Miniature Manipulator Design and Cartesian Control for Minimally Invasive Transluminal Endoscopic Surgery

Abstract

1. Introduction

- ⮚

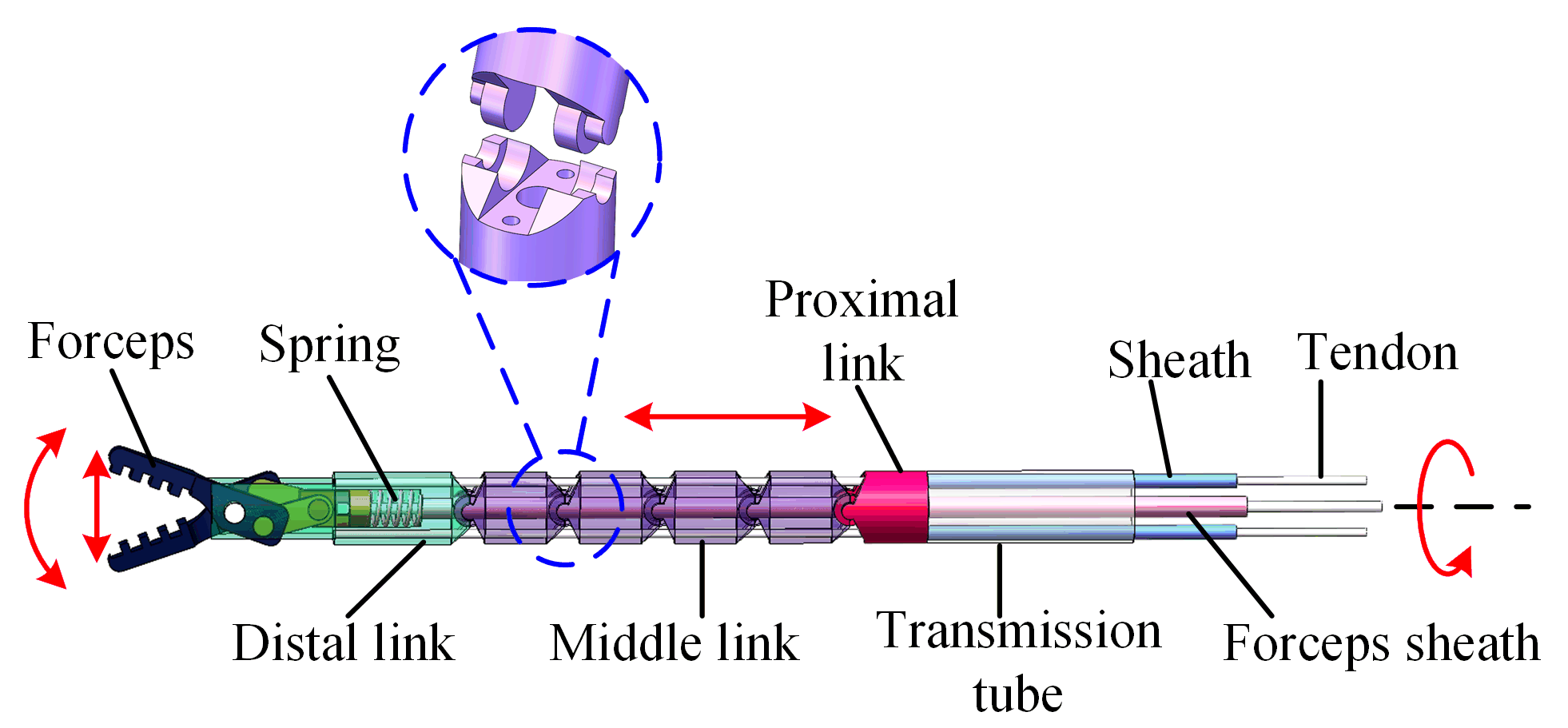

- A miniature manipulator with a diameter of 3.5 mm was proposed that can pass through the instrument channel of the endoscope. The manipulator, which can achieve four DoFs of movement, is driven by a tendon–sheath system and transmission tube. The sufficient dexterity and compact size of the manipulator make it suitable for minimally invasive transluminal endoscopic surgery. The special hollow design of the manipulator allows the forceps sheath to pass through. The forceps sheath, which has a sufficient elasticity, not only acts as the backbone of the manipulator but also decouples the movement of the forceps and manipulator.

- ⮚

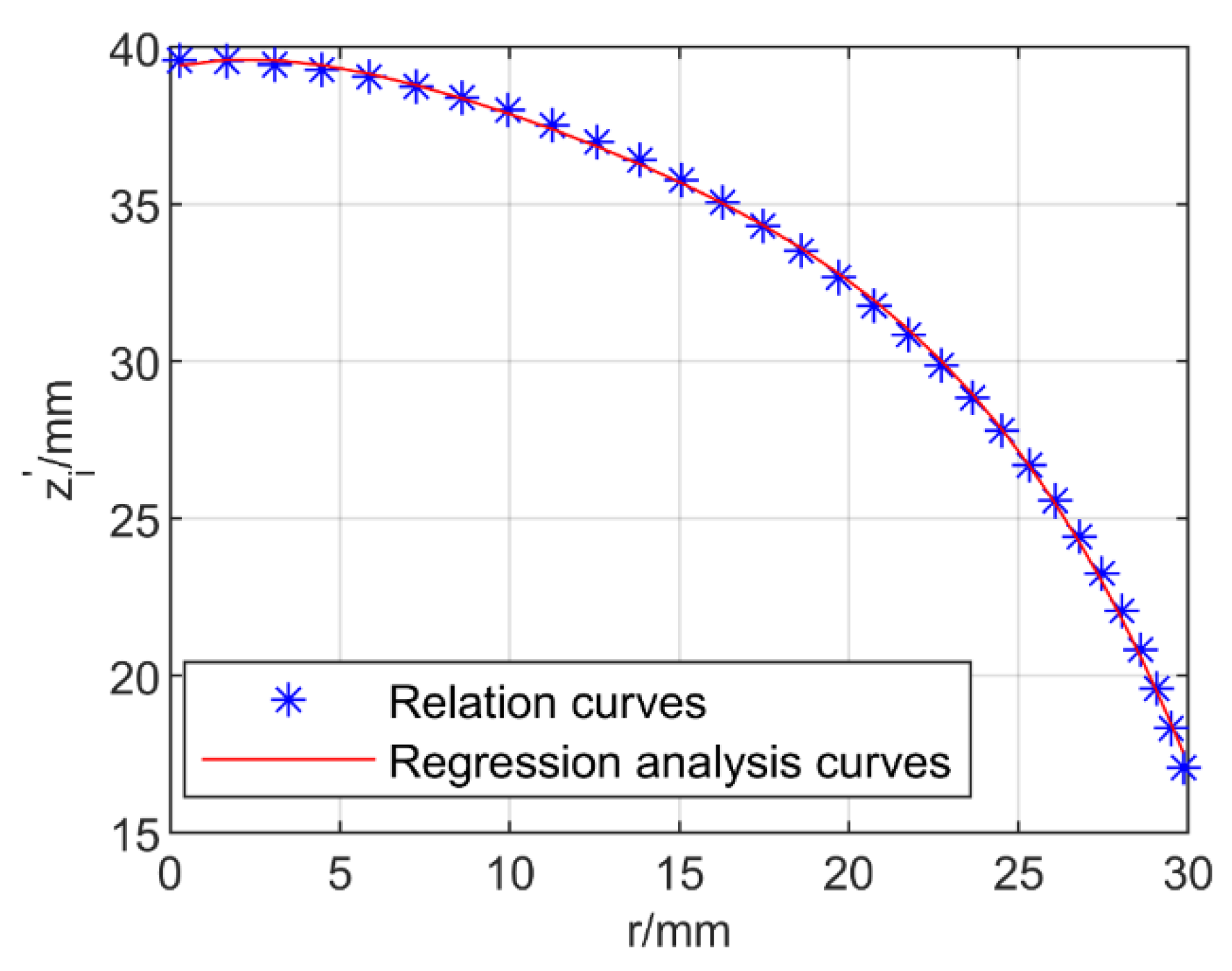

- By introducing the regression analysis method, the implicit equation was solved, and the analytical solution of inverse kinematics was obtained. Through geometric analysis of the adjacent joints, the inverse kinematics from the joint space to the drive space was obtained. By comparing the workspace with the task space, the workspace of the manipulator was able to meet the needs of the surgery.

- ⮚

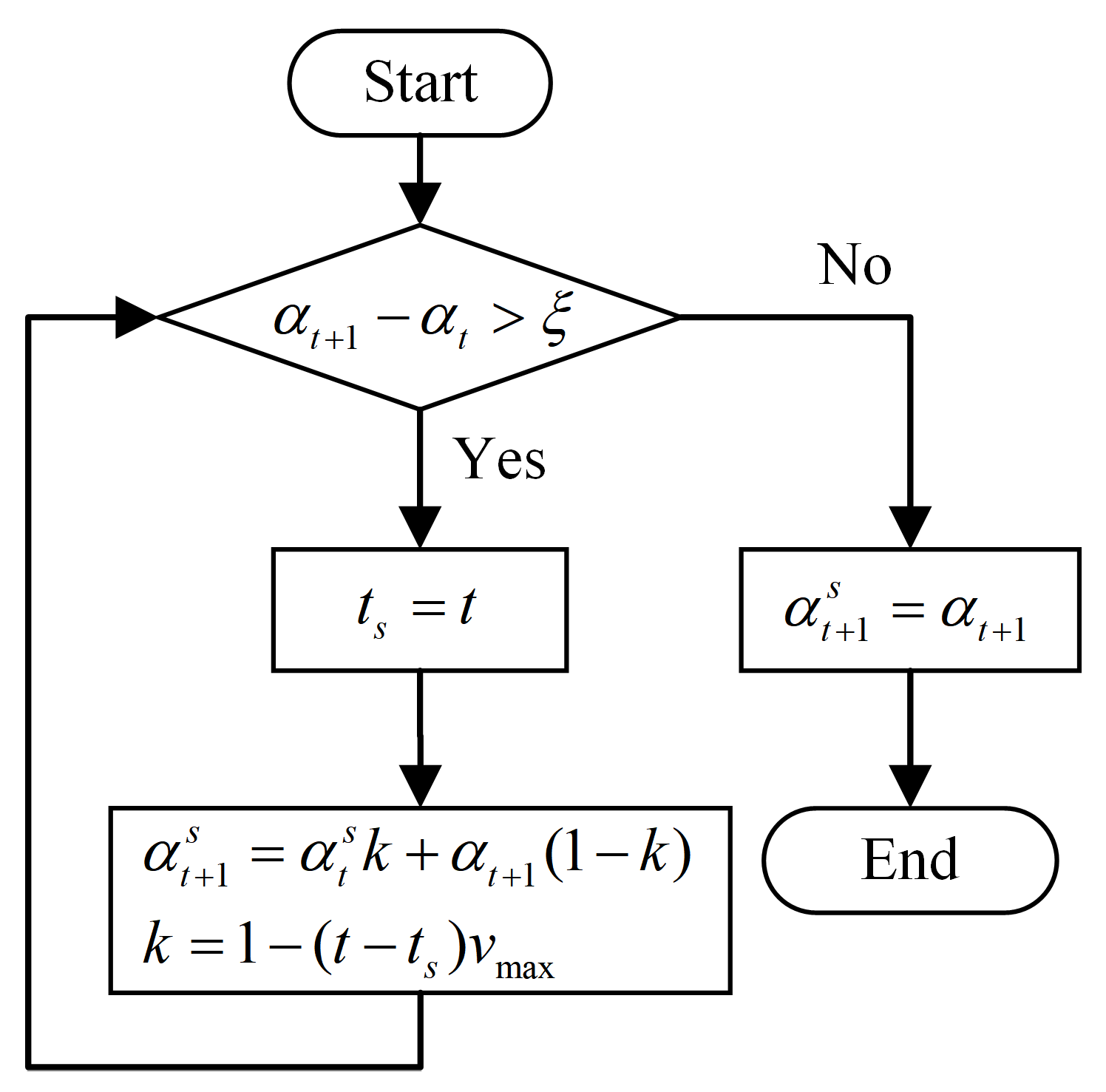

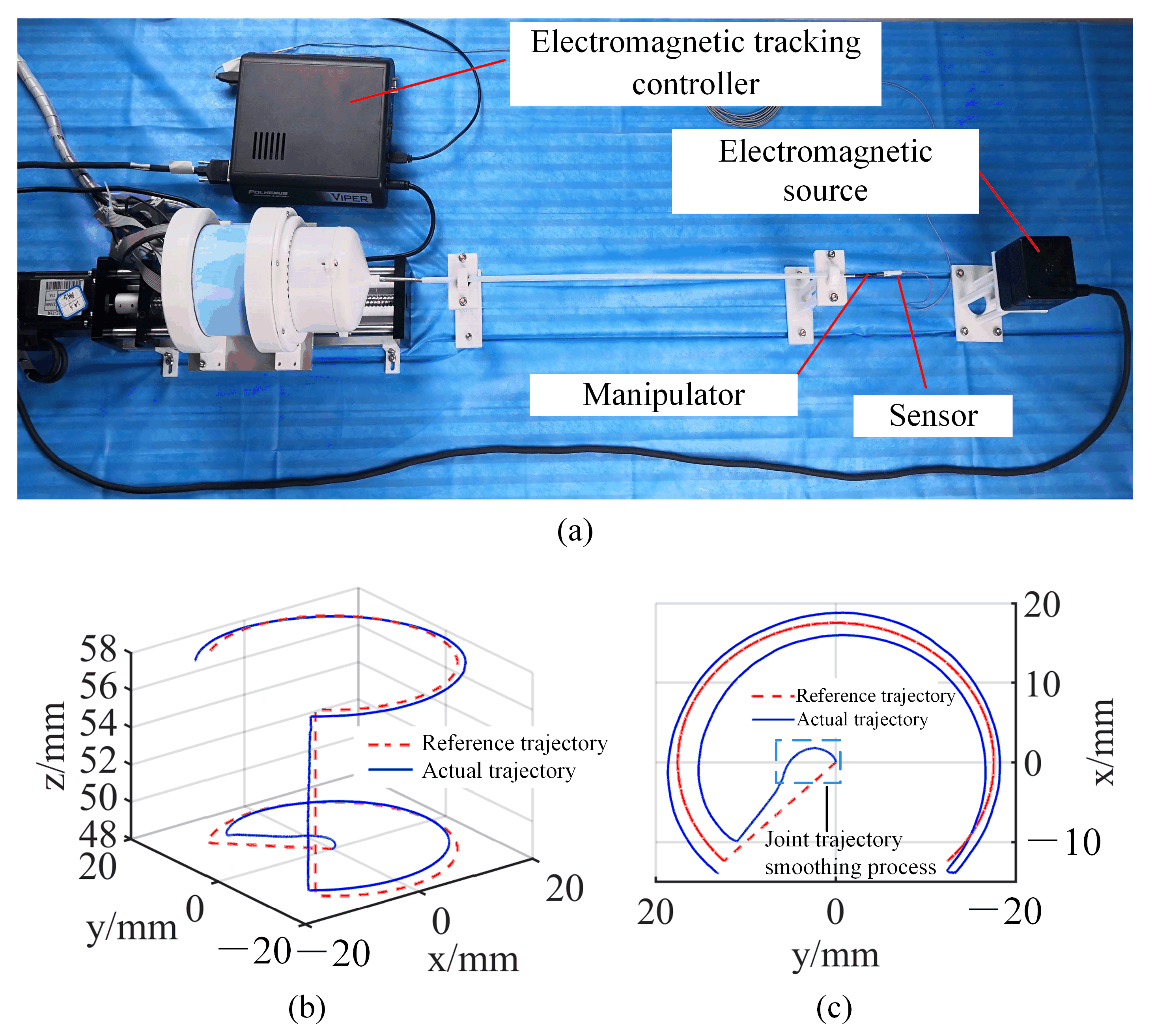

- The singularity and primary–secondary control mode of the manipulator were analyzed. The application of joint trajectory smoothing overcame the speed mutation of the manipulator at the singularity and also realized the Cartesian control of the manipulator. The effectiveness of the trajectory-smoothing algorithm was verified by the trajectory tracking and primary–secondary control experiments. The manipulator’s performance in the dexterous operation procedures was demonstrated in the needle-threading test.

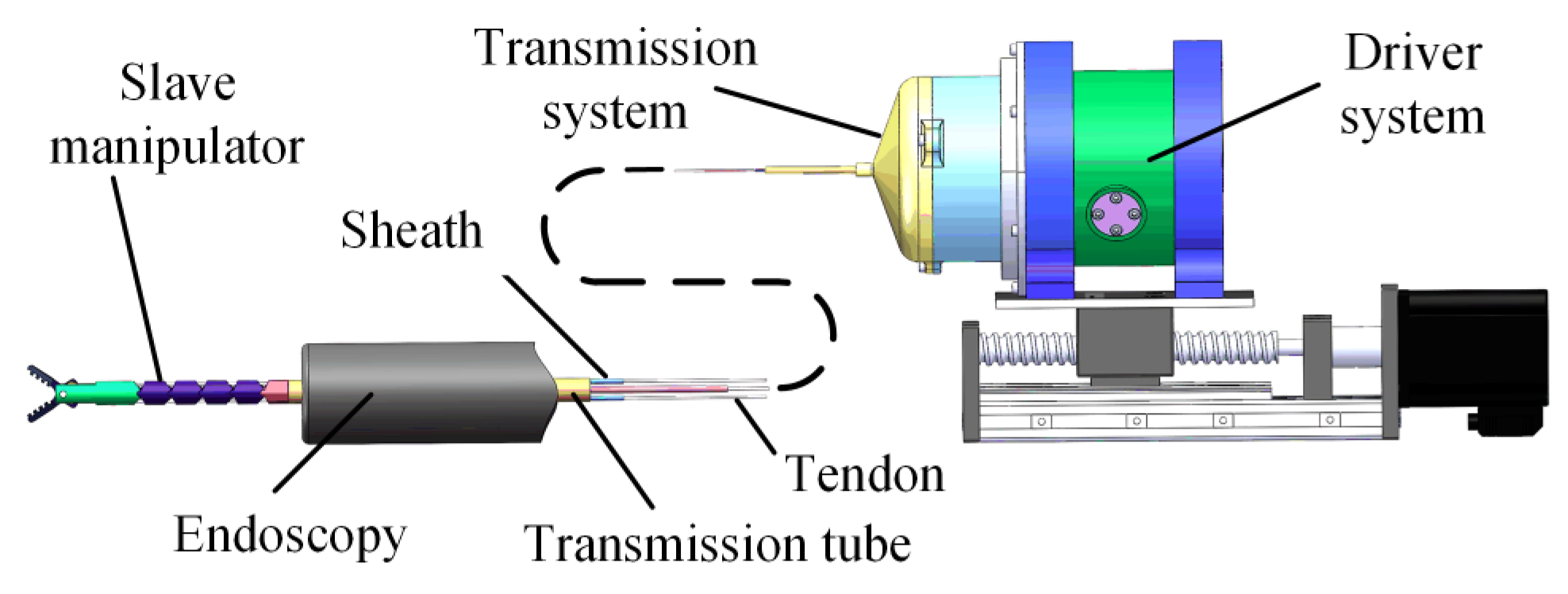

2. System Description

2.1. System Overview

2.2. Manipulator

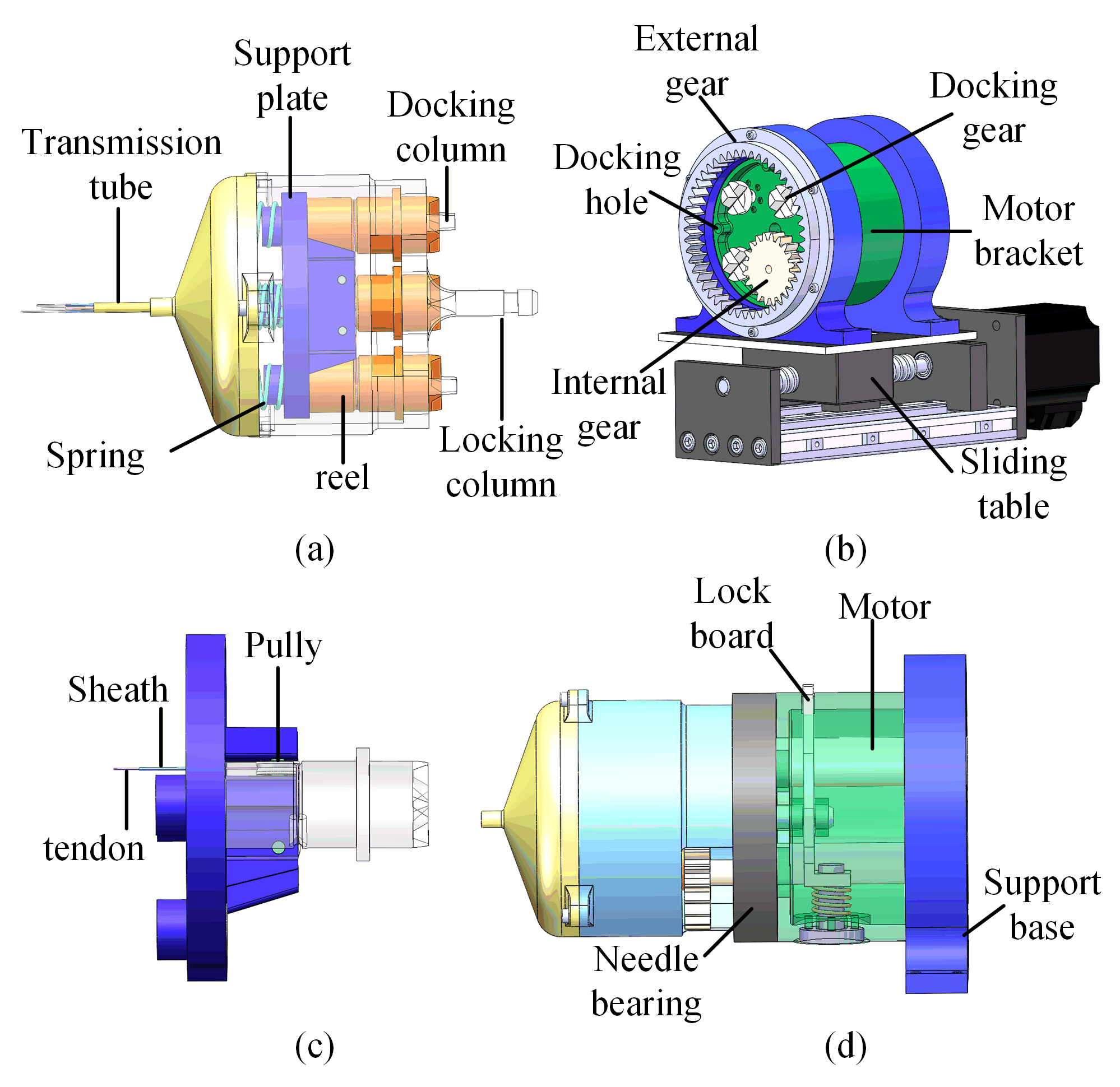

2.3. Transmission System

2.4. Driver System

3. Analysis

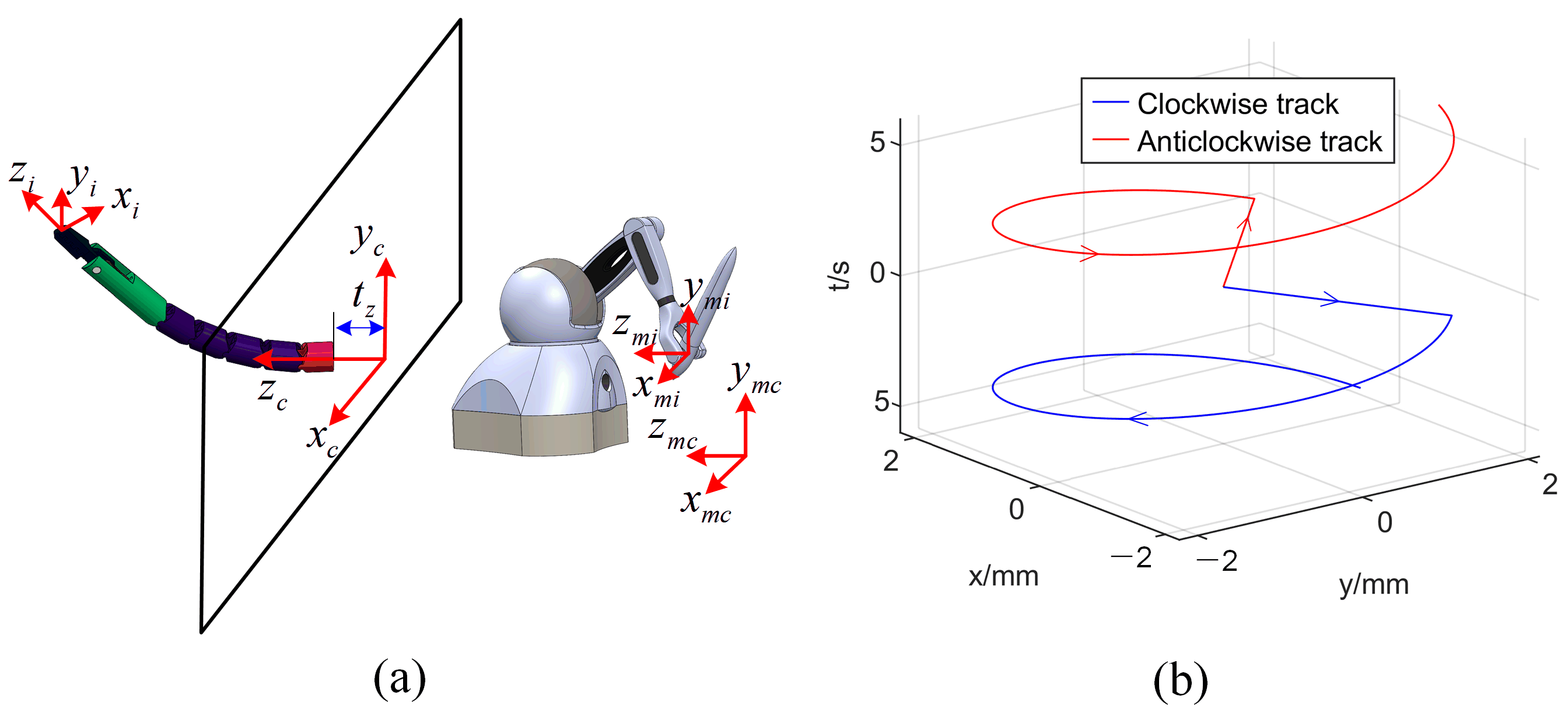

3.1. Kinematics of Manipulator

3.2. Inverse Kinematics

3.3. Jacobian and Singularities

3.4. Singularity Transition

4. Experiments and Results

4.1. Trajectory-Tracking Experiment

4.2. Test for Primary–Secondary Control

4.3. Performance Test

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ikenoyama, Y.; Hirasawa, T.; Ishioka, M.; Namikawa, K.; Yoshimizu, S.; Horiuchi, Y.; Ishiyama, A.; Yoshio, T.; Tsuchida, T.; Takeuchi, Y.; et al. Detecting early gastric cancer: Comparison between the diagnostic ability of convolutional neural networks and endoscopists. Digest. Endosc. 2021, 33, 141–150. [Google Scholar] [CrossRef]

- Bray, F.; Ferlay, J.; Soerjomataram, I.; Siegel, R.L.; Torre, L.A.; Jemal, A. Global cancer statistics 2018: GLOBOCAN estimates of incidence and mortality worldwide for 36 cancers in 185 countries. CA Cancer J. Clin. 2018, 68, 394–424. [Google Scholar] [CrossRef]

- Katai, H.; Ishikawa, T.; Akazawa, K.; Isobe, Y.; Miyashiro, I.; Oda, I.; Tsujitani, S.; Ono, H.; Tanabe, S.; Nunobe, S.; et al. Five-year survival analysis of surgically resected gastric cancer cases in Japan: A retrospective analysis of more than 100,000 patients from the nationwide registry of the Japanese Gastric Cancer Association (2001–2007). Gastric Cancer. 2018, 21, 144–154. [Google Scholar] [CrossRef]

- Miyazaki, R.; Hirose, K.; Ishikawa, Y.; Kanno, T.; Kawashima, K. A Master-Slave Integrated Surgical Robot With Active Motion Transformation Using Wrist Axis. IEEE ASME Trans. Mechatron. 2018, 23, 1215–1225. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, C.; Wu, Z.; Zhao, J.; Yang, B.; Huang, J.; Luo, Q.; Wang, L.; Xu, K. The SHURUI System: A Modular Continuum Surgical Robotic Platform for Multiport, Hybrid-Port, and Single-Port Procedures. IEEE ASME Trans. Mechatron. 2022, 27, 3186–3197. [Google Scholar] [CrossRef]

- Chen, Z.; Peng, M.; Wang, L.; Xu, Z. Efficacy and safety of endoscopic resection in treatment of small gastric stromal tumors: A state-of-the-art review. World J. Gastrointest. Oncol. 2021, 13, 462–471. [Google Scholar] [CrossRef] [PubMed]

- Gifari, M.W.; Naghibi, H.; Stramigioli, S.; Abayazid, M. A review on recent advances in soft surgical robots for endoscopic applications. Int. J. Med. Robot. Comput. Assist. Surg. 2019, 15, e2010. [Google Scholar] [CrossRef]

- Burgner-Kahrs, J.; Rucker, D.C.; Choset, H. Continuum Robots for Medical Applications: A Survey. IEEE Trans. Robot. 2015, 31, 1261–1280. [Google Scholar] [CrossRef]

- Swanstrom, L.L.; Kozarek, R.; Pasricha, P.J.; Gross, S.; Birkett, D.; Park, P.O.; Saadat, V.; Ewers, R.; Swain, P. Development of a New Access Device for Transgastric Surgery. J. Gastrointest. Surg. 2005, 9, 1129–1137. [Google Scholar] [CrossRef] [PubMed]

- Fuchs, K.; Breithaupt, W. Transgastric small bowel resection with the new multitasking platform EndoSAMURAI™ for natural orifice transluminal endoscopic surgery. Surg. Endosc. 2012, 26, 2281–2287. [Google Scholar] [CrossRef] [PubMed]

- Spaun, G.O.; Zheng, B.; Swanström, L.L. A multitasking platform for natural orifice translumenal endoscopic surgery (NOTES): A benchtop comparison of a new device for flexible endoscopic surgery and a standard dual-channel endoscope. Surg. Endosc. 2009, 23, 2720–2727. [Google Scholar] [CrossRef] [PubMed]

- Spaun, G.O.; Zheng, B.; Martinec, D.V.; Cassera, M.A.; Dunst, C.M.; Swanström, L.L. Bimanual coordination in natural orifice transluminal endoscopic surgery: Comparing the conventional dual-channel endoscope, the R-Scope, and a novel direct-drive system. Gastrointest. Endosc. 2009, 69, e39–e45. [Google Scholar] [CrossRef] [PubMed]

- Phee, S.J.; Low, S.C.; Huynh, V.A.; Kencana, A.P.; Sun, Z.L.; Yang, K. Master and slave transluminal endoscopic robot (MASTER) for natural orifice transluminal endoscopic surgery (NOTES). In Proceedings of the 2009 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Minneapolis, MN, USA, 3–6 September 2009; pp. 1192–1195. [Google Scholar] [CrossRef]

- Abbott, D.J.; Becke, C.; Rothstein, R.I.; Peine, W.J. Design of an endoluminal NOTES robotic system. In Proceedings of the 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Diego, CA, USA, 29 October–2 November 2007; pp. 410–416. [Google Scholar] [CrossRef]

- De Donno, A.; Zorn, L.; Zanne, P.; Nageotte, F.; Mathelin, M. Introducing STRAS: A new flexible robotic system for minimally invasive surgery. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation (ICRA), Karlsruhe, Germany, 6–10 May 2013; pp. 1213–1220. [Google Scholar] [CrossRef]

- Li, C.; Yan, Y.; Xiao, X.; Gu, X.; Gao, H.; Duan, X.; Zuo, X.; Li, Y.; Ren, H. A Miniature Manipulator with Variable Stiffness Towards Minimally Invasive Transluminal Endoscopic Surgery. IEEE Robot. Autom. Lett. 2021, 6, 5541–5548. [Google Scholar] [CrossRef]

- Hwang, M.; Kwon, D.S. K-FLEX: A flexible robotic platform for scar-free endoscopic surgery. Int. J. Med. Robot. Comput. Assist. Surg. 2020, 16, e2078. [Google Scholar] [CrossRef]

- De Donno, A.; Nageotte, F.; Zanne, P.; Zorn, L.; Mathelin, M. Master/slave control of flexible instruments for minimally invasive surgery. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Tokyo, Japan, 3–7 November 2013; pp. 483–489. [Google Scholar] [CrossRef]

- Ahn, J.; Kim, J.; Lee, H.; Hwang, M.; Kwon, D.S. A Highly Intuitive and Ergonomic Redundant Joint Master Device for 4-Degrees of Freedom Flexible Endoscopic Surgery Robot. Int. J. Med. Robot. Comput. Assist. Surg. 2021, 17, 1–14. [Google Scholar] [CrossRef]

- Lau, K.C.; Leung, E.Y.Y.; Chiu, P.W.Y.; Yam, Y.; Lau, J.Y.W.; Poon, C.C.Y. A Flexible Surgical Robotic System for Removal of Early-Stage Gastrointestinal Cancers by Endoscopic Submucosal Dissection. IEEE Trans. Ind. Inform. 2016, 12, 2365–2374. [Google Scholar] [CrossRef]

- Lei, Y.; Li, Y.; Song, R.; Du, F. A novel deployable arm for natural orifice transluminal endoscopic surgery(NOTES). Int. J. Med. Robot. Comput. Assist. Surg. 2021, 17, e2232. [Google Scholar] [CrossRef]

- Lu, J.; Du, F.; Zhang, T.; Wang, D.; Lei, Y. An Efficient Inverse Kinematics Algorithm for Continuum Robot with a Translational Base. In Proceedings of the 2020 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Boston, MA, USA, 6–9 July 2020; pp. 1754–1759. [Google Scholar] [CrossRef]

- Lu, J.; Du, F.; Li, Y.; Lei, Y.; Zhang, T.; Zhang, G. A novel inverse kinematics algorithm using the Kepler oval for continuum robots. Appl. Math. Model. 2021, 93, 206–225. [Google Scholar] [CrossRef]

- Chikhaoui, M.T.; Granna, J.; Starke, J.; Burgner-Kahrs, J. Toward Motion Coordination Control and Design Optimization for Dual-Arm Concentric Tube Continuum Robots. IEEE Robot. Autom. Lett. 2018, 3, 1793–1800. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, M.; Lei, Y.; Du, F.; Song, R.; Li, Y. Analysis of Dynamic Friction and Elongation Characteristics of the Tendon Sheath System. In Proceedings of the 2021 International Conference on Intelligent Robotics and Applications (ICIRA), Yantai, China, 22–25 October 2021; pp. 145–154. [Google Scholar] [CrossRef]

- Oyama, T.; Tomori, A.; Hotta, K.; Morita, S.; Kominato, K.; Tanaka, M.; Miyata, Y. Endoscopic submucosal dissection of early esophageal cancer. Clin. Gastroenterol. Hepatol. 2005, 3, S67–S70. [Google Scholar] [CrossRef]

- Cao, L.; Li, X.; Phan, P.T.; Tiong, A.M.H.; Liu, J.; Phee, S.J. A novel robotic suturing system for flexible endoscopic surgery. In Proceedings of the 2019 IEEE International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 1514–1520. [Google Scholar] [CrossRef]

- Akimoto, T.; Goto, O.; Nishizawa, T.; Yahagi, N. Endoscopic closure after intraluminal surgery. Digest. Endosc. 2017, 29, 547–558. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Li, X.; Phan, P.T.; Tiong, A.M.H.; Kaan, H.L.; Liu, J.; Lai, W.; Huang, Y.; Le, H.M.; Miyasaka, M.; et al. Sewing up the wounds: A robotic suturing system for flexible endoscopy. IEEE Robot. Autom. Mag. 2020, 27, 45–54. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, Y.; Li, Y.; Zhang, X.; Zhang, G.; Du, F. Miniature Manipulator Design and Cartesian Control for Minimally Invasive Transluminal Endoscopic Surgery. Micromachines 2022, 13, 2171. https://doi.org/10.3390/mi13122171

Lei Y, Li Y, Zhang X, Zhang G, Du F. Miniature Manipulator Design and Cartesian Control for Minimally Invasive Transluminal Endoscopic Surgery. Micromachines. 2022; 13(12):2171. https://doi.org/10.3390/mi13122171

Chicago/Turabian StyleLei, Yanqiang, Yibin Li, Xingyao Zhang, Gang Zhang, and Fuxin Du. 2022. "Miniature Manipulator Design and Cartesian Control for Minimally Invasive Transluminal Endoscopic Surgery" Micromachines 13, no. 12: 2171. https://doi.org/10.3390/mi13122171

APA StyleLei, Y., Li, Y., Zhang, X., Zhang, G., & Du, F. (2022). Miniature Manipulator Design and Cartesian Control for Minimally Invasive Transluminal Endoscopic Surgery. Micromachines, 13(12), 2171. https://doi.org/10.3390/mi13122171