Simulation and Experimental Study of Non-Resonant Vibration-Assisted Lapping of SiCp/Al

Abstract

1. Introduction

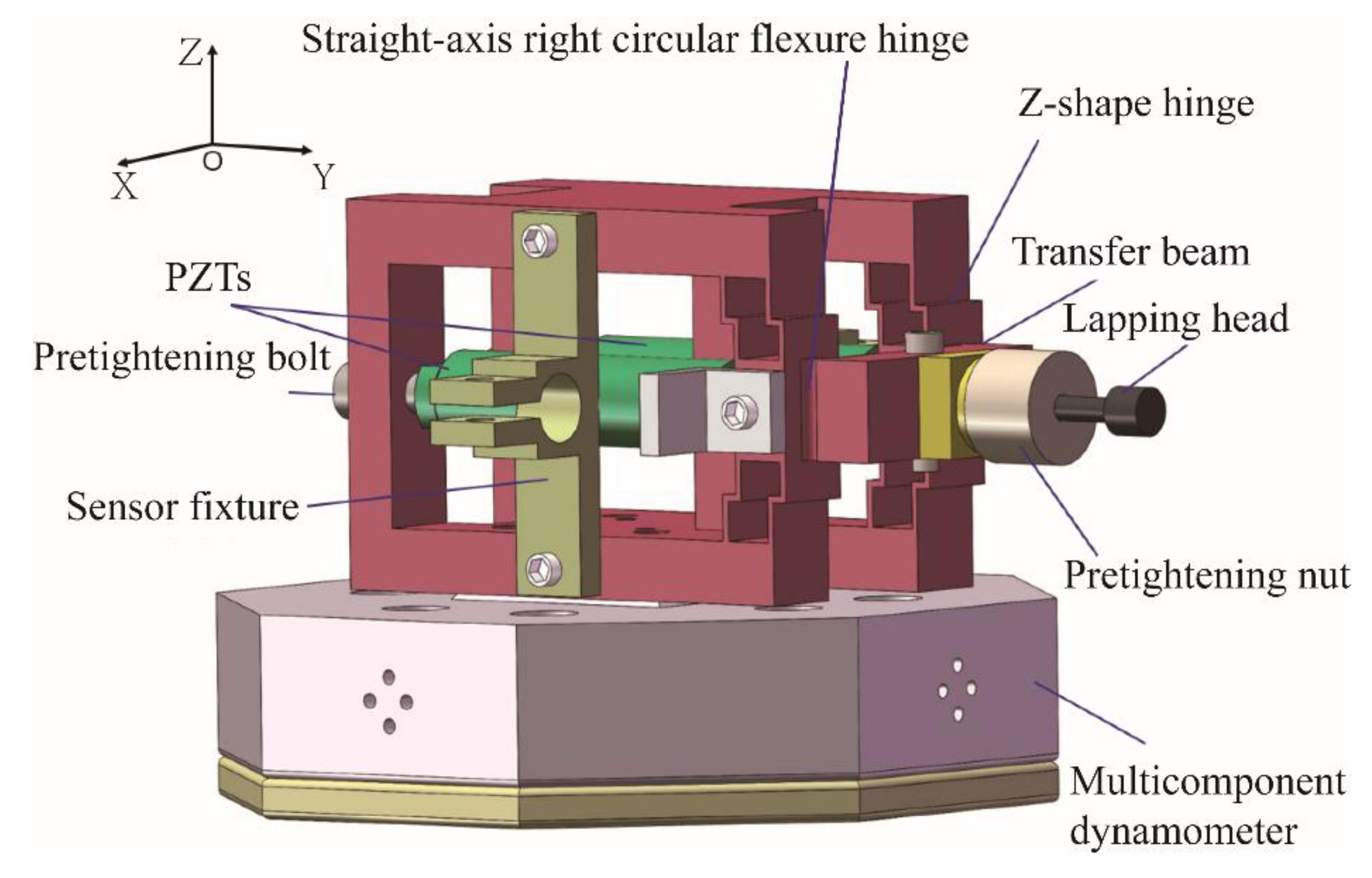

2. Principle of Processing

3. Design and Analysis of VLD

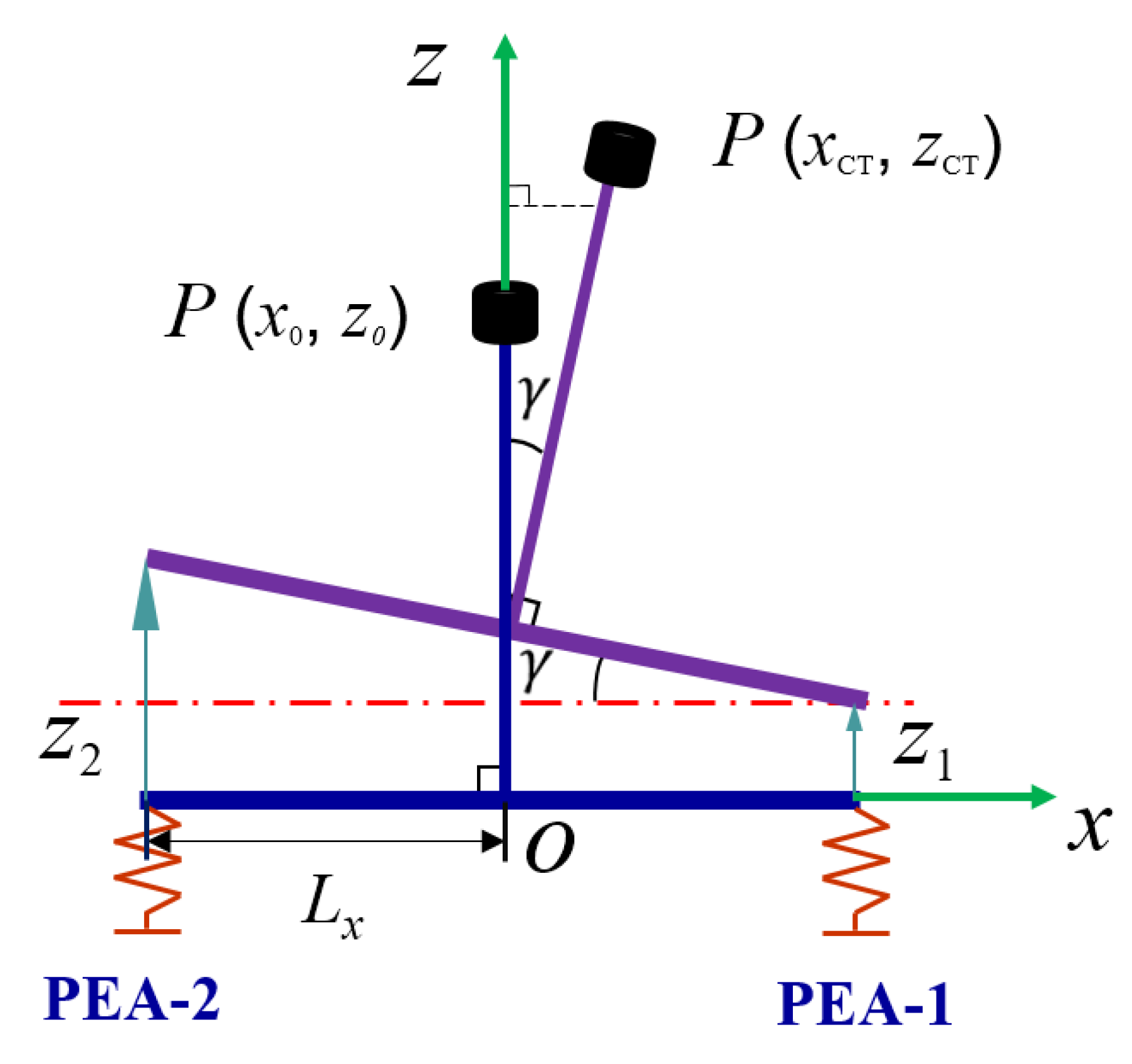

3.1. Vibration Trajectory Analysis

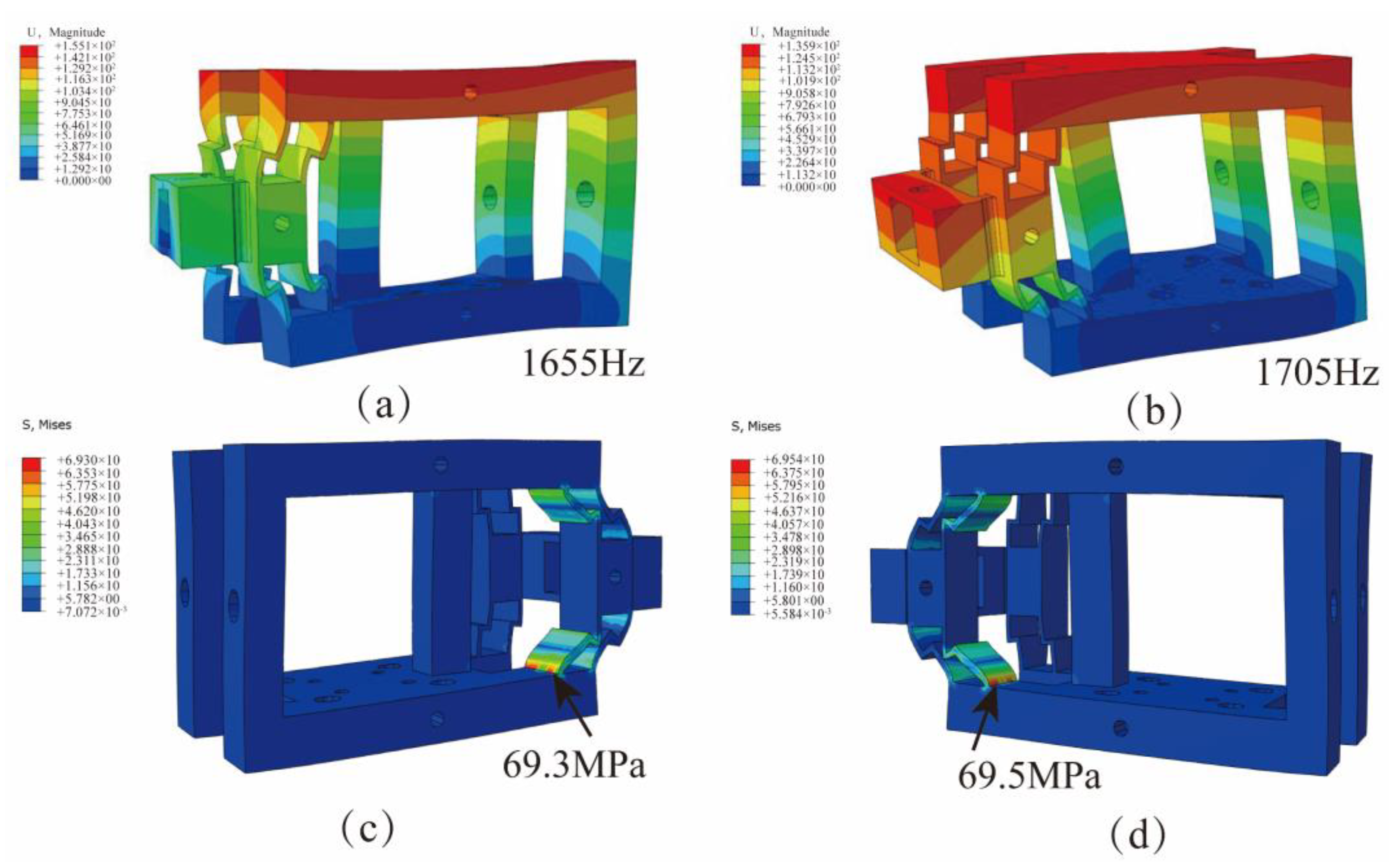

3.2. The Simulation Analysis of VLD

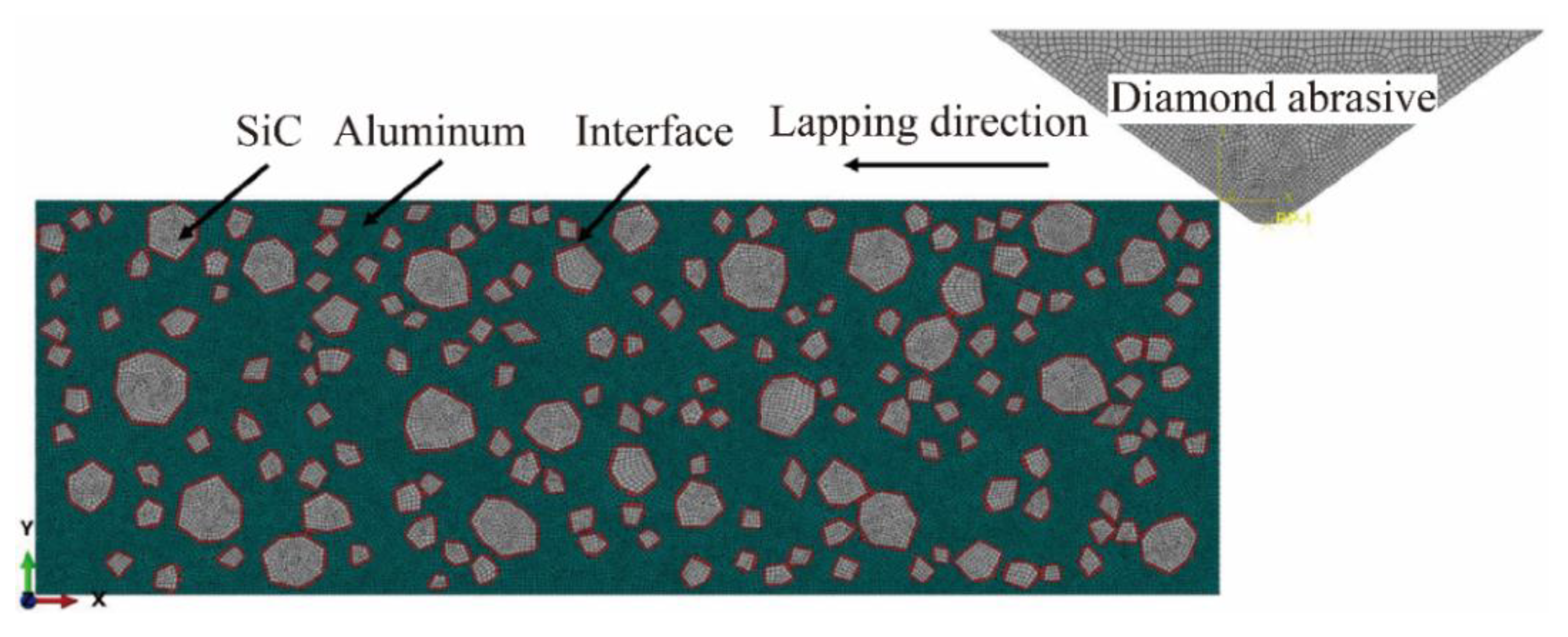

4. Simulation of NVL for SiCp/Al Composites

4.1. Finite Element Model Setting of NVL for SiCp/Al Composites

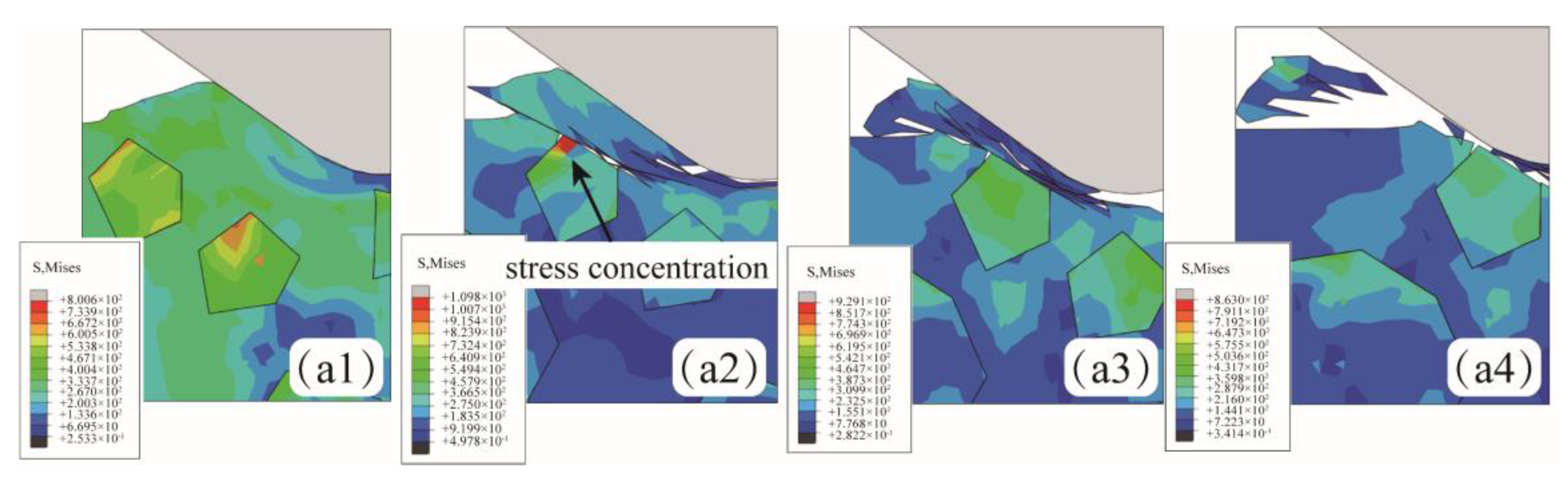

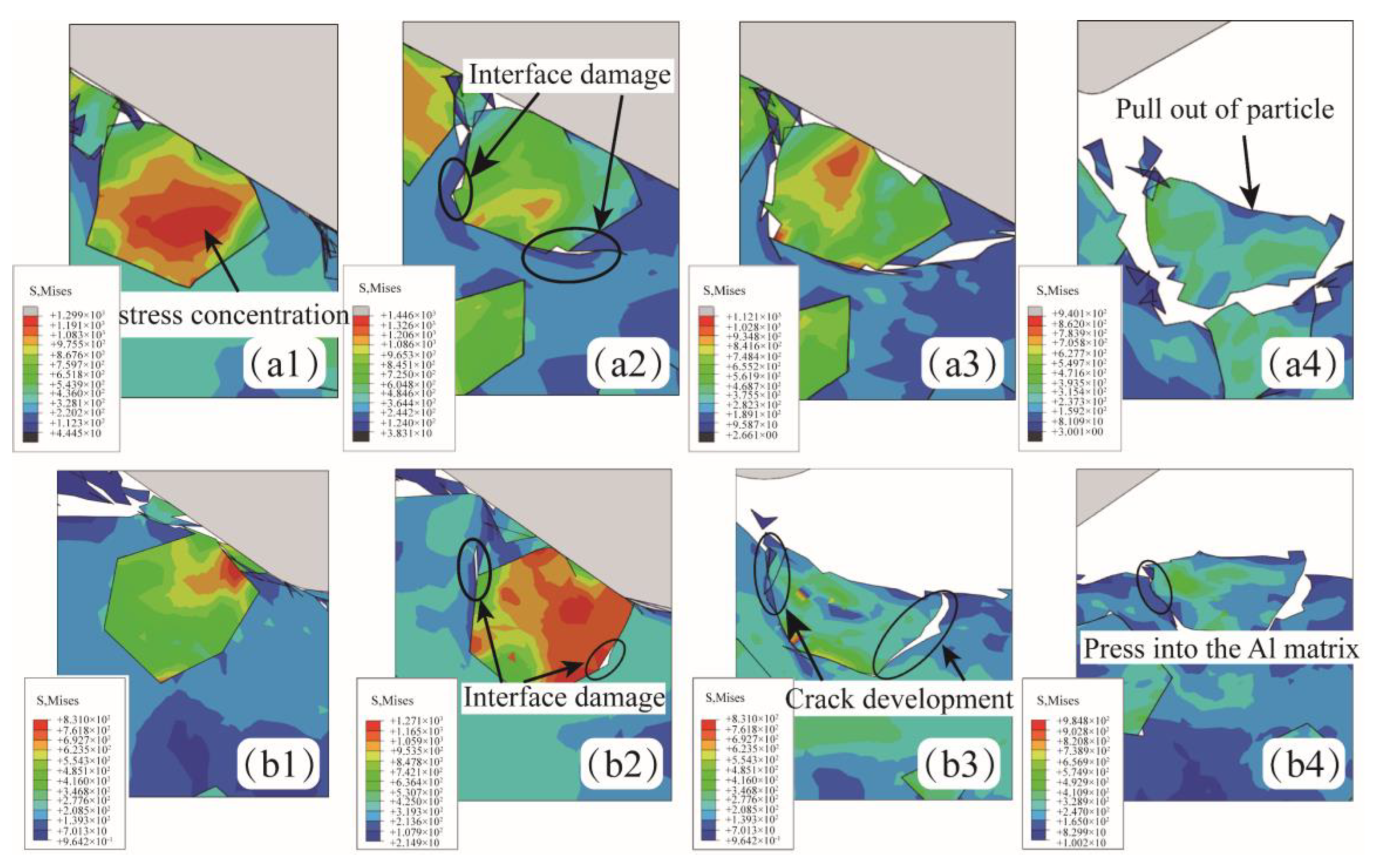

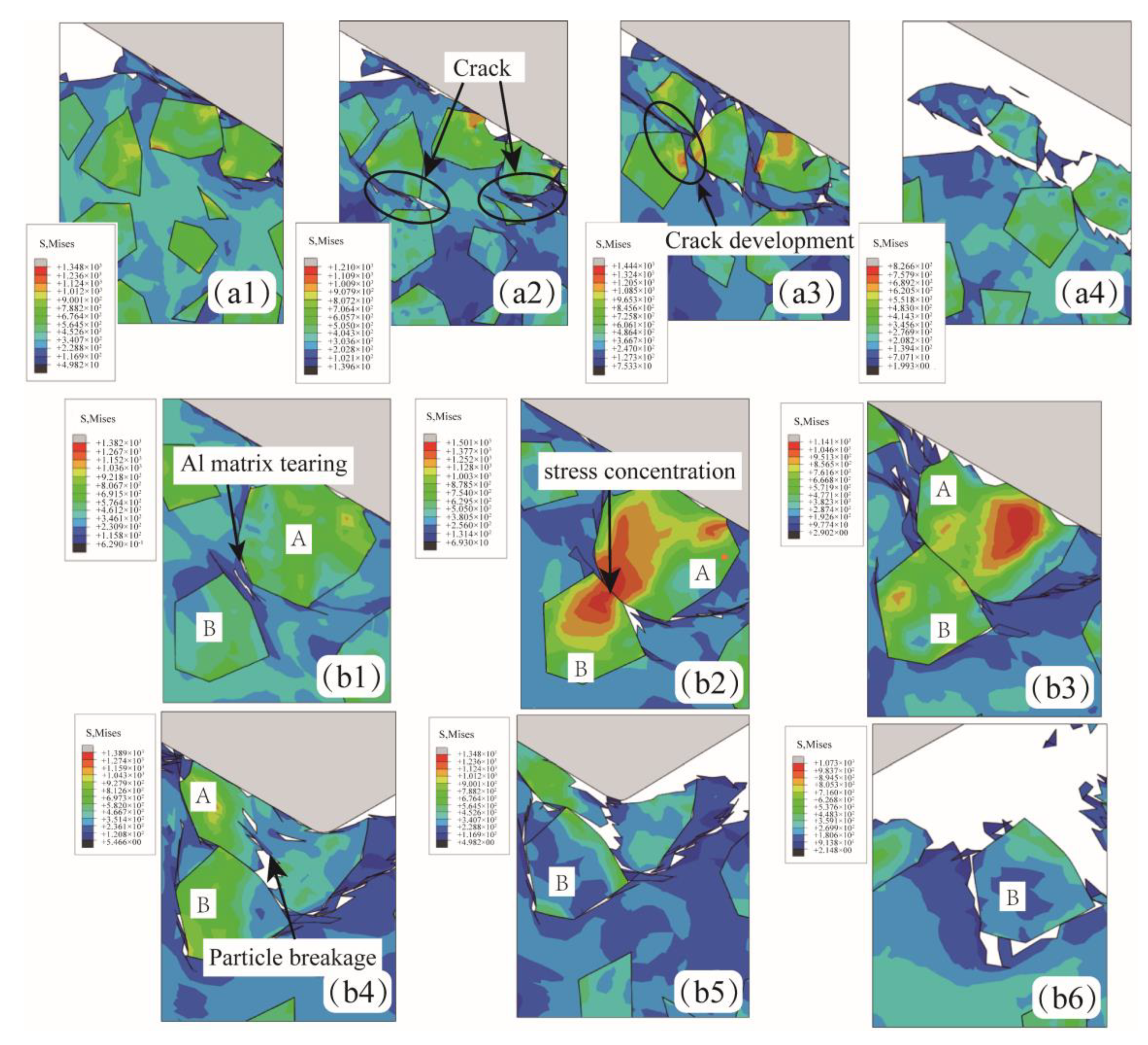

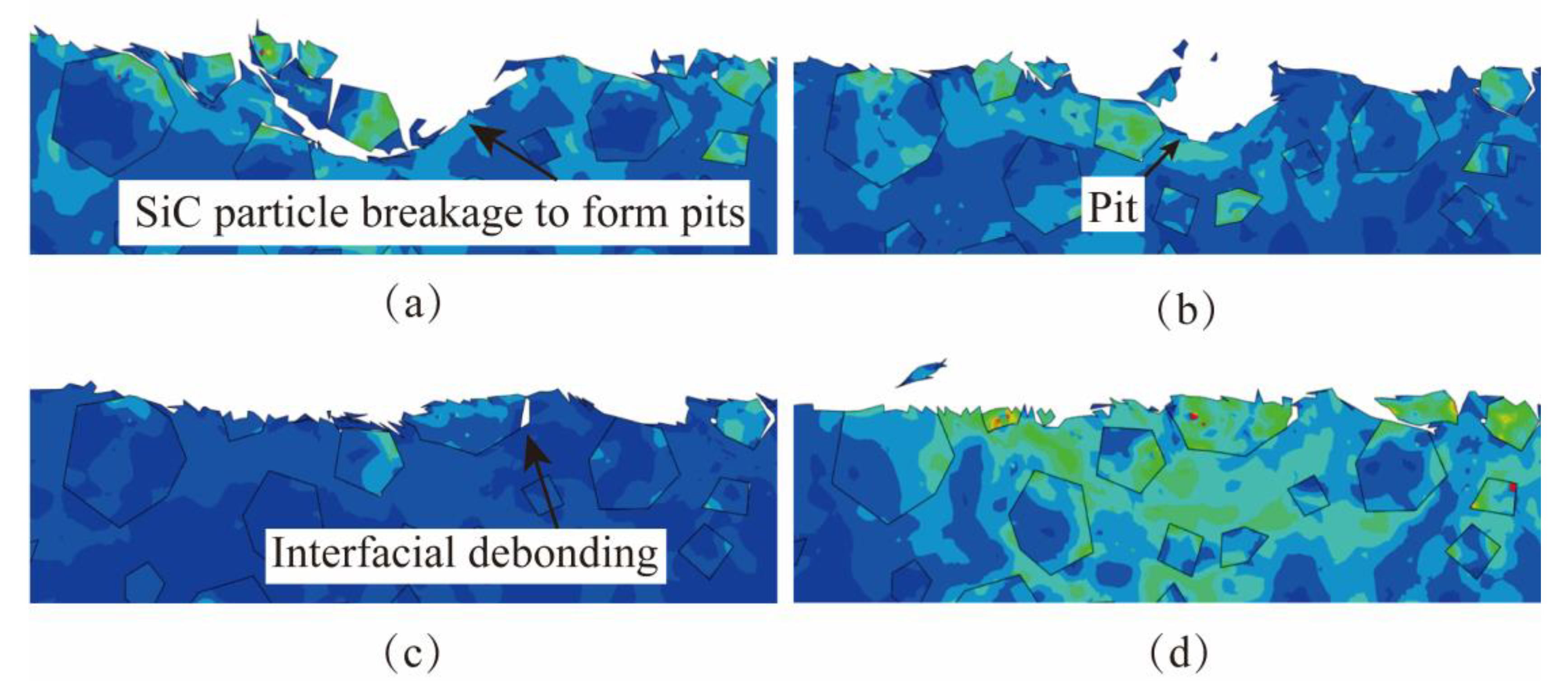

4.2. Simulation Study on SiCp/Al Removal Characteristics of NVL

4.3. Influence of Machining Parameters on SiCp/Al Lapping Surface Quality

5. Test of Vibration-Assisted Lapping Device and Lapping Experiment

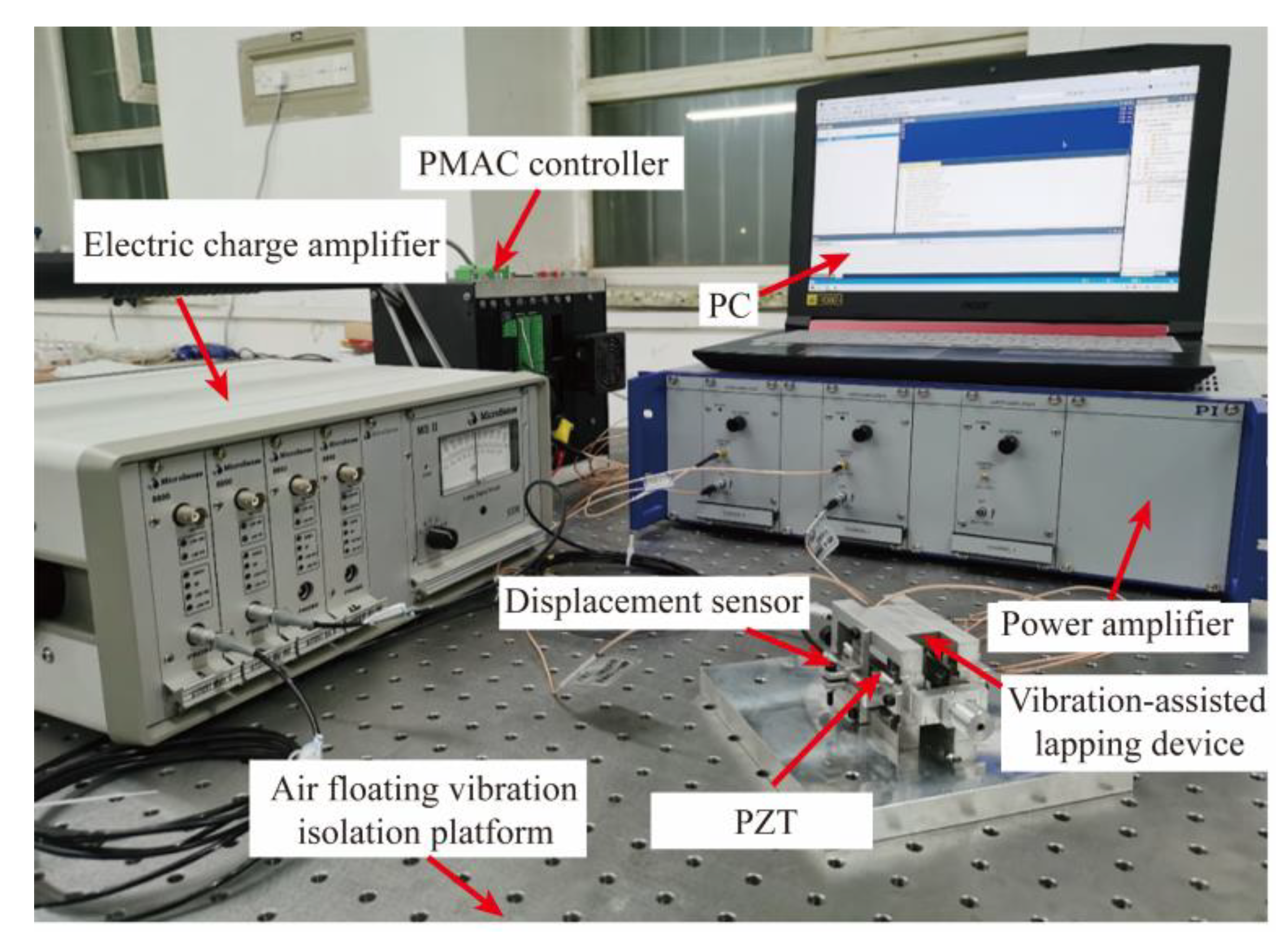

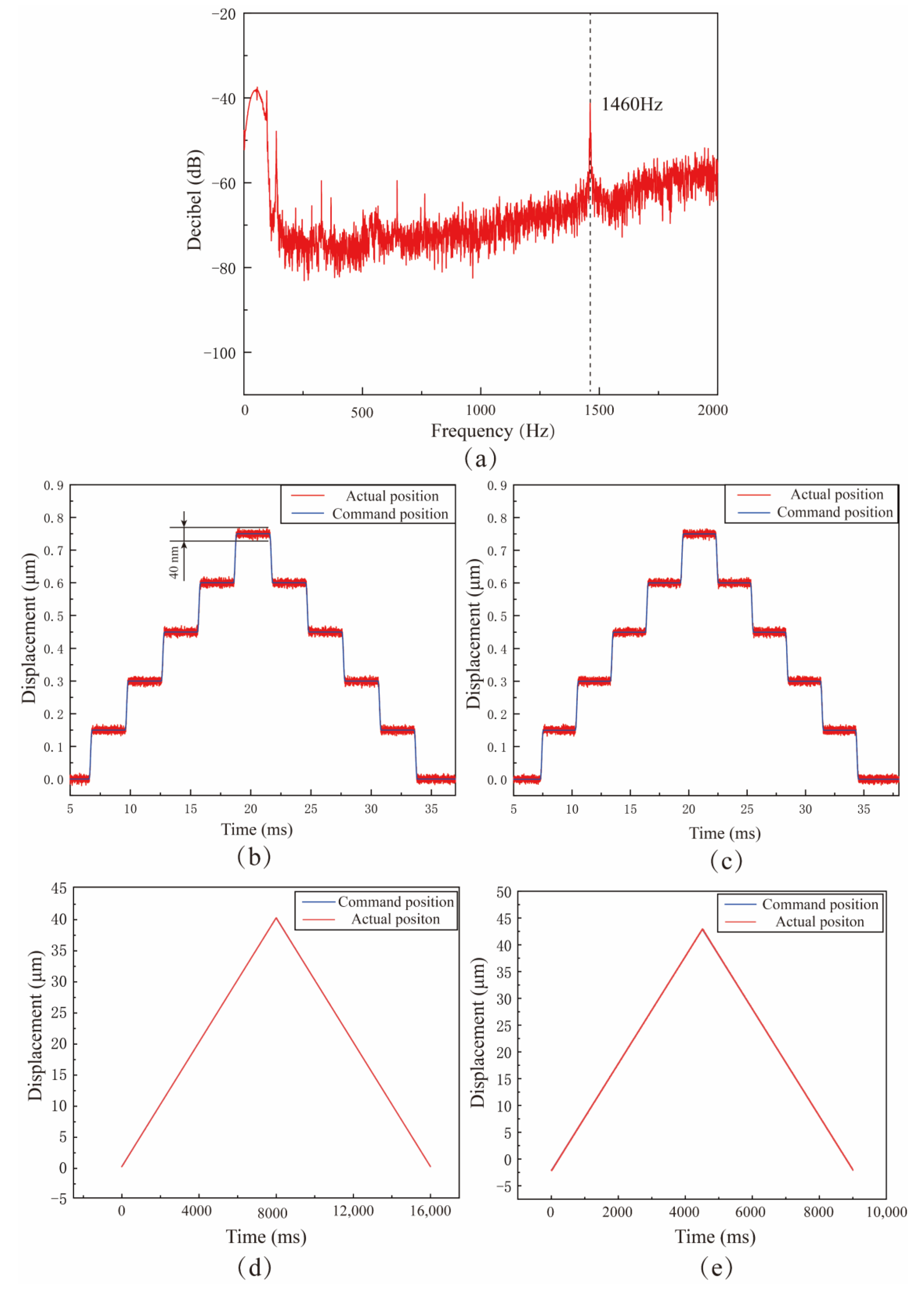

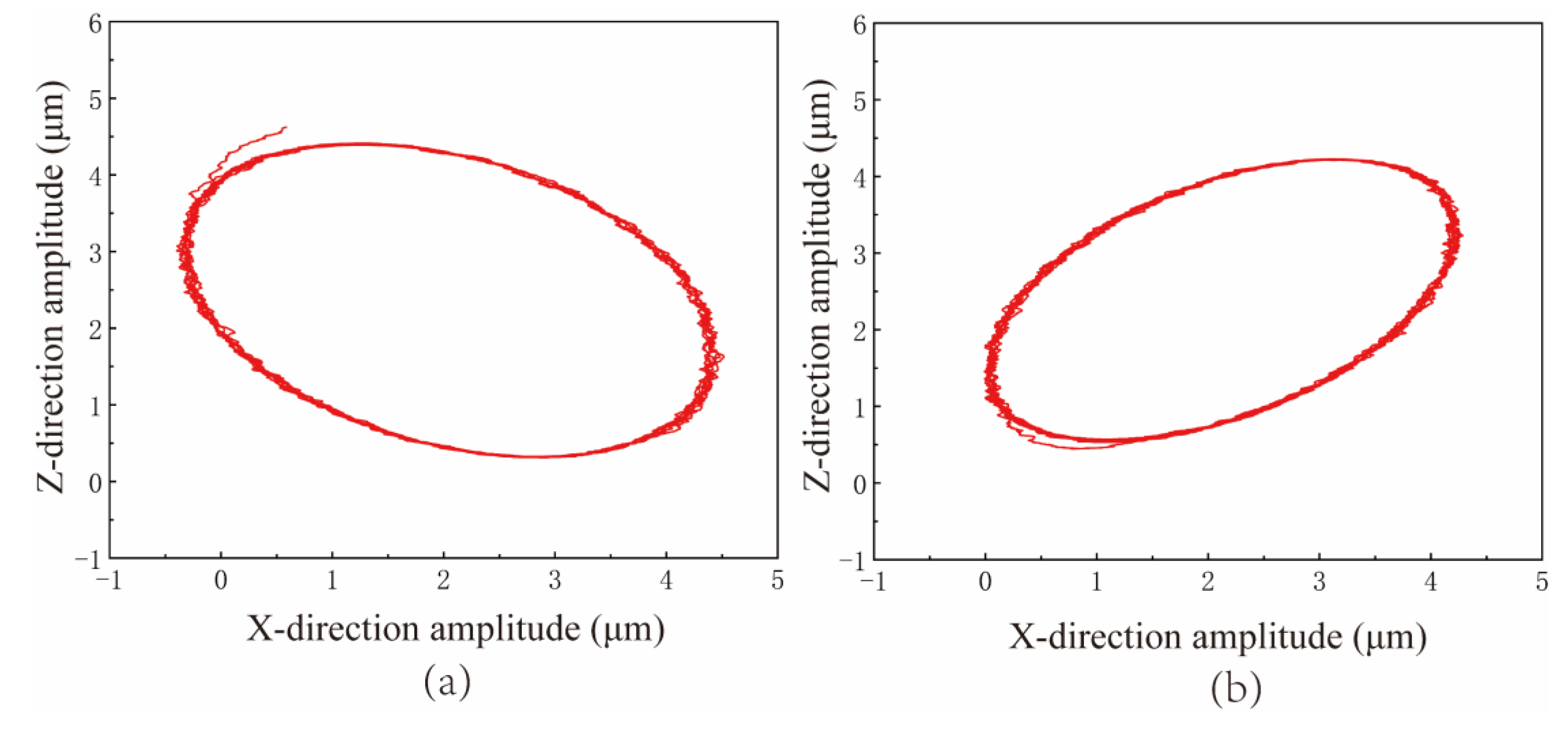

5.1. Performance Test of VLD

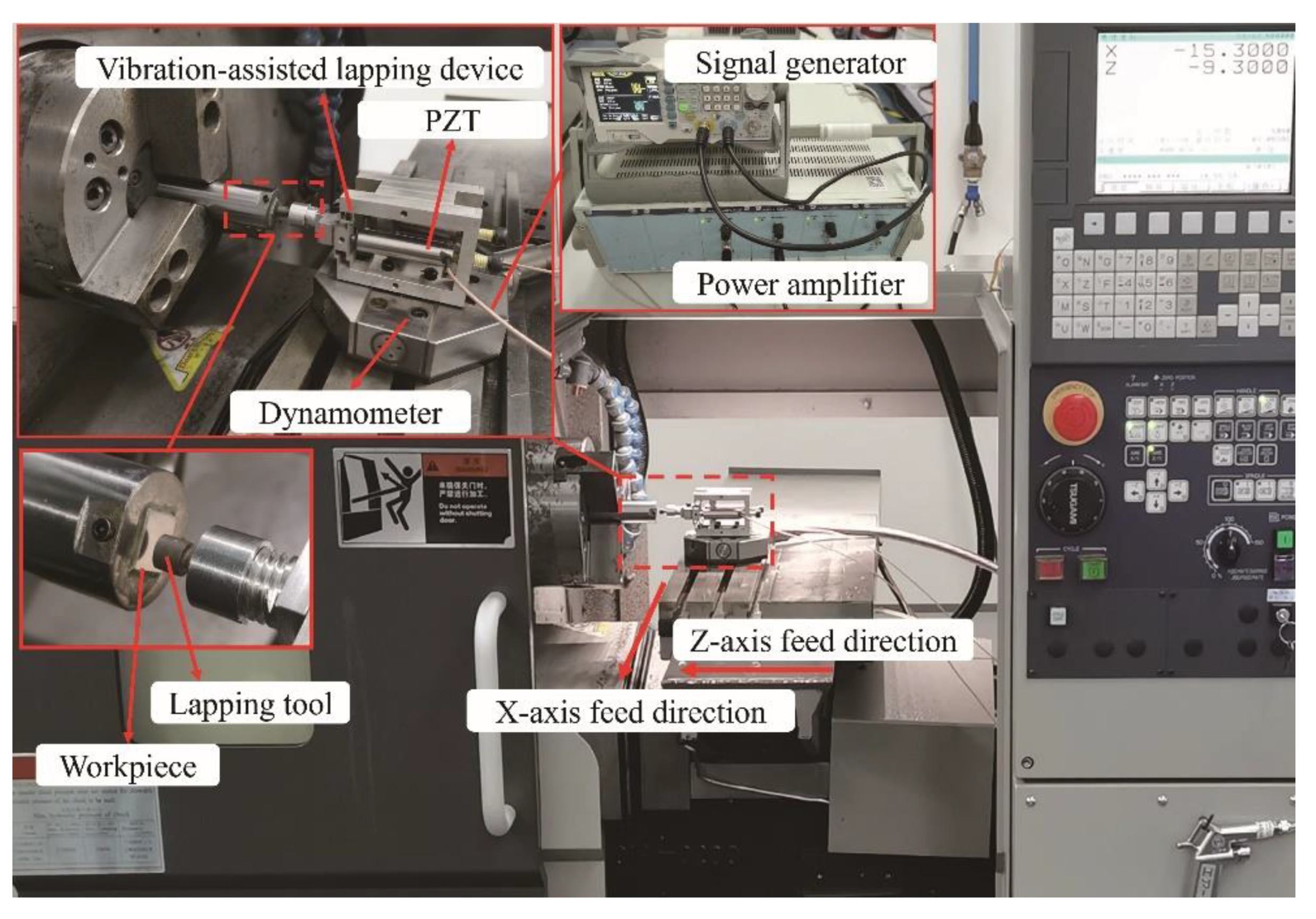

5.2. Experiment on NVL of SiCp/Al Composites

5.3. Effect of Process Parameters

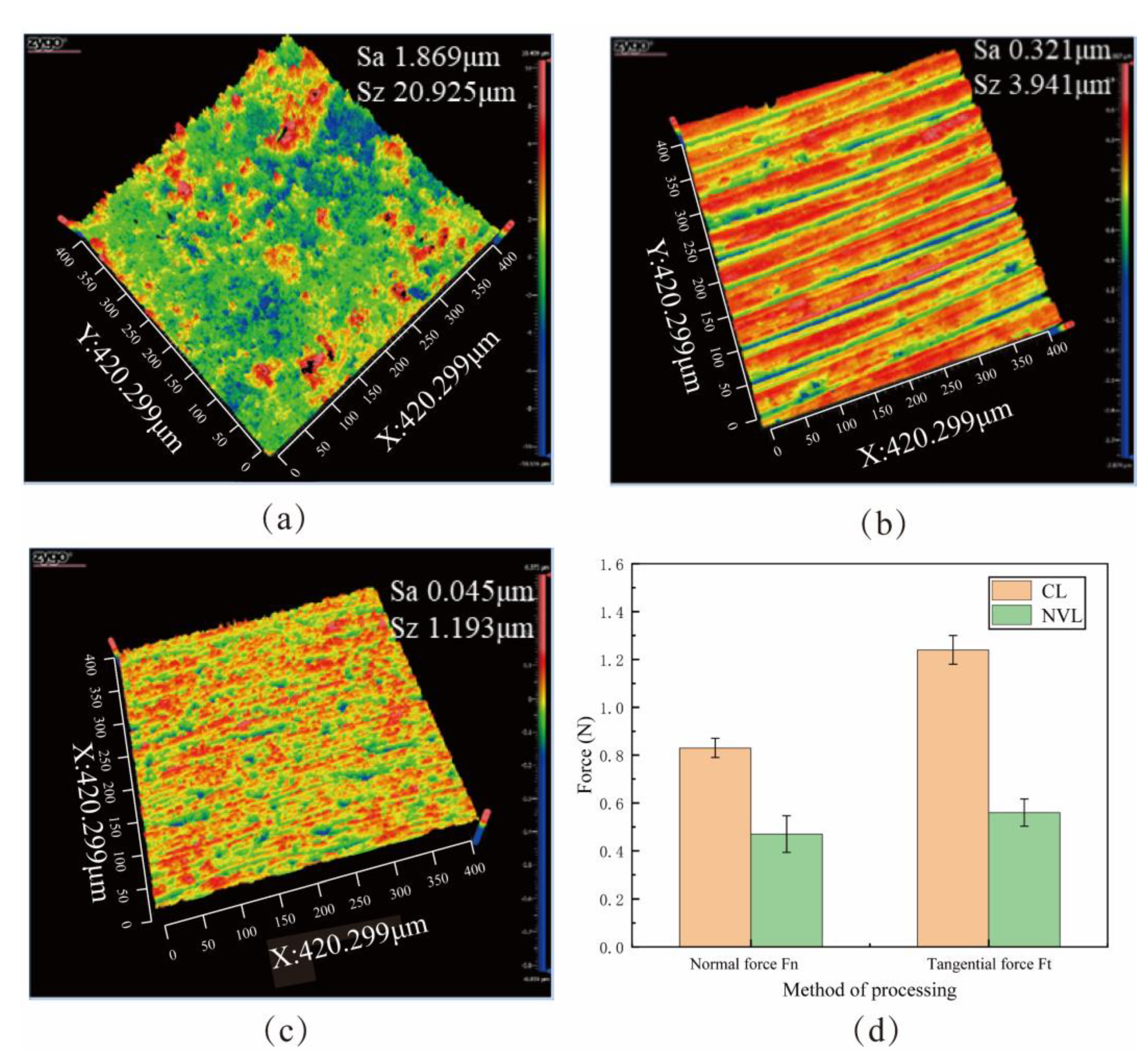

5.3.1. Comparison of NVL and CL

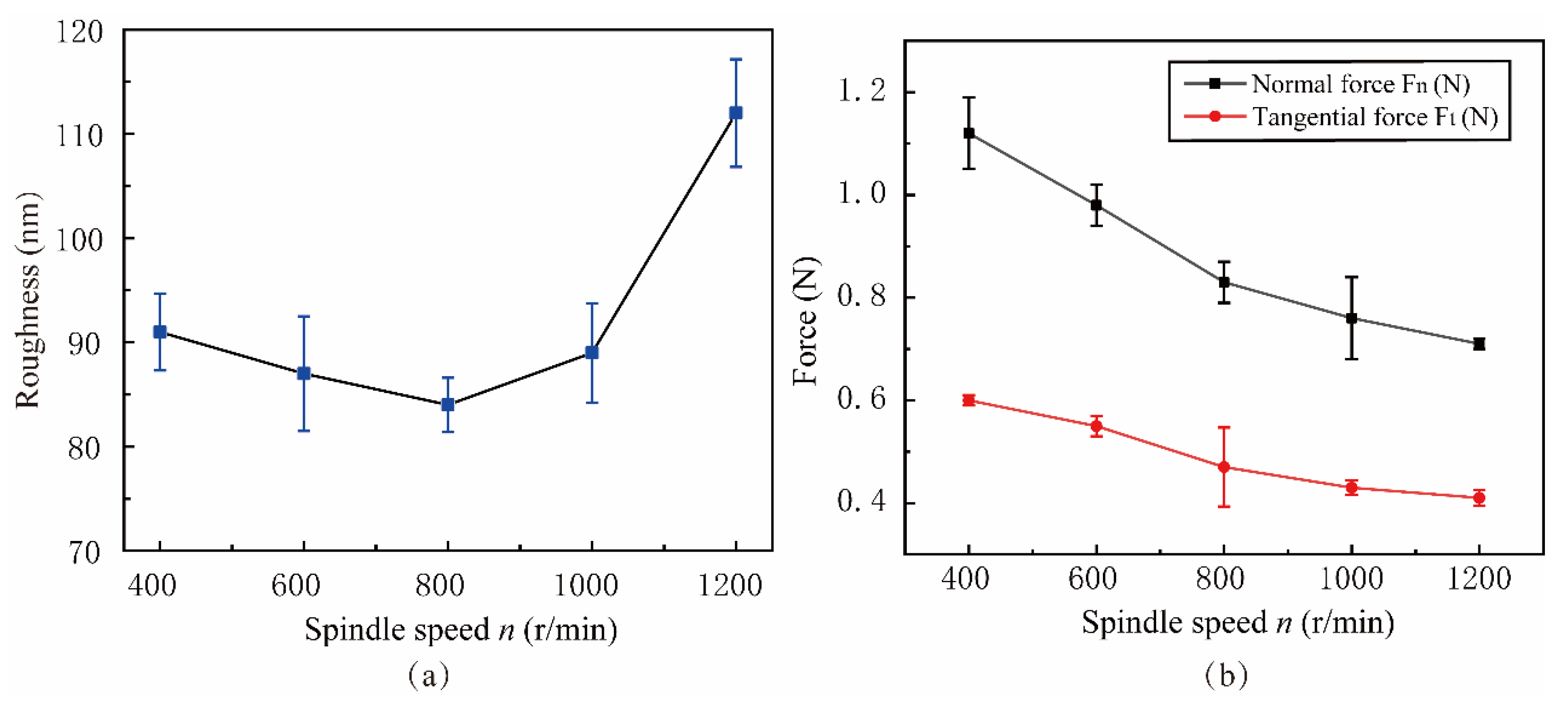

5.3.2. Effect of Spindle Speed n

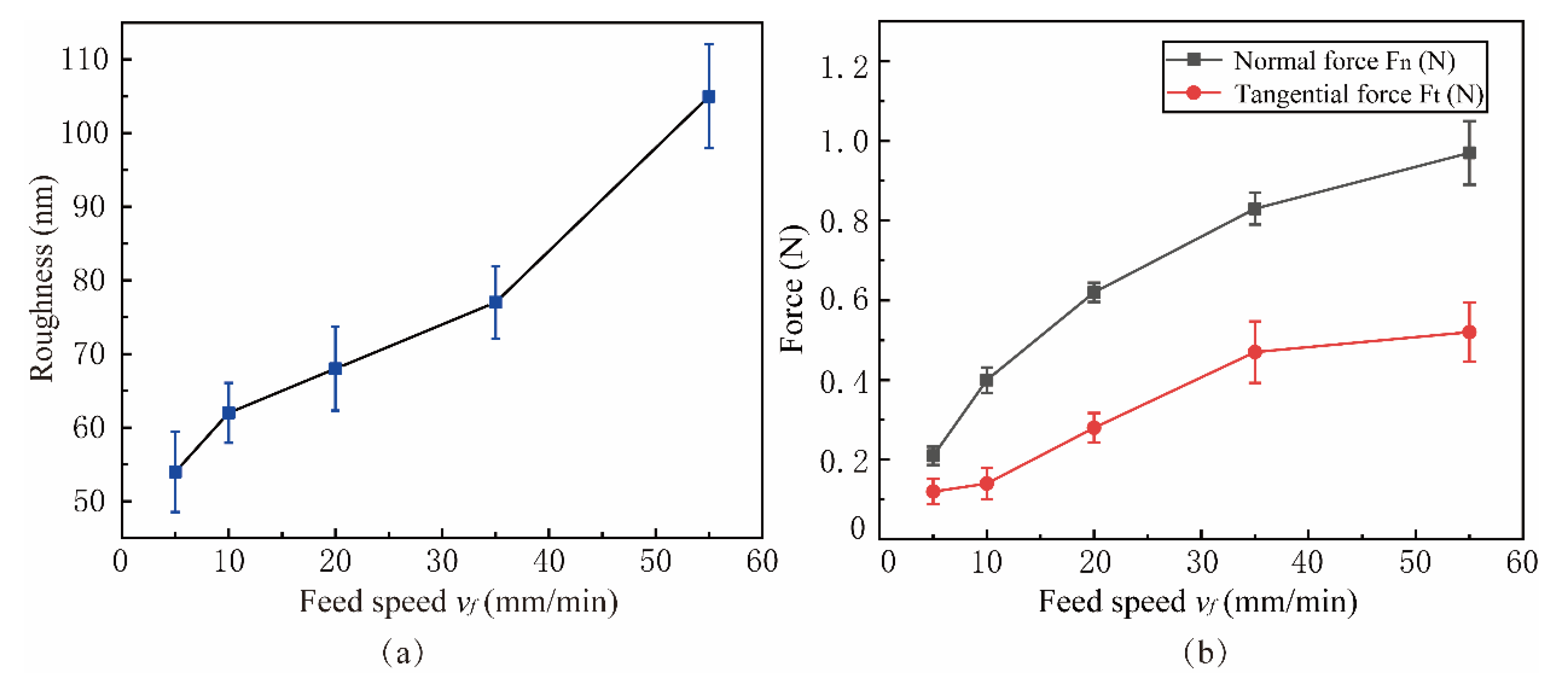

5.3.3. Effect of Feed Speed vf

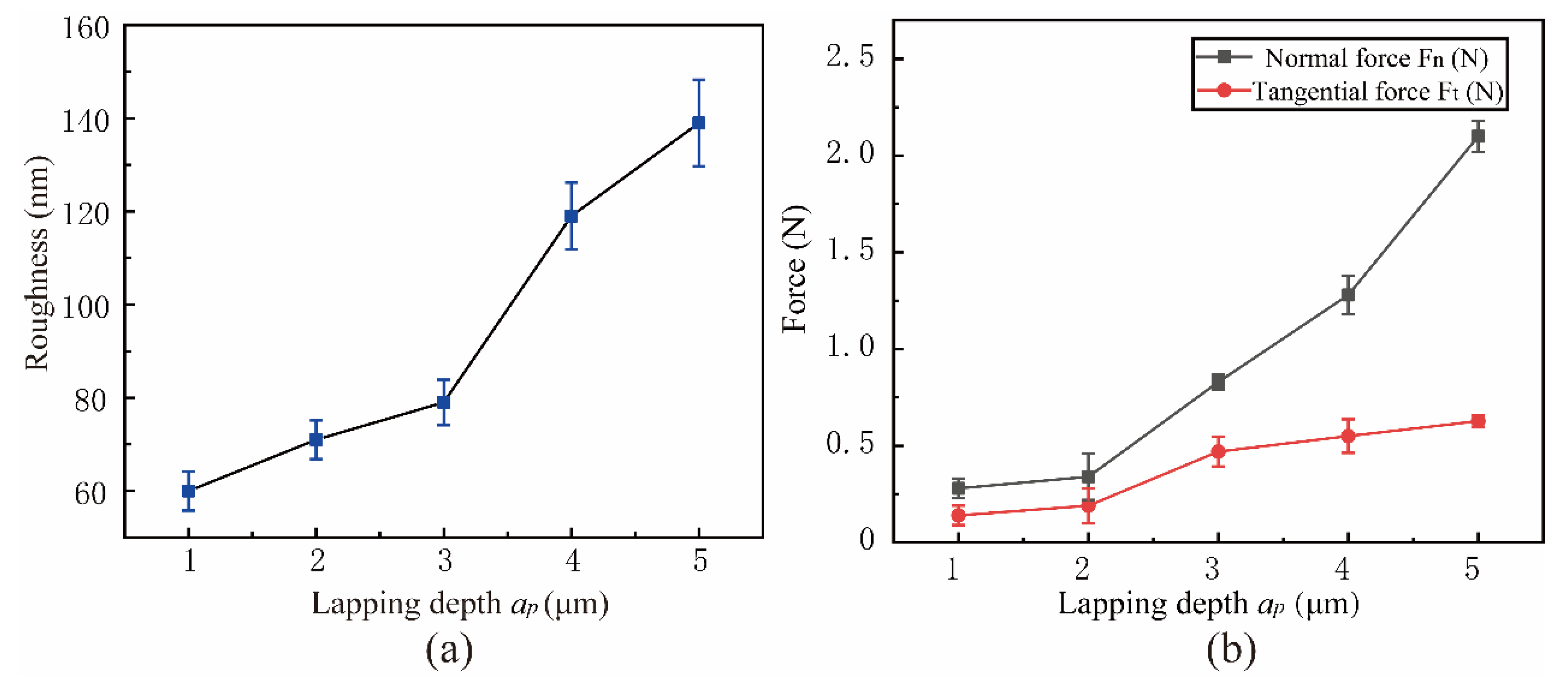

5.3.4. Effect of Lapping Depth ap

5.3.5. Effect of Vibration Frequency f

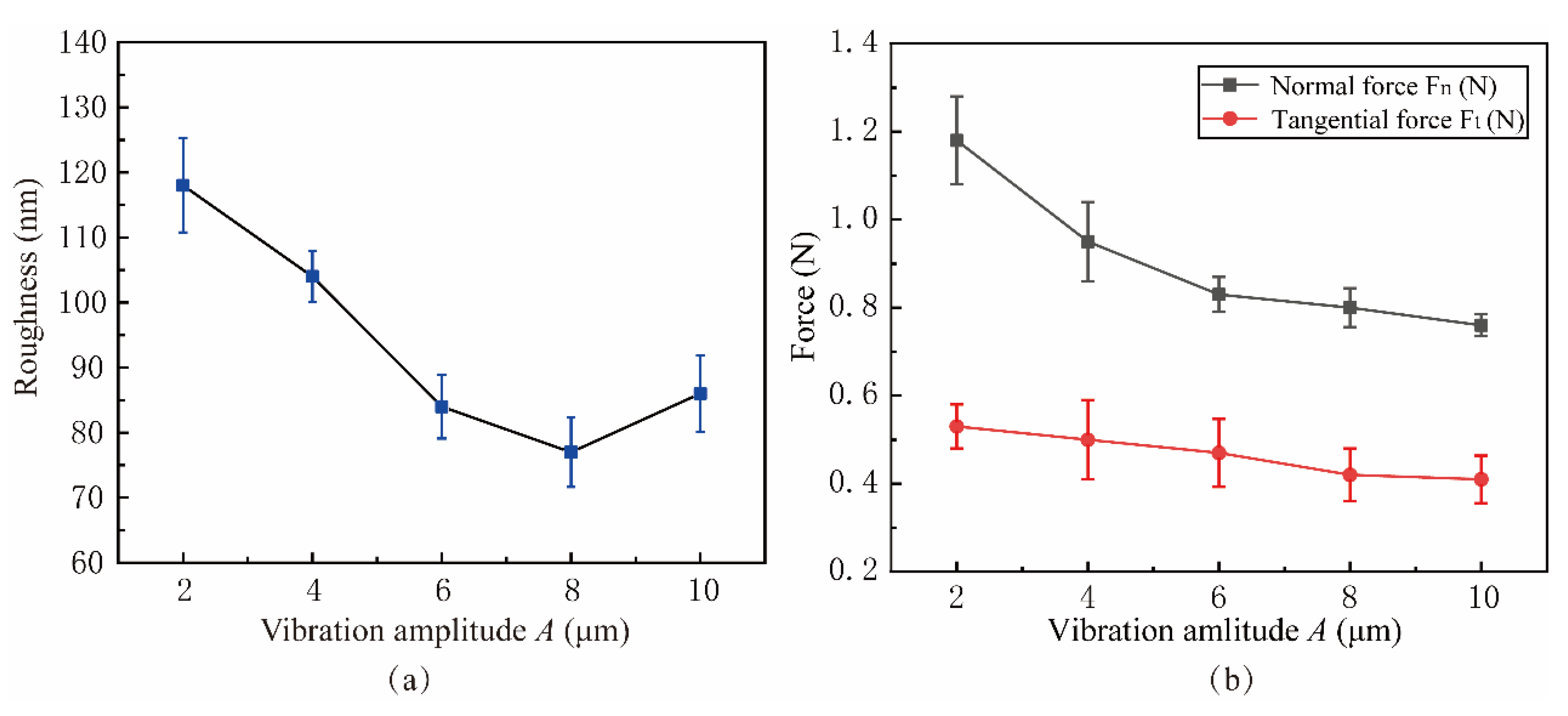

5.3.6. Effect of Vibration Amplitude A

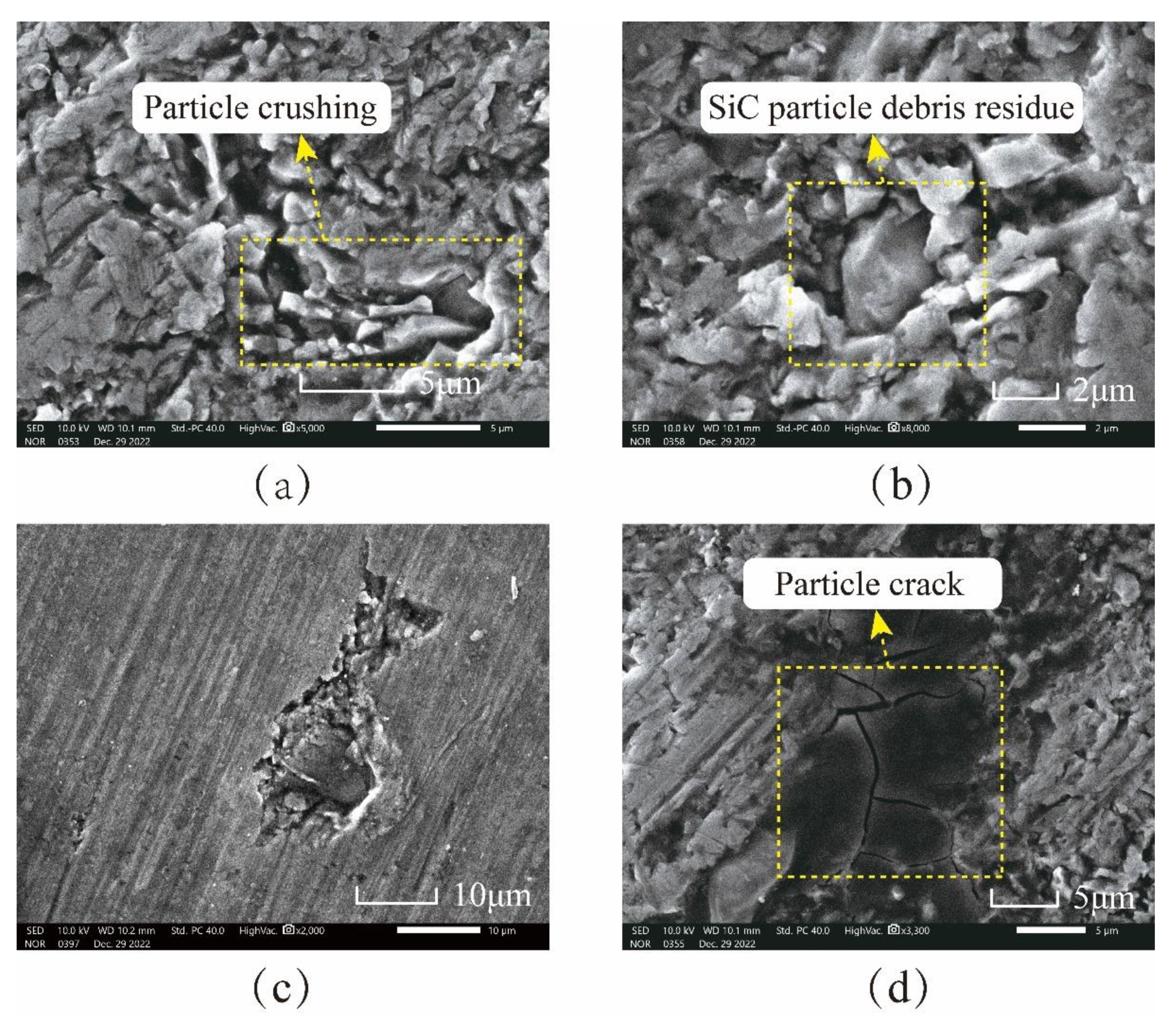

5.4. Analysis of Lapping Surface Micro-Morphology

6. Conclusions

- A VLD is designed. The motion trajectory of the VLD is analyzed, and its modal and stress distribution are simulated by the simulation method. The test results show that the first-order natural frequency is 1460 Hz, the resolution is 40 nm, and the two-axis stroke is 45 μm and 40 μm, respectively;

- NVL SiCp/Al can reduce the lapping force. Spindle speed, vibration amplitude, and vibration frequency are inversely correlated with lapping force, and the lapping force reaches the minimum value at f = 900 Hz, A = 10 μm and n = 1200 r/min, respectively. The feed speed and lapping depth positively correlate to the lapping force;

- NVL lapping SiCp/Al effectively reduces the surface roughness. The vibration amplitude and spindle speed decreased first, then increased, reaching the minimum values at A = 8 μm and n = 800 r/min, respectively. The lapping depth and feed speed were inversely correlated with the surface roughness. Reaches the minimum values of 0.054 μm and 0.059 μm at vc = 5 mm/min and ap = 1 μm, respectively. The vibration frequency is proportional to the surface roughness and reaches a minimum of 0.081 μm at f = 900 Hz. The changing trend of process parameters in machining experiments is similar to that in simulation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chak, V.; Chattopadhyay, H.; Dora, T.L. A review on fabrication methods, reinforcements and mechanical properties of aluminum matrix composites. J. Manuf. Process. 2020, 56, 1059–1074. [Google Scholar] [CrossRef]

- Wang, Z.Y.; He, Y.J.; Yu, T.B. Surface quality and milling force of SiCp/Al ceramic for ultrasonic vibration-assisted milling. Ceram. Int. 2022, 48, 33819–33834. [Google Scholar] [CrossRef]

- Zheng, W.; Qu, D.; Qiao, G.H. Multi-phase modeling of SiC particle removal mechanism in ultrasonic vibration–assisted scratching of SiCp/Al composites. Int. J. Adv. Manuf. Technol. 2021, 113, 535–551. [Google Scholar] [CrossRef]

- Liu, H.Z.; Wang, S.J.; Zong, W.J. Tool rake angle selection in micro-machining of 45 vol.% SiCp/2024Al based on its brittle-plastic properties. J. Manuf. Process. 2019, 37, 556–562. [Google Scholar] [CrossRef]

- Gao, Q.; Guo, G.Y.; Wang, Q.Z. Study on micro-grinding mechanism and surface quality of high-volume fraction SiCp/Al composites. J. Mech. Sci. Technol. 2021, 35, 2885–2894. [Google Scholar] [CrossRef]

- Yin, G.Q.; Wang, D.; Cheng, J. Experimental investigation on micro-grinding of SiCp/Al metal matrix composites. Int. J. Adv. Manuf. Technol. 2019, 102, 3503–3517. [Google Scholar] [CrossRef]

- Brehl, D.E.; Dow, T.A. Review of vibration-assisted machining. Precis. Eng. 2008, 32, 153–172. [Google Scholar] [CrossRef]

- Ding, W.F.; Huang, Q.; Zhao, B.; Cao, Y.; Tang, M.L.; Deng, M.M.; Liu, G.L.; Zhao, Z.C.; Chen, Q.L.; Deng, M. Wear characteristics of white corundum abrasive wheel in ultrasonic vibration-assisted gapping of AISI 9310 steel. Ceram. Int. 2023, 49, 12832–12839. [Google Scholar] [CrossRef]

- Bie, W.B.; Zhao, B.; Zhao, C.Y.; Yin, L.; Guo, X.C. System design and experimental research on the tangential ultrasonic vibration-assisted grinding gear. Int. J. Adv. Manuf. Technol. 2021, 116, 597–610. [Google Scholar] [CrossRef]

- Yin, J.T.; Zhao, J.; Song, F.Q.; Xu, X.Q.; Lan, Y.S. Processing Optimization of Shear Thickening Fluid Assisted Micro-Ultrasonic Machining Method for Hemispherical Mold Based on Integrated CatBoost-GA Model. Materials 2023, 16, 2683. [Google Scholar] [CrossRef]

- Cao, Y.; Ding, W.F.; Zhao, B.; Wen, X.B.; Li, S.P.; Wang, Z.J. Effect of intermittent cutting behavior on the ultrasonic vibration-assisted grinding performance of Inconel718 nickel-based superalloy. Precis. Eng. 2022, 78, 248–260. [Google Scholar] [CrossRef]

- Chen, Y.R.; Su, H.H.; Qian, N.; He, J.Y.; Gu, J.Q.; Xu, J.H.; Ding, K. Ultrasonic vibration-assisted grinding of silicon carbide ceramics based on actual amplitude measurement: Grinding force and surface quality. Ceram. Int. 2021, 47, 15433–15441. [Google Scholar] [CrossRef]

- Jiang, J.L.; Sun, S.F.; Wang, D.X.; Yang, Y.; Liu, X.F. Surface texture formation mechanism based on the ultrasonic vibration-assisted gapping process. Int. J. Mach. Tools Manuf. 2020, 156, 103595. [Google Scholar] [CrossRef]

- Gu, P.; Zhu, C.M.; Sun, Y.C.; Wang, Z.; Tao, Z.; Shi, Z.Q. Surface roughness prediction of SiCp/Al composites in ultrasonic vibration-assisted gapping. J. Manuf. Process. 2023, 101, 687–700. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, Y.J.; Zhou, M.; Wang, Q.; Ling, L. Material deformation and removal mechanism of SiCp/Al composites in ultrasonic vibration assisted scratch test. Ceram. Int. 2018, 44, 15133–15144. [Google Scholar] [CrossRef]

- Li, Q.L.; Yuan, S.M.; Gao, X.X.; Zhang, Z.K.; Chen, B.C.; Li, Z.; Batako, A. Surface and subsurface formation mechanism of SiCp/Al composites under ultrasonic scratching. Ceram. Int. 2023, 49, 817–833. [Google Scholar] [CrossRef]

- Wu, X.; Qin, H.B.; Zhu, X.J.; Feng, Y.; Zhou, R.F.; Ye, L.Z. Investigation of the longitudinal-flexural resonating spindle in ultrasound-assisted grinding of SiCp/Al composites. Int. J. Adv. Manuf. Technol. 2022, 121, 3511–3526. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, J.F.; Xiang, Y.C.; Wang, R.; Xu, X.Q.; Ji, S.M.; Hang, W. Effect of a protective coating on the surface integrity of a microchannel produced by microultrasonic machining. J. Manuf. Process. 2021, 61, 280–295. [Google Scholar] [CrossRef]

- Zheng, L.; Chen, W.Q.; Huo, D.H. Review of vibration devices for vibration-assisted machining. Int. J. Adv. Manuf. Technol. 2020, 108, 1631–1651. [Google Scholar] [CrossRef]

- Kang, M.S.; Gu, Y.; Lin, J.Q.; Zhou, X.Q.; Zhang, S.; Zhao, H.B.; Li, Z.; Yu, B.J.; Fu, B. Material removal mechanism of non-resonant vibration-assisted magnetorheological finishing of silicon carbide ceramics. Int. J. Mech. Sci. 2024, 242, 107986. [Google Scholar] [CrossRef]

- Yuan, Y.J.; Yu, K.K.; Zhang, C.; Chen, Q.; Yang, W.X. Generation of Textured Surfaces by Vibration-Assisted Ball-End Milling. Nanomanuf. Metrol. 2023, 6, 19. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Zhang, W.C.; Zhao, P.C.; Liu, W.D.; Wang, X.H.; Zhang, L.F.; Hu, G.F. Development of a novel piezoelectric-driven non-resonant elliptical vibrator with adjustable characteristics. Rev. Sci. Instrum. 2023, 94, 065008. [Google Scholar] [CrossRef]

- Wang, Z.J.; Luo, X.C.; Liu, H.T.; Ding, F.; Chang, W.L.; Yang, L.; Zhang, J.G.; Cox, A. A high-frequency non-resonant elliptical vibration-assisted cutting device for diamond turning microstructured surfaces. Int. J. Adv. Manuf. Technol. 2021, 112, 3247–3261. [Google Scholar] [CrossRef]

- Zhou, J.K.; Lu, M.M.; Lin, J.Q.; Du, Y.S. Elliptic vibration assisted cutting of metal matrix composite reinforced by silicon carbide: An investigation of machining mechanisms and surface integrity. J. Mater. Res. Technol. 2021, 15, 1115–1129. [Google Scholar] [CrossRef]

- Zheng, L.; Chen, W.Q.; Huo, D.H. Investigation on the tool wear suppression mechanism in non-resonant vibration-assisted micro milling. Micromachines 2020, 11, 380. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Li, Z.; Lin, J.Q.; Zhou, X.Q.; Xu, Z.S.; Zhou, W.D.; Zhang, S.; Gao, Y.H. Enhanced machinability of aluminium-based silicon carbide by non-resonant vibration-assisted magnetorheological finishing. J. Mater. Process. Technol. 2024, 324, 118223. [Google Scholar] [CrossRef]

- Gu, Y.; Fu, B.; Lin, J.Q.; Chen, X.Y.; Zhou, W.D.; Yu, B.J.; Zhao, H.B.; Li, Z.; Xu, Z.S. A novel wheel-type vibration-magnetorheological compound finishing method. Int. J. Adv. Manuf. Technol. 2023, 125, 4213–4235. [Google Scholar] [CrossRef]

- Wang, G.L.; Lv, B.G.; Zheng, Q.C.; Zhou, H.B.; Liu, Z.Z. Polishing trajectory planning of three-dimensional vibration assisted finishing the structured surface. AIP Adv. 2019, 9, 015012. [Google Scholar] [CrossRef]

- Prabhu, P.; Rao, M. Investigations on piezo actuated micro XY stage for vibration-assisted micro milling. J. Micromech. Microeng. 2021, 31, 065007. [Google Scholar] [CrossRef]

- Zhao, J.; Ge, J.Y.; Khudoley, A.; Chen, H.Y. Numerical and experimental investigation on the material removal profile during polishing of inner surfaces using an abrasive rotating jet. Tribol. Int. 2024, 191, 109125. [Google Scholar] [CrossRef]

- Storchak, M.; Rupp, P.; Möhring, H.; Stehle, T. Determination of Johnson–Cook constitutive parameters for cutting simulations. Metals 2019, 9, 473. [Google Scholar] [CrossRef]

- Miao, Q.; Ding, W.F.; Gu, Y.L.; Xu, J.H. Comparative investigation on wear behavior of brown alumina and microcrystalline alumina abrasive wheels during creep feed grinding of different nickel-based superalloys. Wear 2019, 426, 1624–1634. [Google Scholar] [CrossRef]

- Xiong, Q.; Nie, X.W.; Lu, J.B.; Yan, Q.S.; Deng, J.Y. Processing performance of vitrified bonded fixed-abrasive lapping plates for sapphire wafers. Int. J. Adv. Manuf. Technol. 2022, 123, 1945–1955. [Google Scholar] [CrossRef]

- Tang, S.Y.; Sun, Y.L.; Lou, Y.S.; Xu, Y.; Lu, W.Z.; Li, J.; Zuo, D.W. Study on the influence of ambient temperature on surface/subsurface damage of monocrystalline germanium lapping wafer. Procedia CIRP 2018, 71, 435–439. [Google Scholar]

- Gao, T.; Zhang, X.P.; Li, C.H.; Zhang, Y.B.; Yang, M.; Jia, D.Z.; Ji, H.J.; Zhao, Y.J.; Li, R.Z.; Yao, P.; et al. Surface morphology evaluation of multi-angle 2D ultrasonic vibration integrated with nanofluid minimum quantity lubrication grinding. J. Manuf. Process. 2020, 51, 44–61. [Google Scholar] [CrossRef]

| Elastic Modulus E (GPa) | Density ρ (kg·m−3) | Poisson’s Ratio μ | Yield Strength σ (MPa) |

|---|---|---|---|

| 71.7 | 2810 | 0.33 | 503 |

| Materials | Sic Particles | 6005 Al |

|---|---|---|

| Young’s modulus (GPa) | 183 | 70 |

| Poisson’s ratio | 0.2 | 0.3 |

| Density (kg/m3) | 3163 | 2700 |

| Thermal conductivity (W/mk) | 81 | 190 |

| Coefficient of thermal expansion (K−1) | 4.9 × 10−6 | 2.3 × 10−5 |

| specific heat capacity (J/gk) | 0.427 | 0.91 |

| Experimental Variable | |||||

|---|---|---|---|---|---|

| Experiment Number | Spindle Speed n (r/min) | Feed Speed vf (mm/min) | Lapping Depth ap (μm) | Vibration Frequency f (Hz) | Vibration Amplitude A (μm) |

| Experiment 1 | 800 | 5 | 1 | 0 | 0 |

| Experiment 2 | 800 | 5 | 1 | 850 | 8 |

| Experiment 3 | 400, 600, 800, 1000, 1200 | 35 | 3 | 750 | 6 |

| Experiment 4 | 800 | 5, 10, 20, 35, 55 | 3 | 750 | 6 |

| Experiment 5 | 800 | 35 | 1, 2, 3, 4, 5 | 750 | 6 |

| Experiment 6 | 800 | 35 | 3 | 450, 550, 650, 750, 850 | 6 |

| Experiment 7 | 800 | 35 | 3 | 750 | 2, 4, 6, 8, 10 |

| Controlled Variable | |

|---|---|

| Diamond abrasive size (μm) | 5 |

| Lapping time t (s) | 30 |

| Initial surface roughness Sa (μm) | 1.869 |

| Diameter of lapping head (mm) | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Gu, Y.; Xi, Y.; Fu, X.; Gao, Y.; Wang, J.; Xie, L.; Liang, G. Simulation and Experimental Study of Non-Resonant Vibration-Assisted Lapping of SiCp/Al. Micromachines 2024, 15, 113. https://doi.org/10.3390/mi15010113

Zhao H, Gu Y, Xi Y, Fu X, Gao Y, Wang J, Xie L, Liang G. Simulation and Experimental Study of Non-Resonant Vibration-Assisted Lapping of SiCp/Al. Micromachines. 2024; 15(1):113. https://doi.org/10.3390/mi15010113

Chicago/Turabian StyleZhao, Huibo, Yan Gu, Yuan Xi, Xingbao Fu, Yinghuan Gao, Jiali Wang, Lue Xie, and Guangyu Liang. 2024. "Simulation and Experimental Study of Non-Resonant Vibration-Assisted Lapping of SiCp/Al" Micromachines 15, no. 1: 113. https://doi.org/10.3390/mi15010113

APA StyleZhao, H., Gu, Y., Xi, Y., Fu, X., Gao, Y., Wang, J., Xie, L., & Liang, G. (2024). Simulation and Experimental Study of Non-Resonant Vibration-Assisted Lapping of SiCp/Al. Micromachines, 15(1), 113. https://doi.org/10.3390/mi15010113