Finite Element Methodology of Hybridity Nanofluid Flowing in Diverse Wavy Sides of Penetrable Cylindrical Chamber under a Parallel Magnetic Field with Entropy Generation Analysis

Abstract

1. Introduction

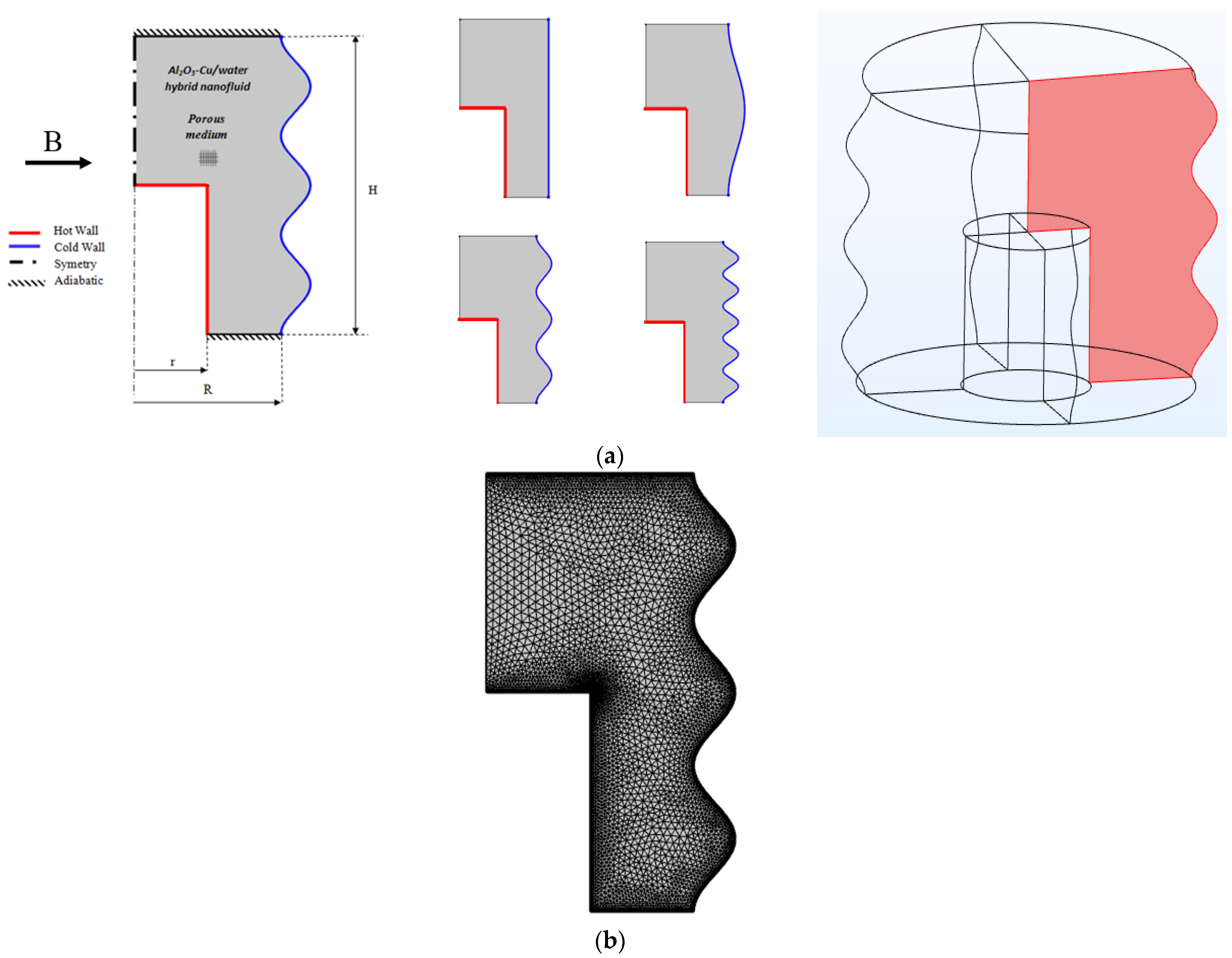

2. Model Equations and Constraints

- The right wavy side:

- The inner side:

- The top and downsides:

Dimensionless Entropy Production

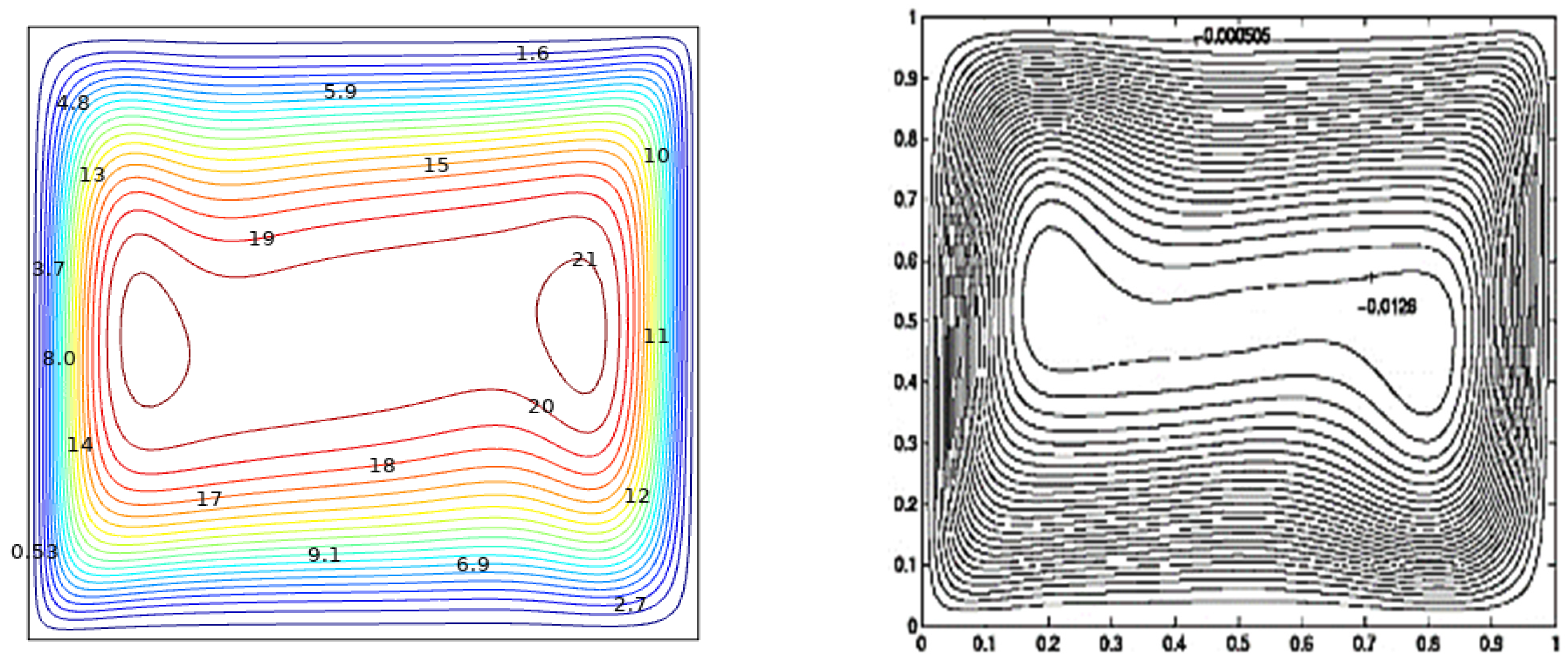

3. Analysis and Validity of Grid-Independence

4. Results and Discussion

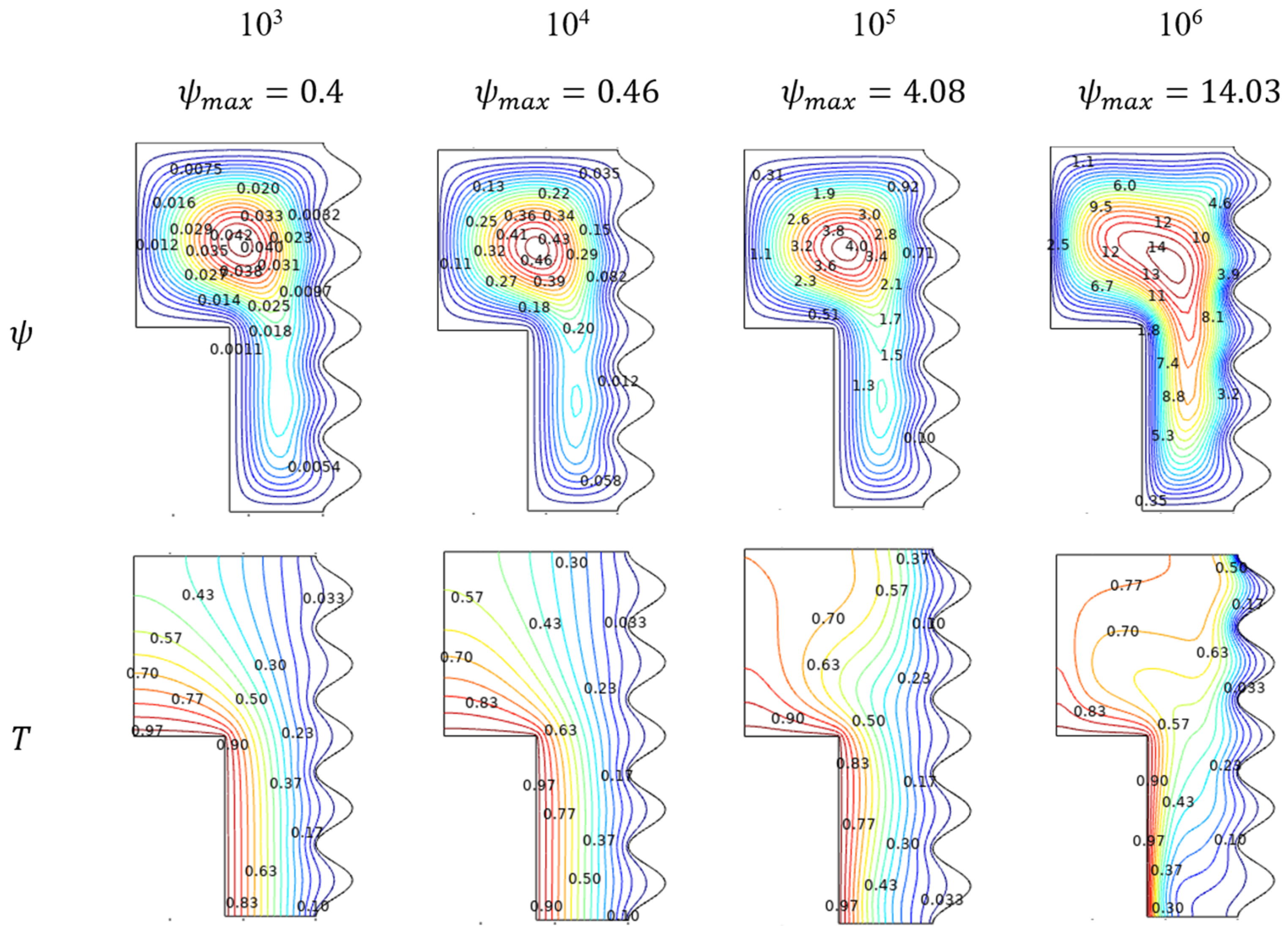

4.1. Effect of Rayleigh-Number

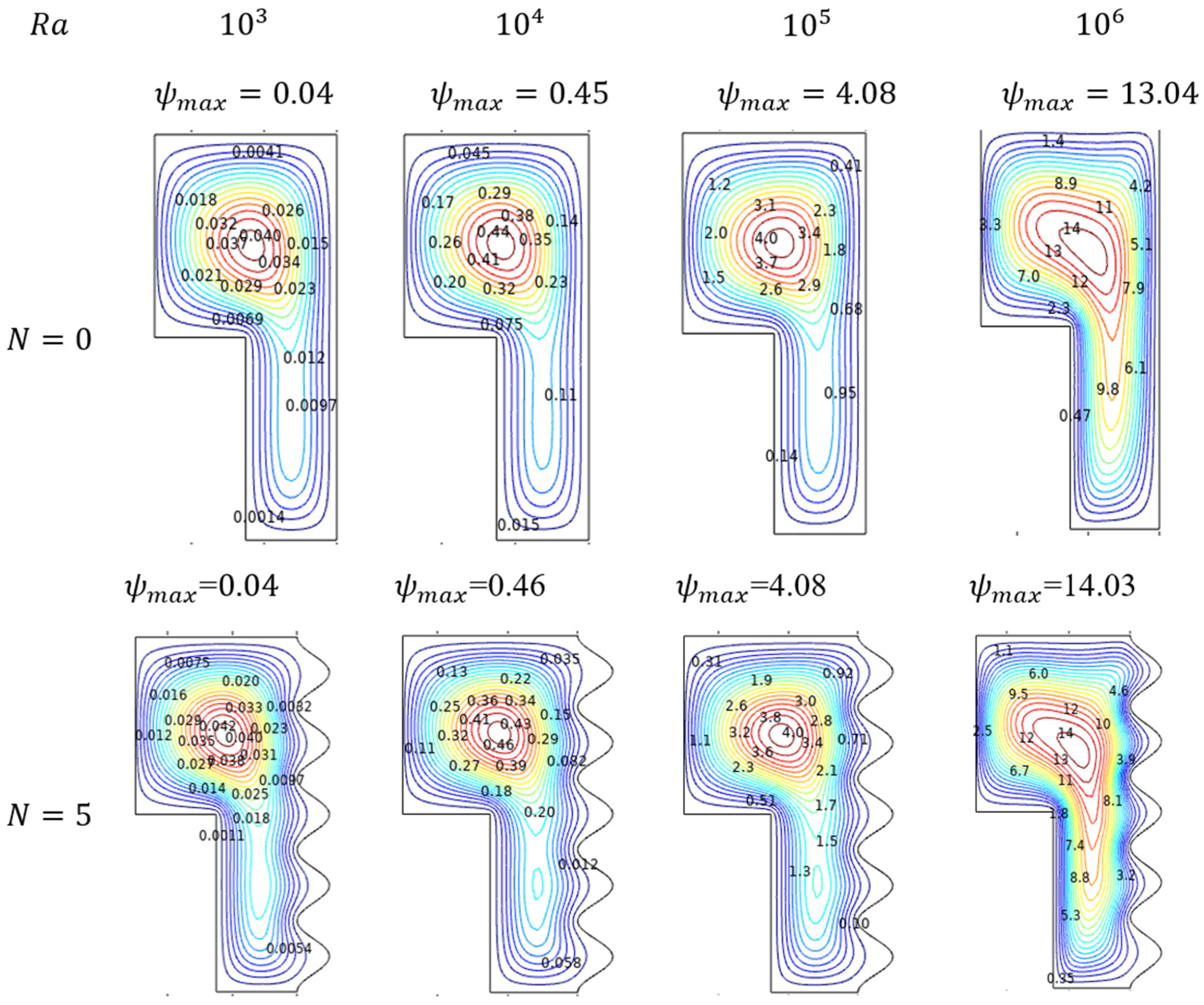

4.1.1. Flow Trends for Rayleigh Number ()

4.1.2. Thermal Trends for Rayleigh Number ()

4.1.3. Rayleigh Number () Impact on Nusselt Number ()

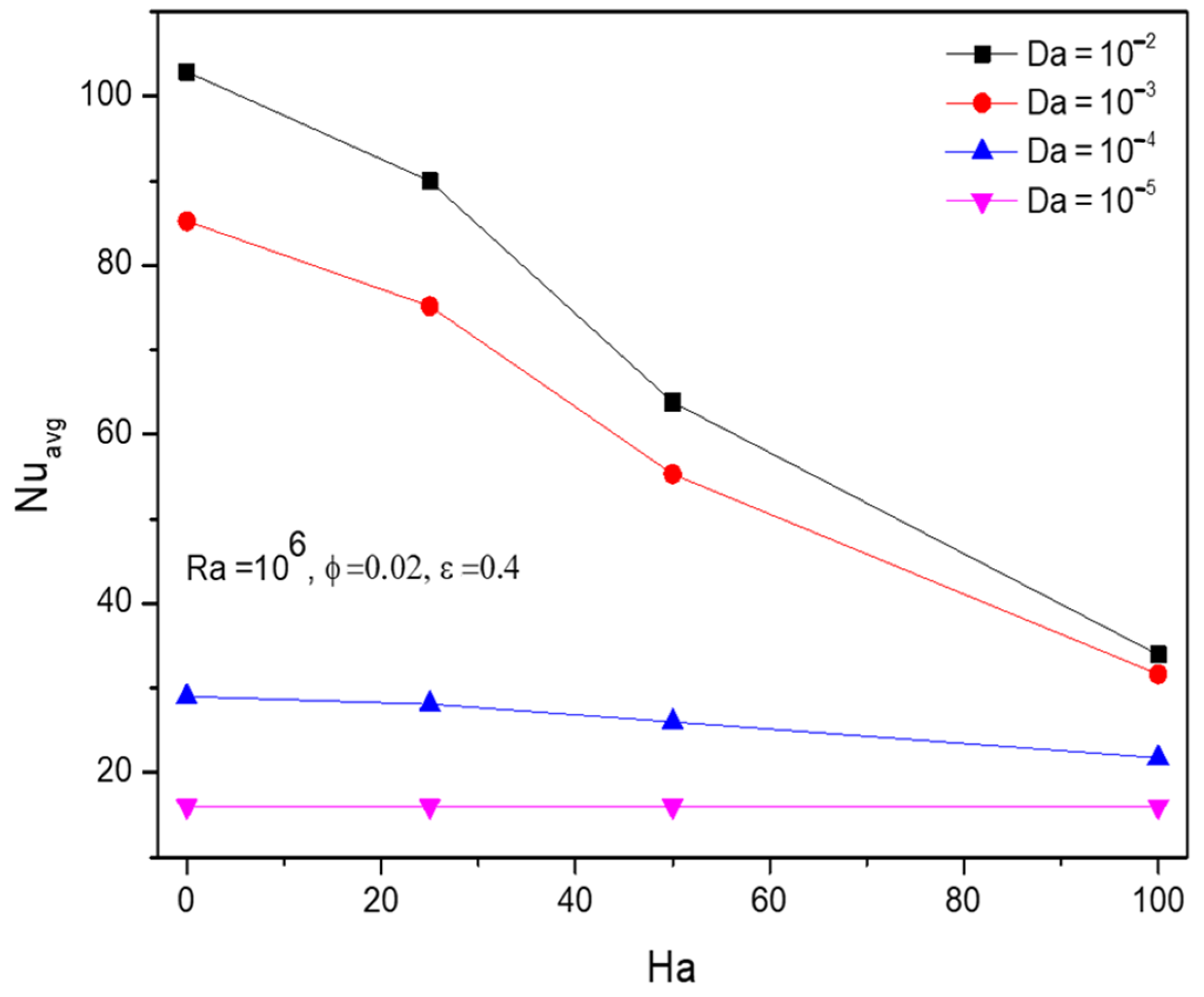

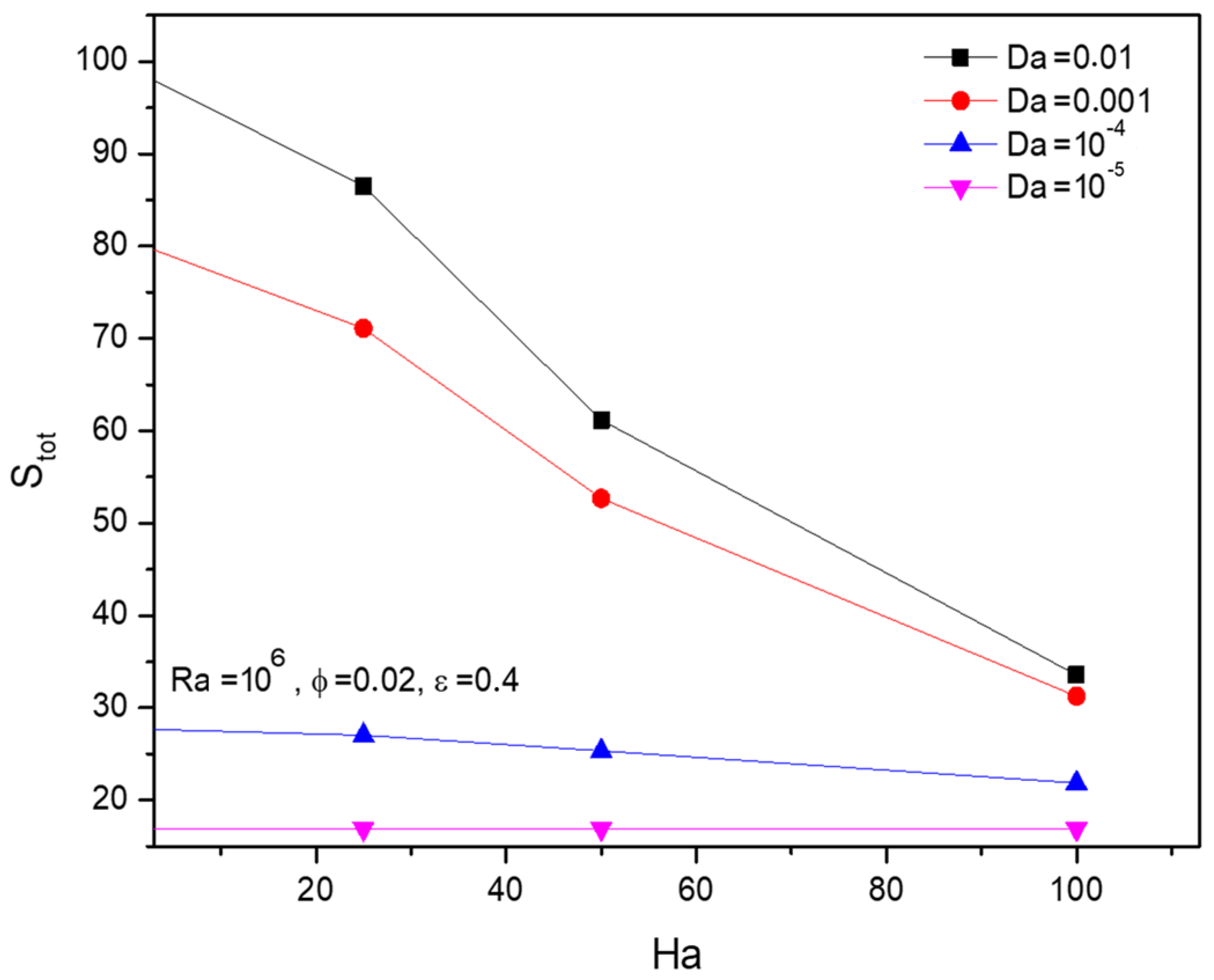

4.2. Effect of Hartmann Number

Nusselt Number () trends for Hartman Number ()

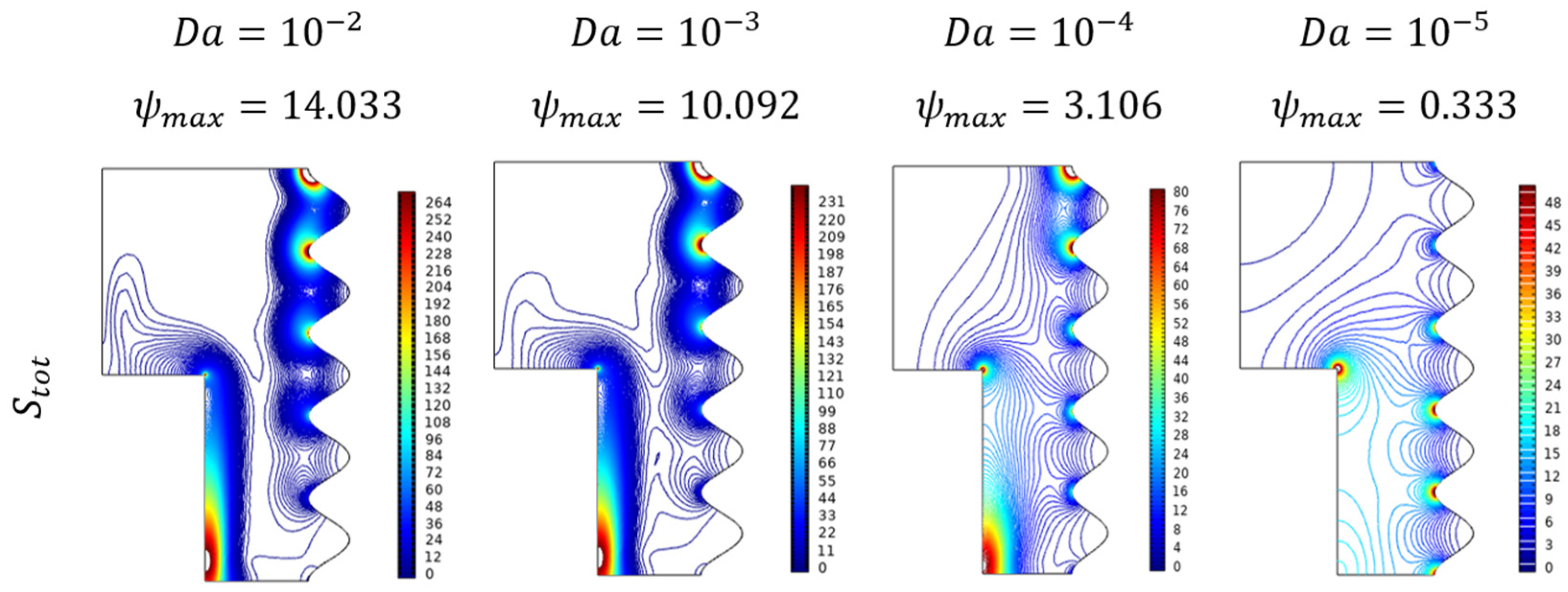

4.3. Effect of Darcy Number

4.3.1. Flow and Thermal Trends for Darcy Number ()

4.3.2. Nusselt Number () Trends for Darcy Number ()

4.4. Effect of Nanofluid Loading

Flow, Thermal, and Nusselt Number () Trends for Nanofluid Loading ()

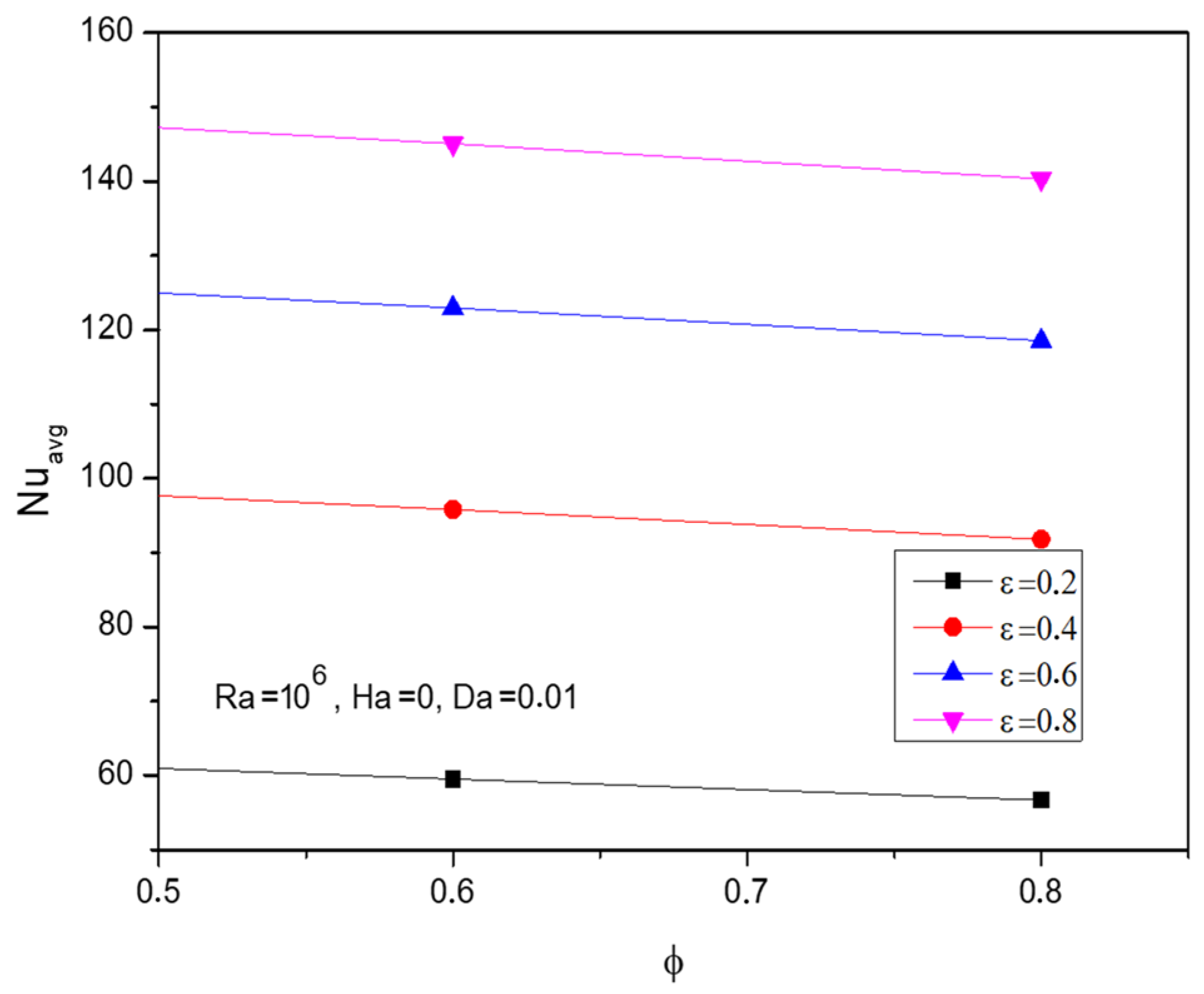

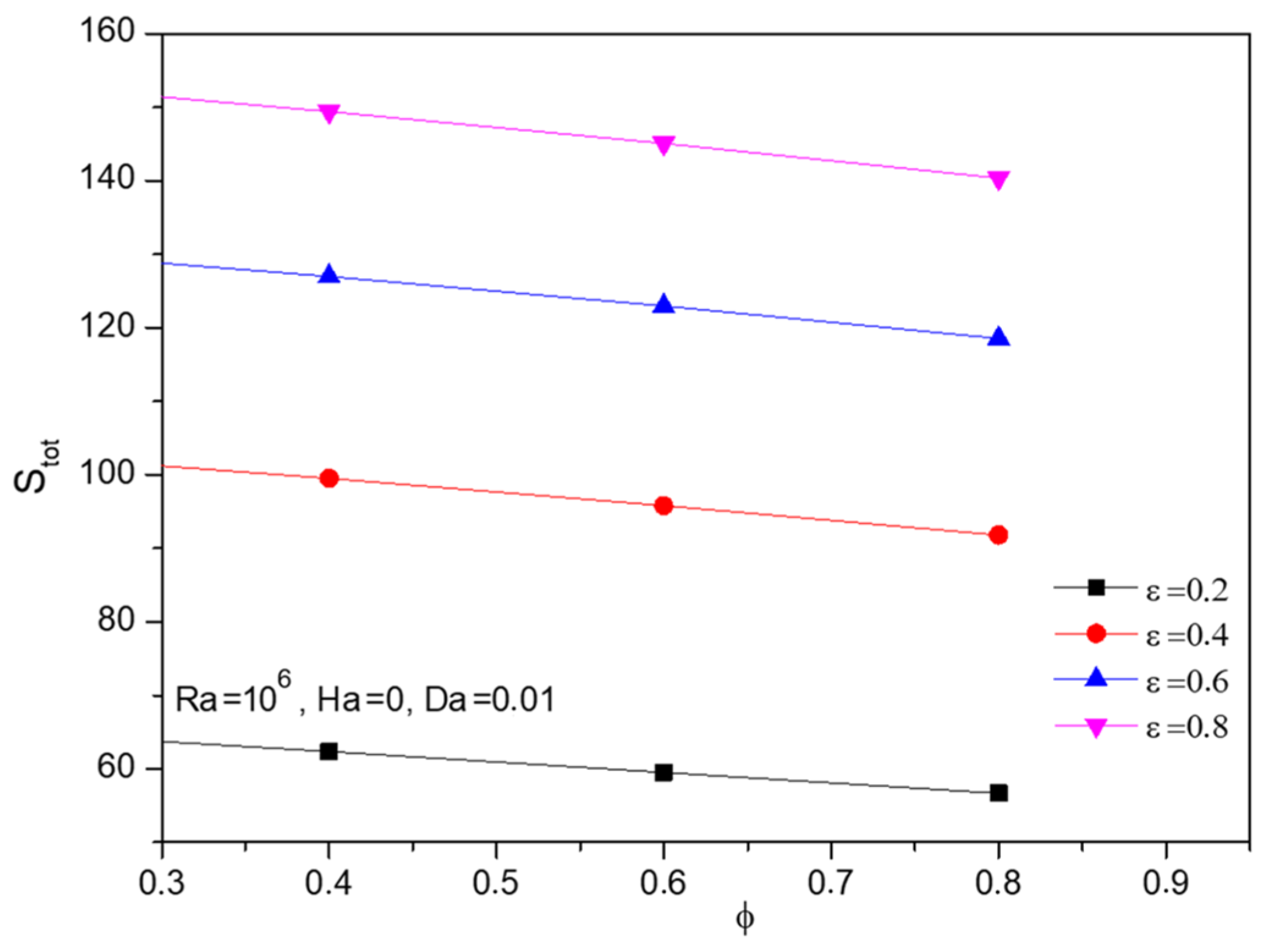

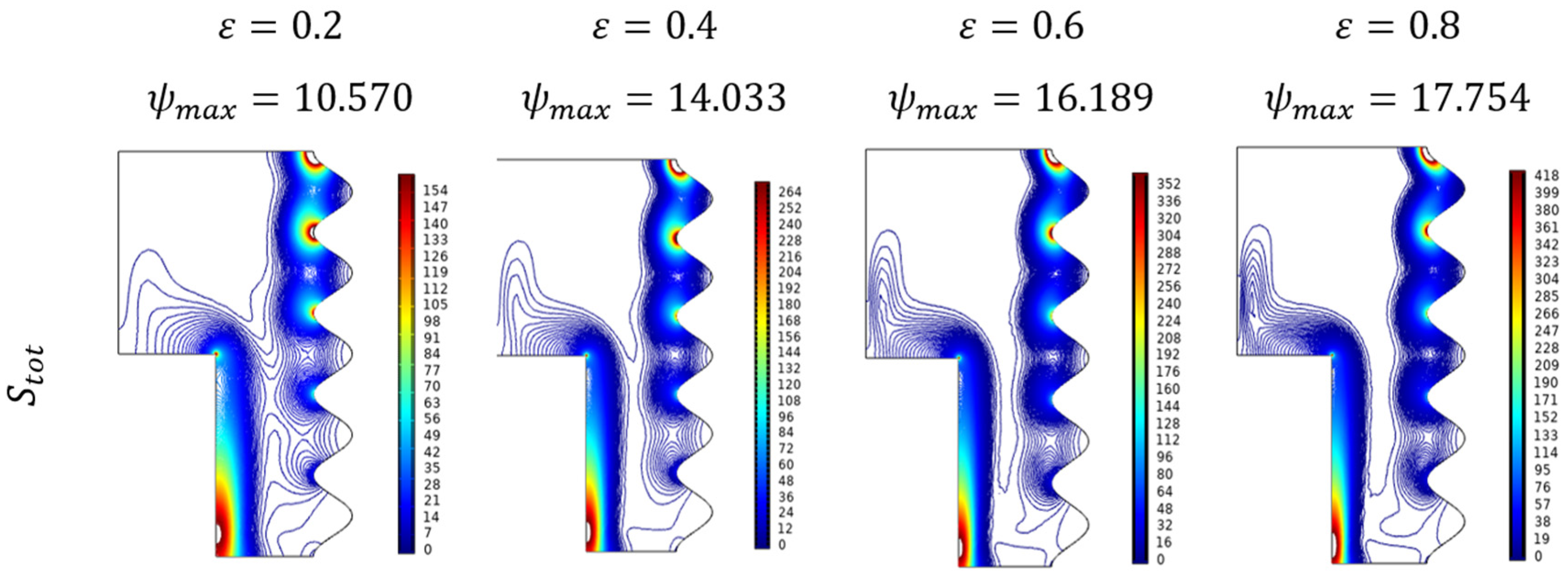

4.5. Effect-of-Porosity

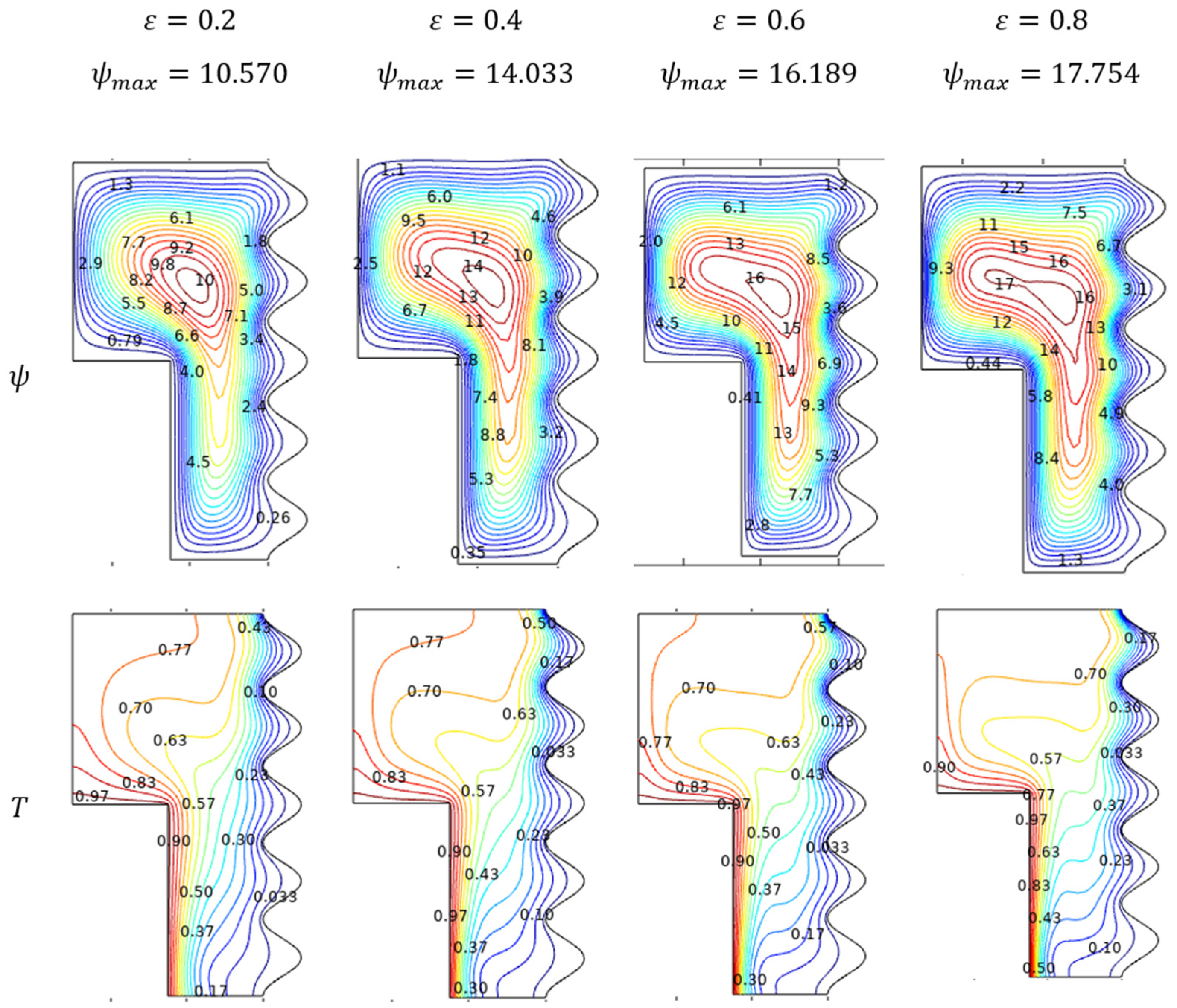

Flow and Thermal Trends for Porosity ()

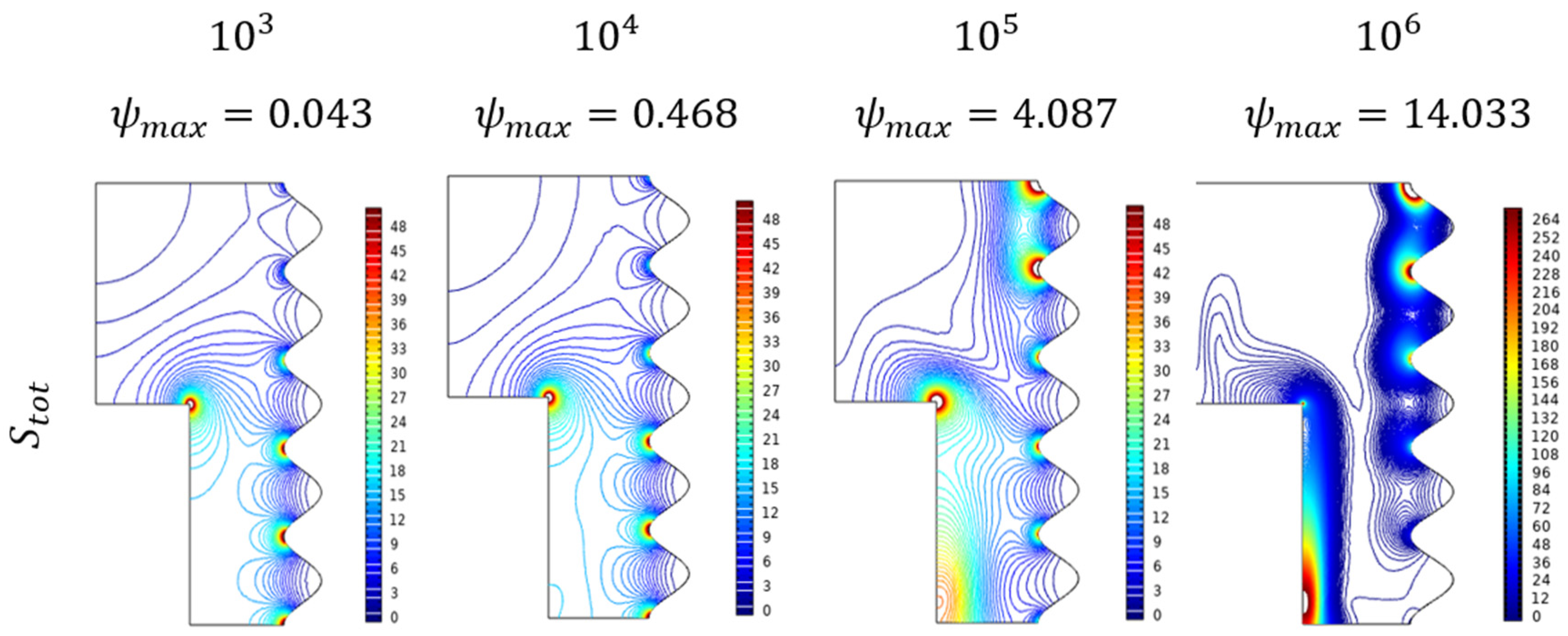

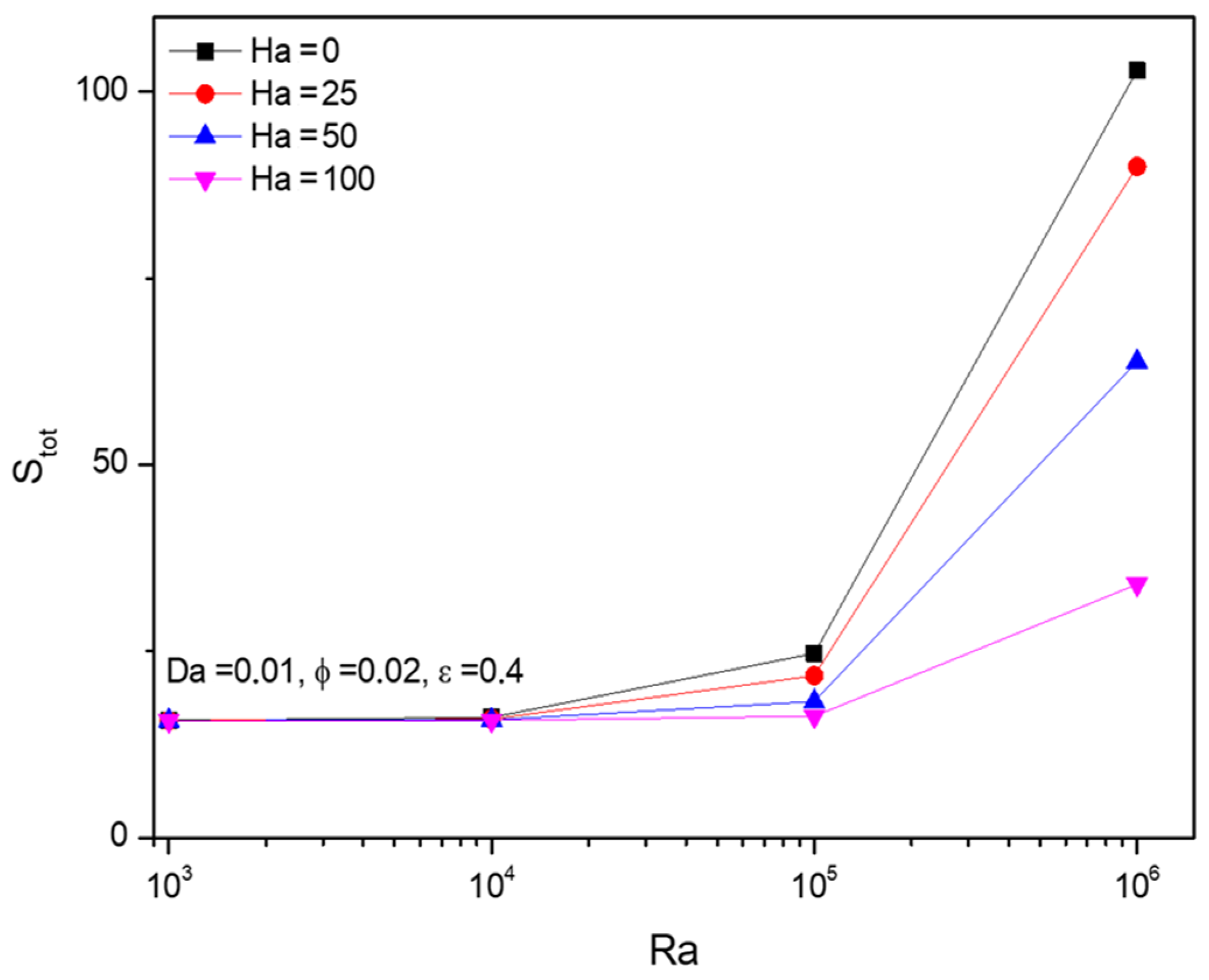

4.6. Effect of General Entropy of Different Non-Dimensional Numbers

Parametrical Studies of Entropy Trends ()

4.7. Effect of Undulations

4.7.1. Flow Trends for Undulations ()

4.7.2. Isothermal Trends for Undulations ()

4.7.3. Entropy Trends for Undulations ()

5. Conclusions

- ❖

- Even though the thermal transmission process was the hotspot of this study, the porous medium includes the fluidity brought under consideration. Vital sign of improved fluidity was commonly found through the extended flow contour towards the narrow path between two distinct walls. Such a trend can be found as increasing for improving amounts of parameters like Rayleigh (), Darcy () numbers, and porosity (). Moderate contour variation towards fluidity can be viewed through nanofluid loading (), while the Hartman number () plays against it.

- ❖

- Thermal distribution with effecting crucial constraints involved in this work has been plotted as a contour and clear sketch graph. Impact of a hybrid nanofluid of Al2O3-Cu/H2O can be significant enough due to its elevated thermal properties than that of usual fluid. A diagonally dominant trend by the inner hot smaller wall and outer wavy cooler wall sets the favorable situation for thermal distribution. It can be found for the parameters such as Darcy number (), nanofluid loading (), and porosity (). Meanwhile, the same trend gets reversed as diagonal to scattering isotherms were formed for the parameters like Hartman number ().

- ❖

- Vital thermal transmitting rate has been traced in terms of the average Nusselt number (). Hartman number () resists the thermal transferring process by slowing the fluidity, and parameters like Darcy number () and porosity () work in favour of thermal transmitting progress. Interestingly, the nanofluid loading () possesses the switching trend in the Nusselt number () which shows the fluctuating effect that happened after those crucial parametric values around and .

- ❖

- To address this issue entropy study has been carried out and parametrical outcomes were plotted as counterplots and graphs. Highest entropy-forming situations were found in higher amounts of , , and initial values of . Parameters like nanofluid loading () and porosity () exert diagonal dominant trends with their improving values.

- ❖

- For the best possible results, it is crucial to take preventative measures to identify and minimize transferred energy loss while conducting tests to find an effective thermal transmitting fluid.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Applied magnetic field | Greek symbols | ||

| Darcy number | Dynamical viscidness | ||

| Hartmann number | Density | ||

| Prandtl number | Thermal-expansion coefficient | ||

| Nusselt number | Thermal diffusion | ||

| Velocity quantities | Nano-solid particles size | ||

| Nondimensional cylindrical coordinates | Porosity | ||

| Temperature | Subscripts | ||

| Nondimensional velocity quantities | Hybrid-nanofluid | ||

| Thermal conductivity | Fluid | ||

| Penetrability of material | |||

References

- Öztop, H.F.; Rahman, M.M.; Ahsan, A.; Hasanuzzaman, M.; Saidur, R.; Al-Salem, K.; Rahim, N.A. MHD natural convection in an enclosure from two semi-circular heaters on the bottom wall. Int. J. Heat Mass Transf. 2012, 55, 1844. [Google Scholar] [CrossRef]

- Benzema, M.; Benkahla, Y.; Labsi, N.; Ouyahia, S.; El Anaoui, M.J. Second law analysis of MHD mixed convection heat transfer in a vented irregular cavity filled with Ag–MgO/water hybrid nanofluid. Therm. Anal. Calorim. 2019, 137, 1113. [Google Scholar] [CrossRef]

- Lahlou, S.; Labsi, N.; Benkahla, Y.; Boudiaf, A.; Ouyahia, S.J. Flow of viscoplastic fluids containing hybrid nanoparticles: Extended Buongiorno’s model. Non-Newton. Fluid Mech. 2020, 281, 104308. [Google Scholar] [CrossRef]

- Benzema, M.; Benkahla, Y.; Labsi, N.; Brunier, E.; Ouyahia, S. Numerical mixed convection heat transfer analysis in a ventilated irregular enclosure crossed by Cu–water nanofluid. Arab. J. Sci. Eng. 2017, 42, 4575. [Google Scholar] [CrossRef]

- Rabbi, K.M.; Saha, S.; Mojumder, S.; Rahman, M.M.; Saidur, R.; Ibrahim, T.A. Numerical investigation of pure mixed convection in a ferrofluid-filled lid-driven cavity for different heater configurations. Alex. Eng. J. 2016, 55, 127. [Google Scholar] [CrossRef]

- Boudiaf, A.; Danane, F.; Benkahla, Y.K.; Berabou, W.; Benzema, M.; Labsi, N.; Ouyahia, S.-E. Numerical study of viscous dissipation and non-Boussinesq model effects on CMC–TiO2 fluid flow over backward facing step with baffle. J. Therm. Anal. Calorim. 2019, 135, 787. [Google Scholar] [CrossRef]

- Haddad, Z.; Oztop, H.F.; Abu-Nada, E.; Mataoui, A. A review on natural convective heat transfer of nanofluids. Renew. Sustain. Energy. Rev. 2012, 16, 5363. [Google Scholar] [CrossRef]

- Taghikhani, M.A. Magnetic Field Effect on Natural Convection Flow with Internal Heat Generation using Fast–Method. J. Appl. Fluid Mech. 2015, 8, 189. [Google Scholar] [CrossRef]

- Bhuiyan, A.S.; Azim, N.H.M.A.; Chowdhury, M.K. Joule heating effects on MHD natural convection flows in presence of pressure stress work and viscous dissipation from a horizontal circular cylinder. J. Appl. Fluid Mech. 2014, 7, 7. [Google Scholar]

- Benzema, M.; Benkahla, Y.K.; Boudiaf, A.; Ouyahia, S.E.; el Ganaoui, M. Magnetic field impact on nanofluid convective flow in a vented trapezoidal cavity using Buongiorno’s mathematical model. Eur. Phys. J. Appl. Phys. 2019, 88, 11101. [Google Scholar] [CrossRef]

- Ouyahia, S.E.; Benkahla, Y.K.; Berabou, W.; Boudiaf, A. Numerical study of the flow in a square cavity filled with Carbopol-TiO2 nanofluid. Powder Tech. 2017, 311, 101. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Suresh, S.; Bose, A.C. Experimental investigations and theoretical determination of thermal conductivity and viscosity of Al2O3/water nanofluid. Exp. Therm. Fluid Sci. 2010, 34, 210. [Google Scholar] [CrossRef]

- Chamkha, A.J.; Dogonchi, A.S.; Ganji, D.D. Magneto-hydrodynamic flow and heat transfer of a hybrid nanofluid in a rotating system among two surfaces in the presence of thermal radiation and Joule heating. AIP Adv. 2019, 9, 025103. [Google Scholar] [CrossRef]

- Dogonchi, A.; Selimefendigil, F.; Ganji, D. Investigation of magneto-hydrodynamic fluid squeezed between two parallel disks by considering Joule heating, thermal radiation, and adding different nanoparticles. Int. J. Numerical. Methods Heat Fluid Flow 2019, 29, 1663. [Google Scholar] [CrossRef]

- Mehryan, S.A.M.; Sheremet, M.A.; Soltani, M.; Izadi, M.J. Natural convection of magnetic hybrid nanofluid inside a double-porous medium using two-equation energy model. Mol. Liq. 2019, 277, 959. [Google Scholar] [CrossRef]

- Mehryan, S.A.M.; Kashkooli, F.M.; Ghalambaz, M.; Chamkha, A.J. Free convection of hybrid Al2O3-Cu water nanofluid in a differentially heated porous cavity. Adv. Powder Technol. 2017, 28, 2295. [Google Scholar] [CrossRef]

- Pordanjani, A.H.; Vahedi, S.M.; Aghakhani, S.; Afrand, M.; Öztop, H.F. Effect of magnetic field on mixed convection and entropy generation of hybrid nanofluid in an inclined enclosure: Sensitivity analysis and optimization. Eur. Phys. J. Plus 2019, 134, 412. [Google Scholar] [CrossRef]

- Vahedi, S.M.; Pordanjani, A.H.; Wongwises, S.; Afrand, M.J. On the role of enclosure side walls thickness and heater geometry in heat transfer enhancement of water–Al2O3 nanofluid in presence of a magnetic field. Therm. Anal. Calorim. 2019, 138, 679. [Google Scholar] [CrossRef]

- Al-Rashed, A.A.A.A.; Sheikhzadeh, G.A.; Aghaei, A.; Monfared, F.; Shahsavar, A.; Afrand, M.J. Effect of a porous medium on flow and mixed convection heat transfer of nanofluids with variable properties in a trapezoidal enclosure. Therm. Anal. Calorim. 2020, 139, 741. [Google Scholar] [CrossRef]

- Ahmed, N.J.S.; Badruddin, I.A.; Zainal, Z.A.; Khaleed, H.M.T.; Kanesan, J. Heat transfer in a conical cylinder with porous medium. Int. J. Heat Mass Transf. 2009, 52, 3070. [Google Scholar] [CrossRef]

- Athani, A.; Ahamad, N.A.; Badruddin, I.A. Application of artificial neural network for heat transfer in porous cone. AIP Conf. Proc. 2018, 1953, 140016. [Google Scholar]

- Seddegh, S.; Tehrani, S.S.M.; Wang, X.; Cao, F.; Taylor, R.A. Comparison of heat transfer between cylindrical and conical vertical shell-and-tube latent heat thermal energy storage systems. Appl. Therm. Eng. 2018, 130, 1349. [Google Scholar] [CrossRef]

- Dogonchi, A.S.; Tayebi, T.; Karimi, N.; Chamkha, A.J.; Alhumade, H.J. Numerical study on the hybrid nanofluid (Co3O4-Go/H2O) flow over a circular elastic surface with non-Darcy medium: Application in solar energy. Taiwan Inst. Chem. Eng. 2021, 124, 162–173. [Google Scholar] [CrossRef]

- Acharya, N. Buoyancy driven magnetohydrodynamic hybrid nanofluid flow within a circular enclosure fitted with fins. Int. Comm. Heat Mass Transf. 2022, 133, 105980. [Google Scholar] [CrossRef]

- Acharya, N.; Mabood, F.; Badruddinc, I.A. Thermal performance of unsteady mixed convective Ag/MgO nanohybrid flow near the stagnation point domain of a spinning sphere. Int. Com. Heat Mass Transf. 2022, 134, 106019. [Google Scholar] [CrossRef]

- Tayebi, T.; Dogonchi, A.S.; Chamkha, A.J.; Hamida, M.B.B.; El-Sapa, S.; Galal, A.M. Micropolar nanofluid thermal free convection and entropy generation through an inclined I-shaped enclosure with two hot cylinders. Case Stud. Therm. Eng. 2022, 31, 101813. [Google Scholar] [CrossRef]

- Brinkman, H.C. The viscosity of concentrated suspensions and solutions. J. Chem. Phys. 1952, 20, 571. [Google Scholar] [CrossRef]

- Naidu, K.K.; Babu, D.H.; Narayana, P.V.S.; Reddy, S.H.; Chalapathi, T. Convective flow of Prandtl hybrid nanofluid (SWCNT-MWCNT/EG) over an exponentially elongated sheet with second-order slip. J. Porous Med. 2022, 25, 43–57. [Google Scholar] [CrossRef]

- Babu, D.H.; Venkateswarlu, B.; Sarojamma, G.; Narayana, P.S. Coupled Impression of Radiative Thermal Flux and Lorentz Force on the Water Carrying Composite Nanoliquid Streaming Past an Elastic Sheet. J. Therm. Sci. Eng. Appl. 2022, 14, 091002. [Google Scholar] [CrossRef]

- Mansour, R.B.; Galanis, N.; Nguyen, C.T. Effect of uncertainties in physical properties on forced convection heat transfer with nanofluids. Appl. Therm. Eng. 2007, 27, 240–249. [Google Scholar] [CrossRef]

- Seyyedi, S.M.; Dogonchi, A.; Nuraei, R.; Ganji, D.; Hashemi-Tilehnoee, M. Numerical analysis of entropy generation of a nanofluid in a semi-annulus porous enclosure with different nanoparticle shapes in the presence of a magnetic field. Eur. Phys. J. Plus 2019, 134, 268. [Google Scholar] [CrossRef]

- Sarkar, S.; Ganguly, S.; Dalal, A. Analysis of entropy generation during mixed convective heat transfer of nanofluids past a square cylinder in vertically upward flow. ASME J. Heat Transf. 2012, 134, 122501. [Google Scholar] [CrossRef]

- Calcagni, B.; Marsili, F.; Paroncini, M. Nanofluid flow and heat transfer in a cavity with variable magnetic field. Appl. Therm. Eng. 2005, 25, 2522–2531. [Google Scholar] [CrossRef]

- Acharya, N.J. Recent Advancements in Emerging Technologies for Healthcare Management Systems: A Survey. Energy Storage 2022, 53, 105198. [Google Scholar] [CrossRef]

- Acharya, N.; Chamkha, A.J. On the magnetohydrodynamic Al2O3-water nanofluid flow through parallel fins enclosed inside a partially heated hexagonal cavity. Int. Commun. Heat Mass Transf. 2022, 132, 105885. [Google Scholar] [CrossRef]

- Acharya, N.; Maity, S.; Kundu, P.K. Entropy generation optimization of unsteady radiative hybrid nanofluid flow over a slippery spinning disk. Part C J. Mech. Eng. Sci. 2022, 236, 09544062211065384. [Google Scholar] [CrossRef]

- Babu, D.H.; Naidu, K.K.; Deo, S.; Narayana, P.S. Impacts of inclined Lorentz forces on hybrid CNTs over an exponentially stretching sheet with slip flow. Int. J. Model. Simul. 2022, 1–15. [Google Scholar] [CrossRef]

- Eid, M.R. 3-D Flow of Magnetic Rotating Hybridizing Nanoliquid in Parabolic Trough Solar Collector: Implementing Cattaneo-Christov Heat Flux Theory and Centripetal and Coriolis Forces. Mathematics 2022, 10, 2605. [Google Scholar] [CrossRef]

- Naidu, K.; Babu, D.H.; Narayana, P.V.S. Bioconvection in magneto hydrodynamics Casson nanoliquid (Fe3O4-sodium alginate) With gyrotactic microorganisms over an exponential stretching sheet. J. Nanofluids 2021, 10, 327–338. [Google Scholar] [CrossRef]

| Properties | ||||

|---|---|---|---|---|

| Pure water | 997.1 | 4179 | 0.613 | 21 × 10−5 |

| Cu | 10,500 | 235 | 429 | 5.4 × 10−5 |

| Al2O3 | 3970 | 879 | 30 | 3.36 × 10−5 |

| Properties | Hybrid Nanofluid |

|---|---|

| Dynamic viscosity | |

| Thermal conductivity | |

| Density | |

| Thermal expansion coefficient | |

| Heat capacitance |

| Grid | 9612 | 17,016 | 25,016 | 31,712 | 51,728 |

| 9.4932 | 9.4932 | 9.4232 | 9.4932 | 9.4942 | |

| 15.217 | 15.217 | 15.217 | 15.217 | 15.217 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Redouane, F.; Jamshed, W.; Eid, M.R.; Uma Devi S, S.; Musa, A.; Eldin, S.M.; Prakash, M.; Ullah, I. Finite Element Methodology of Hybridity Nanofluid Flowing in Diverse Wavy Sides of Penetrable Cylindrical Chamber under a Parallel Magnetic Field with Entropy Generation Analysis. Micromachines 2022, 13, 1905. https://doi.org/10.3390/mi13111905

Redouane F, Jamshed W, Eid MR, Uma Devi S S, Musa A, Eldin SM, Prakash M, Ullah I. Finite Element Methodology of Hybridity Nanofluid Flowing in Diverse Wavy Sides of Penetrable Cylindrical Chamber under a Parallel Magnetic Field with Entropy Generation Analysis. Micromachines. 2022; 13(11):1905. https://doi.org/10.3390/mi13111905

Chicago/Turabian StyleRedouane, Fares, Wasim Jamshed, Mohamed R. Eid, Suriya Uma Devi S, Awad Musa, Sayed M. Eldin, M. Prakash, and Imran Ullah. 2022. "Finite Element Methodology of Hybridity Nanofluid Flowing in Diverse Wavy Sides of Penetrable Cylindrical Chamber under a Parallel Magnetic Field with Entropy Generation Analysis" Micromachines 13, no. 11: 1905. https://doi.org/10.3390/mi13111905

APA StyleRedouane, F., Jamshed, W., Eid, M. R., Uma Devi S, S., Musa, A., Eldin, S. M., Prakash, M., & Ullah, I. (2022). Finite Element Methodology of Hybridity Nanofluid Flowing in Diverse Wavy Sides of Penetrable Cylindrical Chamber under a Parallel Magnetic Field with Entropy Generation Analysis. Micromachines, 13(11), 1905. https://doi.org/10.3390/mi13111905