gentle mechanical forces are applied using devices such as an ultrasound

transducer or a mechanical probe. These loading systems are designed to be

comfortable and painless and induce only slight loads on patients’ bodies,

consequently resulting in small displacements and geometric linearity.

To capture the scale effects that are

related to the effective stress nonlocality, Eringen’s theory is used [

44]. According to this theory, the

effective stress at a particular point depends not only on the strain

components at that point but also on the strain components at all other points

of the porous material. The stress nonlocality assumption made in Eringen’s

theory allows us to take into account small-scale interactions from a

mechanical point of view. Based on the nonlocal theory of poroelasticity, the

effective stresses are expressed in terms of strain components as

where

Here

and

are Lamé

coefficients, and

G and

K represent the shear and bulk moduli of

the spherical inclusion, respectively.

and

are a calibration parameter and an

internal characteristics size, respectively. The product of these two features

is widely known as the nonlocal parameter (

). In addition,

and

are the strain component and

volumetric strain, respectively. This internal length-scale parameter could be

associated with the average distance between fundamental components within the

inclusion.

Figure 1b gives an example of a biomedical inclusion in the form of early

breast tumours. In the tumour, individual cells have developed in closer

proximity to each other compared to the surrounding healthy tissue. The

conditions of the above nonlocal constitutive equations are stress–strain

linearity and material homogeneity. Furthermore, reduced partial differential

equations of nonlocal elasticity, which were introduced by Eringen

[

44]

for a group of physically

admissible kernels, have been utilised. These constitutive equations were

obtained from the integral form of nonlocal elasticity by assuming that the

nonlocal modulus is Green’s function of a linear differential operator

[

44].

For spherical inclusions, strain

components can be written as

In Equations (18) and (19),

is the displacement along the radial

direction. The effective stress–strain Equations (15) and (16), together with

the equilibrium Equation (14), form three coupled partial differential

equations that govern the deformation behaviour of the inclusion. To calculate

the displacement, strain and fluid pressure, these differential equations need

to be decoupled first. For the sake of brevity, the procedure of decoupling is

not mentioned here. Substituting Equations (17)–(19) into the resultant

decoupled equation leads to

Using the relation of the volumetric

strain given by Equation (19), the mass balance Equation (9) can be rewritten

as

From the above equations, it is found

that the equilibrium equation in terms of the radial displacement and pressure

is dependent on nonlocal influences, while the mass balance equation is not

affected by the stress nonlocality, as expected. When the scale effects

associated with the stress nonlocality are ignored (i.e.,

), the governing differential

equations of the poroelastic material with an ultrasmall spherical inclusion

need to be reduced to those derived based on the classical poroelasticity

theory. Setting the nonlocal parameter equal to zero in Equation (20) yields

On the other hand,

the

first derivative of the volumetric

strain with respect to the radial distance is obtained from Equation (19) as

Substituting Equation (23) into Equation

(22), one obtains

Equation (24), together with the mass

balance Equation (21), are exactly the same as those widely reported in the literature for large-scale

porous spherical inclusions using the classical poroelasticity

[

5].

3. Solution Procedure Using Galerkin Technique and PIM

To discretise the nonlocal

scale-dependent governing equations using the Galerkin method, the radial

displacement and fluid pressure are required to be approximated by a set of

appropriate base functions that satisfy the boundary conditions. Consider a

spherical inclusion of radius

R embedded in a poroelastic medium under a

uniform radial compression, as shown in

Figure 1. From the symmetric condition, the radial

displacement is zero at the inclusion centre, while it reaches its maximum

value at the surface. By contrast, the fluid pressure is at its maximum at the

centre, whereas it is equal to that of the background medium at the inclusion

surface due to the continuity condition. Moreover, since the inclusion and its

loading are symmetric around the centre, there is no fluid flow at the centre

and, thus, the fluid pressure gradient is zero at that point. These boundary

conditions can be written as

in which

,

and

are the maximum radial displacement,

maximum fluid pressure and the background pressure, respectively. In general,

the nonlocal boundary conditions that are imposed on the displacement

components of the inclusion, such as the radial displacement boundary

conditions given by Equation (25), are the same as those of the classical

poroelasticity model. However, nonlocal boundary conditions associated with

stress components such as force resultants and moments deviate from their

classical counterparts because of the effects of the nonlocal constitutive

equations [

13]. In

this analysis, only stress nonlocality within the solid phase of the

poroelastic medium is considered, and thus all boundary conditions related to

the fluid phase, such as those specified by Equation (26), are the same as

their corresponding classical boundary conditions.

Based on the boundary conditions given

by Equations (25) and (26), the following expressions are suggested for the

radial displacement and the fluid pressure inside the spherical inclusion

where

and

are the base functions of the radial

displacement and fluid pressure, respectively. The number of base functions for

the inclusion displacement and pressure are denoted by

M and

N,

respectively. The proposed solution for the displacement and fluid pressure are

not uniform, as can be seen from Equations (27) and (28). The second part of

the solution on the right-hand side of these equations describes how radial

displacement and fluid pressure change by the radial coordinate

r.

However, it is assumed that the loading condition on the surface of the

inclusion is uniform. This assumption is made since the average size of the

inclusion is very small compared to the background medium and, thus, the load

is applied at a far distance from the inclusion. This makes the remote-load

assumption valid and, hence, the loading condition on the inclusion surface is

uniform according to the Eshelby theory [

5,

42]. In general, there are two types of widely used ultrasound

elastography: (1) quasi-static and (2) dynamic. In the quasi-static technique,

an external mechanical force is applied by a gradual compressive load, while in

dynamic elastography, mechanical load is induced using vibrating probes or

applying acoustic radiation forces [

45]. In this analysis, the ultrasound elastography mode is of a

quasi-static form, resulting in a static uniform load on the inclusion surface.

Substituting Equations (27) and (28)

into Equations (20) and (21), multiplying both sides of each governing equation

by its appropriate base function, and integrating over the whole volume of the

spherical inclusion, the following discretised equations are obtained

In general, the volume element in the

spherical coordinate system is

, where

and

are the azimuthal and polar angles,

respectively. Due to the symmetry of the problem, the element volume used to

perform the integration over the inclusion body in the above discretised

equations is

. The fluid pressure of the background

at the interface is assumed to be zero (

) [

5]. To avoid any numerical error caused by unscaled features and

parameters, a set of dimensionless parameters is introduced by

Here,

Hag is the aggregate modulus of the spherical inclusion. The discretised Equations (29) and (30) can be written in a compact way, as follows

where

,

,

and

are

calculated using Equations (29) and (30) by performing all integrations over the inclusion body. For the

sake of convenience, Equations (32) and (33) can be expressed in a matrix form

as

where

Equations (34) and (35) give a set of

time-dependent ordinary differential

equations in a matrix form. From these two equations, one can obtain

in which

is the initial value of the vector

at

. Matrix

H is defined by

Based on the

procedure

used in the precise integration method (PIM), a time step

dimensionless parameter

is introduced by [

46,

47]

Using Equation (40), the vector of

dimensionless

pressure

is calculated as

where

and

The recommended value for the

is twenty [

47], which is

commonly utilised in PIM. From Equation (43) and by adopting such a big value for

, it is found that the new time

interval

is very small. Thus, the following

approximation of the exponential function is valid by employing the Taylor

expansion

where

In Equation (44),

denotes the identity matrix. In view

of Equations (44) and (42), we have

The time-dependent part of the fluid pressure of the spherical inclusion is obtained by substituting Equation (46) into Equation (41). The time-dependent part of the radial displacement can be calculated by Equation (37). The

resultant time-dependent parts are then substituted into Equations (27) and (28) to obtain the final solution.

6. Analytical Solution for Local Large-Scale Spherical Inclusions

For the sake of comparison and

validation, an analytical solution is obtained for local large-scale spherical

inclusions where there are no scale effects. Setting the nonlocal parameter

equal to zero (

), the governing equations of the

inclusion are reduced to

Integrating both sides of Equation

(62) with respect to the radial coordinate parameter

r, the volumetric

strain is obtained by

where

denotes the

integration

constant that is generally related to the initial condition. For

simplification and ease of use, the subscripts “

tot” and “

ag” are

dropped from the microfiltration coefficient and aggregate modulus (i.e.,

and

),

respectively. The volumetric strain, fluid pressure and the integration

constant are [

5]

Substituting Equation (65) into Equation

(64) leads to

The second and first derivatives of Equation

(66) with respect to

r are

Using Equations (63), (66) and (67),

the following relation is obtained for the spherical inclusion

The integration constant is affected

by the initial conditions, and they can be taken in a way that this constant

becomes zero (

) [

5]. Let us define two dimensionless parameters as

and

. Using these definitions, Equation

(68) is expressed by

Now, a new parameter is introduced for

the sake of convenience as

Equation (70) is used to change the

variable in Equation (69) as

Performing the Laplace transform on

both sides of Equation (71) leads to the following equation in the

domain

where

It is observed that the Laplace

transform in conjunction with the change in variables results in a less complex

differential equation that is easier to be solved analytically. The solution of

Equation (72) can be written as

where

C1 and

C2

depend only on

s and are obtained by using the boundary conditions.

Substituting Equation (74) into Equation (70), we have

Using the first relation of Equation

(65), together with the definition of dimensionless time (

), the following relation is obtained

between

and

Taking the Laplace transform of Equation

(76) leads to

To calculate the coefficients of

, namely

C1 and

C2, the

boundary conditions of the spherical inclusion are used as follows [

49]

and

Here

,

and

are Poisson ratio, Young’s modulus and stress on the spherical inclusion surface, respectively. Taking the Laplace transform of Equations (78) and (79), and substituting Equations (75)–(77) into the resultant relations of the boundary conditions, one can obtain

Substituting Equation (80) into Equation

(75) leads to the following relation

Using the complex inversion integral

[

40], the Laplace transform inverse

of Equation (81) can be calculated as

where

is obtained from the following relation

7. Integration of Nonlocal Poroelastic Model with Light Gradient Boosting Machine

The nonlocal poroelastic model has

been developed based on some assumptions and limitations including material

linearity, spherical shapes for inclusions and small ratios of inclusion radius

to poroelastic medium length. However, in practical applications, a violation

of at least one of these assumptions could happen, which restricts the

application of the scale-dependent nonlocal poroelastic model. Overcoming all

the limitations of the above nonlocal model by the use of nonlinear nonlocal

poroelasticity is either impossible or comes with significant mathematical

challenges and computational costs. Integration of the nonlocal continuum model

of poroelasticity with a light gradient boosting machine (LGBM) enables greater

flexibility for extracting patterns in experimental and computational data, as

well as for incorporating additional effects such as nonlinearity and

geometrical imperfections. The LGBM is an open source, fast and efficient

gradient boosting framework developed by Microsoft [

50]

that has been recently used

for many machine learning tasks in various applications

[

51,

52,

53]. Its high speed, lower

memory usage and efficient performance, particularly when working on

large-scale datasets, make this machine learning algorithm an ideal candidate

to be integrated with the nonlocal poroelastic model. Another reason for

suitability of the LGBM is the capability of handling both regression and

classification problems. Inclusion models are often used to detect

imperfections and abnormalities such as solid tumours, in which both

classifications and regression tasks might be needed.

In the LGBM, a strong predictive model

is created by the combination of several weak estimators (decision trees). The

estimators are developed sequentially, in which each estimator tries to correct

the errors caused by the previous ensembled decision trees. A leaf-wise tree

growth approach is used, in which only leaves with maximum reduction in the

loss function are chosen to expand the decision tree. Compared to level-wise

tree growth, this approach generally leads to lower loss values and higher

accuracies. However, leaf-wise tree growth algorithms are more prone to

overfitting, especially on small datasets.

In this analysis, three different

types of boosting strategies are utilised for the LGBM integrated with the

nonlocal continuum model: (1) gradient-based one-side sampling (GOSS), (2)

dropouts meet multiple additive regression trees (DART) and (3) traditional

gradient boosting decision tree (GBDT). The GOSS utilises a subsampling

procedure to place more emphasis on subsamples with higher gradients. In fact,

subsamples with high gradients play a more significant role in building

decision trees. In addition to the general advantages of subsampling such as

variety introduction, rapid training process and less chance of overfitting,

GOSS-based subsampling benefits from improved efficiency, less memory usage and

faster convergence. On the other hand, the DART boosting algorithm addresses

the problem of over-specialisation by employing the idea of dropouts from deep

learning. During each iteration, random dropouts are conducted to avoid

over-reliance on earlier trees and improve the generalisation of the model.

Figure 2 shows the required steps involved in the integration of the

nonlocal poro-elasticity model and the LGBM algorithm of machine learning.

First, inclusion features such as average radius, nonlocal scale coefficient,

elastic modulus, Poisson’s ratio and hydraulic conductivity, as well as the

times of interest, are given to the nonlocal scale-dependent model of

poroelasticity, and the inclusion’s pressure and radial displacement are

obtained. The calculated fluid pressures and displacements are then employed to

build a training dataset for fitting the LGBM model. Depending on the

availability of experimental tools and measurements, empirical observations can

also be supplied, leading to a more robust and accurate hybrid model of

poroelastic inclusions that would be capable of incorporating additional

effects such as nonlinearity and geometrical imperfections. Overall, nonlocal

poroelasticity results account for the underlying physics of the inclusion

problem, while the experimental data could help incorporate the violation of

any assumption made in the nonlocal continuum modelling.

In this study, the light gradient

boosting machine learning model is developed using open-source python libraries

including scikit-learn 1.2.2, pandas version 1.5.3, lightGBM 3.3.5 and NumPy

1.24.3. The scaling process is performed on numerical features such as

inclusion radius and nonlocal scale coefficient using the ‘StandardScaler’

function from the scikit-learn preprocessing package [

54]. This process is necessary to

assure that all numerical features are in the same standard scale, facilitating

model convergence and preventing certain features from being overshadowed by

others. A dataset of 34,100 data points obtained by the scale-dependent

nonlocal poroelastic model of small-scale spherical inclusions is used. The

test size is set to 30%, making training and test datasets of 23,870 and 10,230

points, respectively. The ‘ColumnTransformer’ function from the scikit-learn

compose package is utilised for the fast and robust transformation operation on

the columns of the data frame with the inclusion’s features. A machine learning

pipeline combined with a grid search cross validation framework is developed

for an efficient and smooth hyperparameter tuning process. The scoring metrics

for ranking machine learning models and finding the best configuration of

hyperparameters is set to the negative root mean squared error. The number of

estimators (decision tress) and leaves on each tree are taken in the range of 1–200

and 1–51, respectively, for the hyperparameter tuning. In addition, different

values of learning rate between 0.01 and 0.2 and various maximum depths in the

range of −1 to 100 are considered. Here, negative values are used to indicate

that there is no restriction on the number of leaves. The machine learning

pipeline includes three different boosting algorithms as GOSS, DART and GBDT.

The best LGBM estimator with the minimum root mean squared error is obtained

and applied for predicting the inclusion fluid pressure or radial displacement

on unseen test data.

8. Results and Discussion

In this section, the results of the

nonlocal poroelastic model and LGBM are presented and discussed on one of the

most common applications of the inclusion–background models, which is the

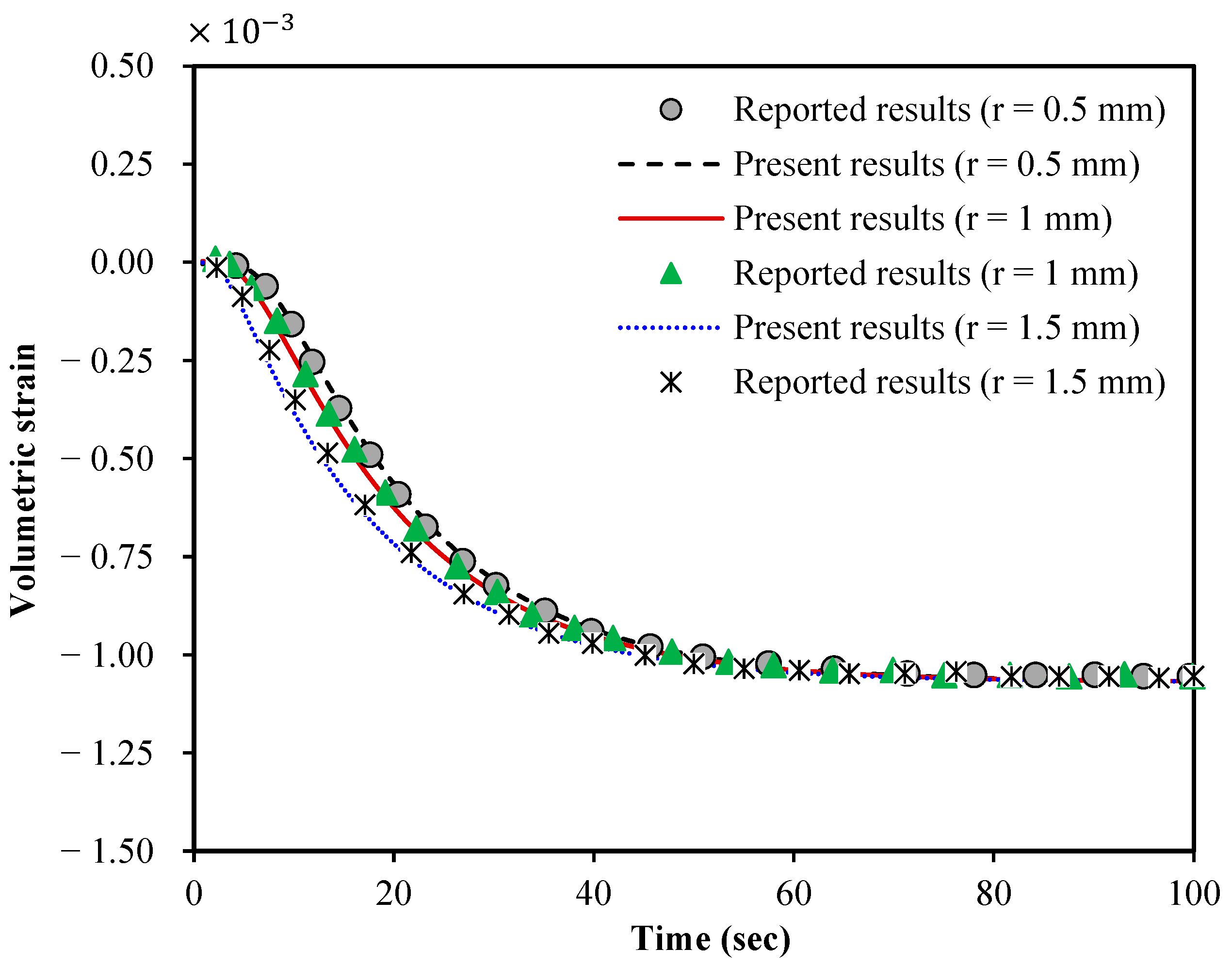

mechanical behaviour of solid tumours. First, to verify the accuracy of the

nonlocal poroelasticity modelling, the volumetric strain of the present model

is plotted in

Figure 3

and compared to the one reported in Ref. [

5]

for local large-scale spherical

tumours using the classical poroelasticity theory. The results are shown at

various radial distances from the centre of the solid tumour. The tumour

radius, Young’s modulus, Poisson’s ratio, hydraulic conductivity per volumetric

weight and microfiltration coefficient are, respectively, taken as

R = 3

mm,

E = 97.02 kPa,

= 0.45,

= 1.8 × 10

−13 m

4/Ns,

= 5 × 10

−9 1/Pa·s [

5]. To make a reasonable

comparison, scale effects related to the stress nonlocality are neglected. It

is found that the results of our modelling approach closely match those

reported in the literature.

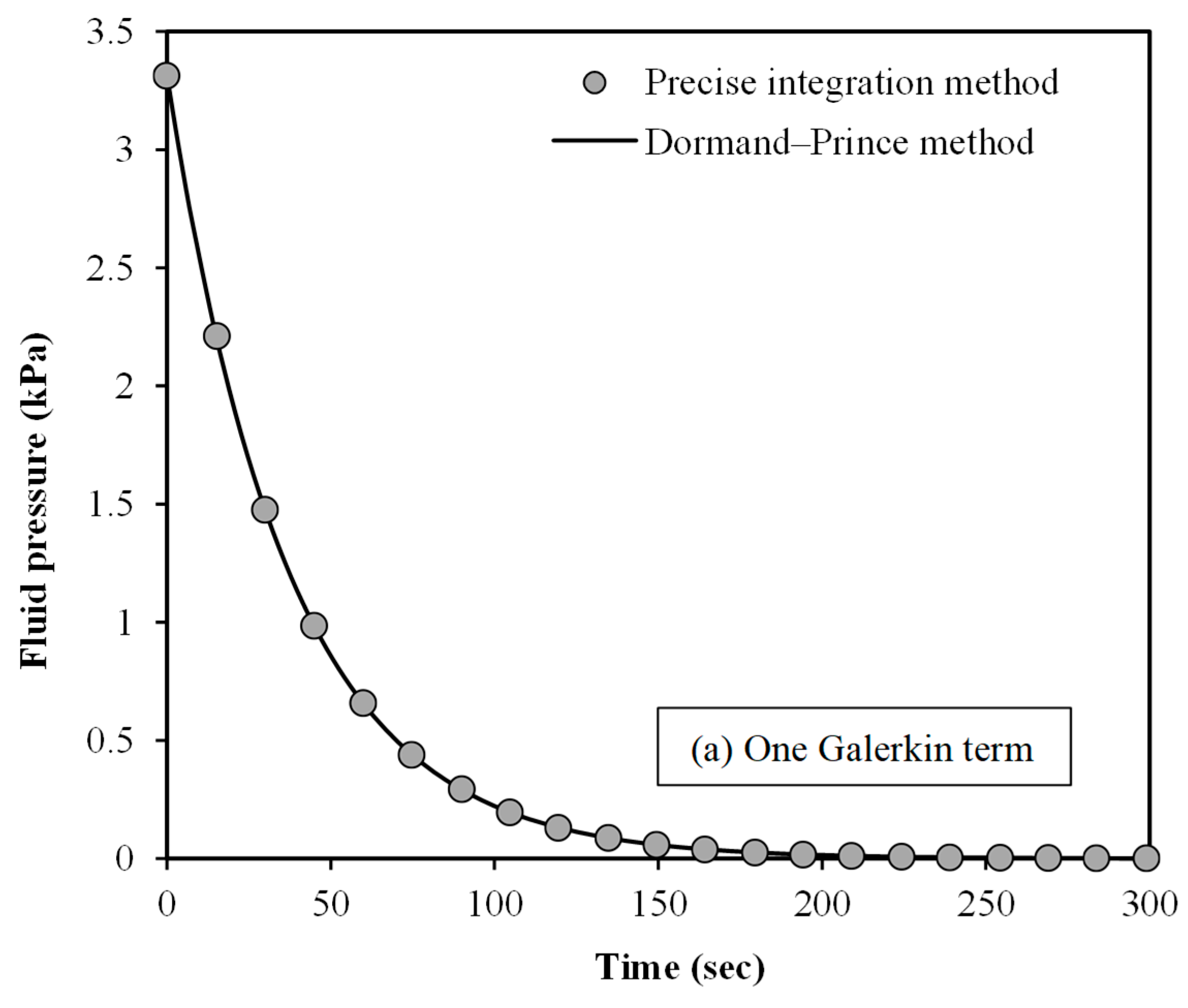

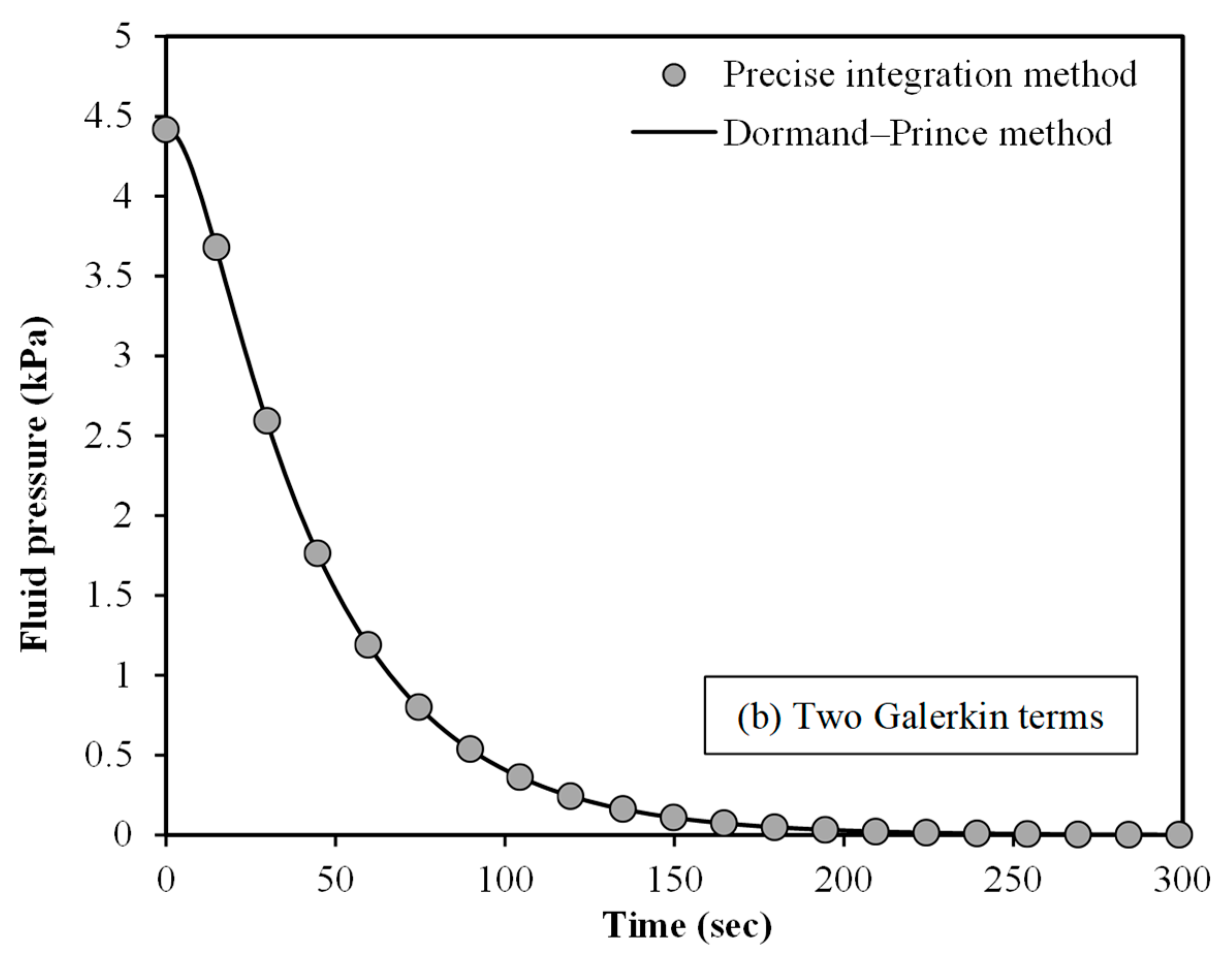

To further prove the validity of the

mathematical scale-dependent modelling, the fluid pressure within the spherical

tumour is plotted against time in

Figure 4. The numerical results are demonstrated for two different solution

procedures: (1) PIM and (2) Dormand–Prince method. Moreover, one and two

Galerkin terms are assumed in

Figure 4a,b, respectively. The fluid pressure is calculated at

r = 0.5

R. The initial value of the dimensionless fluid pressure is set to 0.01.

The Dormand–Prince solution procedure is implemented using a Matlab program. An

excellent match is found between the two numerical techniques for the fluid

pressure of spherical tumours using the scale-dependent nonlocal

poroelasticity.

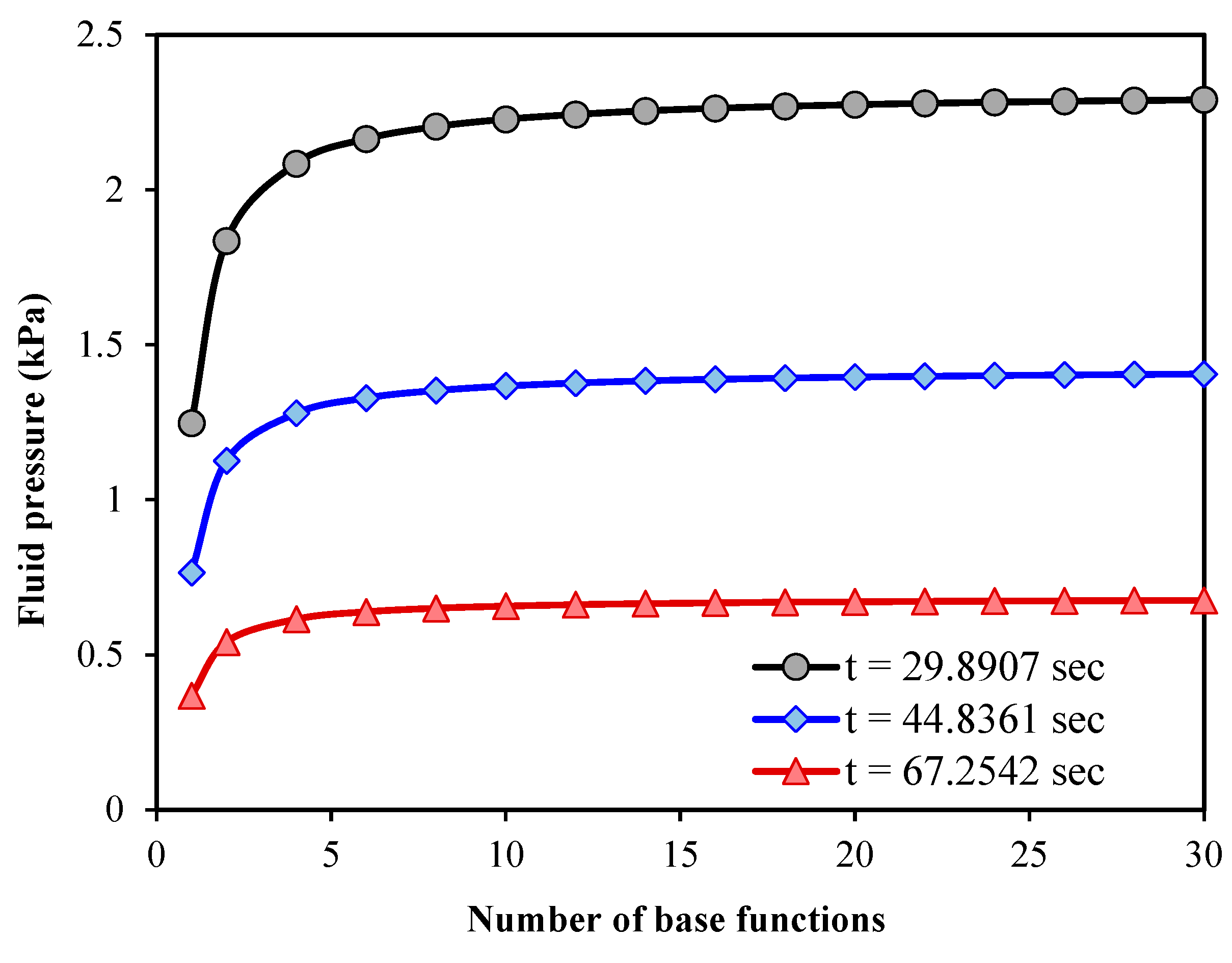

To show the convergence of the

solution, the tissue fluid pressure is shown in

Figure 5 versus the number of

base functions. The calculations are performed for three different time values.

The tumour radius, Young’s modulus, Poisson’s ratio, hydraulic conductivity per

volumetric weight and microfiltration coefficient are the same as those mentioned

above for plotting

Figure 3. The fluid pressure is numerically obtained at the midpoint between

the tumour centre and surface. It is found that after about ten base functions,

the results are converged in all cases.

Figure 6 illustrates the fluid pressure of a spherical tumour

against time for four various Galerkin terms (base functions). This figure

shows how important it is to consider a sufficient number of Galerkin terms in

calculating the fluid pressure of the tumour. Neither one nor two Galerkin

terms are sufficient to obtain a reliable numerical solution. However, the

cases of ten and fifteen base functions are very close to each other, which

indicates that the results converge.

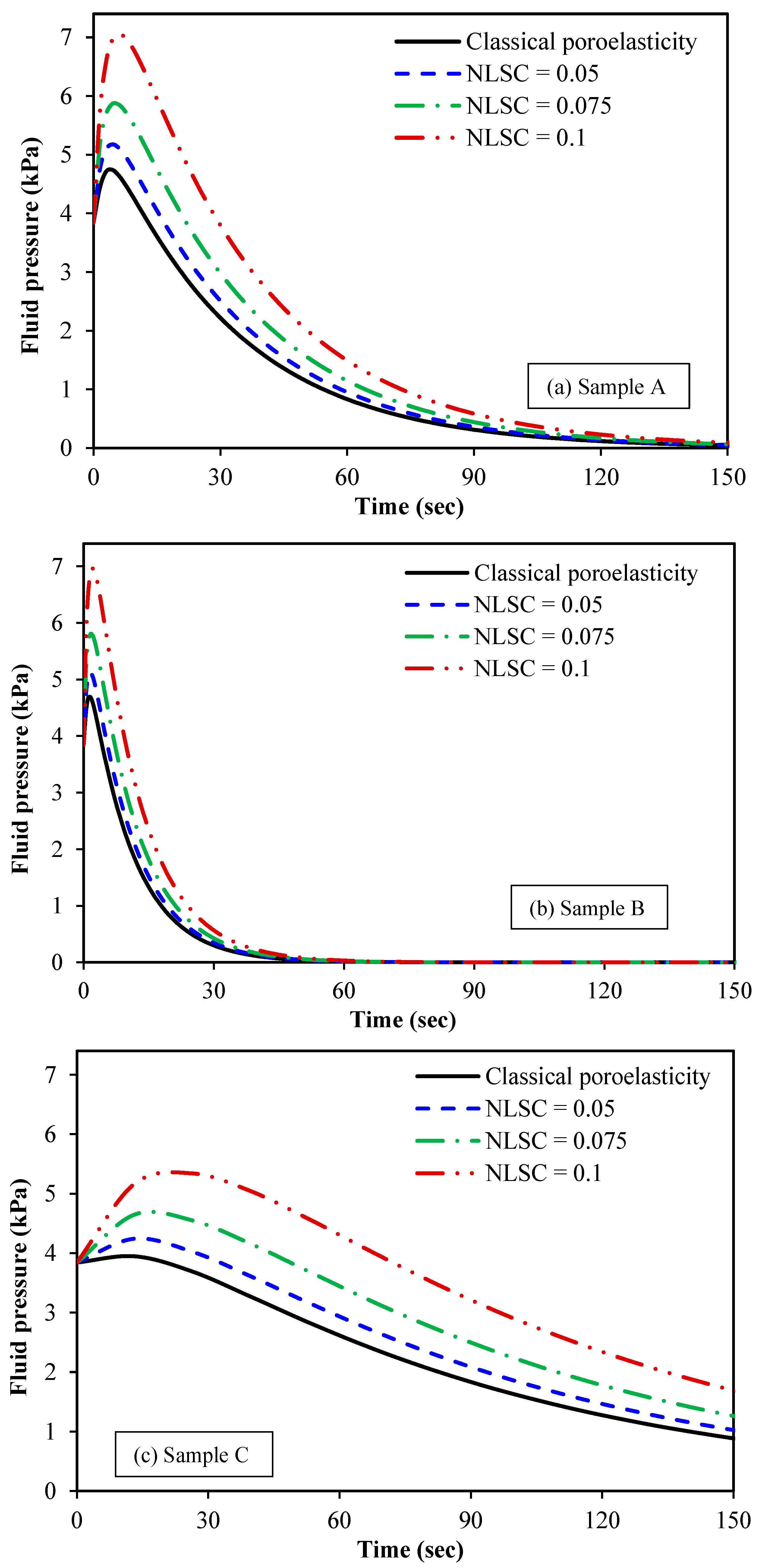

Figure 7 is plotted to discuss the influence of the nonlocal scale

coefficient (NLSC) on the fluid pressure of the spherical tumour. The NLSC is

defined as the ratio of nonlocal parameter to the tumour radius as

, leading to a dimensionless scale

parameter related to the stress nonlocality. Ten base functions are considered

for both radial displacement and fluid pressure of the spherical tumour. Three

different biological samples are taken into account for the spherical tumour.

The poroelastic properties of these samples are listed in

Table 1. The radius of the

spherical tumour is set at

R = . For comparison purposes, the case of

classical local poroelasticity, in which scale effects are ignored, is also

considered. It is observed that as the NLSC is increased from 0 to 0.1, the

fluid pressure at

r = 0.5

R increases. This can be interpreted as

one consequence of stiffness reduction due to the nonlocal effect. An increase

in the NLSC leads to a considerable decrease in the structural stiffness of the

tissue solid matrix, and this means that the tissue becomes softer and the pore

fluid pressure is enhanced. From a clinical point of view, this finding is very

important as it would result in improving the resolution of elastography

imaging.

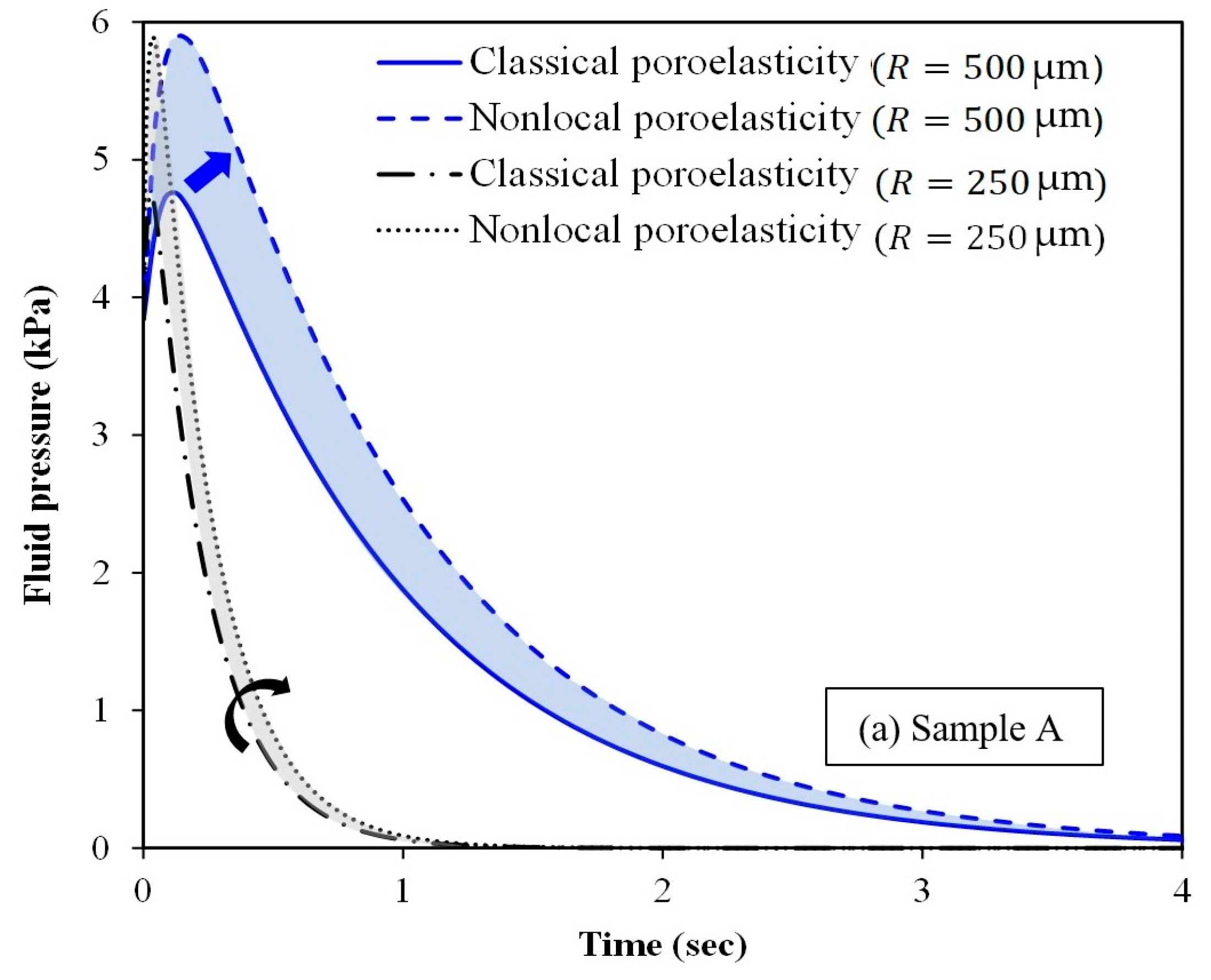

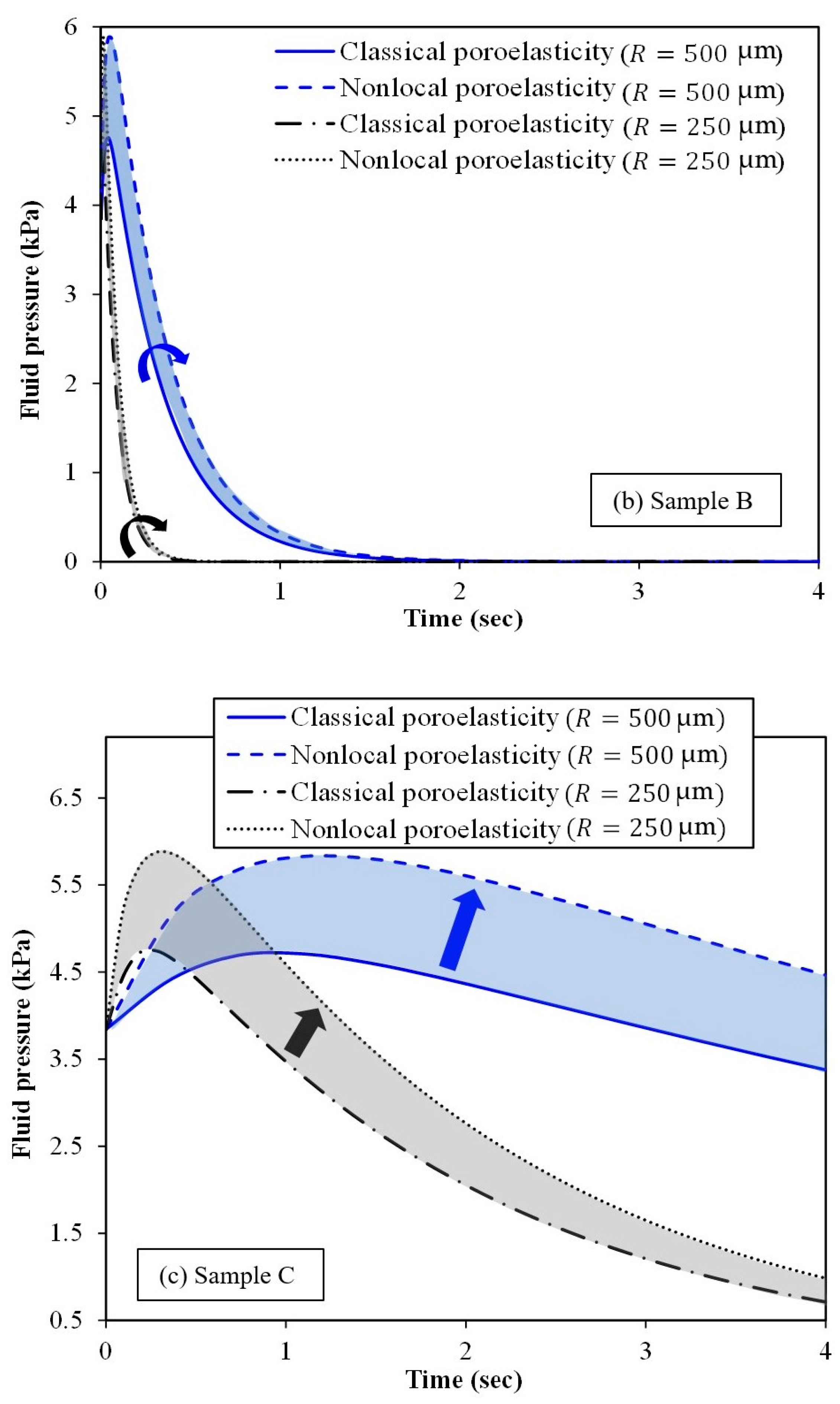

Figure 8 depicts the effect of spherical tumour size and time on the fluid

pressure at the half space between the tumour centre and surface. The figure

also compares the nonlocal scale-dependent poroelasticity with the classical

one for three different samples (samples A, B and C). When the radius of the

spherical tumour decreases, the fluid pressure decreases as well. Furthermore,

the fluid pressure gradually reduces over time. The only exception is the very

early moments of imposing the applied compressive loading. At a certain time

long enough after the loading, the fluid pressure vanishes inside the spherical

tumour. For smaller tumours, the specific time corresponding to the loss of

fluid pressure is considerably lower.

Figure 8 demonstrates the promising capability of the nonlocal

scale-dependent poroelasticity compared to the classical poroelasticity in

estimating the fluid pressure within spherical tumours of ultrasmall sizes

(less than 500 µm in radius). The clinical use of the proposed nonlocal

poroelasticity model could result in a substantial improvement in the accuracy

and sensitivity of the tissue mechanical property measurement using

elastography imaging, especially for tumours of small-scale sizes.

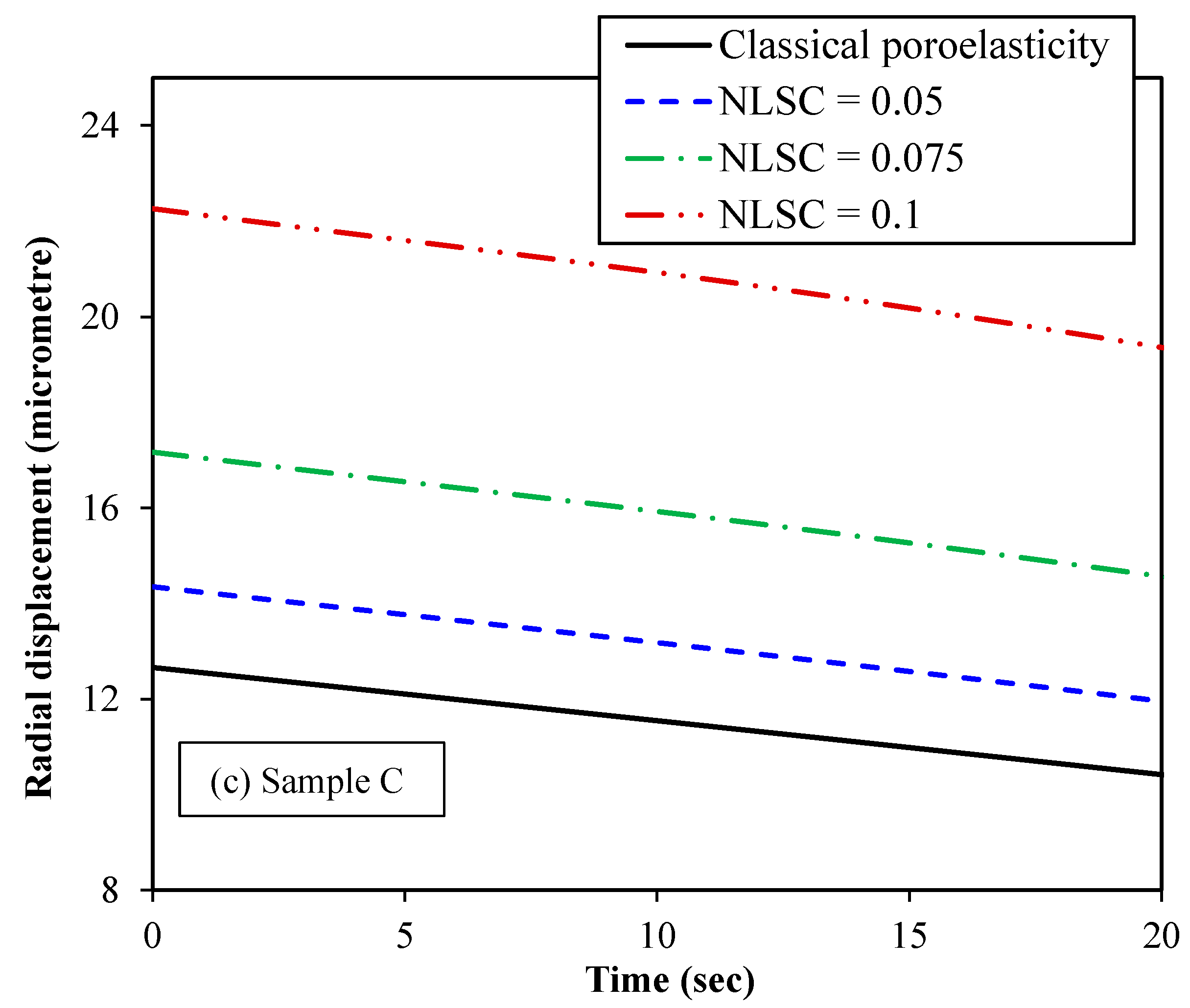

The variation in the radial

displacement with time is plotted in

Figure 9

for various values of NLSCs for the three different

biological samples. Young’s modulus, Poisson’s ratio and the geometrical

features of the three samples are the same. However, they differ in terms of

the hydraulic conductivity per volumetric weight and microfiltration

coefficient, as can be seen from

Table 1. The radial displacement is calculated at

r = 0.5

R.

Ten base functions (ten Galerkin terms) are supposed for both the radial

displacement and fluid pressure of the spherical tumour in all case studies.

From

Figure 9, it

can be concluded that the nonlocal scale coefficient has a vital role to play

in the mechanical behaviour of small-scale tumours. As the scale effect related

to the solid stress nonlocality inside the spherical tumour increases, larger

radial displacements are observed. The validity of this finding is backed up by

the evidence that nonlocal effects lead to a reduction in stiffness, making the

tissue more prone to mechanical deformation. This finding is very important

from a clinical point of view as the sensitivity and accuracy of the

elastography-based cancer diagnosis could be significantly improved by taking

into account these effects using the nonlocal poroelasticity theory.

A light gradient boosting machine

(LGBM) algorithm is presented and integrated with the scale-dependent nonlocal

poroelastic model of small-scale spherical inclusions. To show the accuracy and

capability of the integrated model, the results of the nonlocal model for

sample A are used as an example to build the training and test datasets. The

radius of the inclusion, dimensionless nonlocal scale coefficient and time are

used as the inputs of the LGBM model, while the fluid pressure at the middle

distance from the inclusion centre to its surface is adopted as the label of

the training and test datasets.

Table 2 lists some general statistical information including the mean,

median, maximum, minimum, first and third quartiles of the input features and

fluid pressure as the target variable. The dataset includes 34,100 records,

with 30% of them as the test data and 70% as the training data. A

hyperparameter tuning procedure based on the grid search cross validation

approach has been conducted to obtain the optimised parameters of the LGBM

model. The negative root mean squared error is used to assess the performance of

each configuration of the model parameters. The number of estimators and leaves

on each tree are taken in the range of 1–200 and 1–51, respectively. Different

learning rates between 0.01 and 0.2 and various maximum depths from −1 to 100

are also considered in the grid search cross validation. A negative maximum

depth means that there is no limitation in terms of the number of leaves on the

decision trees. Three different boosting types, GOSS, DART and GBDT, are

considered in this analysis.

Table 3 lists the results of the hyperparameter tuning for six different

LGBM configurations. The mean test score is the negative root mean squared

error of the training data. The optimised parameters of the best LGBM model are

obtained as learning rate = 0.1, maximum depth = 100, number of decision trees

= 200 and number of leaves = 51 (boosting type = GOSS). The root mean squared

errors of this model on training and test data are 0.03389 and 0.03083,

respectively. These values indicate the high accuracy of the LGBM model and no

sign of overfitting as the performance of the model is even better on the

unseen test data compared to the training data. In

Table 4, the predicted fluid

pressure is compared with the actual test fluid pressure obtained by the

nonlocal model at the mid-distance from the centre to the surface of the

spherical inclusion. Various values of the inclusion radii and nonlocal

coefficients are taken into consideration. It is found that the results of the

LGBM are in excellent agreement with those of the scale-dependent nonlocal

model of poroelasticity, indicating the promising capability of the light

gradient boosting frameworks to predict the mechanics of poroelastic

inclusions.

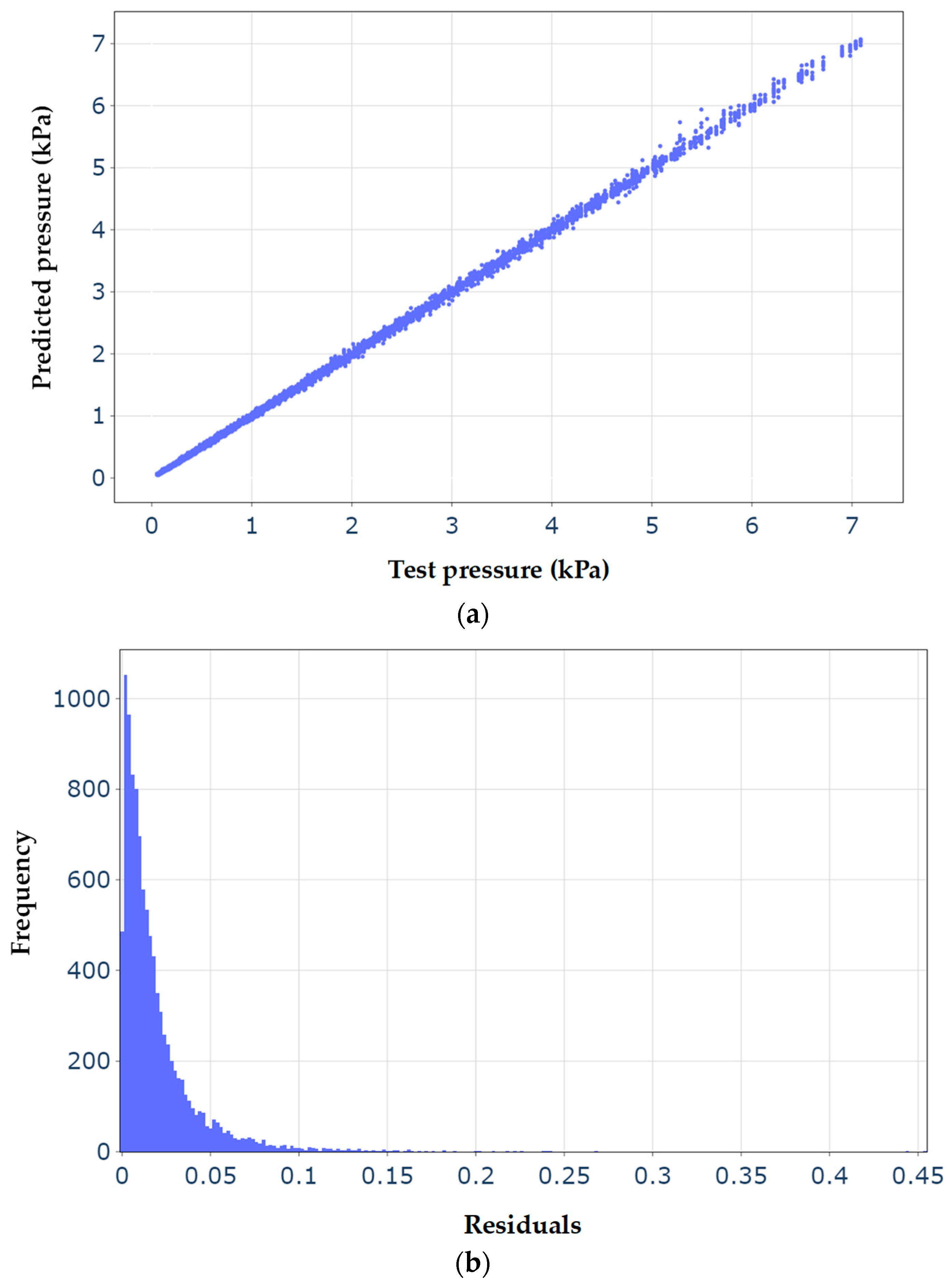

Figure 10a shows the variation in the fluid pressure of the small-scale

spherical inclusion predicted by the best model of the LGBM versus the

reference test fluid pressure obtained by the scale-dependent nonlocal

poroelasticity model. To plot this figure, all 10,230 records of the test dataset

are used to give an overview of the performance of the machine learning model.

In addition, the histogram of the residuals of the fluid pressure within the spherical poroelastic inclusion is described in

Figure 10b. The residuals are

defined as the difference between the predicated and test fluid pressure. It

can be concluded that the predicted fluid pressures closely match those of the

test data almost in all cases. In addition, the majority of residuals are less

than 0.075, providing an additional indicator of the goodness of the optimised

LGBM model.

In the machine

learning model, the fluid pressure at the middle of the inclusion radius is

adopted to train the model and obtain optimised hyperparameters. The optimised

model is then used to make reasonable estimations on unseen new data, as

evidenced by our test data verification outlined above. In practice, there are

two scenarios in which the present model would be useful: (1) When the size of

the inclusion is determined by other imaging techniques such as magnetic

resonance imaging (MRI) or computed tomography (CT); in this case, the model

can be used to determine the inclusion type. For example, in biomedical

applications, the model plays a crucial role in distinguishing benign tumours

from malignant ones by comparing estimated mechanical characteristics with

benchmark data. (2) A trial-and-error procedure for estimating the size of an

inclusion involves systematically adjusting the parameters of a model until a

satisfactory match is achieved between the predicted outcomes and observed

data. In the context of this work’s case study on tumours and interstitial

fluid pressure, this could refer to the process of iteratively refining the

parameters related to the size of the tumour till the predictions align with

experimental or clinical measurements. The present model relates the

interstitial fluid pressure to the mechanical characteristics and size of the

inclusion and could be useful in the iterative process to minimise the

difference between the observation and theoretical estimation. In terms of

proof of possibility, it is noteworthy that experimental studies have

demonstrated that the interstitial fluid pressure is an important biomarker in

solid tumours, significantly affecting the cancer microenvironment [

55]. The clinical measurement

of fluid pressure can be achieved using direct (invasive) techniques such as

servo-controlled micropipette and wick-in-needle, as well as indirect

(non-invasive) methods including ultrasound elastography and dynamic contrast MRI [

56].