Experimental Study on Shear Rheological Polishing of Si Surface of 4H-SiC Wafer

Abstract

1. Introduction

2. Materials and Methods

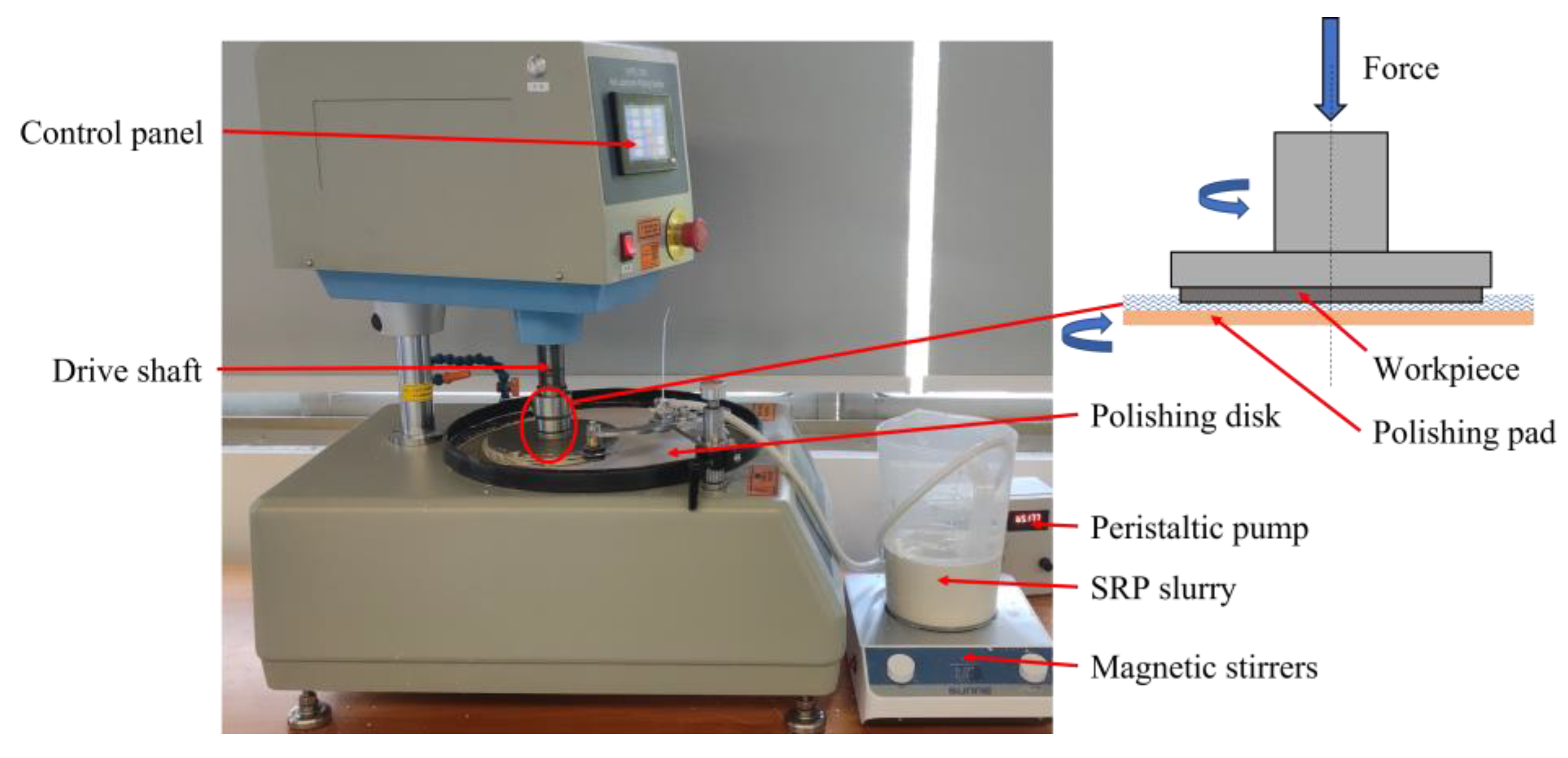

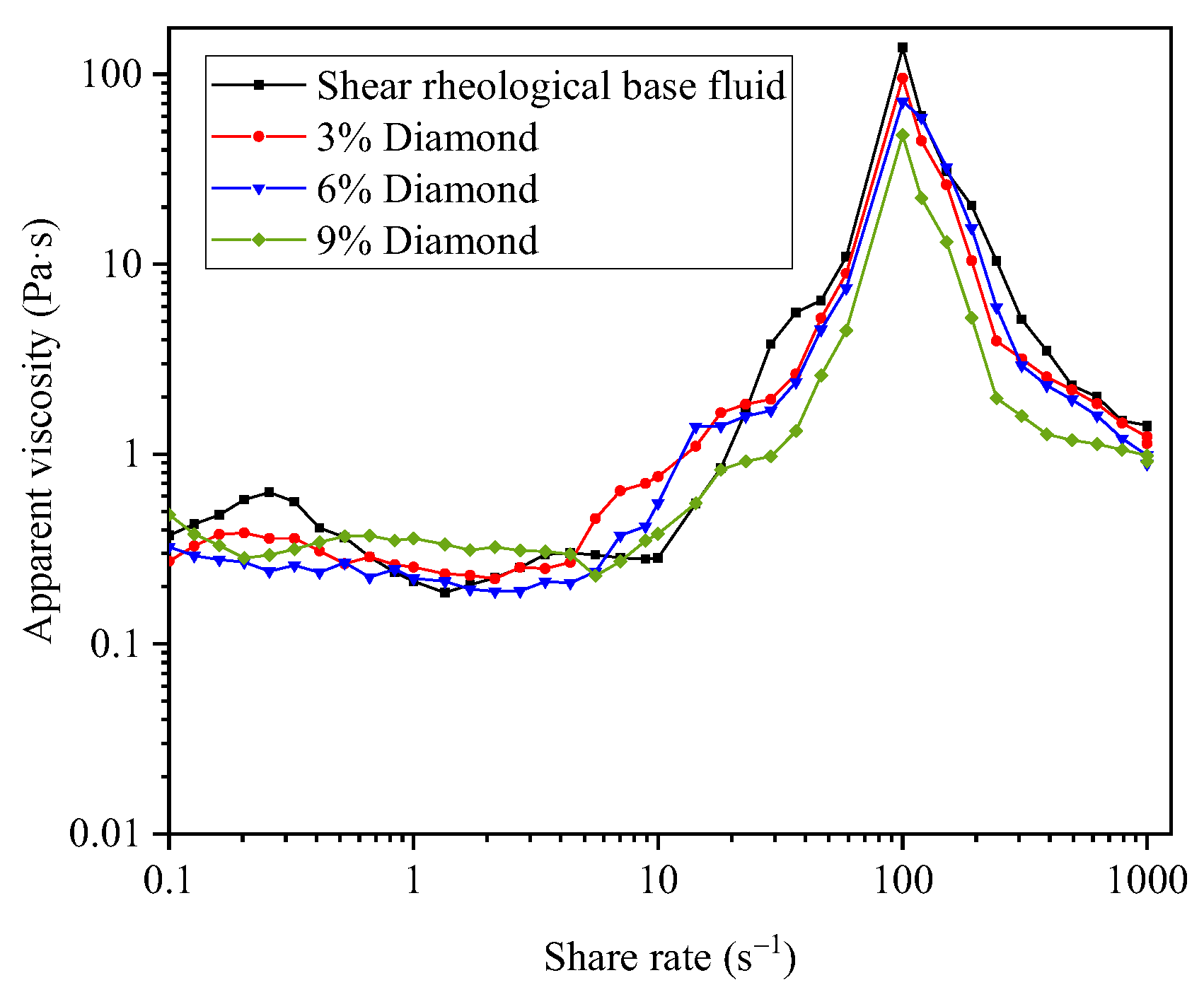

2.1. Principle of Shear Rheological Polishing of SiC Wafer

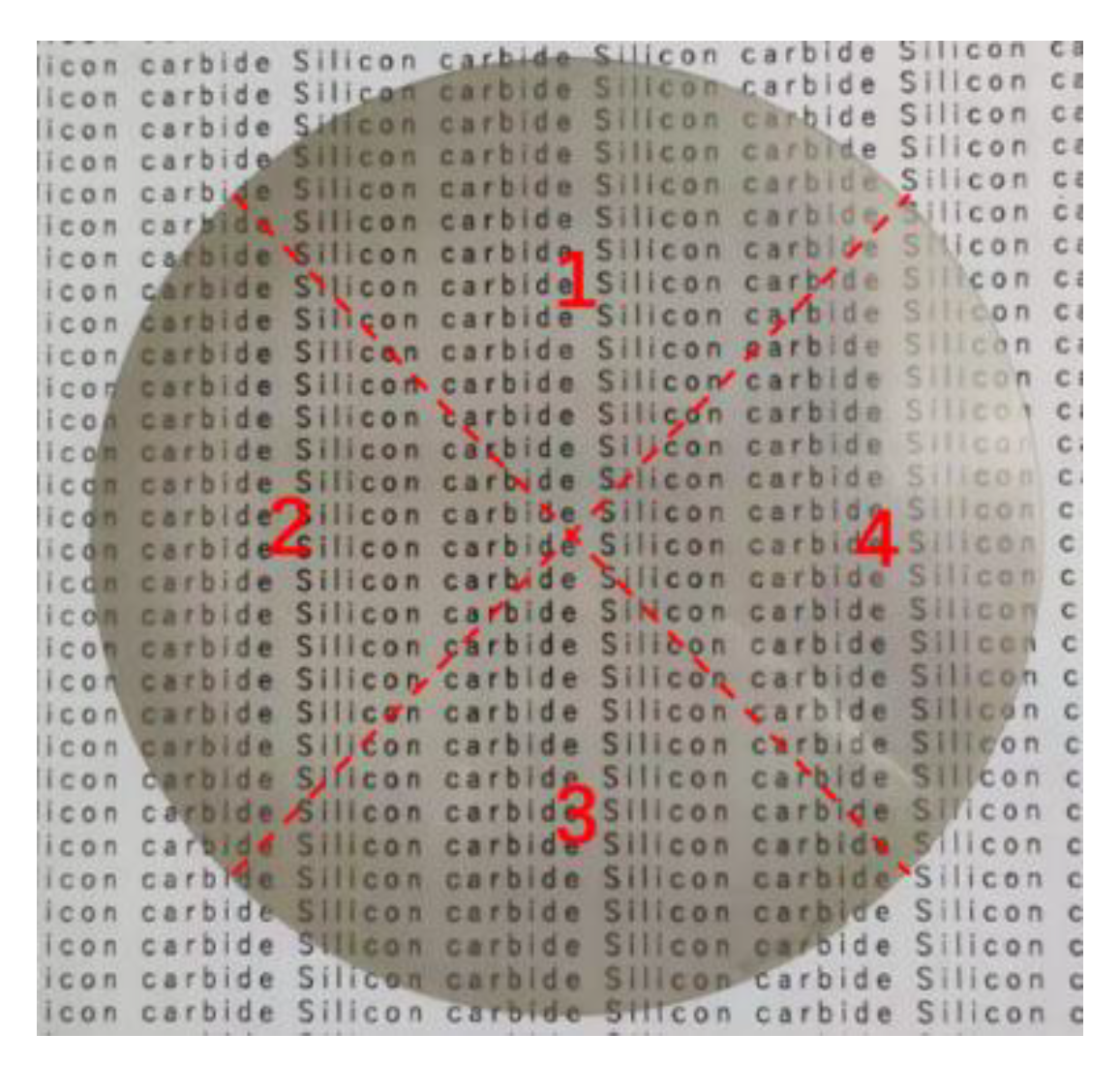

2.2. Experimental Process and Conditions

2.3. Experimental Design

3. Results and Discussion

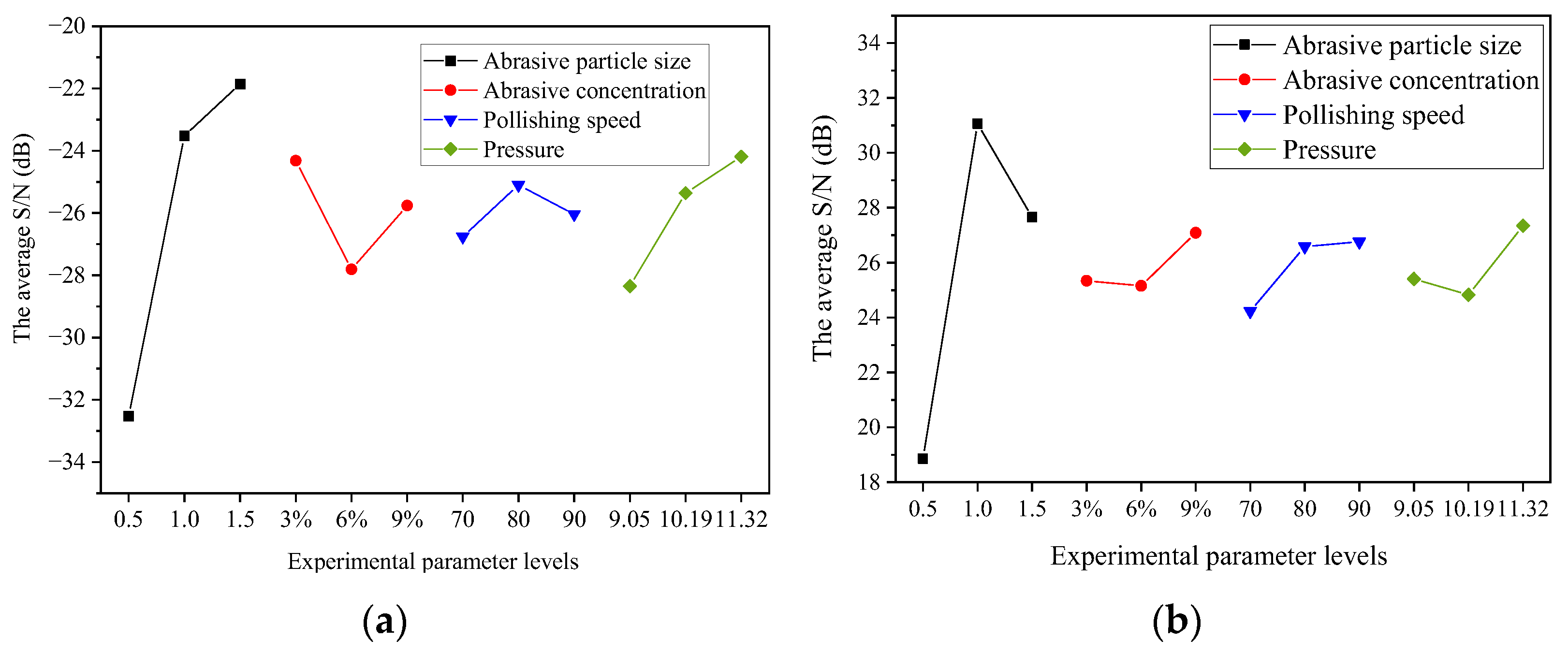

3.1. Analysis of Average Response of S/N

3.2. Effect of Abrasive Particle Size

3.3. Effect of Abrasive Particle Concentration

3.4. Effect of Polishing Speed

3.5. Effect of Polishing Pressure

3.6. Analysis of Variance

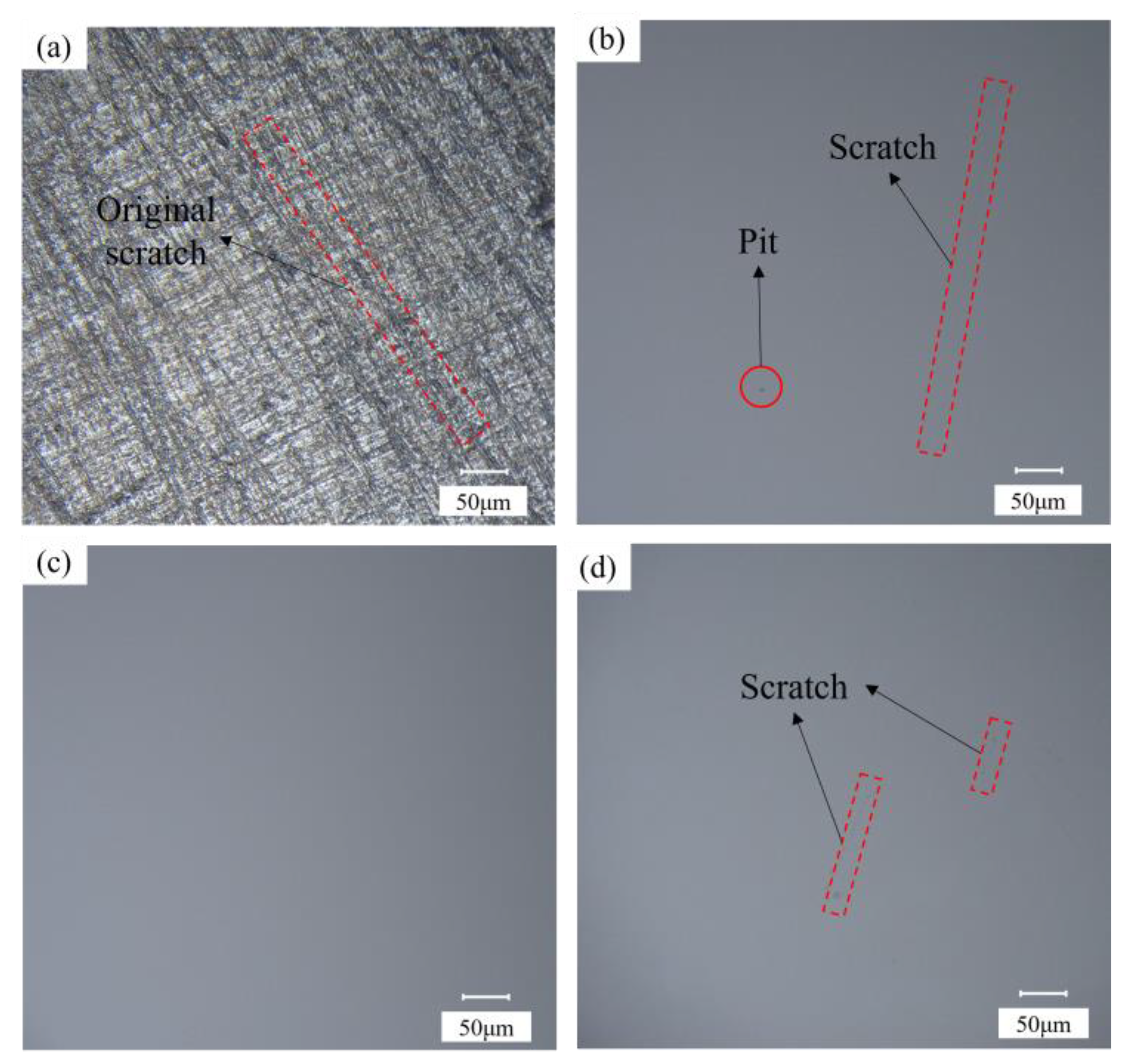

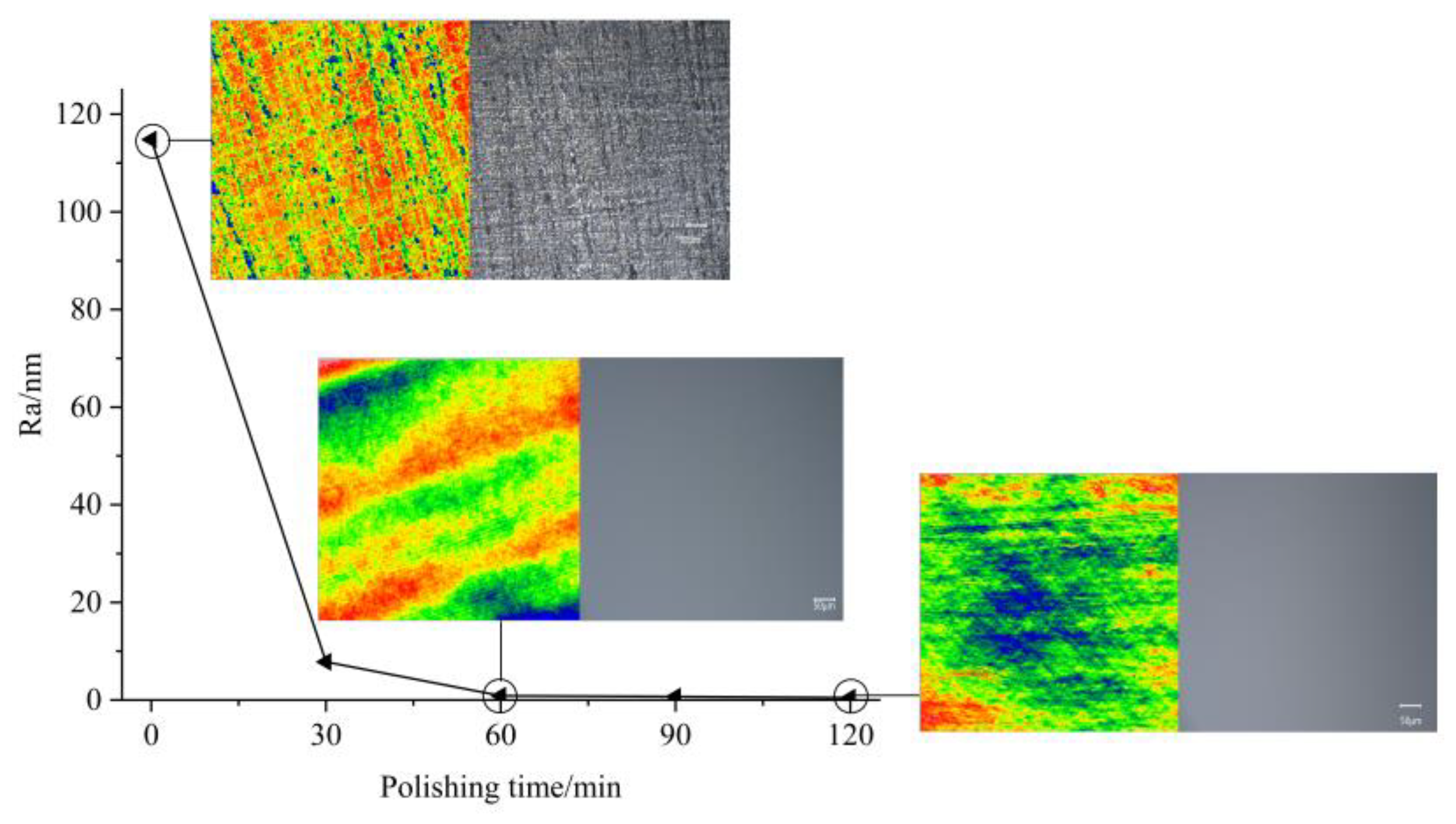

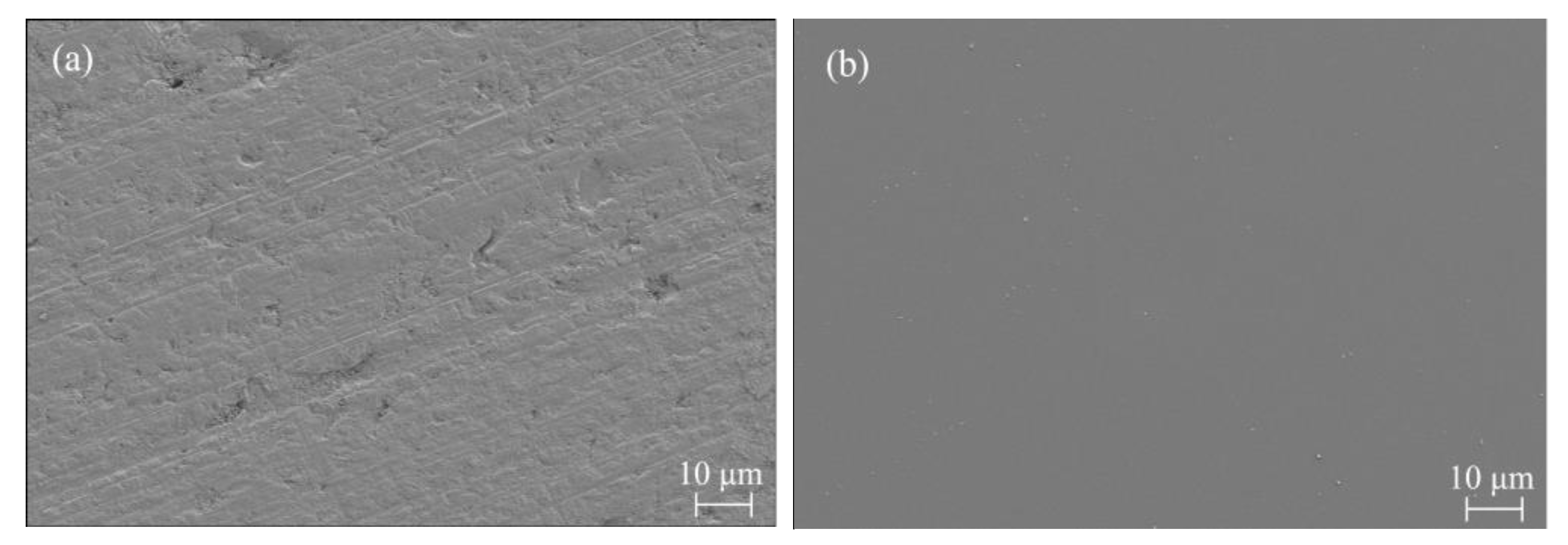

3.7. Verification Experiment on Shear Rheological Polishing of Si Surface of SiC Wafer

4. Conclusions

- Based on the ANOVA results, the wear particle size (85.98%) had the most significant influence on the surface roughness. This was followed by the polishing pressure (9.45%) and abrasive concentration (3.25%). The polishing speed had the least significant effect on surface roughness (1.32%);

- Through an average response analysis of the S/N, the optimal process parameters obtained by synthesizing the optimized process parameters (Ra and MRR) and recombining them were as follows. The particle size was 1.5 μm, the particle concentration was 3% (mass fraction), the polishing speed was 80 r/min, and the polishing pressure was 20 kg. After the Si polishing of the 4H-SiC wafer for 60 min using this set of parameters, the surface roughness Ra decreased from 114.8 to 0.9 nm, with a change rate of 99.2%. After further polishing for 60 min, the ultrasmooth surface with a surface roughness Ra of 0.5 nm and an MRR of 20.83 nm/min was obtained;

- The shear rheological polishing method can effectively remove scratches on the Si surface of 4H-SiC wafers and improve the Si surface quality of 4H-SiC wafers. This study provides a new method for polishing the Si surface of 4H-SiC wafers with high efficiency and quality.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kassakian, J.G.; Jahns, T.M. Evolving and Emerging Applications of Power Electronics in Systems. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 47–58. [Google Scholar] [CrossRef]

- Wyk, J.D.; Lee, F.C. On a Future for Power Electronics. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 59–72. [Google Scholar]

- Xie, X.Z.; Peng, Q.F.; Chen, G.P.; Li, J.; Long, J.; Pan, G. Femtosecond Laser Modification of Silicon Carbide Substrates and Its Influence on CMP Process. Ceram. Int. 2021, 47, 13322–13330. [Google Scholar] [CrossRef]

- Cong, P.; Young, D.J. Single Crystal 6H-SiC MEMS Fabrication based on Smart-Cut Technique. J. Micromech. Macroing. 2005, 15, 2243–2248. [Google Scholar] [CrossRef]

- Doi, T.K.; Seshimo, K.; Yamazaki, T.; Ohtsubo, M.; Ichikawa, D.; Miyashita, T.; Takagi, M.; Saeki, T.; Aida, H. Smart Polishing of Hard-to-Machine Materials with an Innovative Dilatancy Pad under High-Pressure, High-Speed, Immersed Condition. ECS J. Solid State Sci. Technol. 2016, 5, 598–607. [Google Scholar] [CrossRef]

- Huang, Y.G.; Tang, F.; Guo, Z.; Wang, X. Accelerated ICP Etching of 6H-SiC by Femtosecond Laser Modification. Appl. Surf. Sci. 2019, 488, 853–864. [Google Scholar] [CrossRef]

- Wang, W.T.; Zhang, B.G.; Shi, Y.H.; Ma, T.; Zhou, J.; Wang, R.; Wang, H.; Zeng, N. Improvement in Chemical Mechanical Polishing of 4H-SiC Wafer by Activating Persulfate through the Synergistic Effect of UV and TiO2. J. Mater. Process. Technol. 2021, 295, 117150. [Google Scholar] [CrossRef]

- Chen, G.M.; Ni, Z.F.; Qian, S.H.; Liu, Y.; Du, C.; Zhou, L.; Xu, Y.; Zhao, Y. Influence of Different Crystallographic Planes on CMP Performance of SiC Wafer. J. Synth. Cryst. 2019, 48, 155–159. [Google Scholar]

- Wang, W.T.; Zhang, B.G.; Shi, Y.H. Improved Chemical Mechanical Polishing Performance in 4H-SiC Substrate by Combining Novel Mixed Abrasive Slurry and Photocatalytic Effect. Appl. Surf. Sci. 2022, 575, 151676. [Google Scholar] [CrossRef]

- Deng, J.Y.; Lu, J.B.; Yan, Q.S.; Pan, J. Enhancement Mechanism of Chemical Mechanical Polishing for Single-Crystal 6H-SiC based on Electro-Fenton Reaction. Diam. Relat. Mater. 2021, 111, 108147. [Google Scholar] [CrossRef]

- Pan, J.S.; Yan, Q.S.; Xu, X.P.; Tong, H.; Zhu, J.; Bai, Z. Cluster Magnetorheological Effect Plane Polishing on SiC Single Crystal Slice. China Mech. Eng. 2013, 24, 2495–2498. [Google Scholar]

- Yin, S.H.; Deng, Z.M.; Guo, Y.F.; Liu, J.; Huang, S.; Yin, J.; Lu, J.; Peng, B. Magnetorheological Polishing Using Large Polishing Tool excited by Electromagnetic Field for Silicon Carbide Wafer. Surf. Technol. 2020, 40, 309–315. [Google Scholar]

- Wang, L.; Wu, R.Z.; Niu, L.; An, Z.; Jin, Z. Study on Electrochemical Mechanical Polishing Process of Silicon Carbide Crystal. Diam. Abras. Eng. 2022, 42, 504–510. [Google Scholar]

- Ballarin, N.; Carraro, C.; Maboudian, R.; Magagnin, L. Electropolishing of N-Type 3C-polycrystalline Silicon Carbide. Electrochem. Commun. 2014, 40, 17–19. [Google Scholar] [CrossRef]

- Li, M.; Lyu, B.H.; Yuan, J.L.; Dong, C.; Dai, W. Shear-Thickening Polishing Method. Int. J. Mach. Tools Manuf. 2015, 94, 88–99. [Google Scholar] [CrossRef]

- Li, M.; Lyu, B.H.; Yuan, J.L.; Yao, W.; Zhou, F.; Zhong, M. Evolution and Equivalent Control Law of Surface Roughness in Shear-Thickening Polishing. Int. J. Mach. Tools Manuf. 2016, 108, 113–126. [Google Scholar] [CrossRef]

- Shao, Q.; Duan, S.X.; Fu, L.; Lyu, B.; Zhao, P.; Yuan, J. Shear Thickening Polishing of Quartz Glass. Micromachines 2021, 12, 956. [Google Scholar] [CrossRef]

- Yang, J.R.; Lyu, B.H.; Fu, L.; Zhou, Y.; Yuan, J. Experimental Study on Shear Rheological Polishing of Large Size Cylindrical Roller. Bearing 2023, 1–7. Available online: http://kns.cnki.net/kcms/detail/41.1148.TH.20220718.2049.005.html (accessed on 19 July 2022).

- Duan, S.X.; Lyu, B.H.; Deng, Q.F. The Effect of Abrasive Type on the Shear Thickening. Surf. Technol. 2022, 51, 337–346. [Google Scholar]

- Shao, Q.; Lyu, B.H.; Yuan, J.L.; Wang, X.; Ke, M.; Zhao, P. Shear Thickening Polishing of the Concave Surface of High-Temperature Nickel-Based Alloy Turbine Blade. J. Mater. Res. Technol. 2021, 11, 72–84. [Google Scholar] [CrossRef]

- Ke, M.F.; Lyu, B.H.; Shao, L.Y.; Shao, Q.; Zhou, Y.; Wang, J.; Yuan, J. Experimental Study on Shearing Thickening Polishing of Rake Surface of Cemented Carbide Inserts. Surf. Technol. 2022, 51, 220–228. [Google Scholar]

- Peters, I.R.; Majumdar, S.; Jaeger, H.M. Direct Observation of Dynamic Shear Jamming in Dense Suspensions. Nature 2016, 532, 214–217. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.P.; Pham, V.D.; Ngo, N.V. Application of TOPSIS to Taguchi Method for Multi-Characteristic Optimization of Electrical Discharge Machining with Titanium Powder Mixed into Dielectric Fluid. Int. J. Adv. Manuf. Technol. 2018, 98, 1179–1198. [Google Scholar] [CrossRef]

- Dai, W.T.; Lyu, B.H.; Weng, H.Z.; Shao, Q. Optimization Experiment of Acoustic Assisted Shear Thickening Polishing of Cylindrical Surface. Surf. Technol. 2016, 45, 188–193. [Google Scholar]

- Weng, H.Z.; Lyu, B.H.; Hu, G.X.; Shao, Q.; Dai, W. Optimization Experiments for Shear Thickening Polishing of Quartz Substrates. Nanotechnol. Precis. Eng. 2017, 15, 227–233. [Google Scholar]

- Shao, Q.; Shao, L.Y.; Lyu, B.H.; Zhao, P.; Wang, J.; Yuan, J. Parameter Optimization by Taguchi Method for Shear Thickening Polishing Process of Quartz Glass. Surf. Technol. 2021, 50, 85–93. [Google Scholar]

| Parameter | Value |

|---|---|

| Crystal type | 4H |

| SiC content (%) | 99.9 |

| Density (g/cm3) | 3.12 |

| Mohs hardness | 9.2 |

| Poisson ratio | 0.18 |

| Parameter | Value |

|---|---|

| Workpiece speed (r·min−1) | 20 |

| Polishing speed (r·min−1) | 70, 80, 90 |

| Pressure (kPa) | 9.05, 10.19, 11.32 |

| Concentration (wt%) of diamond particles | 3, 6, 9 |

| Size of diamond particles (μm) | 0.5, 1, 1.5 |

| Experimental observation interval (min) | 30 |

| Polishing fluid flow rate (ml·min−1) | 12 |

| i | Combination | Abrasive Particle Size (A) (μm) | Abrasive Concentration (B) (wt%) | Polishing Speed (C) (r·min−1) | Pressure (D) (kPa) |

|---|---|---|---|---|---|

| 1 | A1B1C1D1 | 0.5 | 3 | 70 | 9.05 |

| 2 | A1B2C2D2 | 0.5 | 6 | 80 | 10.19 |

| 3 | A1B3C3D3 | 0.5 | 9 | 90 | 11.32 |

| 4 | A2B1C2D3 | 1.0 | 3 | 80 | 11.32 |

| 5 | A2B2C3D1 | 1.0 | 6 | 90 | 9.05 |

| 6 | A2B3C1D2 | 1.0 | 9 | 70 | 10.19 |

| 7 | A3B1C3D2 | 1.5 | 3 | 90 | 10.19 |

| 8 | A3B2C1D3 | 1.5 | 6 | 70 | 11.32 |

| 9 | A3B3C2D1 | 1.5 | 9 | 80 | 9.05 |

| i | Surface Roughness, Ra (nm) | S/N (dB) | ||||||

|---|---|---|---|---|---|---|---|---|

| Point 1 | Point 2 | Point 3 | Point 4 | Average Mean | MRR nm/min | Ra | MRR | |

| 1 | 59.5 | 43.6 | 54.7 | 41.8 | 49.9 | 6.5 | −34.06 | 17.38 |

| 2 | 31.8 | 50.2 | 48.3 | 44.1 | 43.6 | 7.8 | −32.91 | 19.82 |

| 3 | 38.4 | 29.3 | 35.2 | 32.3 | 33.8 | 13.3 | −30.62 | 22.48 |

| 4 | 9.7 | 8.3 | 10.6 | 7.7 | 9.1 | 43.4 | −20.86 | 32.75 |

| 5 | 21.2 | 27.8 | 19.7 | 28.5 | 24.3 | 34.7 | −26.63 | 31.93 |

| 6 | 15.3 | 11.5 | 11.0 | 20.2 | 14.5 | 30.3 | −23.50 | 29.63 |

| 7 | 12.4 | 7.4 | 9.6 | 8.4 | 9.5 | 22.4 | −19.68 | 27.00 |

| 8 | 13.0 | 15.4 | 8.9 | 16.2 | 13.4 | 21.9 | −22.72 | 27.92 |

| 9 | 16.7 | 12.2 | 15.6 | 12.5 | 14.3 | 28.7 | −24.17 | 29.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Yuan, J.; Zhu, M.; Zhou, J.; Lyu, B. Experimental Study on Shear Rheological Polishing of Si Surface of 4H-SiC Wafer. Micromachines 2023, 14, 853. https://doi.org/10.3390/mi14040853

Li P, Yuan J, Zhu M, Zhou J, Lyu B. Experimental Study on Shear Rheological Polishing of Si Surface of 4H-SiC Wafer. Micromachines. 2023; 14(4):853. https://doi.org/10.3390/mi14040853

Chicago/Turabian StyleLi, Peng, Julong Yuan, Minghui Zhu, Jianxing Zhou, and Binghai Lyu. 2023. "Experimental Study on Shear Rheological Polishing of Si Surface of 4H-SiC Wafer" Micromachines 14, no. 4: 853. https://doi.org/10.3390/mi14040853

APA StyleLi, P., Yuan, J., Zhu, M., Zhou, J., & Lyu, B. (2023). Experimental Study on Shear Rheological Polishing of Si Surface of 4H-SiC Wafer. Micromachines, 14(4), 853. https://doi.org/10.3390/mi14040853