A Novel Mini-Channel Heat Sink Design with Arc-Type Design Domain by Topology Optimization

Abstract

:1. Introduction

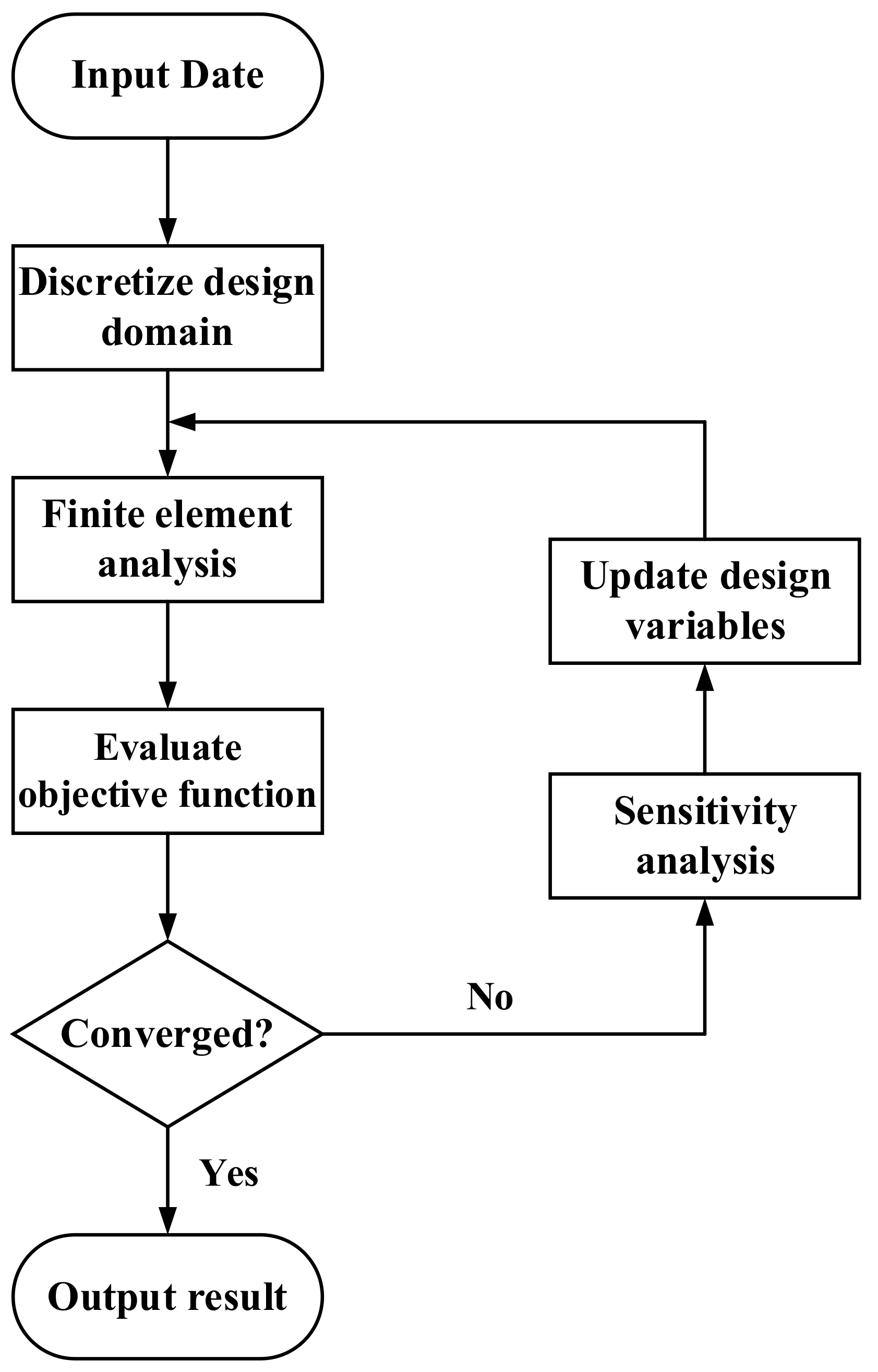

2. Problem Description

3. Model and Topology Optimization Design

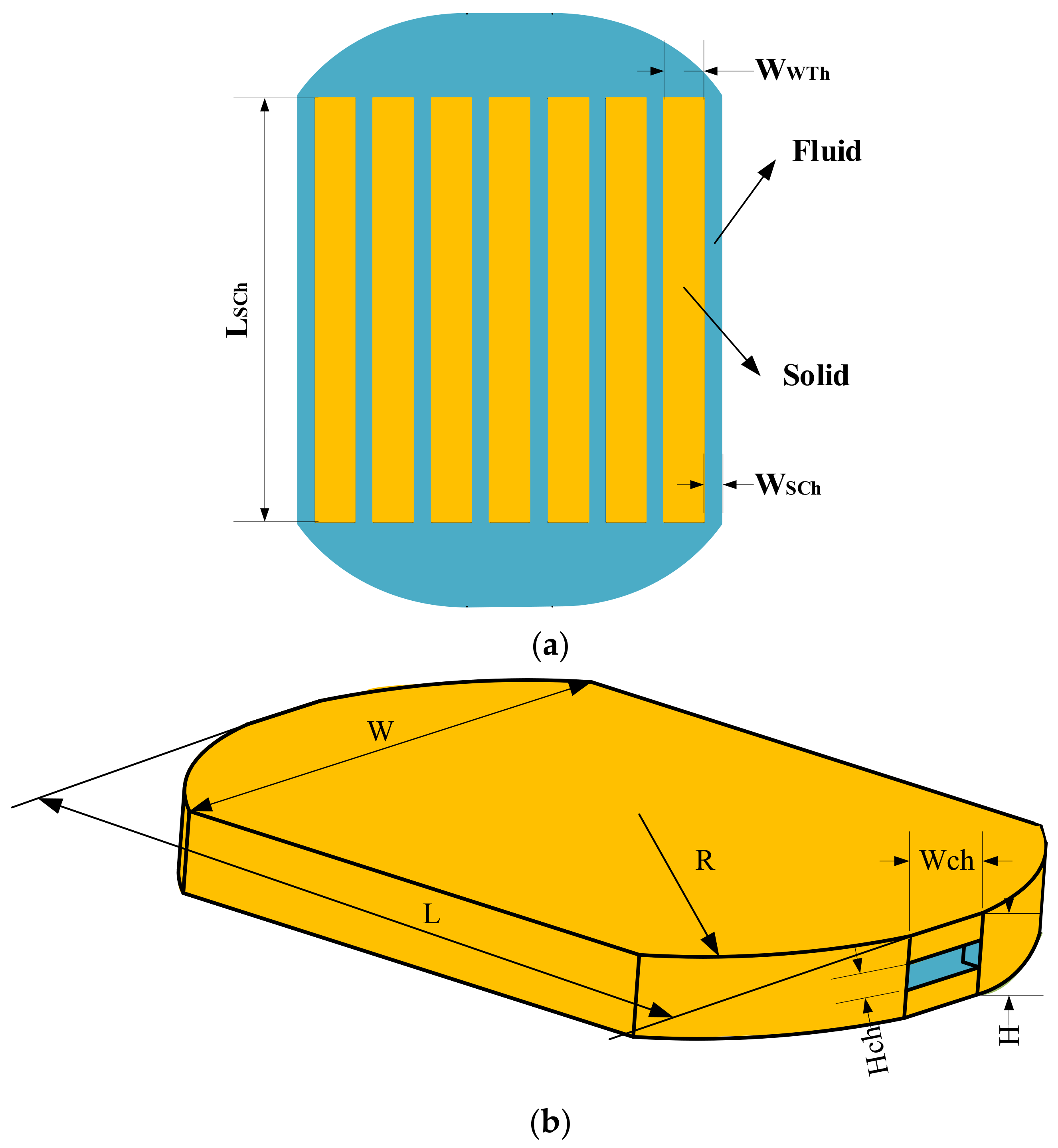

3.1. Design Model Date and Initial Conditions

3.2. Flow Field and Thermal Field Design

3.3. Topology Optimization Model Design

3.4. Topology Optimization Objectives

3.5. Topology Optimization Platform

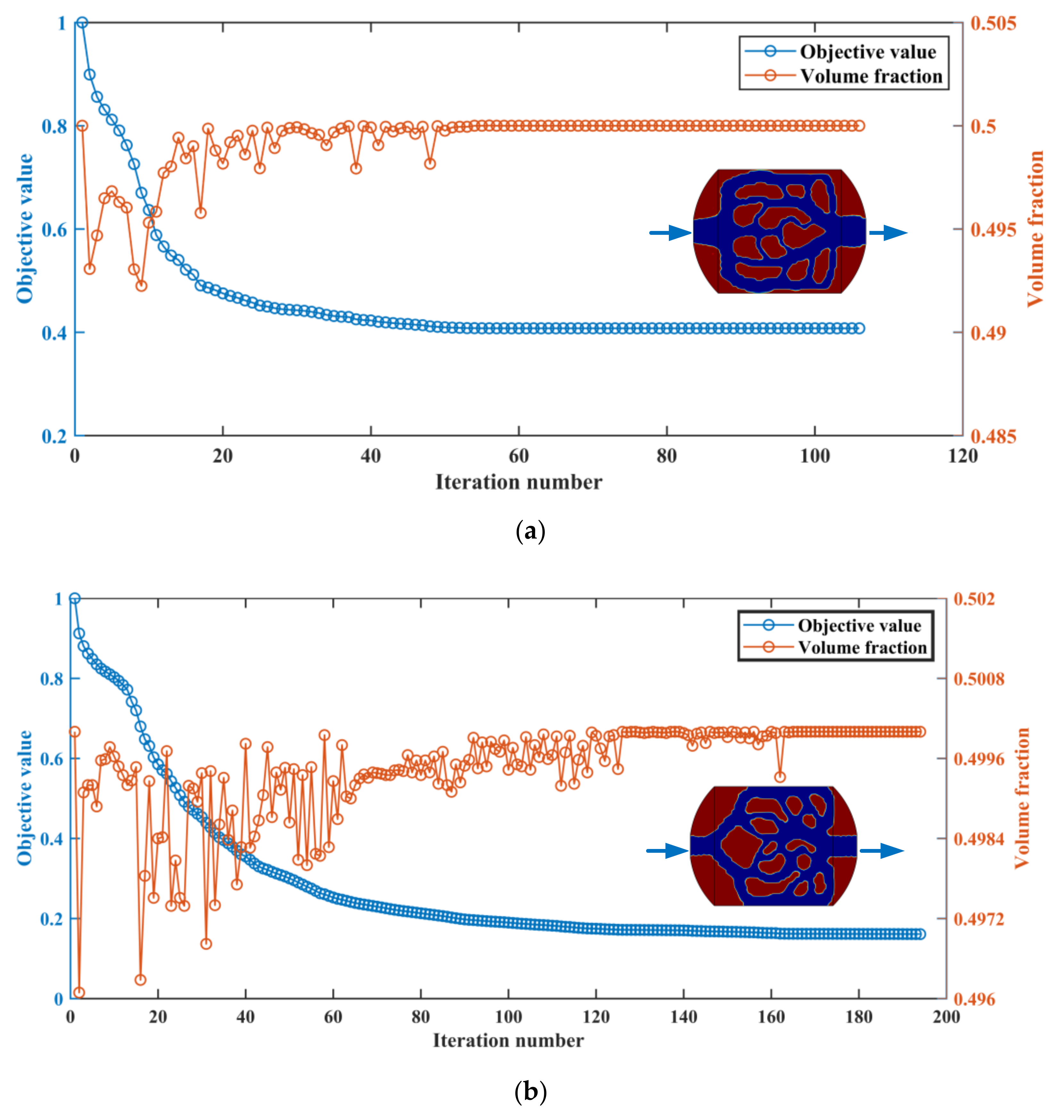

3.6. Topology Optimization Results

4. Numerical Simulation Verification

4.1. Numerical Simulation Model

4.2. Numerical Simulation Platform

4.3. Numerical Simulation Governing Equation

- The fluid is single phase and incompressible;

- The flow is laminar;

- The effects of radiation and gravity are ignored;

- Except for the heat sink bottom plate, the others are adiabatic.

4.4. Boundary Parameter Setting

4.5. Grid Independence Tests

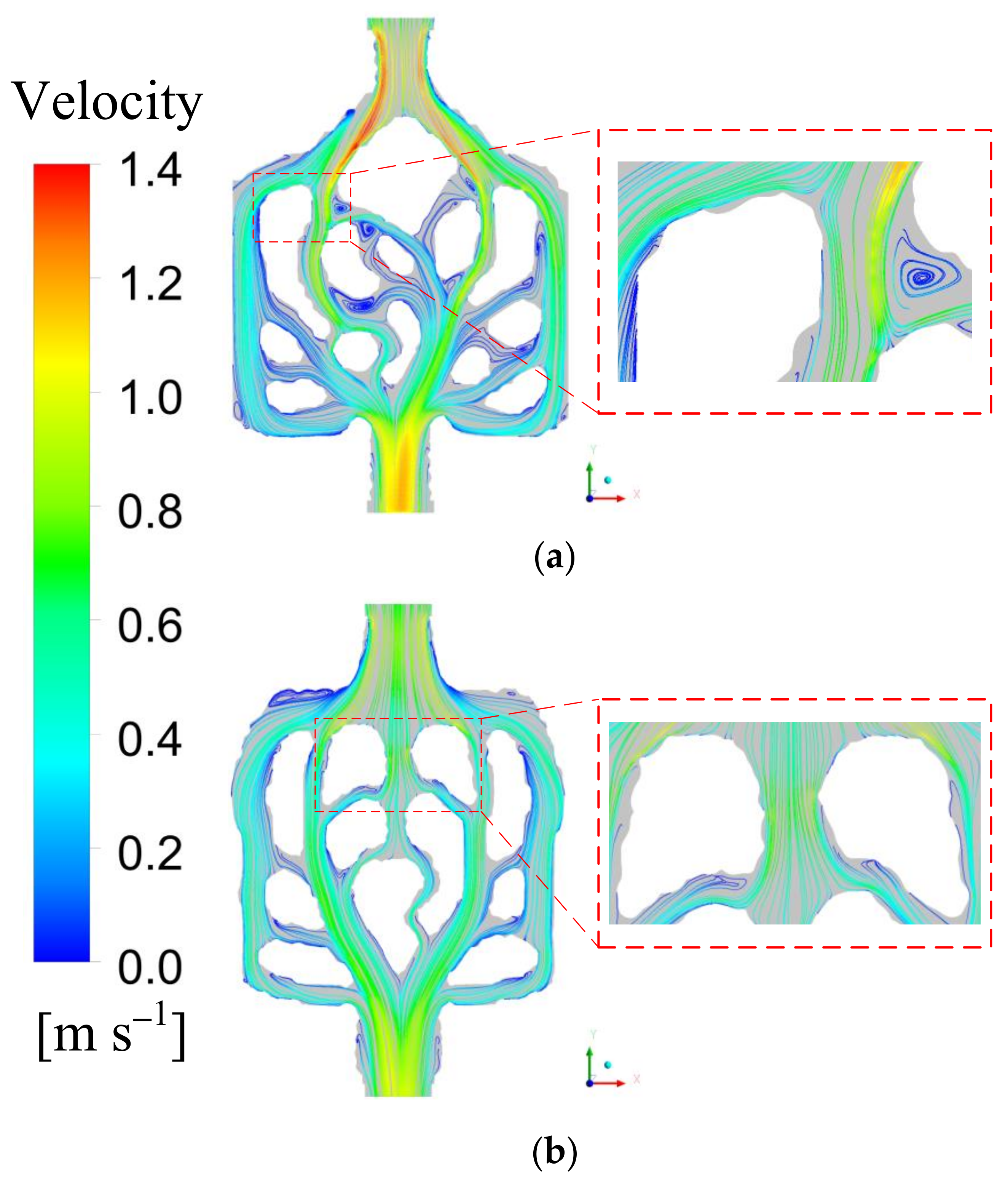

4.6. Flow Characteristics Discussion

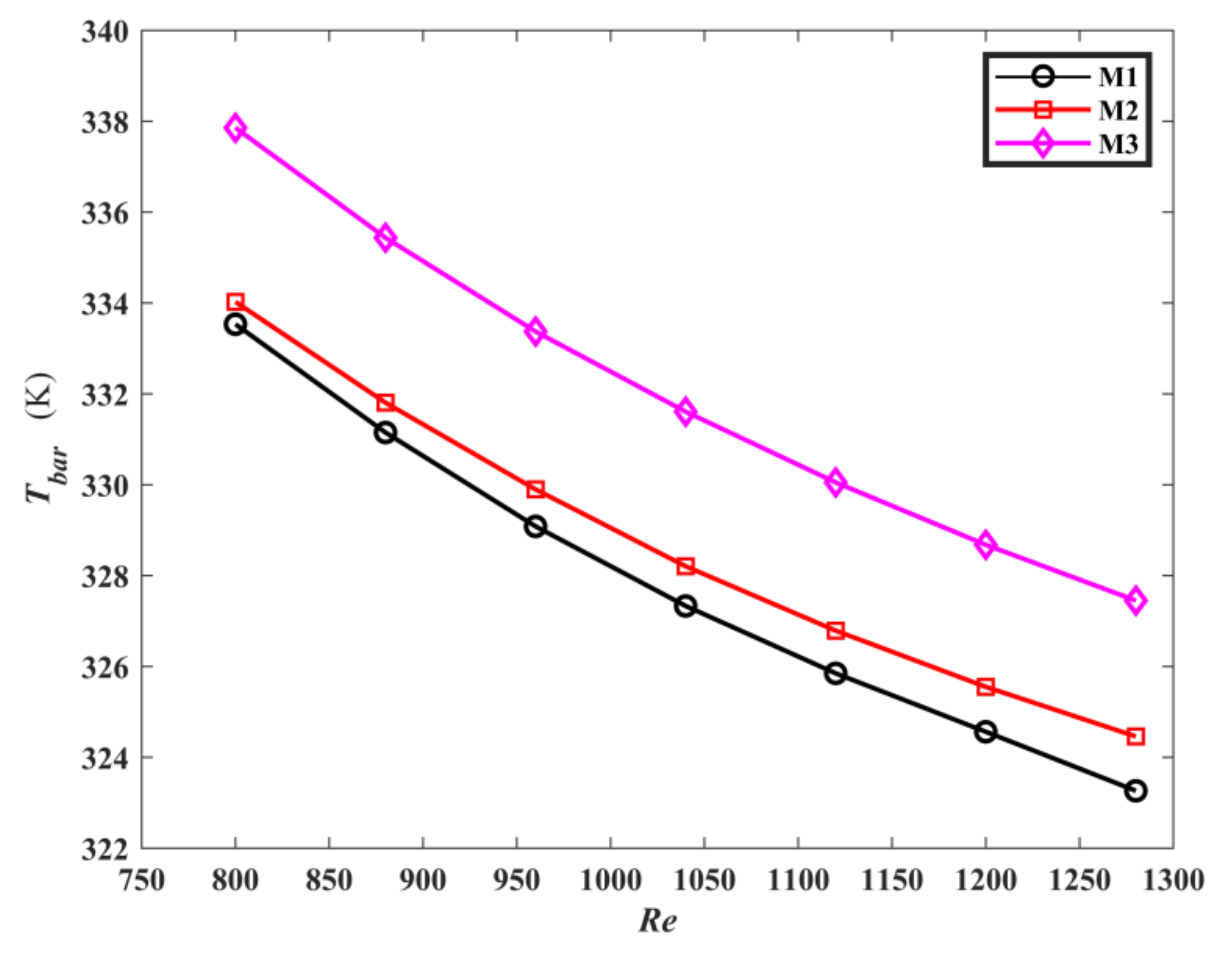

4.7. Thermal Characteristics Discussion

4.8. Performance Valuation Discussion

5. Experimental Verification

5.1. Model Manufacturing

5.2. Experimental Procedure and Apparatus

5.3. Experimental Post-Treatment

5.3.1. Wall Temperature Calculation

5.3.2. Uncertainty Calculation

5.3.3. Experimental Result Analysis

6. Conclusions

- Compared with the traditional straight mini-channel heat sink, the topological mini-channel heat sink design had better flow and heat transfer performances.

- Compared with M2, the ΔP of M1 was decreased by 30.9%. Compared with M3, the ΔT of M1 and M2 were decreased by 31.6% and 42.48%, respectively.

- Compared with M3, the Nu of M1 and M2 were increased by 34.43% and 15.86%, respectively. Compared with M3, the Rth of M1 and M2 were decreased by 10.8% and 12.8%, respectively.

- M1 is the best design for flow and heat transfer performance.

- The simulation results agree well with the experimental results.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Aeff | Effective heat transfer area, m2 |

| C | Diameter of the pipe, m |

| Dh | Hydraulic diameter, m |

| ENu | Average Nusselt number enhancement |

| EΔP | Pressure drop enhancement |

| H | Height of heat sink, m |

| Hch | Height of channel, m |

| h | The local surface heat transfer coefficient, W/m2∙K |

| L | Length of heat sink, m |

| LSCh | Length of straight channel, m |

| LWTh | Wall thickness of straight channel, m |

| Nu | Nusselt number |

| pα | Penalty factor of resistance coefficient |

| pλ | Penalty factor of thermal conductivity |

| pC | penalty factor of specific heat capacity |

| pρ | Penalty factor of density |

| Pp | Pump power, W |

| Qv | Volume flow rate, mL/s |

| Qin | Total heat input, W |

| R | Design domain radius, m |

| Re | Reynolds number |

| Rth | Thermal resistance, K/W |

| r | Filter radius, m |

| Tbar | Average substrate temperature, K |

| Twall,bar | Average wall temperature, K |

| Tfbar | Average fluid temperature, K |

| Tsurf,max | Maximum substrate temperature, K |

| Tytci | Thermocouple temperature, K |

| Twtci | Wall temperature by calculating, K |

| ufin | Fluid velocity at inlet, m/s |

| W | Width of heat sink, m |

| Wch | Width of channel, m |

| WSCh | Width of straight channel, m |

| α | Resistance coefficient of porous media |

| β | Projection slope |

| γ | Design variable |

| Filter design variable | |

| λ | Thermal conductivity, W/m∙K |

| ρ | Density, kg/m3 |

| ϕ1 | Average temperature function, K |

| ϕ2 | Temperature difference function, K2 |

| μ | Dynamic viscosity of fluid, Pa∙s |

| Π | Double objective function |

| f | Fluid |

| s | Solid |

| avg | Average |

| max | Maximum |

| min | Minimum |

| tci | Thermocouple location |

Appendix A

References

- Yang, L.; Huang, J.N.; Mao, M.; Jia, W.K. Numerical assessment of Ag-water nano-fluid flow in two new microchannel heatsinks: Thermal performance and thermodynamic considerations. Int. Commun. Heat Mass Transf. 2020, 110, 104415. [Google Scholar] [CrossRef]

- Liu, H.L.; Qi, D.H.; Shao, X.D.; Wang, W.D. An experimental and numerical investigation of heat transfer enhancement in annular microchannel heat sinks. Int. J. Therm. Sci. 2019, 142, 106–120. [Google Scholar] [CrossRef]

- Wang, G.L.; Qian, N.; Ding, G. Heat transfer enhancement in microchannel heat sink with bidirectional rib. Int. J. Heat Mass Transf. 2019, 132, 597–609. [Google Scholar] [CrossRef]

- Ghani, I.A.; Sidik, N.A.C.; Kamaruzaman, N. Hydrothermal performance of microchannel heat sink: The effect of channel design. Int. J. Heat Mass Transf. 2017, 107, 21–44. [Google Scholar] [CrossRef]

- Zhang, C.P.; Lian, Y.F.; Yu, X.F.; Liu, W.J.; Teng, J.T.; Xu, T.T. Numerical and experimental studies on laminar hydrodynamic and thermal characteristics in fractal-like microchannel networks. Part A: Comparisons of two numerical analysis methods on friction factor and Nusselt number. Int. J. Heat Mass Transf. 2013, 66, 930–938. [Google Scholar] [CrossRef]

- Chen, H.H. Forced convection heat transfer in microchannel heat sinks. Int. J. Heat Mass Transf. 2007, 50, 2182–2189. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Lu, T.J. Analysis of microchannel heat sinks for electronics cooling. Int. J. Heat Mass Transf. 2002, 45, 4857–4869. [Google Scholar] [CrossRef]

- Li, J.; Peterson, G.P.; Cheng, P. Three-dimensional analysis of heat transfer in a micro-heat sink with single phase flow. Int. J. Heat Mass Transf. 2004, 47, 4215–4231. [Google Scholar] [CrossRef]

- Al-Neama, A.F.; Kapur, N.; Summers, J.; Thompson, H.M. An experimental and numerical investigation of the use of liquid flow in serpentine microchannels for microelectronics cooling. Appl. Therm. Eng. 2017, 116, 709–723. [Google Scholar] [CrossRef]

- Bi, B.; Tang, G.H.; Tao, W.Q. Heat transfer enhancement in microchannel heat sinks with dimples and cylindrical grooves. Appl. Therm. Eng. 2013, 55, 121–132. [Google Scholar] [CrossRef]

- Zhou, F.; Zhou, W.; Zhang, C.Y.; Qiu, Q.F.; Yuan, D.; Chu, X.Y. Experimental and numerical studies on heat transfer enhancement of microchannel heat sink embedded with different shape micropillars. Appl. Therm. Eng. 2020, 175, 115296. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, M. Simulation Analysis of the Heat Transfer Performance of an N-type Microchannel Heat sink. Chem. Eng. Technol. 2007, 50, 2182–2189. [Google Scholar]

- Moradikazerouni, A.; Shoele, K. Computational study of Rayleigh-Bernard convection in a cylindrical pressurized cryogenic tank. Bull. Am. Phys. Soc. 2021, 66, F06. [Google Scholar]

- Ma, Y.L.; Shahsavar, A.; Moradi, I.; Rostami, S.; Moradikazerouni, A.; Yarmand, H. Using finite volume method for simulating the natural convective heat transfer of nano-fluid flow inside an inclined enclosure with conductive walls in the presence of a constant temperature heat source. Physica A 2021, 580, 123035. [Google Scholar] [CrossRef]

- Estebe, C.; Liu, Y.; Vahab, M. A Low Mach Number, Adaptive Mesh Method for Simulating Multi-phase Flows in Cryogenic Fuel Tanks. In Proceedings of the SIAM Conference on Computational Science and Engineering, Philadelphia, PA, USA, 5 March 2021. [Google Scholar]

- Moradikazerouni, A.; Vahab, M.; Shoele, K. A 0D/3D nodal-CFD method of cylindrical pressurized tanks. In Proceedings of the 73rd Annual Meeting of the APS Division of Fluid Dynamics, Online, 24 November 2020. [Google Scholar]

- Lu, S.; Vafai, K. A comparative analysis of innovative microchannel heat sinks for electronic cooling. Int. Commun. Heat Mass Transf. 2016, 76, 271–284. [Google Scholar] [CrossRef]

- Deng, D.; Wan, W.; Tang, Y.; Shao, H.; Huang, Y. Experimental and numerical study of thermal enhancement in reentrant copper microchannels. Int. J. Heat Mass Transf. 2015, 91, 656–670. [Google Scholar] [CrossRef]

- Moradikazerouni, A.; Afrand, M.; Alsarraf, J. Investigation of a computer CPU heat sink under laminar forced convection using a structural stability method. Int. J. Heat Mass Transf. 2019, 134, 1218–1226. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Kikuchi, N. Generating optimal topologies in structural design using a homogenization method. Comput. Meth. Appl. Mechanics Eng. 1988, 71, 197–224. [Google Scholar] [CrossRef]

- Borrvall, T.; Petersson, J. Topology optimization of fluids in stokes flow. Int. J. Numer. Methods Fluids. 2003, 41, 77–107. [Google Scholar] [CrossRef]

- Dede, E.M. Multiphysics topology optimization of heat transfer and fluid flow systems. In Proceedings of the COMSOL Conference, Boston, MA, USA, 8 October 2009. [Google Scholar]

- Zhang, B.; Zhu, J.H. Topology optimization design of nanofluid-cooled microchannel heat sink with temperature-dependent fluid properties. Appl. Therm. Eng. 2020, 176, 115354. [Google Scholar] [CrossRef]

- Joo, Y.; Lee, I.; Kim, S.J. Efficient three-dimensional topology optimization of heat sinks in natural convection using the shape-dependent convection model. Int. J. Heat Mass Transf. 2018, 127, 32–40. [Google Scholar] [CrossRef]

- Han, X.H.; Liu, H.L.; Xie, G.N.; Sang, L.; Zhou, J.Z. Topology optimization for spider web heat sinks for electronic cooling. Appl. Therm. Eng. 2021, 195, 117154. [Google Scholar] [CrossRef]

- Qiu, G.Q.; Wei, P.; Huang, P.N.; Pan, M.Q. Topology Optimization Design of a Microchannel Plate Based on Velocity Distribution. Chem. Eng. Technol. 2021, 44, 681–689. [Google Scholar] [CrossRef]

- Zhou, T.; Chen, B.C.; Liu, H.L. Study of the Performance of a Novel Radiator with Three Inlets and One Outlet Based on Topology Optimization. Micromachines 2021, 12, 594. [Google Scholar] [CrossRef]

- Liu, H.L.; An, X.K.; Wang, S.C. Heat transfer performance of T-Y type micro-channel heat sink with liquid GaInSn coolant. Int. J. Therm. Sci. 2017, 120, 203–219. [Google Scholar] [CrossRef]

- Wang, J.Y. Theory and practice of flow field designs for fuel cell scaling-up: A critical review. Appl. Therm. Eng. 2015, 157, 640–663. [Google Scholar] [CrossRef]

- Vinodhan, V.L.; Rajan, K. Computational analysis of new microchannel heat sink configurations. Energy Convers. Manag. 2015, 157, 640–663. [Google Scholar] [CrossRef]

- Li, H.; Ding, X.; Jing, D.; Xiong, M.; Meng, F. Experimental and numerical investigation of liquid-cooled heat sinks designed by topology optimization. Int. J. Therm. Sci. 2019, 146, 106065. [Google Scholar] [CrossRef]

- Hu, D.H.; Zhang, Z.W. Numerical study on flow and heat transfer characteristics of microchannel designed using topological optimizations method. Technol. Sci. 2020, 63, 105–115. [Google Scholar] [CrossRef]

- Yaji, K.; Yamada, T. A topology optimization method for a coupled thermal–fluid problem using level set boundary expressions. Int. J. Heat Mass Transf. 2015, 81, 878–888. [Google Scholar] [CrossRef]

- Bendsøe, M.P. Optimal shape design as a material distribution problem. Struct. Optim. 1989, 1, 193–202. [Google Scholar] [CrossRef]

- Bruns, T.E. Topology optimization of convection-dominated, steady-state heat transfer problems. Int. J. Heat Mass Transf. 2007, 50, 285–289. [Google Scholar] [CrossRef]

- Lazarov, B.S.; Sigmund, O. Filters in topology optimization based on Helmholtz-type differential equations. Int. J. Numer. Methods Eng. 2010, 86, 765–781. [Google Scholar] [CrossRef]

- Wang, F.; Lazarov, B.S.; Sigmund, O. On projection methods, convergence and robust formulations in topology optimization. Struct. Multidiscip. Optim. 2011, 43, 767–784. [Google Scholar] [CrossRef]

- Patankar, S.V. Numerical Heat Transfer and Fluid Flow, 3rd ed.; CRC Press: Boca Raton, FL, USA, 1980; pp. 39–76. [Google Scholar]

- Liu, H.L.; Yao, Y.; Xie, G.N.; Xie, Z.L. Improved thermal performance of new staggered double P-type minichannel heat exchangers. Appl. Therm. Eng. 2021, 196, 117293. [Google Scholar] [CrossRef]

- Wang, X.Q.; Mujumdar, A.S.; Yap, C. Thermal characteristics of tree-shaped microchannel nets for cooling of a rectangular heat sink. Int. J. Therm. Sci. 2006, 45, 1103–1112. [Google Scholar] [CrossRef]

- Gong, L.; Kota, K.; Tao, W.Q.; Joshi, Y. Thermal performance of microchannels with wavy walls for electronics cooling. IEEE Trans. Compon. Packag. Manufac. Technol. 2011, 1, 1029–1035. [Google Scholar] [CrossRef]

- Lee, Y.J.; Lee, P.S.; Chou, S.K. Enhanced thermal transport in microchannel using oblique fins. J. Heat Transfer. 2012, 134, 101901. [Google Scholar] [CrossRef]

- Schultz, R.; Cole, R. Uncertainty analysis in boiling nucleation. Am. Inst. Chem. Eng. 1979, 75, 32–38. [Google Scholar]

- ASME. PTC 19.1-2013. (Revision of ASME PTC 19.1-2005). Test Uncertainty; ASME: New York, NY, USA, 2005. [Google Scholar]

| Material | ρ (kg/m3) | C (J/kg·K) | λ (W/m·K) | μ (Pa·s) |

|---|---|---|---|---|

| Aluminum | 2719 | 871 | 202.4 | - |

| Water | 998.2 | 4182 | 0.62 | 1 × 10−3 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| pα | 0.02 | γβ | 0.5 |

| pρ | 0.01 | β | 10 |

| pλ | 0.01 | ||

| pC | 100 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| H (mm) | 3 | R (mm) | 14.14 |

| Hch (mm) | 1 | WWTh (mm) | 1.83 |

| L (mm) | 30 | WSCh (mm) | 0.9 |

| Wch (mm) | 4 | LSCh (mm) | 20 |

| W (mm) | 22 |

| v (m/s) | Qv (mL/s) | Re |

|---|---|---|

| 0.5 | 2.0 | 800 |

| 0.55 | 2.2 | 880 |

| 0.6 | 2.4 | 960 |

| 0.65 | 2.6 | 1040 |

| 0.7 | 2.8 | 1120 |

| 0.75 | 3.0 | 1200 |

| 0.8 | 3.2 | 1280 |

| Model | Grids | Tbar (K) | Error (%) | ΔP (Pa) | Error (%) |

|---|---|---|---|---|---|

| M1 | 4,917,623 | 335.276 | 0.52 | 491.437 | 1.3 |

| 7,046,210 | 333.533 | - | 485.049 | - | |

| 9,092,764 | 332.270 | 0.38 | 480.865 | 0.87 | |

| M2 | 5,026,975 | 335.838 | 0.54 | 723.521 | 1.27 |

| 7,243,672 | 334.025 | - | 714.333 | - | |

| 9,115,764 | 332.793 | 0.37 | 708.312 | 0.85 | |

| M3 | 4,028,948 | 339.963 | 0.62 | 628.438 | 1.5 |

| 6,262,361 | 337.856 | - | 619.012 | - | |

| 8,638,427 | 336.004 | 0.55 | 611.671 | 1.2 |

| Parameter | Absolute Uncertainty | Relative Uncertainty |

|---|---|---|

| Channel width (W) | ±0.01 mm | - |

| Channel height (H) | ±0.01 mm | - |

| Temperature (T) | ±0.2 K | - |

| Power (Pin) | - | ±0.2% |

| Pressure drop (ΔP) | - | ±0.3% |

| Volume flow rate (Qv) Nusselt number (Nu) | - | ±0.1% |

| - | 3.7% |

| v (m/s) | ΔP(sim) (Pa) | ΔP(exp) (Pa) | Error (%) | Twall,bar(sim) (K) | Twall,avg(exp) (K) | Error (%) |

|---|---|---|---|---|---|---|

| 0.5 | 485.0 | 508.7 | 4.6 | 333.5 | 329.6 | 1.2 |

| 0.55 | 562.3 | 591.6 | 4.9 | 331.2 | 327.8 | 1.0 |

| 0.6 | 645.8 | 676.2 | 4.5 | 329.1 | 325.6 | 1.1 |

| 0.65 | 734.6 | 752.8 | 2.4 | 327.3 | 323.5 | 1.2 |

| 0.7 | 827.8 | 862.7 | 4.0 | 325.9 | 321.2 | 1.5 |

| 0.75 | 924.8 | 970.4 | 4.7 | 324.6 | 320.3 | 1.4 |

| 0.8 | 1027.3 | 1060.2 | 3.1 | 323.3 | 317.8 | 1.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, T.; Guo, C.; Shao, X. A Novel Mini-Channel Heat Sink Design with Arc-Type Design Domain by Topology Optimization. Micromachines 2022, 13, 180. https://doi.org/10.3390/mi13020180

Zhou T, Guo C, Shao X. A Novel Mini-Channel Heat Sink Design with Arc-Type Design Domain by Topology Optimization. Micromachines. 2022; 13(2):180. https://doi.org/10.3390/mi13020180

Chicago/Turabian StyleZhou, Tao, Chao Guo, and Xiaodong Shao. 2022. "A Novel Mini-Channel Heat Sink Design with Arc-Type Design Domain by Topology Optimization" Micromachines 13, no. 2: 180. https://doi.org/10.3390/mi13020180

APA StyleZhou, T., Guo, C., & Shao, X. (2022). A Novel Mini-Channel Heat Sink Design with Arc-Type Design Domain by Topology Optimization. Micromachines, 13(2), 180. https://doi.org/10.3390/mi13020180