Working Mechanisms and Experimental Research of Piezoelectric Pump with a Cardiac Valve-like Structure

Abstract

:1. Introduction

2. Structure and Working Principle of PPCVLS

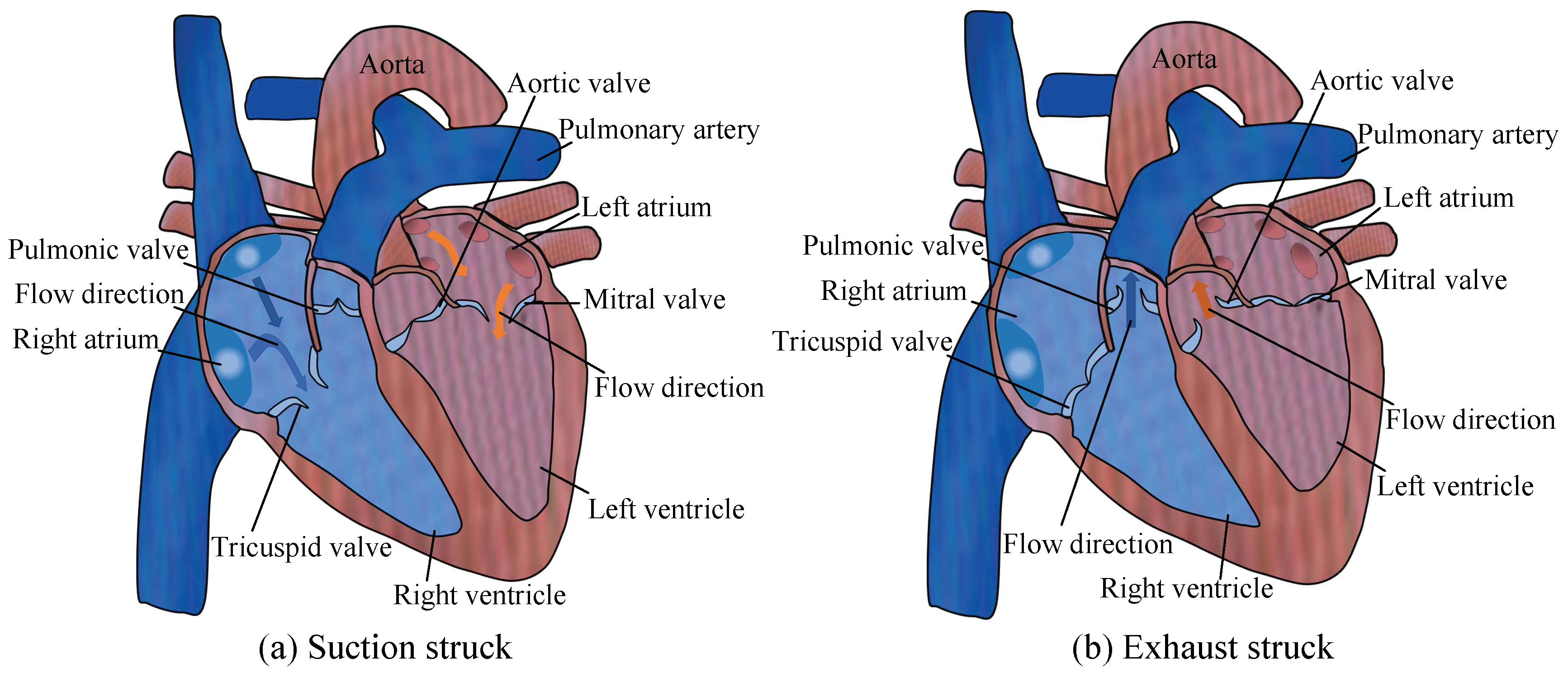

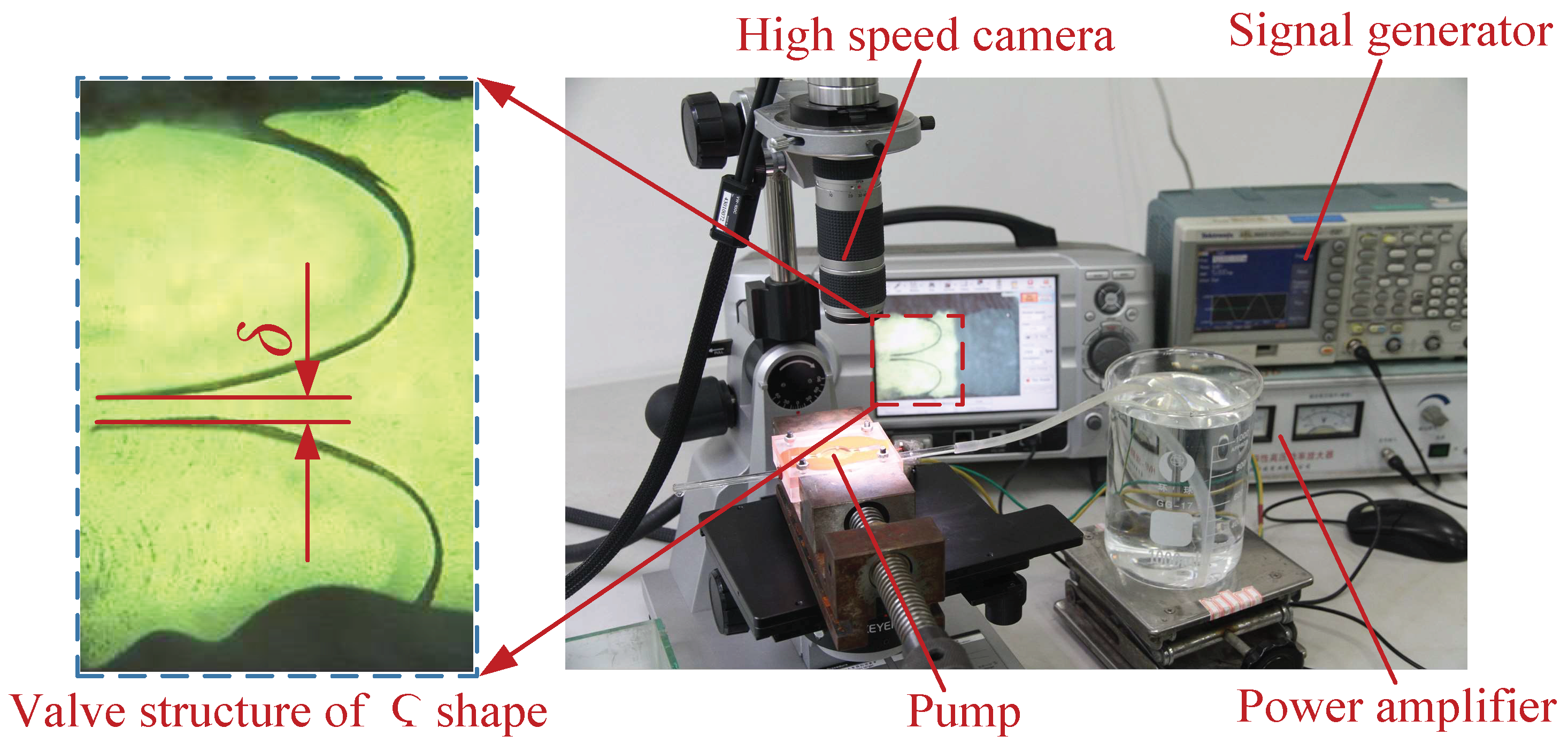

2.1. Proposal of CVLS

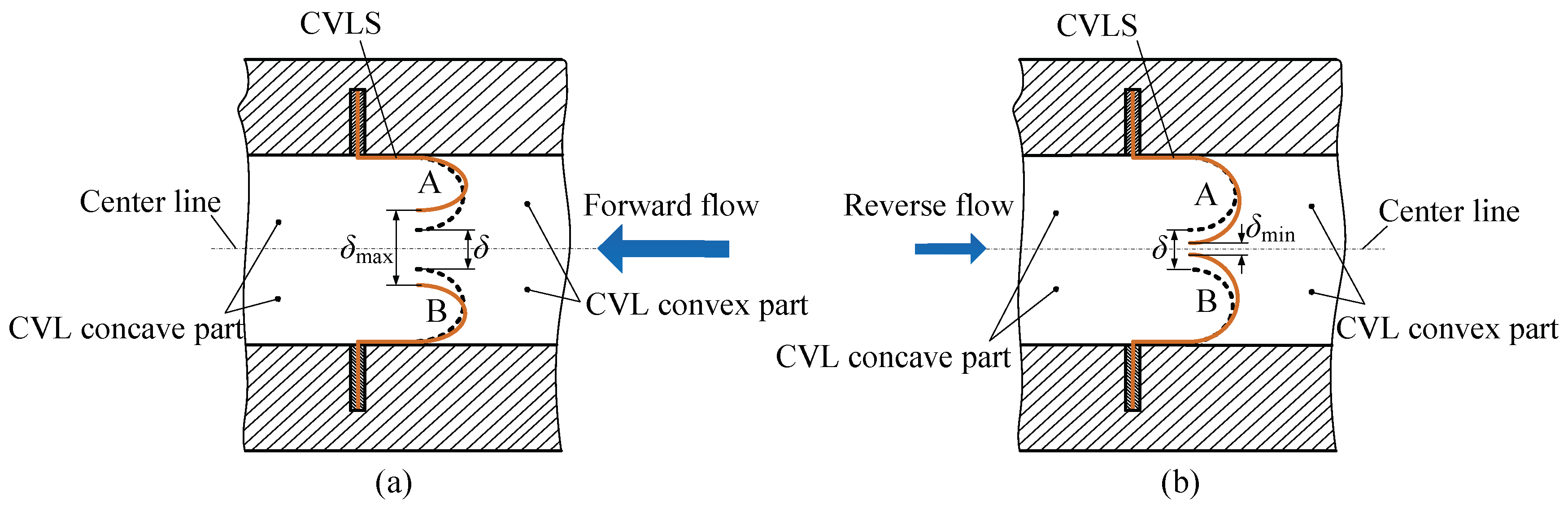

2.2. Valve’s Operating Principle

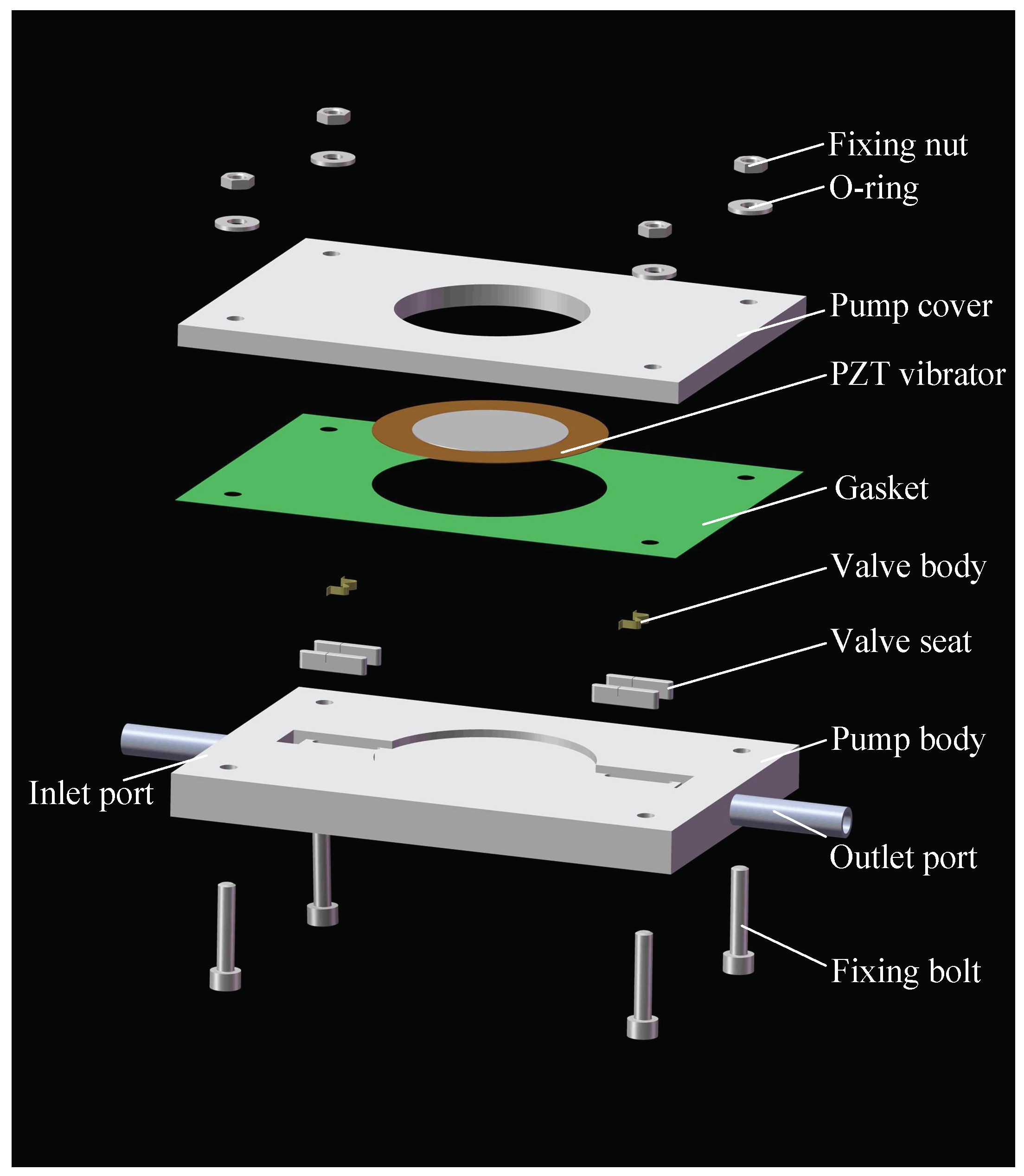

2.3. Structure

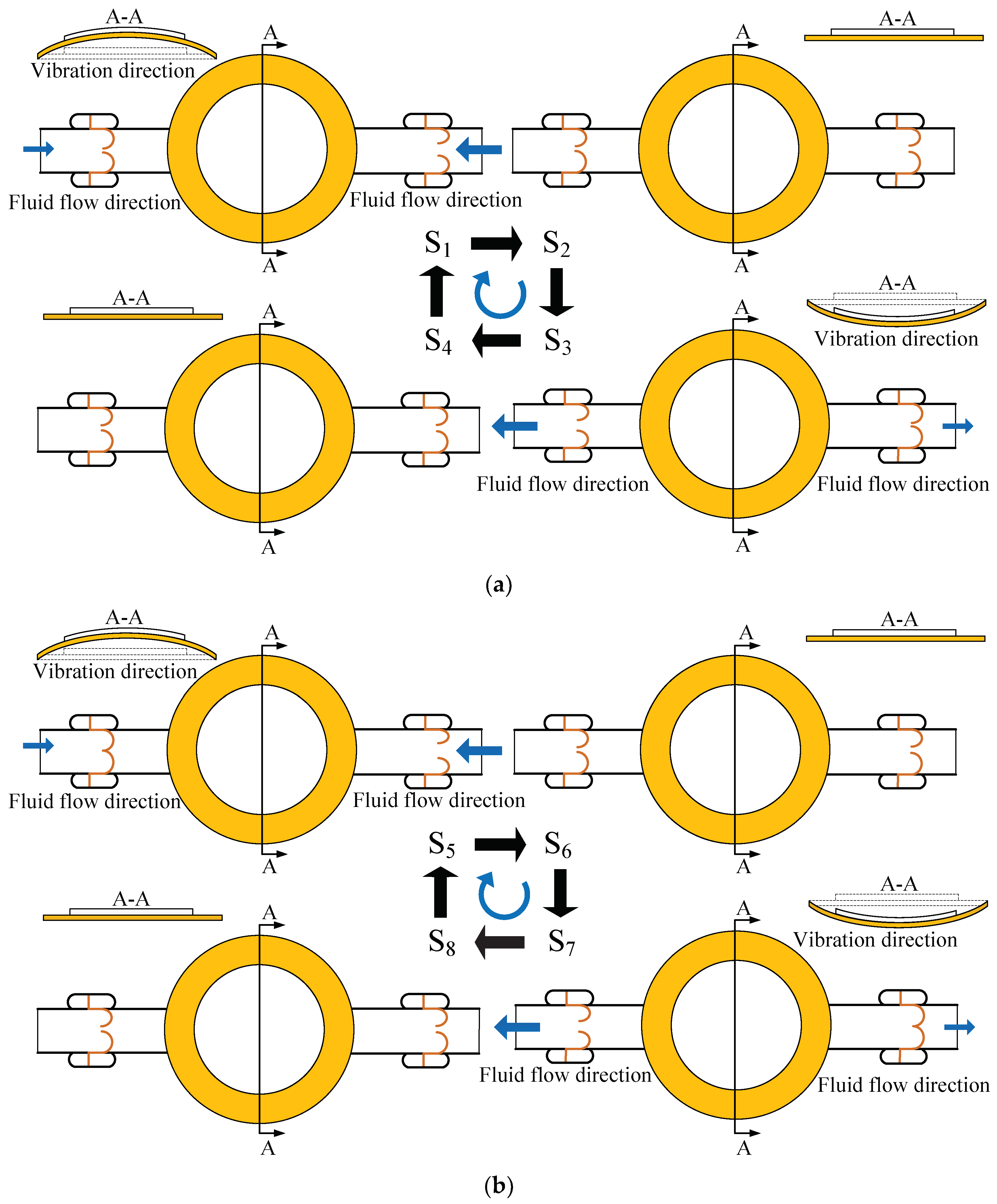

2.4. Working Principle of the Piezoelectric Pump with Cardiac-Valve-Like Structure

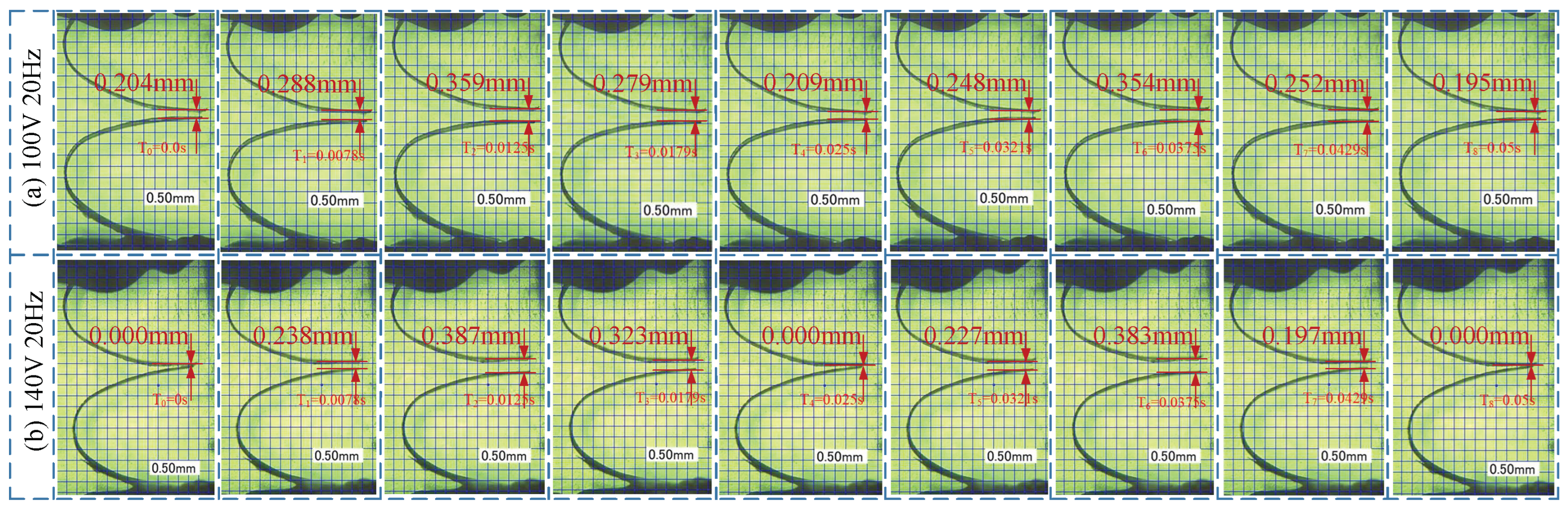

3. Working-State Analysis of Cardiac-Valve-like Structure

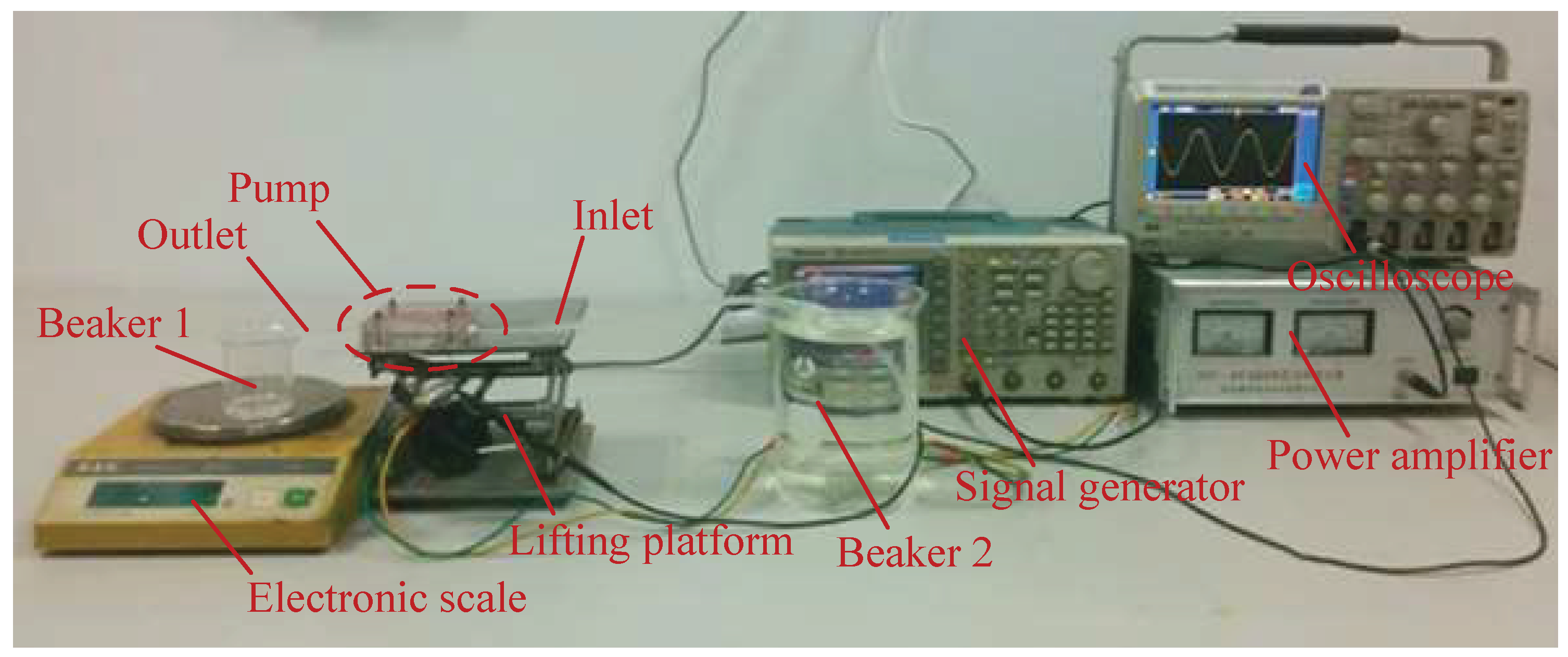

4. Experiments

4.1. Fabrication of PPCVLS

4.2. Experimental Design

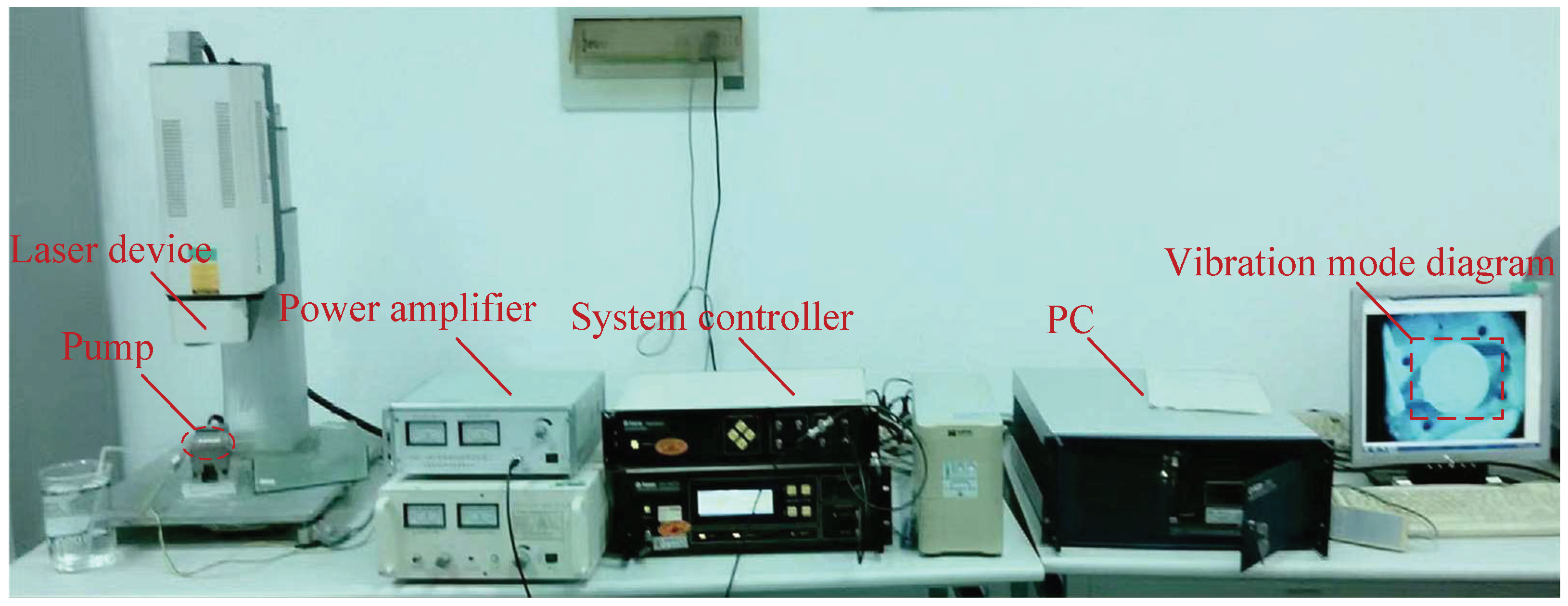

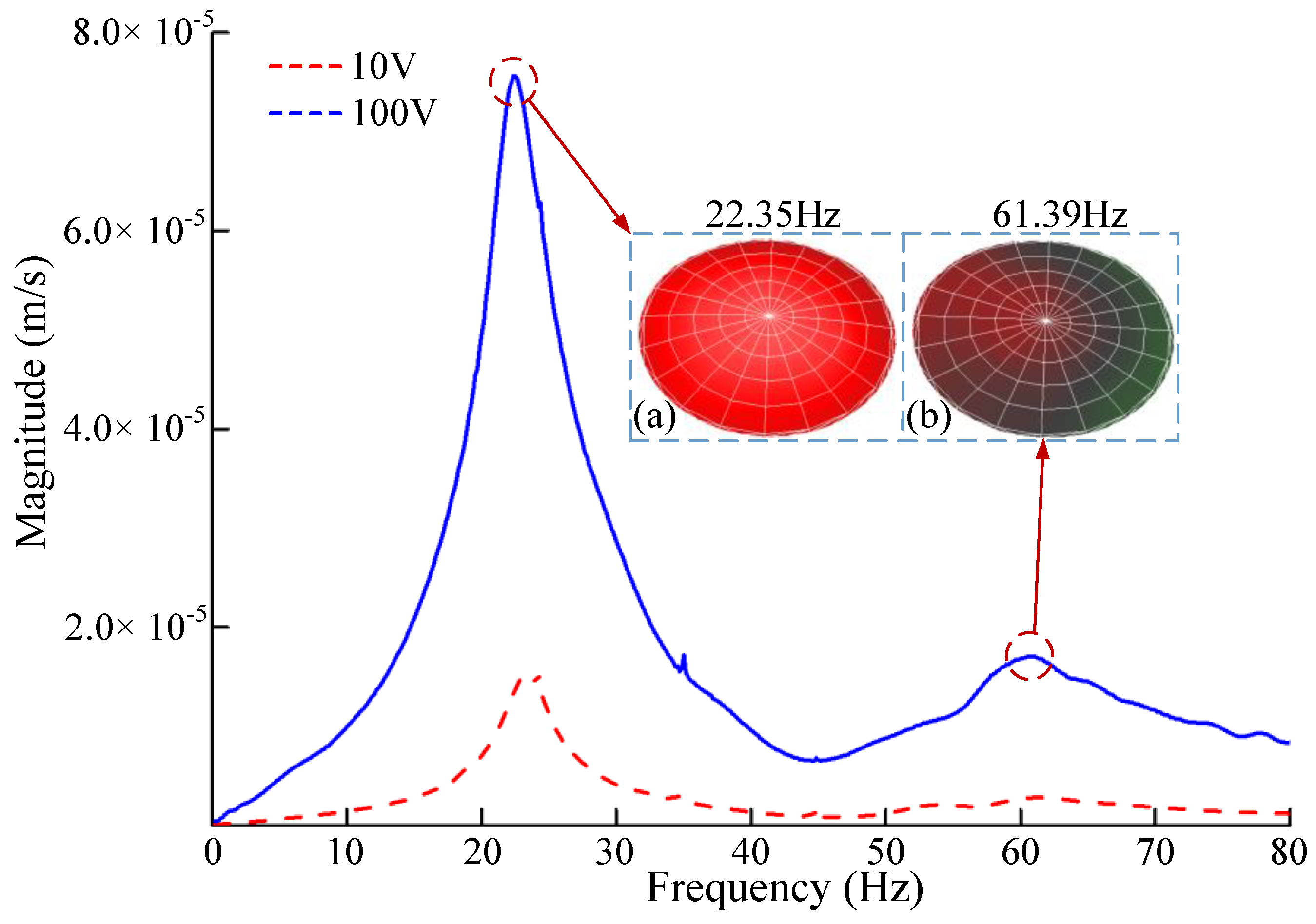

4.2.1. The Frequency-Scanning Test

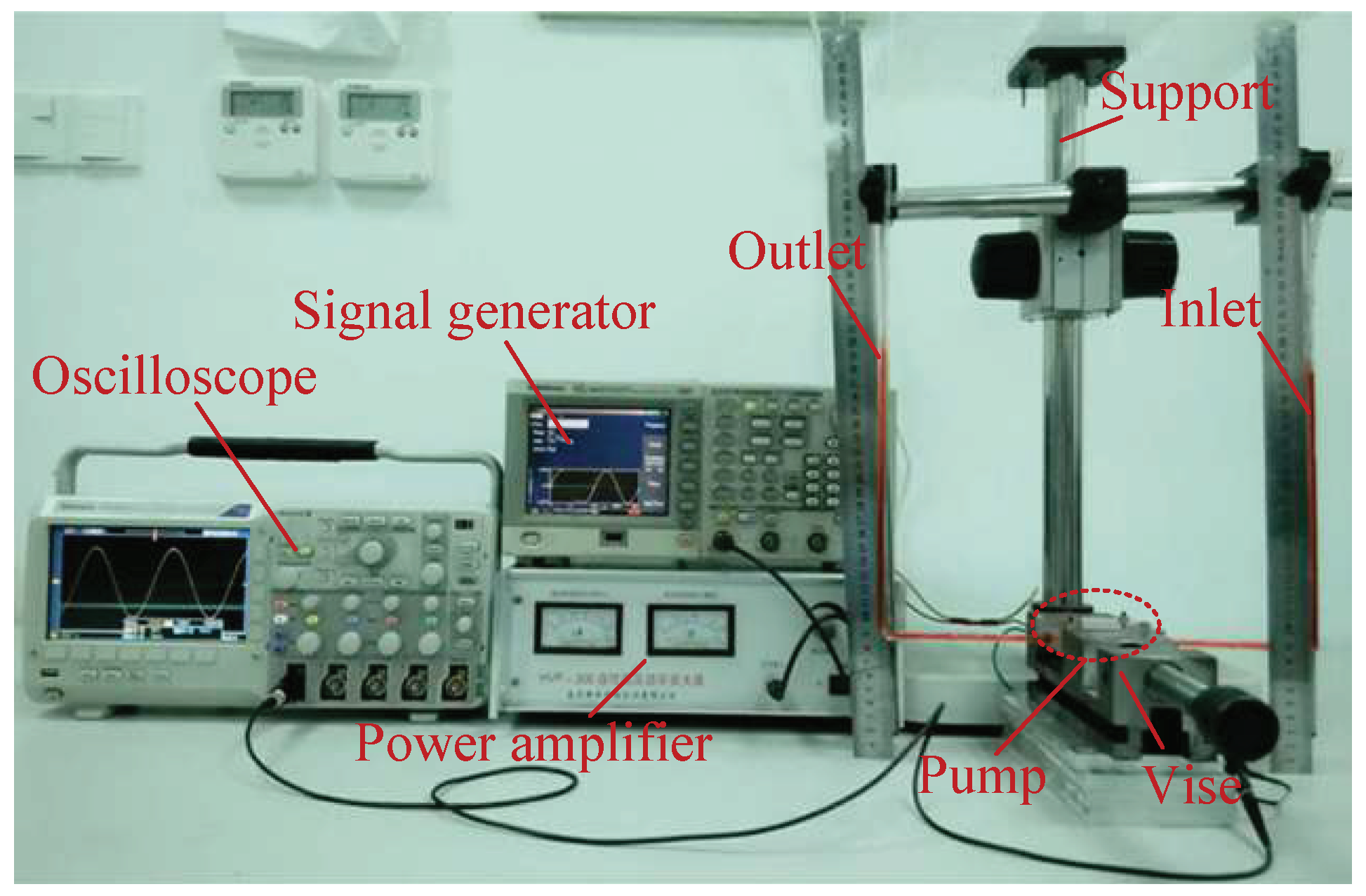

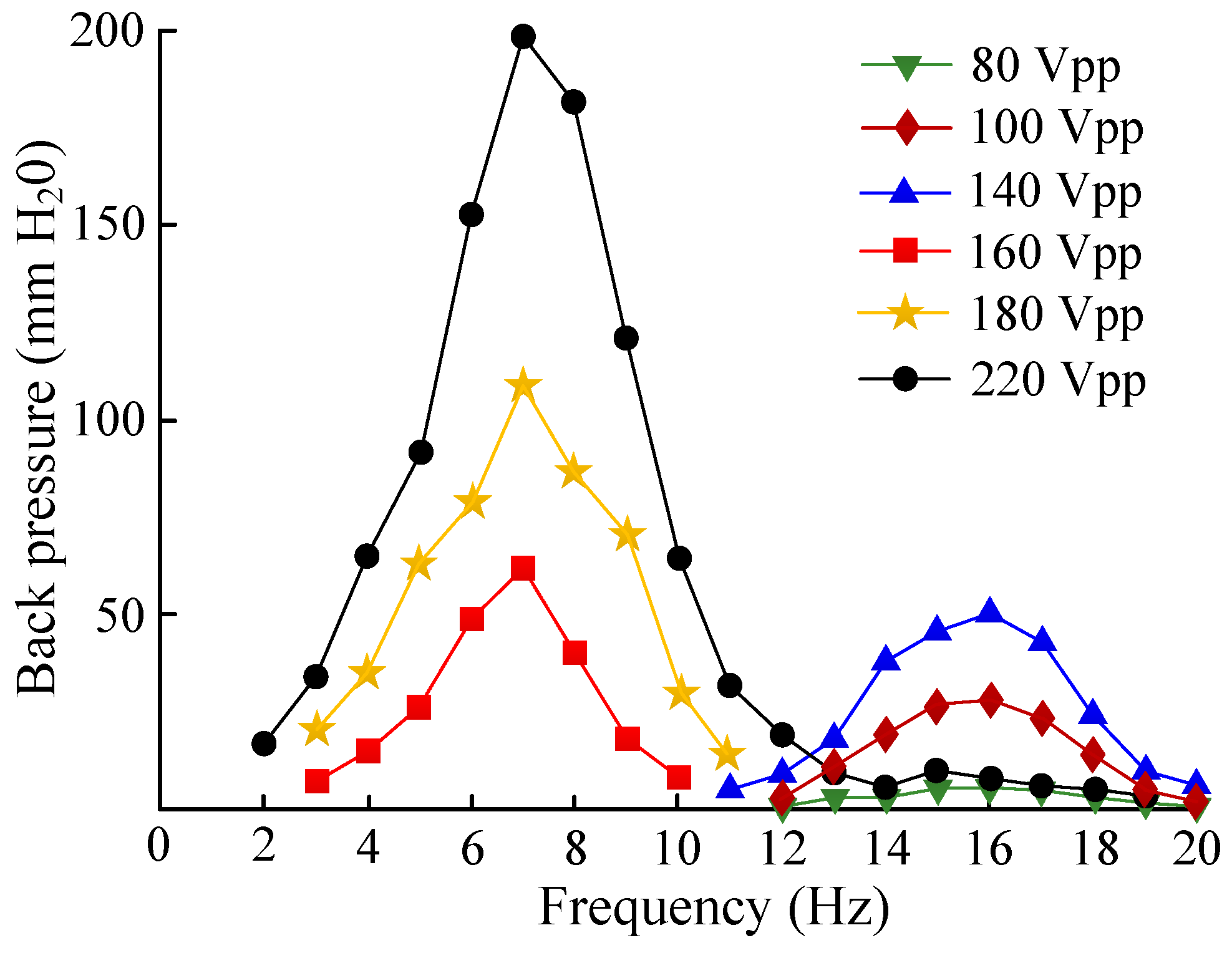

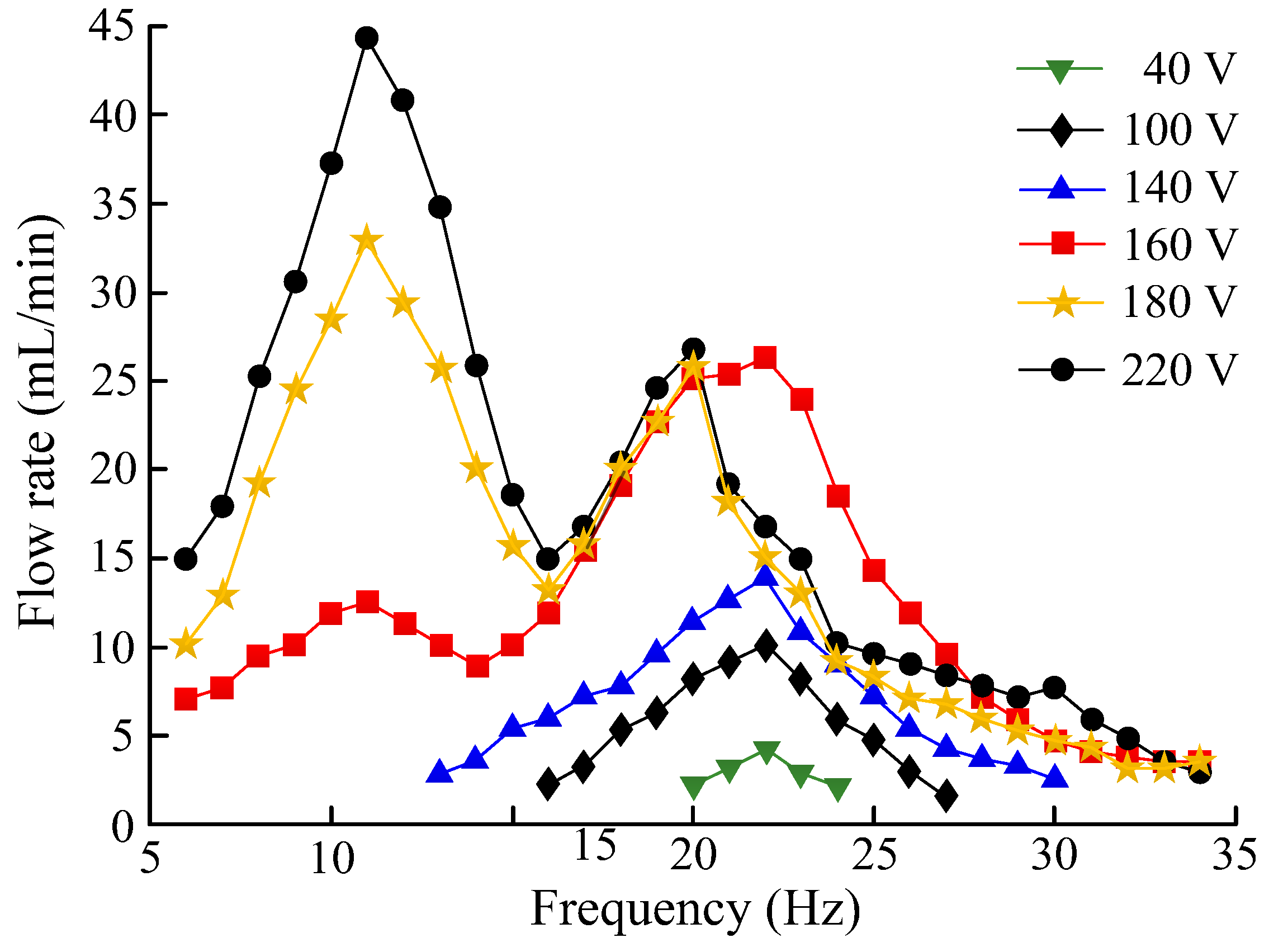

4.2.2. Measurement of PPCVLS Output Performance

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.H.; Fu, J.; Zhang, F.; Zhou, Y.; Huang, J.; Huang, W.Q.; Bian, K.; Liu, P.C. Redefining valves in volume pump. In Proceedings of the 16th International Conference on New Actuators, Bremen, Germany, 25–27 June 2018; pp. 125–129. [Google Scholar]

- Yannopoulos, S.I.; Lyberatos, G.; Theodossiou, N.; Li, W.; Valipour, M.; Tamburrino, A.; Angelakis, A.N. Evolution of water lifting devices (pumps) over the centuries worldwide. Water 2015, 2015, 5031–5060. [Google Scholar] [CrossRef]

- Sun, X.L.; Liu, Z.M.; Zhang, Y. Research and development of LNG submerged pump. Cryogenics 2010, 174, 20–23. [Google Scholar]

- Kim, D.K.; Kim, J.H. A study on structural analysis of globe valve for LNG carrier. J. Korean Soc. Mar. Eng. 2007, 31, 1013–1019. [Google Scholar]

- Bumann, A.B.; Durasiewicz, C.P.; Kibler, S.H.A.; Wald, C.K. Piezoelectric titanium based microfluidic pump and valves for implantable medical application. Sens. Actuators A Phys. 2021, 323, 112649. [Google Scholar] [CrossRef]

- Chen, S.; Hu, H.D.; Ji, J.J.; Kan, J.W.; Zhang, Z.H. An indirect drug delivery device driven by piezoelectric pump. Smart Mater. Struct. 2020, 29, 075030. [Google Scholar] [CrossRef]

- Chen, X.S.; Chen, Z.L.; Gui, Z.Z.; Zhang, F.; Zhang, W.R.; Zhou, X.S.; Huang, X.; Zhang, J.H. A novel valve-less piezoelectric micro pump generating recirculating flow. Eng. Appl. Comput. Fluid Mech. 2021, 15, 1473–1490. [Google Scholar]

- Yang, Q.L.; Ma, Y.L.; Shi, K.Q.; Yang, G.S.; Zhu, J.S. Electrostatic coated controlled porosity osmotic pumps with ultrafine powders. Powder Technol. 2018, 333, 71–77. [Google Scholar] [CrossRef]

- Alameh, A.H.; Nabki, F. A 0.13-mu m CMOS dynamically reconfigurable charge pump for electrostatic MEMS actuation. IEEE Trans. Very Large Scale Integr. (VLSI) Syst. 2017, 25, 1261–1270. [Google Scholar] [CrossRef]

- Zwier, M.P.; van Gerner, H.J.; Wits, W.W. Modelling and experimental investigation of a thermally driven self-oscillating pump. Appl. Therm. Eng. 2017, 126, 1126–1133. [Google Scholar] [CrossRef]

- Pumaneratkul, C.; Iwamoto, Y.; Niu, X.D.; Kuwahara, T.; Yamaguchi, H. Characteristics of thermally driven pump in supercritical CO2 solar rankine cycle system. Int. J. Mech. Prod. Eng. 2015, 3, 1–6. [Google Scholar]

- Yan, Q.F.; Yin, Y.K.; Sun, W.T.; Fu, J. Advances in valveless pumps. Appl. Sci. 2021, 11, 7061. [Google Scholar] [CrossRef]

- Li, H.Y.; Liu, J.K.; Li, K.; Liu, Y.X. A review of recent studies on piezoelectric pumps and their application. Mech. Syst. Signal Process. 2021, 151, 107393. [Google Scholar] [CrossRef]

- Narasaki, T. Layered type bimorph vibrator pump. In Proceedings of the 13th Intersociety Energy Conversion Engineering Conference, San Diego, CA, USA, 20–25 August 1978; Society of Automotive Engineers: Warrendale, PA, USA, 1978; pp. 2005–2006. [Google Scholar]

- Wu, X.Q.; He, L.P.; Hou, Y.; Tian, X.C.; Zhao, X.L. Advances in passive check valve piezoelectric pumps. Sens. Actuators A Phys. 2021, 323, 112647. [Google Scholar] [CrossRef]

- Chen, S.; Qian, C.P.; Cheng, W.T.; Kan, J.W.; Ji, J.J.; Zhang, Z.H.; Wang, J.T. A low frequency driven piezoelectric pump with flexible valve. Sens. Actuators A Phys. 2021, 319, 112567. [Google Scholar] [CrossRef]

- Dong, J.S.; Liu, C.; Chen, Q.Q.; Xu, Z.; Chen, W.H.; Wu, Y.; Yang, Z.G. Design and experimental research of piezoelectric pump based on macro fiber composite. Sens. Actuators A Phys. 2020, 312, 112123. [Google Scholar] [CrossRef]

- Kaçar, A.; Özer, M.B.; Tascıoğlu, Y. A novel artificial pancreas: Energy efficient valve-less piezoelectric actuated closed-loop insulin pump for T1DM. Appl. Sci. 2020, 10, 5294. [Google Scholar] [CrossRef]

- Shim, S.; Belanger, M.C.; Harris, A.R.; Munson, J.M.; Pompano, R.R. Two-way communication between exvivo tissues on a microfluidic chip: Application to tumorlymph node interaction. Lab A Chip 2019, 19, 1013–1026. [Google Scholar] [CrossRef]

- Tandon, V.; Kang, W.S.; Robbins, T.A.; Spencer, A.J.; Kim, E.S.; Mckenna, M.J.; Kujawa, S.G.; Fiering, J.; Pararas EE, L.; Mescher, M.J.; et al. Microfabricated reciprocation micropump for intracochlear drug delivery with integrated drug/fluid storage and electronically controlled dosing. Lab A Chip 2016, 16, 829–846. [Google Scholar] [CrossRef]

- Wang, X.Y.; Ma, Y.T.; Yan, G.Y.; Huang, D.; Feng, Z.H. High flow-rate piezoelectric micropump with two fixed ends polydimethylsiloxane valves and compressible spaces. Sens. Actuators A Phys. 2014, 218, 94–104. [Google Scholar] [CrossRef]

- Park, J.H.; Seo, M.Y.; Ham, Y.B.; Yun, S.N.; Kim, D.I. A study on high-output piezoelectric micropumps for application in DMFC. J. Elecyroceramics 2013, 30, 102–107. [Google Scholar] [CrossRef]

- Luo, C.X. Study on a PZT-actuated diaphragm pump for air supply for micro fuel cells. Sens. Actuators A Phys. 2006, 130–131, 531–536. [Google Scholar]

- Ding, J.; Cao, Y.; Chen, Q.Q.; Dong, J.S.; Xu, Z.; Tian, D.Y.; Liu, C.; Zhang, B.W.; Zeng, P.; Wu, Y.; et al. Development of a novel piezoelectric-actuated inertial pump using bionic valve. J. Intell. Mater. Syst. Struct. 2021, 32, 2190–2200. [Google Scholar] [CrossRef]

- Li, H.Y.; Liu, J.K.; Li, K.; Deng, J.; Liu, Y.X. Development of a high-pressure self-priming valve-based piezoelectric pump using bending transducers. IEEE Trans. Ind. Electron. 2022, 69, 2759–2768. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, J.H.; Xun, X.C.; Wang, S.Y. Theory and experimental verification on valve-less piezoelectric pump with multistage Y-shape treelike bifurcate tubes. Chin. J. Mech. Eng. 2013, 26, 462–468. [Google Scholar] [CrossRef]

- Tseng, L.Y.; Yang, A.S.; Lee, C.Y.; Cheng, C.H. Investigation of a piezoelectric valve-less micro pump with an integrated stainlesssteel diffuser/nozzle bulge-piece design. Smart Mater. Struct. 2013, 22, 085023. [Google Scholar] [CrossRef]

- Zhang, J.H.; Leng, X.F.; Zhao, C.S. A spiral-tube-type valve-less piezoelectric pump with gyroscopic effect. Chin. Sci. Bull. 2014, 59, 1885–1889. [Google Scholar] [CrossRef]

- Fu, J.; Zhang, J.H.; Wang, Y.; Yan, Q.F. Research on Semi-flexible Valve Piezoelectric Pump. J. Vib. Meas. Diagn. 2019, 39, 1005–1010, 1133. [Google Scholar]

- Huang, W.Q.; Lai, L.Y.; Chen, Z.L.; Chen, X.S.; Huang, Z.; Dai, J.T.; Zhang, F.; Zhang, J.H. Research on a Piezoelectric Pump with Flexible Valves. Appl. Sci. 2021, 11, 2909. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Hardness (HB) | 80 |

| Compressive strength (kg/mm2) | 24 |

| Flexural strength (kg/mm2) | 11 |

| Voltage resilience (kv/mm) | 18–21 |

| Impact strength (kg/mm2) | 8.5 |

| Parameters | Values |

|---|---|

| Resonant frequency (kHz) | 2.6 ± 0.5 |

| Plate material | Brass |

| Plate diameter (mm) | 35 ± 0.1 |

| Plate thickness (mm) | 0.18 ± 0.01 |

| Plate density (kg/m3) | 8.5 × 103 |

| Plate elastic modulus (Gpa) | 60.4 |

| Plate Poisson ratio | 0.3 |

| Ceramic disc diameter (mm) | 23 ± 0.1 |

| Ceramic disc thickness (mm) | 0.3 ± 0.02 |

| Ceramic disc density (kg/m3) | 7.5 × 103 |

| Ceramic disc elastic modulus (Gpa) | 112 |

| Ceramic disc Poisson ratio | 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Sun, W.; Fu, J.; Liu, H.; Wang, H.; Yan, Q. Working Mechanisms and Experimental Research of Piezoelectric Pump with a Cardiac Valve-like Structure. Micromachines 2022, 13, 1621. https://doi.org/10.3390/mi13101621

Zhou J, Sun W, Fu J, Liu H, Wang H, Yan Q. Working Mechanisms and Experimental Research of Piezoelectric Pump with a Cardiac Valve-like Structure. Micromachines. 2022; 13(10):1621. https://doi.org/10.3390/mi13101621

Chicago/Turabian StyleZhou, Jiayue, Wanting Sun, Jun Fu, Huixia Liu, Hongmei Wang, and Qiufeng Yan. 2022. "Working Mechanisms and Experimental Research of Piezoelectric Pump with a Cardiac Valve-like Structure" Micromachines 13, no. 10: 1621. https://doi.org/10.3390/mi13101621

APA StyleZhou, J., Sun, W., Fu, J., Liu, H., Wang, H., & Yan, Q. (2022). Working Mechanisms and Experimental Research of Piezoelectric Pump with a Cardiac Valve-like Structure. Micromachines, 13(10), 1621. https://doi.org/10.3390/mi13101621