3.1. Optical Digital Microscopy Investigation

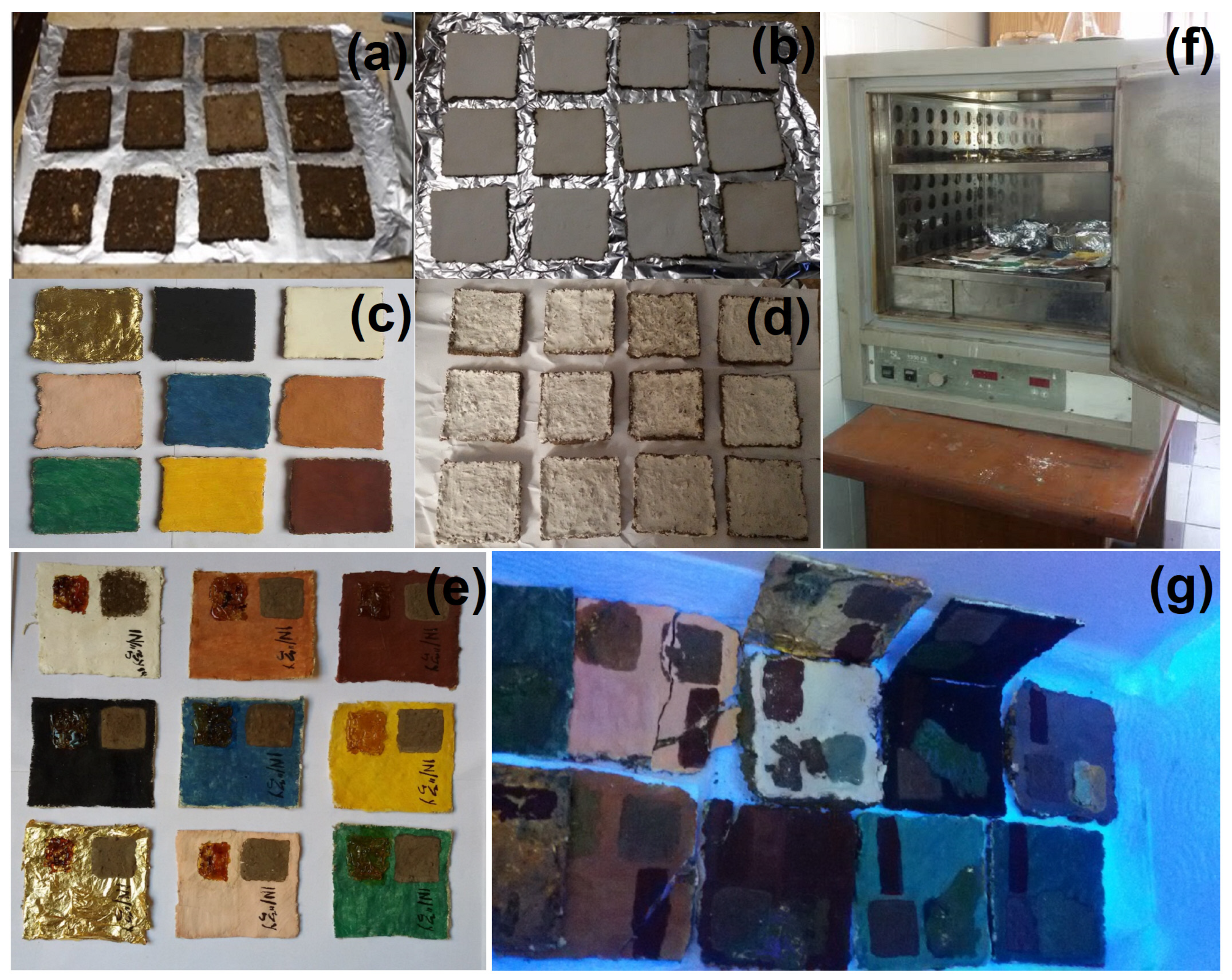

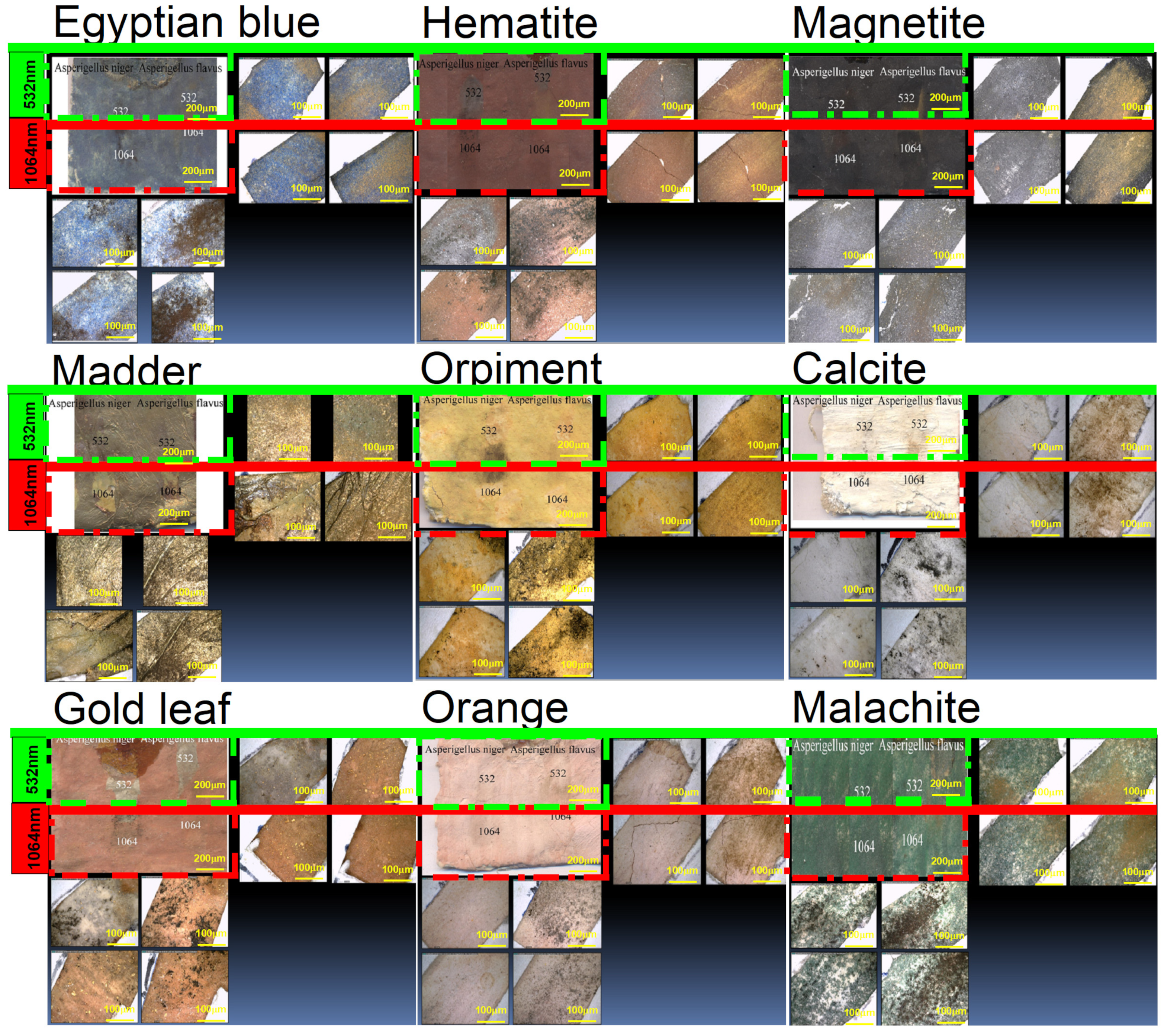

In the present work, the effect of using lasers to clean the painting layer was studied. The painting layers consisted of hematite, magnetite, Egyptian blue, orpiment, malachite, orange as a mixture of orpiment and hematite, calcite, and madder, with gilding applied over an orange bole layer (goethite). The painting layers suffered from the appearance of some forms damage on their surface, such as clay (mud), rosin resin, color, microbiological damage, and dust stains, which may have resulted from the impact in an uncontrolled museum environment or from soil during extraction, which was not removed most of the time due to the weakness of the archaeological material. Another form damage of appeared: resin stains that may be produced intentionally or unintentionally as a result of the use of resin in embalming mummies. These forms are first cleaned mechanically under a digital microscope (USB) using cotton, wooden steaks, and chemical methods (using alcohol), which are sometimes not suitable if the painting layer is weak. This is why the lasers were used at 532 and 1064 nm. A comparison study was conducted using a digital microscope to clean mud (clay), dust, color, microbiological damage, and resin stains, which was carried out on clay (mud) stains and resin stains, as shown in

Figure 4,

Figure 5,

Figure 6,

Figure 7 and

Figure 8.

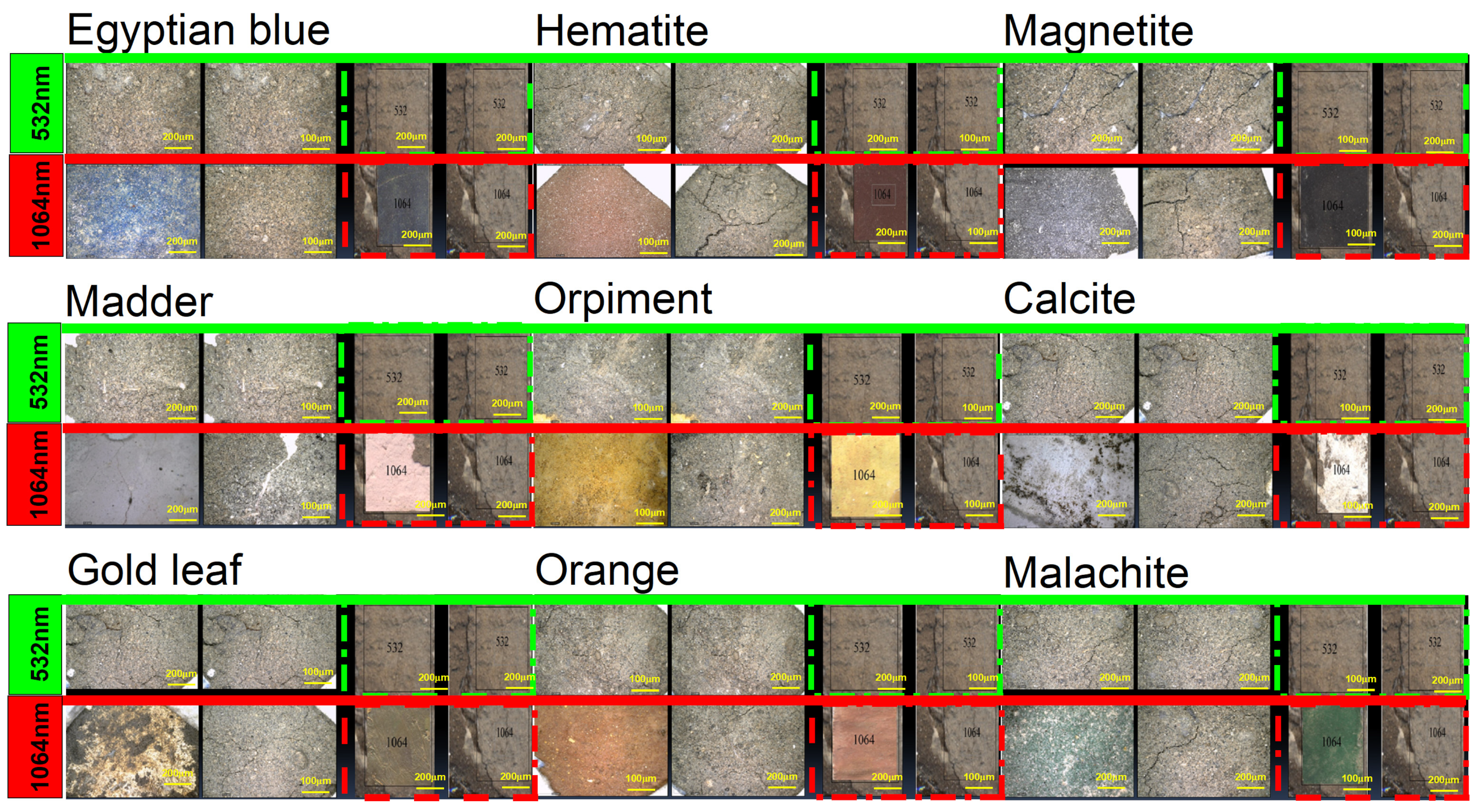

In the case of clay (mud) stains, as shown in

Figure 4, it is not preferable to use the 532 nm laser on the orange, hematite, madder, malachite, orpiment, calcite, Egyptian blue, and gilding layers because the clay stain remained the same without any benefit and did not give any result. It is preferable to use a laser with a wavelength of 1064 nm on the orange, hematite, madder, malachite, orpiment, calcite, Egyptian blue, and gilding layers, but in the beginning, mechanical cleaning with a wooden steak should be performed before laser cleaning. We found that if mechanical cleaning works to reduce the clay layer only and it is not completely removed, then lasers can be used to remove the remaining light layer of clay.

In the case of the resin stain, as shown in

Figure 5, the orange color showed that the 1064 nm laser is preferred for cleaning because it gave an excellent result in removing the resin without any damage to the colored surface. However, it is not preferable to use a 532 nm laser for cleaning resin stains over the orange color because the laser removed the resin, the color layer, and the calcium carbonate preparation layer until it reached the support layer. On calcite and madder, it was shown that the use of a 532 nm laser works to partially break down the resin bonds, and it requires continued use of the laser, but this will waste time and the laser. As for the use of a 1064 nm laser, we find that it works to completely remove the resin, but a brown layer remains on the color, which is one of the resin residues. Therefore, the use of the laser is good, but a layer of resin remains. On hematite, it was shown that it is preferable to use the 1064 nm laser when cleaning the resin stain because it gives an excellent result in removing the resin without any damage to the colored surface. The 532 nm laser is not preferred for cleaning resin stains over hematite since it completely removes the resin but causes blackening. It is preferable to use the 1064 nm laser when cleaning the resin on the gilding layer because the laser works to completely remove the resin, giving an excellent result without any damage to the colored surface. The 532 nm laser is not preferred on the gilding layer because the resin spot remained the same, without any success. It is not preferable to use a 532 nm laser over malachite because the laser works to partially break the resin bonds, and by continually using the laser, it works to completely remove the resin, but it causes discoloration from light green to dark green. The 1064 nm laser is not preferred because it removes the resin completely, but causes discoloration from light green to dark green. On magnetite, it was shown that it is preferable to use the 1064 nm laser when cleaning resin stains because it gives excellent results in removing the resin without any damage to the colored surface. We find that using the 532 nm laser to clean resin stains on magnetite is good because it removes the resin and gives a very good result without causing any damage to the colored surface. It is not preferable to use either the 532 nm or the 1064 nm laser to clean resin stains over orpiment because both wavelengths work to remove the resin and the paint layer and a layer of calcium carbonate until it reaches the support layer. It was shown that that the 1064 nm laser is preferred to clean resin stains over Egyptian blue because it gave an excellent result in removing the resin without any damage to the colored surface. We find that the use of a 532 nm laser when cleaning resin stains on Egyptian blue only breaks the resin bonds without removing it, and with the continued use of the laser, it removes the resin completely.

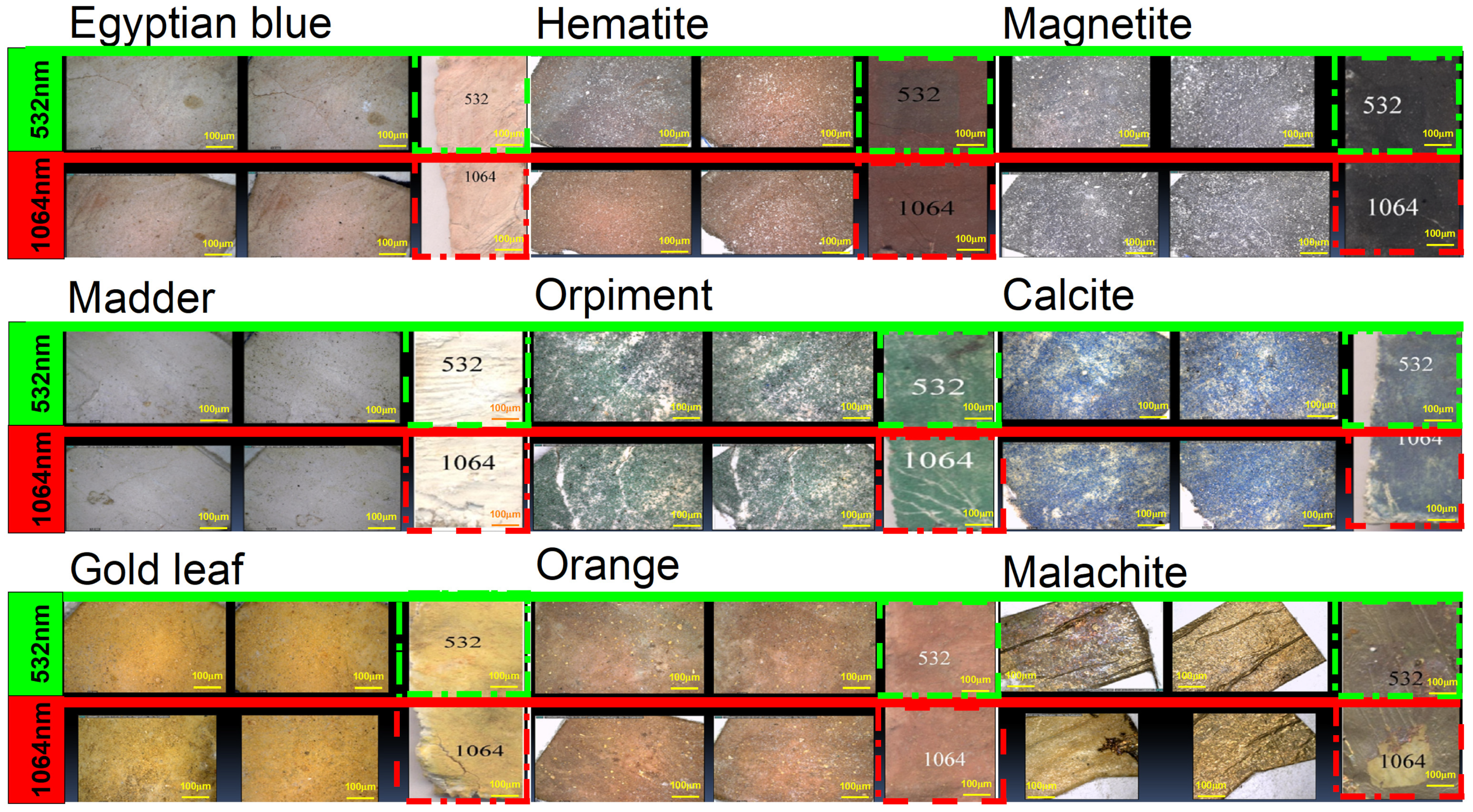

In the case of color stains, as shown in

Figure 6, it is not preferable to use a laser with a wavelength of 532 nm or 1064 nm to clean color stains on orange, malachite, and orpiment, as the laser beam cannot distinguish between colors, writings, and the paint layer as it works to remove the color stain until it reaches the calcium carbonate preparation layer and thus removes all of it. Its result is harmful to the sample. On calcite, it was shown that a laser that uses both colors to clean the color stain on white paint is good because it works to partially remove the red color stain. On madder, it was shown that using a 532 nm laser to clean the color stain is good because it partially removes the red color stain. However, the use of a laser with a wavelength of 1064 nm to clean the color stain is harmful because it works to clean the color stain, but the writing is removed because the laser beam cannot distinguish colors. It was found that a 532 nm laser in color stain on hematite is good, but it makes the material black. However, using a laser with a wavelength of 1064 nm to clean color stains on hematite is harmful because it cleans the color stain but removes the writing because the laser beam cannot distinguish the colors. The use of a 532 nm wavelength laser to clean color stains on gilding layer was shown to be good, but it blackens red color stains. It is not preferable to use a laser with a wavelength of 1064 nm to clean color stains on the gilding layer because it works to remove the color stain and the gilding layer down to the underlying layers because the laser beam cannot distinguish colors, and thus its result is harmful to the sample. On magnetite, it was shown that using a 532 nm laser to clean color stains is good, but it works to blacken red color stains without any removal effect, so the stain remains the same. It is not preferable to use a laser with a wavelength of 1064 nm to clean red color stains on magnetite because it works to remove the color stain, writings, and the black coloring layer down to the preparation layer of calcium carbonate because the laser beam cannot distinguish colors, and thus its result is harmful to the sample. It is not preferable to use a laser with a wavelength of 532 nm to clean red color stains on Egyptian blue because it blackens the blue color and only removes part of the color stain because the laser beam cannot distinguish colors. It is not advisable to use a laser with a wavelength of 1064 nm to clean color stains on Egyptian blue because it works to remove the color stain, writings, and the blue coloring layer down to the preparing layer of calcium carbonate because the laser beam cannot distinguish colors.

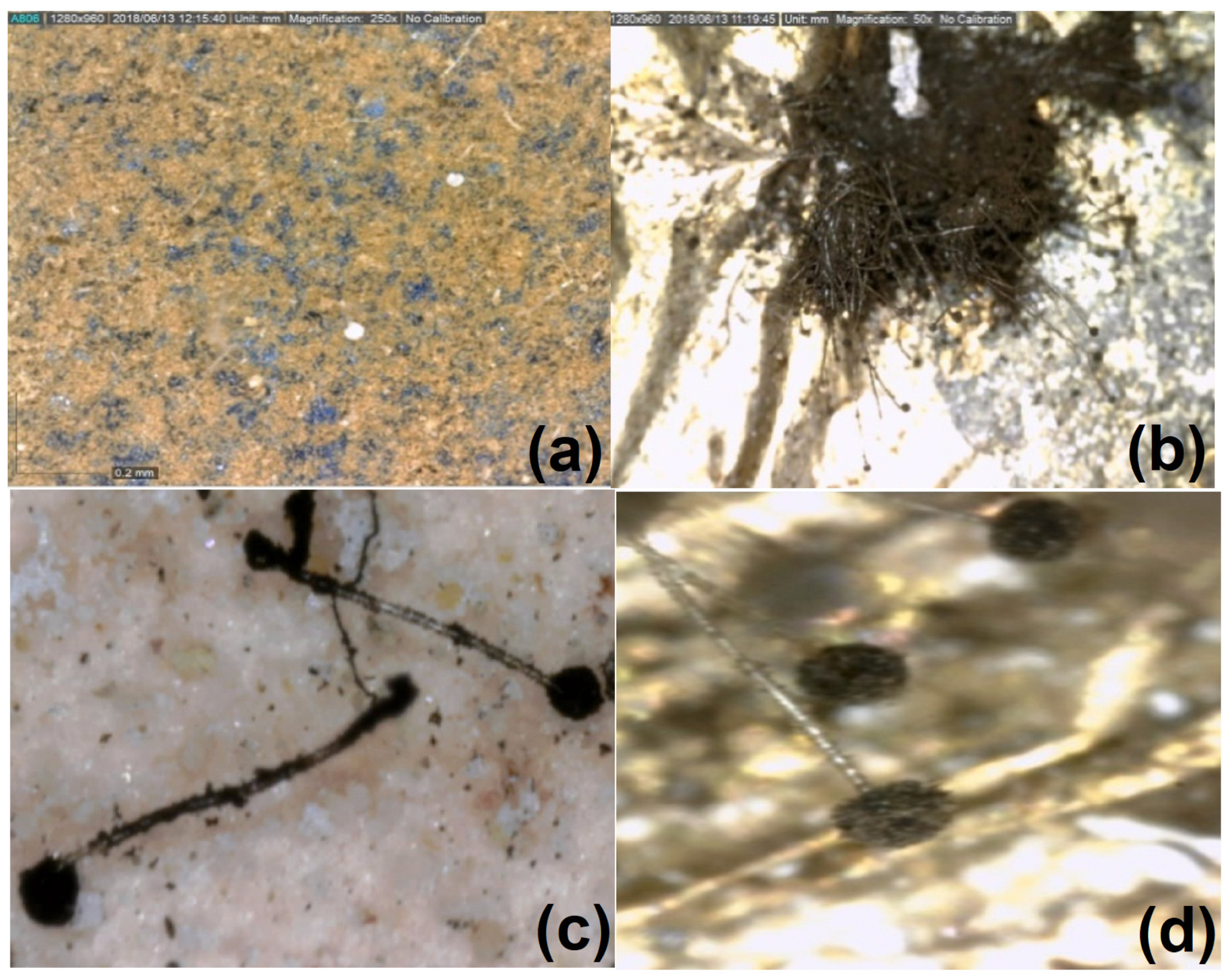

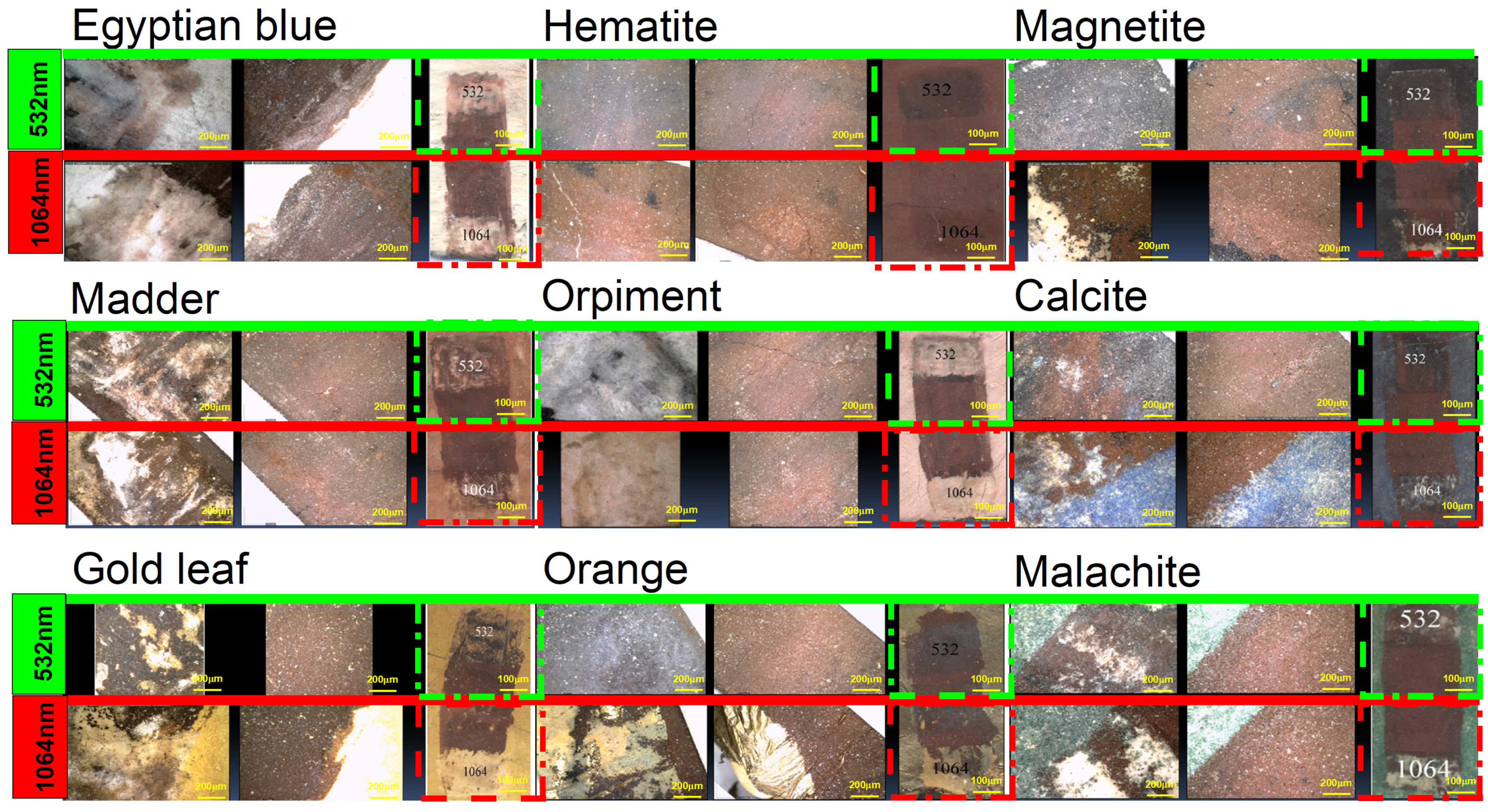

In the case of microbiological damage such as from

Asperigellus flavus and

Asperigellus niger, as shown

Figure 7, it is preferable to use a laser with a wavelength of 1064 nm when cleaning fungus stains from

Asperigellus flavus and

Asperigellus niger over the orange color because it gives an excellent result in removing the fungus stains without any damage to the colored surface. It is not preferable to use the 532 nm laser when cleaning fungus stains from

Asperigellus flavus over the orange color because it works to remove the fungus stain, paint layer, and preparation layer of calcium carbonate until it reaches to support layer. On calcite, madder, malachite, Egyptian blue, and magnetite, it was shown that lasers with both wavelengths are preferred for cleaning fungus stains from

Asperigellus flavus and

Asperigellus niger because they give excellent results in removing the fungus stains without any damage to the colored surface. On hematite, it is preferable to use the 1064 nm laser when cleaning

Asperigellus flavus stain and

Asperigellus niger stains because it gives an excellent result in removing the fungus stains without any damage to the colored surface. The 532 nm laser is not preferred when cleaning fungus stains from

Asperigellus flavus and

Asperigellus niger over hematite because it completely removes the fungus stains but blackens the hematite. On the gilding layer, it was shown that the 1064 nm wavelength laser is preferred for cleaning

Asperigellus flavus stains and

Asperigellus niger stains because it gives excellent results in removing the fungus stains without any damage to the colored surface. However, the 532 nm laser is not preferred for cleaning

Asperigellus flavus stains and

Asperigellus niger stain on the gilding layer because it creates a discoloration effect on the gilding layer, turning it to a reddish color, and completely removes it and affects the appearance of the orange bole layer (goethite). It is preferable to use a laser with a wavelength of 532 nm when cleaning fungus stains from

Asperigellus flavus and

Asperigellus niger over orpiment, as it gives an excellent result in removing the fungus stains without any damage to the colored surface. It is not preferable to use a laser with a wavelength of 1064 nm when cleaning fungus stains from

Asperigellus flavus and

Asperigellus niger over orpiment because it works to remove the fungus but also removes the orange bole layer (goethite) until it reaches the preparing layer of calcium carbonate.

In the case of dust stains, as shown in

Figure 8, it is preferable to use the 1064 nm laser when cleaning the orange color and related dust because it gives an excellent result in removing the dust stains without any damage to the colored surface. It is not preferable to use a laser with a wavelength of 532 nm for cleaning orange color and related dust because it works by discoloring the color from orange to dark brown. It is preferable to use the lasers with a wavelength of 532 nm and 1064 nm when cleaning calcite, madder, malachite, Egyptian blue, and magnetite and their related dust, as they give excellent results in removing dirt stains without any damage to the colored surfaces. It was shown that the laser with a wavelength of 1064 nm is preferred for cleaning hematite and related dust, as it gives an excellent result in removing dust stains without any damage to the colored surface. However, the 532 nm laser is not preferred for cleaning hematite and related dust, as it works to blacken the hematite. It is preferable to use a laser with a wavelength of 1064 nm to clean the gilding layer and the dust associated with it because it provides an excellent result in removing dust stains without causing any damage to the colored surface. It is not preferable to use the 532 nm laser when cleaning the gilding layer and the dust associated with it, as it makes the gilding paper discolor to a reddish color. It is preferable to use the laser with a wavelength of 532 nm when cleaning orpiment and its related dust because it gives an excellent result in removing dust stains without any damage to the colored surface. It is not preferable to use the laser with a wavelength of 1064 nm when cleaning the orpiment and related dust because it causes discoloration from yellow to dark yellow.

3.2. Measurement of Color Change by Spectrophotometer

The measurement of the degree of a color change depends on the measurement of the color area of the material in an area of 1 cm

2, which is the window area of the device, where the coordinates (a × b × L) are recorded under the color scale. The values of the change in L express the color’s niche from light to dark. The values of a × b express the color’s direction to the red region, where its decrease reflects the direction to the green area, while an increase of b expresses the direction to the yellow area, and its decrease expresses the direction to the blue region [

31,

32]. The measurements were made for the experimental aging samples after cleaning the stains on the surface of those pigments to identify the effect of the used wavelengths and to measure the total color change. The results are as follows.

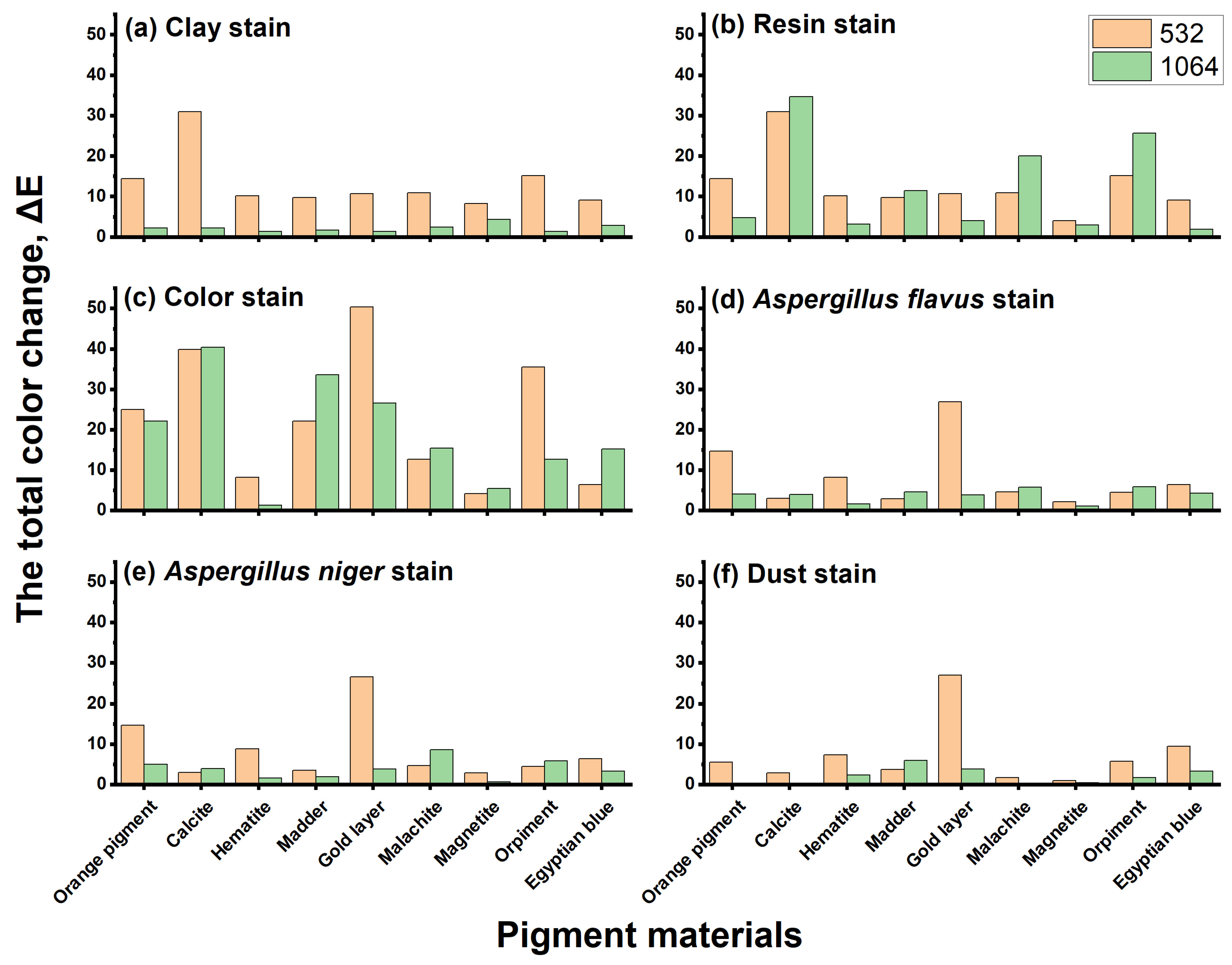

The results of the total color change of the samples, as shown in

Figure 9 and

Table 1, show the effect of artificial aging on the pigment materials. The results showed the total color change of the orange color, which gave a value equal to (ΔE = 4.98), while calcium carbonate gave a value equal to (E = 5.3), hematite gave a value equal to (ΔE = 5.89), madder gave a value equal to (ΔE = 5.8), the gilding paper gave a value equal to (ΔE = 5.8), and malachite gave a value equal to (ΔE = 5.97). Each of these colored materials (orange, calcium carbonate, hematite, malachite, madder and gilding paper) had a color change that can be seen with the naked eye. As for magnetite, it gave a value equal to (ΔE = 8.2), while orpiment gave a value equal to (ΔE = 8.4) and Egyptian blue gave a value equal to (ΔE = 14.65). Each of these colored materials (magnetite, orpiment, and Egyptian blue) experience great discoloration and distorted properties.

By discussing the previous results, it becomes clear that Egyptian blue is the most damaged pigment material when exposed to aging, followed by orpiment, then magnetite. Meanwhile, the orange color had a color change that can be seen with the naked eye, followed by calcium carbonate, hematite, malachite, madder, and the gilding paper. Also, the color change results after cleaning the stains on the surface of the samples using the wavelengths used in this study are tabulated in S1:S6 and appear in

Figure 10.

In the case of cleaning clay stains, the color changes in the pigment samples that were cleaned with the 532 nm laser are greater than those that were cleaned with the 1064 nm laser. In addition, we found severe visual distortions in the samples, and the use of the 1064 nm laser helped to remove the clay stains on the almost colored pigment and had no discernible color change, but it caused a slight color change on magnetite that can be observed with the naked eye.

In the case of cleaning resin stains, some color changes in the pigment samples before and after laser cleaning on the resin area were seen on the colored materials when using the 532 nm and 1064 nm lasers. From these results, it is clear that the use of the 532 nm laser in removing the resin stain on magnetite resulted in a slight color change that is noticeable to the naked eye, similar to the other pigment materials with severe visual distortions of the samples. However, the use of a 1064 nm laser to remove the resin stain on magnetite and Egyptian blue resulted in no discernible color change. As for the other pigment materials, such as orange, hematite, and gilding paper, they had slight color changes that can be seen with the naked eye. As for the other coloring materials, such as calcium carbonate, madder, malachite, and orpiment, we found severe visual distortions in the samples.

In the case of cleaning color stains, the samples before and after laser cleaning of the color stain showed the appearance of some color changes when using the 532 nm and 1064 nm lasers. It is evident that the use of a 532 nm laser to remove the color stain on magnetite resulted in a slight color change, but it is noticeable to the naked eye associated with severe visual distortions in the samples. Meanwhile, using the 1064 nm laser to remove the color spot on hematite, no discernible color changes occurred associated with many severe visual distortions.

In the case of cleaning microbiological stains (Aspergillus flavus), the samples before and after laser cleaning on the stain of Aspergillus flavus show the presence of color changes when using the 532 nm and 1064 nm lasers. It becomes clear that the use of the 532 nm laser to remove Aspergillus flavus fungus stains on calcium carbonate resulted in color changes, while the magnetite did not have a noticeable color change; for the other colored materials (orange, hematite, gilding paper, and Egyptian blue), we found severe visual distortions in the samples. In other words, by using a 1064 nm laser to remove the stains from the fungus Aspergillus flavus, there was no noticeable change in hematite and magnetite that can be seen with the naked eye.

In the case of cleaning microbiological stains (Aspergellus niger), the results of the total color change of the samples appear before and after laser cleaning of the stain from the fungus Asperigellus niger using 532 nm and 164 nm lasers. It is clear that the use of a 532 nm laser to remove Asperigellus niger fungus stains on calcium carbonate and magnetite did not result in significant color changes, while the other colored materials such as foah, malachite, and orpiment had a slight color change which can be seen with the naked eye. For other colored materials such as orange, hematite, gilding paper, and Egyptian blue, it severe visual distortions were found in the samples. In other words, using a 1064 nm laser to remove the stain from Asperigellus niger on hematite, the nozzle, and magnetite, these materials did not experience significant color changes. Other colored materials, namely orange, calcium carbonate, gilding paper, orpiment, and Egyptian blue, had a slight color change that can be seen with the naked eye. As for the remaining colored materials, such as malachite, we find severe visual distortions in the samples.

In the case of cleaning dust stains, the total color changes in the samples appear before and after the laser cleaning on the paint layer after cleaning with 532 nm and 1064 nm lasers. It is clear that using the 532 nm laser on calcium carbonate, malachite, and magnetite did not result in significant color changes, while other coloring materials, such as orange, madder, and orpiment, had a slight color change that can be seen with the naked eye. In addition, colored materials such as gilding paper, hematite, and Egyptian blue showed severe visual distortions in the samples. When using the 1064 nm laser with orange, calcium carbonate, hematite, malachite, magnetite, and orpiment, they did not experience significant color change. In addition, the other colored materials, such as madder, gilding paper, and Egyptian blue, had slight color changes that can be seen with the naked eye.

3.4. Elemental Investigation

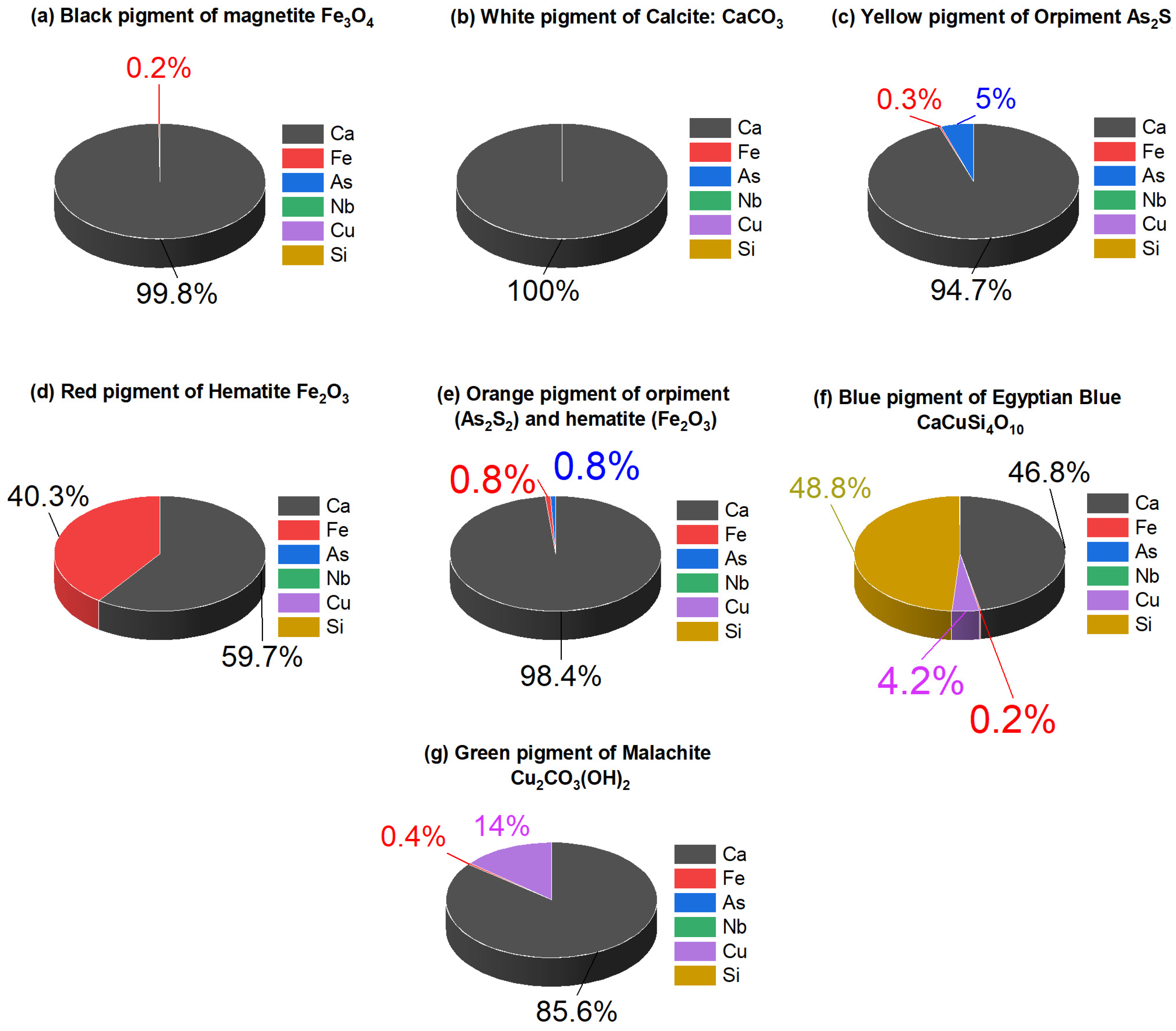

An X-ray fluorescent device has been used in two directions. The first direction is to ensure that the pigments used in experimental samples are the same pigments used in archaeological cartonnage (the main XRF results are presented in

Supplementary File—Figure S1).

For the black and white samples, the XRF spectra of the black paint (

Figure 12a) exhibit iron (1%), suggesting the presence of the iron in the black pigment is magnetite (Fe

3O

4), and calcium (99%), which is a sign of the preparation layer. The XRF spectra of the white paint (

Figure 12b) revealed the presence of calcium (100%), which confirmed the use of calcite. For the yellow paint sample, the XRF spectra of the yellow paint (

Figure 12c) detected the presence of arsenic (5%) and sulfur (0.26%), which confirmed the yellow paint is orpiment (As

2S

2). Calcium (94.74%) was also found as a major element, most likely from the underlying preparation layer. For red and orange paint samples, the XRF analysis (

Figure 12d) suggested the application iron (13.74%), which showed the use of hematite (Fe

2O

3) as a red pigment. Using XRF analysis (

Figure 12e) in orange paint showed the presence of arsenic (1%) and iron (2%) that confirmed the orange paint is admixed with hematite and orpiment. In the red and the orange paint, a noticeable amount of calcite from the underlying plaster layer was also identified. For the blue and green paint sample, the XRF analysis (

Figure 12f) confirmed the use of Egyptian blue (CaCuSi

4O

10), as copper (58.77%), silicon (4.18%), and calcium (36.88%) were detected. The XRF analysis (

Figure 12g) of green paint confirmed the use of malachite (Cu

2CO

3(OH)

2), as copper (4.99%) and calcium (94.59%) were detected. In blue and green paint, a noticeable amount of calcite from the underlying plaster layer was also identified.

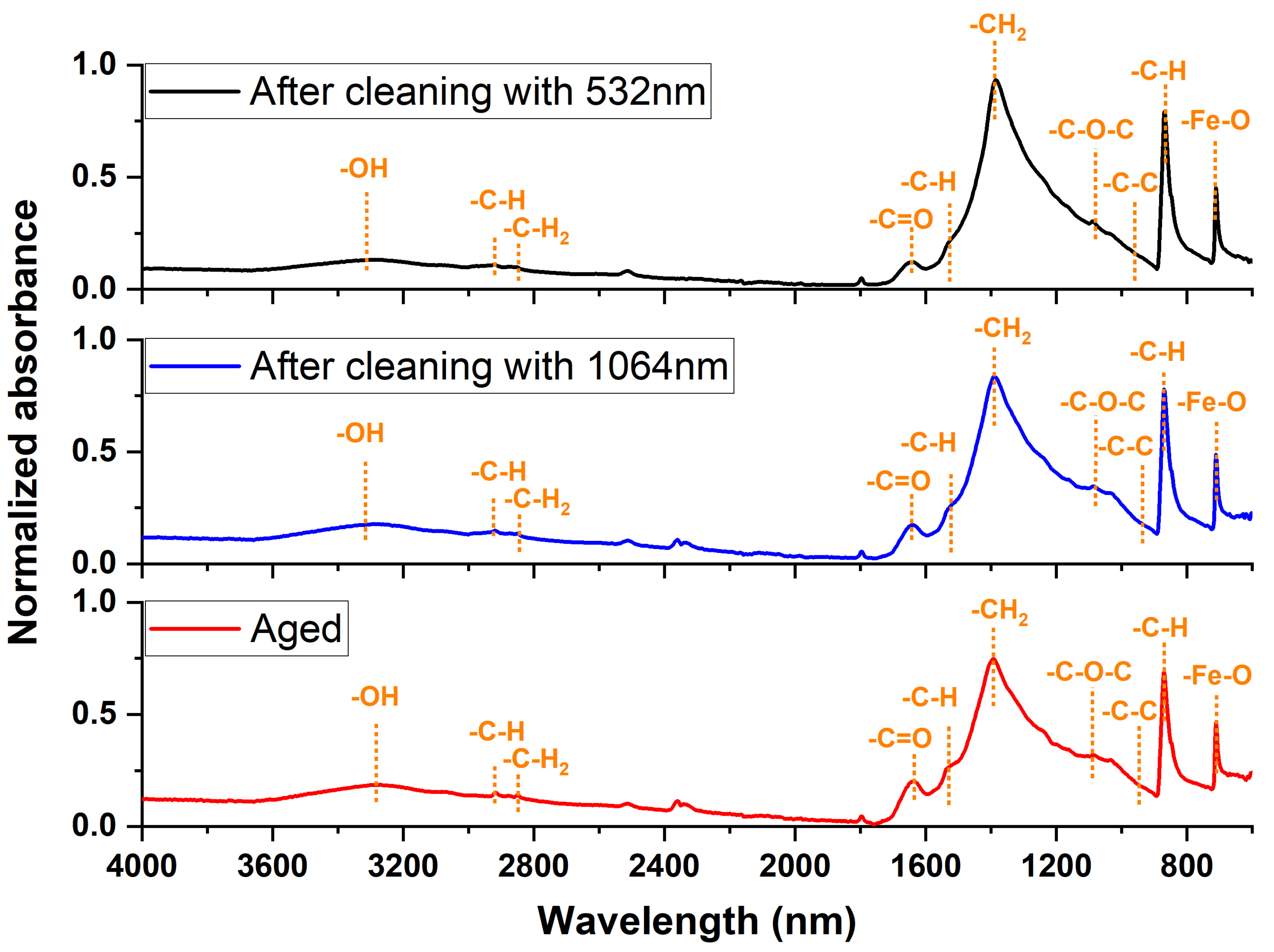

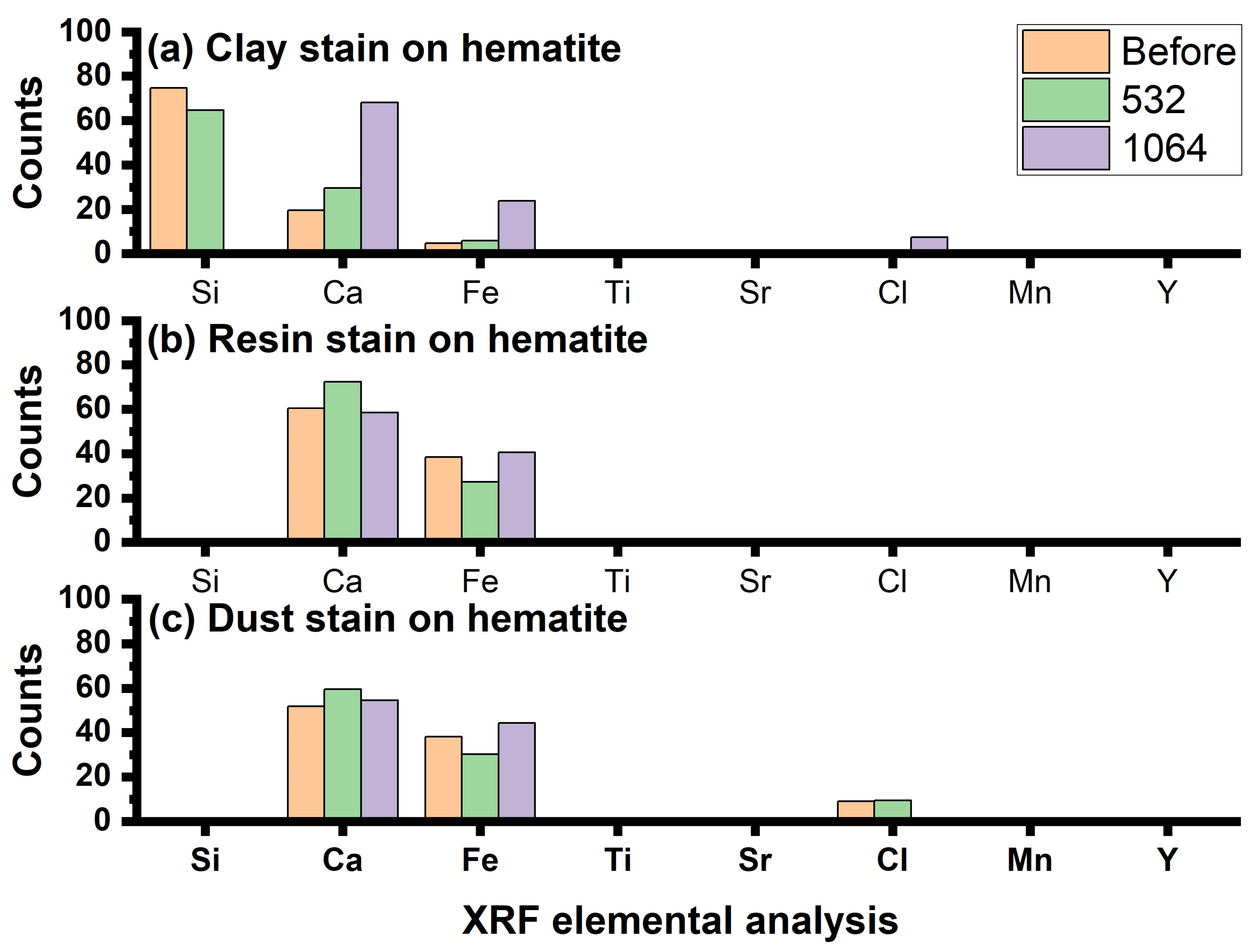

The second direction was based on making a comparison between the constituent elements of hematite pigments before and after cleaning different types of stains (clay, resin, and dust) using 532 and 1064 nm lasers on red hematite, which is represented by the graph in

Figure 13 (the main results from the XRF data are presented in the

Supplementary File—Figures S2–S4).

In the case of cleaning the clay stain, before using the laser, we found a high percentage of silica up to 74%, which is the main component of the clay stain, in addition to finding a decrease in the iron percentage of 4%, which is the main component of hematite, and a decrease in the percentage of calcium to 19%, which is the main component of the preparation layer. After using the 532 nm laser to clean the clay stain, we found a decrease in the percentage of silica, but not to a large degree, about 10%, and an increase in the percentage of iron to reach 5%, which is the main component of hematite, in addition to an increase in the percentage of calcium to reach 29%, which is the main component of the preparation layer. These results indicate that the effect was not desirable due to the fact that the 532 nm laser only reduces clay, but it is not completely removed. Also, after using the 1064 nm laser to clean clay stain, we observed the disappearance of silica and a big increase in the iron component by 23%, which is the main component of hematite, in addition to an increase in the percentage of calcium to 68%, which is the main component of the preparation layer; these results indicate that the 1064 nm laser has a proven ability to remove the clay stain completely and effectively [

36,

37].

In the case of cleaning resin stains, before using lasers to clean resin stains, we found that the percentage of iron was 38%, which is the main component of hematite. In addition to that, we find that the percentage of calcium is up to 60%, which is the main component of the preparation layer. After using the 532 nm laser to clean the resin stains, we found a decrease in the percentage of iron to 27%, which is the main component of hematite, in addition to an increase in the percentage of calcium to 72%, which is the main component of the preparation layer; these results indicate that the effect was not desirable because the 532 nm laser works to blacken and reduce the iron that forms the hematite. Also, after using the 1064 nm laser to clean the resin stains, we found a big increase in the percentage of iron to 40%, which is the main component of hematite, in addition to a decrease in the percentage of calcium to 58%, which is the main component of the preparation layer; these results indicate that the 1064 nm laser has a proven ability to remove the resin stain completely and effectively [

38,

39].

In the case of cleaning dust stains, before using lasers to clean the stains, we found that the percentage of iron reached 38%, which is the main component of hematite, in addition to increasing the percentage of calcium to reach 51%, which is the main component of the preparation layer. After using the 532 nm laser to clean the dust stains, we observed a decrease in the percentage of iron to 30%, which is the main component of hematite, in addition to an increase in the percentage of calcium to 59%, the main component of the preparation layer, which indicates that the result was not desirable because the 532 nm laser works to blacken and reduce the iron that forms hematite. Also, after using the 1064 nm laser to clean the dust stains, we find a large increase in the percentage of iron to 44%, which is the main component of hematite, in addition to a decrease in the percentage of calcium to reach 54%, which is the main component of the preparation layer, which indicates that the 1064 nm laser has proven its ability to remove dust stains from the red hematite.

Based on the results obtained in the present study, it was concluded that it is preferable to use a 1064 nm laser to remove the clay (mud), dust, resin, and microbiological stains. It gave very good results in terms of the degree of color change and the degree of cleaning compared to using the 532 nm laser.

The experimental study demonstrated the good effect of laser with a wavelength of 1064 nm, it did not result in noticeable discoloration nor any chemical changes to the most studied material. It also gave perfect results when used to clean most stains. It cleaned the stains without any damage to the pigment surface, whereas the 532 nm laser, when used in removing resin, damages the pigment layer (removing the pigment layer completely). When it was used to clean the resin stains on the surfaces of the pigments, the laser at 1064 nm gave excellent results on the pigment materials such as orange, hematite, magnetite, orpiment, calcite, Egyptian blue, and the gilding layer. It did not cause any noticeable color changes at the end of the process. With the exception of calcite and madder, which have a slight brown color on their surfaces, cleaning reveals the remainder of the resin layer, and a slight darkening occurs when used to clean malachite. By comparing these results with the results of cleaning resins from surfaces using the 532 nm laser, the tests proved that the 532 nm laser gave very bad results when used on gilded surfaces, as it did not give noticeable results to remove the resin and did not give good results when cleaning the orange color, as it removes the resin and the color layer together as it operates. It breaks the resin bonds on the layer of calcite, madder, malachite, and Egyptian blue in part, although it takes longer to achieve the same results as the 1064 nm laser cleaning, and it results in darkening of the malachite and works to blacken the hematite surface after removing the resin stains. However, it is noted to give good results when cleaning resin stains from the surfaces of magnetite and did not result in noticeable color changes.

The results of using wavelengths of 1064 and 532 nm to remove color spots were also proven. The samples gave different results, and it is preferable not to use them in general, as the 532 nm and 1064 nm lasers gave poor results when cleaning the color spots in orange, madder, Egyptian blue, hematite, and magnetite, where the results ranged in the removal of part of the original color layer. With color stains and blackening layers of coloring, it gives good results when removing color spots on calcite surfaces only.

The results of using the 532 nm and 1064 nm lasers have also proven successful in removing microbiological damage stains from the surfaces of calcite, mouth, malachite, Egyptian blue, and magnetite, but the 1064 nm laser is preferred when cleaning the orange, hematite, and gilding layers, as it removes microbiological stains excellently without damaging the original coloring layer, while the 532 nm laser is preferred when cleaning the armpit, as the 1064 nm laser removes the accent layer.

The results of using the laser to remove dust from the surfaces of pigment materials showed the success of the 1064 nm and 532 nm lasers in removing dust from the surfaces of calcite, mouth, malachite, Egyptian blue, and magnetite, while the 1064 nm laser was recommended to clean the gilding layer, orange color, and hematite, as it gives an excellent result when removing dust and dirt without any damage to the colored surface compared to the 532 nm laser, which caused a color change from brown to orange, the blackening of hematite, and also worked to change the color of the gilding layer to a reddish color. By using it on the orpiment layer, the results proved to be more successful than the 1064 nm laser, as it did not cause any color changes.

When using lasers to clean mud stains, it is preferable to start with mechanical cleaning to reduce the thickness of the layer of clay, and then use a laser to remove the remaining light layer of mud. The thickness of the clay (mud) stain was determined by using the wooden steak under the microscope. Then, the samples were exposed to the laser with a wavelength of 1064 nm, and three consecutive pulses were applied to the surface. The results of the cleaning of the clay showed improvement compared to the sample before using the Nd:YAG laser. When the sample was examined using a digital microscope with 50× magnification, the microphotos showed that the pigment layer was not affected by the cleaning operations and no fading process occurred compared to the sample before cleaning. It has also been used to remove surface plankton as well as dust and incoherent dirt on the pigment surface. The 532 nm laser caused discoloration of the mixed orange, hematite, madder, malachite, calcite, and Egyptian blue, and the cleaning process of the mud stain on the golden sheets using the 532 nm laser did not give good results in reducing or removing the stain.