Compensation of the Stress Gradient in Physical Vapor Deposited Al1−xScxN Films for Microelectromechanical Systems with Low Out-of-Plane Bending

Abstract

:1. Introduction

2. Background and Theory

2.1. Average Film Stress Measurement

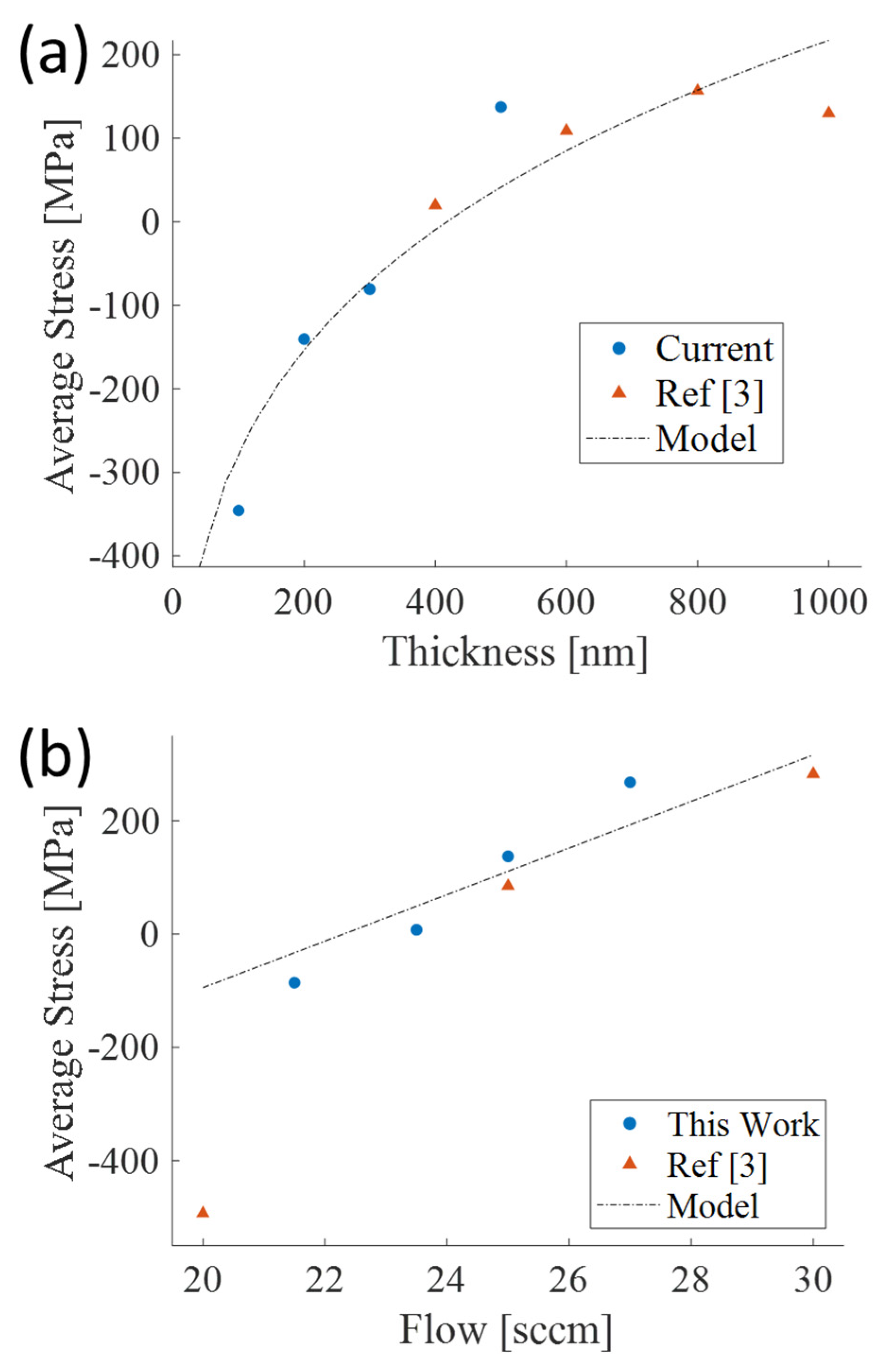

2.2. Relationship between the Total Process Gas Flow and the Resulting Film Stress

3. Experimentation Details

4. Results and Discussion

4.1. Through-Thickness Stress Gradients in Sputtered Al1−xScxN films

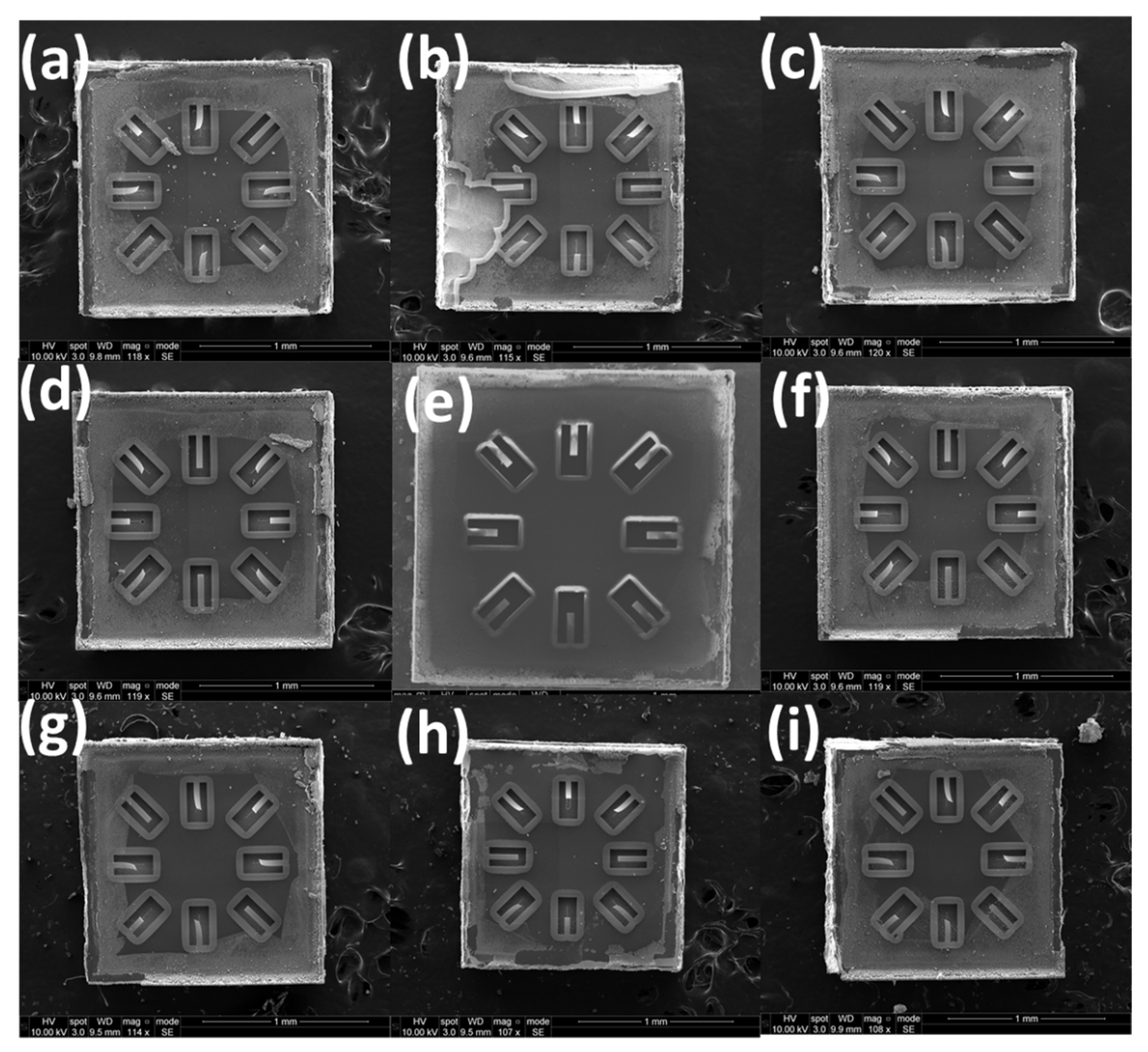

4.2. Out-of-Plane Cantilever Deflection in Uncompensated Al1−xScxN Materials

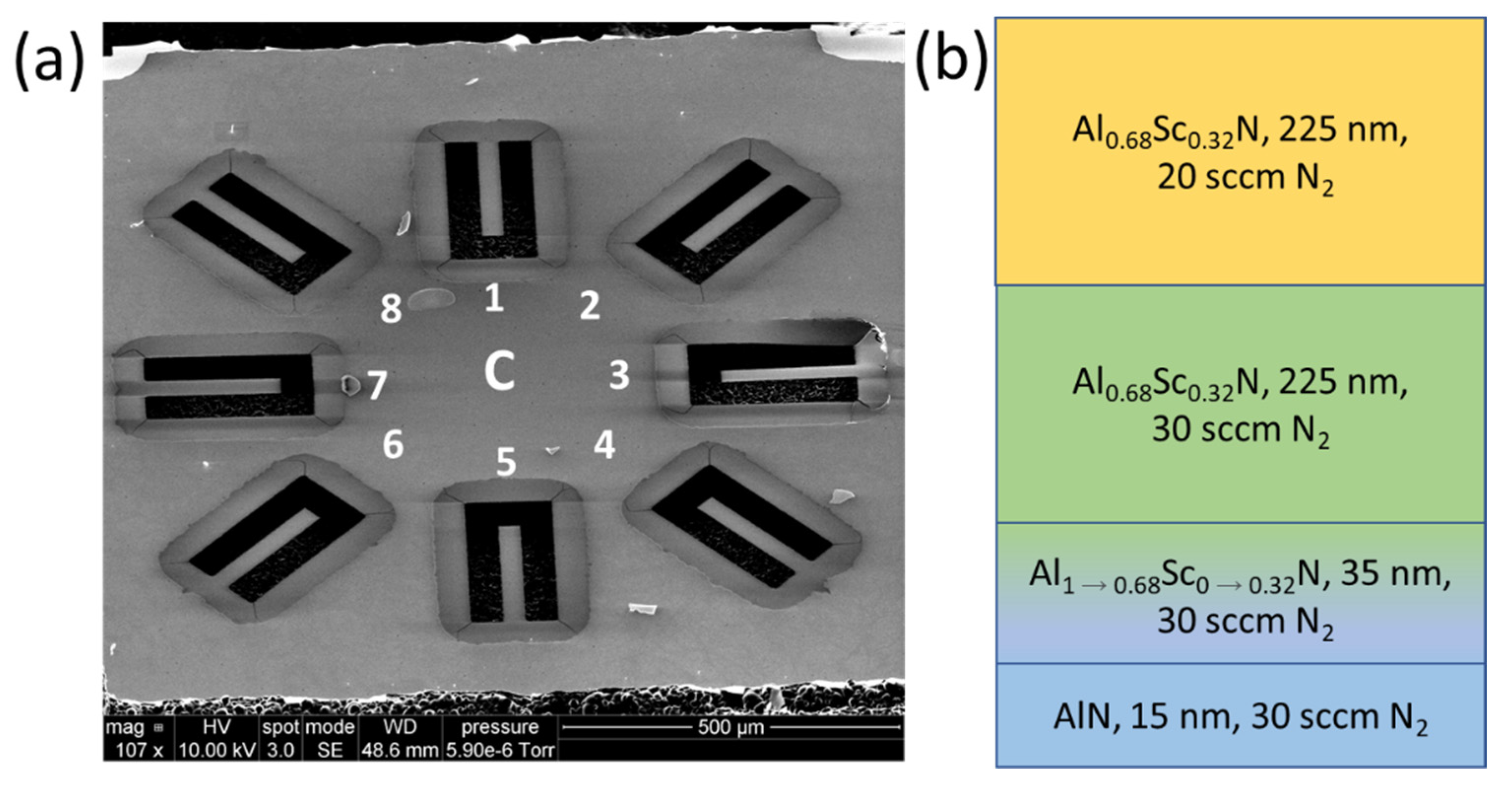

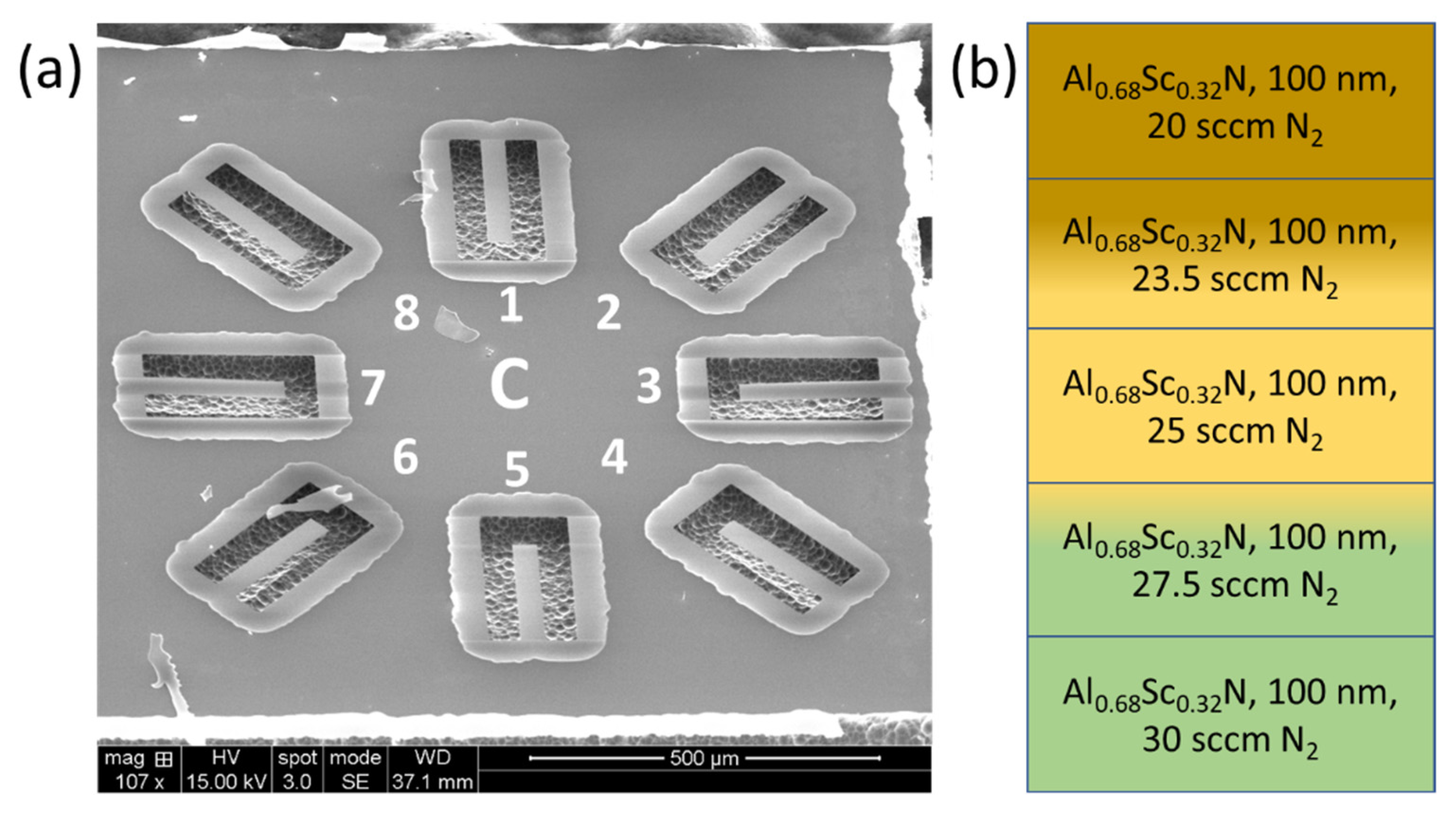

4.3. Stress Gradient Compensated Al1−xScxN Films and Cantilevers

4.4. Discussion of Stress Gradient Cancellation Trends

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Esteves, G.; Berg, M.; Wrasman, K.D.; Henry, M.D.; Griffin, B.A.; Douglas, E.A. CMOS compatible metal stacks for suppression of secondary grains in Sc0.125Al0.875N. J. Vac. Sci. Technol. A Vac. Surf. Film. 2019, 37, 021511. [Google Scholar] [CrossRef]

- Olsson, R.H.; Tang, Z.; D’Agati, M. Doping of aluminum nitride and the impact on thin film piezoelectric and ferroelectric device performance. In Proceedings of the 2020 IEEE Custom Integrated Circuits Conference (CICC), Boston, MA, USA, 22–25 March 2020; IEEE: New York, NY, USA, 2020; pp. 1–6. [Google Scholar]

- Beaucejour, R.; Roebisch, V.; Kochhar, A.; Moe, C.; Hodge, D.; Olsson, R.H., III. Controlling Residual Stress and Suppression of Anomalous Grains in Aluminum Scandium Nitride Films Grown Directly on Silicon. J. Microelectromech. Syst. 2022, 1–8. Available online: https://ieeexplore.ieee.org/document/9770129 (accessed on 1 June 2022). [CrossRef]

- Hong, Y.; Sui, L.; Zhang, M.; Shi, G. Theoretical analysis and experimental study of the effect of the neutral plane of a composite piezoelectric cantilever. Energy Convers. Manag. 2018, 171, 1020–1029. [Google Scholar] [CrossRef]

- Wang, Q.M.; Yang, Z.; Li, F.; Smolinski, P. Analysis of thin film piezoelectric microaccelerometer using analytical and finite element modeling. Sens. Actuators Phys. 2004, 113, 1–11. [Google Scholar] [CrossRef]

- Akiyama, M.; Kamohara, T.; Kano, T.; Teshigahara, A.; Takeuchi, Y.; Kawahara, N. Enhancement of piezoelectric response in scandium aluminum nitride alloy thin films prepared by dual reactive cosputtering. Adv. Mater. 2009, 21, 593–596. [Google Scholar] [CrossRef]

- Reusch, M.; Cherneva, S.; Lu, Y.; Žukauskaitė, A.; Kirste, L.; Holc, K.; Datcheva, M.; Stoychev, D.; Levdeve, V.; Ambacher, O. Microstructure and mechanical properties of stress-tailored piezoelectric AlN thin films for electro-acoustic devices. Appl. Surf. Sci. 2017, 407, 307–314. [Google Scholar] [CrossRef]

- Park, M.; Hao, Z.; Dargis, R.; Clark, A.; Ansari, A. Epitaxial aluminum scandium nitride super high frequency acoustic resonators. J. Microelectromech. Syst. 2020, 29, 490–498. [Google Scholar] [CrossRef]

- Fichtner, S.; Reimer, T.; Chemnitz, S.; Lofink, F.; Wagner, B. Stress controlled pulsed direct current co-sputtered Al1− xScxN as piezoelectric phase for micromechanical sensor applications. APL Mater. 2015, 3, 116102. [Google Scholar] [CrossRef] [Green Version]

- Rossnagel, S.M. Thin film deposition with physical vapor deposition and related technologies. J. Vac. Sci. Technol. A Vac. Surf. Film. 2003, 21, S74–S87. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, Y.; Ansari, A. Ferroelectric Aluminum Scandium Nitride Thin Film Bulk Acoustic Resonators with Polarization-Dependent Operating States. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2021, 15, 2100034. [Google Scholar] [CrossRef]

- Thornton, J.A.; Hoffman, D.W. Stress-related effects in thin films. Thin Solid Film. 1989, 171, 5–31. [Google Scholar] [CrossRef]

- Panjan, P.; Drnovšek, A.; Gselman, P.; Čekada, M.; Panjan, M. Review of growth defects in thin films prepared by PVD techniques. Coatings 2020, 10, 447. [Google Scholar] [CrossRef]

- Knisely, K.E.; Hunt, B.; Troelsen, B.; Douglas, E.; Griffin, B.A.; Stevens, J.E. Method for controlling stress gradients in PVD aluminum nitride. J. Micromech. Microeng. 2018, 28, 115009. [Google Scholar] [CrossRef]

- Henry, M.D.; Young, T.R.; Douglas, E.A.; Griffin, B.A. Reactive sputter deposition of piezoelectric Sc0.12Al0.88N for contour mode resonators. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2018, 36, 03E104. [Google Scholar] [CrossRef]

- Pulskamp, J.S.; Wickenden, A.; Polcawich, R.; Piekarski, B.; Dubey, M.; Smith, G. Mitigation of residual film stress deformation in multilayer microelectromechanical systems cantilever devices. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2003, 21, 2482–2486. [Google Scholar] [CrossRef]

- Sedky, S.; Howe, R.T.; King, T. Pulsed-laser annealing, a low-thermal-budget technique for eliminating stress gradient in poly-SiGe MEMS structures. J. Microelectromech. Syst. 2004, 13, 669–675. [Google Scholar] [CrossRef]

- Zhu, W.Z.; Assylbekova, M.; McGruer, N.E. Limitations on MEMS design resulting from random stress gradient variations in sputtered thin films. J. Micromech. Microeng. 2021, 31, 045004. [Google Scholar] [CrossRef]

- Mulloni, V.; Giacomozzi, F.; Margesin, B. Controlling stress and stress gradient during the release process in gold suspended micro-structures. Sens. Actuators A Phys. 2010, 162, 93–99. [Google Scholar] [CrossRef]

- Shao, S.; Luo, Z.; Lu, Y.; Mazzalai, A.; Tosi, C.; Wu, T. High Quality Co-Sputtering AlScN Thin Films for Piezoelectric Lamb-Wave Resonators. J. Microelectromech. Syst. 2022, 31, 328–337. [Google Scholar] [CrossRef]

- Dubois, M.A.; Muralt, P. Stress and piezoelectric properties of aluminum nitride thin films deposited onto metal electrodes by pulsed direct current reactive sputtering. J. Appl. Phys. 2001, 89, 6389–6395. [Google Scholar] [CrossRef]

- Kusaka, K.; Taniguchi, D.; Hanabusa, T.; Tominaga, K. Effect of input power on crystal orientation and residual stress in AlN film deposited by dc sputtering. Vacuum 2000, 59, 806–813. [Google Scholar] [CrossRef]

- Ng, D.K.T.; Zhang, T.; Siow, L.Y.; Xu, L.; Ho, C.P.; Cai, H.; Lee, L.Y.T.; Zhang, Q.; Singh, N. A functional CMOS compatible MEMS pyroelectric detector using 12%-doped scandium aluminum nitride. Appl. Phys. Lett. 2020, 117, 183506. [Google Scholar] [CrossRef]

- Su, J.; Niekiel, F.; Fichtner, S.; Thormaehlen, L.; Kirchhof, C.; Meyners, D.; Quandt, E.; Wagner, B.; Lofink, F. AlScN-based MEMS magnetoelectric sensor. Appl. Phys. Lett. 2020, 117, 132903. [Google Scholar] [CrossRef]

- Olsson, R.H.; Wojciechowski, K.E.; Baker, M.S.; Tuck, M.R.; Fleming, J.G. Post-CMOS-Compatible Aluminum Nitride Resonant MEMS Accelerometers. J. Microelectromech. Syst. 2009, 18, 671–678. [Google Scholar] [CrossRef]

- Khanna, V.K. Flexible Electronics; IOP Publishing Limited: Bristol, UK, 2019; Volume 2. [Google Scholar]

- Konno, A.; Sumisaka, M.; Teshigahara, A.; Kano, K.; Hashimo, K.Y.; Hirano, H.; Esashi, M.; Kodota, M.; Tanaka, S. ScAlN Lamb wave resonator in GHz range released by XeF2 etching. In Proceedings of the 2013 IEEE International Ultrasonics Symposium (IUS), Prague, Czech Republic, 21–25 July 2013; IEEE: New York, NY, USA, 2013; pp. 1378–1381. [Google Scholar]

| Process Parameter | Value |

|---|---|

| Temperature | 350 °C |

| Sputter Power Al Cathode | 1000 W |

| Sputter Power Sc Cathode | 555 W |

| DC Pulsing Frequency | 150 kHz |

| N2 Flow | 20–30 sccm |

| Film Thickness | 100–1000 nm |

| Base Pressure | <3 × 10−7 mbar |

| # of Layers | ||||

|---|---|---|---|---|

| Single | Double | Quintuple | ||

| N2 Flow [sccm] | 25 | 30/20 | 30/27.5/25/23.5/20 | |

| Average Stress [MPa] | 137.4 | 349.6 | 78.6 | |

| Seed Layer | Yes | Yes | No | |

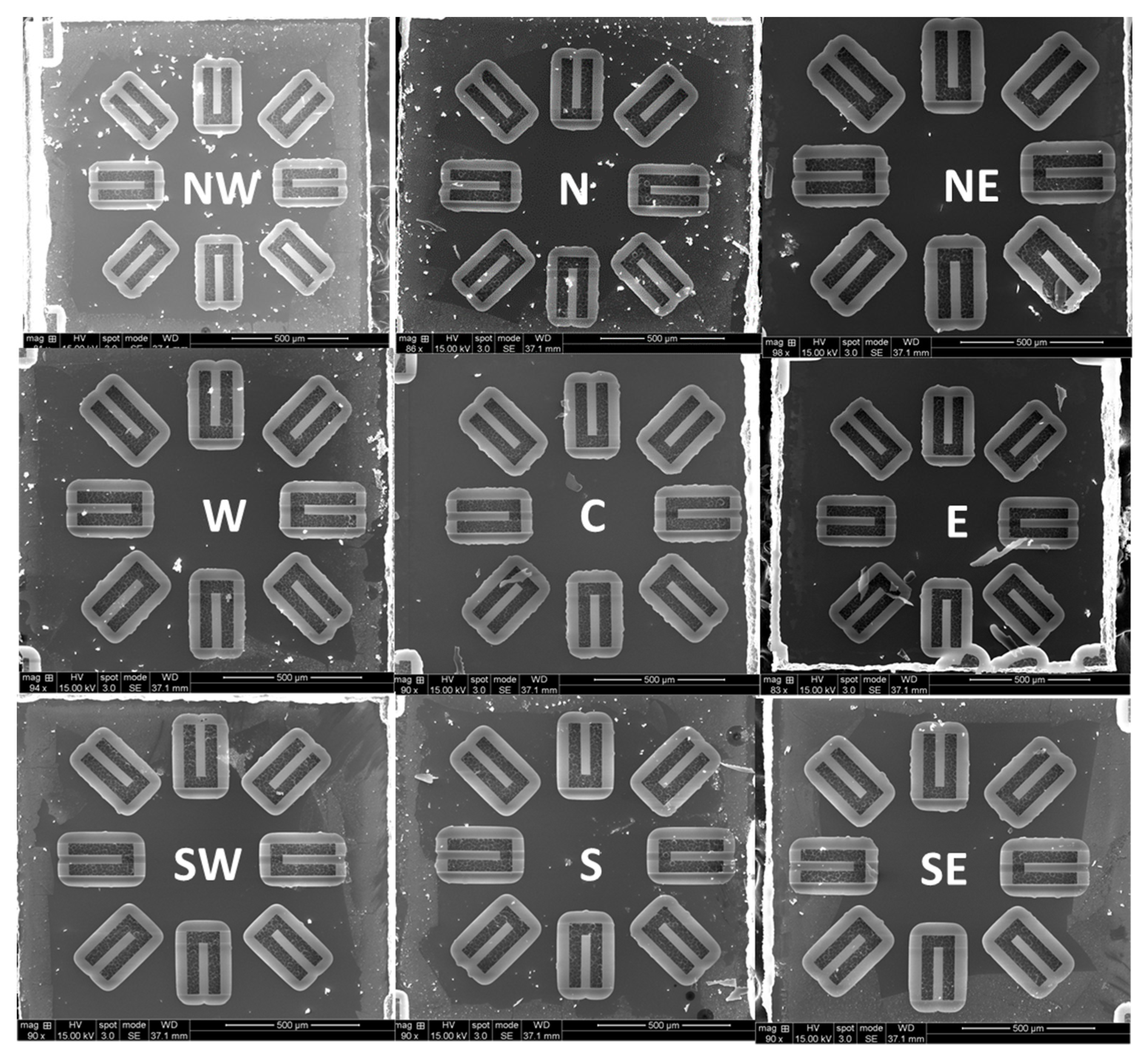

| Wafer Location | Device Position | Out-of-Plane Deflection [µm] | ||

| Center | 1 | 115.2 +/− 1.2 | −3.2 +/− 0.1 | −5.8 +/− 0.4 |

| 2 | 108.6 +/− 4.2 | −0.7 +/−0.2 | −7.6 +/− 0.4 | |

| 3 | 117.1 +/− 0.9 | 0.0 +/− 0.1 | −4.0 +/−0.4 | |

| North | 1 | 50.1 +/− 0.1 | 0.9 +/− 0.3 | 7.4 +/− 0.4 |

| 2 | 121.0 +/− 0.7 | −1.4 +/− 0.2 | −7.7 +/− 0.3 | |

| 3 | 145.9 +/− 0.2 | −2.8 +/− 0.8 | −20.0 +/− 0.1 | |

| Northeast | 1 | 125.1 +/− 0.3 | −7.0 +/− 0.2 | −15.6 +/− 0.4 |

| 2 | 49.3 +/− 0.1 | −4.0 +/− 0.1 | −21.1 +/− 0.6 | |

| 3 | 120.6+/− 0.4 | 0.1 +/− 0.1 | −0.9 +/− 0.3 | |

| East | 1 | 128.9 +/− 0.9 | 0.9 +/− 0.2 | −20.9 +/− 1.9 |

| 2 | 126.9 +/− 42 | 6.2 +/− 0.2 | 6.4 +/− 0.2 | |

| 3 | 60.3 +/− 0.6 | 6.6 +/− 0.1 | 22.0 +/− 0.2 | |

| N2 Flow [sccm] | 25 | 27.5/22.5 | 30/22.5 | 30/20 |

|---|---|---|---|---|

| Seed Layer | Yes | Yes | Yes | Yes |

| Device Position | Out-of-Plane Deflection [µm] | |||

| 1 | 115.2 +/− 1.2 | 60.8 +/− 0.1 | 24.1 +/− 0.1 | −3.2 +/− 0.1 |

| 2 | 108.6 +/− 4.2 | 55.0 +/− 0.1 | 28.2 +/− 1.2 | −0.7 +/− 0.2 |

| 3 | 117.1 +/− 0.9 | 51.4 +/− 0.3 | 30.5 +/− 0.4 | −0.0 +/−0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beaucejour, R.; D’Agati, M.; Kalyan, K.; Olsson, R.H., III. Compensation of the Stress Gradient in Physical Vapor Deposited Al1−xScxN Films for Microelectromechanical Systems with Low Out-of-Plane Bending. Micromachines 2022, 13, 1169. https://doi.org/10.3390/mi13081169

Beaucejour R, D’Agati M, Kalyan K, Olsson RH III. Compensation of the Stress Gradient in Physical Vapor Deposited Al1−xScxN Films for Microelectromechanical Systems with Low Out-of-Plane Bending. Micromachines. 2022; 13(8):1169. https://doi.org/10.3390/mi13081169

Chicago/Turabian StyleBeaucejour, Rossiny, Michael D’Agati, Kritank Kalyan, and Roy H. Olsson, III. 2022. "Compensation of the Stress Gradient in Physical Vapor Deposited Al1−xScxN Films for Microelectromechanical Systems with Low Out-of-Plane Bending" Micromachines 13, no. 8: 1169. https://doi.org/10.3390/mi13081169

APA StyleBeaucejour, R., D’Agati, M., Kalyan, K., & Olsson, R. H., III. (2022). Compensation of the Stress Gradient in Physical Vapor Deposited Al1−xScxN Films for Microelectromechanical Systems with Low Out-of-Plane Bending. Micromachines, 13(8), 1169. https://doi.org/10.3390/mi13081169