Micromixing Intensification within a Combination of T-Type Micromixer and Micropacked Bed

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

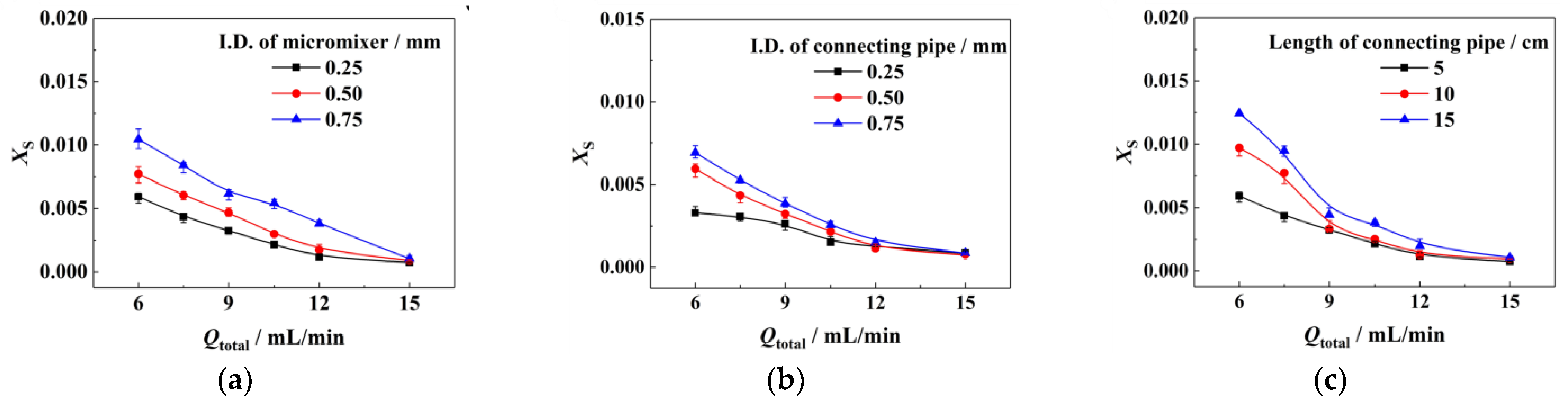

3.1. Micromixing Performance of Various Combined Microstructures

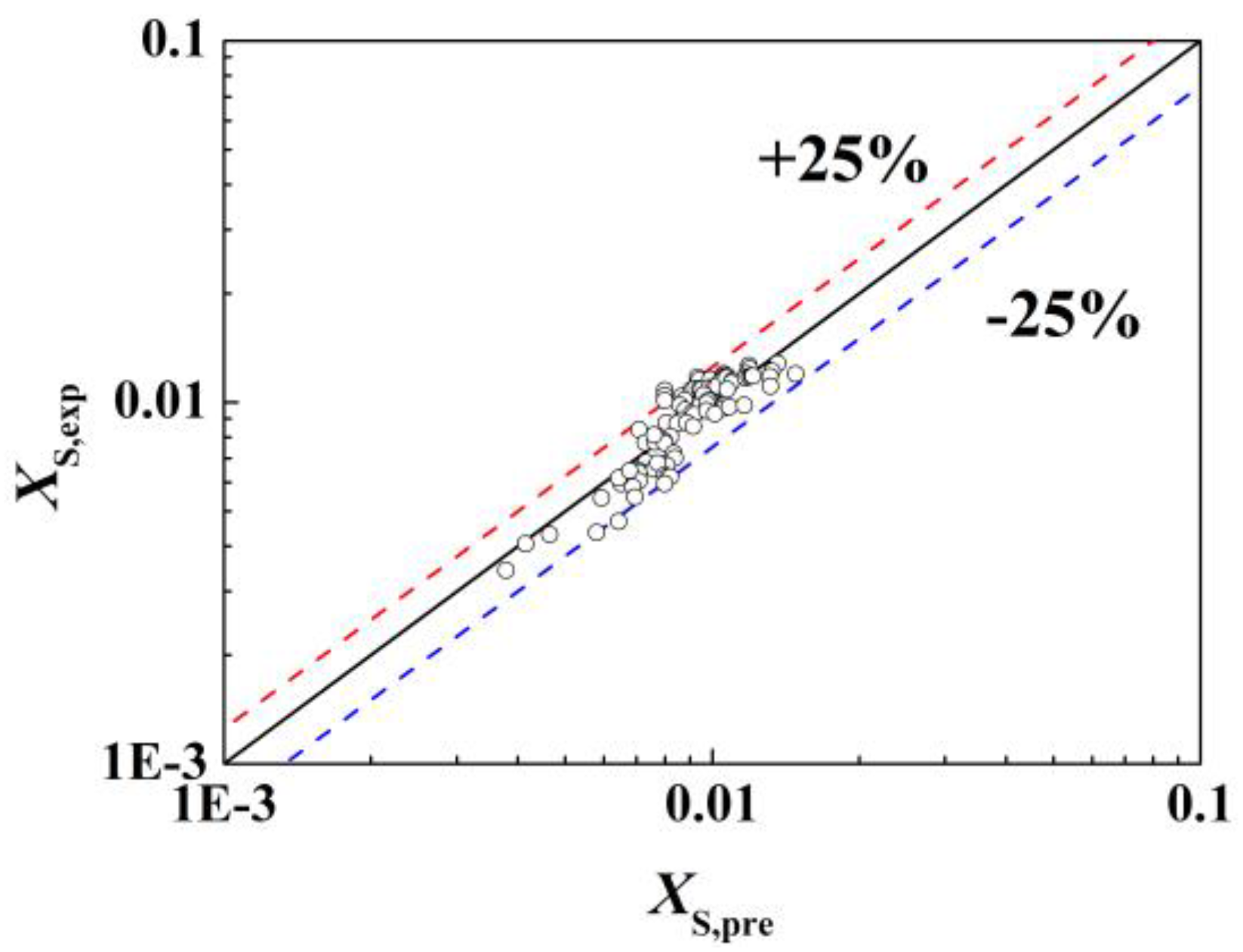

3.2. Correlation and Prediction of Micromixing Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, K.; Li, L.; Xie, P.; Luo, G. Liquid-liquid microflow reaction engineering. React. Chem. Eng. 2017, 2, 611–627. [Google Scholar] [CrossRef]

- Wang, K.; Luo, G. Microflow extraction: A review of recent development. Chem. Eng. Sci. 2017, 169, 18–33. [Google Scholar] [CrossRef]

- Weeranoppanant, N. Enabling tools for continuous-flow biphasic liquid-liquid reaction. React. Chem. Eng. 2019, 4, 235–243. [Google Scholar] [CrossRef]

- Lan, Z.; Lu, Y. Continuous nitration of o-dichlorobenzene in micropacked-bed reactor: Process design and modelling. J. Flow Chem. 2021, 11, 171–179. [Google Scholar] [CrossRef]

- Su, Y.; Zhao, Y.; Jiao, F.; Chen, G.; Yuan, Q. The intensification of rapid reactions for multiphase systems in a microchannel reactor by packing microparticles. AIChE J. 2011, 57, 1409–1418. [Google Scholar] [CrossRef]

- Cui, Y.; Song, J.; Du, C.; Deng, J.; Luo, G. Determination of the kinetics of chlorobenzene nitration using a homogeneously continuous microflow. AIChE J. 2022, 68, e17564. [Google Scholar] [CrossRef]

- Kulkarni, A.A. Continuous flow nitration in miniaturized devices. Beilstein J. Org. Chem. 2014, 10, 405–424. [Google Scholar] [CrossRef]

- Borovinskaya, E.; Khaydarov, V.; Strehle, N.; Musaev, A.; Reschetilowski, W. Experimental studies of ethyl acetate saponification using different reactor systems: The effect of volume flow rate on reactor performance and pressure drop. Appl. Sci. 2019, 9, 532. [Google Scholar] [CrossRef]

- Kamiouji, A.; Hashimoto, K.; Kominami, H.; Ito, S. Continuous saponification of methyl laurate using long narrow tubes as a reactor. Ind. Eng. Chem. Res. 2008, 47, 1464–1467. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, Y.; Yang, B.; Luo, G. Controllable preparation of poly(butyl acrylate) by suspension polymerization in a coaxial capillary microreactor. Ind. Eng. Chem. Res. 2011, 50, 11853–11862. [Google Scholar] [CrossRef]

- Yadav, A.K.; Carlos de la Cal, J.; Jesus Barandiaran, M. Feasibility of tubular microreactors for emulsion polymerization. Macromol. React. Eng. 2011, 5, 69–77. [Google Scholar] [CrossRef]

- Liu, X.; Lu, Y.; Luo, G. Continuous flow synthesis of polystyrene nanoparticles via emulsion polymerization stabilized by a mixed nonionic and anionic emulsifier. Ind. Eng. Chem. Res. 2017, 56, 9489–9495. [Google Scholar] [CrossRef]

- Watanabe, T.; Karita, K.; Tawara, K.; Soga, T.; Ono, T. Rapid synthesis of poly(methyl methacrylate) particles with high molecular weight by soap-free emulsion polymerization using water-in-oil slug flow. Macromol. Chem. Phys. 2019, 220, 1900021. [Google Scholar] [CrossRef]

- Lin, X.Y.; Wang, K.; Zhang, J.S.; Luo, G.S. Liquid-liquid mixing enhancement rules by microbubbles in three typical micro-mixers. Chem. Eng. Sci. 2015, 127, 60–71. [Google Scholar] [CrossRef]

- Plutschack, M.B.; Pieber, B.; Gilmore, K.; Seeberger, P.H. The hitchhiker’s guide to flow chemistry. Chem. Rev. 2017, 117, 11796–11893. [Google Scholar] [CrossRef]

- Gutmann, B.; Cantillo, D.; Kappe, C.O. Continuous-flow technologya tool for the safe manufacturing of active pharmaceutical ingredients. Angew. Chem., Int. Ed. 2015, 54, 6688–6728. [Google Scholar] [CrossRef]

- Porta, R.; Benaglia, M.; Puglisi, A. Flow chemistry: Recent developments in the synthesis of pharmaceutical products. Org. Process Res. Dev. 2016, 20, 2–25. [Google Scholar] [CrossRef]

- Kashid, M.N.; Kiwi-Minsker, L. Microstructured reactors for multiphase reactions: State of the art. Ind. Eng. Chem. Res. 2009, 48, 6465–6485. [Google Scholar] [CrossRef]

- Lee, H.-J.; Roberts, R.C.; Im, D.J.; Yim, S.-J.; Kim, H.; Kim, J.T.; Kim, D.-P. Enhanced controllability of fries rearrangements using high-resolution 3D-printed metal microreactor with circular channel. Small 2019, 15, 1905005. [Google Scholar] [CrossRef]

- Mielke, E.; Plouffe, P.; Mongeon, S.S.; Aellig, C.; Filliger, S.; Macchi, A.; Roberge, D.M. Micro-reactor mixing unit interspacing for fast liquid-liquid reactions leading to a generalized scale-up methodology. Chem. Eng. J. 2018, 352, 682–694. [Google Scholar] [CrossRef]

- Zhang, Y.; Born, S.C.; Jensen, K.F. Scale-up investigation of the continuous phase-transfer-catalyzed hypochlorite oxidation of alcohols and aldehydes. Org. Process Res. Dev. 2014, 18, 1476–1481. [Google Scholar] [CrossRef]

- Sharma, M.; Acharya, R.B.; Kulkarni, A.A. Exploring the steady operation of a continuous pilot plant for the di-nitration reaction. Chem. Eng. Technol. 2019, 42, 2241–2251. [Google Scholar] [CrossRef]

- Su, Y.; Chen, G.; Zhao, Y.; Yuan, Q. Intensification of liquid-liquid two-phase mass transfer by gas agitation in a microchannel. AIChE J. 2009, 55, 1948–1958. [Google Scholar] [CrossRef]

- Su, Y.; Zhao, Y.; Chen, G.; Yuan, Q. Liquid-liquid two-phase flow and mass transfer characteristics in packed microchannels. Chem. Eng. Sci. 2010, 65, 3947–3956. [Google Scholar] [CrossRef]

- Su, Y.; Chen, G.; Yuan, Q. Ideal micromixing performance in packed microchannels. Chem. Eng. Sci. 2011, 66, 2912–2919. [Google Scholar] [CrossRef]

- von Keutz, T.; Cantillo, D.; Kappe, C.O. Enhanced mixing of biphasic liquid-liquid systems for the synthesis of gem-dihalocyclopropanes using packed bed reactors. J. Flow Chem. 2019, 9, 27–34. [Google Scholar] [CrossRef]

- Kashid, M.N.; Renken, A.; Kiwi-Minsker, L. Microstructured Devices for Chemical Processing; Wiley: Hoboken, NJ, USA, 2014. [Google Scholar] [CrossRef]

- Luo, G.; Lu, Y.; Wang, K. Micro Chemical Engineering and Technology; Chemical Industry Press: Beijing, China, 2020. [Google Scholar]

- Wong, S.H.; Ward, M.C.L.; Wharton, C.W. Micro T-mixer as a rapid mixing micromixer. Sens. Actuators, B 2004, 100, 359–379. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, D.S.; Lee, S.S.; Kwon, T.H. A split and recombination micromixer fabricated in a PDMS three-dimensional structure. J. Micromech. Microeng. 2006, 16, 1067–1072. [Google Scholar] [CrossRef]

- Fournier, M.C.; Falk, L.; Villermaux, J. A new parallel competing reaction system for assessing micromixing efficiency—Experimental approach. Chem. Eng. Sci. 1996, 51, 5053–5064. [Google Scholar] [CrossRef]

- Fournier, M.C.; Falk, L.; Villermaux, J. A new parallel competing reaction system for assessing micromixing efficiency—Determination of micromixing time by a simple mixing model. Chem. Eng. Sci. 1996, 51, 5187–5192. [Google Scholar] [CrossRef]

- Arian, E.; Pauer, W. Sucrose solution as a new viscous test fluid with tunable viscosities up to 2 Pa·s for micromixing characterization by the Villermaux-Dushman reaction. J. Flow Chem. 2021, 11, 579–588. [Google Scholar] [CrossRef]

- Berton, M.; de Souza, J.M.; Abdiaj, I.; McQuade, D.T.; Snead, D.R. Scaling continuous API synthesis from milligram to kilogram: Extending the enabling benefits of micro to the plant. J. Flow Chem. 2020, 10, 73–92. [Google Scholar] [CrossRef]

- Bourne, J.R. Mixing and the selectivity of chemical reactions. Org. Process Res. Dev. 2003, 7, 471–508. [Google Scholar] [CrossRef]

- Schwolow, S.; Hollmann, J.; Schenkel, B.; Roeder, T. Application-oriented analysis of mixing performance in microreactors. Org. Process Res. Dev. 2012, 16, 1513–1522. [Google Scholar] [CrossRef]

- Fitschen, J.; Hofmann, S.; Wutz, J.; Kameke, A.v.; Hoffmann, M.; Wucherpfennig, T.; Schlüter, M. Novel evaluation method to determine the local mixing time distribution in stirred tank reactors. Chem. Eng. Sci. 2021, 10, 100098. [Google Scholar] [CrossRef]

- Rodriguez, G.; Micheletti, M.; Ducci, A. Macro- and micro-scale mixing in a shaken bioreactor for fluids of high viscosity. Chem. Eng. Res. Des. 2018, 132, 890–901. [Google Scholar] [CrossRef]

- Eltayeb, A.; Tan, S.; Ala, A.A.; Zhang, Q. The study of the influence of slug density on the mixing performance in the reactor vessel, using PLIF experiment and FLUENT simulation. Prog. Nucl. Energy 2021, 131, 103558. [Google Scholar] [CrossRef]

- Ribeiro, J.P.; Brito, M.S.C.A.; Santos, R.J.; Nunes, M.I. Reactive PLIF Method for Characterisation of Micromixing in Continuous High-Throughput Chemical Reactors. Processes 2022, 10, 1916. [Google Scholar] [CrossRef]

- Duan, X.; Feng, X.; Mao, Z.-S.; Yang, C. Numerical simulation of reactive mixing process in a stirred reactor with the DQMOM-IEM model. Chem. Eng. J. 2019, 360, 1177–1187. [Google Scholar] [CrossRef]

- Taghavi, M.; Moghaddas, J. Using PLIF/PIV techniques to investigate the reactive mixing in stirred tank reactors with Rushton and pitched blade turbines. Chem. Eng. Res. Des. 2019, 151, 190–206. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, W.; Shao, T.; Yang, J.; Cheng, Y. Visualization of reactive and non-reactive mixing processes in a stirred tank using planar laser induced fluorescence (PLIF) technique. Chem. Eng. Res. Des. 2012, 90, 524–533. [Google Scholar] [CrossRef]

- Zhang, W.P.; Wang, X.; Feng, X.; Yang, C.; Mao, Z.S. Investigation of mixing performance in passive micromixers. Ind. Eng. Chem. Res. 2016, 55, 10036–10043. [Google Scholar] [CrossRef]

- Liu, Z.D.; Lu, Y.C.; Wang, J.W.; Luo, G.S. Mixing characterization and scaling-up analysis of asymmetrical T-shaped micromixer: Experiment and CFD simulation. Chem. Eng. J. 2012, 18, 597–606. [Google Scholar] [CrossRef]

- Du, C.C.; Wang, P.C.; Hu, Y.P.; Zhang, J.S.; Luo, G.S. Liquid-liquid mass transfer enhancement in milliscale packed beds. Ind. Eng. Chem. Res. 2020, 59, 4048–4057. [Google Scholar] [CrossRef]

- Lan, Z.; Lu, Y.C. An intensified chlorination process of 4-nitroaniline in a liquid-liquid microflow system. React. Chem. Eng. 2021, 6, 2259–2265. [Google Scholar] [CrossRef]

- Guichardon, P.; Falk, L. Characterisation of micromixing efficiency by the iodide-iodate reaction system. Part I: Experimental procedure. Chem. Eng. Sci. 2000, 55, 4233–4243. [Google Scholar] [CrossRef]

- Guichardon, P.; Falk, L.; Villermaux, J. Characterisation of micromixing efficiency by the iodide-iodate reaction system. Part II: Kinetic study. Chem. Eng. Sci. 2000, 55, 4245–4253. [Google Scholar] [CrossRef]

- Liu, G.; Ma, L.; Liu, J. Chemical Properties Data Book (Organic Volume); Chemical Industry Press: Beijing, China, 2002. [Google Scholar]

- Izadi, M.; Rahimi, M.; Beigzadeh, R. An investigation of mixing performance in helically coiled microchannels by the Villermaux/Dushman reaction. Chem. Eng. Res. Des. 2018, 134, 507–517. [Google Scholar] [CrossRef]

| Reactant | Concentration/mol/L | |

|---|---|---|

| Solution A | KI | 0.03 |

| KIO3 | 0.006 | |

| H3BO3 | 0.09 | |

| NaOH | 0.09 | |

| Solution B a | H2SO4 | 0.005 |

| Items | Data |

|---|---|

| μA/mPa·s | 2.5~25 |

| μB/mPa·s | 1~10 |

| ReA | 6.73~100 |

| ReB | 1.35~84.6 |

| QA:QB | 1:1~10:1 |

| dp/mm | 0.105~0.710 |

| tc/s | 0.016~0.530 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lan, Z.; Lu, Y. Micromixing Intensification within a Combination of T-Type Micromixer and Micropacked Bed. Micromachines 2023, 14, 45. https://doi.org/10.3390/mi14010045

Lan Z, Lu Y. Micromixing Intensification within a Combination of T-Type Micromixer and Micropacked Bed. Micromachines. 2023; 14(1):45. https://doi.org/10.3390/mi14010045

Chicago/Turabian StyleLan, Zhou, and Yangcheng Lu. 2023. "Micromixing Intensification within a Combination of T-Type Micromixer and Micropacked Bed" Micromachines 14, no. 1: 45. https://doi.org/10.3390/mi14010045

APA StyleLan, Z., & Lu, Y. (2023). Micromixing Intensification within a Combination of T-Type Micromixer and Micropacked Bed. Micromachines, 14(1), 45. https://doi.org/10.3390/mi14010045