Electric-Force Conversion Performance of Si-Based LiNbO3 Devices Based on Four Cantilever Beams

Abstract

1. Introduction

2. Methods

2.1. Mechanism Analysis of Cantilever Beams Vibration

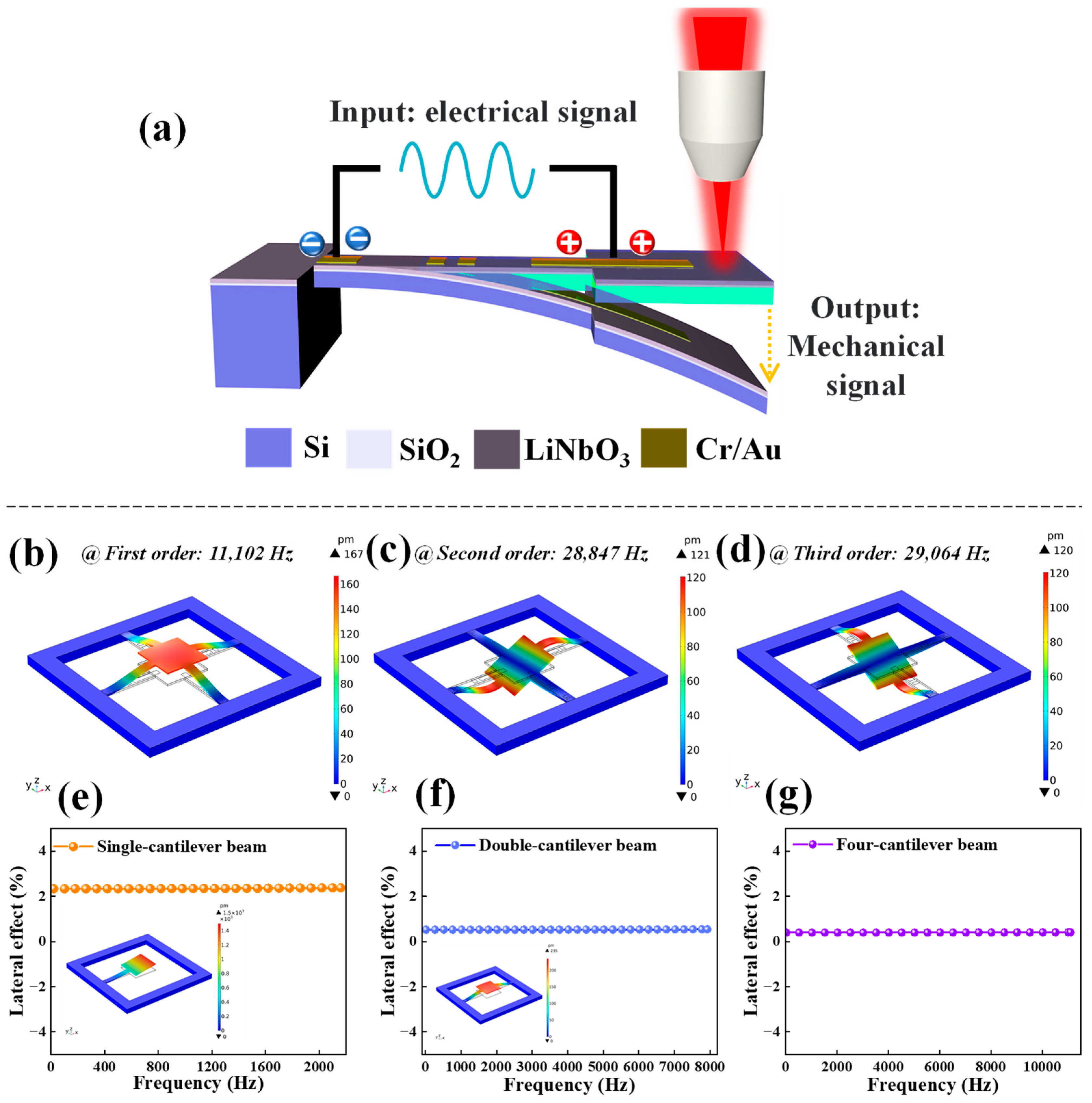

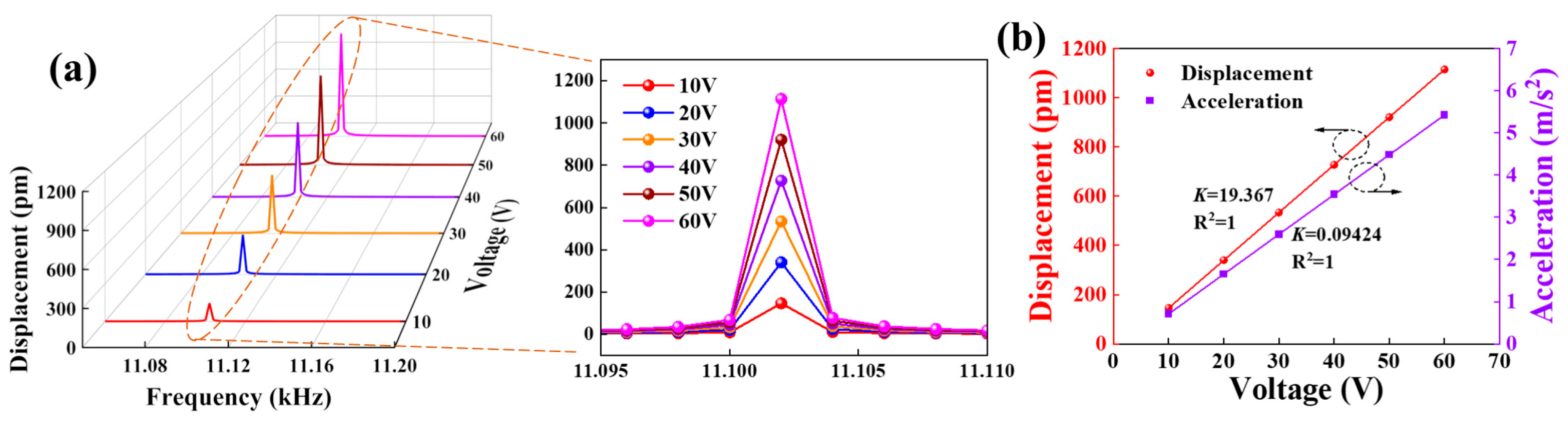

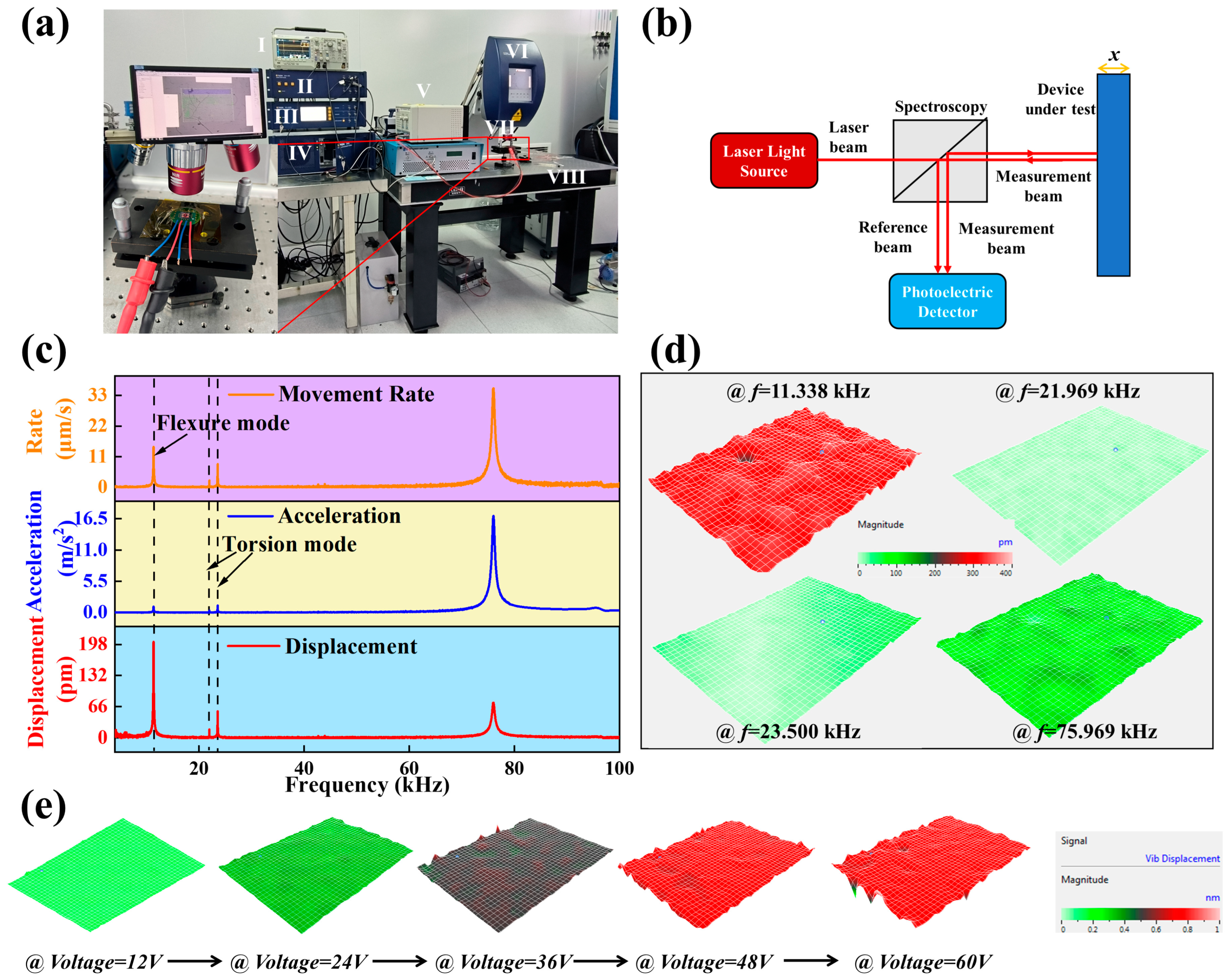

2.2. Experimental Design and Simulation

2.3. Analysis of Kinetic Characteristics

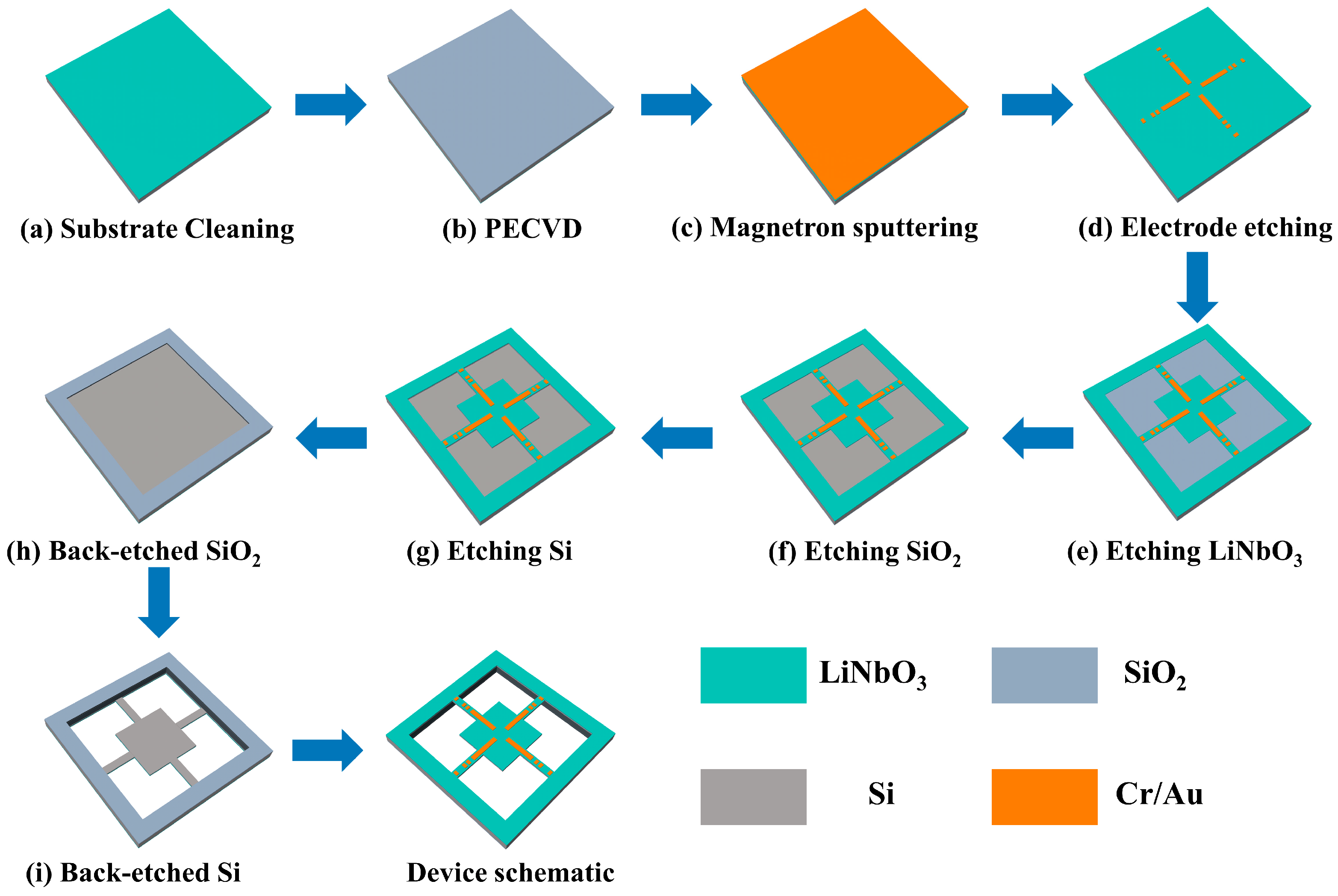

2.4. Devices Preparation Process

- a.

- Clean the Si-based bonding sheet to ensure clean surfaces (Figure 3a).

- b.

- A 2 μm thick SiO2 film is grown on the surface of Si layer for use as a hard pickle film layer when used for Si cavity etching (Figure 3b).

- c.

- The electrodes to be prepared by magnetron sputtering a Cr/Au (20 nm/200 nm) metal layer, followed by photolithography, development and ion beam etching (Figure 3c,d).

- d.

- Ion beam etching technique based on photolithography to complete the etching of 5 μm LiNbO3 piezoelectric beams (Figure 3e).

- e.

- Etching of the 2 μm SiO2 film is completed on the basis of step d using reactive ion etching technique (Figure 3f).

- f.

- Spraying photoresist on the basis of step e, ensuring adhesive thickness of at least 4 μm, followed by the deep Si etching process to complete Si beam etching with thickness of 100 μm (Figure 3g).

- g.

- Complete 2 μm SiO2 film and 400 μm Si substrate etching on the backside of bonded sheets (Figure 3h,i).

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Subbaramaiah, R.; Al-Jufout, S.A.; Ahmed, A.; Mozumdar, M.M. Design of Vibration-Sourced Piezoelectric Harvester for Battery-Powered Smart Road Sensor Systems. IEEE Sens. J. 2020, 20, 13940–13949. [Google Scholar] [CrossRef]

- Yuksel, M.B.; Koyuncuoglu, A.; Kulah, H. Thin-Film PZT-Based Multi-Channel Acoustic MEMS Transducer for Cochlear Implant Applications. IEEE Sens. J. 2021, 22, 3052–3060. [Google Scholar] [CrossRef]

- Du, X.; Wang, Y.; Chen, H.; Li, C.; Han, Y.; Yurchenko, D.; Wang, J.; Yu, H. Vortex-induced piezoelectric cantilever beam vibration for ocean wave energy harvesting via airflow from the orifice of oscillation water column chamber. Nano Energy 2022, 104, 107870. [Google Scholar] [CrossRef]

- Le Scornec, J.; Guiffard, B.; Seveno, R.; Le Cam, V. Frequency tunable, flexible and low cost piezoelectric micro-generator for energy harvesting. Sens. Actuators A Phys. 2020, 312, 112148. [Google Scholar] [CrossRef]

- Xin, Y.; Tong, J.; Hou, T.; Liu, H.; Cui, M.; Song, X.; Wang, Y.; Lin, T.; Wang, L.; Wang, G. BiScO3-PbTiO3 nanofibers piezoelectric sensor for high-temperature pressure and vibration measurements. Measurement 2023, 212, 112694. [Google Scholar] [CrossRef]

- Gong, X.; Kuo, Y.-C.; Zhou, G.; Wu, W.-J.; Liao, W.-H. An aerosol deposition based MEMS piezoelectric accelerometer for low noise measurement. Microsystems Nanoeng. 2023, 9, 23. [Google Scholar] [CrossRef]

- Mehamud, I.; Marklund, P.; Björling, M.; Shi, Y. Machine condition monitoring enabled by broad range vibration frequency detecting triboelectric nano-generator (TENG)-based vibration sensors. Nano Energy 2022, 98, 107292. [Google Scholar] [CrossRef]

- Felix, S.; Horowitz, R. Integration of Thin Film Strain Sensors into Hard Drives for Active Feedback Vibration Suppression. IEEE Sens. J. 2012, 13, 1708–1715. [Google Scholar] [CrossRef]

- Atsumi, T.; Yabui, S. Quadruple-Stage Actuator System for Magnetic-Head Positioning System in Hard Disk Drives. IEEE Trans. Ind. Electron. 2019, 67, 9184–9194. [Google Scholar] [CrossRef]

- Zhang, T.; Li, H.G.; Cai, G.P. Time delay stability analysis for vibration suppression of a smart cantilever beam with hysteresis property. J. Low Freq. Noise Vib. Act. Control. 2020, 40, 898–915. [Google Scholar] [CrossRef]

- Urasaki, S.; Yabuno, H. Amplitude control for sensorless self-excited oscillation of cantilever based on a piezoelectric device. Nonlinear Dyn. 2022, 108, 15–25. [Google Scholar] [CrossRef]

- Singh, K.; Sharma, S.; Kumar, R.; Talha, M. Vibration control of cantilever beam using poling tuned piezoelectric actuator. Mech. Based Des. Struct. Mach. 2021, 51, 2217–2240. [Google Scholar] [CrossRef]

- Hofmann, V.; Twiefel, J. Self-Sensing with loaded piezoelectric Bending actuators. Sens. Actuators A Phys. 2017, 263, 737–743. [Google Scholar] [CrossRef]

- Geng, W.; He, J.; Qiao, X.; Niu, L.; Zhao, C.; Xue, G.; Bi, K.; Mei, L.; Wang, X.; Chou, X. Conductive Domain-Wall Temperature Sensors of LiNbO3 Ferroelectric Single-Crystal Thin Films. IEEE Electron Device Lett. 2021, 42, 1841–1844. [Google Scholar] [CrossRef]

- Geng, W.; Qiao, X.; He, J.; Mei, L.; Bi, K.; Wang, X.; Chou, X. Permanent charged domain walls under tip-poling engineering. J. Mater. Chem. C 2021, 9, 15797–15803. [Google Scholar] [CrossRef]

- Qu, M.; Shen, Y.; Wu, L.; Fu, X.; Cheng, X.; Wang, Y. Homogenous and ultra-shallow lithium niobate etching by focused ion beam. Precis. Eng. 2019, 62, 10–15. [Google Scholar] [CrossRef]

- Li, Y.; Lan, T.; Yang, D.; Xiang, M.; Dai, J.; Li, C.; Wang, Z. Research of selective etching in LiNbO3 using proton-exchanged wet etching technique. Mater. Res. Express 2020, 7, 056202. [Google Scholar] [CrossRef]

- Xiang, B.-X.; Wang, L.; Ma, Y.-J.; Yu, L.; Han, H.-P.; Ruan, S.-C. Supercontinuum Generation in Lithium Niobate Ridge Waveguides Fabricated by Proton Exchange and Ion Beam Enhanced Etching. Chin. Phys. Lett. 2017, 34, 024203. [Google Scholar] [CrossRef]

- Wei, H.; Geng, W.; Bi, K.; Li, T.; Li, X.; Qiao, X.; Shi, Y.; Zhang, H.; Zhao, C.; Xue, G.; et al. High-Performance Piezoelectric-Type MEMS Vibration Sensor Based on LiNbO3 Single-Crystal Cantilever Beams. Micromachines 2022, 13, 329. [Google Scholar] [CrossRef]

- Ibrahim, A.; Hassan, M. Extended bandwidth of 2DOF double impact triboelectric energy harvesting: Theoretical and experimental verification. Appl. Energy 2023, 333, 120593. [Google Scholar] [CrossRef]

- Mousavi, M.; Ziaei-Rad, S.; Karimi, A.H. Piezoelectric-based energy harvesting from bridge vibrations subjected to moving successive vehicles by functionally graded cantilever beams—Theoretical and experimental investigations. Mech. Syst. Signal Process. 2023, 188, 110015. [Google Scholar] [CrossRef]

- Zhao, C.; Hu, G.; Yang, Y. A cantilever-type vibro-impact triboelectric energy harvester for wind energy harvesting. Mech. Syst. Signal Process. 2022, 177, 109185. [Google Scholar] [CrossRef]

- Blue, R.; Brown, J.G.; Li, L.; Bauer, R.; Uttamchandani, D. MEMS Gas Flow Sensor Based on Thermally Induced Cantilever Resonance Frequency Shift. IEEE Sens. J. 2020, 20, 4139–4146. [Google Scholar] [CrossRef]

- Chen, Z.-H.; Li, C.-Y.; Chen, Y.-H.; Chu, S.-Y.; Tsai, C.-C.; Hong, C.-S. Enhancement of c-Axis Oriented Aluminum Nitride Films via Low Temperature DC Sputtering. IEEE Sens. J. 2021, 21, 17673–17677. [Google Scholar] [CrossRef]

- Wang, J.; Xue, Z.; Cai, C.; Wang, D.B. A Novel Piezoelectric Energy Harvester with Different Circular Arc Spiral Cantilever Beam. IEEE Sens. J. 2022, 22, 11016–11022. [Google Scholar] [CrossRef]

- Li, Z.; Gao, Y.; Chen, M.; Lou, L.; Ren, H. An AlN Piezoelectric Micromachined Ultrasonic Transducer-Based Liquid Density Sensor. IEEE Trans. Electron Devices 2022, 70, 261–268. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, B.; Cai, Y.; Zhou, J.; Liu, W.; Tovstopyat, A.; Wu, G.; Sun, C. Design and Performance of ScAlN/AlN Trapezoidal Cantilever-Based MEMS Piezoelectric Energy Harvesters. IEEE Trans. Electron Devices 2021, 68, 2971–2976. [Google Scholar] [CrossRef]

- Saxena, S.; Sharma, R.; Pant, B.D. Design and development of guided four beam cantilever type MEMS based piezoelectric energy harvester. Microsyst. Technol. 2016, 23, 1751–1759. [Google Scholar] [CrossRef]

- Shanmugavel, S.; Yao, K.; Luong, T.D.; Oh, S.R.; Chen, Y.; Tan, C.Y.; Gaunekar, A.; Ng, P.H.Y.; Li, M.H.L. Miniaturized acceleration sensors with in- plane polarized piezoelectric thin films produced by micromachining. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2011, 58, 2289–2296. [Google Scholar] [CrossRef]

- Wu, J.; Hu, Z.; Gao, X.; Cheng, M.; Zhao, X.; Su, W.; Wang, L.; Guan, M.; Du, Y.; Mao, R.; et al. Unconventional piezoelectric coefficients in perovskite piezoelectric ceramics. J. Materiomics 2020, 7, 254–263. [Google Scholar] [CrossRef]

- Erturk, A.; Inman, D.J. A Distributed Parameter Electromechanical Model for Cantilevered Piezoelectric Energy Harvesters. J. Vib. Acoust. 2008, 130, 041002. [Google Scholar] [CrossRef]

- Du, X.; Zhou, Y.; Li, L.; Persson, C.; Ferguson, S.J. The porous cantilever beam as a model for spinal implants: Experimental, analytical and finite element analysis of dynamic properties. Math. Biosci. Eng. 2023, 20, 6273–6293. [Google Scholar] [CrossRef] [PubMed]

- Joubert, A.; Allaire, G.; Amstutz, S.; Diani, J. Damping optimization of viscoelastic cantilever beams and plates under free vibration. Comput. Struct. 2022, 268, 106811. [Google Scholar] [CrossRef]

- Yan, H.; Zhou, X.; Gao, X.; Chen, J.; Xia, W.; Su, B.; Song, M. Development of the fine-grained Mg−0.6Zr sheets with enhanced damping capacity by high strain rate rolling. Mater. Charact. 2020, 172, 110826. [Google Scholar] [CrossRef]

- Erturk, A.; Inman, D. On Mechanical Modeling of Cantilevered Piezoelectric Vibration Energy Harvesters. J. Intell. Mater. Syst. Struct. 2008, 19, 1311–1325. [Google Scholar] [CrossRef]

- Adair, D.; Jaeger, M. A power series solution for rotating nonuniform Euler–Bernoulli cantilever beams. J. Vib. Control. 2017, 24, 3855–3864. [Google Scholar] [CrossRef]

- Gao, F.; Liao, W.-H.; Wu, X. Being gradually softened approach for solving large deflection of cantilever beam subjected to distributed and tip loads. Mech. Mach. Theory 2022, 174, 104879. [Google Scholar] [CrossRef]

- Tan, T.; Yan, Z.; Hajj, M. Electromechanical decoupled model for cantilever-beam piezoelectric energy harvesters. Appl. Phys. Lett. 2016, 109, 101908. [Google Scholar] [CrossRef]

- Wei, H.; Geng, W.; Bi, K.; Li, T.; Li, X.; Zhang, H.; Li, Y.; Xun, M.; Chou, X. Effect of γ-ray irradiation on performance of LiNbO3-based piezoelectric vibration sensors. Europhys. Lett. 2022, 136, 67001. [Google Scholar] [CrossRef]

- Gates, R.S.; Osborn, W.A.; Shaw, G.A. Accurate flexural spring constant calibration of colloid probe cantilevers using scanning laser Doppler vibrometry. Nanotechnology 2015, 26, 235704. [Google Scholar] [CrossRef][Green Version]

- Courtois, J.; Bielska, K.; Hodges, J.T. Differential cavity ring-down spectroscopy. J. Opt. Soc. Am. B 2013, 30, 1486–1495. [Google Scholar] [CrossRef]

- Jenewein, J.; Hartmann, S.; Roura, A.; Giese, E. Bragg-diffraction-induced imperfections of the signal in retroreflective atom interferometers. Phys. Rev. A 2022, 105, 063316. [Google Scholar] [CrossRef]

- Chen, N.; Yan, P.; Ouyang, J. A generalized approach on bending and stress analysis of beams with piezoelectric material bonded. Sens. Actuators A Phys. 2019, 290, 54–61. [Google Scholar] [CrossRef]

- Chou, X.; Guan, X.; Lv, Y.; Geng, W.; Liu, J.; Xue, C.; Zhang, W. Superior Electrostrictive Strain Behavior of Antiferroelectric (Pb, La)(Zr, Ti)O3 Thick Film Microcantilevers for MEMS Device Applications. IEEE Electron DeviceLett. 2013, 34, 1187–1189. [Google Scholar] [CrossRef]

| Symbol | Meaning | Numerical Value |

|---|---|---|

| Lmass | The length of the mass block | 3600 μm |

| Wmass | The width of the mass block | 460 μm |

| Lbeam | The length of the cantilever beam | 2260 μm |

| Hbeam | The height of the cantilever beam | 100 μm |

| ρLN | Density of LN | 4700 kg/m3 |

| εrLN | Relative dielectric constants of LN | {43.6, 43.6, 29.16} |

| ρSi | Density of Si | 2329 kg/m3 |

| εrSi | Relative dielectric constants of Si | 11.7 |

| vSi | Poisson’s ratios of Si | 0.28 |

| YSi | Young’s modulus of Si. | 1.7 × 1011 Pa |

| ρAu | Density of Au | 19,300 kg/m3 |

| vAu | Poisson’s ratios of Au | 0.44 |

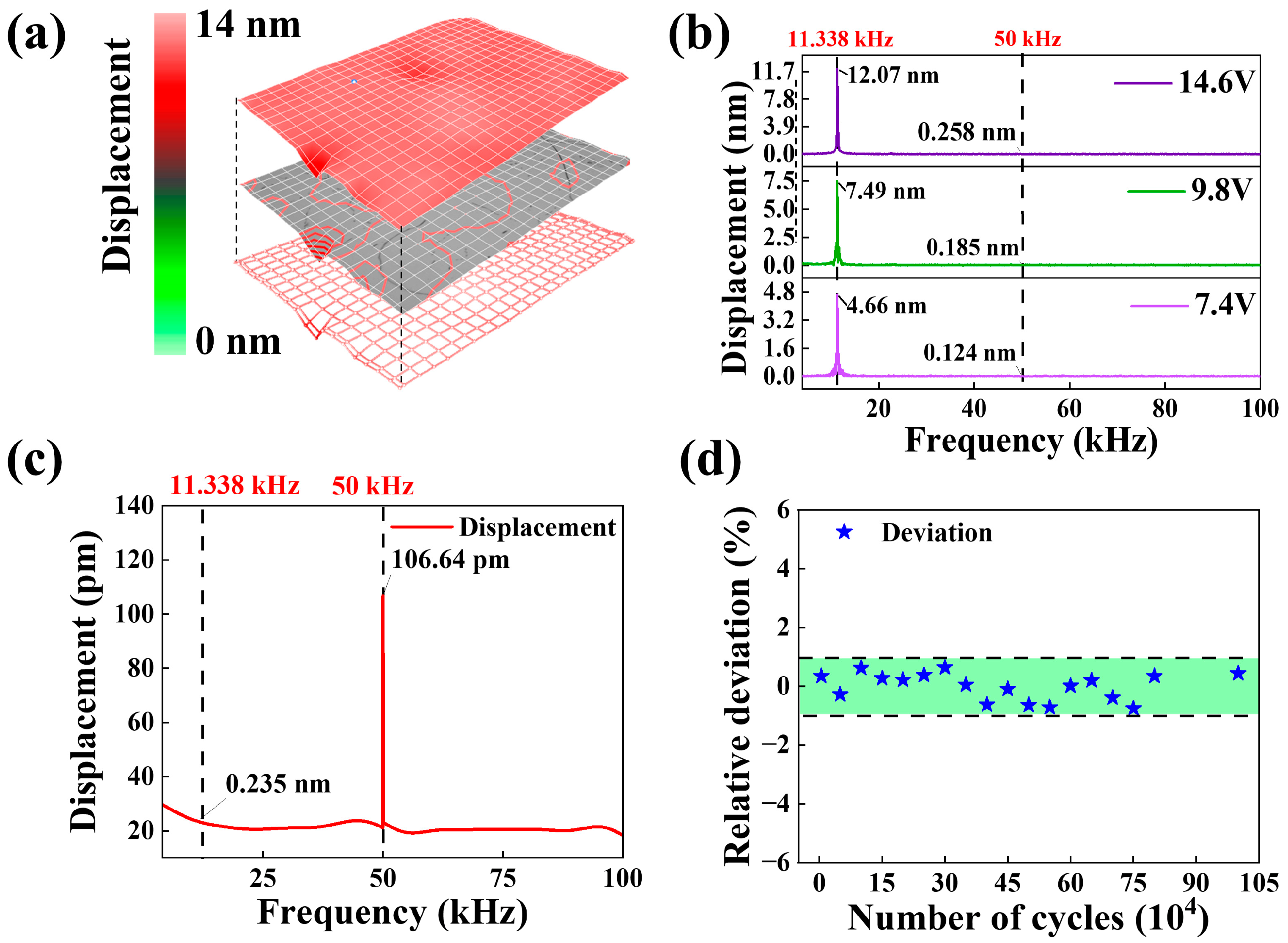

| Mode of Simulation | Measurement Frequency | Description |

|---|---|---|

| 1st | 11.338 kHz | flexure |

| 2nd | 21.953 kHz | torsion |

| 3rd | 23.547 kHz | torsion |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Qiao, X.; Wei, H.; Li, X.; Wu, X.; Yu, N.; Lu, H.; Guo, T.; Chou, X.; Geng, W. Electric-Force Conversion Performance of Si-Based LiNbO3 Devices Based on Four Cantilever Beams. Micromachines 2023, 14, 1988. https://doi.org/10.3390/mi14111988

Zhang H, Qiao X, Wei H, Li X, Wu X, Yu N, Lu H, Guo T, Chou X, Geng W. Electric-Force Conversion Performance of Si-Based LiNbO3 Devices Based on Four Cantilever Beams. Micromachines. 2023; 14(11):1988. https://doi.org/10.3390/mi14111988

Chicago/Turabian StyleZhang, Huiyi, Xiaojun Qiao, Huifen Wei, Xiaohuang Li, Xiaohui Wu, Nanxin Yu, Hao Lu, Tao Guo, Xiujian Chou, and Wenping Geng. 2023. "Electric-Force Conversion Performance of Si-Based LiNbO3 Devices Based on Four Cantilever Beams" Micromachines 14, no. 11: 1988. https://doi.org/10.3390/mi14111988

APA StyleZhang, H., Qiao, X., Wei, H., Li, X., Wu, X., Yu, N., Lu, H., Guo, T., Chou, X., & Geng, W. (2023). Electric-Force Conversion Performance of Si-Based LiNbO3 Devices Based on Four Cantilever Beams. Micromachines, 14(11), 1988. https://doi.org/10.3390/mi14111988