Comparison of Anodic and Au-Au Thermocompression Si-Wafer Bonding Methods for High-Pressure Microcooling Devices

Abstract

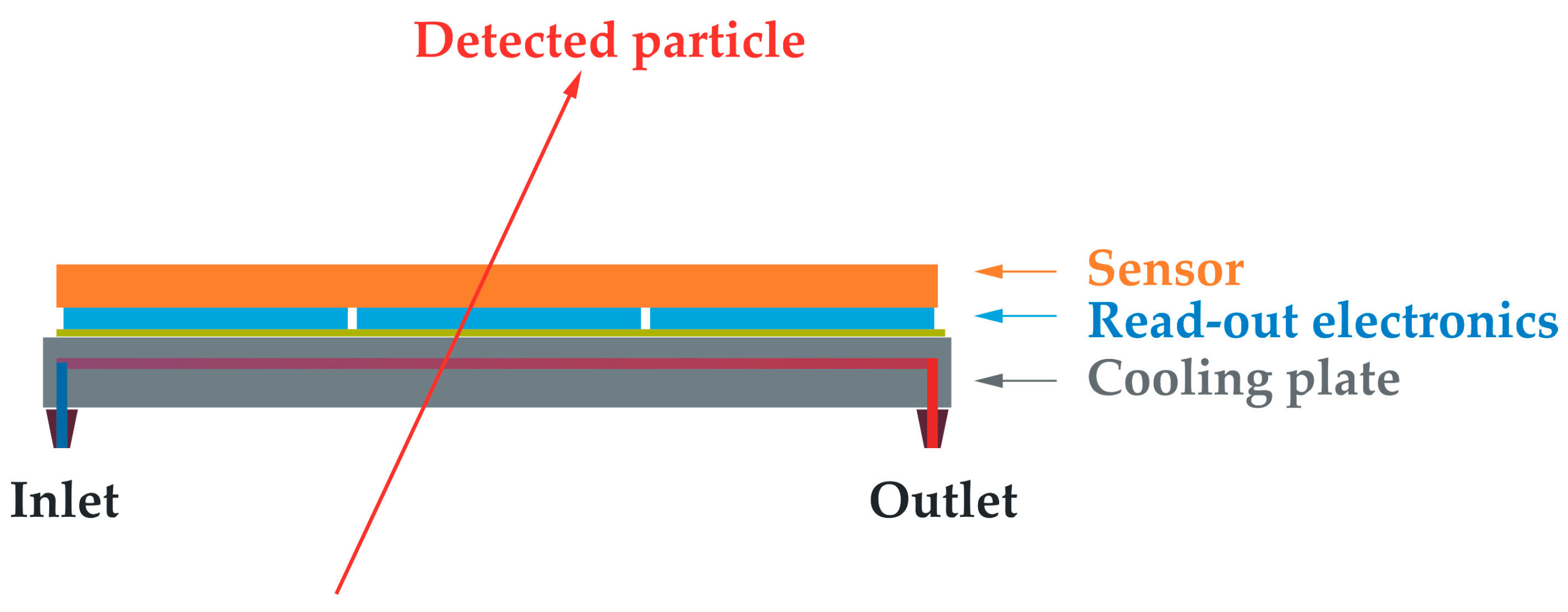

1. Introduction

- As the sensor must operate at low temperatures (typically −10 to −30 °C) to mitigate the radiation damage, the coefficient of thermal expansion (CTE) of the cooling system must match that of the sensor;

- As matter perturbs the trajectory of the impinging particles, the cooling plate must be made of a light material and remain as thin as possible (≪1 mm), while maintaining the required mechanical stability, which can be of the order of tens of microns;

- When in-channel evaporative cooling is used, the cooling plate must withstand a very high pressure (up to several hundred bar, depending on the refrigerant chosen).

- Si-Glass-Si anodic bonding (AB) with a thin-film intermediate borosilicate glass;

- Au-Au thermocompression (TC) bonding.

2. Materials and Methods

2.1. Design of Test Structures

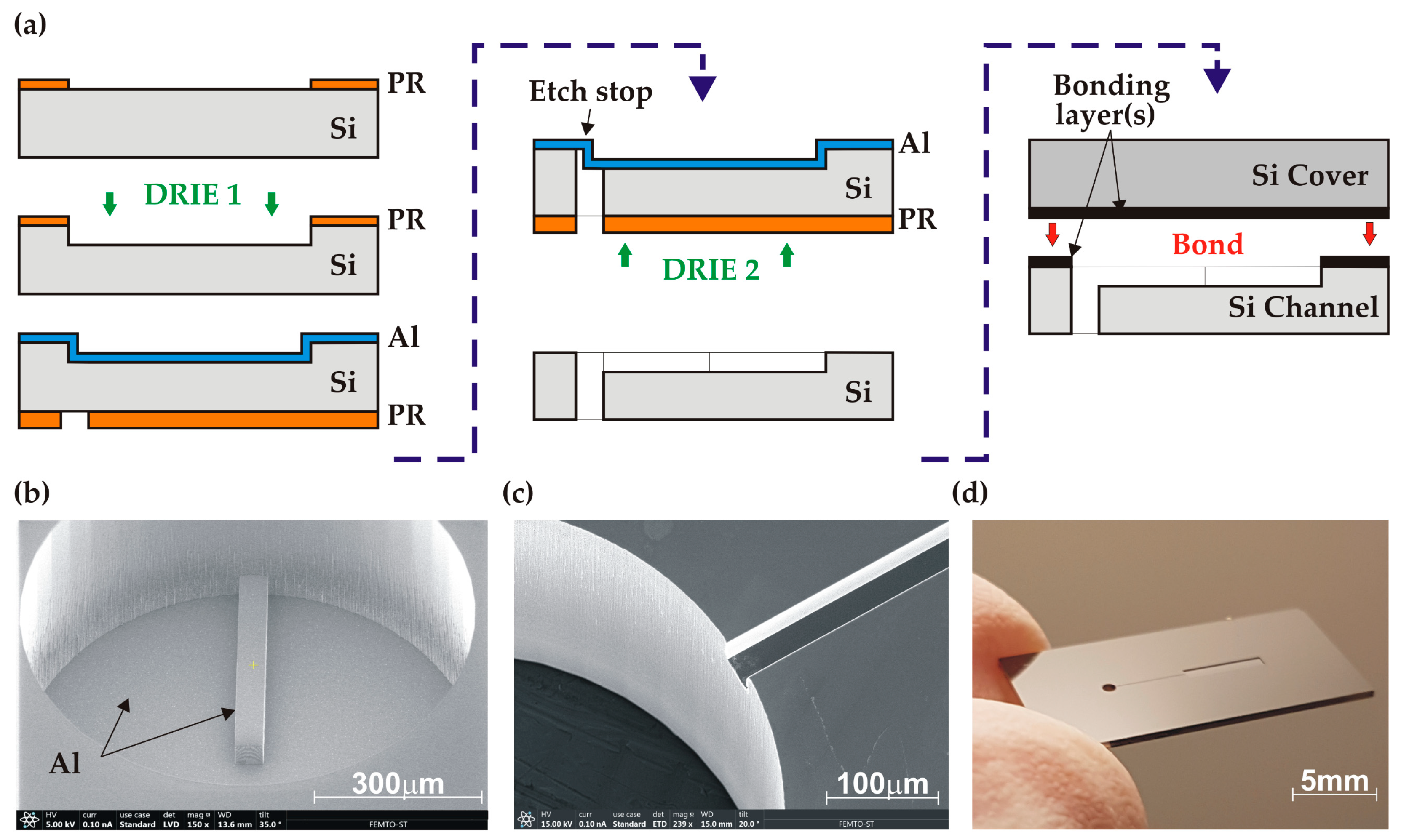

2.2. Fabrication and Characterization of Test Wafers

2.2.1. Cover Wafer for Anodic Bonding Studies

2.2.2. Cover Wafer for Thermocompression Bonding

2.2.3. Channel Wafers

2.3. Bonding Procedure

2.3.1. Wafer Preparation

2.3.2. Bonding Equipment

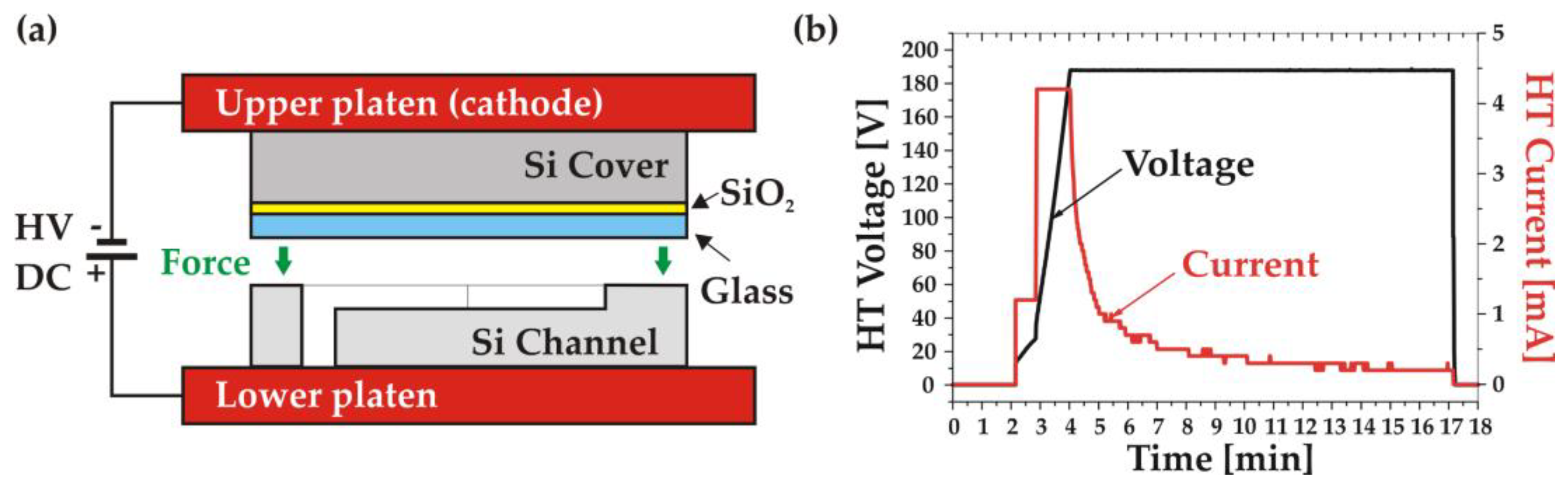

2.3.3. Anodic Bonding Process

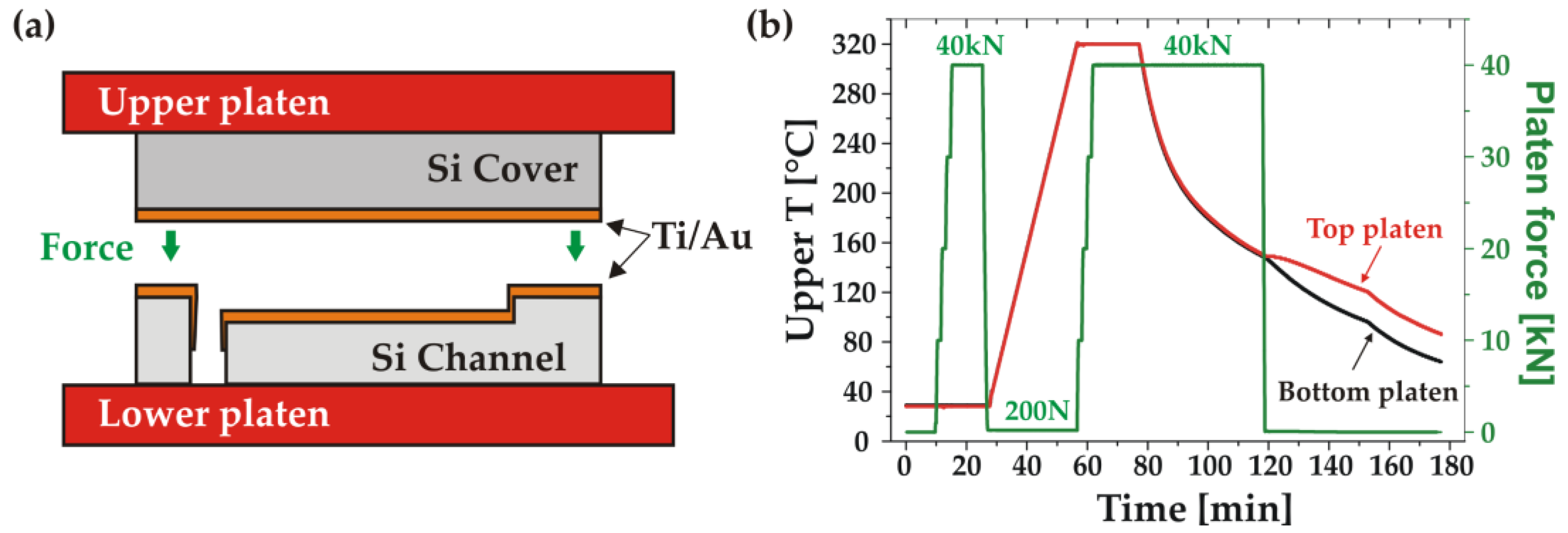

2.3.4. Au-Au Thermocompression Bonding

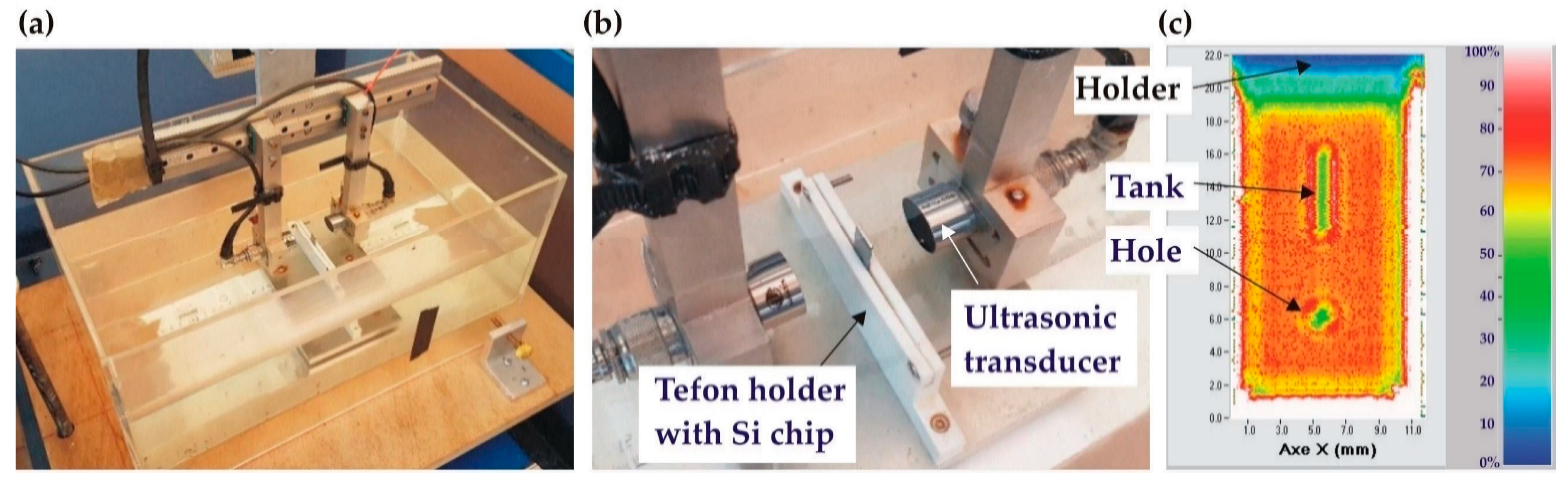

2.4. Acoustic Imaging Analysis

2.5. Wafer Dicing

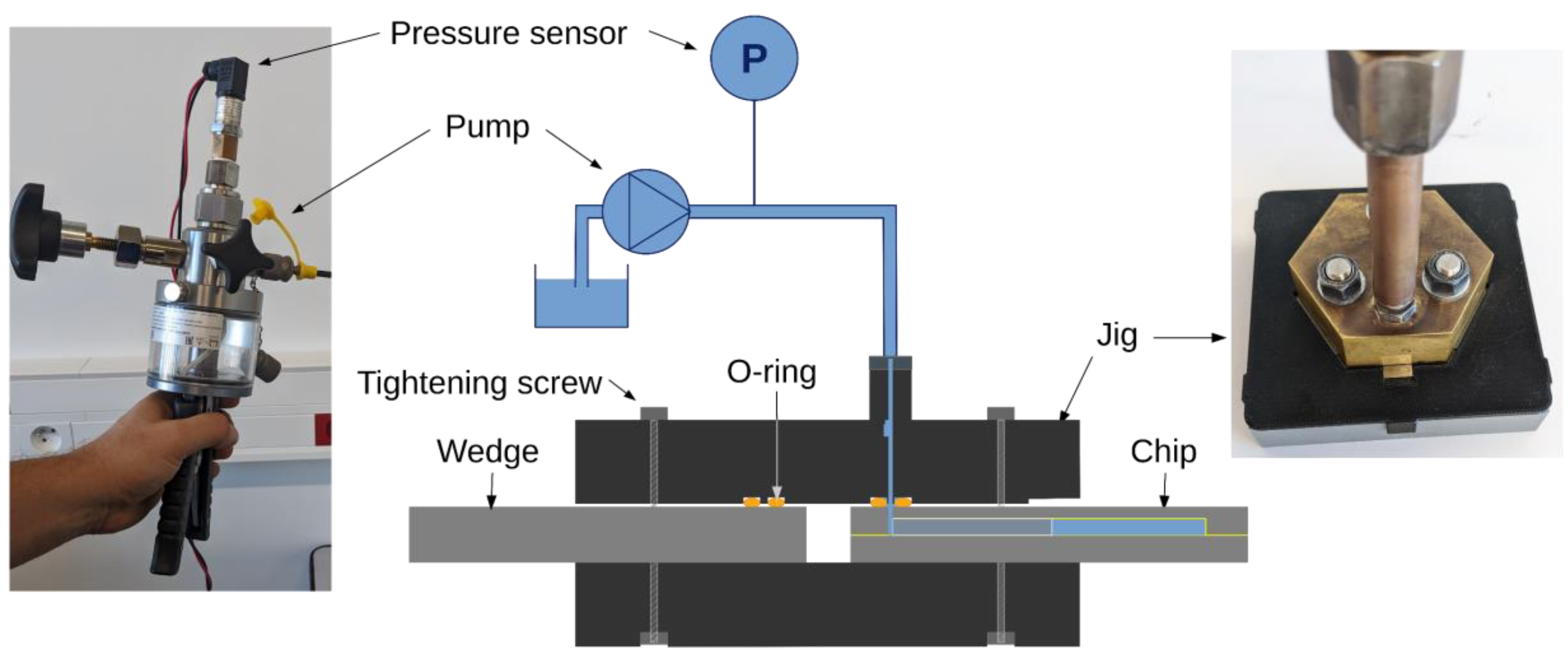

2.6. Pressure Resistance Test Bench

2.7. Analysis after High-Pressure Destructive Test

3. Results

3.1. Anodic Bonding Results

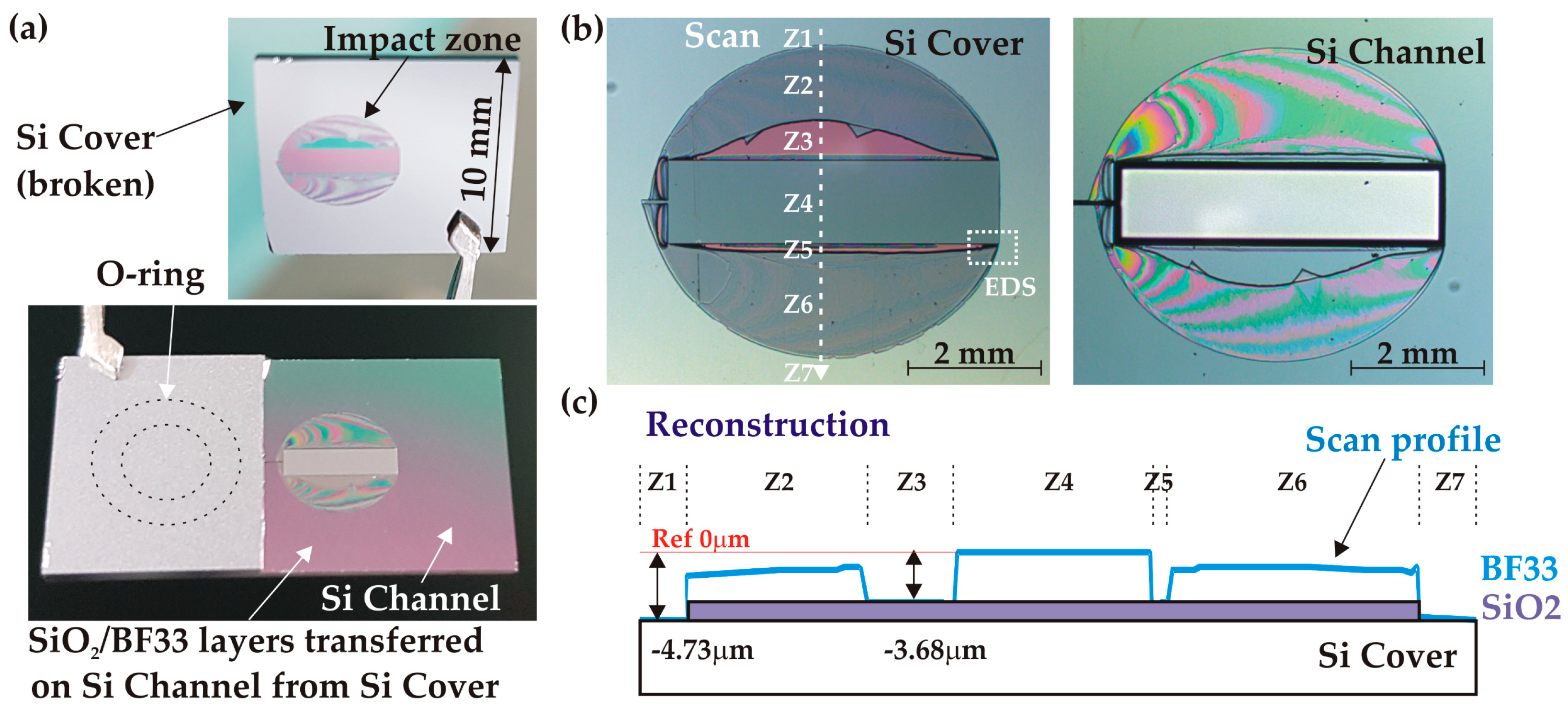

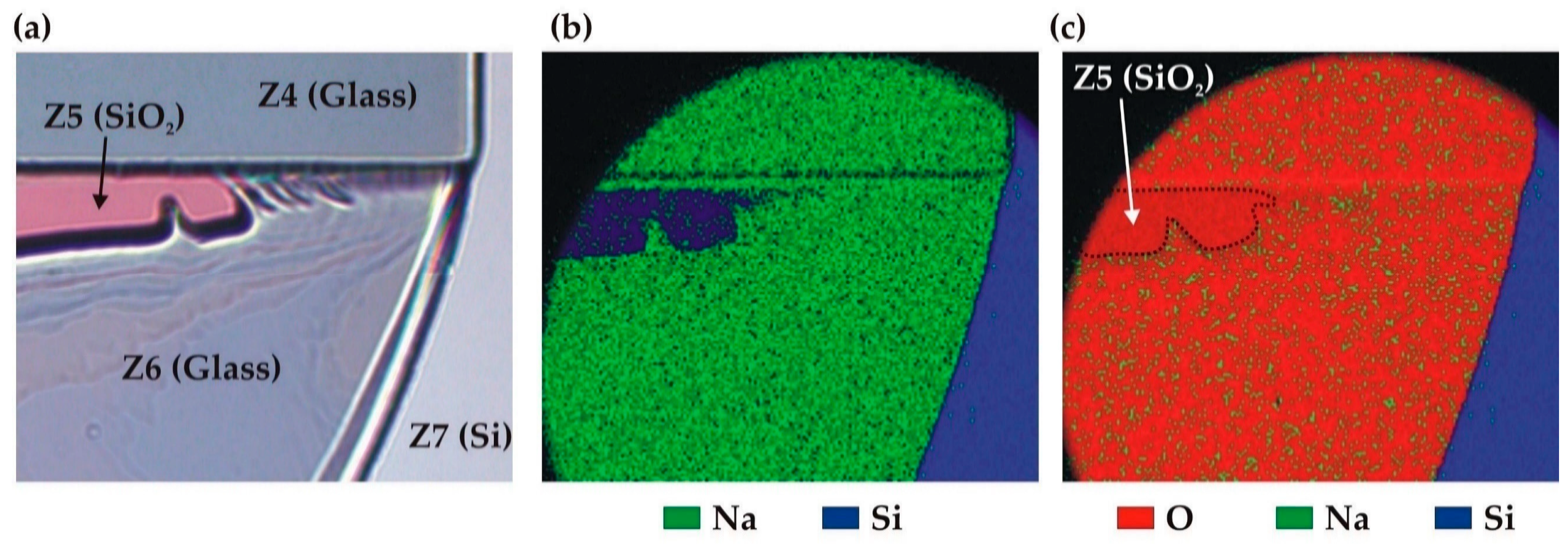

3.1.1. Thin-Film BF33 Glass Characterization

3.1.2. Bonding Process

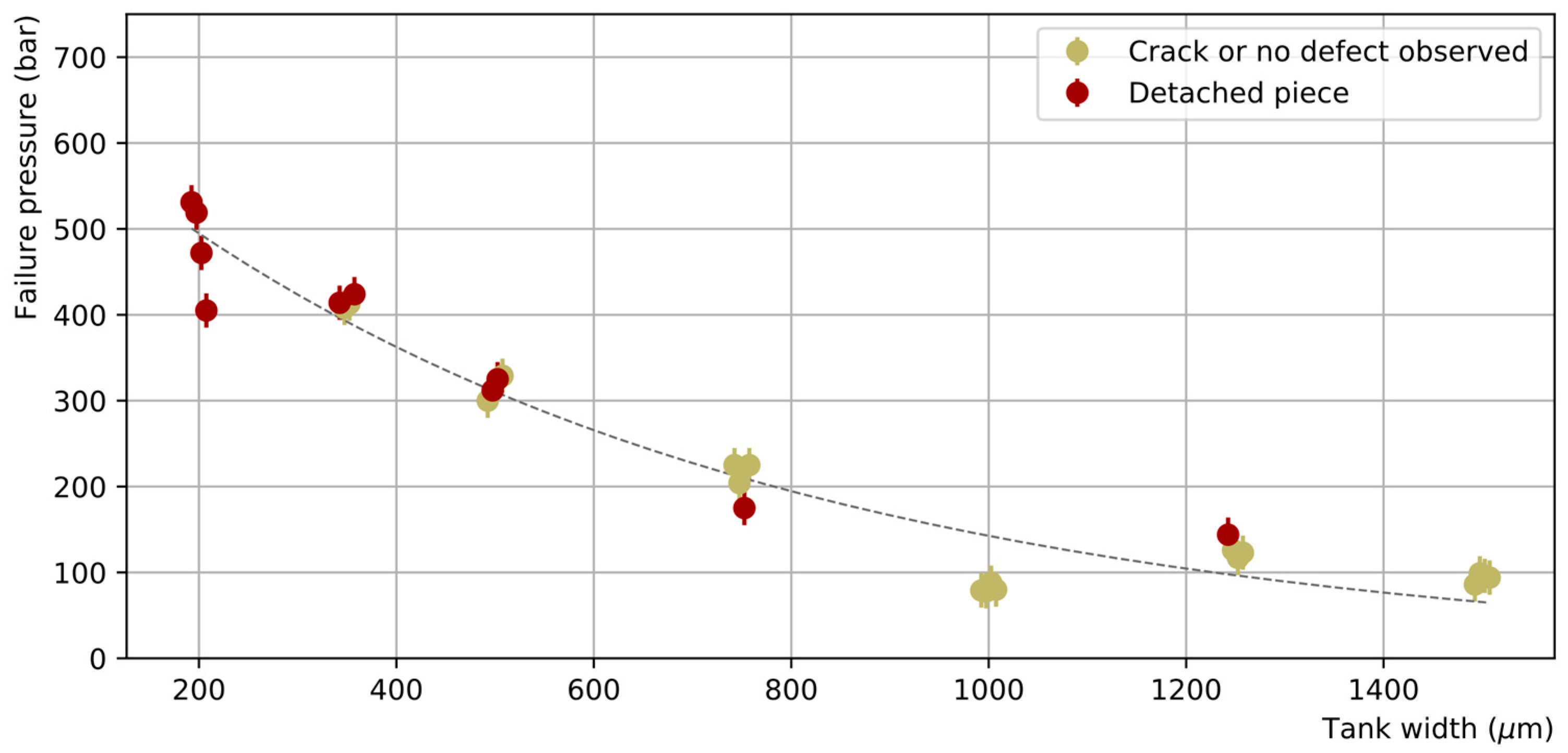

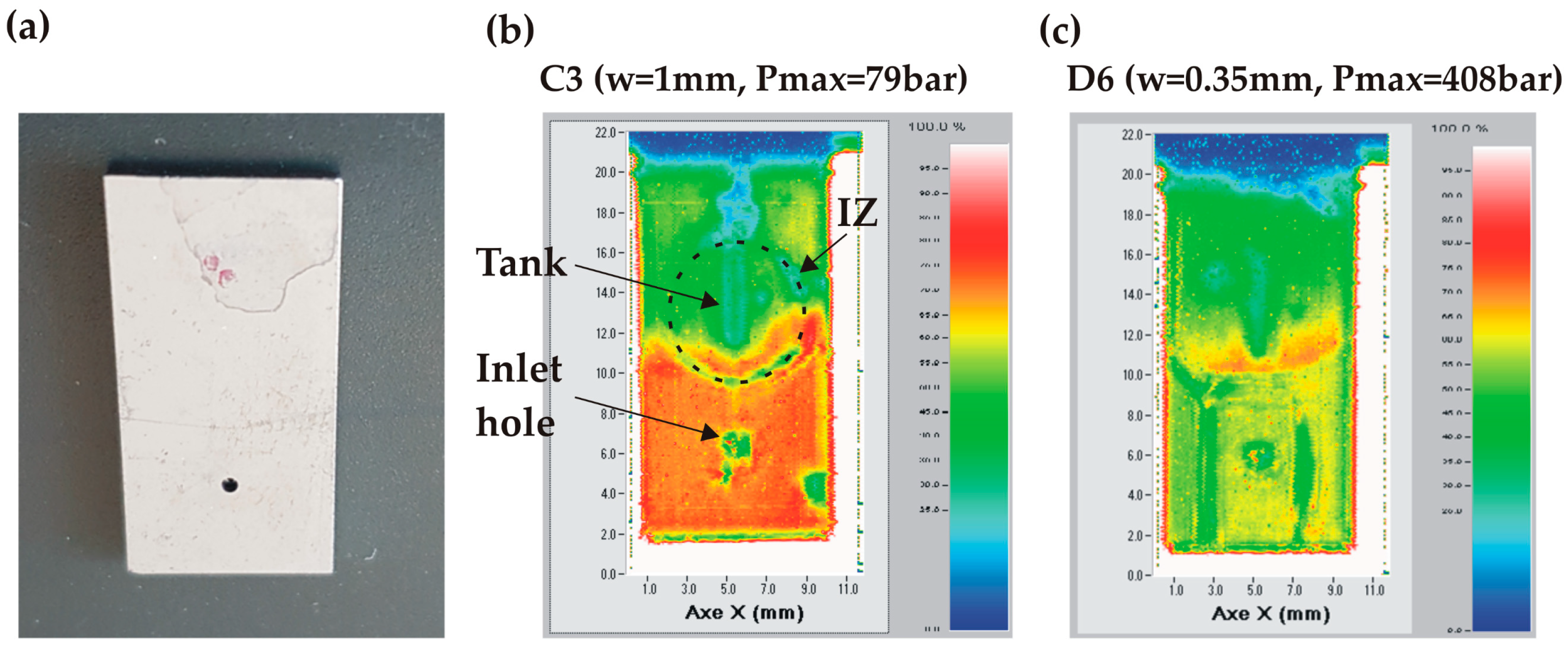

3.1.3. Pressure Resistance Tests

3.1.4. Post-Pressure Test Analysis

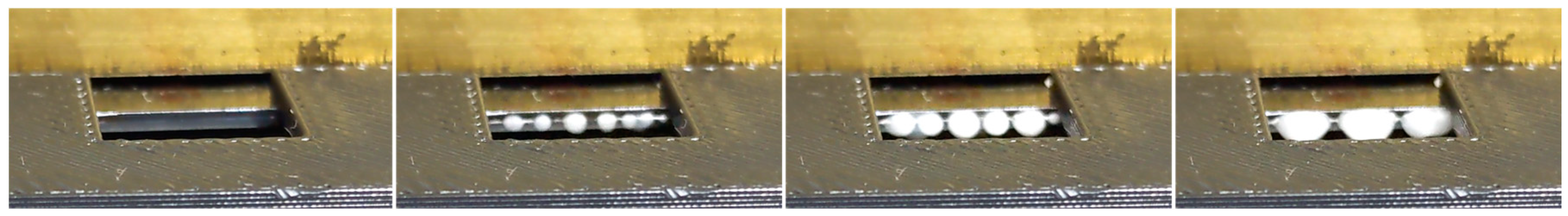

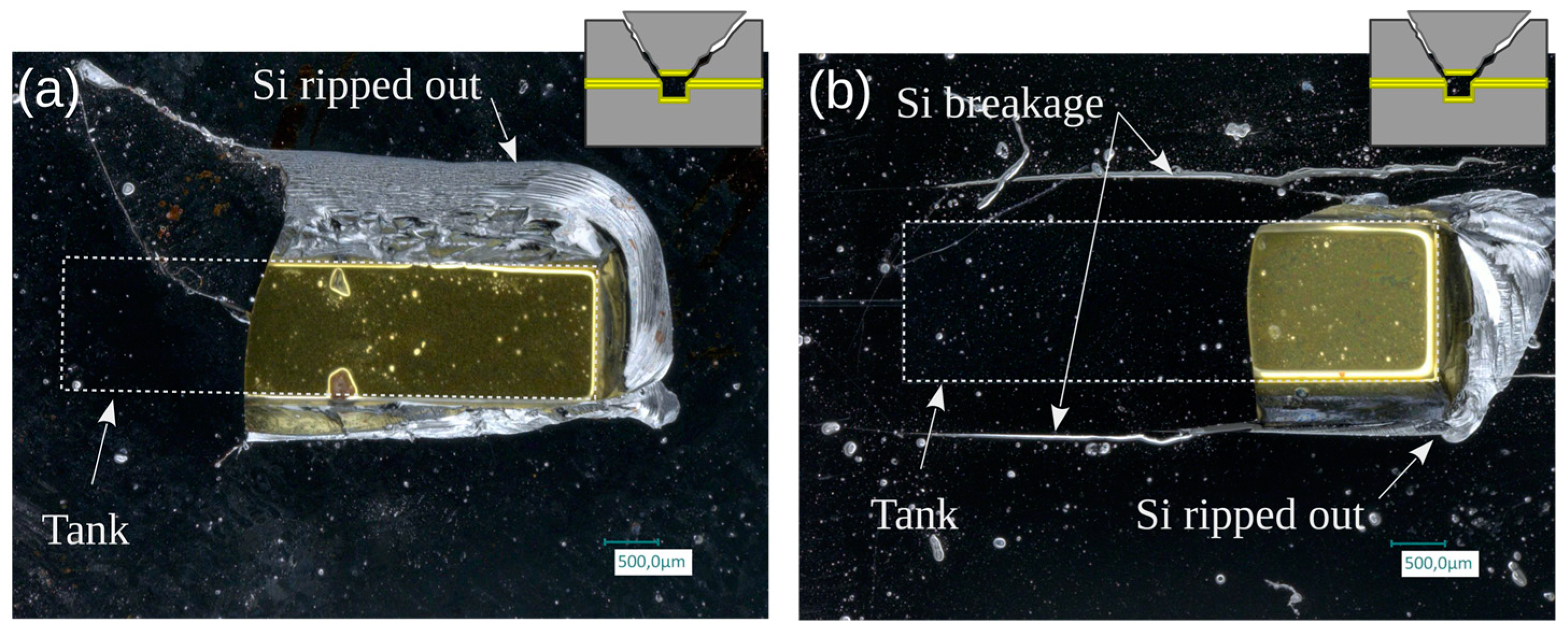

First Failure Type: Detached Piece

Second Failure Type: Leak at the Interface

3.2. Thermocompression Bonding Results

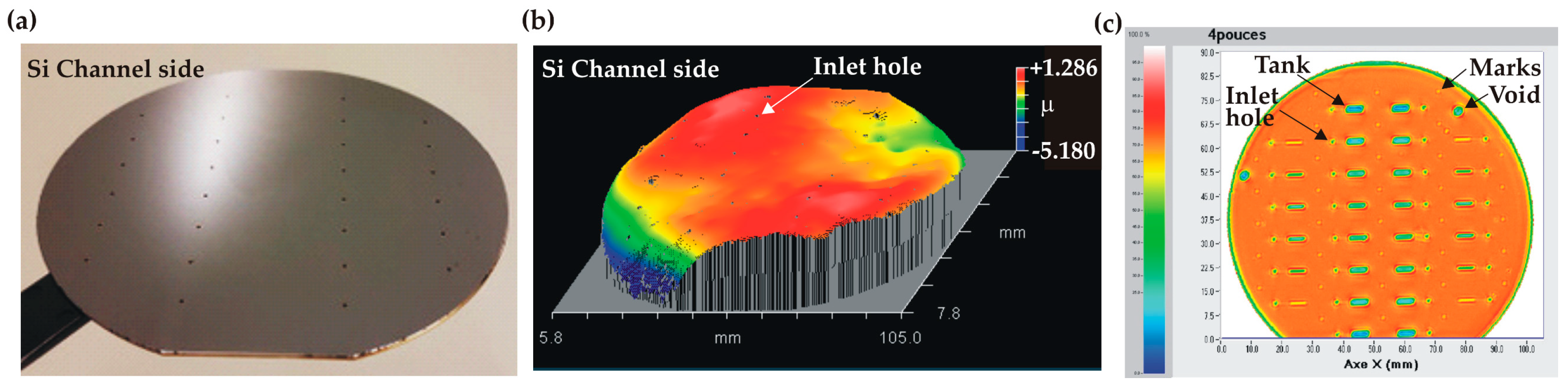

3.2.1. Bonding Process

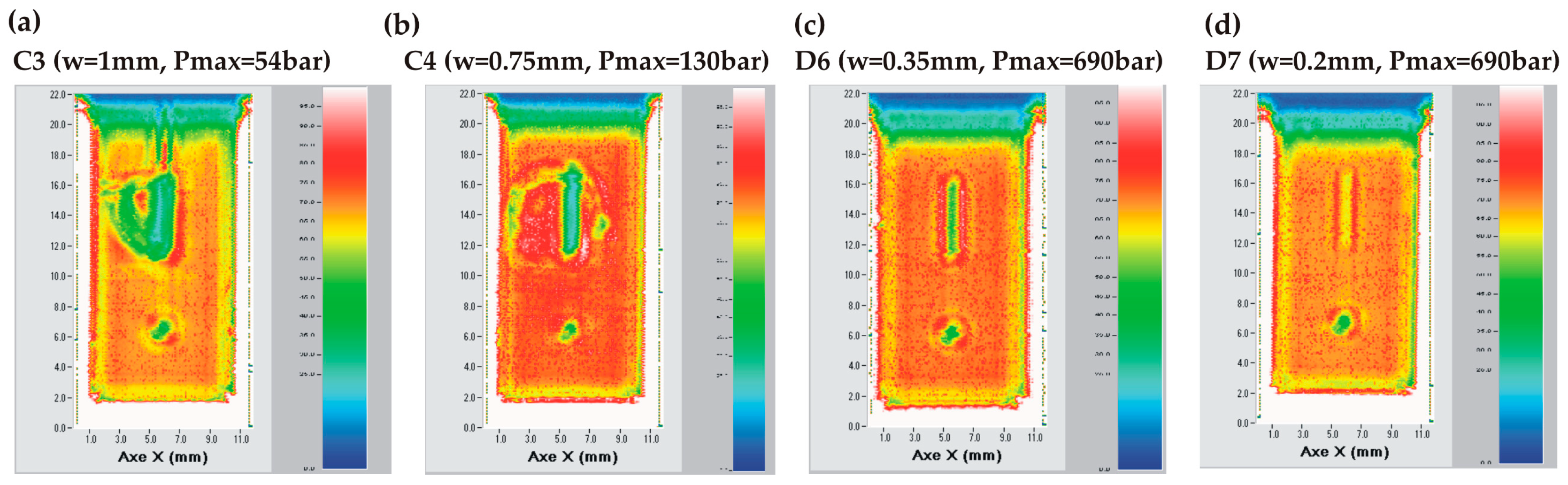

3.2.2. Pressure Resistance Tests

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Erp, R.; Soleimanzadeh, R.; Nela, L.; Kampitsis, G.; Matioli, E. Co-Designing Electronics with Microfluidics for More Sustainable Cooling. Nature 2020, 585, 211–216. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.-Y.; Vafai, K. Comparative Analysis of Jet Impingement and Microchannel Cooling for High Heat Flux Applications. Int. J. Heat Mass Transf. 1999, 42, 1555–1568. [Google Scholar] [CrossRef]

- Tuckerman, D.B.; Pease, R.F.W. High-Performance Heat Sinking for VLSI. IEEE Electron Device Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Kandlikar, S.G. History, Advances, and Challenges in Liquid Flow and Flow Boiling Heat Transfer in Microchannels: A Critical Review. In Proceedings of the 2010 14th International Heat Transfer Conference, Washington, DC, USA, 8–13 August 2010; Volume 8. [Google Scholar] [CrossRef][Green Version]

- Moriyama, K.; Inoue, A.; Ohira, H. The Thermohydraulic Characteristics of Two-Phase Flow in Extremely Narrow Channels: The Frictional Pressure Drop and Void Fraction of Adiabatic Two-Component Two-Phase Flow. Heat Transf.—Jpn. Res. 1993, 21, 823–837. [Google Scholar] [CrossRef][Green Version]

- Rinella, G.A.; Feito, D.A.; Arcidiacono, R.; Biino, C.; Bonacini, S.; Ceccucci, A.; Chiozzi, S.; Gil, E.C.; Ramusino, A.C.; Danielsson, H.; et al. The NA62 GigaTracKer: A Low Mass High Intensity Beam 4D Tracker with 65 Ps Time Resolution on Tracks. J. Instrum. 2019, 14, P07010. [Google Scholar] [CrossRef]

- De Aguiar Francisco, O.A.; Byczynski, W.; Akiba, K.; Bertella, C.; Bitadze, A.; Brock, M.; Bulat, B.; Button, G.; Buytaert, J.; De Capua, S.; et al. Microchannel Cooling for the LHCb VELO Upgrade I. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2022, 1039, 166874. [Google Scholar] [CrossRef]

- ECFA Detector R&D Roadmap Process Group. The 2021 ECFA Detector Research and Development Roadmap; CERN: Geneva, Switzerland, 2020. [Google Scholar] [CrossRef]

- Gösele, U.; Bluhm, Y.; Kästner, G.; Kopperschmidt, P.; Kräuter, G.; Scholz, R.; Schumacher, A.; Senz, S.; Tong, Q.-Y.; Huang, L.-J.; et al. Fundamental Issues in Wafer Bonding. J. Vac. Sci. Technol. A Vac. Surf. Film. 1999, 17, 1145–1152. [Google Scholar] [CrossRef]

- Brooks, A.D.; Donovan, R.P.; Hardesty, C.A. Low-Temperature Electrostatic Silicon-to-Silicon Seals Using Sputtered Borosilicate Glass. J. Electrochem. Soc. 1972, 119, 545. [Google Scholar] [CrossRef]

- Hanneborg, A.; Nese, M.; Ohlckers, P. Silicon-to-Silicon Anodic Bonding with a Borosilicate Glass Layer. J. Micromech. Microeng. 1991, 1, 139. [Google Scholar] [CrossRef]

- Leib, J.; Hansen, U.; Maus, S.; Feindt, H.; Hauck, K.; Zoschke, K.; Toepper, M. Anodic Bonding at Low Voltage Using Microstructured Borosilicate Glass Thin-Films. In Proceedings of the 3rd Electronics System Integration Technology Conference ESTC, Berlin, Germany, 13–16 September 2010. [Google Scholar] [CrossRef]

- Sassen, S.; Kupke, W.; Bauer, K. Anodic Bonding of Evaporated Glass Structured with Lift-off Technology for Hermetical Sealing. Sens. Actuators A Phys. 2000, 83, 150–155. [Google Scholar] [CrossRef]

- Conti, L.; Dumont-Fillon, D.; Lintel, H.; van Chappel, E. Silicon-to-Silicon Anodic Bonding via Intermediate Borosilicate Layer for Passive Flow Control Valves. Int. J. Mech. Ind. Aerosp. Sci. 2018, 12, 701–704. [Google Scholar] [CrossRef]

- Tsau, C.H.; Schmidt, M.A.; Spearing, S.M. Characterization of Low Temperature, Wafer-Level Gold-Gold Thermocompression Bonds. MRS Proc. 1999, 605, 171. [Google Scholar] [CrossRef]

- Goorsky, M.S.; Schjølberg-Henriksen, K.; Beekley, B.; Bai, T.; Mani, K.; Ambhore, P.; Bajwa, A.; Malik, N.; Iyer, S.S. Characterization of Interfacial Morphology of Low Temperature, Low Pressure Au-Au Thermocompression Bonding. Jpn. J. Appl. Phys. 2018, 57, 02BC03. [Google Scholar] [CrossRef]

- Charlot, S.; Pons, P.; Dilhan, M.; Vallet, I.; Brida, S. Hermetic Cavities Using Gold Wafer Level Thermocompression Bonding. In Proceedings of the Eurosensors 2017, Paris, France, 3–6 September 2017. [Google Scholar] [CrossRef]

- Blom, M.T.; Tas, N.R.; Pandraud, G.; Chmela, E.; Gardeniers, J.G.E.; Tijssen, R.; Elwenspoek, M.; van den Berg, A. Failure Mechanisms of Pressurized Microchannels: Model and Experiments. J. Microelectromechan. Syst. 2001, 10, 158–164. [Google Scholar] [CrossRef]

| Detector Name | Dimensions (cm²) | Total Plate Thickness (µm) | Refrigerant Type | Operating Pressure (bar) | Operating Temp. (°C) |

|---|---|---|---|---|---|

| NA62 GigaTracKer | 7 × 8 | 210 | Liquid C6F14 | 3 | [−10; 20] |

| Upgraded LHCb-VELO | 11.37 × 11.65 | 500 | Bi-phase CO2 | 14–57 | [−30; 20] |

| Tank width (µm) | 200 | 350 | 500 | 750 | 1000 | 1250 | 1500 |

| Detached piece | 4 | 2 | 2 | 1 | - | 1 | - |

| Leak at interface | - | 2 | 2 | 3 | 4 | 3 | 4 |

| Bonding Type | Tank Width | Min. Si Thickness | Max. Failure Pressure | Failure Type | Ref. |

|---|---|---|---|---|---|

| DB | 200 µm | 140 µm | >450 bar | No failure | [7] |

| AB | 200 µm | 430 µm | 530 bar | Interface | This work |

| TC | 200 µm | 430 µm | >690 bar | No failure | This work |

| DB | 500 µm | 140 µm | 280 bar | Si breakage | [7] |

| AB | 500 µm | 430 µm | 330 bar | Interface | This work |

| TC | 500 µm | 430 µm | >690 bar | No failure | This work |

| DB | 1250 µm | 140 µm | 80 bar | Si breakage | [7] |

| AB | 1250 µm | 430 µm | 125 bar | Interface | This work |

| TC | 1250 µm | 430 µm | 430 bar | Si breakage | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bargiel, S.; Cogan, J.; Queste, S.; Oliveri, S.; Gauthier-Manuel, L.; Raschetti, M.; Leroy, O.; Beurthey, S.; Perrin-Terrin, M. Comparison of Anodic and Au-Au Thermocompression Si-Wafer Bonding Methods for High-Pressure Microcooling Devices. Micromachines 2023, 14, 1297. https://doi.org/10.3390/mi14071297

Bargiel S, Cogan J, Queste S, Oliveri S, Gauthier-Manuel L, Raschetti M, Leroy O, Beurthey S, Perrin-Terrin M. Comparison of Anodic and Au-Au Thermocompression Si-Wafer Bonding Methods for High-Pressure Microcooling Devices. Micromachines. 2023; 14(7):1297. https://doi.org/10.3390/mi14071297

Chicago/Turabian StyleBargiel, Sylwester, Julien Cogan, Samuel Queste, Stefania Oliveri, Ludovic Gauthier-Manuel, Marina Raschetti, Olivier Leroy, Stéphan Beurthey, and Mathieu Perrin-Terrin. 2023. "Comparison of Anodic and Au-Au Thermocompression Si-Wafer Bonding Methods for High-Pressure Microcooling Devices" Micromachines 14, no. 7: 1297. https://doi.org/10.3390/mi14071297

APA StyleBargiel, S., Cogan, J., Queste, S., Oliveri, S., Gauthier-Manuel, L., Raschetti, M., Leroy, O., Beurthey, S., & Perrin-Terrin, M. (2023). Comparison of Anodic and Au-Au Thermocompression Si-Wafer Bonding Methods for High-Pressure Microcooling Devices. Micromachines, 14(7), 1297. https://doi.org/10.3390/mi14071297