Fine Control of Optical Properties of Nb2O5 Film by Thermal Treatment

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

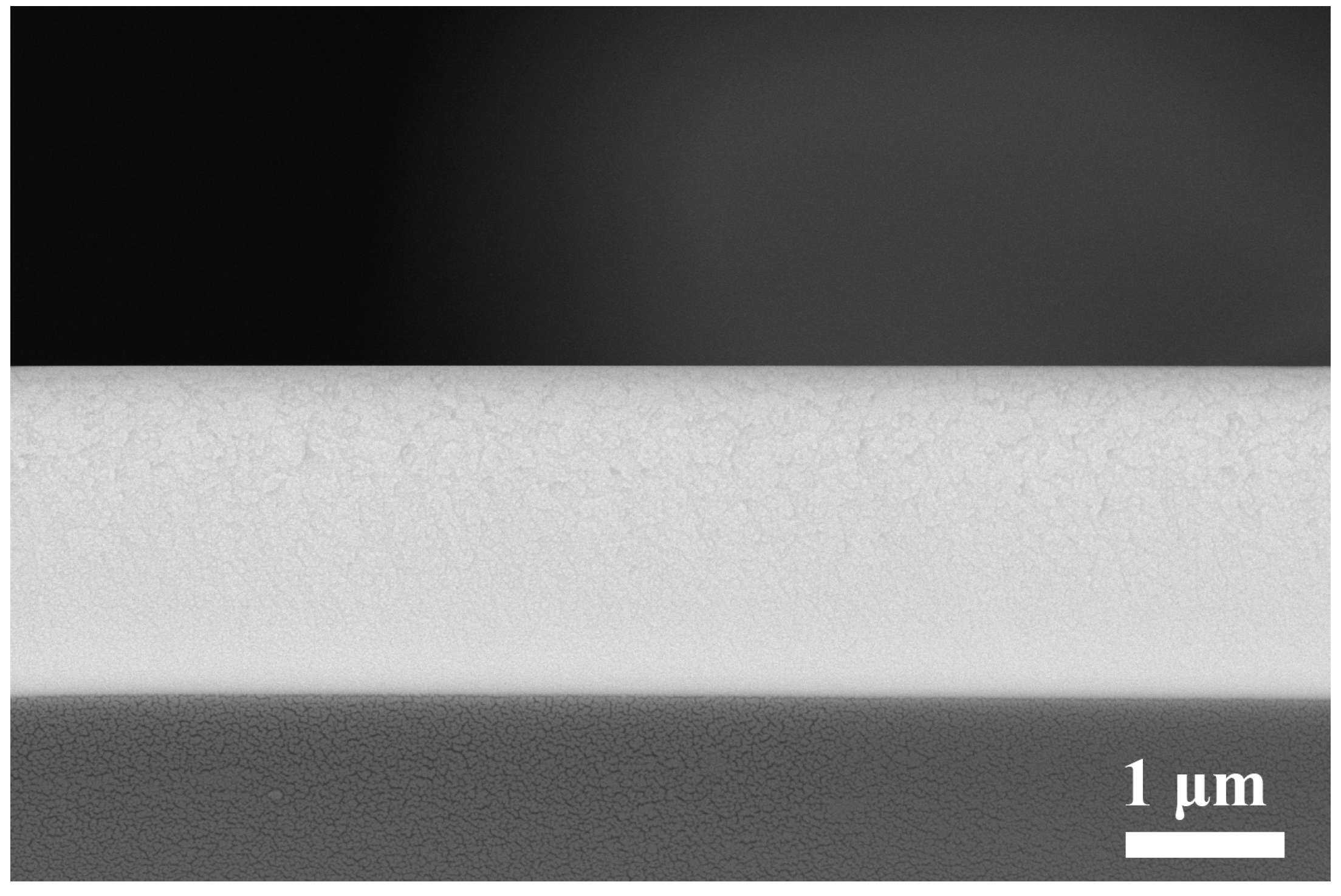

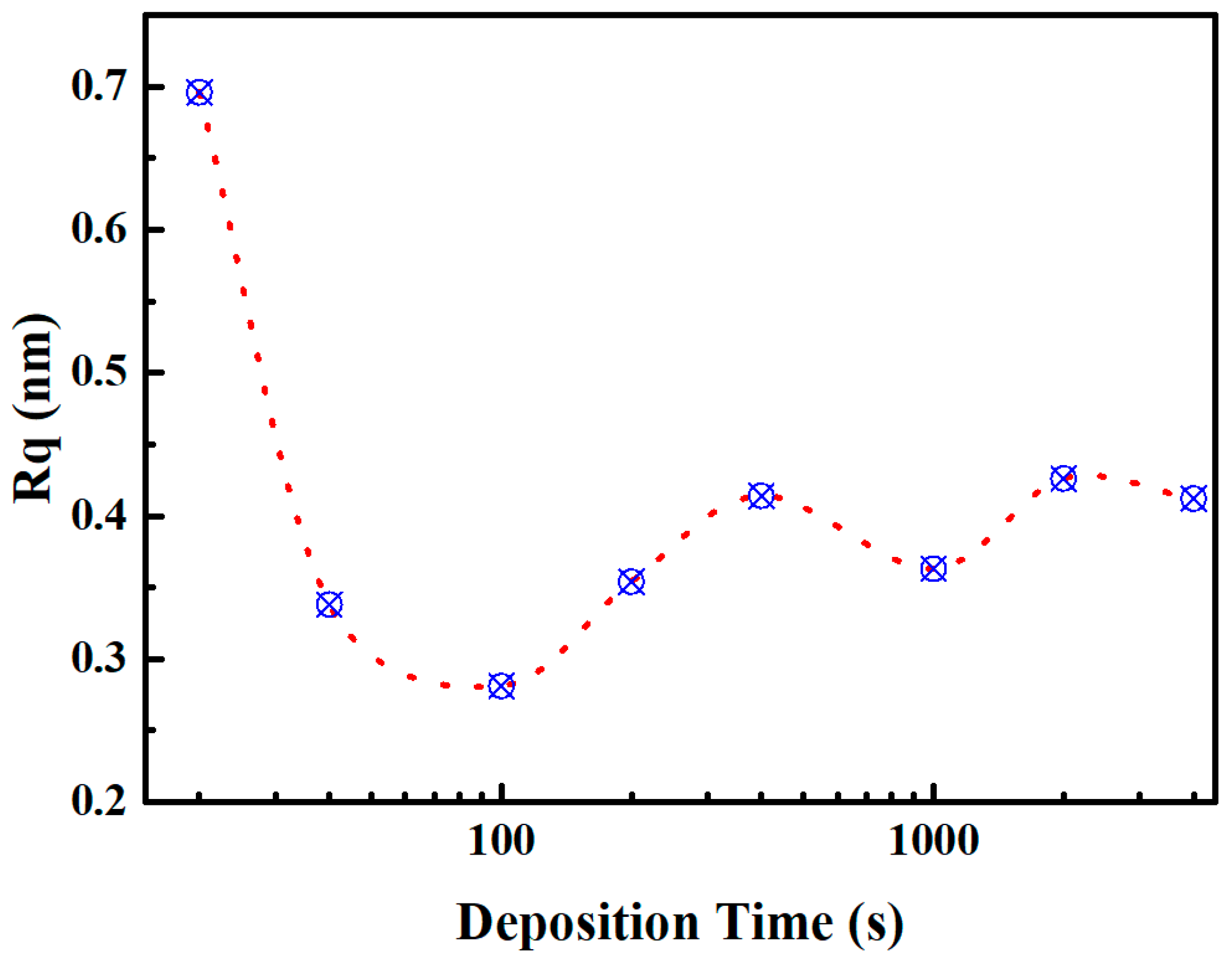

3.1. Growth of Nb2O5 Film

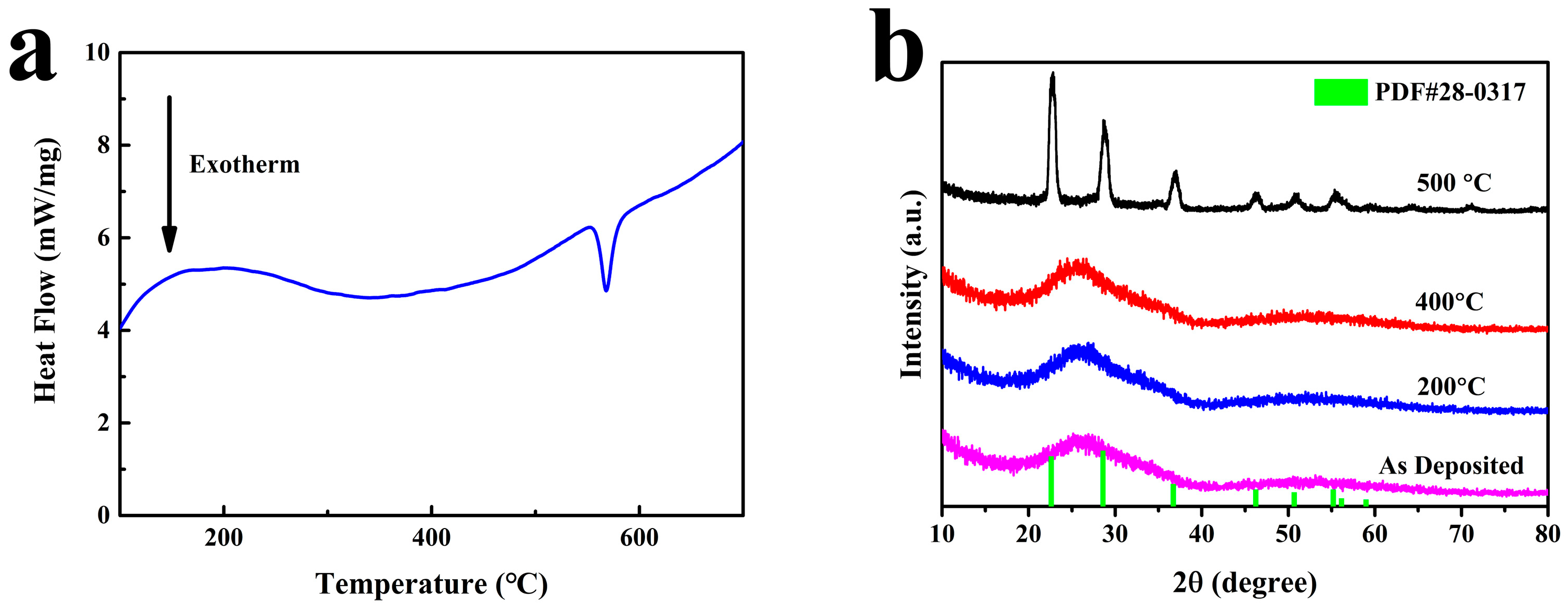

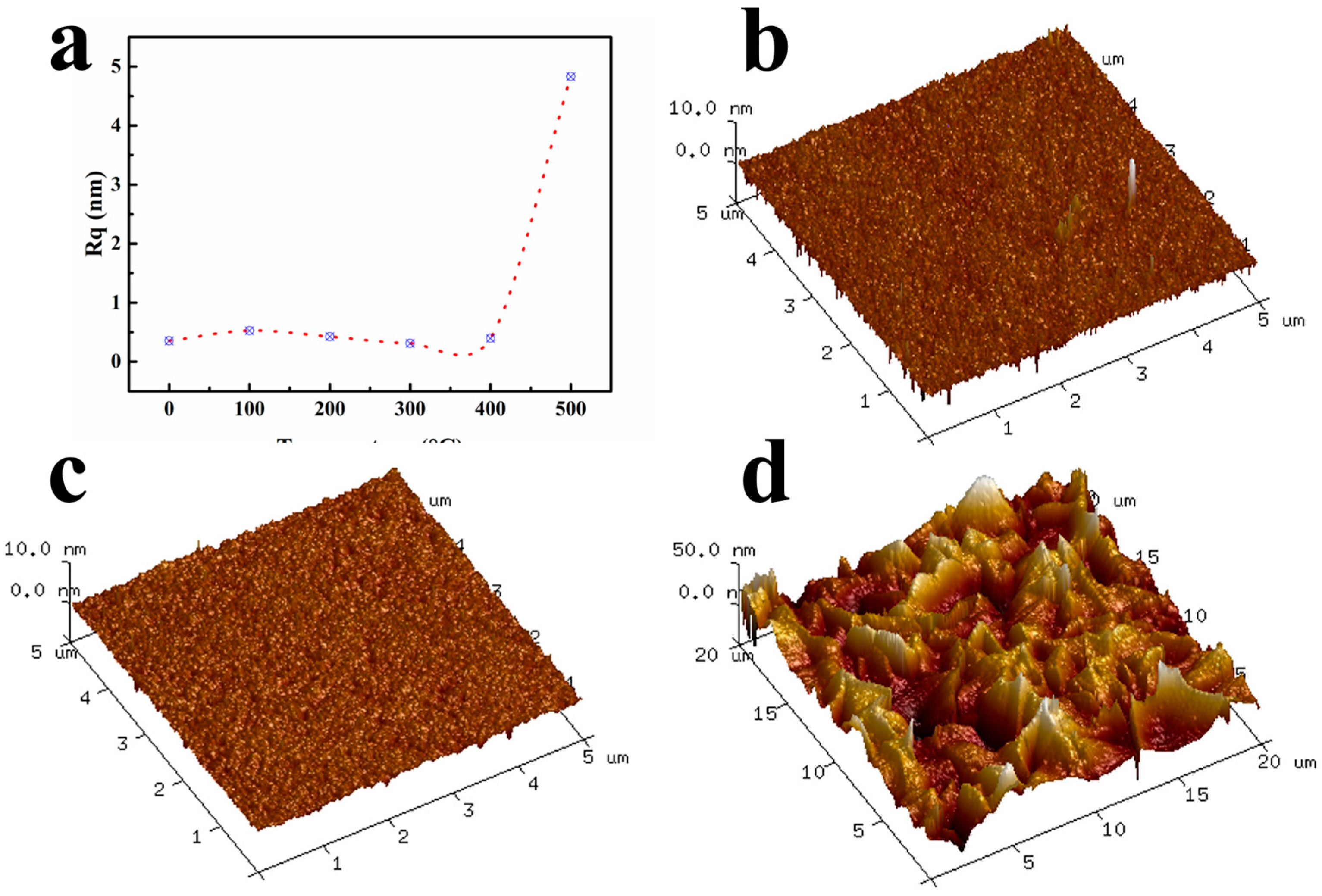

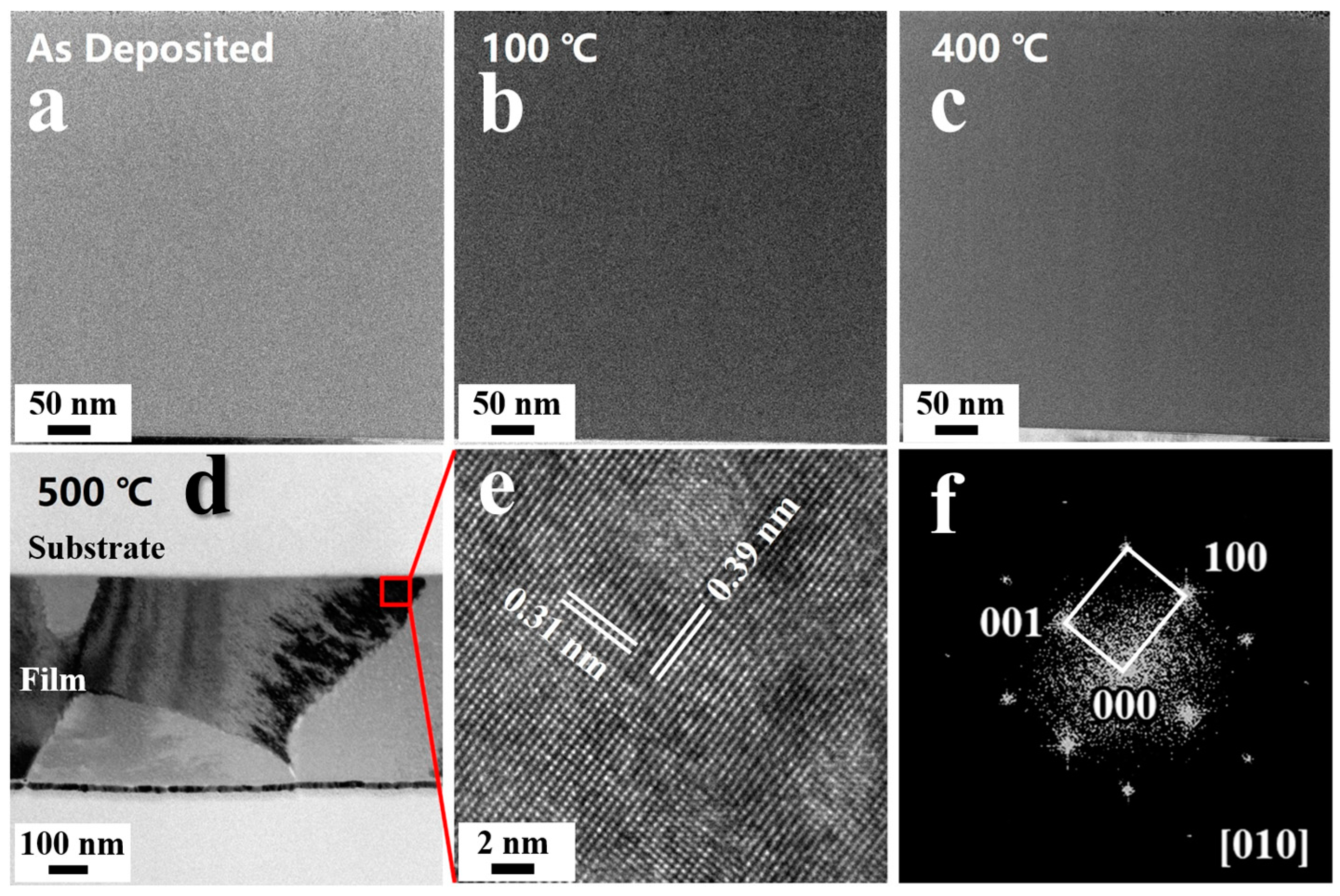

3.2. Structure Changes

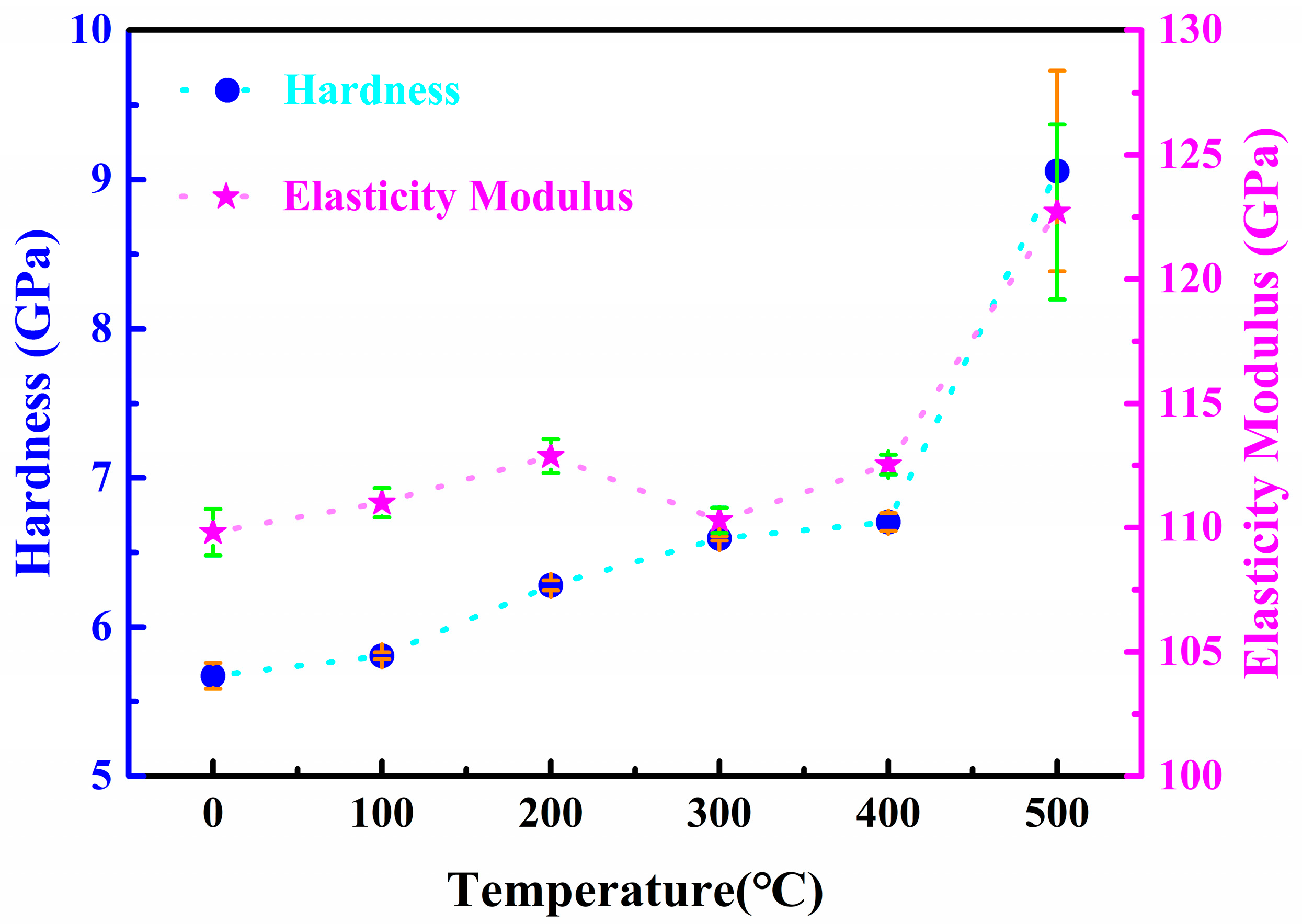

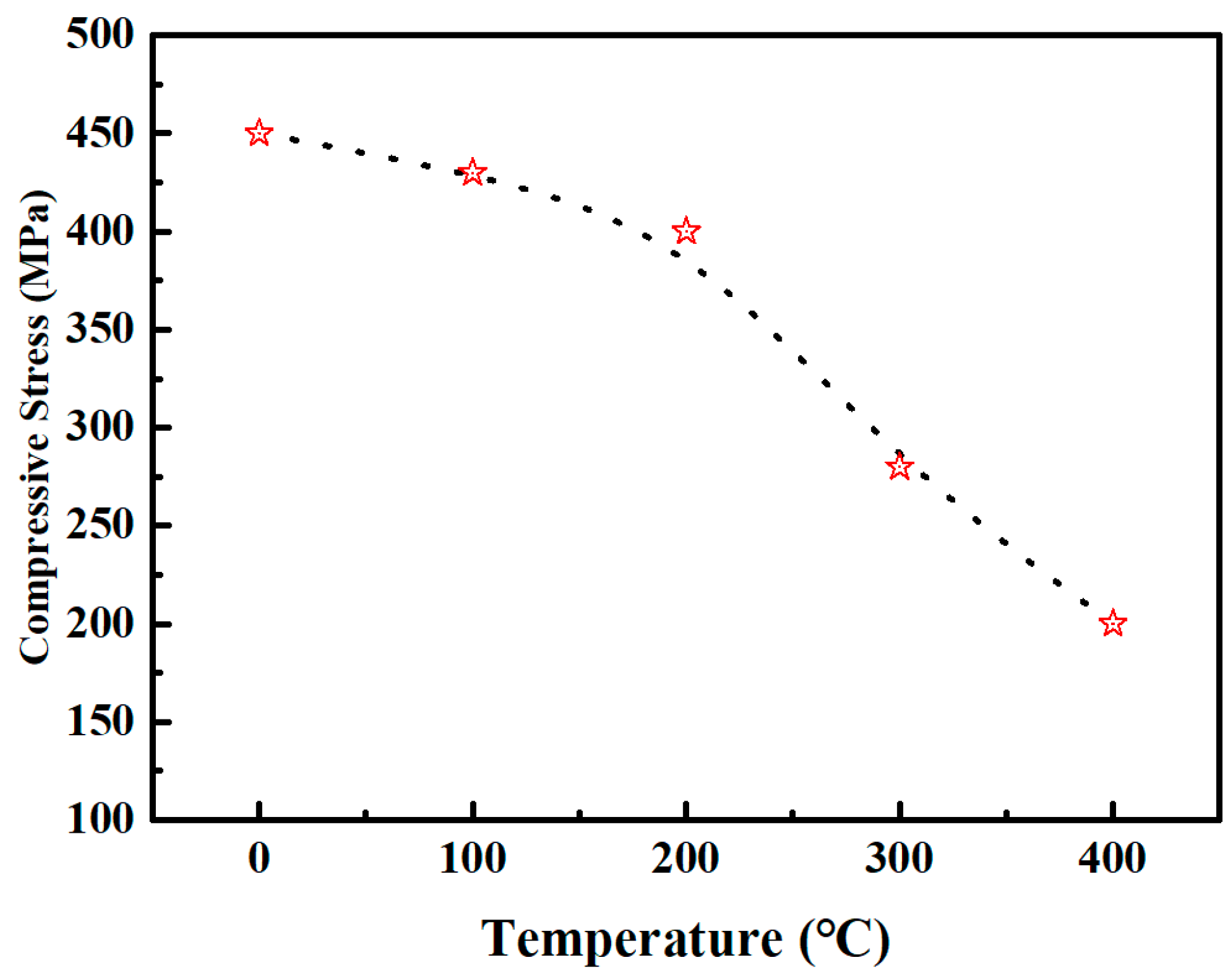

3.3. Effect on Mechanical Properties

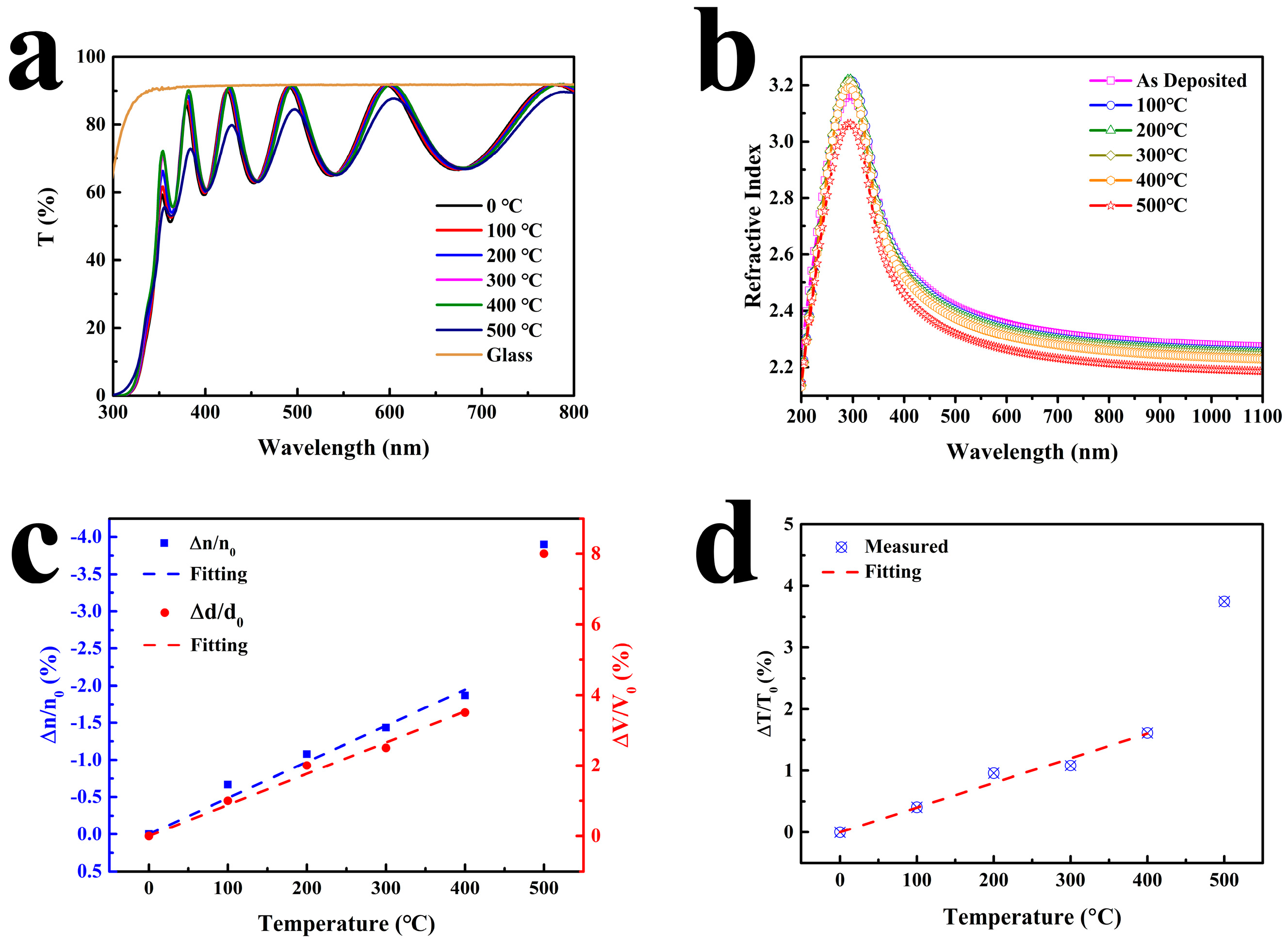

3.4. Changes in Optical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zambrano-Mera, D.F.; Espinoza-González, R.; Rosenkranz, A.; Harvey, T.J.; Polcar, T.; Valenzuela, P.; Gacitúa, W. Enhanced erosion resistance of anti-reflective TiO2/SiO2 coatings induced by Zr-oxide doping. Sol. Energy Mater. Sol. Cells 2023, 250, 112079. [Google Scholar] [CrossRef]

- Benjamin Reichman, A.J.B. Electrochromism at Niobium Pentoxide Electrodes in Aqueous and Acetonitrile Solutions. J. Electrochem. Soc. 1980, 127, 241. [Google Scholar] [CrossRef]

- Jiang, K.-J.; Masaki, N.; Xia, J.-B.; Noda, S.; Yanagida, S. A novel ruthenium sensitizer with a hydrophobic 2-thiophen-2-yl-vinyl-conjugated bipyridyl ligand for effective dye sensitized TiO2 solar cells. Chem. Commun. 2006, 23, 2460–2462. [Google Scholar] [CrossRef] [PubMed]

- Rani, R.A.; Zoolfakar, A.S.; O’Mullane, A.P.; Austin, M.W.; Kalantar-Zadeh, K. Thin films and nanostructures of niobium pentoxide: Fundamental properties, synthesis methods and applications. J. Mater. Chem. A 2014, 2, 15683–15703. [Google Scholar] [CrossRef]

- Hota, M.; Bera, M.; Verma, S.; Maiti, C. Studies on switching mechanisms in Pd-nanodot embedded Nb2O5 memristors using scanning tunneling microscopy. Thin Solid Film. 2012, 520, 6648–6652. [Google Scholar] [CrossRef]

- Yoon, S.G.; Kim, H.K.; Kim, M.J.; Lee, H.M.; Yoon, D.H. Effect of substrate temperature on surface roughness and optical properties of Ta2O5 using ion-beam sputtering. Thin Solid Film. 2005, 475, 239–242. [Google Scholar] [CrossRef]

- Yoon, S.G.; Kim, Y.T.; Kim, H.K.; Kim, M.J.; Lee, H.M.; Yoon, D.H. Comparision of residual stress and optical properties in Ta2O5 thin films deposited by single and dual ion beam sputtering. Mater. Sci. Eng. B 2005, 118, 234–237. [Google Scholar] [CrossRef]

- Pillis, M.F.; Geribola, G.A.; Scheidt, G.; de Araújo, E.G.; de Oliveira, M.C.L.; Antunes, R.A. Corrosion of thin, magnetron sputtered Nb2O5 films. Corros. Sci. 2016, 102, 317–325. [Google Scholar] [CrossRef]

- Tong, H.; Kou, Z.; Zhao, M.; Zhuang, D.; Wang, C.; Li, Y. Effects of annealing temperature and atmosphere on performances of Zn0.9Mg0.1O buffer layers for CIGS solar cell. Ceram. Int. 2022, 48, 24523–24530. [Google Scholar] [CrossRef]

- Al-Baradi, A.M.; El-Nahass, M.M.; Hassanien, A.M.; Atta, A.A.; Alqahtani, M.S.; Aldawsari, A.O. Influence of RF sputtering power on structural and optical properties of Nb2O5 thin films. Optik 2018, 168, 853–863. [Google Scholar] [CrossRef]

- Horcholle, B.; Labbé, C.; Portier, X.; Marie, P.; Frilay, C.; Yuan, W.; Jadwisienczak, W.; Ingram, D.; Grygiel, C.; Cardin, J. Growth and study of Tb3+ doped Nb2O5 thin films by radiofrequency magnetron sputtering: Photoluminescence properties. Appl. Surf. Sci. 2022, 597, 153711. [Google Scholar] [CrossRef]

- Juškevičius, K.; Audronis, M.; Subačius, A.; Kičas, S.; Tolenis, T.; Buzelis, R.; Drazdys, R.; Gaspariūnas, M.; Kovalevskij, V.; Matthews, A.; et al. Fabrication of Nb2O5/SiO2 mixed oxides by reactive magnetron co-sputtering. Thin Solid Film. 2015, 589, 95–104. [Google Scholar] [CrossRef]

- Dong, H.; Yu, S.; Song, L.; Wang, X.; Wu, C. Fabrication of high-quality flexible transparent conductive thin films with a Nb2O5/AgNWs/Nb2O5 sandwich structure. Ceram. Int. 2022, 48, 15348–15354. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, Y.; Chen, Z.; Zhou, B.; Gao, J.; Wu, Y.; Ma, Y.; Hei, H.; Yu, S. Fabrication and properties of N-doped top layer of Ga2O3 films by magnetron sputtering. Appl. Surf. Sci. 2022, 604, 154666. [Google Scholar] [CrossRef]

- Lv, Q.; Huang, M.; Zhang, S.; Deng, S.; Gong, F.; Wang, F.; Pan, Y.; Li, G.; Jin, Y. Effects of Annealing on Residual Stress in Ta2O5 Films Deposited by Dual Ion Beam Sputtering. Coatings 2018, 8, 150. [Google Scholar] [CrossRef]

- Coşkun, Ö.D.; Demirel, S.; Atak, G. The effects of heat treatment on optical, structural, electrochromic and bonding properties of Nb2O5 thin films. J. Alloys Compd. 2015, 648, 994–1004. [Google Scholar] [CrossRef]

- Fridriksson, E.G.; Tryggvason, T.K.; Arnalds, U.B.; Ingason, A.S.; Magnus, F. Growth of NbO, NbO2 and Nb2O5 thin films by reactive magnetron sputtering and post-annealing. Vacuum 2022, 202, 111179. [Google Scholar] [CrossRef]

- Xu, C.; Xiao, Q.; Ma, J.; Jin, Y.; Shao, J.; Fan, Z. High temperature annealing effect on structure, optical property and laser-induced damage threshold of Ta2O5 films. Appl. Surf. Sci. 2008, 254, 6554–6559. [Google Scholar] [CrossRef]

- Anandan, R.; Rajendran, J.; Piraviperumal, M. Synergistic Influence of the Deposition Method, Postdeposition Annealing, and Textured Substrates on the Properties of ITO Thin Films. ACS Appl. Electron. Mater. 2022, 4, 5506–5518. [Google Scholar] [CrossRef]

- Suresh, S.; Unni, G.E.; Ni, C.; Sreedharan, R.S.; Krishnan, R.R.; Satyanarayana, M.; Shanmugam, M.; Pillai, V.P.M. Phase modification and morphological evolution in Nb2O5 thin films and its influence in dye- sensitized solar cells. Appl. Surf. Sci. 2017, 419, 720–732. [Google Scholar] [CrossRef]

- Angerer, P.; van Karsbergen, V.; Weinberger, N.; Strauss, G.; Neubauer, E.; Friessnegger, B.; Marsoner, S. In-situ high-temperature X-ray diffraction investigations of magnetron sputtered niobium oxide layers up to 900 °C. Thin Solid Film. 2019, 674, 33–38. [Google Scholar] [CrossRef]

- Hossain, N.; Günes, O.; Zhang, C.; Koughia, C.; Li, Y.; Wen, S.-J.; Wong, R.; Kasap, S.; Yang, Q. Structural and physical properties of NbO2 and Nb2O5 thin films prepared by magnetron sputtering. J. Mater. Sci. Mater. Electron. 2019, 30, 9822–9835. [Google Scholar] [CrossRef]

- Lai, F.; Li, M.; Wang, H.; Hu, H.; Wang, X.; Hou, J.G.; Song, Y.; Jiang, Y. Optical scattering characteristic of annealed niobium oxide films. Thin Solid Film. 2005, 488, 314–320. [Google Scholar] [CrossRef]

- Çetinörgü-Goldenberg, E.; Klemberg-Sapieha, J.E.; Martinu, L. Effect of postdeposition annealing on the structure, composition, and the mechanical and optical characteristics of niobium and tantalum oxide film. Appl. Opt. 2012, 51, 6498–6507. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Dong, G.; Xu, C.; He, H.; Qi, H.; Fan, Z.; Shao, J. Structure and optical properties of Nb2O5 sculptured thin films by glancing angle deposition. Appl. Surf. Sci. 2008, 255, 2192–2195. [Google Scholar] [CrossRef]

- Stenzel, O.; Wilbrandt, S.; Kaiser, N.; Vinnichenko, M.; Munnik, F.; Kolitsch, A.; Chuvilin, A.; Kaiser, U.; Ebert, J.; Jakobs, S.; et al. The correlation between mechanical stress, thermal shift and refractive index in HfO2, Nb2O5, Ta2O5 and SiO2 layers and its relation to the layer porosity. Thin Solid Film. 2009, 517, 6058–6068. [Google Scholar] [CrossRef]

- Lorenz, R.; O’Sullivan, M.; Fian, A.; Sprenger, D.; Lang, B.; Mitterer, C. Effects of bias pulse frequencies on reactively sputter deposited NbOx films. Thin Solid Film. 2018, 660, 335–342. [Google Scholar] [CrossRef]

- Atta, A.A.; El-Nahass, M.M.; Hassanien, A.M.; Elsabawy, K.M.; Abd El-Raheem, M.M.; Alhuthali, A.; Alomariy, S.E.; Algamdi, M.S. Effect of thermal annealing on structural, optical and electrical properties of transparent Nb2O5 thin films. Mater. Today Commun. 2017, 13, 112–118. [Google Scholar] [CrossRef]

- Masse, J.P.; Szymanowski, H.; Zabeida, O.; Amassian, A.; Klemberg-Sapieha, J.E.; Martinu, L. Stability and effect of annealing on the optical properties of plasma-deposited Ta2O5 and Nb2O5 films. Thin Solid Film. 2006, 515, 1674–1682. [Google Scholar] [CrossRef]

| Parameters | PVD |

|---|---|

| Target | Nb |

| Argon Flow | 35 SCCM |

| Oxygen Flow | 40-55 SCCM |

| MF Power | 4700 W |

| Temperature | 180 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, X.; Liu, B.; Yuan, Q.; Lin, X.; Ren, S.; Zhao, S.; Yin, X.; Fei, S. Fine Control of Optical Properties of Nb2O5 Film by Thermal Treatment. Micromachines 2024, 15, 1453. https://doi.org/10.3390/mi15121453

Liang X, Liu B, Yuan Q, Lin X, Ren S, Zhao S, Yin X, Fei S. Fine Control of Optical Properties of Nb2O5 Film by Thermal Treatment. Micromachines. 2024; 15(12):1453. https://doi.org/10.3390/mi15121453

Chicago/Turabian StyleLiang, Xianpeng, Bowen Liu, Quan Yuan, Xiaomin Lin, Shaopeng Ren, Shuaifeng Zhao, Xiaojun Yin, and Shuguo Fei. 2024. "Fine Control of Optical Properties of Nb2O5 Film by Thermal Treatment" Micromachines 15, no. 12: 1453. https://doi.org/10.3390/mi15121453

APA StyleLiang, X., Liu, B., Yuan, Q., Lin, X., Ren, S., Zhao, S., Yin, X., & Fei, S. (2024). Fine Control of Optical Properties of Nb2O5 Film by Thermal Treatment. Micromachines, 15(12), 1453. https://doi.org/10.3390/mi15121453