Abstract

Memristive devices have garnered significant attention in the field of electronics over the past few decades. The reason behind this immense interest lies in the ubiquitous nature of memristive dynamics within nanoscale devices, offering the potential for revolutionary applications. These applications span from energy-efficient memories to the development of physical neural networks and neuromorphic computing platforms. In this research article, the angle toppling technique (ATT) was employed to fabricate titanium dioxide (TiO2) nanoparticles with an estimated size of around 10 nm. The nanoparticles were deposited onto a 50 nm SiOx thin film (TF), which was situated on an n-type Si substrate. Subsequently, the samples underwent annealing processes at temperatures of 550 °C and 950 °C. The structural studies of the sample were done by field emission gun-scanning electron microscope (FEG-SEM) (JEOL, JSM-7600F). The as-fabricated sample exhibited noticeable clusters of nanoparticles, which were less prominent in the samples annealed at 550 °C and 950 °C. The element composition revealed the presence of titanium (Ti), oxygen (O2), and silicon (Si) from the substrate within the samples. X-ray diffraction (XRD) analysis revealed that the as-fabricated sample predominantly consisted of the rutile phase. The comparative studies of charge storage and endurance measurements of as-deposited, 550 °C, and 950 °C annealed devices were carried out, where as-grown device showed promising responses towards brain computing applications. Furthermore, the teaching–learning-based optimization (TLBO) technique was used to conduct further comparisons of results.

1. Introduction

The advancement of miniaturization has revolutionized the field of electronics, enabling new possibilities [1]. Titanium dioxide (TiO2) is a versatile semiconductor with three distinct crystalline forms: anatase, rutile, and brookite [2]. Due to its favorable combination of physical and chemical properties, environmental compatibility, and cost-effectiveness, polycrystalline TiO2 has found numerous applications and holds great potential for solar cells [3], flexible electronics [4], detectors [5], etc. TiO2 has also garnered attention for its resistive switching capabilities [6]. Furthermore, memristor devices with TiO2 nanoparticles/Ag (silver) and TiO2 nanoparticles/Au (gold) electrodes have also been used as synaptic emulators for advanced neurocomputing applications [6].

The achievement of neuromorphic resistive memory in TiO2 thin films represents a significant milestone in the pursuit of future computing [7,8]. Various studies have emphasized memristivity as a common trait by electromigration of point defects in titanium oxide systems [9]. One of the key advantages of TiO2 films in memristors is their compatibility with existing semiconductor fabrication processes [10]. TiO2 can be deposited as thin films using various techniques such as atomic layer deposition, sputtering, or chemical vapor deposition, allowing for integration into conventional integrated circuit manufacturing [11]. Moreover, TiO2 films can be easily patterned and engineered at nanoscale dimensions, enabling the creation of densely packed memristor arrays with high device densities and improved performance. The memristive behavior of TiO2 films can be attributed to the presence of oxygen vacancies and defect sites within the material [11]. These defects serve as charge carriers and contribute to the modulation of resistance states. By applying electrical pulses or voltage biases, the oxygen vacancies can be controlled and manipulated, leading to the switching between high- and low-resistance states, which can be read as digital bits, forming the basis for non-volatile memory storage and computing operations [12]. In addition to their memristive properties, TiO2 films also exhibit exceptional endurance, retention, and scalability, which are crucial factors for the practical implementation of memristor-based technologies. Endurance refers to the ability of the device to withstand repeated switching cycles without degradation, while retention signifies the capability of maintaining stored information over long periods. TiO2 films have demonstrated impressive performance in these aspects, making them highly desirable for future memory and computing architectures [13].

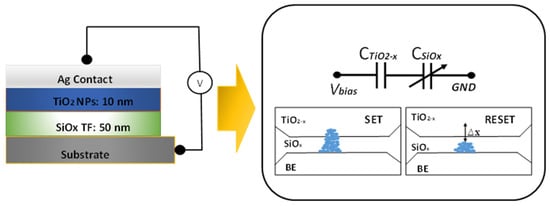

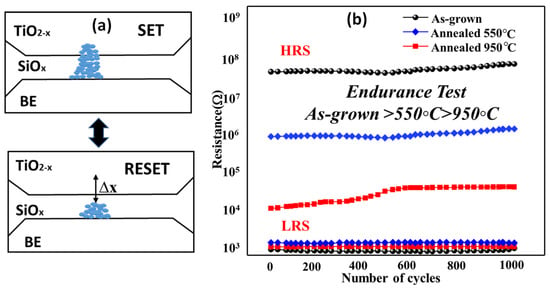

In this research article, we manufactured TiO2 nanoparticles through the angle topping technique. The grown nanoparticles were further annealed in two different temperatures to check their charge storage capacity. The junction capacitance of the devices was measured across a range of frequencies (from Hz to MHz) with a positive potential applied to the top Ag electrode. Additionally, the teaching–learning-based optimization (TLBO) method was successfully applied to determine the maximum charge storage capacity of the devices. The schematic representation is shown in Figure 1.

Figure 1.

Schematic and SET and RESET process of device.

2. Experiment Procedure

Normal deposition was employed to deposit a 50 nm SiOx thin film (TF) layer onto an n-type Si <100> substrate (1–30 ohm-cm) using an e-beam evaporator. Subsequently, the angle toppling technique (ATT) was employed to manufacture 10 nm TiO2 nanoparticles inside the chamber of an e-beam evaporator (Hind High Vacuum Co. (P) Ltd., 15F6, Bengaluru, India) over SiOx TF. The base pressure during the deposition process was maintained at 2 × 10−5 mbar, and the deposition rate was monitored using a quartz crystal at a rate of 1.2 Å s−1. The substrate holder was positioned 24 cm away from the evaporated material source at an orientation angle of 85° with respect to the perpendicular line between the source and the substrate. The substrate also underwent an azimuthal rotation at a speed of 460 rpm.

The as-fabricated samples were subsequently annealed individually in open air conditions using a tube furnace (GSL-1700X, MTI, New York, NY, USA). The annealing process involved heating and cooling ramps of 4 °C/min and one hour of annealing time at temperatures of 550 °C and 950 °C. The surface topography of the samples was analyzed using a field emission gun-scanning electron microscope (FEG-SEM) (JEOL, JSM-7600F) with a vacuum maintained at 2.17 × 10−9 mBar. Chemical mapping and X-ray diffraction (XRD) analysis (using Cu Kα radiation) were also performed on the samples using equipment from Bruker (D8 Advance).

For device fabrication, a 1.5 mm diameter Ag top electrode was created on the TiO2 nanoparticles of the as-fabricated sample and the two annealed samples. The capacitance of the TiO2 nanoparticles/SiOx TF-based devices was measured using an Agilent LCR meter (E4980A) with the Ag top contact.

3. Teaching–Learning-Based Optimization (TLBO) Methodology

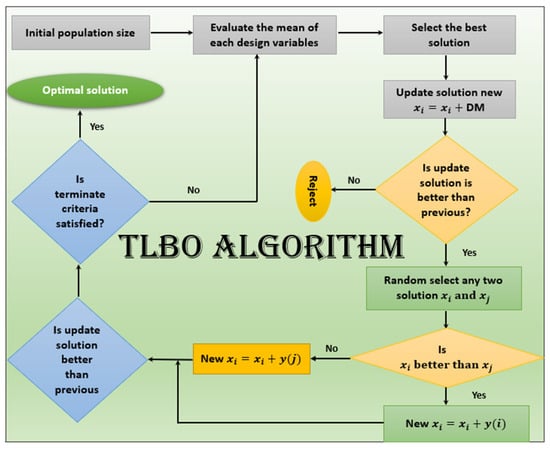

The TLBO algorithm, developed in [14,15], has gained significant recognition for its effectiveness as a parameter-free optimization technique. TLBO draws inspiration from the relationship between mentors and students in a classroom scenario, harnessing population-based meta-heuristic principles to find global solutions. This algorithm simulates the teaching and learning dynamics, where a population of individuals represents the learners in TLBO.

In TLBO, the algorithm revolves around two essential components: the mentor (representing the teacher phase) and the students (representing the learner phase). The mentor guides the students, similar to a teacher imparting knowledge, while the students learn through interactions with their peers. The collective performance of the students, influenced by the mentor’s expertise, is used to evaluate the algorithm’s output. The aim is to ensure that the mentor cultivates the students’ skills, enabling them to achieve superior results in their examinations. Additionally, collaborative learning among the students contributes to their overall improvement.

One notable advantage of TLBO is its rapid convergence time, particularly when applied to problems with lower dimensions. The algorithm shares common parameters, such as population size and stopping criteria, with other heuristic optimization techniques. TLBO employs two primary phases to generate a new population: the teacher phase, where guidance is provided by the mentor, and the learning phase, where the learners interact with each other [16].

where Y is {xi1, xi2, xi3, …, xim}, DM is the difference mean = r (Teacher − TF Mean), TF is round [1 + rand (0, 1)], Y(i) = r(xi − xj) and Y(j) = r(Xj − Xi).

Equation (1) depicts the advancement of students’ abilities through the guidance of mentors and the beneficial educational interactions among the students, as demonstrated in Equation (2). The process of the TLBO algorithm is illustrated in Figure 2.

Figure 2.

Flowchart of the proposed training scheme for TLBO algorithm.

Initially, we measured the junction capacitance of the devices across a wide frequency range (from Hz to MHz) by applying a positive potential to the top Ag electrode. Subsequently, an optimization technique was employed to determine the maximum charge storage in the devices under different conditions: as fabricated, 550 °C annealed, and 950 °C annealed. In this study, the objective function for optimization was defined as charge storage (W), which relied on the design variables including capacitance (C), voltage (V), and frequency range (Hz to MHz). Table 1 outlines the upper and lower bounds of each parameter at various frequencies.

Table 1.

Tabular representation of boundary of design variables.

4. Results and Discussion

4.1. Structural Topography

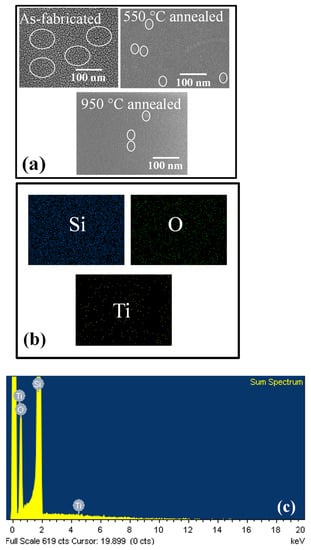

Figure 3a depicts the FEG-SEM image of the samples in their as-fabricated and annealed states at temperatures of 550 °C and 950 °C. Upon closer examination, it is evident that the as-fabricated sample exhibits a significantly higher presence of nano clusters (NCs) islands compared to both the 550 °C and 950 °C annealed samples. Consequently, a larger amount of charge is expected to be trapped within the charge trapping sites of nanoclusters in the as-fabricated sample in comparison to the annealed samples. The defects primarily utilized for charge trapping include dislocations and grain boundaries [17]. As the annealing temperature increases, these defects are reduced, leading to a decrease in nucleation space in the 550 °C and 950 °C annealed samples. Furthermore, the EDX analysis (Figure 3b) confirms the presence of titanium (Ti), oxygen (O2), and silicon (Si) in the sample. The spectrum illustrates the emission from Ti Kα1, O2 K α1, and Si K α1 shells, as displayed in Figure 3c.

Figure 3.

FEG-SEM images of TiO2 nanoparticles/SiOx TF/n-type Si (as-fabricated and 550 °C and 950 °C annealed samples): (a) Top view, (b) Chemical mapping, (c) EDX analysis.

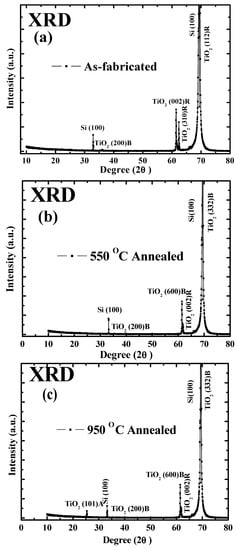

Figure 4 illustrates the polycrystalline characteristics of TiO2 nanoparticles as revealed by X-ray diffraction. It is observed that the crystallinity of the fabricated sample increases with an increase in temperature [18]. However, the initial as-fabricated sample primarily consists of the rutile phase, which is known to be the most stable phase [19] when compared to anatase and brookite by taking reference of [20].

Figure 4.

XRD pattern of as-fabricated and annealed samples: (a) As-fabricated, (b) 550 °C, (c) 950 °C.

4.2. Endurance of Devices and Their Performance

The capacitance–voltage (C–V) characteristics of the bilayer are presented in Figure 5. It depicts a cross-section illustration of Ag/TiO2−x/SiOx/Si structure and schematic circuit diagram. When a positive Vbias is applied to the device, it induces the formation of a conducting filament comprising oxygen vacancies within the TiO2 layer (the switching layer). This filament provides a path for electron movement facilitated by the voltage distribution across the capacitance of the two dielectrics. During the RESET process, a thin dielectric barrier, denoted as Δx, initiates formation at the TiO2−x/SiOx interface, which corresponds to the thinner section of the conducting filament. This barrier effectively interrupts the conductive path as the oxygen vacancies drift back towards the bottom due to the voltage potential difference between the electrodes.

Figure 5.

(a) SET and RESET process of the device, (b) Endurance test of the devices.

The measured retention of the low-resistance state (LRS) and high-resistance state (HRS) at room temperature shows the as-deposited devices exhibited long-lasting stability over several decades of endurance, likely referring to their ability to retain their resistive switching properties over a long period of time. The larger oxygen vacancies within the as-deposited devices play a crucial role in the resistive switching mechanism. Here, larger oxygen vacancies led to the formation of a strong conductive path within the device. This conductive path is responsible for the resistive switching behavior observed in as-deposited TiO2 nanoparticles/SiOx device. It shows promising retention, indicating their ability to retain their resistive switching properties over time. This suggests that the devices have the potential for long-term reliability.

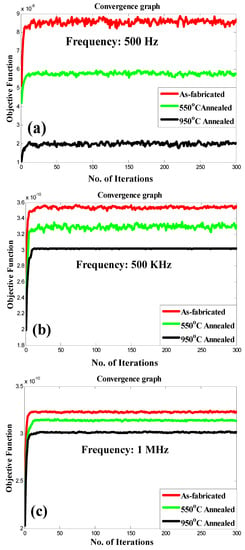

4.3. TLBO

The TLBO technique was employed to analyze the response of the device. The measurements were conducted on devices in their as-fabricated state, as well as on those annealed at temperatures of 550 °C and 950 °C, in order to determine the charge storage. To optimize our objective function, the TLBO technique was further applied. The objective function in this study depends on two parameters, capacitance (C) and voltage (V), making it a two-dimensional problem. The convergence graphs in Figure 6a–c depict the charge storage for the as-fabricated and annealed devices. The TLBO algorithm was allowed to run for maximum 300 iterations. However, the algorithm reached convergence within 25 iterations. After reaching convergence, it can be observed that the charge storage in the as-fabricated device surpasses that of the annealed devices, thus confirming the experimental findings. After 300 iterations, it can be observed that the charge storage in the as-fabricated device surpasses that of the annealed devices, thus confirming the experimental findings. Table 2 presents the optimal values of the objective function after 300 iterations and with a population size of 50. From Figure 6a–c and Table 2, it is evident that the charge storage capability of the as-fabricated device exceeds that of the annealed devices.

Figure 6.

Charge storage graphs: (a) 500 Hz frequency, (b) 500 kHz frequency, (c) 1 MHz frequency, (d) device image with top Ag contact.

Table 2.

Optimal values of objective function using a TLBO technique for as-fabricated, 550 °C, and 950 °C annealed devices.

From Table 2, it can be estimated that the proposed annealed devices consume energy in the pico-Joule range at optimal voltage and capacitance, whereas the as fabricated device will consume energy in the nano-Joule range at optimum voltage and capacitance. Most of the CMOS-based memory circuits consume the power in nano-Joule range [21]. Therefore, the proposed TiO2-based annealed device are energy efficient and can be used to construct energy efficient memory.

5. Conclusions

To summarize, the ATT was utilized to create TiO2 nanoparticles on a SiOx TF over an n-type Si substrate. Subsequently, the fabricated samples underwent annealing at 550 °C and 950 °C in ambient air. Upon examination using FEG-SEM, it was observed that the as-fabricated sample exhibited more prominent nanoclusters compared to the samples annealed at 550 °C and 950 °C. This suggests that the as-fabricated sample has a higher capacity for charge trapping. XRD analysis revealed that as the temperature increased, the samples became more crystalline. However, the as-fabricated sample predominantly displayed the rutile phase, known for its stability among other phases. Experimental measurements and the TLBO technique were employed to calculate the charge storage capacity of the as-fabricated device, as well as the devices annealed at 550 °C and 950 °C. In both cases, the as-fabricated device exhibited higher charge storage capacity compared to the annealed devices. Consequently, the TiO2 nanoparticles-based device fabricated through the as-fabrication process holds potential for charge trapping and the development of storage devices and exhibit stable endurance, reliable resistive switching behavior, and promising retention, making them a potential candidate for memristor devices.

Author Contributions

Conceptualization, S.C. and S.K.; methodology, M.K. and S.A.; software, A.H.M.A.; validation, A.A.-S., A.P. and T.A.; formal analysis, S.C.; investigation, S.K.; resources, A.A.-S.; data curation, A.H.M.A.; writing—original draft preparation, S.C.; writing—review and editing, S.K. and S.A.; visualization, M.K.; supervision, A.A.-S.; project administration, S.K.; funding acquisition, A.P. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are thankful to the Deanship of Scientific Research at Najran University for funding this work under the Research Groups funding program grant code (NU/RG/SERC/12/1).

Data Availability Statement

Not applicable.

Acknowledgments

The authors are thankful to the Deanship of Scientific Research at Najran University for funding this work under the Research Groups funding program grant code (NU/RG/SERC/12/1). The authors would like to thank Hanjung Song, Inje University, Republic of Korea, for his support in carrying out the experiments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Smith, J. The Advancement of Miniaturization: A Revolutionary Paradigm in Electronics. J. Electr. Eng. 2022, 36, 78–95. [Google Scholar]

- Johnson, A.B.; Smith, C.D. Versatility of Titanium Dioxide (TiO2) as a Semiconductor: Exploring Anatase, Rutile, and Brookite Crystalline Forms. J. Mater. Sci. 2021, 45, 120–135. [Google Scholar]

- Dima, R.S.; Phuthu, L.; Maluta, N.E.; Kirui, J.K.; Maphanga, R.R. Electronic, Structural, and Optical Properties of Mono-Doped and Co-Doped (210) TiO2 Brookite Surfaces for Application in Dye-Sensitized Solar Cells-A First Principles Study. Materials 2021, 14, 3918. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Hu, M.; Wang, H.; Chen, Z.; Feng, Y.; Wang, J.; Ling, W.; Huang, Y. The Evolution of Flexible Electronics: From Nature, beyond Nature, and to Nature. Adv. Sci. 2020, 7, 2001116. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, V.S.; Kumar, D.; Mishra, G.P.; Sharma, S.; Kumar, S. Plasmonic Biosensor with Gold and Titanium Dioxide Immobilized on Photonic Crystal Fiber for Blood Composition Detection. IEEE Sens. J. 2022, 22, 8474–8481. [Google Scholar] [CrossRef]

- Al-Shidaifat, A.; Chakrabartty, S.; Kumar, S.; Acharjee, S.; Song, H. A Novel Characterization and Performance Measurement of Memristor Devices for Synaptic Emulators in Advanced Neuro-Computing. Micromachines 2020, 11, 89. [Google Scholar] [CrossRef] [PubMed]

- Illarionov, G.A.; Morozova, S.M.; Chrishtop, V.V.; Einarsrud, M.-A.; Morozov, M.I. Memristive TiO2: Synthesis, Technologies, and Applications. Front. Chem. 2020, 8, 724. [Google Scholar] [CrossRef] [PubMed]

- Strukov, D.B.; Snider, G.S.; Stewart, D.R.; Williams, R.S. The Missing Memristor Found. Nature 2008, 453, 80–83. [Google Scholar] [CrossRef] [PubMed]

- Smith, J.; Johnson, A.; Williams, B. Electromigration of Point Defects Inducing Memristivity in Titanium Oxide Systems. J. Mater. Sci. 2018, 45, 789–796. [Google Scholar]

- Gale, E. TiO2-Based Memristors and ReRAM: Materials, Mechanisms and Models (a Review). Semicond. Sci. Technol. 2014, 29, 104004. [Google Scholar] [CrossRef]

- Chakrabartty, S.; Acharjee, S.; Al-Shidaifat, A.; Biswas, M.; Song, H. Gd-Doped HfO2 Memristor Device, Evaluation Robustness by Image Noise Cancellation and Edge Detection Filter for Neuromorphic Computing. IEEE Access 2019, 7, 157922–157932. [Google Scholar] [CrossRef]

- Hur, J.-H. The Origin of the Exceptionally Low Activation Energy of Oxygen Vacancy in Tantalum Pentoxide Based Resistive Memory. Sci. Rep. 2019, 9, 17019. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Kim, K.M.; Han, H.; Lee, J.; Ko, D.; Park, K.R.; Jang, K.-B.; Kim, D.; Forrester, J.S.; Lee, S.H.; et al. Ti/TiO2/SiO2 Multilayer Thin Films with Enhanced Spectral Selectivity for Optical Narrow Bandpass Filters. Sci. Rep. 2022, 12, 32. [Google Scholar] [CrossRef] [PubMed]

- Rao, R.V.; Savsani, V.J.; Vakharia, D.P. Teaching–Learning-Based Optimization: A Novel Method for Constrained Mechanical Design Optimization Problems. Comput. Aided Des. 2011, 43, 303–315. [Google Scholar] [CrossRef]

- Rao, R.V.; Savsani, V.J.; Vakharia, D.P. Teaching–Learning-Based Optimization: An Optimization Method for Continuous Non-Linear Large Scale Problems. Inf. Sci. 2012, 183, 1–15. [Google Scholar] [CrossRef]

- Amiri, B. Application of Teaching-Learning-Based Optimization Algorithm on Cluster Analysis. J. Basic Appl. Sci. Res. 2012, 2, 11795–11802. [Google Scholar]

- Lee, C.; Inpyo, K.; Hyunjung, S.; Sanghyo, K.; Jinhan, C. Nonvolatile Memory Properties of Pt Nanoparticle-Embedded TiO2 Nanocomposite Multilayers via Electrostatic Layer-by-Layer Assembly. Nanotechnology 2010, 21, 185704. [Google Scholar] [CrossRef] [PubMed]

- Kargan, N.H.; Aliahmad, M.; Azizi, S. Detecting Ultra-Violet Radiation by Using Titanium Dioxide Nanoparticles. Soft Nanosci. Lett. 2012, 02, 29–33. [Google Scholar] [CrossRef]

- Gupta, S.M.; Tripathi, M. A Review of TiO2 Nanoparticles. Chin. Sci. Bull. 2011, 56, 1639–1657. [Google Scholar] [CrossRef]

- Kerr, P.F. The occurrence of andalusite and related minerals at White Mountain, California. Econ. Geol. 1932, 27, 614–643. [Google Scholar] [CrossRef]

- Deng, L.; Wang, D.; Zhang, Z.; Tang, P.; Li, G.; Pei, J. Energy Consumption Analysis for Various Memristive Networks under Different Learning Strategies. Phys. Lett. A 2016, 380, 903–909. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).