Flexible Piezoresistive Sensors from Polydimethylsiloxane Films with Ridge-like Surface Structures

Abstract

:1. Introduction

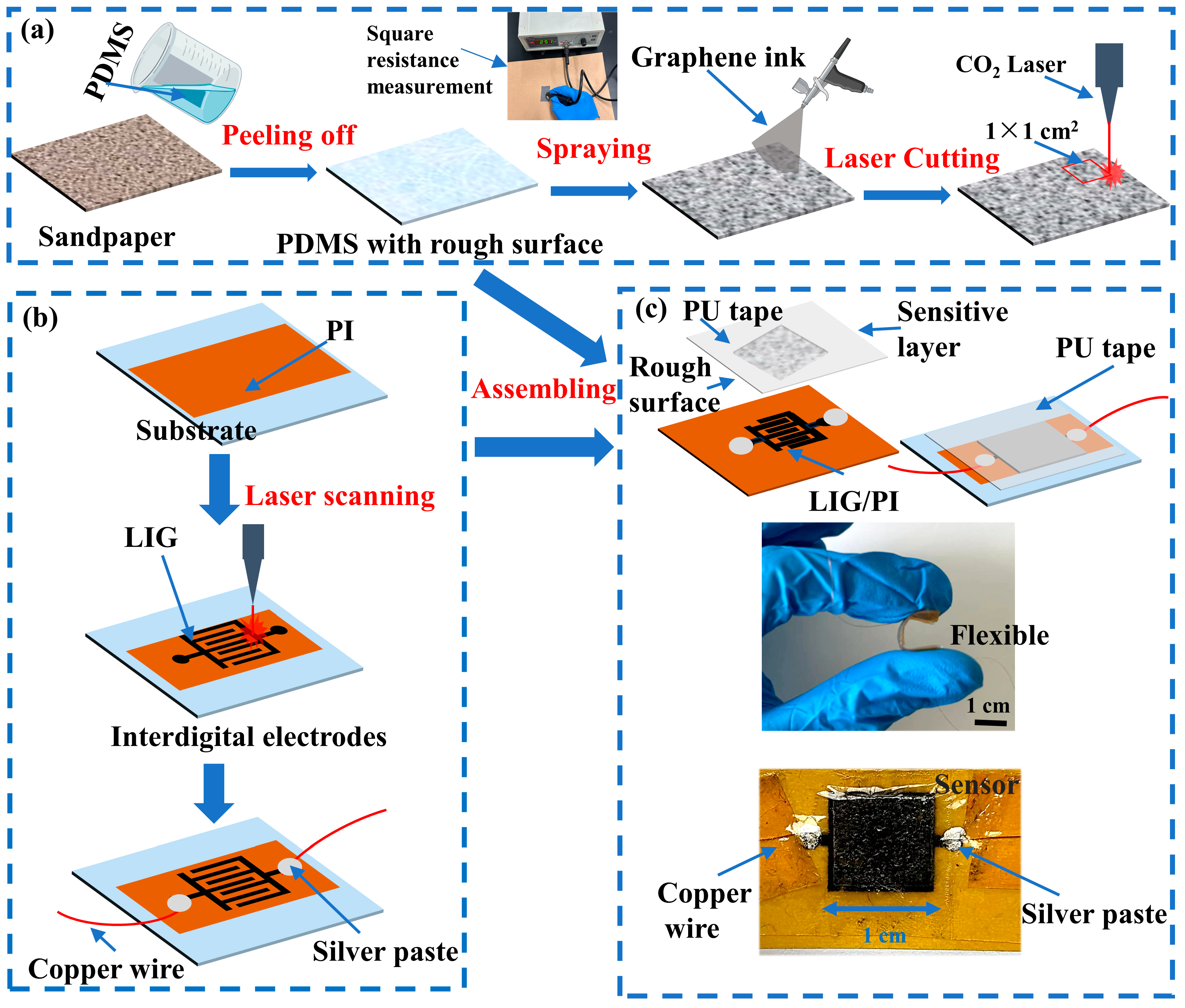

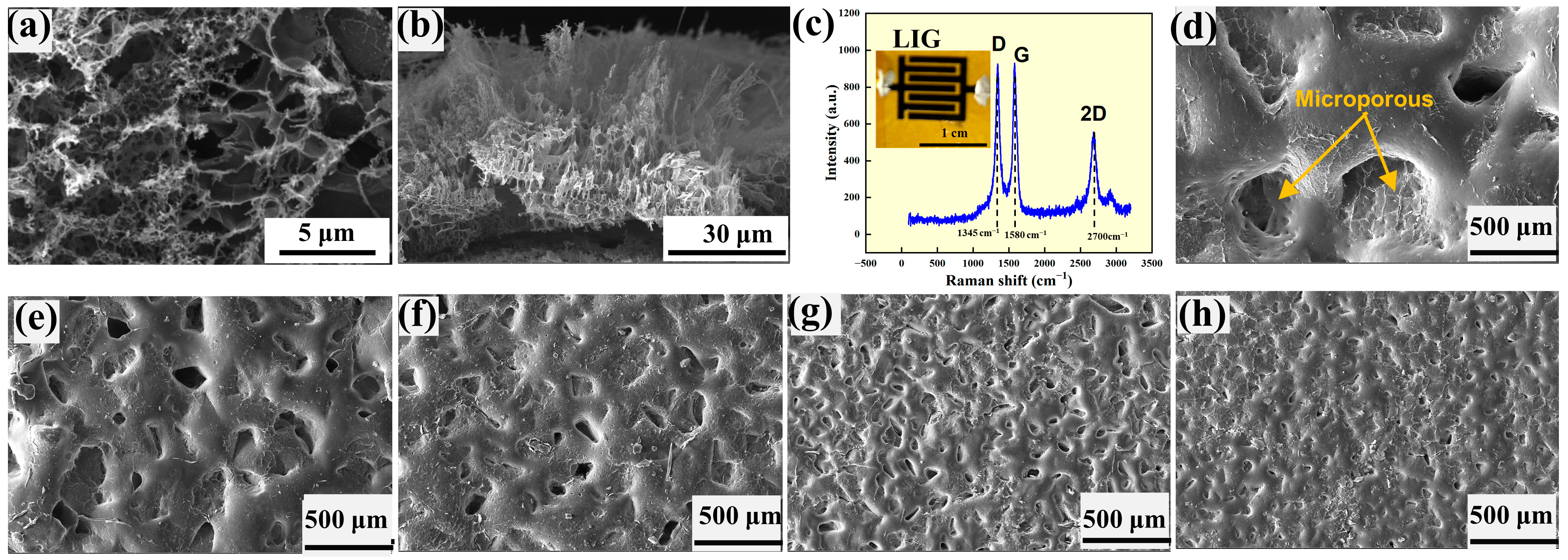

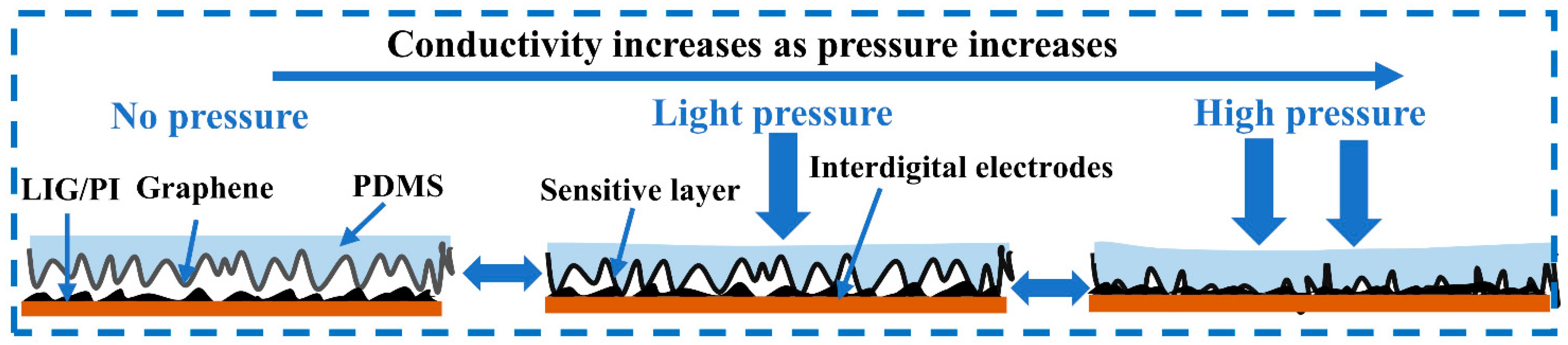

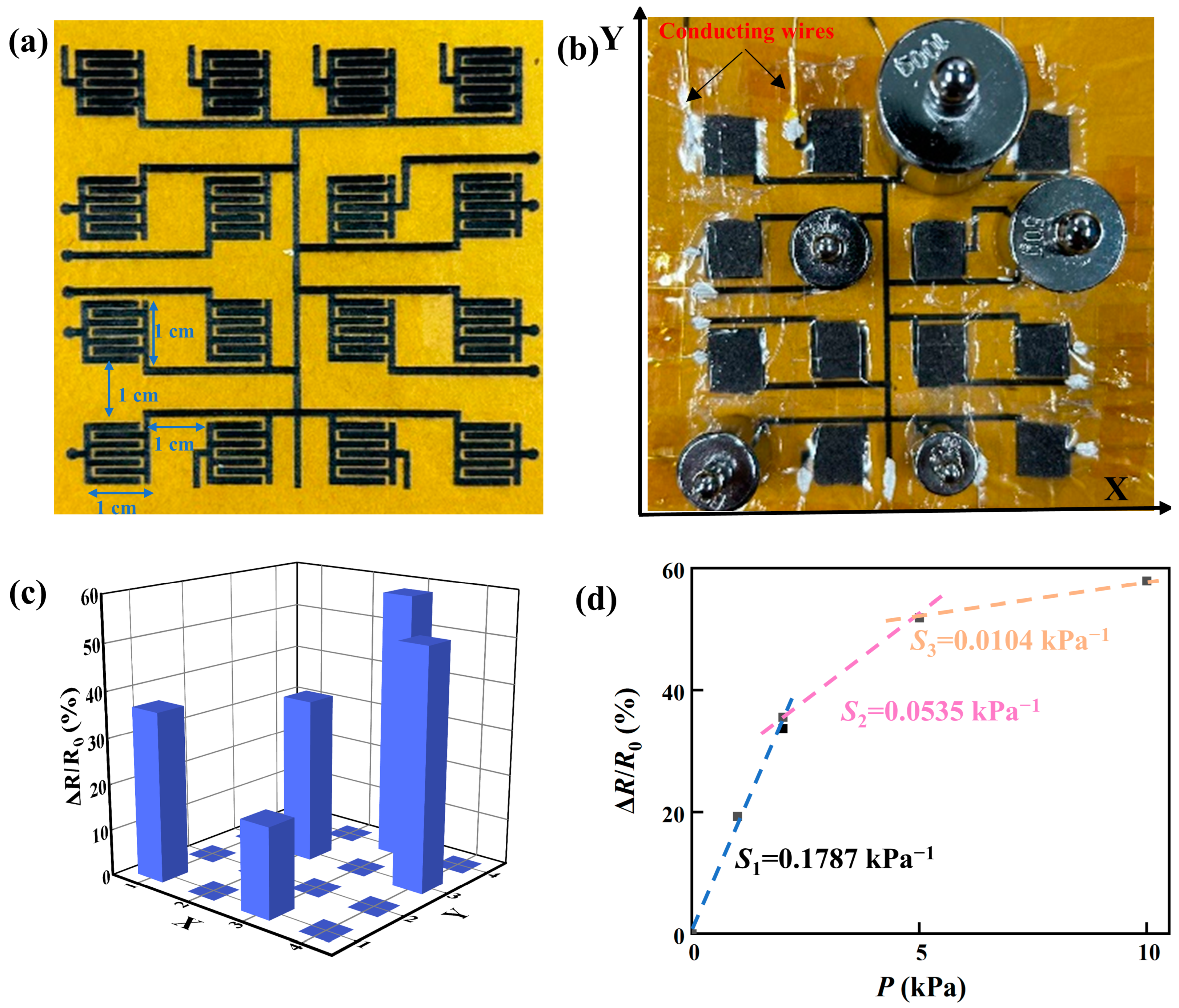

2. Construction of Flexible Sensors

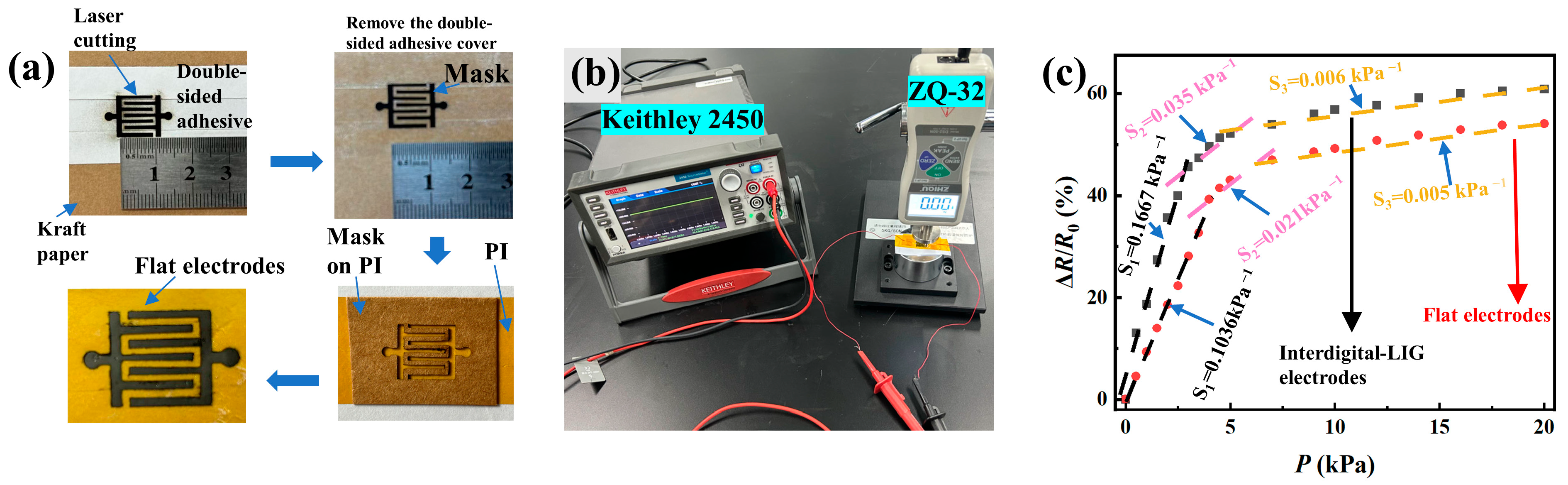

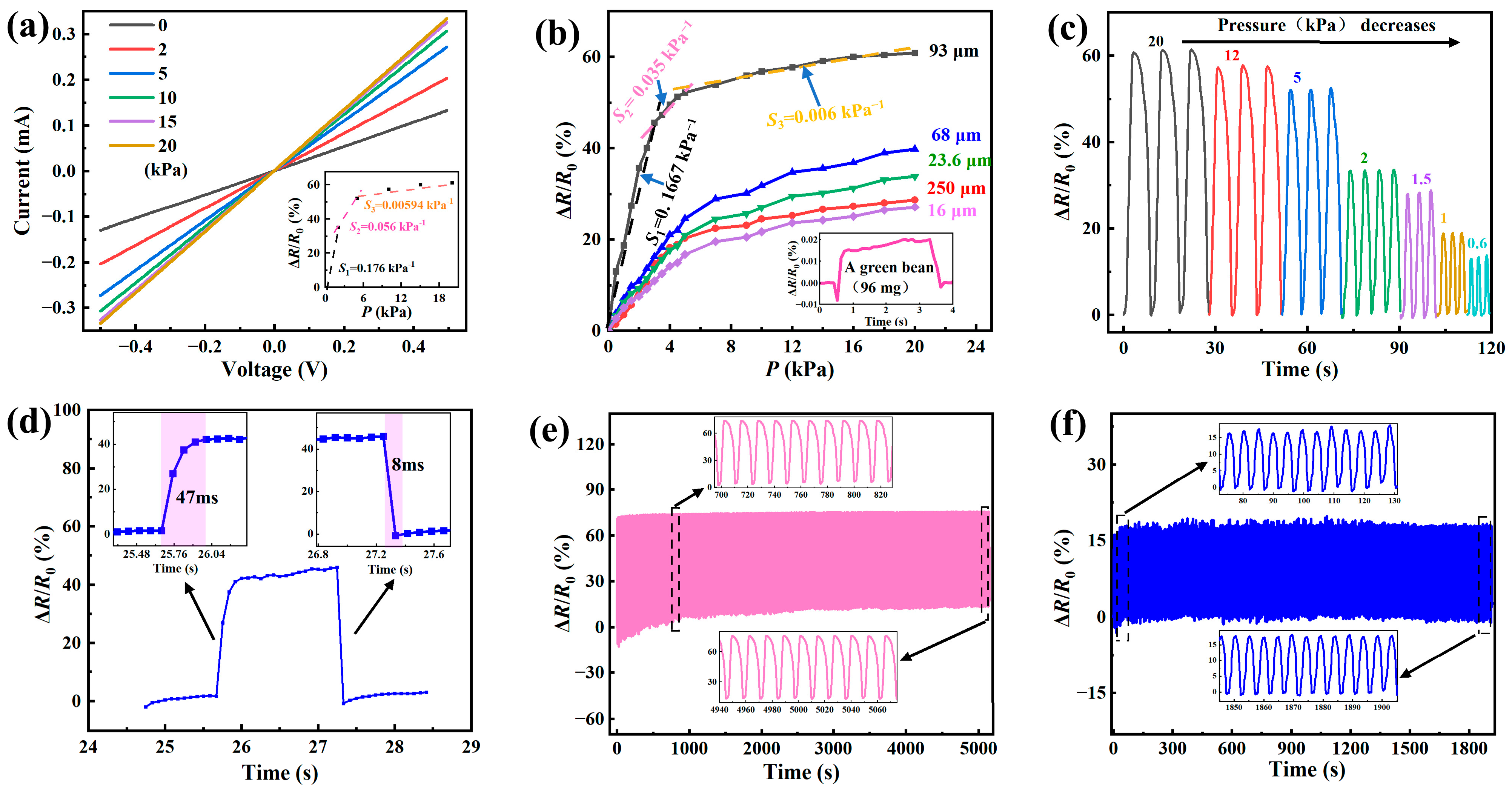

3. Results and Discussion

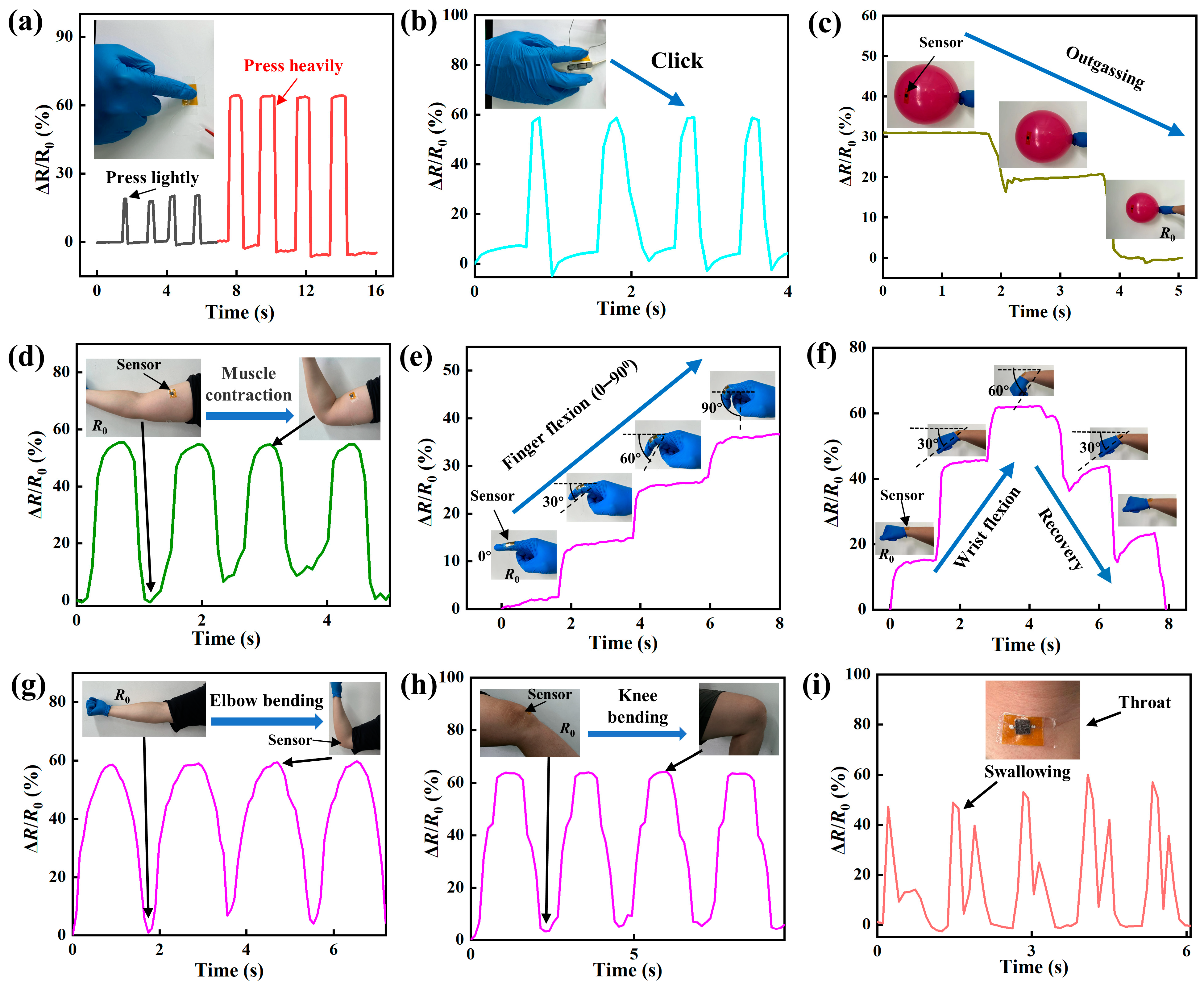

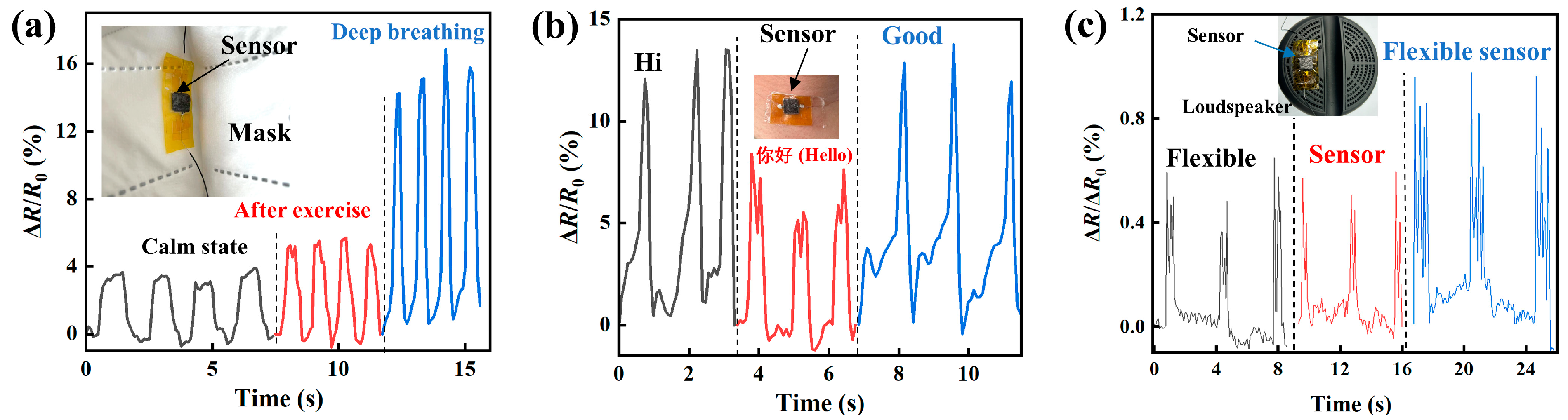

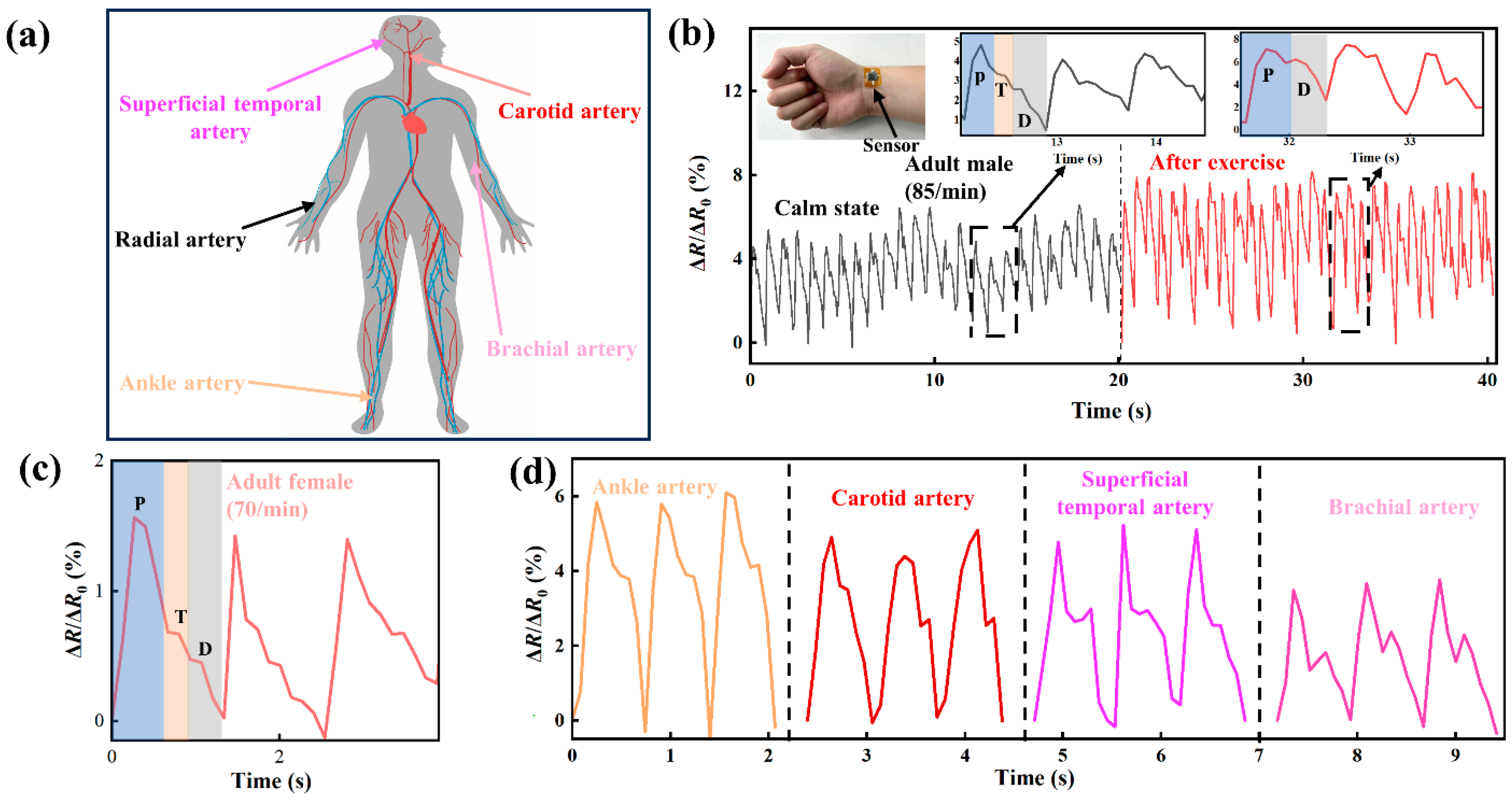

4. Applications of the Piezoresistive Sensors

5. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, Y.; Guo, Z.; Zhong, M.; Wan, P.; Zhang, W.; Zhang, L. A Flexible Wearable Pressure Sensor with Bioinspired Microcrack and Interlocking for Full-Range Human-Machine Interfacing. Small 2018, 14, 1803018. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Nassar, J.; Xu, C.; Min, J.; Yang, Y.; Dai, A.; Doshi, R.; Huang, A.; Song, Y.; Gehlhar, R.; et al. Biofuel-powered soft electronic skin with multiplexed and wireless sensing for human-machine interfaces. Sci. Robot. 2020, 5, eaaz7946. [Google Scholar] [CrossRef]

- Yin, J.W.; Guo, S.N.; E, M.F.; Liu, H.; Liu, Z.H.; Ding, W.Y.; Li, D.M.; Cui, Y.X. Self-Powered Rapid Response Flexible Pressure Sensor for Wearable Application. Adv. Eng. Mater. 2023, 25, 2201678. [Google Scholar] [CrossRef]

- Wang, X.; Feng, Z.P.; Li, P.; Wang, L.N.; Chen, L.; Wu, Y.F.; Yang, J. A Flexible Pressure Sensor with a Mesh Structure Formed by Lost Hair for Human Epidermal Pulse Wave Monitoring. Sensors 2023, 23, 45. [Google Scholar] [CrossRef] [PubMed]

- Qureshi, A.; Niazi, J.H. Graphene-interfaced flexible and stretchable micro-nano electrodes: From fabrication to sweat glucose detection. Mater. Horiz. 2023, 10, 1580–1607. [Google Scholar] [CrossRef]

- Tan, C.X.; Dong, Z.G.; Li, Y.H.; Zhao, H.G.; Huang, X.Y.; Zhou, Z.C.; Jiang, J.W.; Long, Y.Z.; Jiang, P.K.; Zhang, T.Y.; et al. A high performance wearable strain sensor with advanced thermal management for motion monitoring. Nat. Commun. 2020, 11, 3530. [Google Scholar] [CrossRef]

- Pan, L.J.; Chortos, A.; Yu, G.H.; Wang, Y.Q.; Isaacson, S.; Allen, R.; Shi, Y.; Dauskardt, R.; Bao, Z.N. An ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure induced elasticity in conducting polymer film. Nat. Commun. 2014, 5, 3002. [Google Scholar] [CrossRef]

- Luo, Y.S.; Shao, J.Y.; Chen, S.R.; Chen, X.L.; Tian, H.M.; Li, X.M.; Wang, L.; Wang, D.R.; Lu, B.H. Flexible Capacitive Pressure Sensor Enhanced by Tilted Micropillar Arrays. ACS Appl. Mater. Interfaces 2019, 11, 17796–17803. [Google Scholar] [CrossRef]

- Yang, J.; Luo, S.; Zhou, X.; Li, J.; Fu, J.; Yang, W.; Wei, D. Flexible, Tunable, and Ultrasensitive Capacitive Pressure Sensor with Microconformal Graphene Electrodes. ACS Appl. Mater. Interfaces 2019, 11, 14997–15006. [Google Scholar] [CrossRef]

- Zheng, R.L.; Wang, Y.Y.; Zhang, Z.X.; Zhang, Y.F.; Liu, J.Z. High sensitivity and broad detection range flexible capacitive pressure sensor based on rGO cotton fiber for human motion detection. Smart Mater. Struct. 2022, 31, 025019. [Google Scholar] [CrossRef]

- Zhou, J.Y.; Gu, Y.; Lu, J.Y.; Xu, L.D.; Zhang, J.C.; Wang, D.; Wang, W.X. An ultra-strong non-pre-irradiation and self-recoverable mechanoluminescent elastomer. Chem. Eng. J. 2020, 390, 124473. [Google Scholar] [CrossRef]

- Tang, X.Y.; Yang, W.D.; Yin, S.R.; Tai, G.J.; Su, M.; Yang, J.; Shi, H.F.; Wei, D.P.; Yang, J. Controllable Graphene Wrinkle for a High-Performance Flexible Pressure Sensor. ACS Appl. Mater. Interfaces 2021, 13, 20448–20458. [Google Scholar] [CrossRef]

- Tang, X.; Wu, C.Y.; Gan, L.; Zhang, T.; Zhou, T.T.; Huang, J.; Wang, H.; Xie, C.S.; Zeng, D.W. Multilevel Microstructured Flexible Pressure Sensors with Ultrahigh Sensitivity and Ultrawide Pressure Range for Versatile Electronic Skins. Small 2019, 15, 1804559. [Google Scholar] [CrossRef]

- Wang, Z.L.; Song, J.H. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef]

- Persano, L.; Dagdeviren, C.; Su, Y.; Zhang, Y.; Girardo, S.; Pisignano, D.; Huang, Y.; Rogers, J.A. High performance piezoelectric devices based on aligned arrays of nanofibers of poly(vinylidenefluoride-co-trifluoroethylene). Nat. Commun. 2013, 4, 1633. [Google Scholar] [CrossRef]

- Duan, Z.H.; Jiang, Y.D.; Huang, Q.; Wang, S.; Zhao, Q.N.; Zhang, Y.J.; Liu, B.H.; Yuan, Z.; Wang, Y.; Tai, H.L. Facilely constructed two-sided microstructure interfaces between electrodes and cellulose paper active layer: Eco-friendly, low-cost and high-performance piezoresistive sensor. Cellulose 2021, 28, 6389–6402. [Google Scholar] [CrossRef]

- Huang, Q.; Jiang, Y.; Duan, Z.; Yuan, Z.; Liu, B.; Zhang, Y.; Zhao, Q.; Li, Y.; Tai, H. Protrusion Microstructure-Induced Sensitivity Enhancement for Zinc Oxide–Carbon Nanotube Flexible Pressure Sensors. ACS Appl. Electron. Mater. 2021, 3, 5506–5513. [Google Scholar] [CrossRef]

- Ding, H.J.; Zeng, Z.P.; Wang, Z.W.; Li, X.L.; Yildirim, T.; Xie, Q.L.; Zhang, H.; Wageh, S.; Al-Ghamdi, A.A.; Zhang, X.; et al. Deep Learning-Enabled MXene/PEDOT:PSS Acoustic Sensor for Speech Recognition and Skin-Vibration Detection. Adv. Intell. Syst. 2022, 4, 2200140. [Google Scholar] [CrossRef]

- Sharma, S.; Chhetry, A.; Sharifuzzaman, M.; Yoon, H.; Park, J.Y. Wearable Capacitive Pressure Sensor Based on MXene Composite Nanofibrous Scaffolds for Reliable Human Physiological Signal Acquisition. ACS Appl. Mater. Interfaces 2020, 12, 22212–22224. [Google Scholar] [CrossRef]

- Xia, S.-Y.; Long, Y.; Huang, Z.; Zi, Y.; Tao, L.-Q.; Li, C.-H.; Sun, H.; Li, J. Laser-induced graphene (LIG)-based pressure sensor and triboelectric nanogenerator towards high-performance self-powered measurement-control combined system. Nano Energy 2022, 96, 107099. [Google Scholar] [CrossRef]

- Gong, S.; Schwalb, W.; Wang, Y.W.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W.L. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef]

- Chen, L.X.; Liu, J.Q.; Wang, X.L.; Ji, B.; Chen, X.A.; Bin, Y. Flexible Capacitive Hydrogel Tactile Sensor with Adjustable Measurement Range Using Liquid Crystal and Carbon Nanotubes Composites. IEEE Trans. Electron. Devices 2017, 64, 1968–1972. [Google Scholar] [CrossRef]

- Jang, H.; Yoon, H.; Ko, Y.; Choi, J.; Lee, S.S.; Jeon, I.; Kim, J.H.; Kim, H. Enhanced performance in capacitive force sensors using carbon nanotube/polydimethylsiloxane nanocomposites with high dielectric properties. Nanoscale 2016, 8, 5667–5675. [Google Scholar] [CrossRef] [PubMed]

- Xu, R.Q.; Wang, D.; Zhang, H.C.; Xie, N.; Lu, S.; Qu, K. Simultaneous Detection of Static and Dynamic Signals by a Flexible Sensor Based on 3D Graphene. Sensors 2017, 17, 1069. [Google Scholar] [CrossRef] [PubMed]

- Cao, M.H.; Su, J.; Fan, S.Q.; Qiu, H.W.; Su, D.L.; Li, L. Wearable piezoresistive pressure sensors based on 3D graphene. Chem. Eng. J. 2021, 406, 126777. [Google Scholar] [CrossRef]

- Huo, Q.S.; Jin, J.Q.; Wang, X.Q.; Lu, S.W.; Zhang, Y.W.; Ma, J.C.; Wang, S. Preparation of graphene-based sensor and its application in human behavior monitoring. Mater. Express 2019, 6, 075613. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, W.; Wang, Z.; Liu, H.; Yin, R.; Liu, C.; Shen, C. Highly compressible and thermal insulative conductive MXene/PEDOT:PSS@melamine foam for promising wearable piezoresistive sensor. Appl. Phys. Lett. 2023, 122, 043507. [Google Scholar] [CrossRef]

- Park, J.; Kim, M.; Lee, Y.; Lee, H.S.; Ko, H. Fingertip skin–inspired microstructured ferroelectric skins discriminate static/dynamic pressure and temperature stimuli. Sci. Adv. 2015, 1, e1500661. [Google Scholar] [CrossRef]

- Han, Z.; Li, H.; Xiao, J.; Song, H.; Li, B.; Cai, S.; Chen, Y.; Ma, Y.; Feng, X. Ultralow-Cost, Highly Sensitive, and Flexible Pressure Sensors Based on Carbon Black and Airlaid Paper for Wearable Electronics. ACS Appl. Mater. Interfaces 2019, 11, 33370–33379. [Google Scholar] [CrossRef]

- Mu, C.H.; Li, J.P.; Song, Y.Q.; Huang, W.T.; Ran, A.; Deng, K.; Huang, J.; Xie, W.H.; Sun, R.J.; Zhang, H.W. Enhanced Piezocapacitive Effect in CaCu3Ti4O12-Polydimethylsiloxane Composited Sponge for Ultrasensitive Flexible Capacitive Sensor. ACS Appl. Nano Mater. 2018, 1, 274–283. [Google Scholar] [CrossRef]

- Sriphan, S.; Charoonsuk, T.; Khaisaat, S.; Sawanakarn, O.; Pharino, U.; Phunpruch, S.; Maluangnont, T.; Vittayakorn, N. Flexible capacitive sensor based on 2D-titanium dioxide nanosheets/bacterial cellulose composite film. Nanotechnology 2021, 32, 155502. [Google Scholar] [CrossRef]

- Lin, J.; Peng, Z.W.; Liu, Y.Y.; Ruiz-Zepeda, F.; Ye, R.Q.; Samuel, E.L.G.; Yacaman, M.J.; Yakobson, B.I.; Tour, J.M. Laser-induced porous graphene films from commercial polymers. Nat. Commun. 2014, 5, 5714. [Google Scholar] [CrossRef]

- Xiao, Y.; Jiang, S.W.; Liu, P.; Xue, Z.W.; Zhu, Y.Y.; Yu, J.T.; Qiu, J.; Zhang, W.L. Highly sensitive and stable printed pressure sensor with microstructured grid arrays. Smart Mater. Struct. 2019, 28, 105027. [Google Scholar] [CrossRef]

- Karbasian, A.; Shirazi, M.; Mahmoudi, A.H. Effect of Surface Roughness on Brinell Hardness and Load-Displacement Curves using a Macro Indentation. Int. J. Eng. Technol. 2023, 36, 914–924. [Google Scholar] [CrossRef]

- Fan, L.; Zhao, L.; Nie, W.; Liu, X. Effects Of Interface Fractal Parameters On Normal Contact Stiffness. Eng. Mech. 2021, 38, 207–215. [Google Scholar]

- Zhu, B.W.; Niu, Z.Q.; Wang, H.; Leow, W.R.; Wang, H.; Li, Y.G.; Zheng, L.Y.; Wei, J.; Huo, F.W.; Chen, X.D. Microstructured Graphene Arrays for Highly Sensitive Flexible Tactile Sensors. Small 2014, 10, 3625–3631. [Google Scholar] [CrossRef] [PubMed]

- Choong, C.L.; Shim, M.B.; Lee, B.S.; Jeon, S.; Ko, D.S.; Kang, T.H.; Bae, J.; Lee, S.H.; Byun, K.E.; Im, J.; et al. Highly Stretchable Resistive Pressure Sensors Using a Conductive Elastomeric Composite on a Micropyramid Array. Adv. Mater. 2014, 26, 3451–3458. [Google Scholar] [CrossRef]

- Bai, X.F.; Gai, C.H.; Wu, D.M.; Zhu, J.S.; Wu, G.Q.; Zhang, M.M.; Liu, Y.; Sun, J.Y.; Zhuang, J.; Huang, Y.; et al. Intelligent Sensing System of the Car Seat with Flexible Piezoresistive Sensor of Double-Layer Conductive Network. IEEE Sens. J. 2022, 22, 3113–3121. [Google Scholar] [CrossRef]

- Boutry, C.M.; Negre, M.; Jorda, M.; Vardoulis, O.; Chortos, A.; Khatib, O.; Bao, Z. A hierarchically patterned, bioinspired e-skin able to detect the direction of applied pressure for robotics. Sci. Robot. 2018, 3, eaau6914. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Lee, Y.; Hong, J.; Ha, M.; Jung, Y.D.; Lim, H.; Kim, S.Y.; Ko, H. Giant Tunneling Piezoresistance of Composite Elastomers with Interlocked Microdome Arrays for Ultrasensitive and Multimodal Electronic Skins. ACS Nano 2014, 8, 4689–4697. [Google Scholar] [CrossRef]

- Bae, G.Y.; Pak, S.W.; Kim, D.; Lee, G.; Kim, D.; Chung, Y.; Cho, K. Linearly and Highly Pressure-Sensitive Electronic Skin Based on a Bioinspired Hierarchical Structural Array. Adv. Mater. 2016, 28, 5300–5306. [Google Scholar] [CrossRef]

- Wang, X.M.; Chai, Y.J.; Zhu, C.C.; Yu, J.B.; Chen, X.P. Ultrasensitive and self-alarm pressure sensor based on laser-induced graphene and sea urchin-shaped Fe2O3 sandwiched structure. Chem. Eng. J. 2022, 448, 137664. [Google Scholar] [CrossRef]

- Jian, M.Q.; Xia, K.L.; Wang, Q.; Yin, Z.; Wang, H.M.; Wang, C.Y.; Xie, H.H.; Zhang, M.C.; Zhang, Y.Y. Flexible and Highly Sensitive Pressure Sensors Based on Bionic Hierarchical Structures. Adv. Funct. Mater. 2017, 27, 1606066. [Google Scholar] [CrossRef]

- Luo, Z.B.; Chen, J.; Zhu, Z.F.; Li, L.; Su, Y.; Tang, W.; Omisore, O.M.; Wang, L.; Li, H. High-Resolution and High-Sensitivity Flexible Capacitive Pressure Sensors Enhanced by a Transferable Electrode Array and a Micropillar-PVDF Film. ACS Appl. Mater. Interfaces 2021, 13, 7635–7649. [Google Scholar] [CrossRef]

- Pang, C.; Koo, J.H.; Amanda, N.; Caves, J.M.; Kim, M.-G.; Chortos, A.; Kim, K.; Wang, P.J.; Tok, J.B.H.; Bao, Z. Highly Skin-Conformal Microhairy Sensor for Pulse Signal Amplification. Adv. Mater. 2015, 27, 634–640. [Google Scholar] [CrossRef]

- Weng, M.C.; Sun, L.Q.; Qu, S.X.; Chen, L.Z. Fingerprint-inspired graphene pressure sensor with wrinkled structure. Extrem. Mech. Lett. 2020, 37, 100714. [Google Scholar] [CrossRef]

- Huang, J.R.; Yang, X.X.; Liu, J.T.; Her, S.C.; Guo, J.Q.; Gu, J.F.; Guan, L.H. Vibration monitoring based on flexible multi-walled carbon nanotube/polydimethylsiloxane film sensor and the application on motion signal acquisition. Nanotechnology 2020, 31, 335504. [Google Scholar] [CrossRef]

- Ji, Y.Q.; Zhang, Y.; Zhu, J.Q.; Geng, P.; Halpert, J.E.; Guo, L. Splashing-Assisted Femtosecond Laser-Activated Metal Deposition for Mold- and Mask-Free Fabrication of Robust Microstructured Electrodes for Flexible Pressure Sensors. Small 2023, 19, 2370173. [Google Scholar] [CrossRef]

- Jiang, Y.G.; He, Q.P.; Cai, J.; Shen, D.W.; Hu, X.H.; Zhang, D.Y. Flexible Strain Sensor with Tunable Sensitivity via Microscale Electrical Breakdown in Graphene/Polyimide Thin Films. ACS Appl. Mater. Interfaces 2020, 12, 58317–58325. [Google Scholar] [CrossRef]

- Lee, J.; Pyo, S.; Kwon, D.S.; Jo, E.; Kim, W.; Kim, J. Ultrasensitive Strain Sensor Based on Separation of Overlapped Carbon Nanotubes. Small 2019, 15, 1805120. [Google Scholar] [CrossRef]

- Zhang, M.C.; Wang, C.Y.; Wang, H.M.; Jian, M.Q.; Hao, X.Y.; Zhang, Y.Y. Carbonized Cotton Fabric for High-Performance Wearable Strain Sensors. Adv. Funct. Mater. 2017, 27, 1604795. [Google Scholar] [CrossRef]

- Tian, Q.; Yan, W.R.; Li, Y.Q.; Ho, D. Bean Pod-Inspired Ultrasensitive and Self-Healing Pressure Sensor Based on Laser-Induced Graphene and Polystyrene Microsphere Sandwiched Structure. ACS Appl. Mater. Interfaces 2020, 12, 9710–9717. [Google Scholar] [CrossRef]

- Guan, H.; Meng, J.W.; Cheng, Z.Y.; Wang, X.Q. Processing Natural Wood into a High-Performance Flexible Pressure Sensor. ACS Appl. Mater. Interfaces 2020, 12, 46357–46365. [Google Scholar] [CrossRef]

- Wan, Y.; Qiu, Z.; Hong, Y.; Wang, Y.; Zhang, J.; Liu, Q.; Wu, Z.; Guo, C.F. A Highly Sensitive Flexible Capacitive Tactile Sensor with Sparse and High-Aspect-Ratio Microstructures. Adv. Electron. Mater. 2018, 4, 1700586. [Google Scholar] [CrossRef]

- Cheng, L.; Wang, R.; Hao, X.; Liu, G. Design of Flexible Pressure Sensor Based on Conical Microstructure PDMS-Bilayer Graphene. Sensors 2021, 21, 289. [Google Scholar] [CrossRef]

- Jia, W.; Zhang, Q.; Cheng, Y.; Zhao, D.; Liu, Y.; Zhang, W.; Sang, S. Flexible and Highly Sensitive Piezoresistive Pressure Sensor with Sandpaper as a Mold. Nano 2019, 14, 13–22. [Google Scholar] [CrossRef]

- Yang, Z.P.; Li, H.Q.; Li, C.K.; Lai, X.J.; Zeng, X.R. Conductive and room-temperature self-healable polydimethylsiloxane-based elastomer film with ridge-like microstructure for piezoresistive pressure sensor. Chem. Eng. J. 2022, 430, 133103. [Google Scholar] [CrossRef]

- Liu, M.; Wu, J.; Cheng, H. Effects of laser processing parameters on properties of laser-induced graphene by irradiating CO2 laser on polyimide. Sci. China-Technol. Sci. 2022, 65, 41–52. [Google Scholar] [CrossRef]

- Yu, Z.; Hu, G.; Chen, J.; Huang, F.; Zhao, Y.; Feng, J. Resonant printing flexible piezoresistive pressure sensor with spherical microstructures. Smart Mater. Struct. 2023, 32, 035020. [Google Scholar] [CrossRef]

- Gao, Y.; Yu, G.H.; Tan, J.P.; Xuan, F.Z. Sandpaper-molded wearable pressure sensor for electronic skins. Sens. Actuators A-Phys. 2018, 280, 205–209. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, L.; Zhang, P.; Liu, J.; Yang, B. A durable flexible pressure sensor with high sensitivity and wide pressure range for health monitoring. In Proceedings of the 35th IEEE International Conference on Micro Electro Mechanical Systems Conference (IEEE MEMS), Tokyo, Japan, 9–13 January 2022; pp. 333–336. [Google Scholar]

- Yang, M.; Cheng, Y.F.; Yue, Y.; Chen, Y.; Gao, H.; Li, L.; Cai, B.; Liu, W.J.; Wang, Z.Y.; Guo, H.Z.; et al. High-Performance Flexible Pressure Sensor with a Self-Healing Function for Tactile Feedback. Adv. Sci. 2022, 9, 2200507. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Qiao, Y.; Guo, R.; Naveed, S.; Hirtz, T.; Li, X.; Fu, Y.; Wei, Y.; Deng, G.; Yang, Y.; et al. Triode-Mimicking Graphene Pressure Sensor with Positive Resistance Variation for Physiology and Motion Monitoring. ACS Nano 2020, 14, 10104–10114. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Wu, N.; Lin, S.; Duan, J.; Xu, Z.; Pan, Y.; Zhang, H.; Xu, Z.; Huang, L.; Hu, B.; et al. Hierarchical elastomer tuned self-powered pressure sensor for wearable multifunctional cardiovascular electronics. Nano Energy 2020, 70, 104460. [Google Scholar] [CrossRef]

| Sensing Material | Sensitivity (kPa−1) | Pressure Range (kPa) | Response/Recovery Times (ms) | Limit of Detection | Reference |

|---|---|---|---|---|---|

| Graphene | 0.1667 | 0–2 | 47/8 | 96 mg | This study |

| 0.035 | 2–5 | ||||

| 0.006 | 5–10 | ||||

| AgNWs | 0.1194 | 0–1.3 | 50/NA | NA | [56] |

| 0.0523 | 1.3–4 | ||||

| Nanotubes | 0.087 | 0–6.1 | 40/117 | 50 Pa | [57] |

| 0.009 | 6.1–29.1 | ||||

| MWCNTs/CNT | 0.024 | 1–20 | 72/105 | NA | [59] |

| 0.0058 | 20–60 | ||||

| CNT | −0.209 | <1 | 195/158 | 5.0 Pa | [60] |

| CNTs | 78.04 | 0–3 | 25/590 | NA | [61] |

| 145.706 | 3–10 | ||||

| 10.79 | 10–500 | ||||

| MXene | 281.5 | 0.36–2.34 | 67.3/44.8 | 7.8 Pa | [62] |

| 509.8 | 2.34–4.57 | ||||

| 66.7 | 4.57–19.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Liu, X.; Yang, F. Flexible Piezoresistive Sensors from Polydimethylsiloxane Films with Ridge-like Surface Structures. Micromachines 2023, 14, 1940. https://doi.org/10.3390/mi14101940

Liu M, Liu X, Yang F. Flexible Piezoresistive Sensors from Polydimethylsiloxane Films with Ridge-like Surface Structures. Micromachines. 2023; 14(10):1940. https://doi.org/10.3390/mi14101940

Chicago/Turabian StyleLiu, Ming, Xianchao Liu, and Fuqian Yang. 2023. "Flexible Piezoresistive Sensors from Polydimethylsiloxane Films with Ridge-like Surface Structures" Micromachines 14, no. 10: 1940. https://doi.org/10.3390/mi14101940

APA StyleLiu, M., Liu, X., & Yang, F. (2023). Flexible Piezoresistive Sensors from Polydimethylsiloxane Films with Ridge-like Surface Structures. Micromachines, 14(10), 1940. https://doi.org/10.3390/mi14101940