Sapphire Selective Laser Etching Dependence on Radiation Wavelength and Etchant

Abstract

1. Introduction

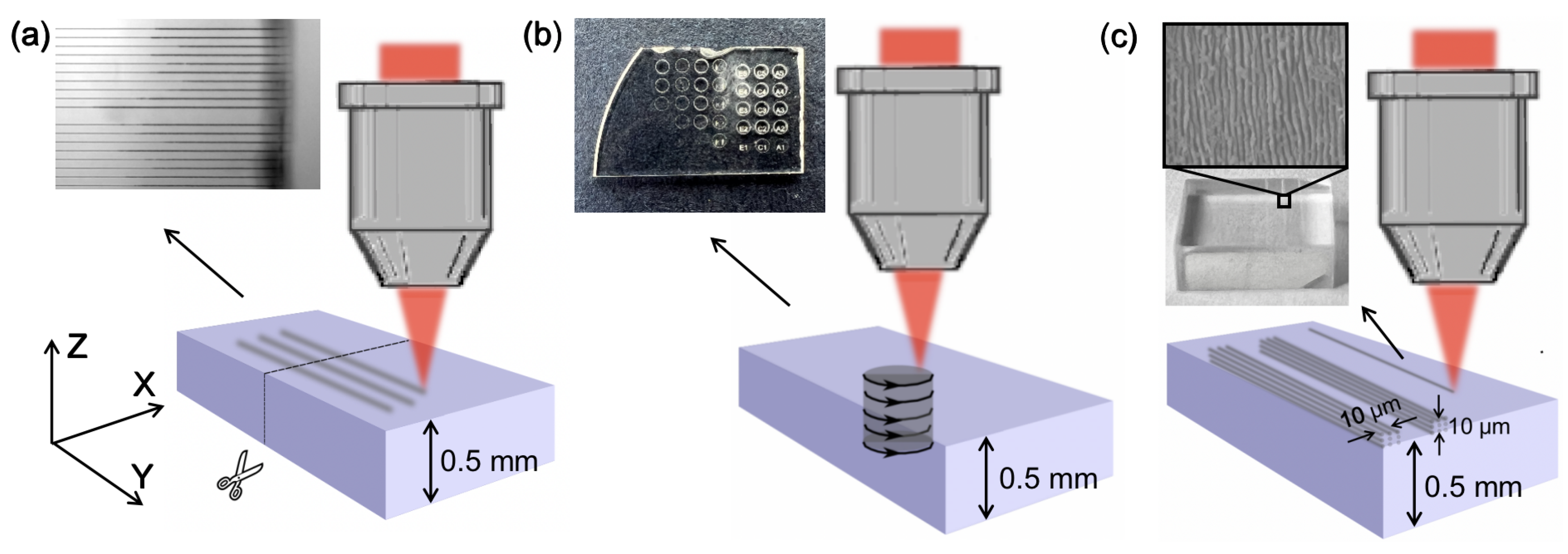

2. Materials and Methods

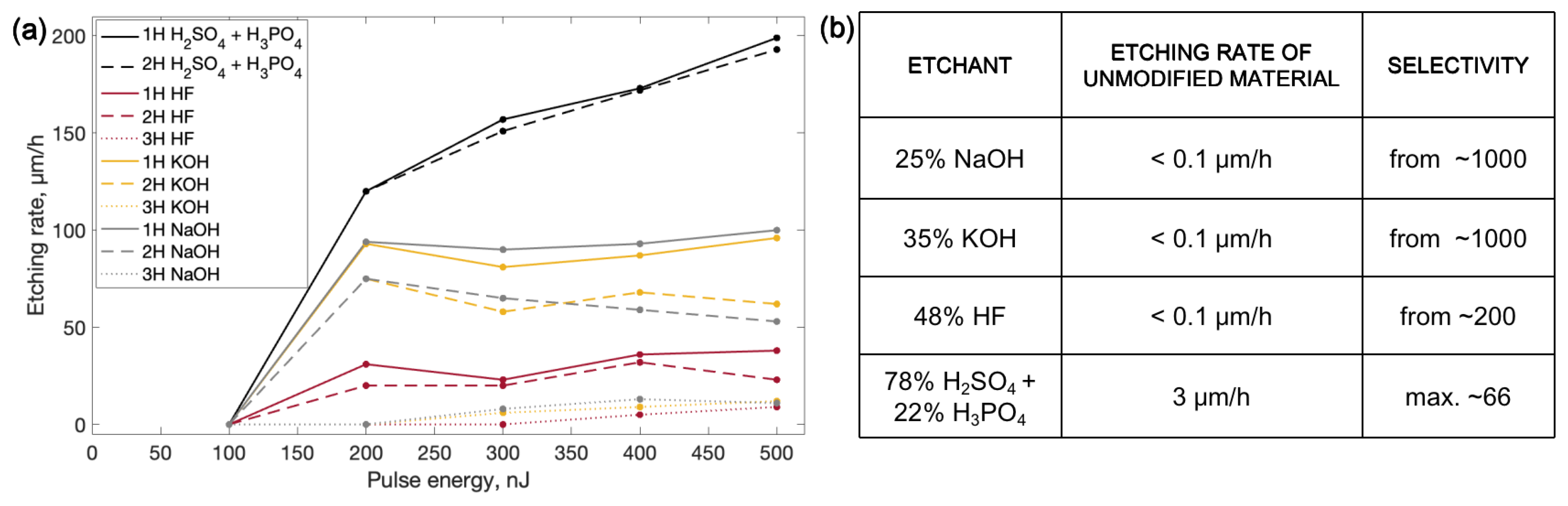

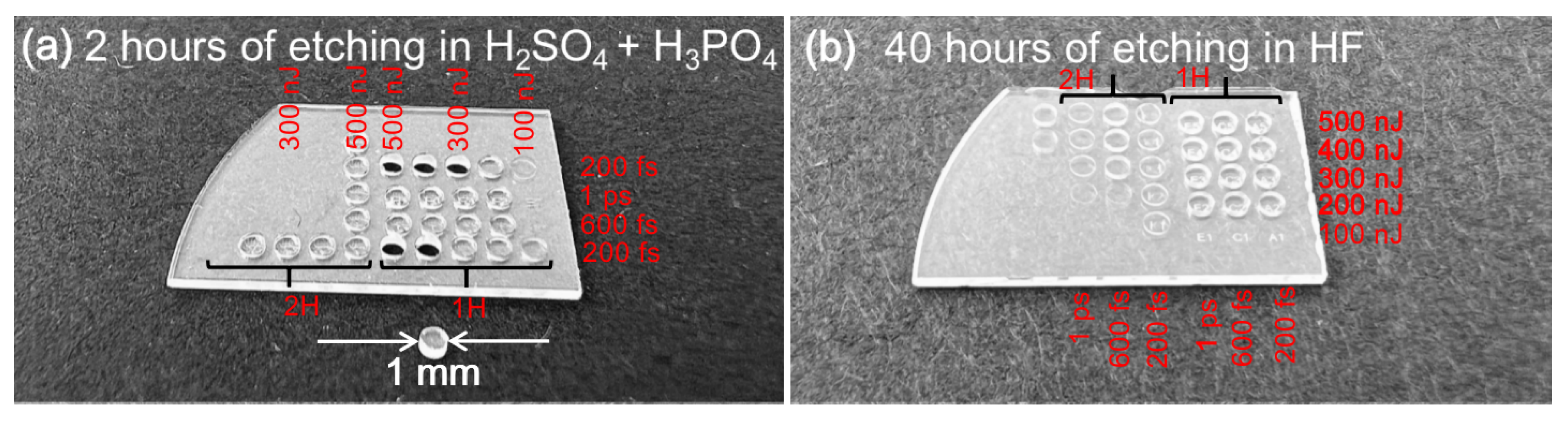

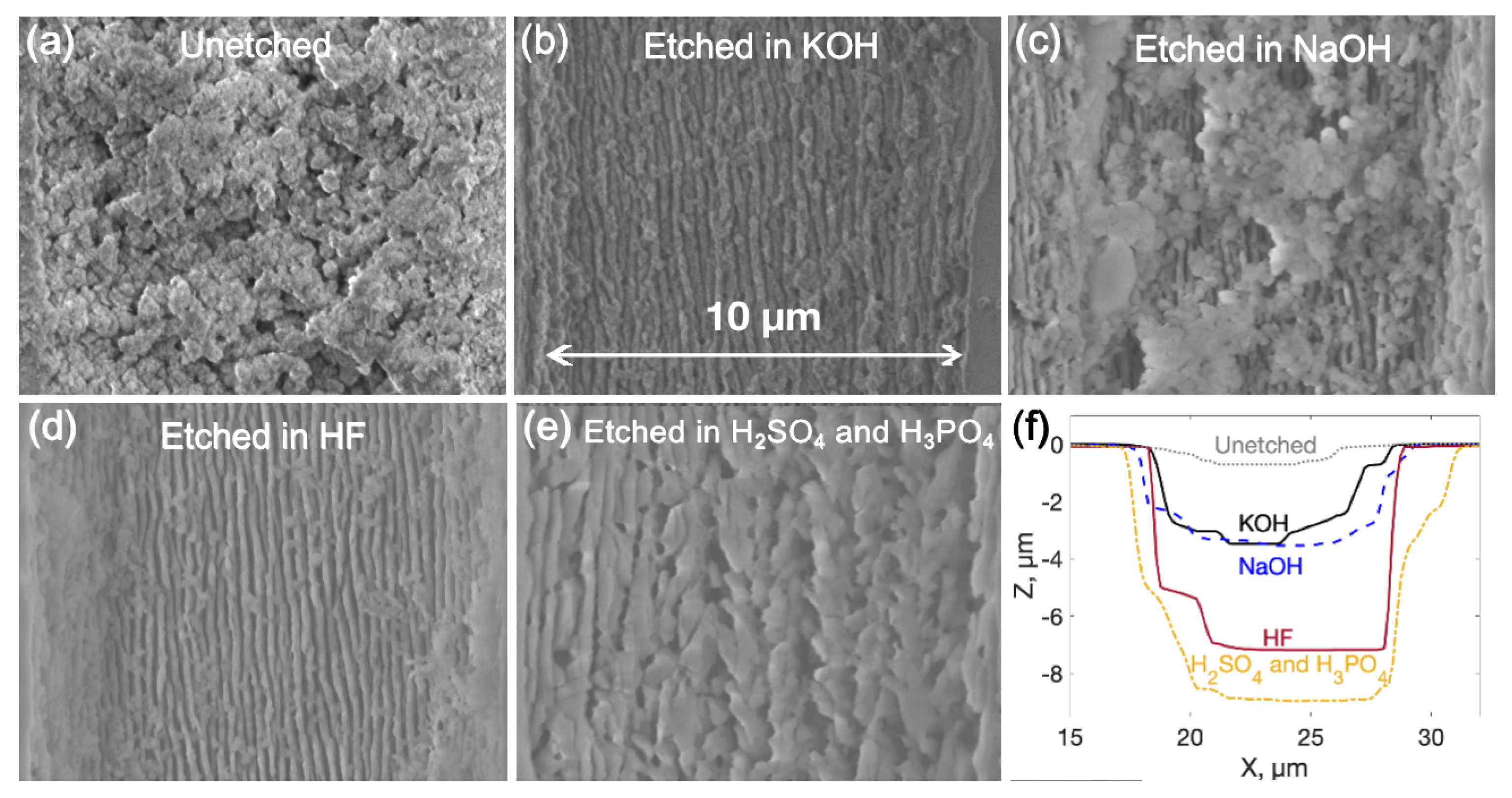

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gedvilas, M.; Mikšys, J.; Berzinš, J.; Stankevič, V.; Račiukaitis, G. Multi-photon absorption enhancement by dual-wavelength double-pulse laser irradiation for efficient dicing of sapphire wafers. Sci. Rep. 2017, 7, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Kudrius, T.; Šlekys, G.; Juodkazis, S. Surface-texturing of sapphire by femtosecond laser pulses for photonic applications. J. Phys. D Appl. Phys. 2010, 43, 145501. [Google Scholar] [CrossRef]

- Qi, L.; Nishii, K.; Yasui, M.; Aoki, H.; Namba, Y. Femtosecond laser ablation of sapphire on different crystallographic facet planes by single and multiple laser pulses irradiation. Opt. Lasers Eng. 2010, 48, 1000–1007. [Google Scholar] [CrossRef]

- Song, Y.; Wang, C.; Dong, X.; Yin, K.; Zhang, F.; Xie, Z.; Chu, D.; Duan, J. Controllable superhydrophobic aluminum surfaces with tunable adhesion fabricated by femtosecond laser. Opt. Laser Technol. 2018, 102, 25–31. [Google Scholar] [CrossRef]

- Jia, X.; Chen, Y.; Liu, L.; Wang, C.; Duan, J. Combined pulse laser: Reliable tool for high-quality, high-efficiency material processing. Opt. Laser Technol. 2022, 153, 108209. [Google Scholar] [CrossRef]

- Ding, K.; Wang, C.; Li, S.; Zhang, X.; Lin, N.; Duan, J. Large-area cactus-like micro-/nanostructures with anti-reflection and superhydrophobicity fabricated by femtosecond laser and thermal treatment. Surf. Interfaces 2022, 33, 102292. [Google Scholar] [CrossRef]

- Ding, K.; Wang, C.; Li, S.; Zhang, X.; Lin, N.; Duan, J. Single-Step femtosecond laser structuring of multifunctional colorful metal surface and its origin. Surf. Interfaces 2022, 34, 102386. [Google Scholar] [CrossRef]

- Li, Y.; Liu, H.; Hong, M. High-quality sapphire microprocessing by dual-beam laser induced plasma assisted ablation. Opt. Express 2020, 28, 6242–6250. [Google Scholar] [CrossRef]

- Chen, J.; Lu, X.; Li, Z.; Wen, Q.; Lu, J.; Jiang, F. Anisotropy of material removal during laser-induced plasma assisted ablation of sapphire. Ceram. Int. 2022, 48, 13880–13889. [Google Scholar] [CrossRef]

- Ding, X.; Sato, T.; Kawaguchi, Y.; Niino, H. Laser-Induced Backside Wet Etching of Sapphire. Jpn. J. Appl. Phys. 2003, 42, L176–L178. [Google Scholar] [CrossRef]

- Tsvetkov, M.Y.; Minaev, N.V.; Akovantseva, A.A.; Timashev, P.S.; Muslimov, A.E.; Kanevskii, V.M. Thermoplasmonic laser-induced backside wet etching of sapphire. Quantum Electron. 2019, 49, 133–140. [Google Scholar] [CrossRef]

- Zhigalina, O.; Khmelenin, D.N.; Atanova, A.V.; Minaev, N.V.; Sviridov, A.P.; Tsvetkov, M.Y. A Nanoscale Modification of Materials at Thermoplasmonic Laser-Induced Backside Wet Etching of Sapphire. Plasmonics 2020, 15, 599–608. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Y.; Li, Q.; Zheng, J.; Lu, Y.; Juodkazis, S.; Chen, Q.; Sun, H. Biomimetic sapphire windows enabled by inside-out femtosecond laser deep-scribing. PhotoniX 2022, 3, 1. [Google Scholar] [CrossRef]

- Cao, X.; Lu, Y.; Fan, H.; Xia, H.; Zhang, L.; Zhang, Y. Wet-etching-assisted femtosecond laser holographic processing of a sapphire concave microlens array. Appl. Opt. 2018, 57, 9604–9608. [Google Scholar] [CrossRef]

- Lu, Y.M.; Liu, X.Q.; Zhu, L.; Chen, Q.D.; Juodkazis, S.; Sun, H.B. Vector scanning subtractive manufacturing technology for laser rapid fabrication. Opt. Lett. 2021, 46, 1963–1966. [Google Scholar] [CrossRef]

- Li, Q.; Chen, Q.; Niu, L.; Yu, Y.; Wang, L.; Sun, Y.; Sun, H. Sapphire-Based Dammann Gratings for UV Beam Splitting. IEEE Photon. J. 2016, 8, 2500208. [Google Scholar] [CrossRef]

- Li, Q.; Yu, Y.; Wang, L.; Cao, X.; Liu, X.; Sun, Y.; Chena, Q.; Duan, J.; Sun, H. Sapphire-Based Fresnel Zone Plate Fabricated by Femtosecond Laser Direct Writing and Wet Etching. IEEE Photon. Technol. Lett. 2016, 28, 1290–1293. [Google Scholar] [CrossRef]

- Gottumukkala, N.R.; Gupta, M.C. Laser processing of sapphire and fabrication of diffractive optical elements. Appl. Opt. 2022, 61, 2391–2397. [Google Scholar] [CrossRef]

- Marcinkevičius, A.; Juodkazis, S.; Watanabe, M.; Miwa, M.; Matsuo, S.; Misawa, H.; Nishii, J. Femtosecond laser-assisted three-dimensional microfabrication in silica. Opt. Lett. 2001, 26, 277–279. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Y.; Long, J.; Shi, D.; Chen, X.; Hou, M.; Gao, J.; Liu, H.; He, Y.; Fan, B.; et al. Achieving a sub-10 nm nanopore array in silicon by metal-assisted chemical etching and machine learning. Int. J. Extrem. Manuf. 2021, 3, 035104. [Google Scholar] [CrossRef]

- Shi, D.; Chen, Y.; Li, Z.; Dong, S.; Li, L.; Hou, M.; Liu, H.; Zhao, S.; Chen, X.; Wong, C.P.; et al. Anisotropic Charge Transport Enabling High-Throughput and High-Aspect-Ratio Wet Etching of Silicon Carbide. Small Methods 2022, 6, 2200329. [Google Scholar] [CrossRef] [PubMed]

- Hermans, M.; Gottmann, J.; Riedel, F. Selective, Laser-Induced Etching of Fused Silica at High Scan-Speeds Using KOH. J. Laser. Micro. Nanoeng. 2014, 9, 126–131. [Google Scholar] [CrossRef]

- Ross, C.A.; MacLachlan, D.G.; Choudhury, D.; Thomson, R.R. Optimisation of ultrafast laser assisted etching in fused silica. Opt. Express 2018, 26, 24343–24356. [Google Scholar] [CrossRef]

- Qi, J.; Wang, Z.; Xu, J.; Lin, Z.; Li, X.; Chu, W.; Cheng, Y. Femtosecond laser induced selective etching in fused silica: Optimization of the inscription conditions with a high-repetition-rate laser source. Opt. Express 2018, 26, 29669–29678. [Google Scholar] [CrossRef]

- Li, X.; Xu, J.; Lin, Z.; Qi, J.; Wang, P.; Chu, W.; Fang, Z.; Wang, Z.; Chai, Z.; Cheng, Y. Polarization-insensitive space-selective etching in fused silica induced by picosecond laser irradiation. Appl. Surf. Sci. 2019, 485, 188–193. [Google Scholar] [CrossRef]

- Stankevič, V.; Račiukaitis, G.; Gečys, P. Chemical etching of fused silica after modification with two-pulse bursts of femtosecond laser. Opt. Express 2021, 29, 31393–31407. [Google Scholar] [CrossRef]

- Butkutė, A.; Baravykas, T.; Stančikas, J.; Tičkūnas, T.; Vargalis, R.; Paipulas, D.; Sirutkaitis, V.; Jonušauskas, L. Femtosecond Laser Assisted 3D Etching Using Inorganic-Organic Etchant. Materials 2022, 15, 2817. [Google Scholar] [CrossRef]

- Bellouard, Y. Shape memory alloys for microsystems: A review from a material research perspective. Mater. Sci. Eng. A 2008, 481–482, 582–589. [Google Scholar] [CrossRef]

- Butkutė, A.; Baravykas, T.; Stančikas, J.; Tičkūnas, T.; Vargalis, R.; Paipulas, D.; Sirutkaitis, V.; Jonušauskas, L. Optimization of selective laser etching (SLE) for glass micromechanical structure fabrication. Opt. Express 2021, 29, 23487–23499. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y.; Midorikawa, K. Three-dimensional micromachining of glass using femtosecond laser for lab-on-a-chip device manufacture. Appl. Phys. A 2005, 81, 1–10. [Google Scholar] [CrossRef]

- Gottmann, J.; Hermans, M.; Repiev, N.; Ortmann, J. Selective Laser-Induced Etching of 3D Precision Quartz Glass Components for Microfluidic Applications-Up-Scaling of Complexity and Speed. Micromachines 2017, 8, 110. [Google Scholar] [CrossRef]

- Kim, J.; Kim, S.; Joung, Y.; Choi, J.; Koo, C. Two-step hybrid process of movable part inside glass substrate using ultrafast laser. Micro Nano Syst. Lett. 2021, 9, 2213–9621. [Google Scholar] [CrossRef]

- Choudhury, D.; Ródenas, A.; Paterson, L.; Jaque, D.; Kar, A.K. 3D microfabrication in YAG crystals by direct laser writing and chemical etching. In Conference on Lasers and Electro-Optics/Pacific Rim; Optical Society of America: Washington, DC, USA, 2013; p. WPE_14. [Google Scholar]

- Rodenas, A.; Gu, M.; Corrielli, G.; Paie, P.; John, S.; Kar, A.K.; Osellame, R. Three-dimensional femtosecond laser nanolithography of crystals. Nat. Photon. 2019, 13, 105–109. [Google Scholar] [CrossRef]

- Hasse, K.; Huber, G.; Kränkel, C. Selective etching of fs-laser inscribed high aspect ratio microstructures in YAG. Opt. Mater. Express 2019, 9, 3627–3637. [Google Scholar] [CrossRef]

- Matsuo, S.; Tabuchi, Y.; Okada, T.; Juodkazis, S.; Misawa, H. Femtosecond laser assisted etching of quartz: Microstructuring from inside. Appl. Phys. A 2006, 84, 99–102. [Google Scholar] [CrossRef]

- Juodkazis, S.; Nishi, Y.; Misawa, H. Femtosecond laser-assisted formation of channels in sapphire using KOH solution. Phys. Status Solidi RRL 2008, 2, 275–277. [Google Scholar] [CrossRef]

- Matsuo, S.; Tokumi, K.; Tomita, T.; Hashimoto, S. Three-Dimensional Residue-Free Volume Removal inside Sapphire by High-Temperature Etching after Irradiation of Femtosecond Laser Pulses. Laser Chem. 2008, 2008, 892721-1–892721-4. [Google Scholar] [CrossRef][Green Version]

- Moser, R.; Ojha, N.; Kunzer, M.; Schwarz, U.T. Sub-surface channels in sapphire made by ultraviolet picosecond laser irradiation and selective etching. Opt. Express 2011, 19, 24738–24745. [Google Scholar] [CrossRef]

- Wortmann, D.; Gottmann, J.; Brandt, N.; Horn-Solle, H. Micro- and nanostructures inside sapphire by fs-laser irradiation and selective etching. Opt. Express 2008, 16, 1517–1522. [Google Scholar] [CrossRef]

- Horstmann-Jungemann, M.; Gottmann, J.; Wortmann, D. Nano- and Microstructuring of SiO2 and Sapphire with Fs-laser Induced Selective Etching. J. Laser. Micro. Nanoeng. 2009, 4, 135–140. [Google Scholar] [CrossRef]

- Hörstmann-Jungemann, M.; Gottmann, J.; Keggenhoff, M. 3D-Microstructuring of Sapphire using fs-Laser Irradiation and Selective Etching. J. Laser. Micro. Nanoeng. 2010, 5, 145–149. [Google Scholar] [CrossRef]

- Capuano, L.; Berenschot, J.; Tiggelaar, R.M.; Feinaeugle, M.; Tas, N.R.; Gardeniers, H.J.; Römer, G.W.R. Fabrication of Microstructures in the Bulk and on the Surface of Sapphire by Anisotropic Selective Wet Etching of Laser Affected Volumes. J. Micromech. Microeng. 2022, 32, 125003. [Google Scholar] [CrossRef]

- Casamenti, E.; Pollonghini, S.; Bellouard, Y. Few pulses femtosecond laser exposure for high efficiency 3D glass micromachining. Opt. Express 2021, 29, 35054–35066. [Google Scholar] [CrossRef] [PubMed]

- Gottmann, J.; Wortmann, D.; Hörstmann-Jungemann, M. Fabrication of sub-wavelength surface ripples and in-volume nanostructures by fs-laser induced selective etching. Appl. Surf. Sci. 2009, 255, 5641–5646. [Google Scholar] [CrossRef]

- Hnatovsky, C.; Taylor, R.S.; Simova, E.; Rajeev, P.P.; Rayner, D.M.; Bhardwaj, V.; Corkum, P.B. Fabrication of microchannels in glass using focused femtosecond laser radiationand selectivechemical etching. Appl. Phys. A 2006, 84, 47–61. [Google Scholar] [CrossRef]

- Capuanoa, L.; Tiggelaar, R.; Berenschot, J.; Gardeniers, J.; Römer, G. Fabrication of millimeter-long structures in sapphire using femtosecond infrared laser pulses and selective etching. Opt. Laser Eng. 2020, 133, 106114. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Z.; Xu, H.; Zheng, S.; Qi, T.; Li, H. Sub-molten salt environmentally benign technology. In Proceedings of the 100th AICHE Annual Meeting, Philadelphia, PA, USA, 16–21 November 2008. [Google Scholar]

- Bhardwaj, V.R.; Simova, E.; Rajeev, P.P.; Hnatovsky, C.; Taylor, R.S.; Rayner, D.M.; Corkum, P.B. Optically Produced Arrays of Planar Nanostructures inside Fused Silica. Phys. Rev. Lett. 2006, 96, 057404. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, X.; Qiu, J. Single femtosecond laser beam induced nanogratings in transparent media—Mechanisms and applications. J. Mater. 2019, 5, 1–14. [Google Scholar] [CrossRef]

- Butkus, S.; Rickus, M.; Sirutkaitis, R.; Paipulas, D.; Sirutkaitis, V. Fabrication of High Aspect Ratio Channels in Fused Silica Using Femtosecond Pulses and Chemical Etching at Different Conditions. J. Laser Micro. Nanoen. 2019, 14, 19–24. [Google Scholar]

- LoTurco, S.; Osellame, R.; Ramponi, R.; Vishnubhatla, K.C. Hybrid chemical etching of femtosecond laser irradiated structures for engineered microfluidic devices. J. Micromech. Microeng. 2013, 23, 1–8. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butkutė, A.; Sirutkaitis, R.; Gailevičius, D.; Paipulas, D.; Sirutkaitis, V. Sapphire Selective Laser Etching Dependence on Radiation Wavelength and Etchant. Micromachines 2023, 14, 7. https://doi.org/10.3390/mi14010007

Butkutė A, Sirutkaitis R, Gailevičius D, Paipulas D, Sirutkaitis V. Sapphire Selective Laser Etching Dependence on Radiation Wavelength and Etchant. Micromachines. 2023; 14(1):7. https://doi.org/10.3390/mi14010007

Chicago/Turabian StyleButkutė, Agnė, Romualdas Sirutkaitis, Darius Gailevičius, Domas Paipulas, and Valdas Sirutkaitis. 2023. "Sapphire Selective Laser Etching Dependence on Radiation Wavelength and Etchant" Micromachines 14, no. 1: 7. https://doi.org/10.3390/mi14010007

APA StyleButkutė, A., Sirutkaitis, R., Gailevičius, D., Paipulas, D., & Sirutkaitis, V. (2023). Sapphire Selective Laser Etching Dependence on Radiation Wavelength and Etchant. Micromachines, 14(1), 7. https://doi.org/10.3390/mi14010007