Dynamic Compressive Properties and Failure Mechanism of the Laser Powder Bed Fusion of Submicro-LaB6 Reinforced Ti-Based Composites

Abstract

1. Introduction

2. Experimental Details

2.1. Raw Materials

2.2. Specimen Preparation

2.3. Characterization and Analysis

3. Results and Discussions

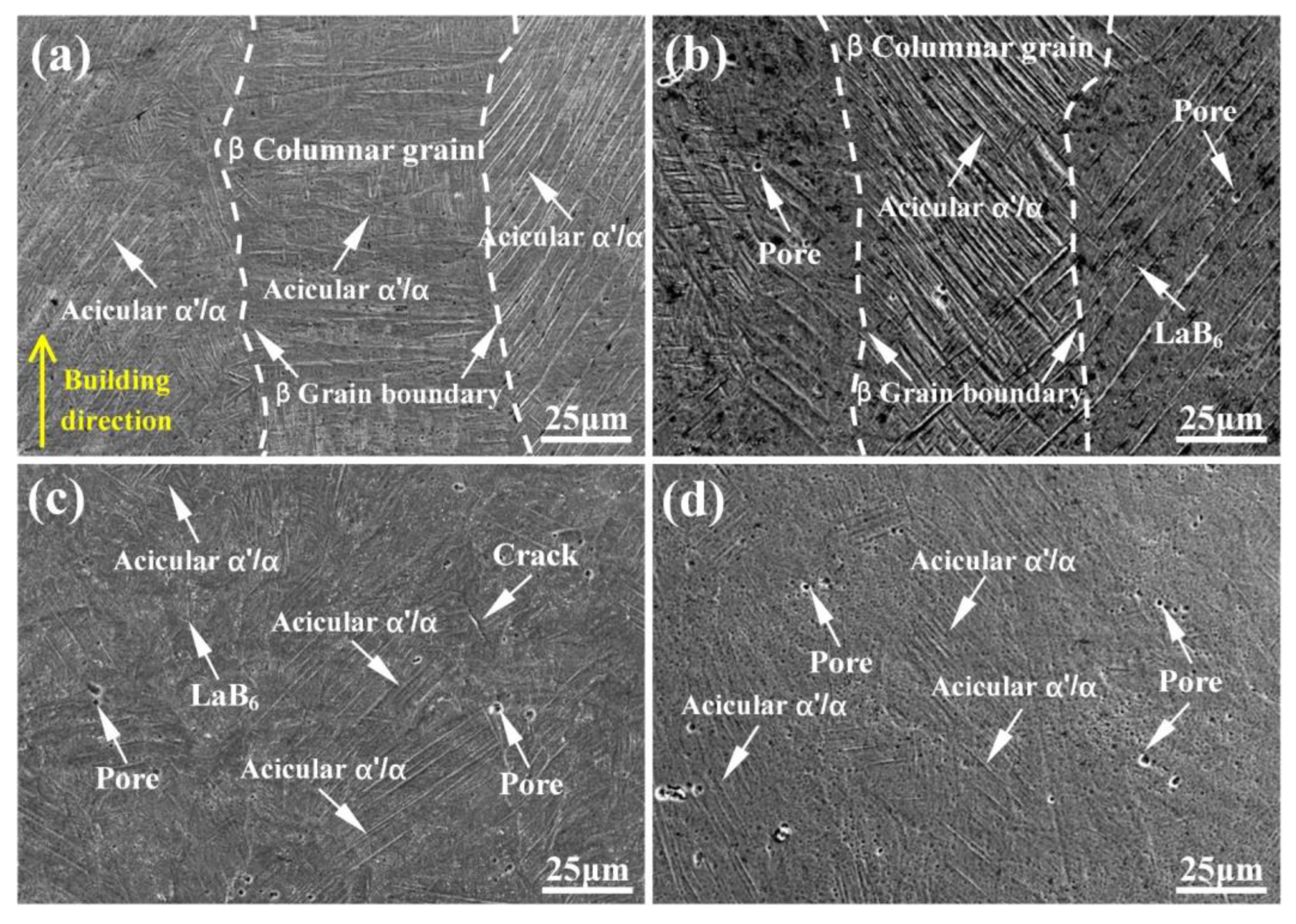

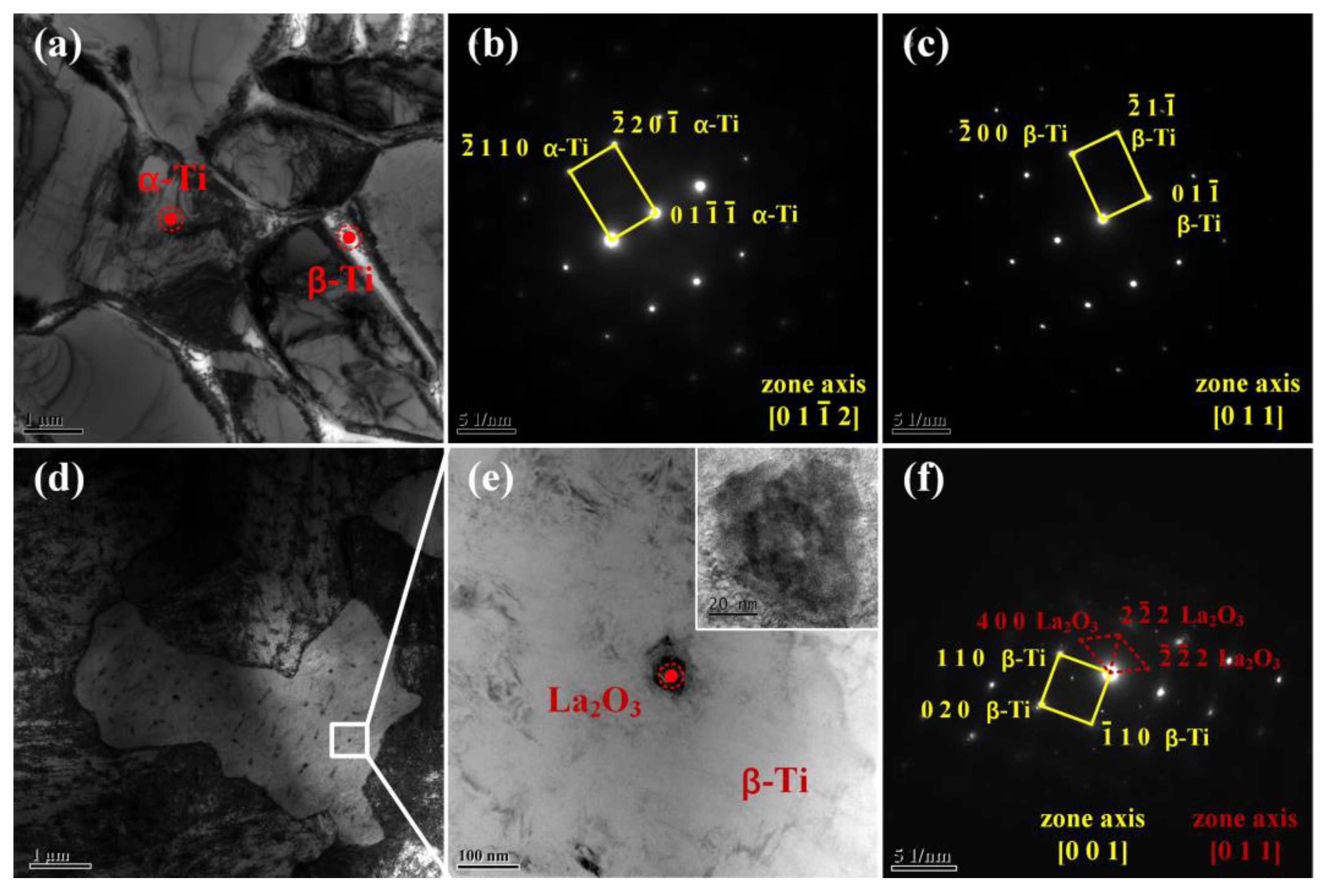

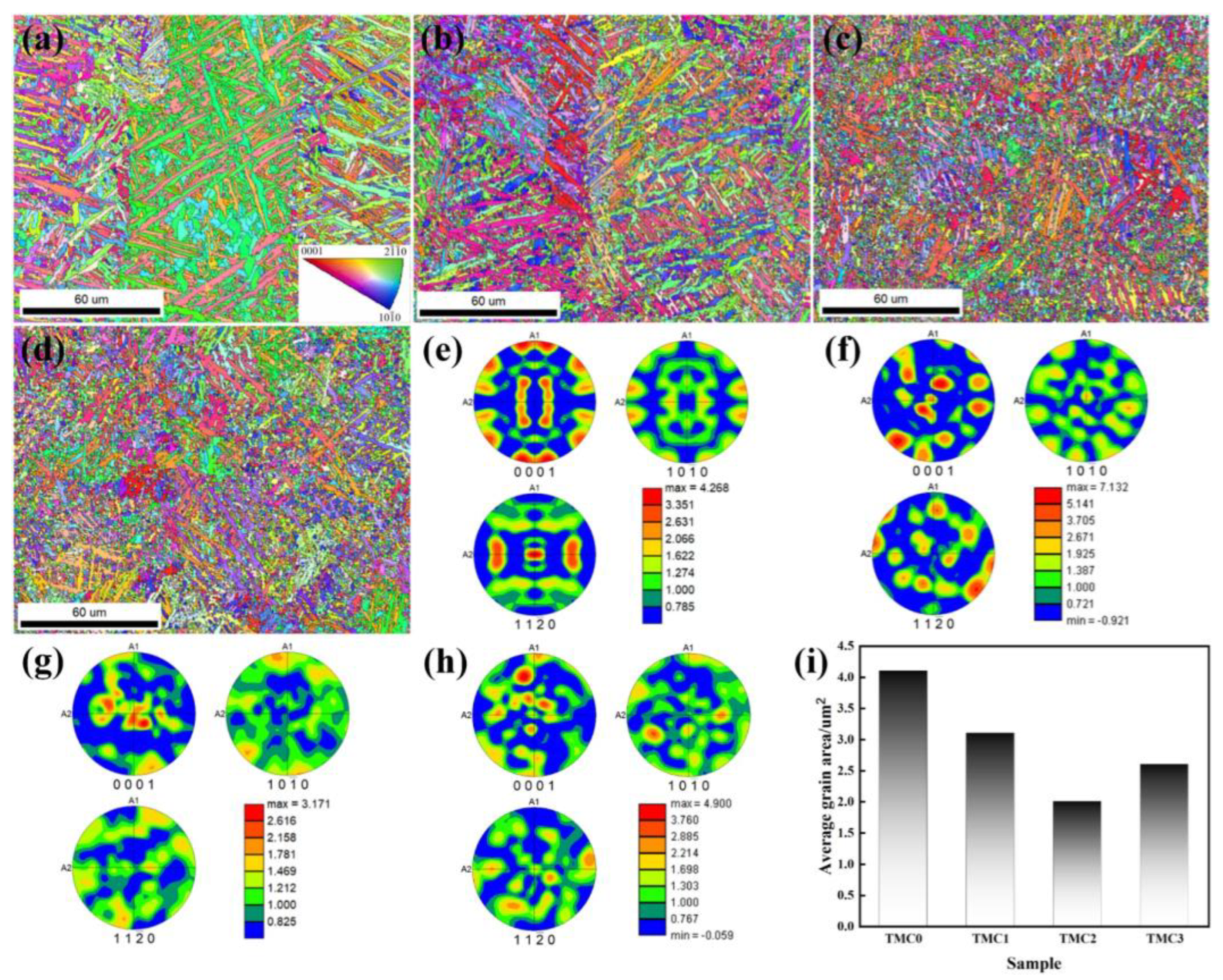

3.1. Initial Microstructure

3.2. Compression Mechanical Properties

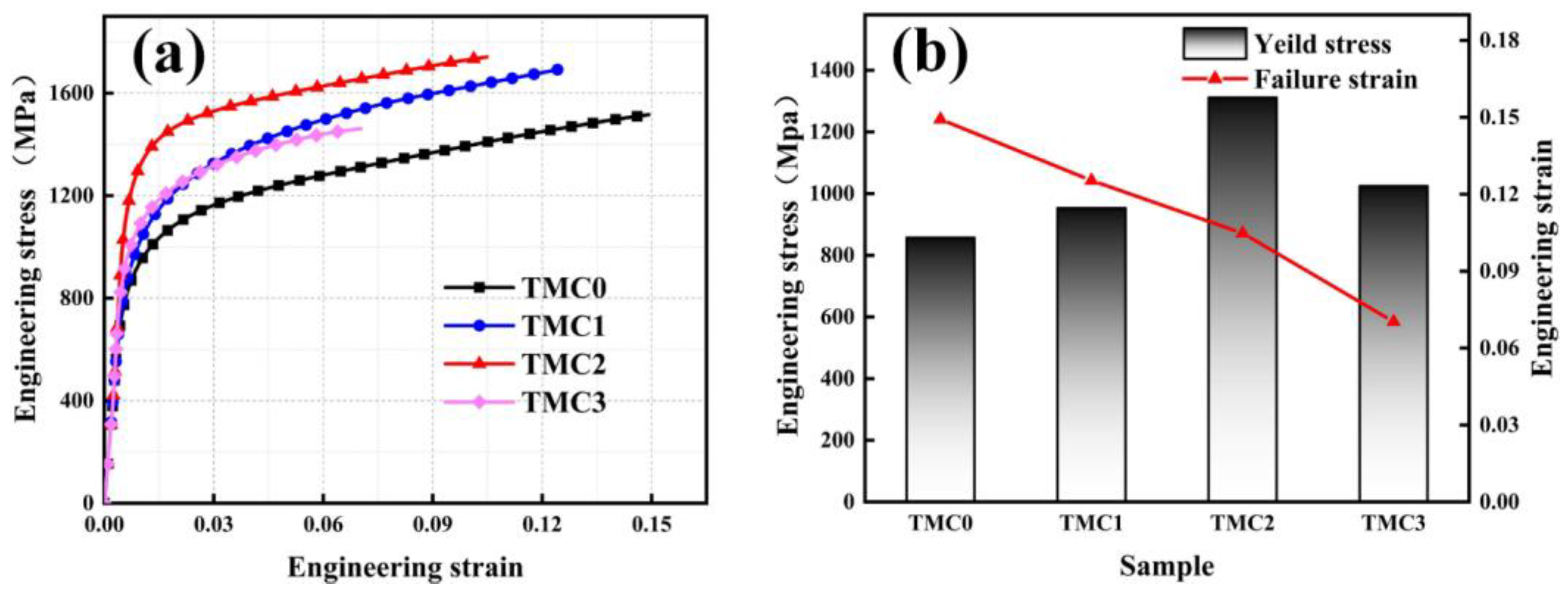

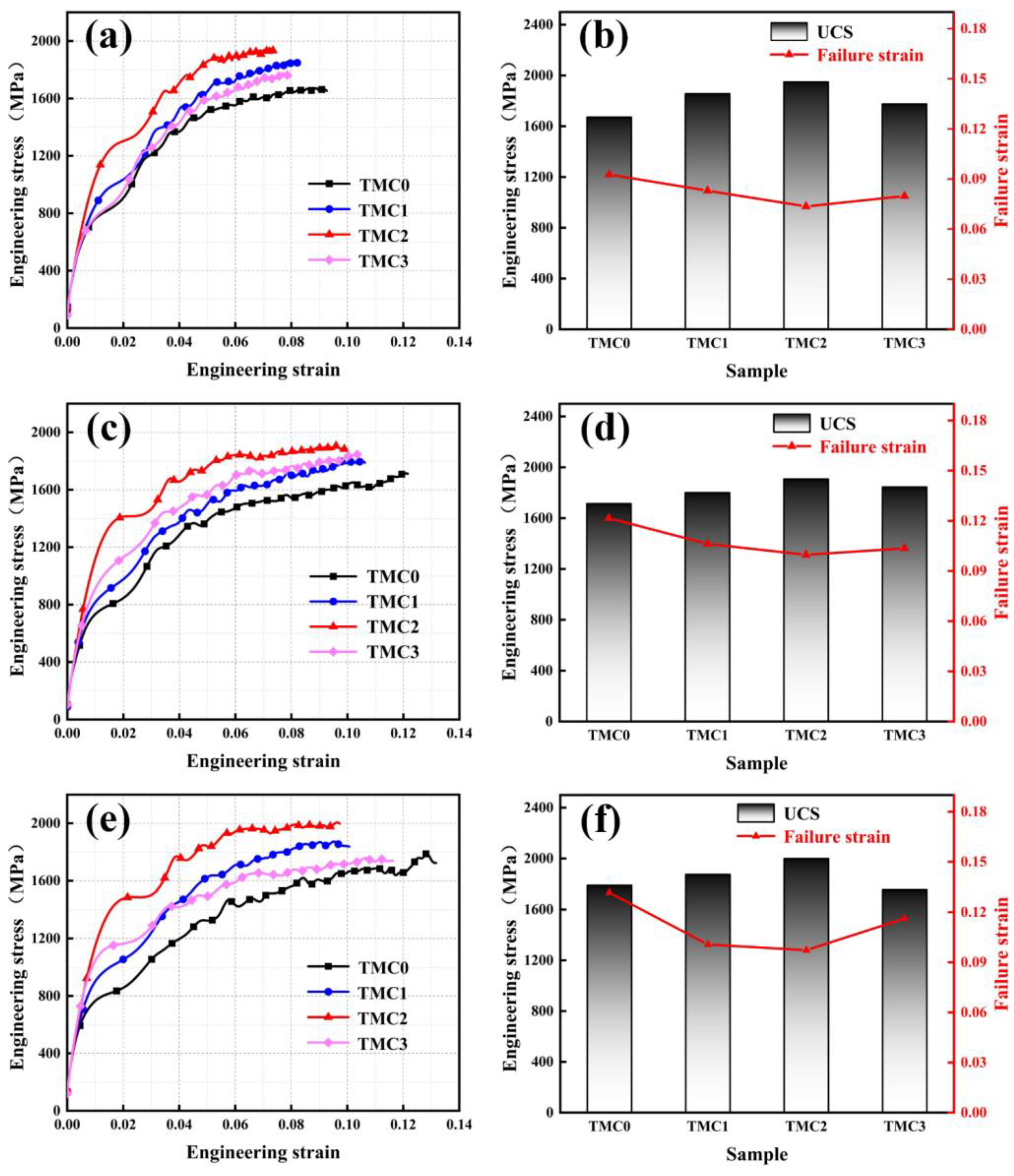

3.2.1. Quasi-Static Compressive Properties

3.2.2. Dynamic Compression Properties

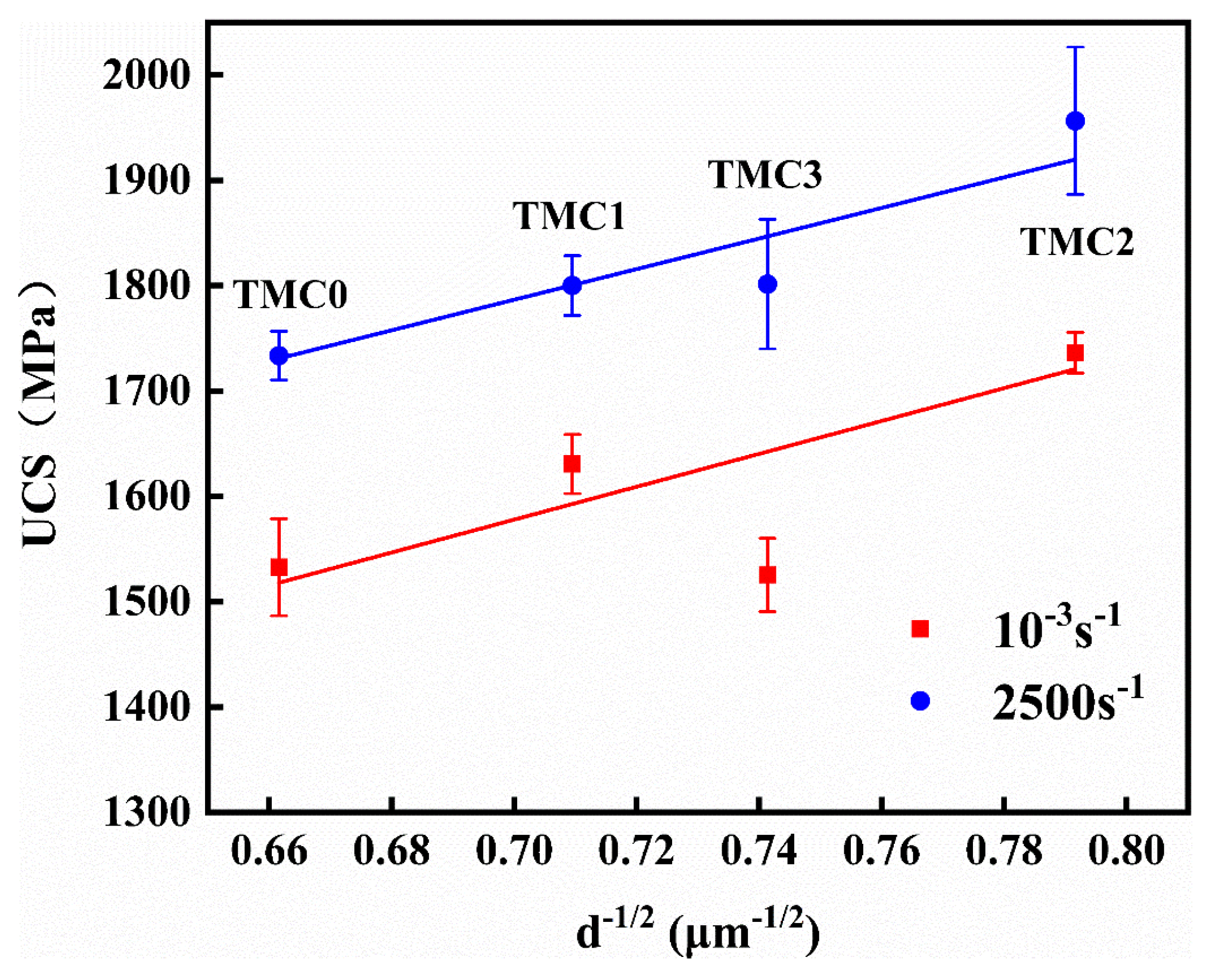

3.2.3. Influence of Grain Size on the UCS

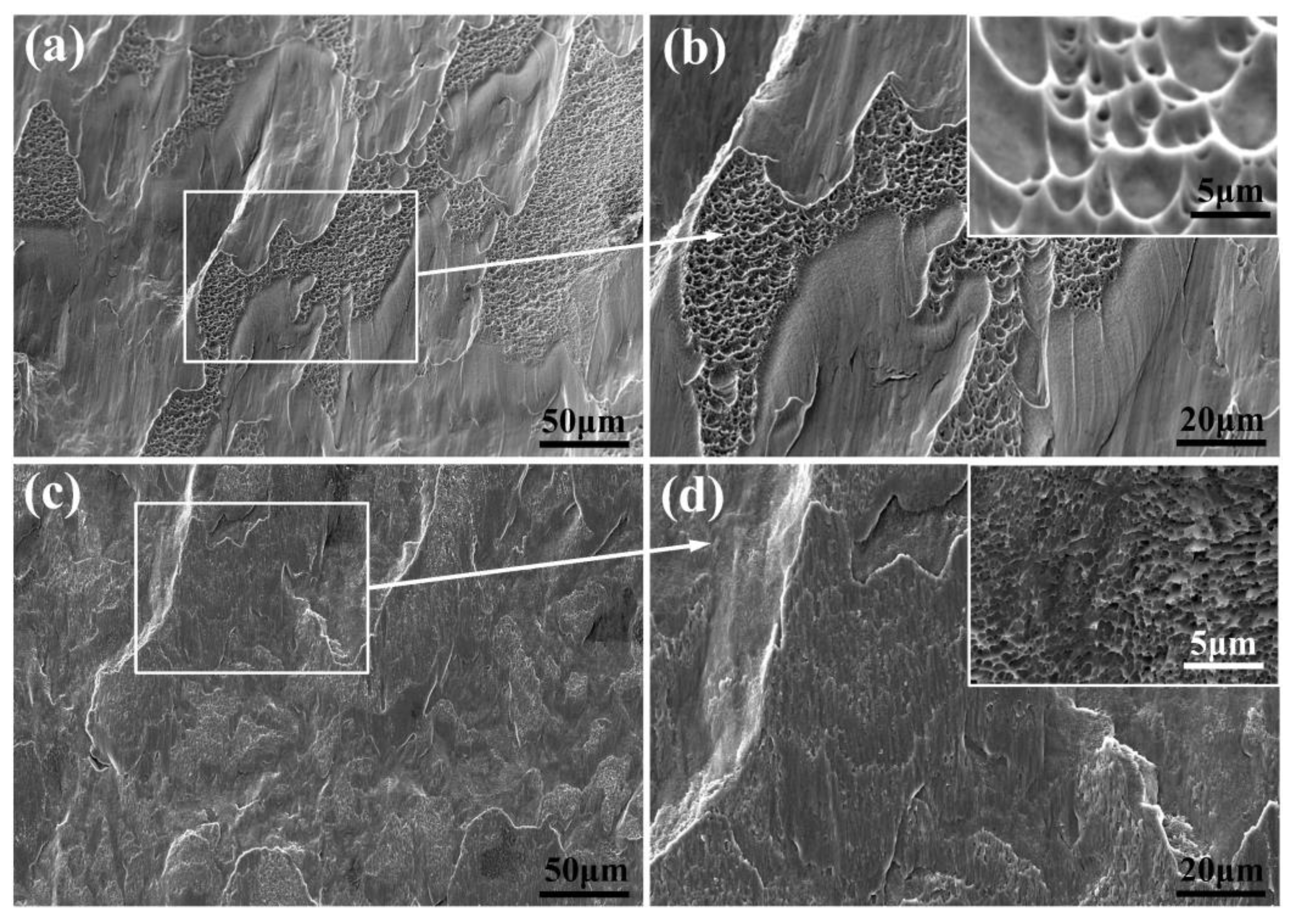

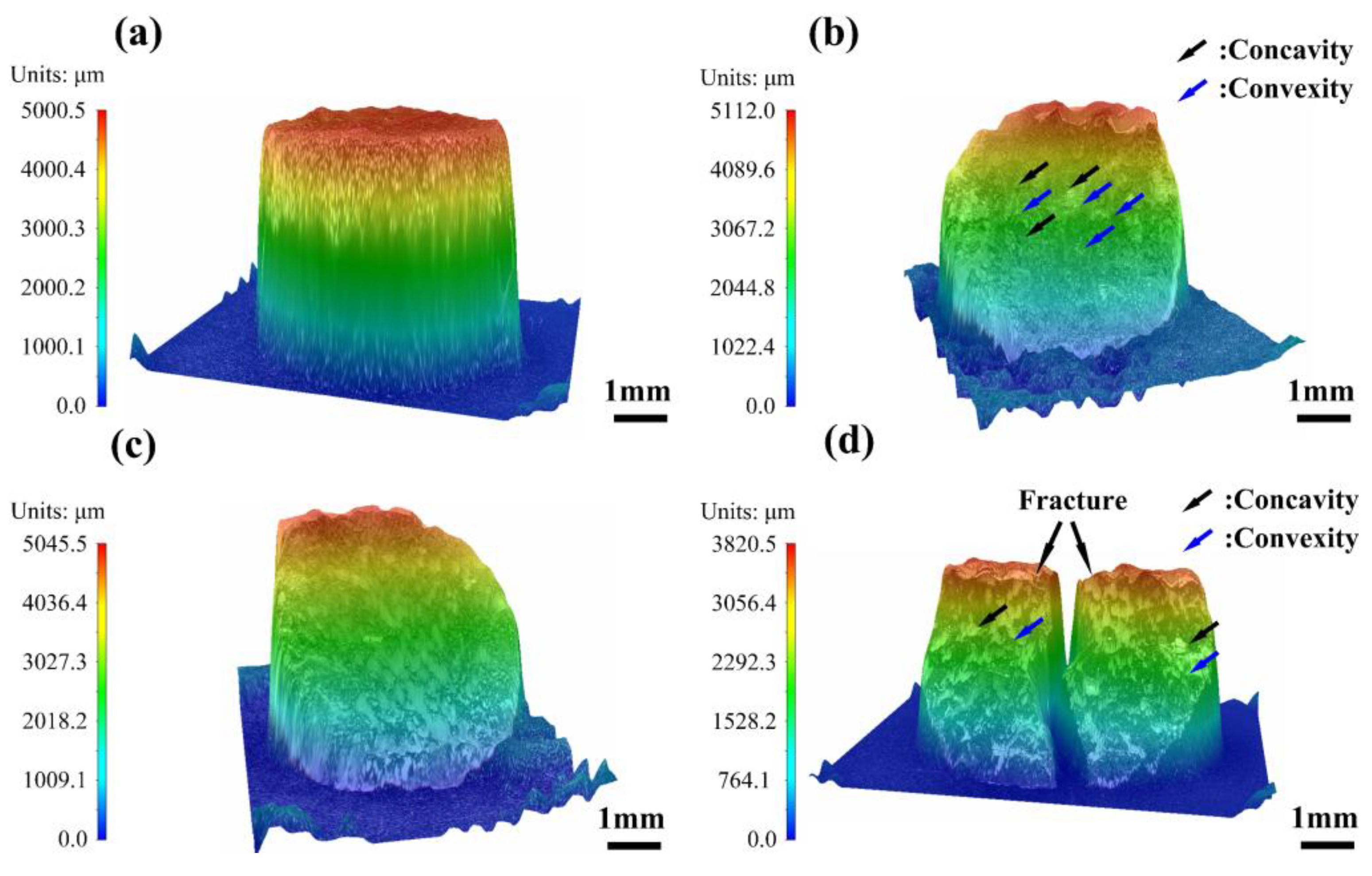

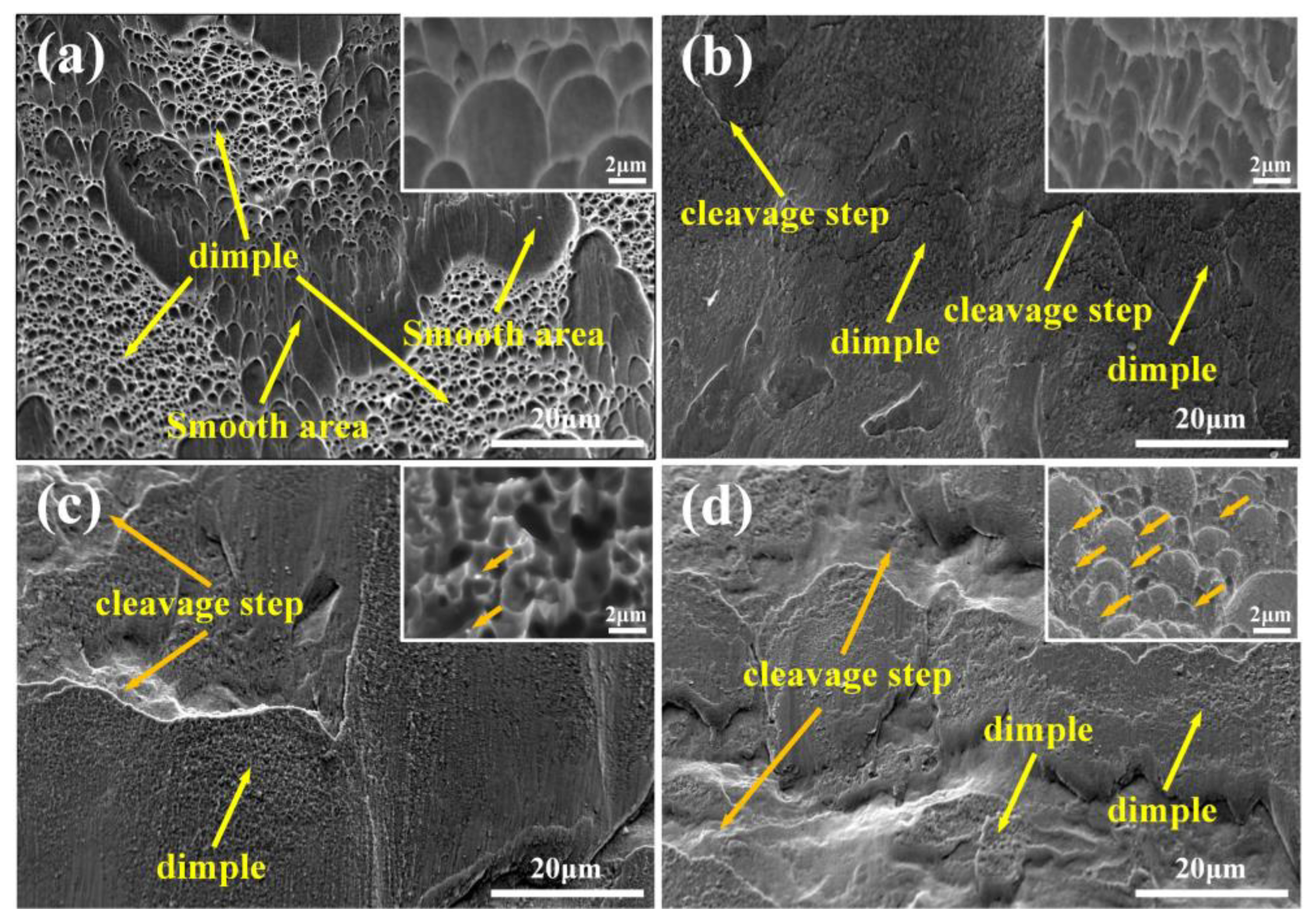

3.3. Fracture Characteristics

4. Conclusions

- (1)

- A small amount of LaB6 had a considerable effect on the microstructure of the titanium matrix composites, and 0.2 wt.% LaB6 weakened and blurred the prior β-columnar grain boundaries and acicular α′/α. LaB6 reached a critical point at 0.5 wt.%, where the boundaries of the prior β-columnar grains became indistinguishable, and the acicular α′/α decreased rapidly. When it increased to 1.0 wt.%, the influence on the change in microstructure was significantly diminished. The addition of LaB6 had a significant grain refinement effect, but when its mass fraction exceeded 0.5 wt.%, the nano-reinforced particulate tended to agglomerate, which had a negative impact on grain refinement.

- (2)

- Benefiting from the fine-grain strengthening and dispersion strengthening of LaB6, the quasi-static compressive strength of the TC4/LaB6 was found to be significantly higher than that of the pure TC4. However, it also led to a decrease in plasticity, especially when the LaB6 fraction was relatively high (1.0 wt.%), and the specimens fractured, even shortly after the end of the elastic segment.

- (3)

- The performance of TC4/LaB6 was related to the mass fraction of LaB6, but higher did not mean better. A critical mass fraction of 0.5 wt.% was found in this study. Excessive LaB6 significantly increased the brittle fracture characteristics of the material, showing a more significant terrace-like fracture surface after extrusion and friction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Guo, A.X.Y.; Cheng, L.; Zhan, S.; Zhang, S.; Xiong, W.; Wang, Z.; Wang, G.; Cao, S.C. Biomedical applications of the powder-based 3D printed titanium alloys: A review. J. Mater. Sci. Technol. 2022, 125, 252–264. [Google Scholar] [CrossRef]

- Li, G.X.; Chandra, S.; Rashid, R.A.R.; Palanisamy, S.; Ding, S.L. Machinability of additively manufactured titanium alloys: A comprehensive review. J. Manuf. Process. 2022, 75, 72–99. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Pramanik, A.; Basak, A.K.; Dong, Y.; Prakash, C.; Debnath, S.; Shankar, S.; Jawahir, I.S.; Dixit, S.; Buddhi, D. A critical review on additive manufacturing of Ti-6Al-4V alloy: Microstructure and mechanical properties. J. Mater. Res. Technol. 2022, 18, 4641–4661. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Kang, L.; Yang, C. A Review on High-Strength Titanium Alloys: Microstructure, Strengthening, and Properties. Adv. Eng. Mater. 2019, 21, 1801359. [Google Scholar] [CrossRef]

- Sen, I.; Tamirisakandala, S.; Miracle, D.B.; Ramamurty, U. Microstructural effects on the mechanical behavior of B-modified Ti-6Al-4V alloys. Acta Mater. 2007, 55, 4983–4993. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Cui, C.; Hu, B.; Zhao, L.; Liu, S. Titanium alloy production technology, market prospects and industry development. Mater. Des. 2011, 32, 1684–1691. [Google Scholar] [CrossRef]

- Huang, X.; Gao, Y.; Wang, Z.; Yi, Y.; Wang, Y. Microstructure, mechanical properties and strengthening mechanisms of in-situ prepared (Ti5Si3+TiC0. 67)/TC4 composites. J. Alloys Compd. 2019, 792, 907–917. [Google Scholar] [CrossRef]

- Hayat, M.D.; Singh, H.; He, Z.; Cao, P. Titanium metal matrix composites: An overview. Compos. Part A 2019, 121, 418–438. [Google Scholar] [CrossRef]

- Ropars, L.; Dehmas, M.; Gourdet, S.; Delfosse, J.; Tricker, D.; Aeby-Gautier, E. Structure evolutions in a Ti-6Al-4V matrix composite reinforced with TiB, characterised using high energy X-ray diffraction. J. Alloys Compd. 2015, 624, 179–188. [Google Scholar] [CrossRef]

- Lagos, M.A.; Agote, I.; Atxaga, G.; Adarraga, O.; Pambaguian, L. Fabrication and characterisation of Titanium Matrix Composites obtained using a combination of Self propagating High temperature Synthesis and Spark Plasma Sintering. Mater. Sci. Eng. A 2016, 655, 44–49. [Google Scholar] [CrossRef]

- Sing, S.L.; Huang, S.; Goh, G.D.; Goh, G.L.; Tey, C.F.; Tan, J.H.K.; Yeong, W.Y. Emerging metallic systems for additive manufacturing: In-situ alloying and multi-metal processing in laser powder bed fusion. Prog. Mater. Sci. 2021, 119, 100795. [Google Scholar] [CrossRef]

- Liu, M.; Liu, S.; Chen, W.; Chen, C.; Lv, Y.; Zhang, X.; Lei, P.; Lin, Y.; Zhou, K. Effect of trace lanthanum hexaboride on the phase, grain structure, and texture of electron beam melted Ti-6Al-4V. Addit. Manuf. 2019, 30, 100873. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Gussone, J.; Stark, A.; Schell, N.; Haubrich, J.; Requena, G. Peritectic titanium alloys for 3D printing. Nat. Commun. 2018, 9, 3426. [Google Scholar] [CrossRef] [PubMed]

- Bermingham, M.J.; Kent, D.; Zhan, H.; StJohn, D.H.; Dargusch, M.S. Controlling the microstructure and properties of wire arc additive manufactured Ti-6Al-4V with trace boron additions. Acta Mater. 2015, 91, 289–303. [Google Scholar] [CrossRef]

- Bermingham, M.J.; McDonald, S.D.; Dargusch, M.S. Effect of trace lanthanum hexaboride and boron additions on microstructure, tensile properties and anisotropy of Ti-6Al-4V produced by additive manufacturing. Mater. Sci. Eng. A 2018, 719, 1–11. [Google Scholar] [CrossRef]

- Ye, T.; Xu, Y.; Ren, J. Effects of SiC particle size on mechanical properties of SiC particle reinforced aluminum metal matrix composite. Mater. Sci. Eng. A 2019, 753, 146–155. [Google Scholar] [CrossRef]

- Mohammadhosseini, A.; Masood, S.H.; Fraser, D.; Jahedi, M. Dynamic compressive behaviour of Ti-6Al-4V alloy processed by electron beam melting under high strain rate loading. Adv. Manuf. 2015, 3, 232–243. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, H.; Zhu, L.; Wang, X.; Han, Q.; Li, S.; Wang, Y.; Setchi, R.; Wang, D. Investigation into the microstructure and dynamic compressive properties of selective laser melted Ti-6Al-4V alloy with different heating treatments. Mater. Sci. Eng. A 2021, 805, 140561. [Google Scholar] [CrossRef]

- Alaghmandfard, R.; Chalasani, D.; Hadadzadeh, A.; Amirkhiz, B.S.; Odeshi, A.; Mohammadi, M. Dynamic compressive response of electron beam melted Ti–6Al–4V under elevated strain rates: Microstructure and constitutive models. Addit. Manuf. 2020, 35, 101347. [Google Scholar] [CrossRef]

- Alaghmandfard, R.; Dharmendra, C.; Odeshi, A.G.; Mohammadi, M. Dynamic mechanical properties and failure characteristics of electron beam melted Ti-6Al-4V under high strain rate impact loadings. Mater. Sci. Eng. A 2020, 793, 139794. [Google Scholar] [CrossRef]

- Cho, J.Y.; Xu, W.; Brandt, M.; Qian, M. Selective laser melting-fabricated Ti-6Al-4V alloy: Microstructural inhomogeneity, consequent variations in elastic modulus and implications. Opt. Laser Technol. 2019, 111, 664–670. [Google Scholar] [CrossRef]

- Mills, K.C.; Keene, B.J. Factors affecting variable weld penetration. Int. Mater. Rev. 1990, 35, 185–216. [Google Scholar] [CrossRef]

- Shirali, A.A.; Mills, K.C.J.W.J. The effect of welding parameters on penetration in GTA welds. Weld. J. 1993, 72, 7. [Google Scholar]

- Liu, Y.; Pang, Z.; Li, M.; Wang, Y.; Wang, D.; Song, C.; Li, S. Investigation into the dynamic mechanical properties of selective laser melted Ti-6Al-4V alloy at high strain rate tensile loading. Mater. Sci. Eng. A 2019, 745, 440–449. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Ning, J.; Li, S.; Zhang, L.; Long, J. Hierarchical grain refinement during the laser additive manufacturing of Ti-6Al-4V alloys by the addition of micron-sized refractory particles. Addit. Manuf. 2021, 45, 102045. [Google Scholar] [CrossRef]

- Li, W.; Yang, Y.; Liu, J.; Zhou, Y.; Li, M.; Wen, S.; Wei, Q.; Yan, C.; Shi, Y. Enhanced nanohardness and new insights into texture evolution and phase transformation of TiAl/TiB2 in-situ metal matrix composites prepared via selective laser melting. Acta Mater. 2017, 136, 90–104. [Google Scholar] [CrossRef]

- He, D.; Wang, H.; Huang, W.; Chen, X.; Lian, G.; Wang, Y. Microstructure and mechanical properties of LaB6/Ti-6Al-4V composites fabricated by selective laser melting. Metals 2023, 13, 264. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S.; Tamirisakandala, S.; Miracle, D.B.; Srinivasan, R. Development of solidification microstructure in boron-modified alloy Ti-6Al-4V-0.1B. Acta Mater. 2011, 59, 5494–5510. [Google Scholar] [CrossRef]

- Feng, Y.; Feng, K.; Yao, C.; Li, Z. Effect of LaB6 addition on the microstructure and properties of (Ti3Al+TiB)/Ti composites by laser cladding. Mater. Des. 2019, 181, 107959. [Google Scholar] [CrossRef]

- Liang, J.; Yin, X.; Lin, Z.; Chen, S.; Liu, C.; Yan, S.; Dong, S. Effects of LaB6 on microstructure evolution and properties of in-situ synthetic TiC+TiBx reinforced titanium matrix composite coatings prepared by laser cladding. Surf. Coat. Technol. 2020, 403, 126409. [Google Scholar] [CrossRef]

- Chong, Y.; Deng, G.; Gao, S.; Yi, J.; Shibata, A.; Tsuji, N. Yielding nature and Hall-Petch relationships in Ti-6Al-4V alloy with fully equiaxed and bimodal microstructures. Scr. Mater. 2019, 172, 77–82. [Google Scholar] [CrossRef]

- Field, J.E.; Walley, S.M.; Proud, W.G.; Goldrein, H.T.; Siviour, C.R. Review of experimental techniques for high rate deformation and shock studies. Int. J. Impact Eng. 2004, 30, 725–775. [Google Scholar] [CrossRef]

- Chen, G.; Ren, C.; Qin, X.; Li, J. Temperature dependent work hardening in Ti-6Al-4V alloy over large temperature and strain rate ranges: Experiments and constitutive modeling. Mater. Des. 2015, 83, 598–610. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, J.; Zhu, L.; Chen, H.; Li, Z.; Li, S.; Wang, D.; Wang, Y.; Kosiba, K. Dynamic compressive properties and underlying failure mechanisms of selective laser melted Ti-6Al-4V alloy under high temperature and strain rate conditions. Addit. Manuf. 2022, 54, 102772. [Google Scholar] [CrossRef]

- Liu, R.; Hui, S.; Ye, W.; Li, C.; Fu, Y.; Yu, Y.; Song, X. Dynamic stress–strain properties of Ti-Al-V titanium alloys with various element contents. Rare Met. 2013, 32, 555–559. [Google Scholar] [CrossRef]

- Zhang, X.M.; Zhang, Y.J.; Mao, X.N. TiC particles for Ti matrix composites by SHS method. Tai Gongye Jinzhan 2003, 2, 18–21. [Google Scholar] [CrossRef]

- Fu, H.; Li, K.; Li, T.; Wu, T.; Zhang, G. Experiment of Cavity Collapse Process in Plastic-Bonded Explosives under Shock Loading. Gaoya Wuli Xuebao 2015, 29, 268–272. [Google Scholar] [CrossRef]

- Kuang, L.; Chen, Z.; Jiang, Y.; Wang, Z.; Wang, R.; Liu, C. Adiabatic shear behaviors in rolled and annealed pure titanium subjected to dynamic impact loading. Mater. Sci. Eng. A 2017, 685, 95–106. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, X.; Xia, T.; Sun, Q.; Liu, Q. Microstructural and textural evolution of high-purity titanium under dynamic loading. Mater. Des. 2017, 126, 123–134. [Google Scholar] [CrossRef]

- Yu, Q.; Shan, Z.-W.; Li, J.; Huang, X.; Xiao, L.; Sun, J.; Ma, E. Strong crystal size effect on deformation twinning. Nature 2010, 463, 335–338. [Google Scholar] [CrossRef] [PubMed]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 64, 747. [Google Scholar] [CrossRef]

- Wang, C.L.; Yu, D.P.; Niu, Z.Q.; Zhou, W.L.; Chen, G.Q.; Li, Z.Q.; Fu, X.S. The role of pyramidal <c plus a> dislocations in the grain refinement mechanism in Ti-6Al-4V alloy processed by severe plastic deformation. Acta Mater. 2020, 200, 101–115. [Google Scholar] [CrossRef]

- Wang, L.; Lu, W.; Qin, J.; Zhang, F.; Zhang, D. Tensile properties of in situ synthesized (TiB+La2O3)/β-Ti composite. Mater. Sci. Eng. C 2009, 29, 1897–1900. [Google Scholar] [CrossRef]

- Zhang, B.; Fu, H.; Sha, P.; Zhu, Z.; Dong, C.; Zhang, H.; Hu, Z. Anisotropic compressive deformation behaviors of tungsten fiber reinforced Zr-based metallic glass composites. Mater. Sci. Eng. A 2013, 566, 16–21. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Zhang, M.; Liu, Y.; Sercombe, T.B.; Wang, S.; Hao, Y.; Yang, R.; Murr, L.E. Comparison of the microstructures and mechanical properties of Ti-6Al-4V fabricated by selective laser melting and electron beam melting. Mater. Des. 2016, 95, 21–31. [Google Scholar] [CrossRef]

- Fadida, R.; Shirizly, A.; Rittel, D. Static and dynamic shear-compression response of additively manufactured Ti6Al4V specimens with embedded voids. Mech. Mater. 2020, 147, 103413. [Google Scholar] [CrossRef]

- Zhang, T.; Huang, Z.; Yang, T.; Kong, H.; Luan, J.; Wang, A.; Wang, D.; Kuo, W.; Wang, Y.; Liu, C.T. In situ design of advanced titanium alloy with concentration modulations by additive manufacturing. Science 2021, 374, 478–482. [Google Scholar] [CrossRef] [PubMed]

- Markovsky, P.E.; Janiszewski, J.; Dekhtyar, O.; Mecklenburg, M.; Prikhodko, S.V. Deformation Mechanism and Structural Changes in the Globular Ti-6Al-4V Alloy under Quasi-Static and Dynamic Compression: To the Question of the Controlling Phase in the Deformation of α+β Titanium Alloys. Crystals 2022, 12, 645. [Google Scholar] [CrossRef]

- Tabachnikova, E.D.; Podolskiy, A.V.; Bengus, V.Z.; Smirnov, S.N.; Bidylo, M.I.; Csach, K.; Miskuf, J.; Saitova, L.R.; Semenova, I.P.; Valiev, R.Z. Mechanical characteristics, failure regularities, and dimple structures on failure surfaces of Ti-6Al-4V ‘ELI’ ultrafine-grained alloy at temperatures from 300 to 4.2K. Mater. Sci. Eng. A 2009, 503, 106–109. [Google Scholar] [CrossRef]

- Song, W.; Ning, J.; Mao, X. Meso-Mechanical Behavior of TiC Particle-Reinforced Titanium Matrix Composites under Dynamic Loadings. Xiyou Jinshu Cailiao Yu Gongcheng 2011, 40, 1555–1560. [Google Scholar]

| Name | Mass Fraction (wt.%) |

|---|---|

| TMC0 | 0 |

| TMC1 | 0.2 |

| TMC2 | 0.5 |

| TMC3 | 1.0 |

| Name | UCS (MPa) | Grain Size d−1/2 (μm−1/2) | |

|---|---|---|---|

| Quasi-Static (10−3/s) | Dynamic (2500/s) | ||

| TMC0 | 1532.7 ± 32.7 | 1733.6 ± 16.4 | 4.1 |

| TMC1 | 1630.6 ± 19.8 | 1800.1 ± 20.1 | 3.1 |

| TMC2 | 1736.3 ± 13.6 | 1956.3 ± 49.5 | 2 |

| TMC3 | 1525.4 ± 24.5 | 1801.7 ± 43.4 | 2.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Liu, Y. Dynamic Compressive Properties and Failure Mechanism of the Laser Powder Bed Fusion of Submicro-LaB6 Reinforced Ti-Based Composites. Micromachines 2023, 14, 2237. https://doi.org/10.3390/mi14122237

Li X, Liu Y. Dynamic Compressive Properties and Failure Mechanism of the Laser Powder Bed Fusion of Submicro-LaB6 Reinforced Ti-Based Composites. Micromachines. 2023; 14(12):2237. https://doi.org/10.3390/mi14122237

Chicago/Turabian StyleLi, Xianghui, and Yang Liu. 2023. "Dynamic Compressive Properties and Failure Mechanism of the Laser Powder Bed Fusion of Submicro-LaB6 Reinforced Ti-Based Composites" Micromachines 14, no. 12: 2237. https://doi.org/10.3390/mi14122237

APA StyleLi, X., & Liu, Y. (2023). Dynamic Compressive Properties and Failure Mechanism of the Laser Powder Bed Fusion of Submicro-LaB6 Reinforced Ti-Based Composites. Micromachines, 14(12), 2237. https://doi.org/10.3390/mi14122237