Analysis and Optimization of a Microgripper Driven by Linear Ultrasonic Motors

Abstract

:1. Introduction

2. Vibration Model

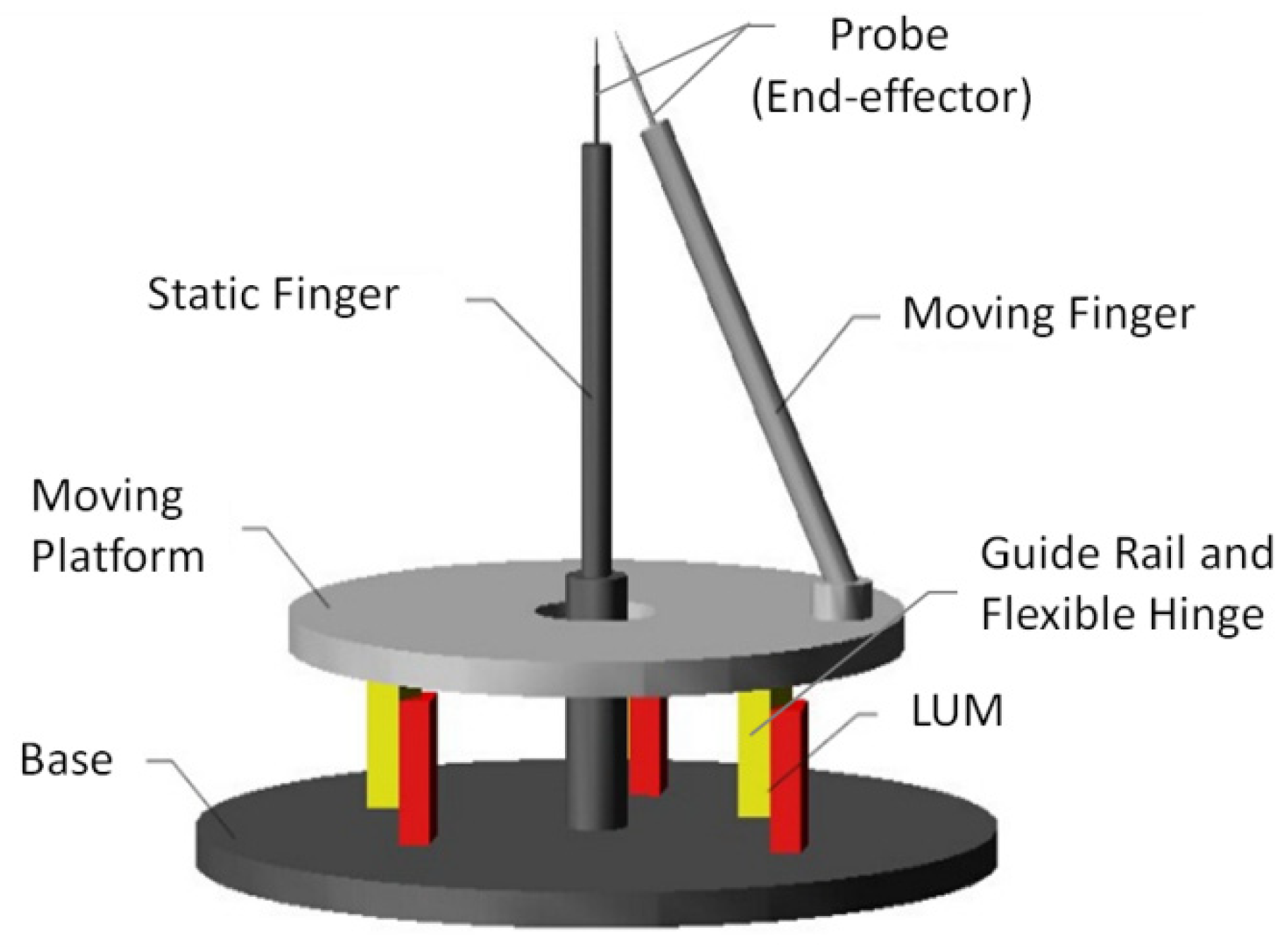

2.1. Structure of Microgripper

2.2. Vibration Equation

2.3. Constraint Conditions

2.3.1. Material Constraints

2.3.2. Geometric Constraints

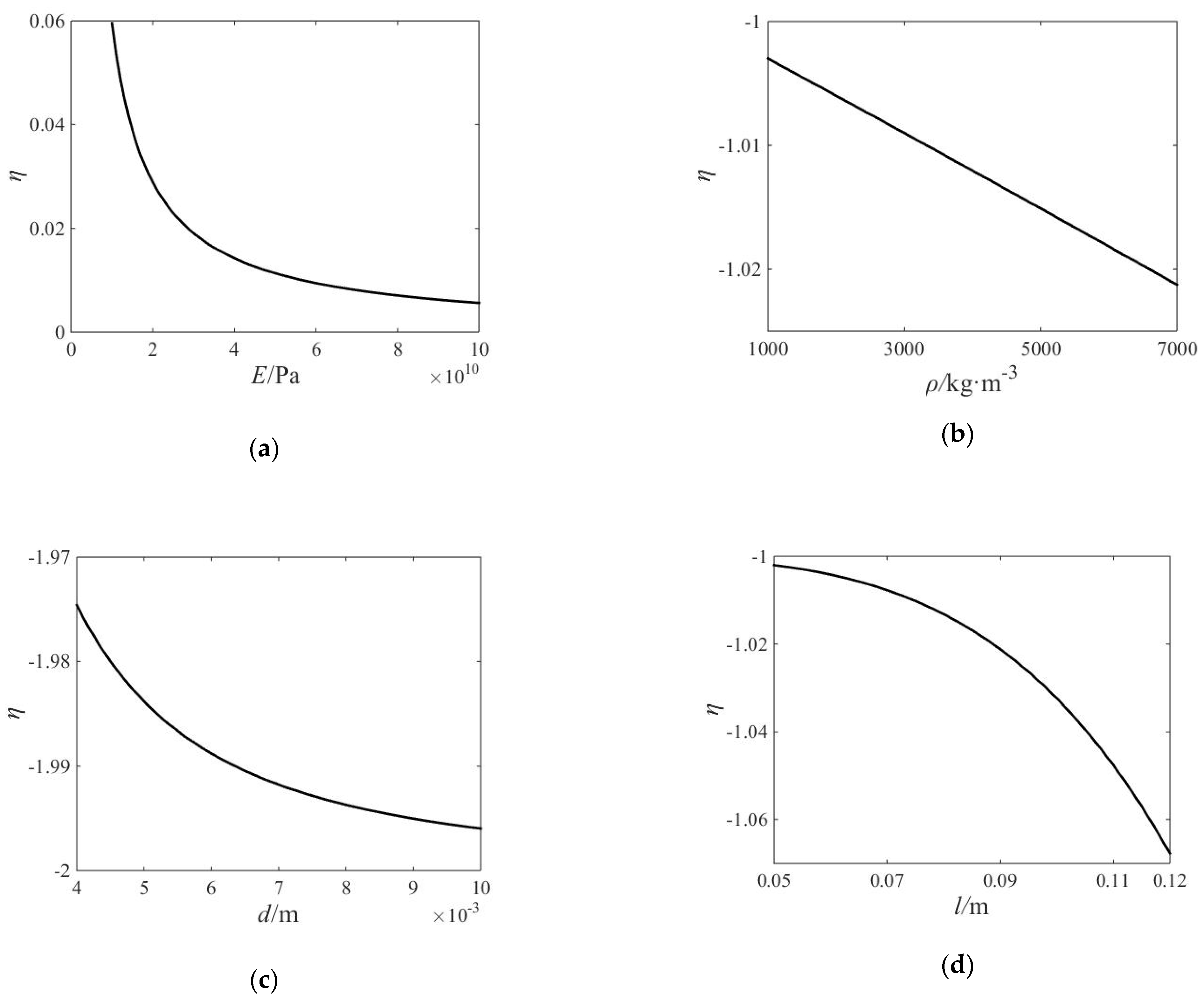

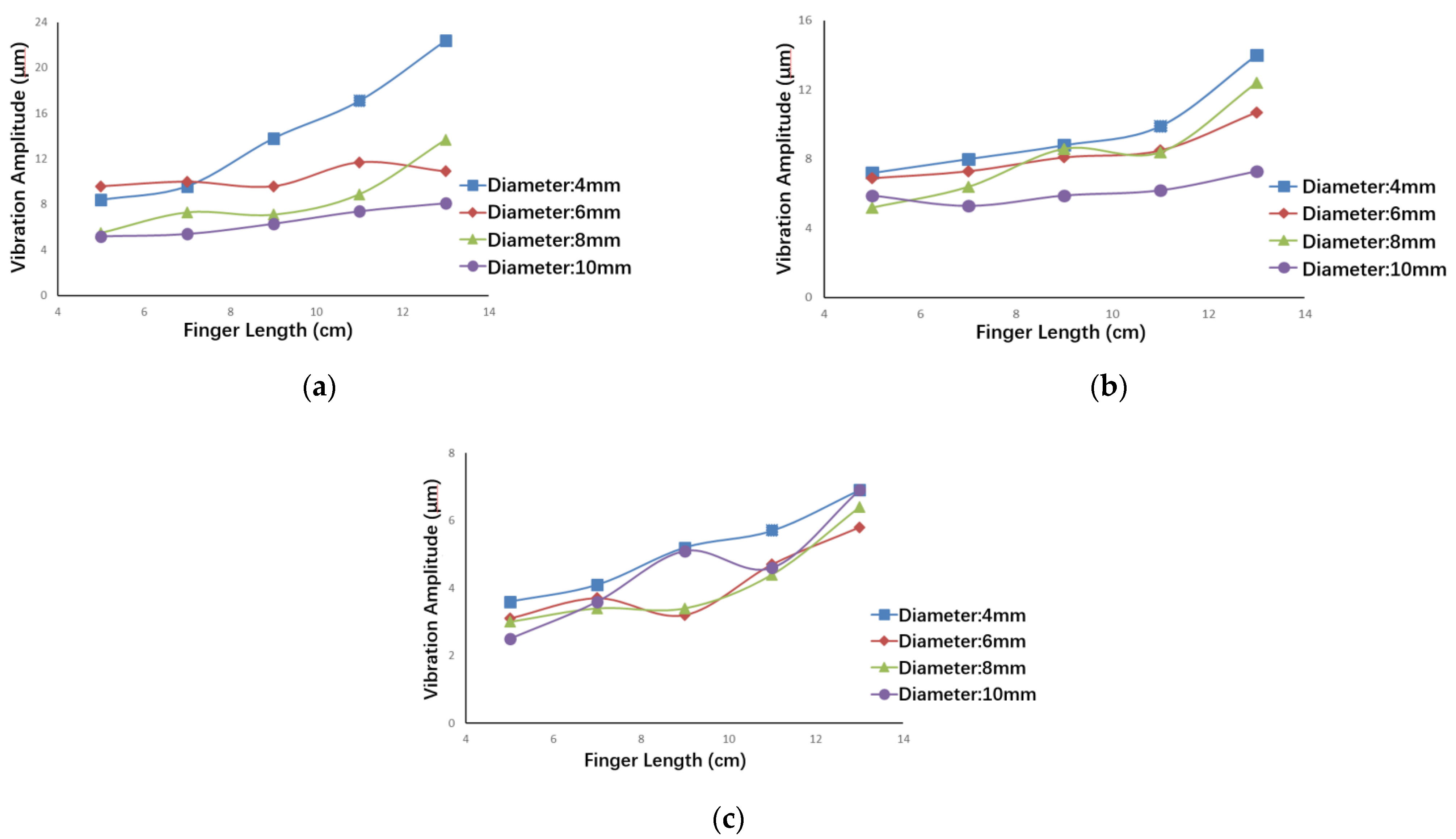

2.4. Sensitivity Analysis

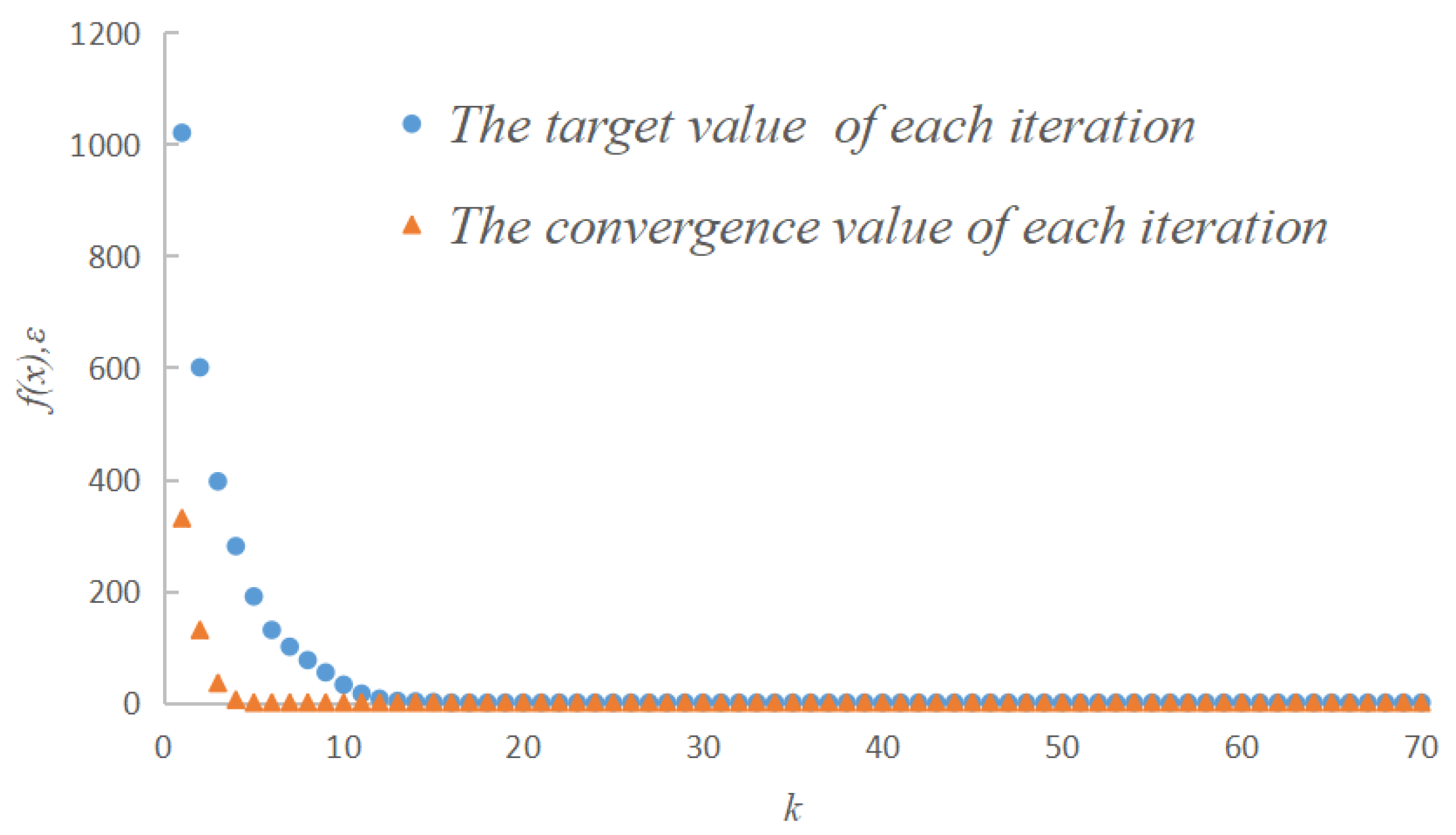

3. Structure Optimization

3.1. Optimization Model

3.2. Optimized Results

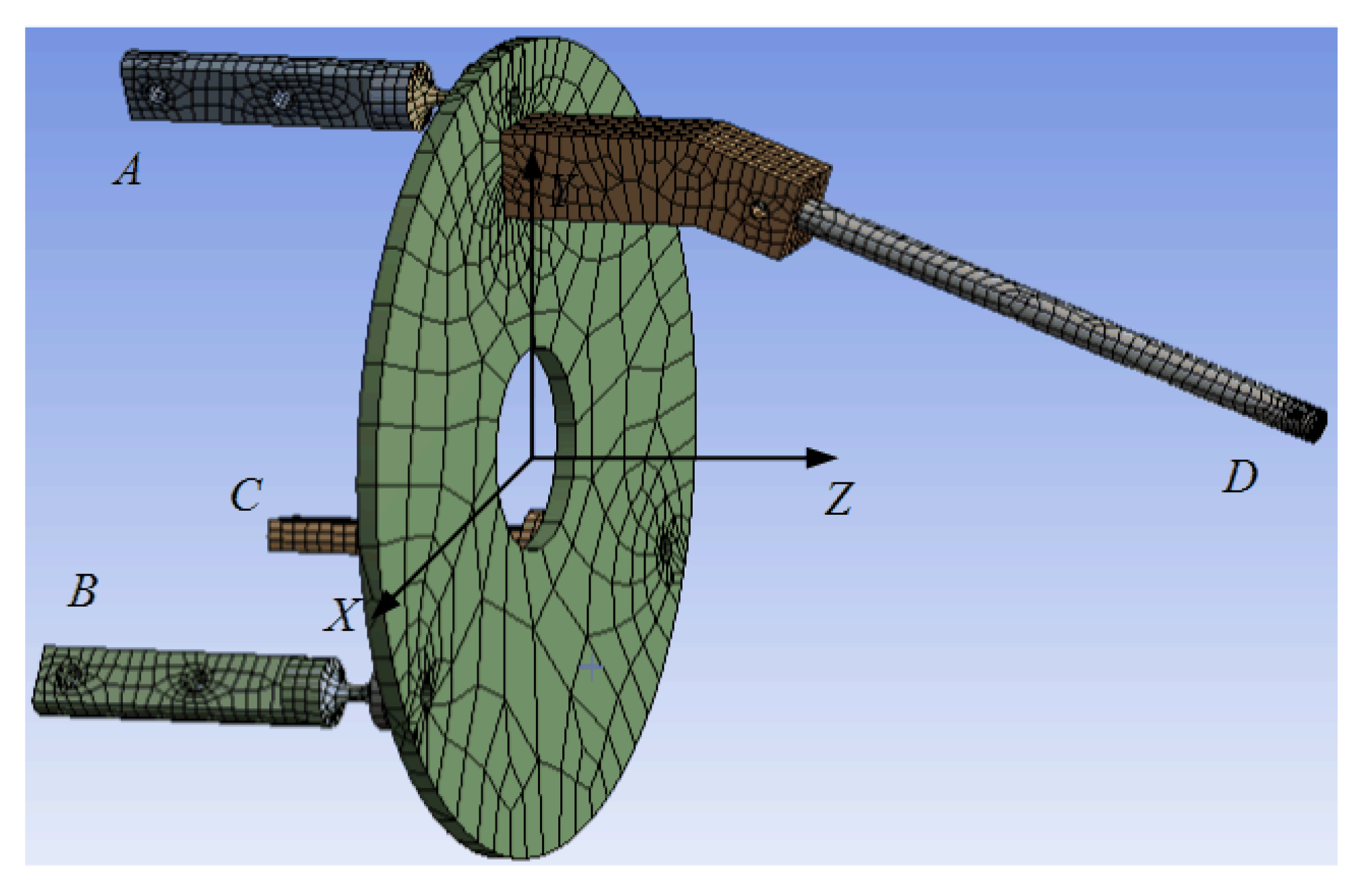

4. The Finite Element Analysis

4.1. Modal Analysis

4.2. Harmonic Response Analysis

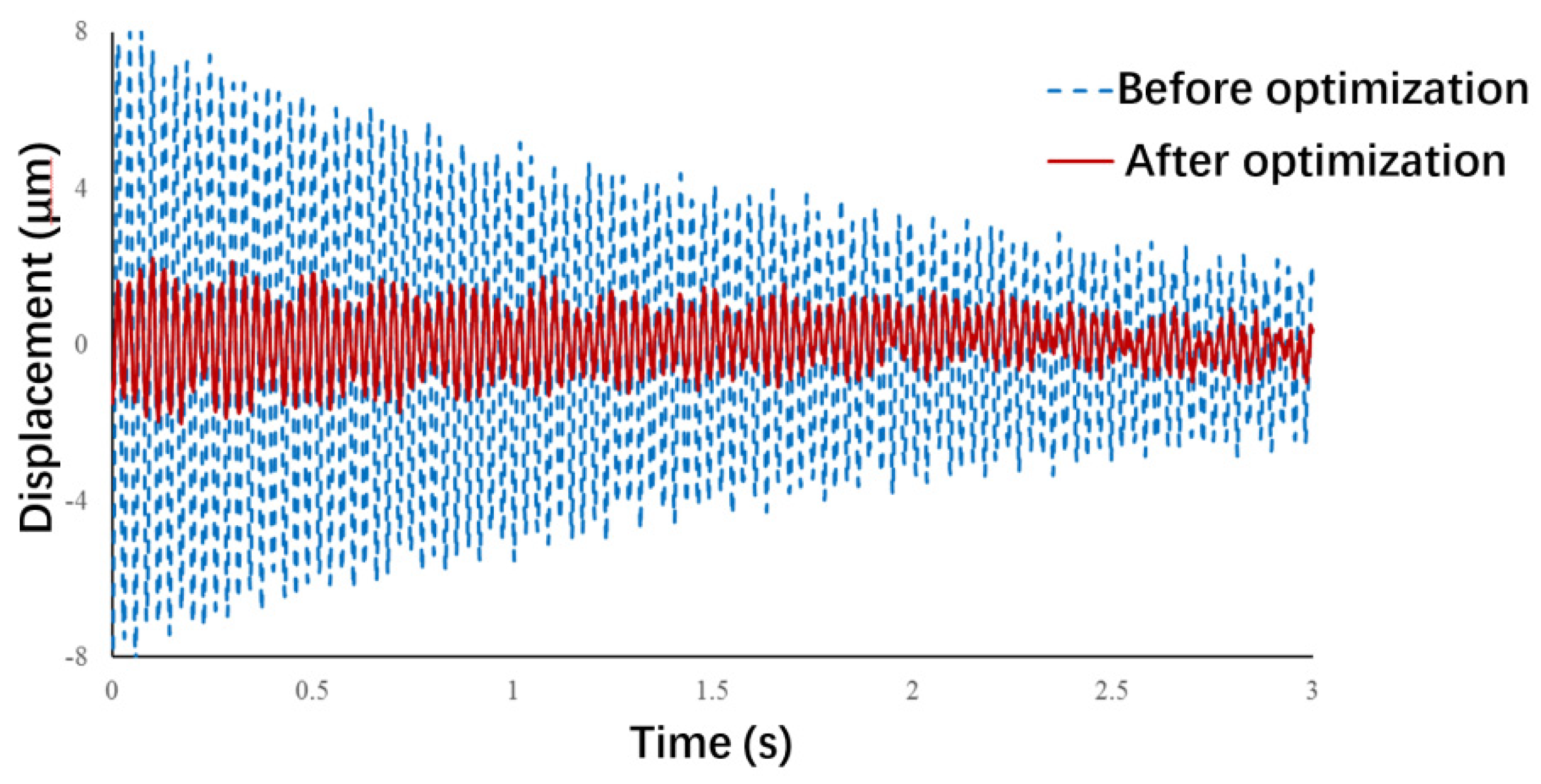

4.3. Transient Dynamics Simulation

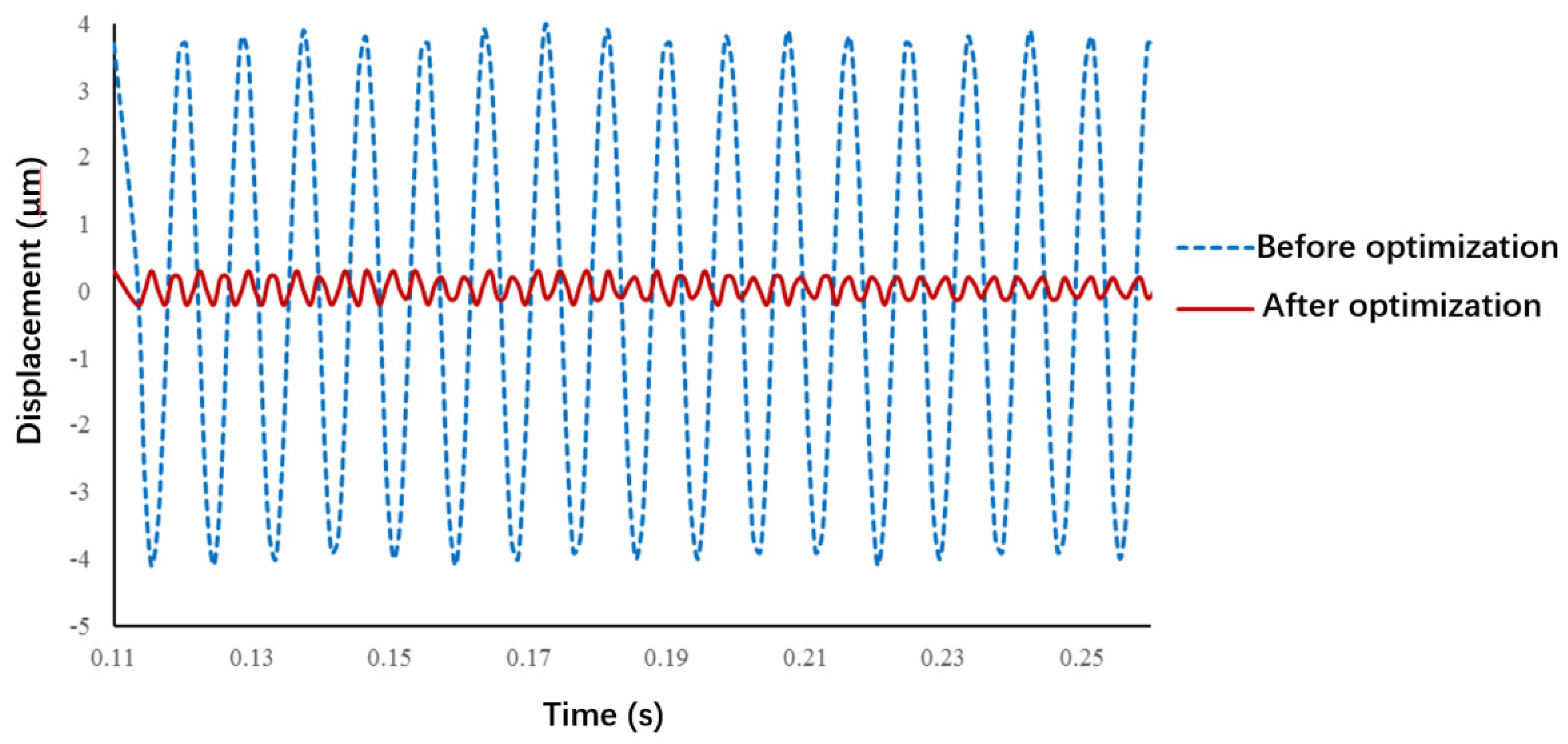

5. Vibration Optimization Performance Test

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Solomon, B.; Mendelson, A.; Ronen, R.; Orenstien, D.; Almog, Y. Micro-operation cache: A power aware frontend for variable instruction length isa. IEEE Trans. Very Large Scale Integr. Syst. 2003, 11, 801–811. [Google Scholar] [CrossRef]

- Tanaka, S.; Nakamura, F. Exploring the Bio-Functional Breaking Point of Living Tissue Subjected to External Physical Pressure. J. Robot. Mechatron. 2022, 34, 319–321. [Google Scholar] [CrossRef]

- Suzuki, H.; Masuda, H.; Hongo, K.; Horie, R.; Yajima, S.; Itotani, Y.; Fujita, M.; Nagasaka, K. Development and testing of force-sensing forceps using FBG for bilateral micro-operation system. IEEE Robot. Autom. Lett. 2018, 3, 4281–4288. [Google Scholar] [CrossRef]

- Cui, F.; Li, Y.; Qian, J. Development of a 3-DOF Flexible Micro-Motion Platform Based on a New Compound Lever Amplification Mechanism. Micromachines 2021, 12, 686. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Liang, F.; Kang, C.; Fang, F. Performance Analysis of Surface Reconstruction Algorithms in Vertical Scanning Interferometry Based on Coherence Envelope Detection. Micromachines 2021, 12, 164. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhao, Z.; Wang, J. Microscopic vision modeling method by direct mapping analysis for micro-gripping system with stereo light microscope. Micron 2016, 83, 93–109. [Google Scholar] [CrossRef]

- Vurchio, F.; Ursi, P.; Orsini, F.; Scorza, A.; Crescenzi, R.; Sciuto, S.A.; Belfiore, N.P. Toward operations in a surgical scenario: Characterization of a microgripper via light microscopy approach. Appl. Sci. 2019, 9, 1901. [Google Scholar] [CrossRef]

- El-Sayed, A.M.; Abo-Ismail, A.; El-Melegy, M.T.; Hamzaid, N.A.; Albu Osman, N.A. Development of a micro-gripper using piezoelectric bimorphs. Sensors 2013, 13, 5826–5840. [Google Scholar] [CrossRef]

- Demaghsi, H.; Mirzajani, H.; Ghavifekr, H.B. Design and simulation of a novel metallic microgripper using vibration to release nano objects actively. Microsyst. Technol. 2014, 20, 65–72. [Google Scholar] [CrossRef]

- Ho, N.L.; Dao, T.P.; Le, H.G.; Chau, N.L. Optimal design of a compliant microgripper for assemble system of cell phone vibration motor using a hybrid approach of ANFIS and Jaya. Arab. J. Sci. Eng. 2019, 44, 1205–1220. [Google Scholar] [CrossRef]

- Das, T.K.; Shirinzadeh, B.; Ghafarian, M.; Al-Jodah, A.; Zhong, Y.; Smith, J. Design, analysis and experimental investigations of a high precision flexure-based microgripper for micro/nano manipulation. Mechatronics 2020, 69, 102396. [Google Scholar] [CrossRef]

- Lyu, Z.; Wu, Z.; Xu, Q. Design and development of a novel piezoelectrically actuated asymmetrical flexible microgripper. Mech. Mach. Theory 2022, 171, 104736. [Google Scholar] [CrossRef]

- Long, Z.; Zhang, J.; Liu, Y.; Han, C.; Li, Y.; Li, Z. Dynamics modeling and residual vibration control of a piezoelectric gripper during wire bonding. IEEE Trans. Compon. Packag. Manuf. Technol. 2017, 7, 2045–2056. [Google Scholar] [CrossRef]

- Yang, Y.; Wei, Y.; Lou, J.; Fu, L.; Fang, S.; Chen, T.H. Dynamic modeling and adaptive vibration suppression of a high-speed macro-micro manipulator. J. Sound Vib. 2018, 422, 318–342. [Google Scholar] [CrossRef]

- Ejima, T.; Ohara, K.; Kojima, M.; Horade, M.; Tanikawa, T.; Mae, Y.; Arai, T. Development of microhand utilizing singularity of parallel mechanism. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 1525–1530. [Google Scholar]

- Yavuz, Ş.; Malgaca, L.; Karagülle, H. Vibration control of a single-link flexible composite manipulator. Compos. Struct. 2016, 140, 684–691. [Google Scholar] [CrossRef]

- Liang, C.; Wang, F.; Shi, B.; Huo, Z.; Zhou, K.; Tian, Y.; Zhang, D. Design and control of a novel asymmetrical piezoelectric actuated microgripper for micromanipulation. Sens. Actuators A Phys. 2018, 269, 227–237. [Google Scholar] [CrossRef]

- Grossard, M.; Rotinat-Libersa, C.; Chaillet, N.; Boukallel, M. Mechanical and control-oriented design of a monolithic piezoelectric microgripper using a new topological optimization method. IEEE/ASME Trans. Mechatron. 2009, 14, 32–45. [Google Scholar] [CrossRef]

- Carrozza, M.C.; Eisinberg, A.; Menciassi, A.; Campolo, D.; Micera, S.; Dario, P. Towards a force-controlled microgripper for assembling biomedical microdevices. J. Micromech. Microeng. 2000, 10, 271. [Google Scholar] [CrossRef]

- Piriyanont, B.; Fowler, A.G.; Moheimani, S.O.R. Force-controlled MEMS rotary microgripper. J. Microelectromech. Syst. 2015, 24, 1164–1172. [Google Scholar] [CrossRef]

- Tian, X.; Liu, Y.; Deng, J.; Wang, L.; Chen, W. A review on piezoelectric ultrasonic motors for the past decade: Classification, operating principle, performance, and future work perspectives. Sens. Actuators A Phys. 2020, 306, 111971. [Google Scholar] [CrossRef]

- Izuhara, S.; Mashimo, T. Linear Piezoelectric Motor Using a Hollow Rectangular Stator. Sens. Actuators A Phys. 2020, 309, 112002. [Google Scholar] [CrossRef]

- Delibas, B.; Koc, B. L1B2 piezo motor using D33 effect. In Proceedings of the 16th International Conference on New Actuators, Bremen, Germany, 25–27 June 2018; pp. 1–4, ISBN 978-3-8007-4675-0. [Google Scholar]

- Tanoue, Y.; Morita, T. Opposing preloads type ultrasonic linear motor with quadruped stator. Sens. Actuators A Phys. 2020, 301, 3773–3776. [Google Scholar] [CrossRef]

- He, Y.; Yao, Z.; Dai, S.; Zhang, B. Hybrid simulation for dynamic responses and performance estimation of linear ultrasonic motors. Int. J. Mech. Sci. 2019, 153, 219–229. [Google Scholar] [CrossRef]

- Yu, H.; Quan, Q.; Tian, X.; Li, H. Optimization and Analysis of a U-Shaped Linear Piezoelectric Ultrasonic Motor Using Longitudinal Transducers. Sensors 2018, 18, 809. [Google Scholar] [CrossRef] [PubMed]

- Lyu, Z.; Xu, Q. Recent design and development of piezoelectric-actuated compliant microgrippers: A review. Sens. Actuators A Phys. 2021, 331, 113002. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Q. Design and testing of a novel 2-DOF compound constant-force parallel gripper. Precis. Eng. 2019, 56, 53–61. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Q. A novel piezoactuated XY stage with parallel, decoupled, and stacked flexure structure for micro-/nanopositioning. IEEE Trans. Ind. Electron. 2010, 58, 3601–3615. [Google Scholar] [CrossRef]

- Chu, H.K.; Mills, J.K.; Cleghorn, W.L. Parallel microassembly with a robotic manipulation system. J. Micromech. Microeng. 2010, 20, 125027. [Google Scholar] [CrossRef]

- Geng, R.R.; Mills, J.K.; Yao, Z.Y. Design and analysis of a novel 3-DOF spatial parallel microgripper driven by LUMs. Robot. Comput. Integr. Manuf. 2016, 42, 147–155. [Google Scholar] [CrossRef]

- Geng, R.R.; Cui, S.; Huang, J.; Bian, R. Mechanical drift modeling and analysis of V-shaped linear ultrasonic motors with a flexible clamp. AIP Adv. 2020, 10, 115303. [Google Scholar] [CrossRef]

- Allaire, G.; Jouve, F.; Toader, A.M. Structural optimization using sensitivity analysis and a level-set method. J. Comput. Phys. 2004, 194, 363–393. [Google Scholar] [CrossRef]

- Zakharova, E.; Minashina, I. Review of multidimensional optimization methods. J. Commun. Technol. Electron. 2015, 60, 625–636. [Google Scholar] [CrossRef]

- Wang, M.Y.; Wang, X.; Guo, D. A level set method for structural topology optimization. Comput. Methods Appl. Mech. Eng. 2003, 192, 227–246. [Google Scholar] [CrossRef]

- Pedersen, N.L. Maximization of eigenvalues using topology optimization. Struct. Multidiscip. Optim. 2000, 20, 2–11. [Google Scholar] [CrossRef]

- Seyranian, A.P.; Lund, E.; Olhoff, N. Multiple eigenvalues in structural optimization problems. Struct. Optim. 1994, 8, 207–227. [Google Scholar] [CrossRef]

| Parameters | E/MPa | d/mm | ρ/kg·m−3 | l/mm |

|---|---|---|---|---|

| Value range | (1 × 104, 1 × 105) | (4.0, 10) | (1 × 103, 7 × 103) | (50, 120) |

| Parameters | E/MPa | d/mm | ρ/kg·m−3 | l/mm |

|---|---|---|---|---|

| Initial value | 7 × 104 | 6.0 | 2700 | 10 |

| The value before improvement | 1 × 104 | 7.1 | 1552 | 90 |

| The value after improvement | 9.9 × 104 | 10.0 | 1001 | 50 |

| Order | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Natural frequency/Hz | 246.57 | 246.91 | 325.18 | 392.05 | 550.14 | 559.55 |

| Peak Point | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Frequency/Hz | 384 | 536 | 808 | 968 |

| Materials | E/MPa | ρ/kg·m−3 |

|---|---|---|

| Duralumin | 7 × 104 | 2700 |

| Copper | 1.19 × 105 | 8900 |

| Carbon fiber plastic | 1.2 × 105 | 1400 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, R.; Yao, Z.; Wang, Y.; Huang, J.; Liu, H. Analysis and Optimization of a Microgripper Driven by Linear Ultrasonic Motors. Micromachines 2022, 13, 1453. https://doi.org/10.3390/mi13091453

Geng R, Yao Z, Wang Y, Huang J, Liu H. Analysis and Optimization of a Microgripper Driven by Linear Ultrasonic Motors. Micromachines. 2022; 13(9):1453. https://doi.org/10.3390/mi13091453

Chicago/Turabian StyleGeng, Ranran, Zhiyuan Yao, Yuqi Wang, Jiacai Huang, and Hanzhong Liu. 2022. "Analysis and Optimization of a Microgripper Driven by Linear Ultrasonic Motors" Micromachines 13, no. 9: 1453. https://doi.org/10.3390/mi13091453

APA StyleGeng, R., Yao, Z., Wang, Y., Huang, J., & Liu, H. (2022). Analysis and Optimization of a Microgripper Driven by Linear Ultrasonic Motors. Micromachines, 13(9), 1453. https://doi.org/10.3390/mi13091453