An Aluminum Electro-Thermally Actuated Micro-Tweezer: Manufacturing and Characterization

Abstract

1. Introduction

2. Materials and Methods

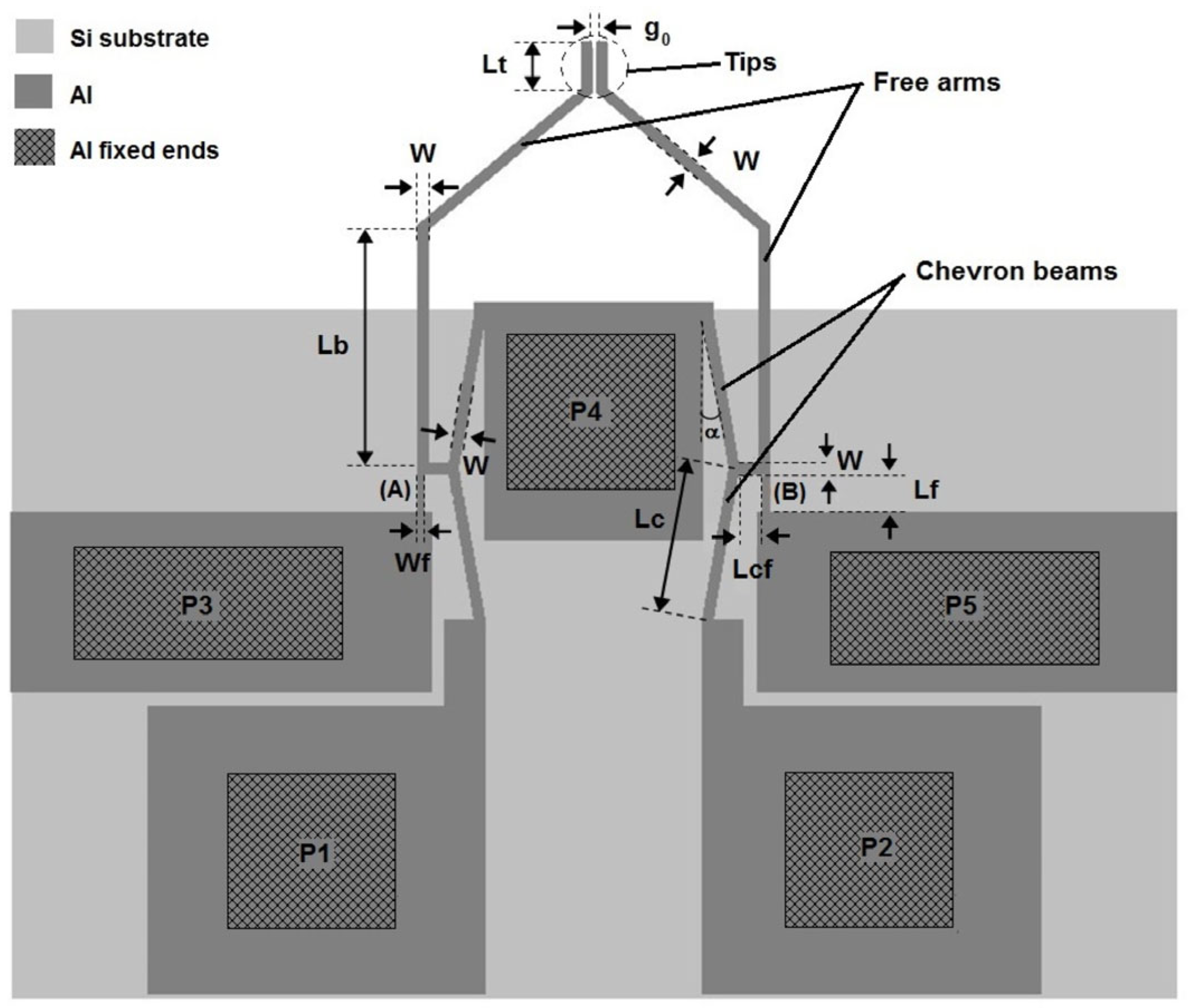

2.1. Micro-Tweezer Design

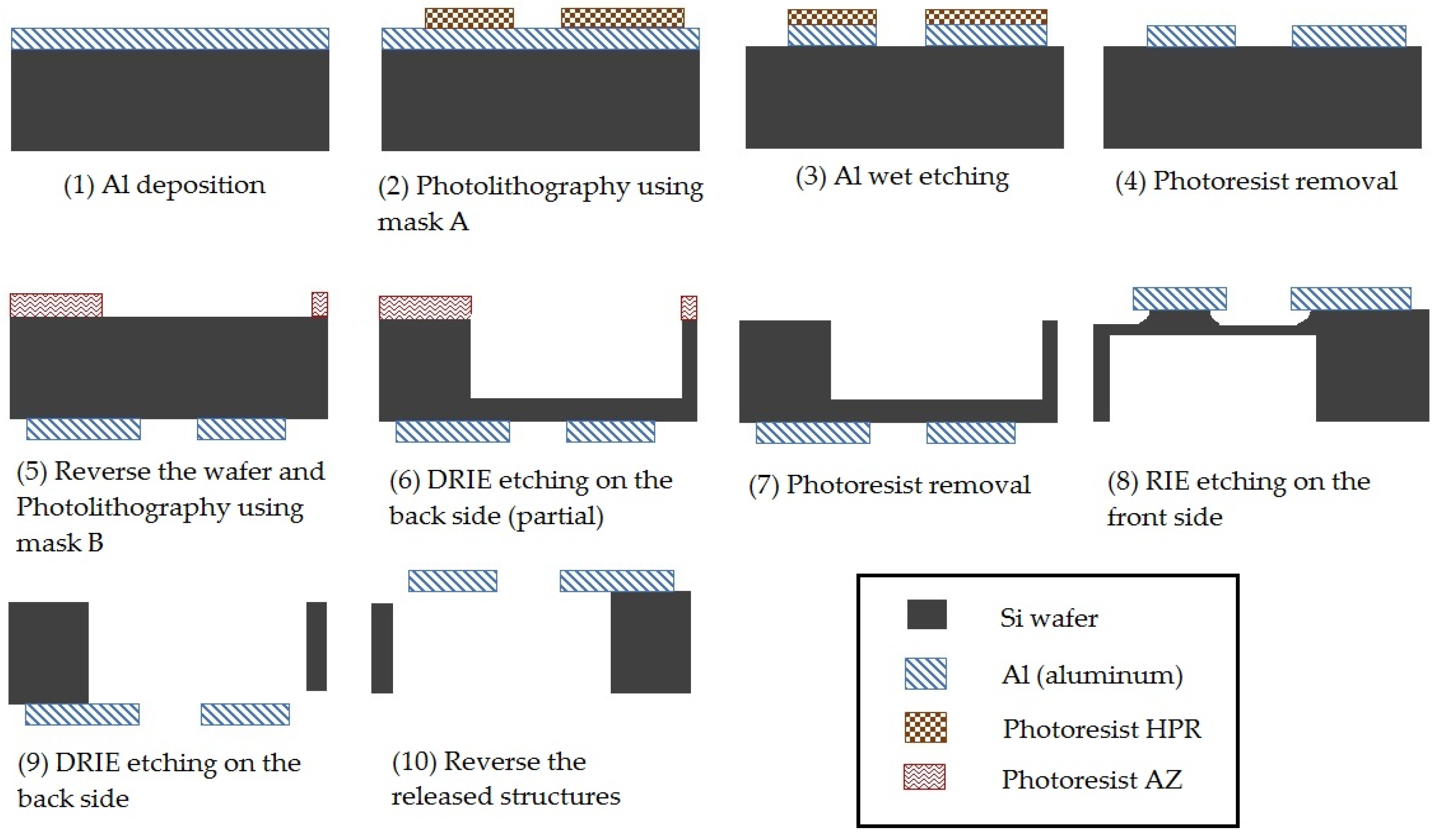

2.2. Materials and Fabrication

- (1)

- A layer of aluminum (Al) 2 µm thick is deposited by evaporation on a silicon (Si) <100> wafer in two steps, each a thickness of approximately 1 µm.

- (2)

- A first photolithography process using the first mask (mask A) is conducted with positive photoresist (HPR 402) on the wafer’s front side to shape the Al layer; HPR 402 was spin-coated on the Al layer at 3000 rpm to obtain a thickness of approximately 1.6 µm. A first thermal treatment was realized firstly, at 90 °C for 30 min and a second one, after exposure at 110 °C for 30 min.

- (3)

- The wet etching of Al is conducted from 4–5 min in a solution composed from CH3COOH, HNO3, and H3PO4.

- (4)

- The HPR photoresist is removed by acetone.

- (5)

- A second photolithography process using the second mask (mask B) is conducted with positive photoresist (AZ 4562) on the back side of the wafer; the AZ 4562 positive photoresist layer was spin-coated at 3000 rpm to obtain a thickness of around 6 µm; a first thermal treatment was realized at 90 °C for 30 min and a second one, after exposure at 125 °C for 30 min.

- (6)

- The dry etching (DRIE) of Si was performed on the back side of the wafer using SF6 gas in order to etch to a depth of around 450 µm.

- (7)

- The photoresist AZ is removed by acetone.

- (8)

- The dry etching–Reactive Ion Etching (RIE) of silicon was performed on the front side of the wafer using an RIE system (Sentech Instruments GmbH, Berlin, Germany) using SF6 gas in order to release the aluminum structures from the silicon substrate.

- (9)

- Another dry etching (DRIE) of Si was performed on the back side of the wafer using SF6 gas in order to completely release the chips with the released structures.

- (10)

- The chips with released structures were reversed with the back side down to test them.

3. Results

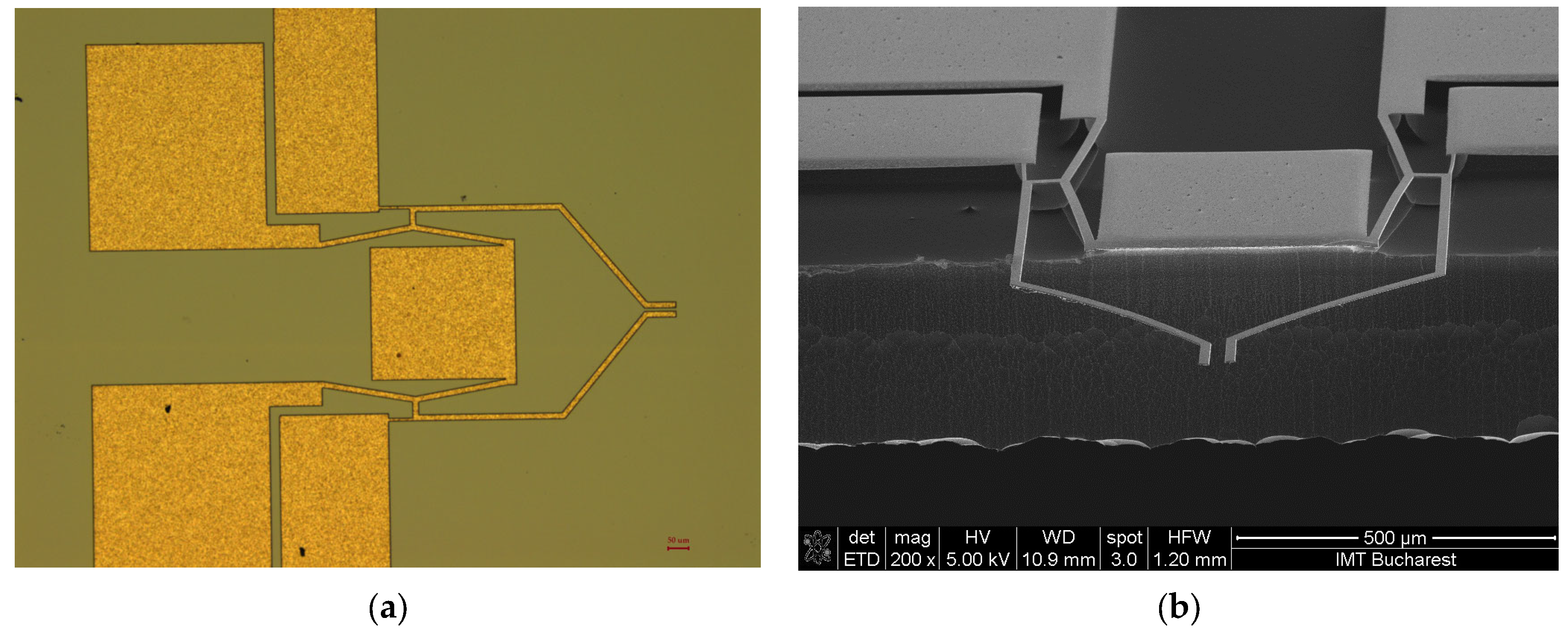

3.1. Dimensional Characterization of the Fabricated Micro-Tweezer

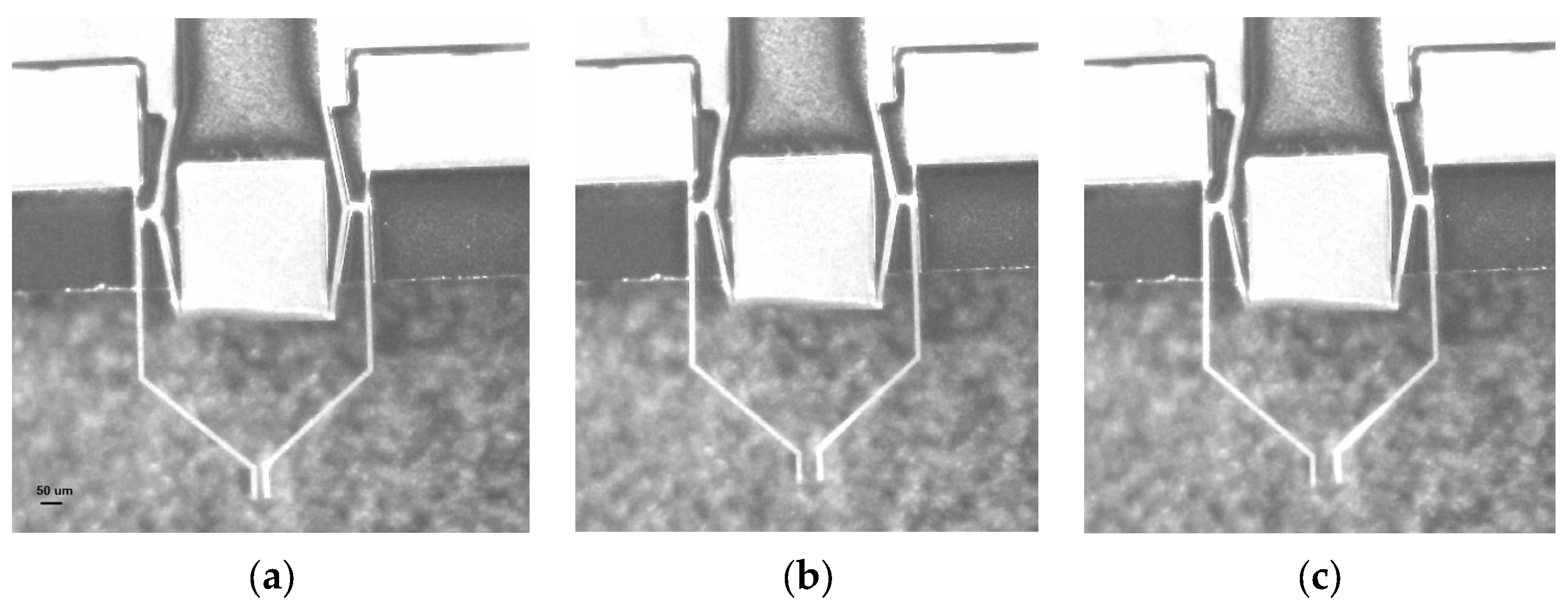

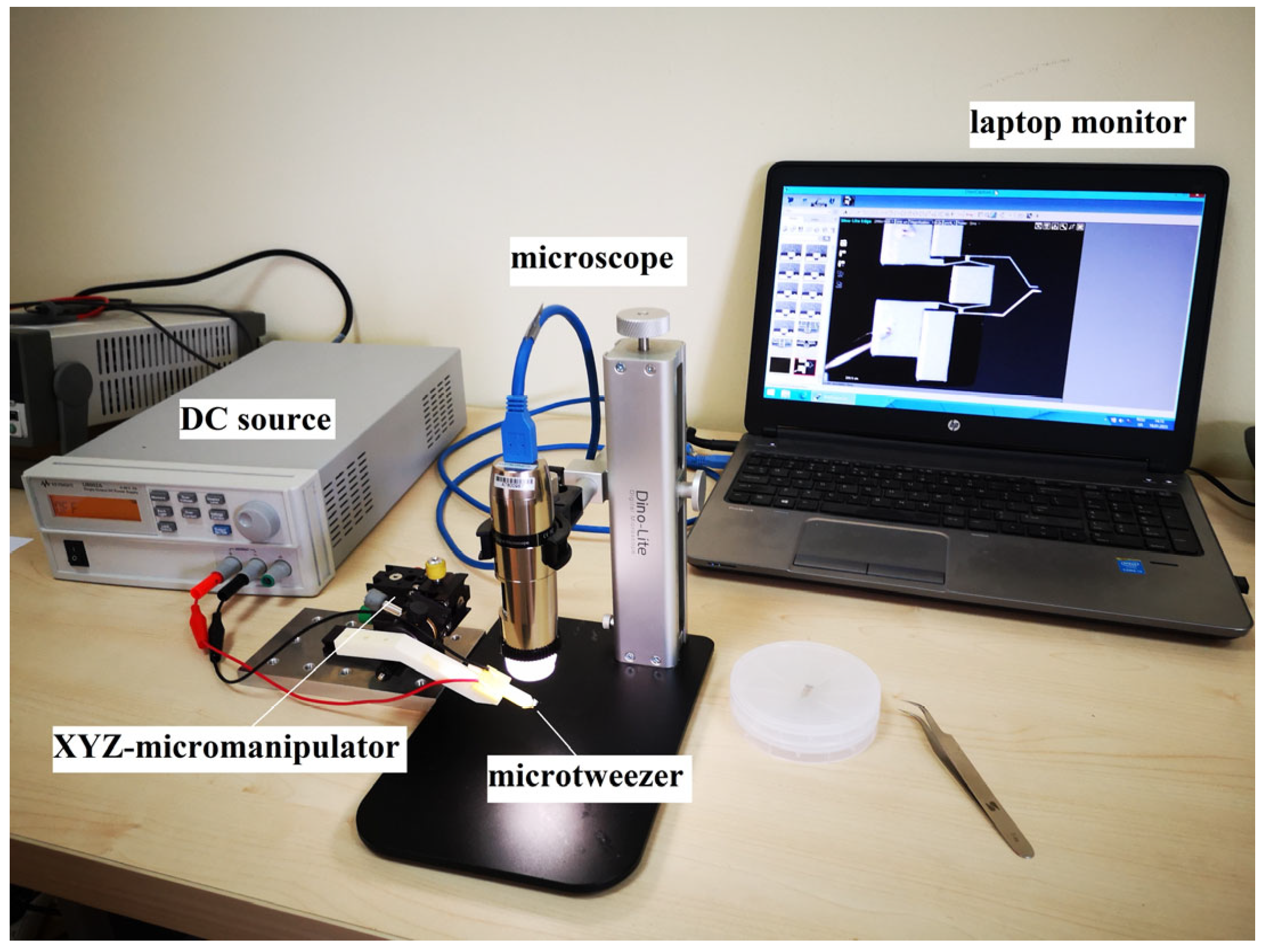

3.2. Actuation Tests of the Micro-Tweezer

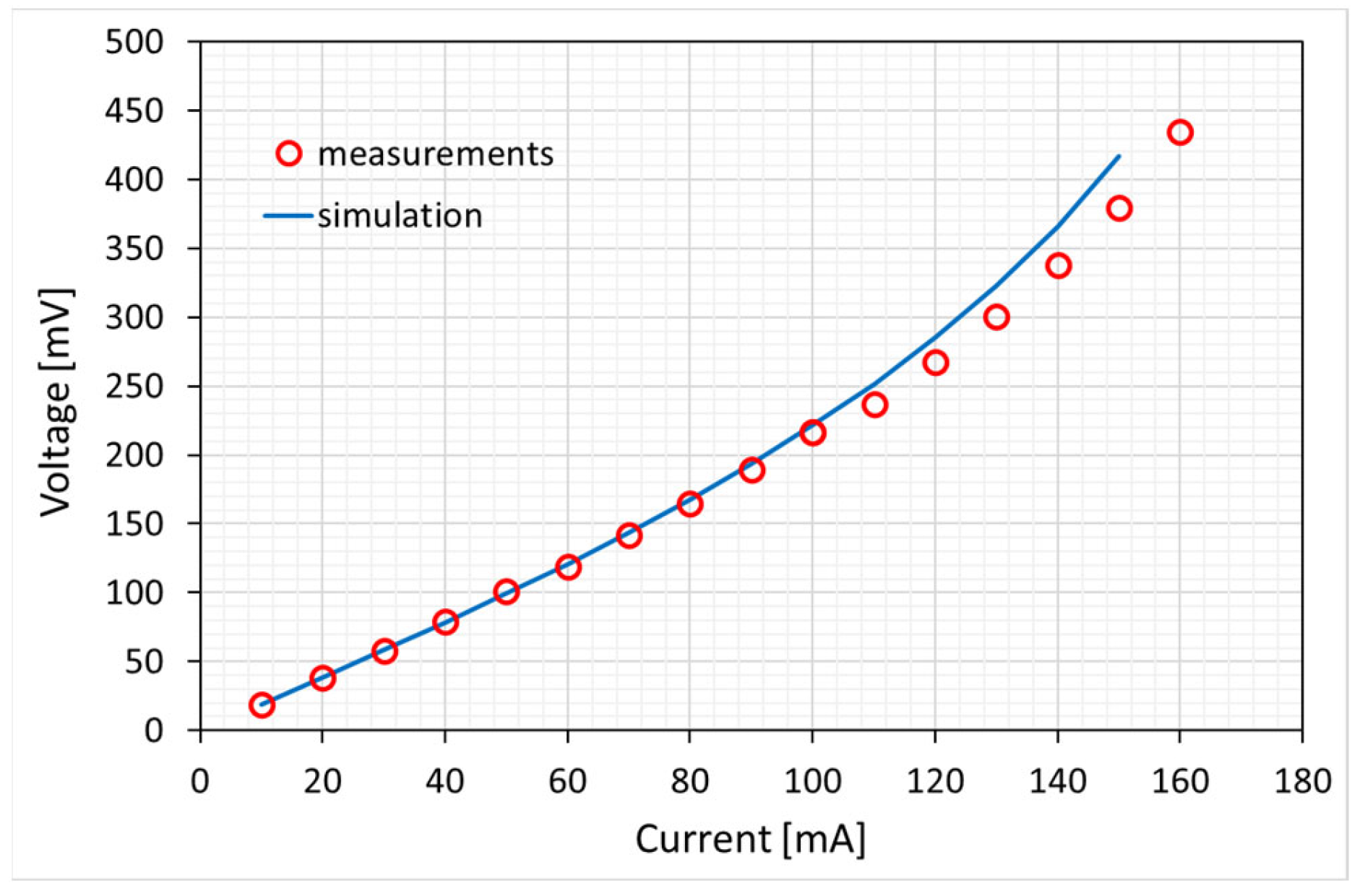

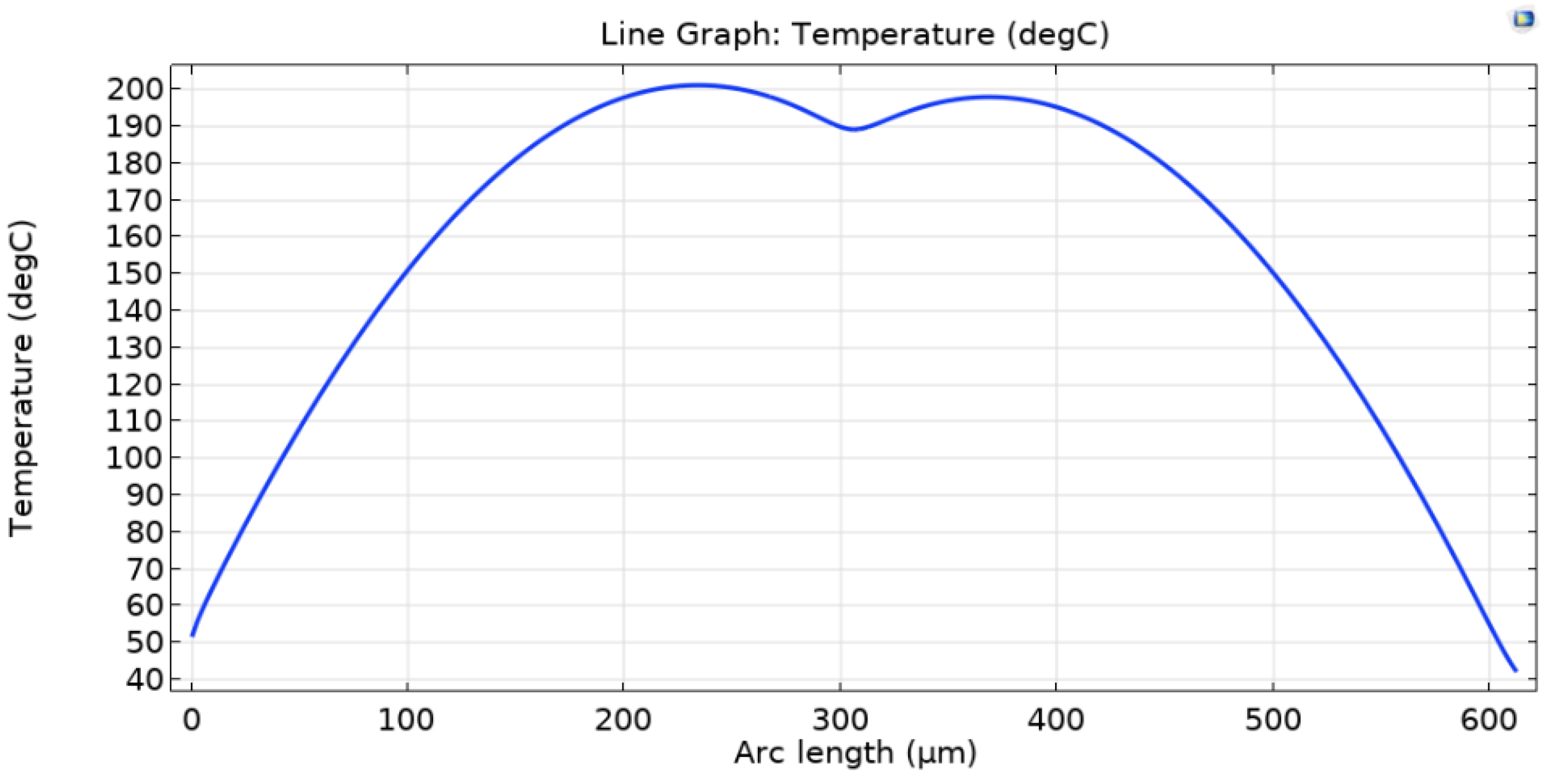

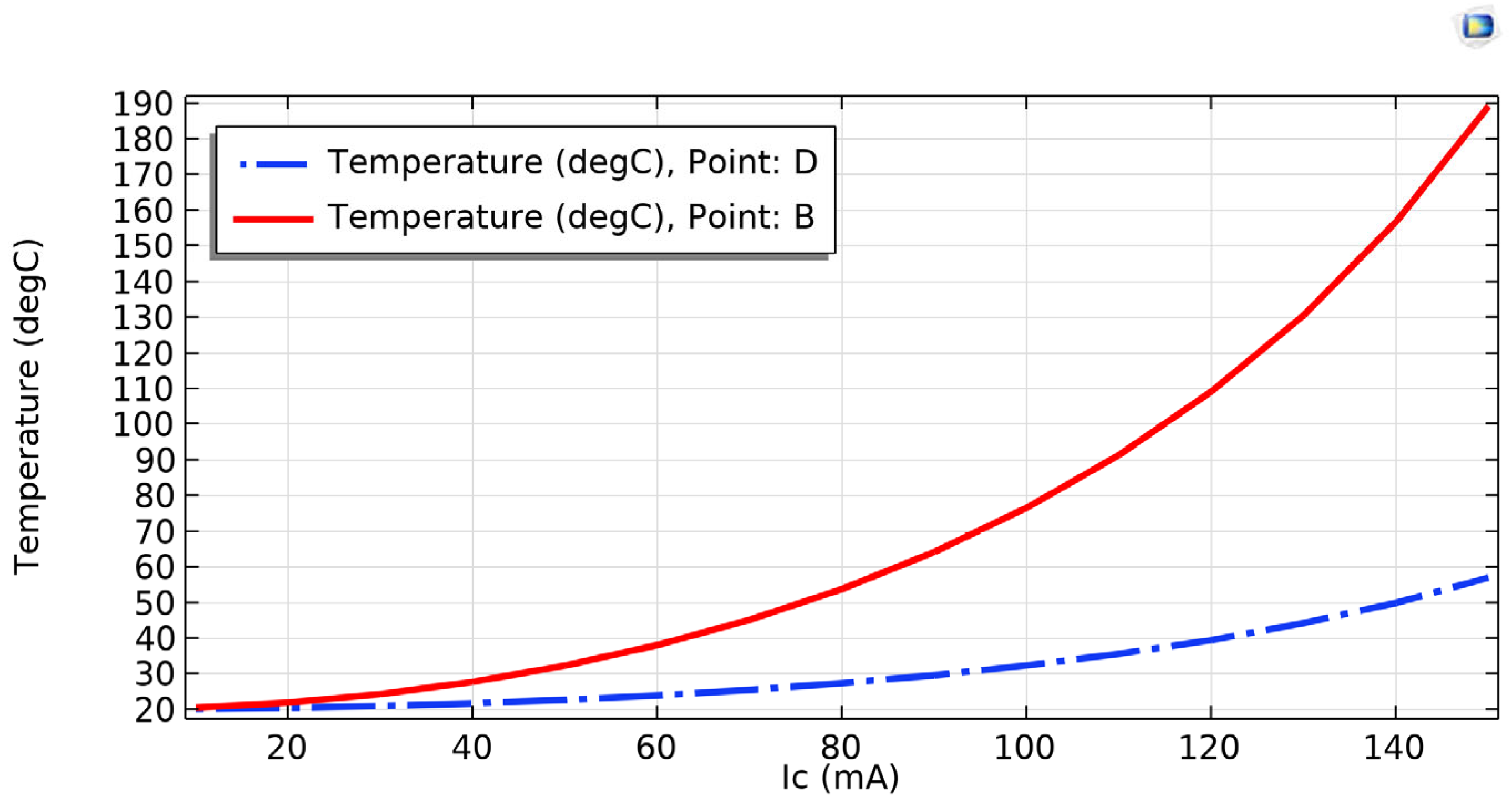

3.3. Characterization by FEM Simulations

- -

- for the mechanical problem, the bottom face of the silicon chip is considered fixed;

- -

- for the thermal problem, natural convection was set on the top faces of the silicon chip and aluminum structure, and fixed temperature (ambient at T0 = 20 °C) on the bottom face of the silicon, as well as on electrical contacts (C1 and C2) on pads P1 and P2, respectively;

- -

- for the electrical problem, the input current (Ic) on the electrical contact C1, and the output current (-Ic) on the electrical contact C2, were set. The C1 and C2 circular areas replicate the contacts of the electrical probes on the chip.

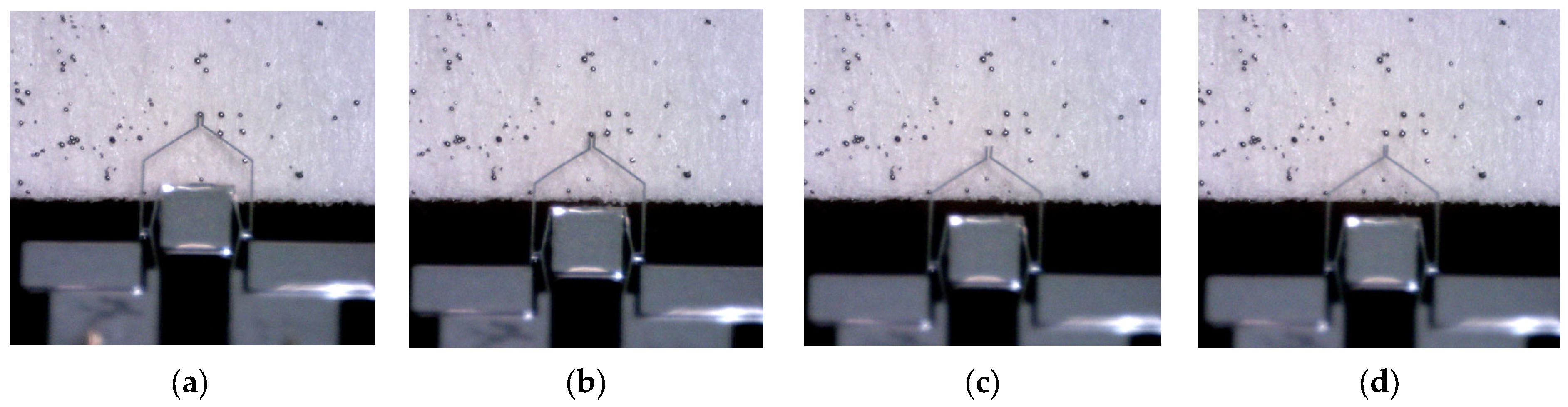

3.4. Functional Tests of the Micro-Tweezer

4. Discussion and Conclusions

- -

- The construction of the virtual 3D model neglected some features occurring in the fabrication, such as the etching profiles and non-uniformity of the deposition of the aluminum on the Si substrate.

- -

- It was not possible to measure all the aluminum properties, such as the coefficient of thermal expansion, resistivity temperature coefficient, or the residual stresses.

- -

- Displacement measurement errors given by the optical limitations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, S.; Xu, Q. A review on actuation and sensing techniques for MEMS-based microgrippers. J. Micro-Bio Robot. 2017, 13, 1–14. [Google Scholar] [CrossRef]

- Basu, J.; Bhattacharyya, T.K. Microelectromechanical system cantilever-based frequency doublers. J. Intell. Mater. Syst. Struct. 2013, 24, 240–246. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Liu, J.; Dai, C.; Sun, Y. Robotic micromanipulation: Fundamentals and applications. Annu. Rev. Control Robot. Auton. Syst. 2019, 2, 181–203. [Google Scholar] [CrossRef]

- Voicu, R.-C. An SU-8 Microgripper Based on the Cascaded V-Shaped Electrothermal Actuators: Design, Fabrication, Simulation and Experimental Investigations. In Actuators; Volosencu, C., Ed.; IntechOpen: London, UK, 2018; pp. 25–38. [Google Scholar] [CrossRef]

- Lyu, Z.; Xu, Q. Recent design and development of piezoelectric-actuated compliant microgrippers: A review. Sens. Actuator A Phys. 2021, 331, 113002. [Google Scholar] [CrossRef]

- Belfiore, N.P. Micromanipulation. In Actuators; MDPI: Basel, Switzerland, 2018; pp. 7–38. [Google Scholar] [CrossRef]

- Yukun, J.; Qingsong, X. MEMS Microgripper Actuators and Sensors: The State-of-the-Art Survey. Recent Pat. Mech. Eng. 2013, 6, 132–142. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, X.; Chen, X. Design, modelling, and characterization of a MEMS electrothermal microgripper. Microsyst. Technol. 2015, 21, 2307–2314. [Google Scholar] [CrossRef]

- Bazaz, S.A.; Khana, F.; Shakoor, R.I. Design, simulation and testing of electrostatic SOI MUMPs based microgripper integrated with capacitive contact sensor. Sens. Actuator A Phys. 2011, 167, 44–53. [Google Scholar] [CrossRef]

- Belfiore, N.P.; Bagolini, A.; Rossi, A.; Bocchetta, G.; Vurchio, F.; Crescenzi, R.; Scorza, A.; Bellutti, P.; Sciuto, S.A. Design, Fabrication, Testing and Simulation of a Rotary Double Comb Drives Actuated Microgripper. Micromachines 2021, 12, 1263. [Google Scholar] [CrossRef]

- Velosa-Moncada, L.A.; Aguilera-Cortés, L.A.; González-Palacios, M.A.; Raskin, J.P.; Herrera-May, A.L. Design of a novel MEMS microgripper with rotatory electrostatic comb-drive actuators for biomedical applications. Sensors 2018, 18, 1664. [Google Scholar] [CrossRef]

- Cauchi, M.; Grech, I.; Mallia, B.; Mollicone, P.; Sammut, N. The effects of cold arm width and metal deposition on the performance of a U-beam electrothermal MEMS microgripper for biomedical applications. Micromachines 2019, 10, 167. [Google Scholar] [CrossRef]

- Chronis, N.; Lee, L.P. Electrothermally activated SU-8 microgripper for single cell manipulation in solution. J. Microelectromech. Syst. 2005, 14, 857–863. [Google Scholar] [CrossRef]

- Zhang, R.; Chu, J.; Wang, H.; Chen, Z. A multipurpose electrothermal microgripper for biological micro-manipulation. Microsyst. Technol. 2012, 19, 89–97. [Google Scholar] [CrossRef]

- Solano, B.; Wood, D. Design and testing of a polymeric microgripper for cell manipulation. Microelectron. Eng. 2007, 84, 1219–1222. [Google Scholar] [CrossRef]

- Si, G.; Sun, L.; Zhang, Z.; Zhang, X. Theoretical Thermal Mechanical Modelling and Experimental Validation of a Three-Dimensional (3D) Electrothermal Microgripper with Three Fingers. Micromachines 2021, 12, 1512. [Google Scholar] [CrossRef]

- Tecpoyotl-Torres, M.; Vargas-Chable, P.; Escobedo-Alatorre, J.; Cisneros-Villalobos, L.; Sarabia-Vergara, J. Z-Shaped Electrothermal Microgripper Based on Novel Asymmetric Actuator. Micromachines 2022, 13, 1460. [Google Scholar] [CrossRef]

- Cauchi, M.; Grech, I.; Mallia, B.; Mollicone, P.; Sammut, N. Analytical, Numerical and Experimental Study of a Horizontal Electrothermal MEMS Microgripper for the Deformability Characterisation of Human Red Blood Cells. Micromachines 2018, 9, 108. [Google Scholar] [CrossRef]

- Akbari, M.; Barazandeh, F.; Barati, H. A novel approach to design and fabricate an electrothermal microgripper for cell manipulation. Sens. Actuator A Phys. 2022, 346, 113877. [Google Scholar] [CrossRef]

- Liang, C.; Wang, F.; Shi, B.; Huo, Z.; Zhou, K.; Tian, Y.; Zhang, D. Design and control of a novel asymmetrical piezolectric actuated microgripper for micromanipulation. Sens. Actuator A Phys. 2018, 269, 227–237. [Google Scholar] [CrossRef]

- Das, T.K.; Shirinzadeh, B.; Ghafarian, M.; Al-Jodah, A.; Zhong, Y.; Smith, J. Design, analysis and experimental investgations of a high precision flexure-based microgripper for micro/nano manipulation. Mechatronics 2020, 69, 102396. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, X.; Liu, Y.; Wang, G.; Hong, K. Design and Control of a Piezoelectric-Driven Microgripper Perceiving Displacement and Gripping Force. Micromachines 2020, 11, 121. [Google Scholar] [CrossRef]

- Salehi, M.; Hamedi, M.; Nohouji, H.S.; Arghavani, J. Mechanical properties identification and design optimization of nitinol shape memory alloy microactuators. Smart Mater. Struct. 2013, 23, 025001. [Google Scholar] [CrossRef]

- Kuo, J.C.; Huang, H.W.; Tung, S.W.; Yang, Y.J. A hydrogel-based intravascular microgripper manipulated using magnetic fields. Sens. Actuators A Phys. 2014, 211, 121–130. [Google Scholar] [CrossRef]

- Guckel, H.; Klein, J.; Christenson, T.; Skrobis, K.; Laudon, M.; Lovell, E.G. Thermo-magnetic metal flexure actuators. In Proceedings of the Technical Digest IEEE Solid-State Sensor and Actuator Workshop, Hilton Head, SC, USA, 22–25 June 1992; pp. 73–75. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, M.G.; Kim, B.; Sun, Y. A superelastic alloy microgripper with embedded electromagnetic actuators and piezoelectric force sensors: A numerical and experimental study. Smart Mater. Struct. 2005, 14, 1265–1272. [Google Scholar] [CrossRef]

- Ahmad, B.; Chambon, H.; Tissier, P.; Bolopion, A. Laser Actuated Microgripper Using Optimized Chevron-Shaped Actuator. Micromachines 2021, 12, 1487. [Google Scholar] [CrossRef] [PubMed]

- Pevec, S.; Donlagic, D. Optically controlled fiber-optic micro-gripper for sub-millimeter objects. Opt. Lett. 2019, 44, 2177–2180. [Google Scholar] [CrossRef]

- Gursky, B.; Bütefisch, S.; Leester-Schädel, M.; Li, K.; Matheis, B.; Dietzel, A. A disposable pneumatic microgripper for cell manipulation with image-based force sensing. Micromachines 2019, 10, 707. [Google Scholar] [CrossRef]

- Lockwood, A.J.; Padmanabhan, A.; Bunyan, R.J.T.; Inkson, B.J. Deformation behaviour of polysilicon components for MEMS. J. Micromech. Microeng. 2012, 22, 105016. [Google Scholar] [CrossRef]

- Lofroth, M.; Avci, E. Development of a Novel Modular Compliant Gripper for Manipulation of Micro Objects. Micromachines 2019, 10, 313. [Google Scholar] [CrossRef]

- Xiao, G.Q.; Gao, N.; Moktadir, Z.; Kraft, M.; Starink, M.J. Fabrication of MEMS components using ultra fine grained aluminium alloys. J. Micromech. Microeng. 2010, 20, 045029. [Google Scholar] [CrossRef]

- Baracu, A.; Voicu, R.; Müller, R.; Avram, A.; Pustan, M.; Chiorean, R.; Birleanu, C.; Dudescu, C. Design and fabrication of a MEMS chevron-type thermal actuator. AIP Conf. Proc. 2015, 1646, 25. [Google Scholar] [CrossRef]

- Aluminium: Specifications, Properties, Classifications and Classes, AZO Materials. 2005. Available online: https://www.azom.com/article.aspx?ArticleID=2863 (accessed on 23 November 2022).

- Quintana, P.; Oliva, A.I.; Ceh, O.; Corona, J.E. Thickness effects on aluminum thin films. Superf. Vacío 1999, 9, 280–282. Available online: https://www.fis.cinvestav.mx/~smcsyv/supyvac/9/sv928099.pdf (accessed on 14 December 2022).

- Voicu, R.-C.; Pustan, M.; Birleanu, C.; Gavrila, R.; Romanitan, C.; Tutunaru, O.; Cismaru, A. A study for an aluminum electro-thermally actuated U-shaped microtweezer. IOP Conf. Ser. Mater. Sci. Eng. 2020, 724, 012053. [Google Scholar] [CrossRef]

- Thangavel, A.; Rengaswamy, R.; Sukumar, P. Design and material analysis for prototyping of four arm mechanical microgripper with self-locking and anti-slipping capability. Microsyst. Technol. 2019, 25, 851–860. [Google Scholar] [CrossRef]

- Llewellyn-Evans, H.; Griffiths, C.A.; Fahmy, A.A. Design process and simulation testing of a shape memory alloy actuated robotic microgripper. Microsyst. Technol. 2020, 26, 885–900. [Google Scholar] [CrossRef]

- Ramya, S.; Kumar, S.P.; Aravind, T.; Srinivasan, T.K.; Ram, G.D.; Lingaraja, D. Thermal Inplane Microgripper for Handling Micro-Objects. In Proceedings of the 7th International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 22–24 June 2022; pp. 210–214. [Google Scholar] [CrossRef]

- Thangavel, A.; Rengaswamy, R.; Sukumar, P.K.; Sekar, R. Modelling of chevron electrothermal actuator and its performance analysis. Microsyst. Technol. 2018, 24, 1767–1774. [Google Scholar] [CrossRef]

- Pustan, M.; Chiorean, R.; Barleanu, C.; Dudescu, C.; Muller, R.; Baracu, A.; Voicu, R. Reliability design of thermally actuated MEMS switches based on V-shape beams. Microsyst. Technol. 2017, 23, 3863–3871. [Google Scholar] [CrossRef]

- Potekhina, A.; Wang, C. Review of Electrothermal Actuators and Applications. Actuators 2019, 8, 69. [Google Scholar] [CrossRef]

- Colinjivadi, K.S.; Lee, J.-B.; Draper, R. Viable cell handling with high aspect ratio polymer chopstick gripper mounted on a precision manipulator. Microsyst. Technol. 2008, 14, 1627–1633. [Google Scholar] [CrossRef]

- Zhang, W.; Gnerlich, M.; Paly, J.J.; Sun, Y.; Jing, G.; Voloshin, A.; Tatic-Lucic, S. A polymer V-shaped electrothermal actuator array for biological applications. J. Micromech. Microeng. 2008, 18, 075020. [Google Scholar] [CrossRef]

- Voicu, R.-C.; Tibeica, C.; Pustan, M.; Birleanu, C.; Muller, R. A Polymeric SU-8 Micro-Twezer with In-Plane Double Action Based on Chevron Actuators. In Proceedings of the 21st International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers), Orlando, FL, USA, 20–24 June 2021; pp. 14–17. [Google Scholar] [CrossRef]

- Voicu, R.-C.; Tibeica, C.; Müller, R.; Dinescu, A.; Pustan, M.; Birleanu, C. SU-8 Microgrippers based on V-shaped Eletrothermal Actuators with Implanted Heaters. Rom. J. Inf. Sci. Technol. 2016, 19, 269–281. Available online: https://www.romjist.ro/content/pdf/voicu.tex.pdf (accessed on 14 December 2022).

- Brandt, R.; Neuer, G. Electrical Resistivity and Thermal Conductivity of Pure Aluminum and Aluminum Alloys up to and above the Melting Temperature. Int. J. Thermophys. 2007, 28, 1429–1446. [Google Scholar] [CrossRef]

- Hust, J.G.; Lankford, A.B. Thermal Conductivity of Aluminum, Copper, Iron, and Tungsten for Temperatures from 1 K to the Melting Point; National Bureau of Standards, U.S. Department of Commerce: Boulder, CO, USA, 1984.

- Greer, Z.L. Temperature, Frequency, and Young’s Modulus an Aluminum Tuning Fork. ISB J. Phys. 2011, 5, 1–4. Available online: http://isjos.org/JoP/vol5iss1/Papers/JoPv5i1-3TuningFork.pdf (accessed on 20 December 2022).

- COMSOL Multiphysics® v. 6.1. COMSOL AB, Stockholm, Sweden. Available online: www.comsol.com (accessed on 7 December 2022).

- Pulavarthy, R.S.R.A. Characterization of Heat Transfer Coefficient at Micro/Nano Scale and the Effect of Heated Zone Size. Master’s Thesis, The Pennsylvania State University, The Graduate School, Department of Mechanical and Nuclear Engineering, State College, PA, USA, August 2015. Available online: https://etda.libraries.psu.edu/files/final_submissions/11142 (accessed on 15 December 2022).

| Parameter | Value |

|---|---|

| Distance between the tips, initial opening, g0 (µm) | 10 |

| Length of the tips, Lt (µm) | 90 |

| Width of the free arms, tips, and chevron beams, W (µm) | 20 |

| Width of the flexural hinges, Wf (µm) | 10 |

| Length of the flexural hinges, Lf (µm) | 78 |

| Length of one chevron beam, Lc (µm) | 303 |

| Length between the chevron beam and the flexural hinges, Lcf (µm) | 40 |

| Length of the free arm before it is bent, Lb (µm) | 460 |

| Angle of the chevron beams, α (o) | 10 |

| Aluminum thickness, t (µm) | 2 |

| Property | Value | Unit | |

|---|---|---|---|

| Aluminum | Silicon | ||

| Density | 2700 | 2329 | kg/m3 |

| Young’s modulus, E | See Equation (1) | 170 × 109 | Pa |

| Poisson’s ratio, ν | 0.35 | 0.28 | |

| Coefficient of thermal expansion, CTE | 23.1 × 10−6 | 2.6 × 10−6 | 1/K |

| Heat capacity at constant pressure, Cp | 904 | 700 | J/(kg·K) |

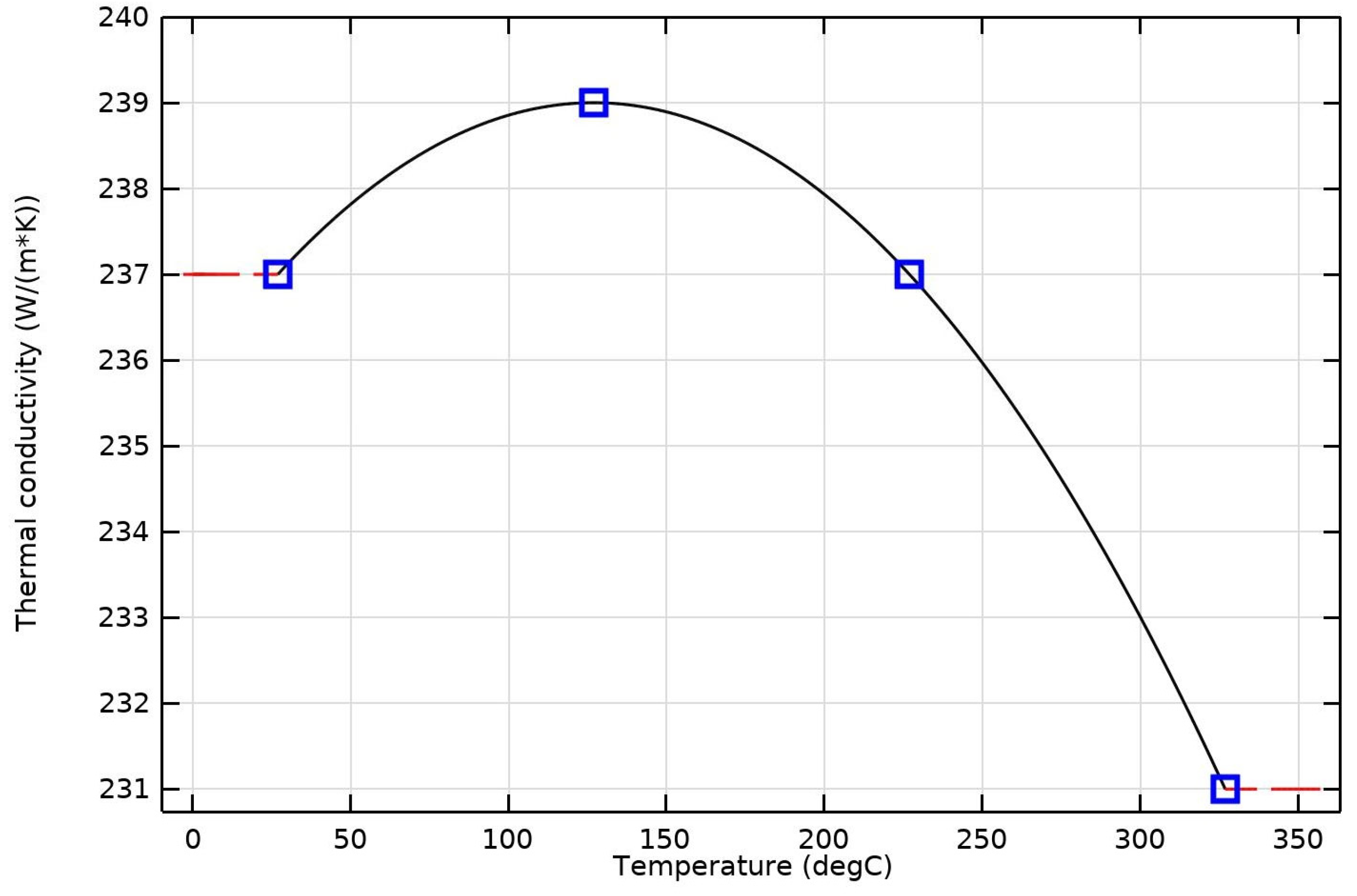

| Thermal conductivity | See Figure 7 | 130 | W/(m·K) |

| Electrical resistivity at T0, | 4.35 × 10−8 | - | Ω·m |

| Resistivity temperature coefficient, α | 0.0038 | - | 1/K |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voicu, R.-C.; Tibeica, C. An Aluminum Electro-Thermally Actuated Micro-Tweezer: Manufacturing and Characterization. Micromachines 2023, 14, 797. https://doi.org/10.3390/mi14040797

Voicu R-C, Tibeica C. An Aluminum Electro-Thermally Actuated Micro-Tweezer: Manufacturing and Characterization. Micromachines. 2023; 14(4):797. https://doi.org/10.3390/mi14040797

Chicago/Turabian StyleVoicu, Rodica-Cristina, and Catalin Tibeica. 2023. "An Aluminum Electro-Thermally Actuated Micro-Tweezer: Manufacturing and Characterization" Micromachines 14, no. 4: 797. https://doi.org/10.3390/mi14040797

APA StyleVoicu, R.-C., & Tibeica, C. (2023). An Aluminum Electro-Thermally Actuated Micro-Tweezer: Manufacturing and Characterization. Micromachines, 14(4), 797. https://doi.org/10.3390/mi14040797