Preparation of Cemented Carbide Insert Cutting Edge by Flexible Fiber-Assisted Shear Thickening Polishing Method

Abstract

1. Introduction

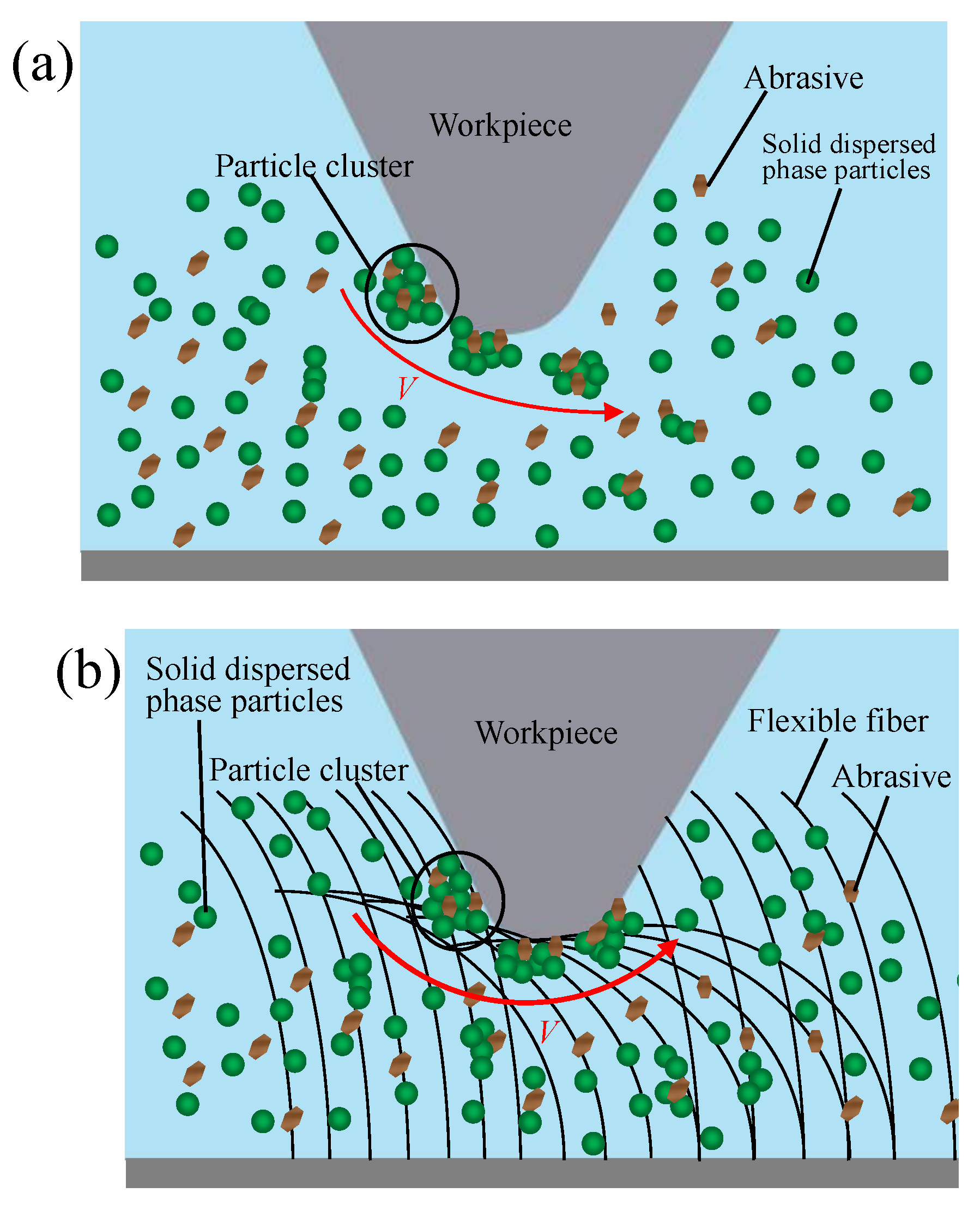

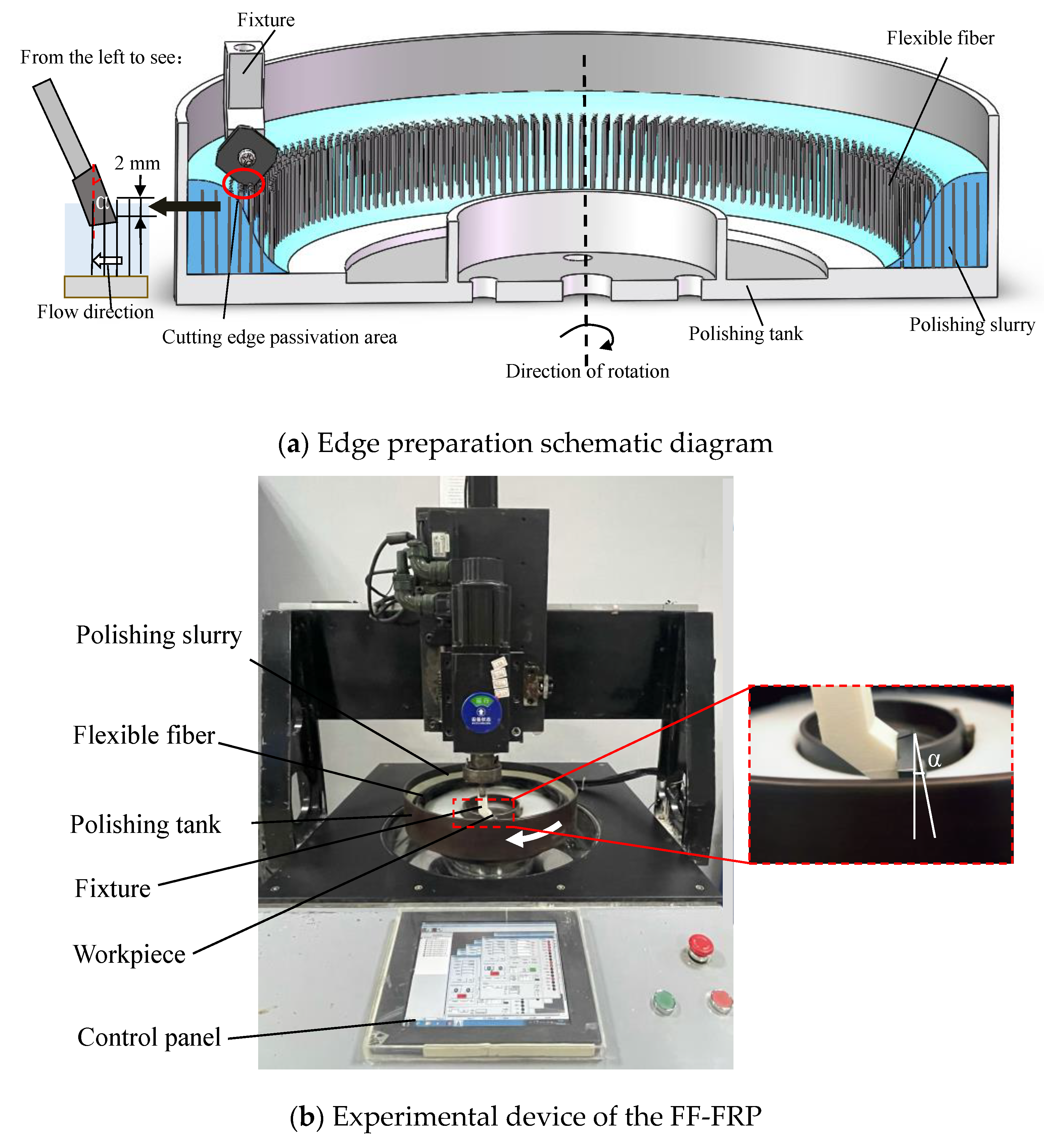

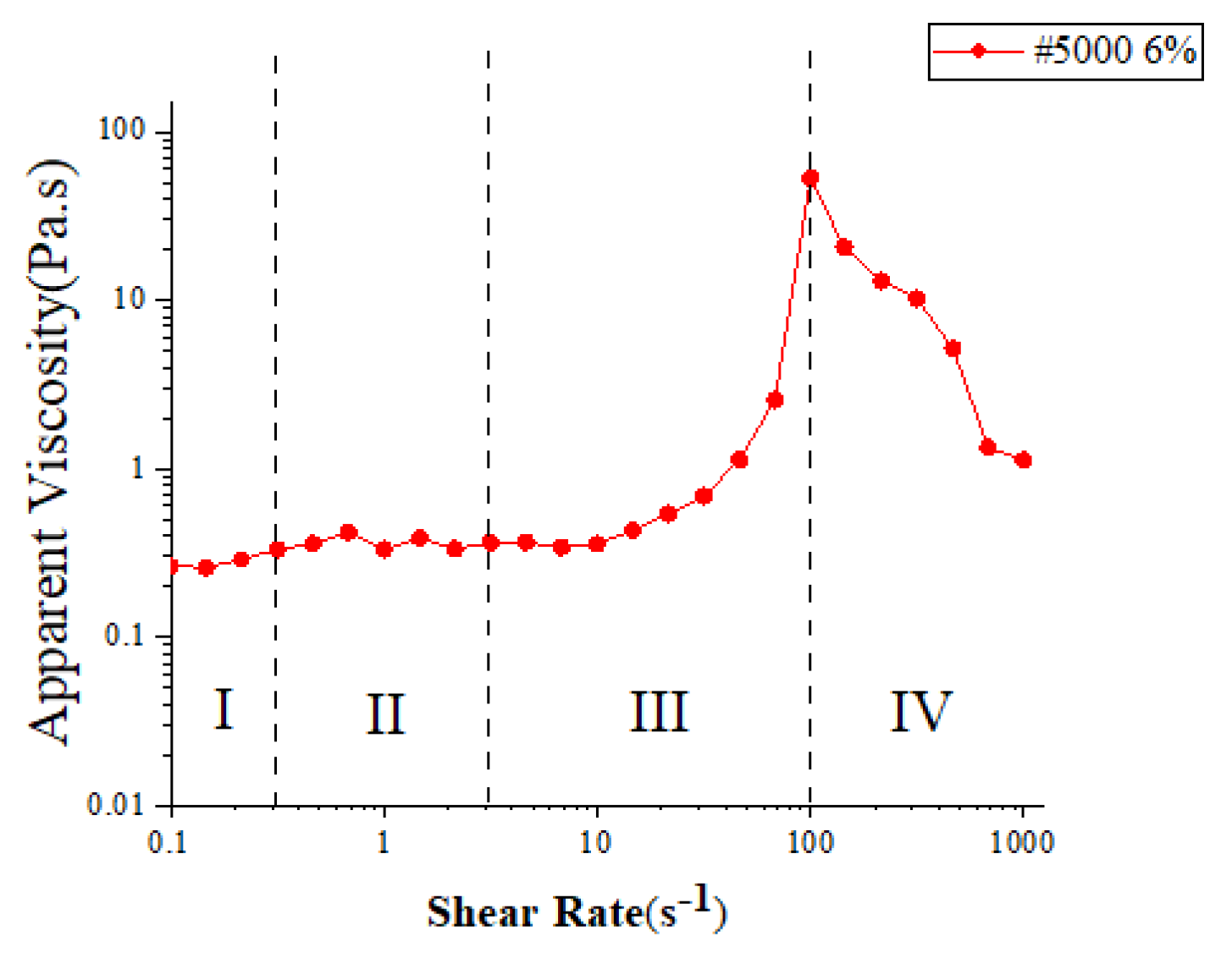

2. Principle of FF-STP

3. Experimental Process and Conditions

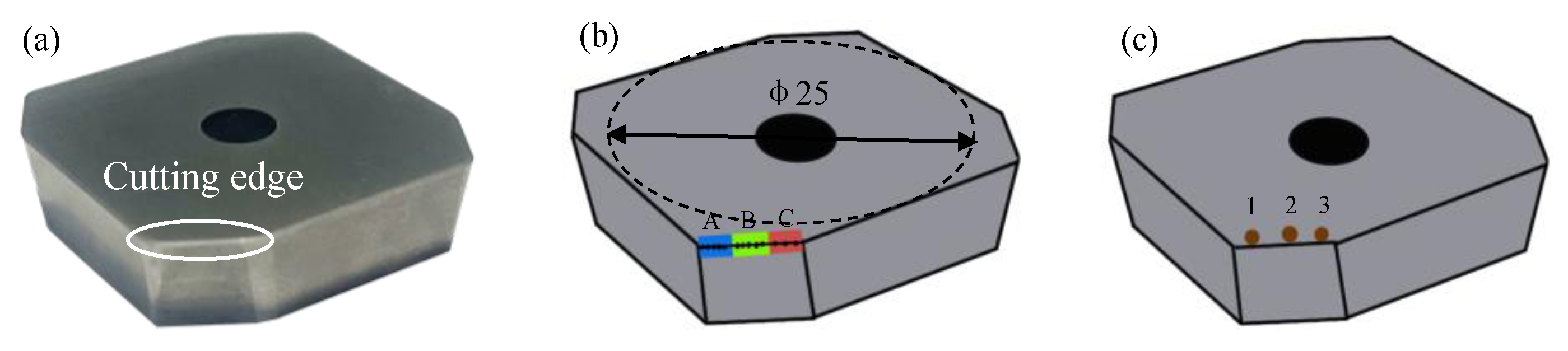

3.1. Experimental Process

3.2. Experimental Conditions

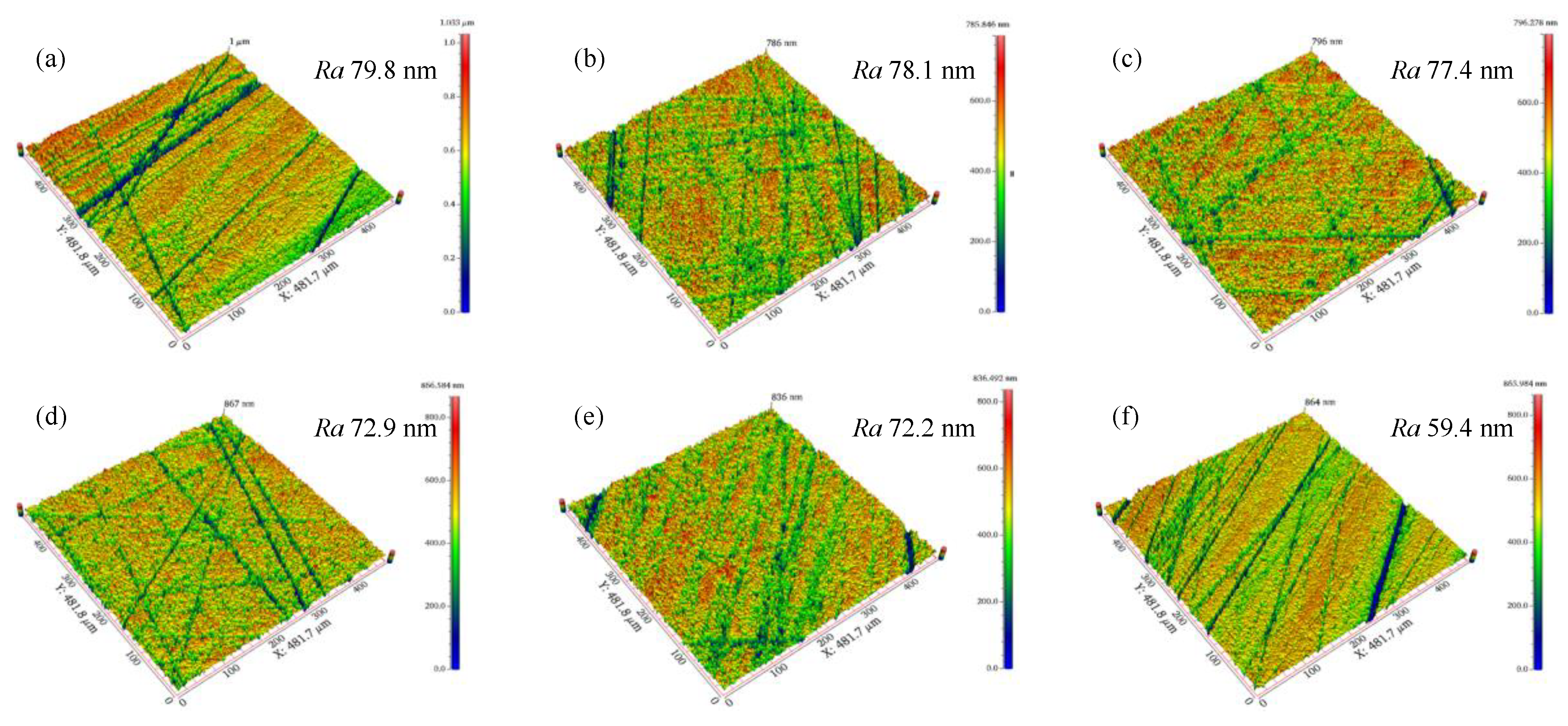

4. Results and Discussion

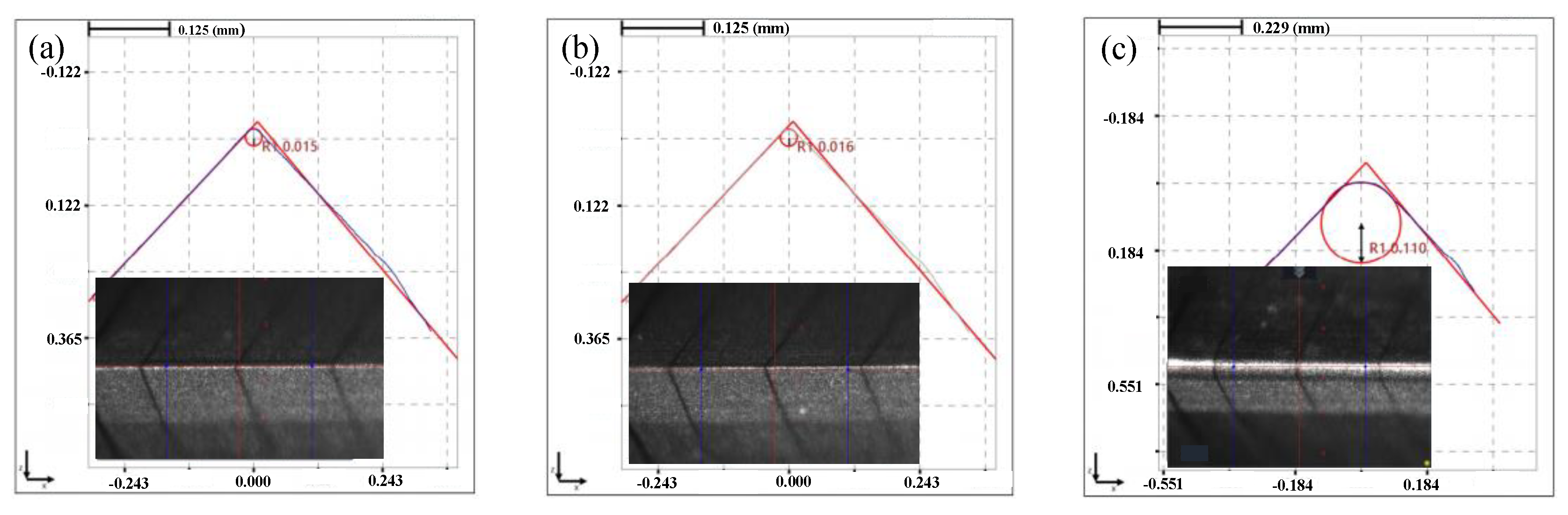

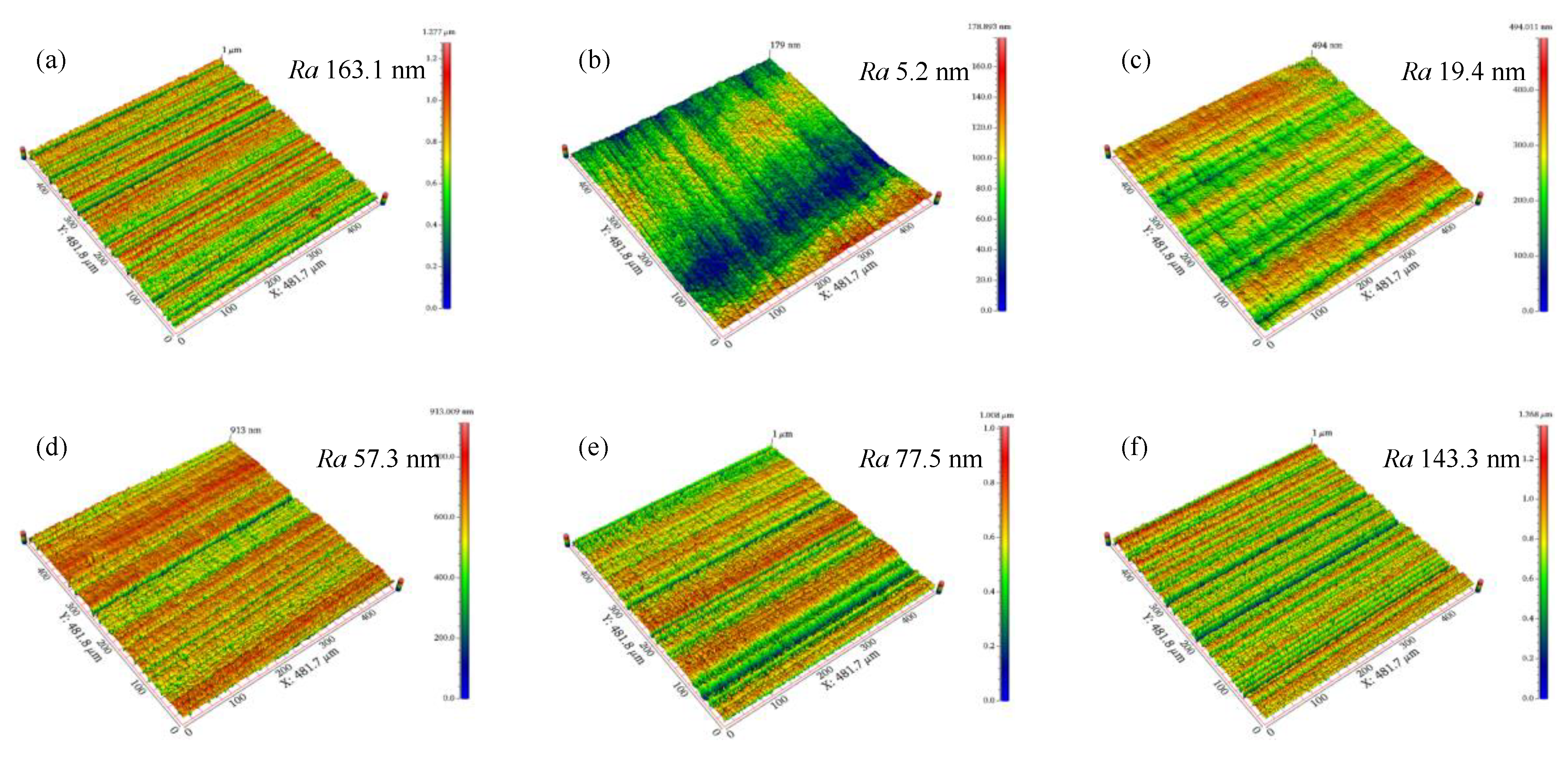

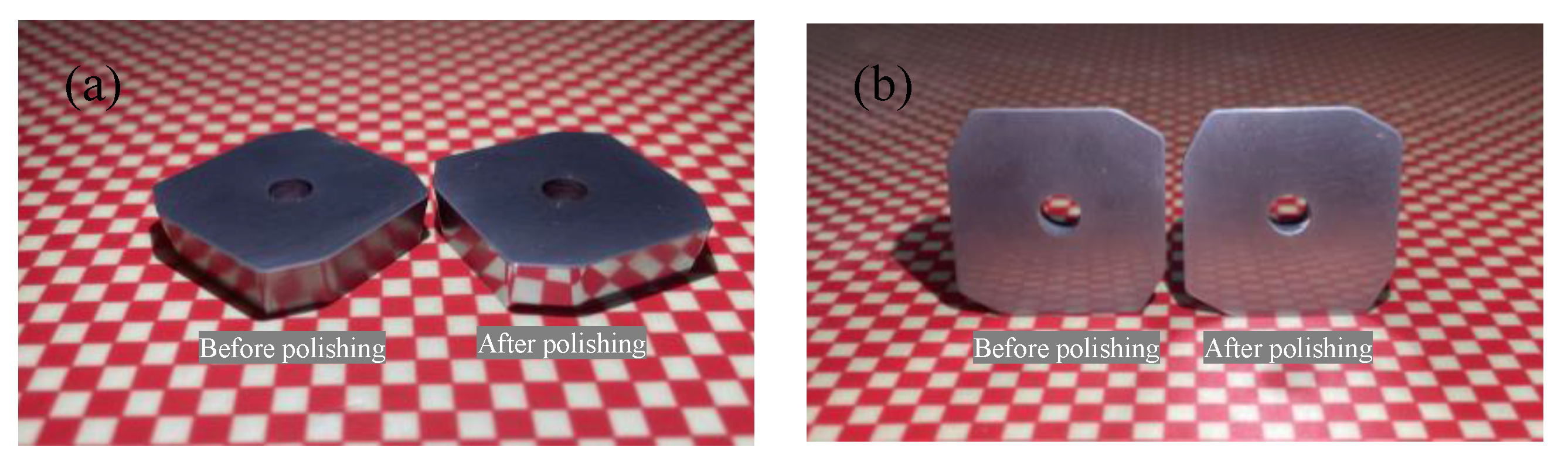

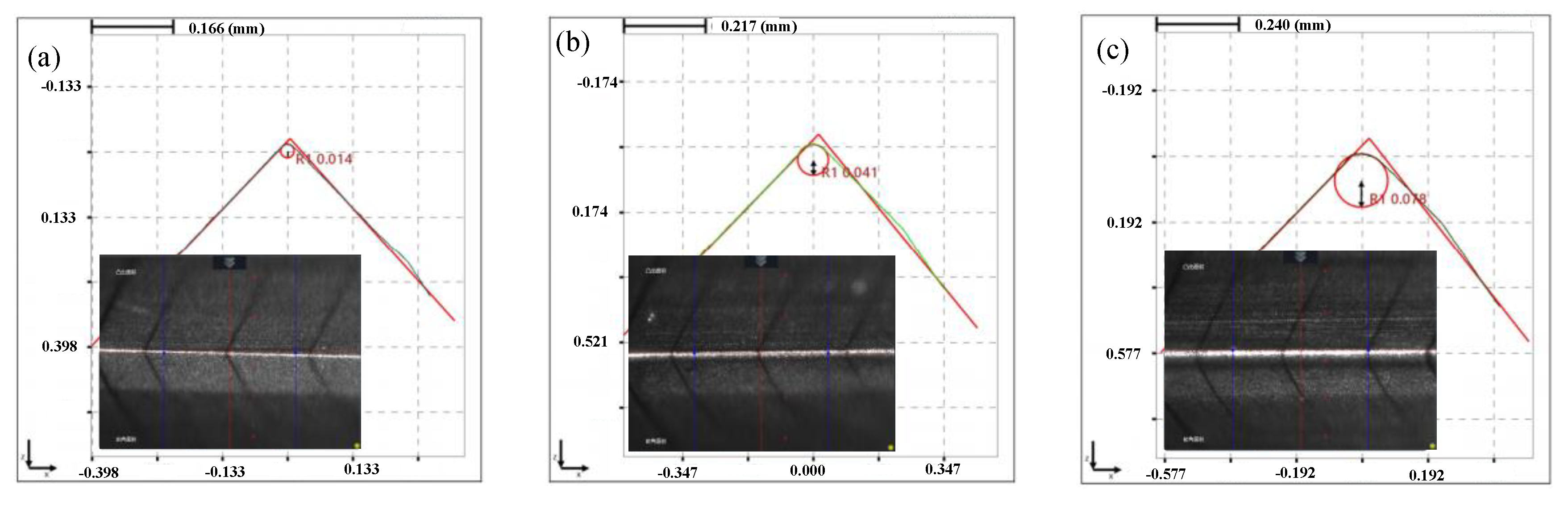

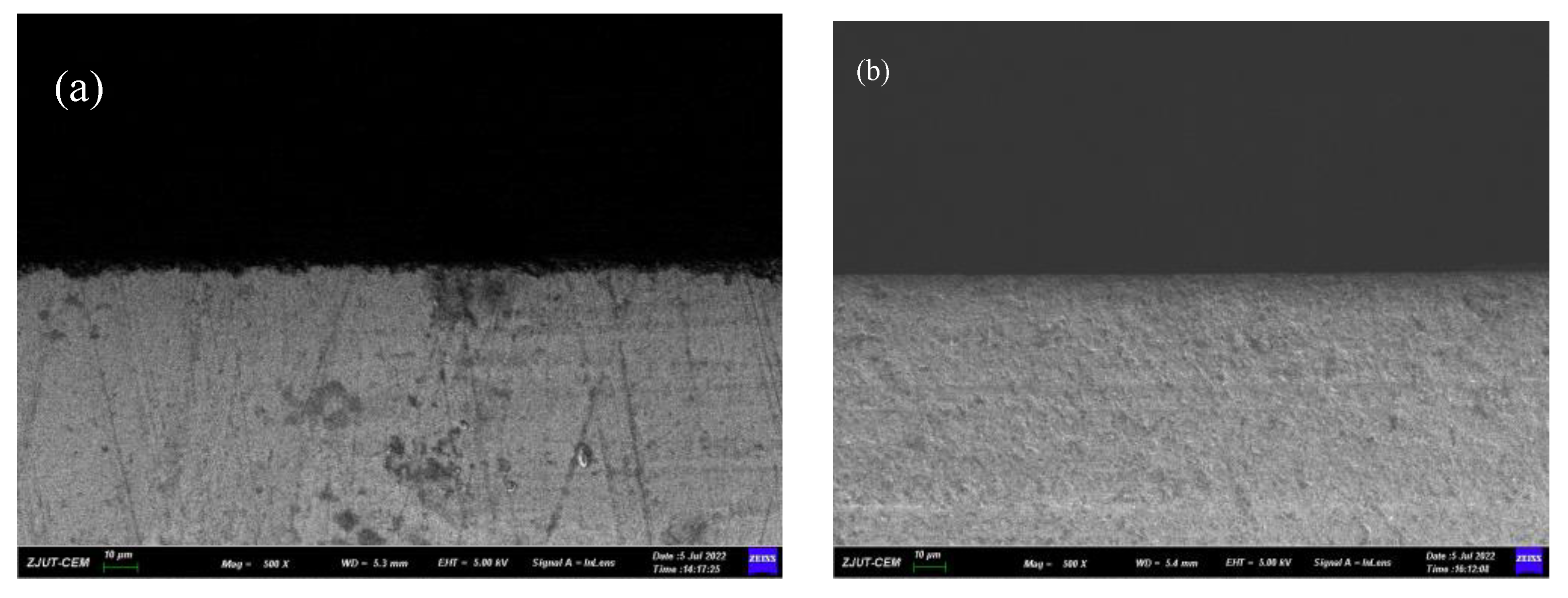

4.1. Comparative Experiment of STP and FF-STP on Cutting Edge Preparation

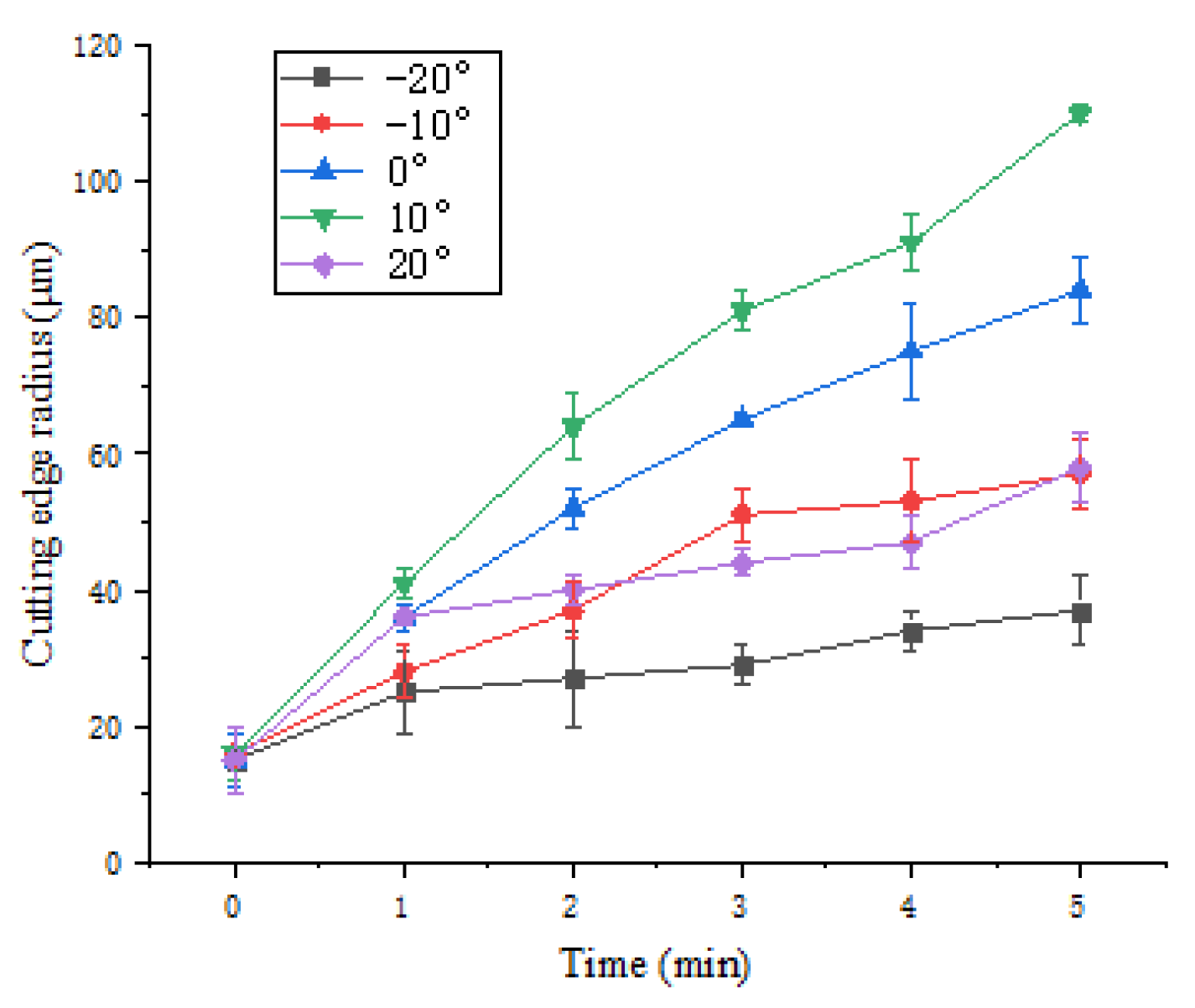

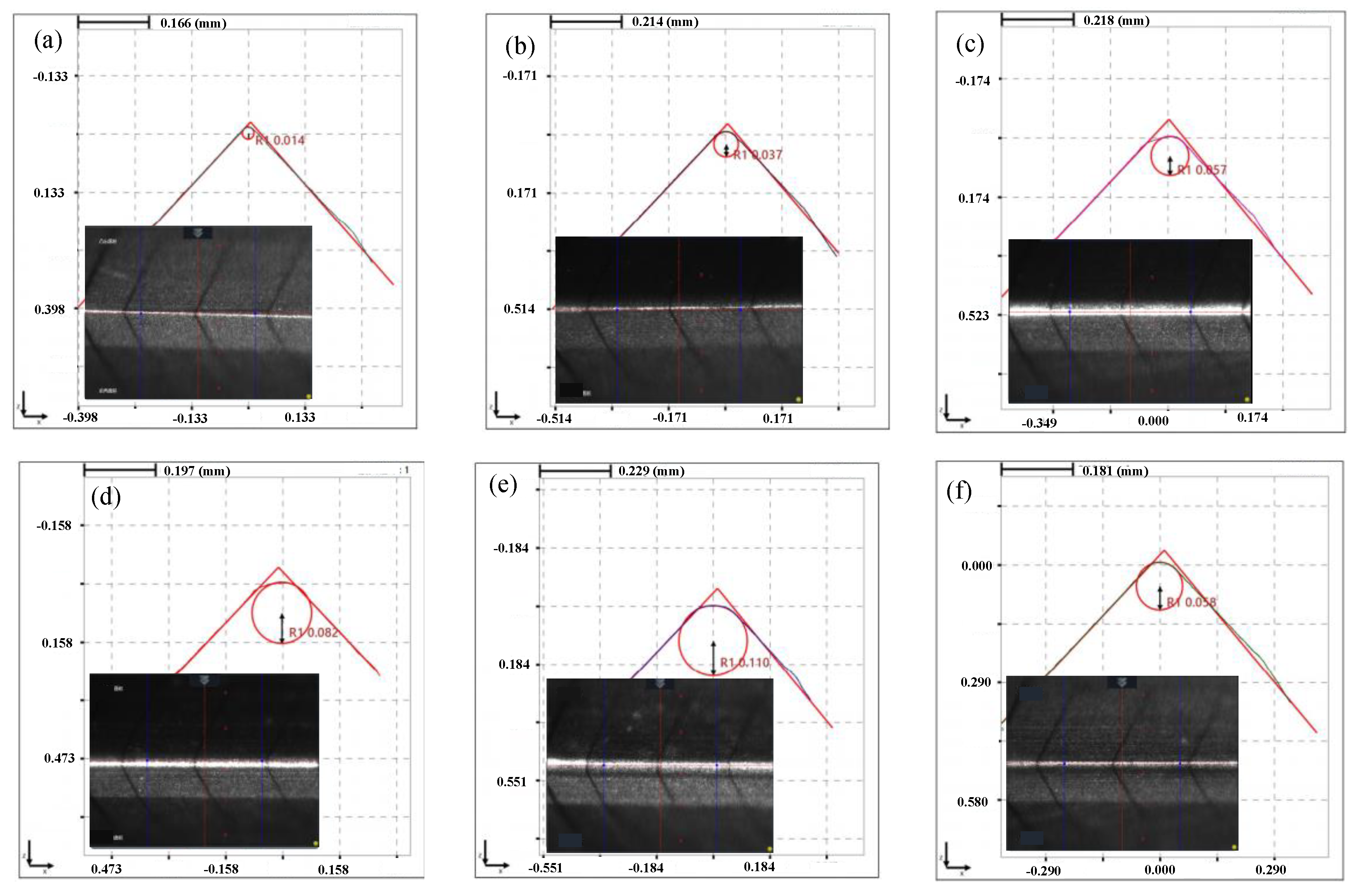

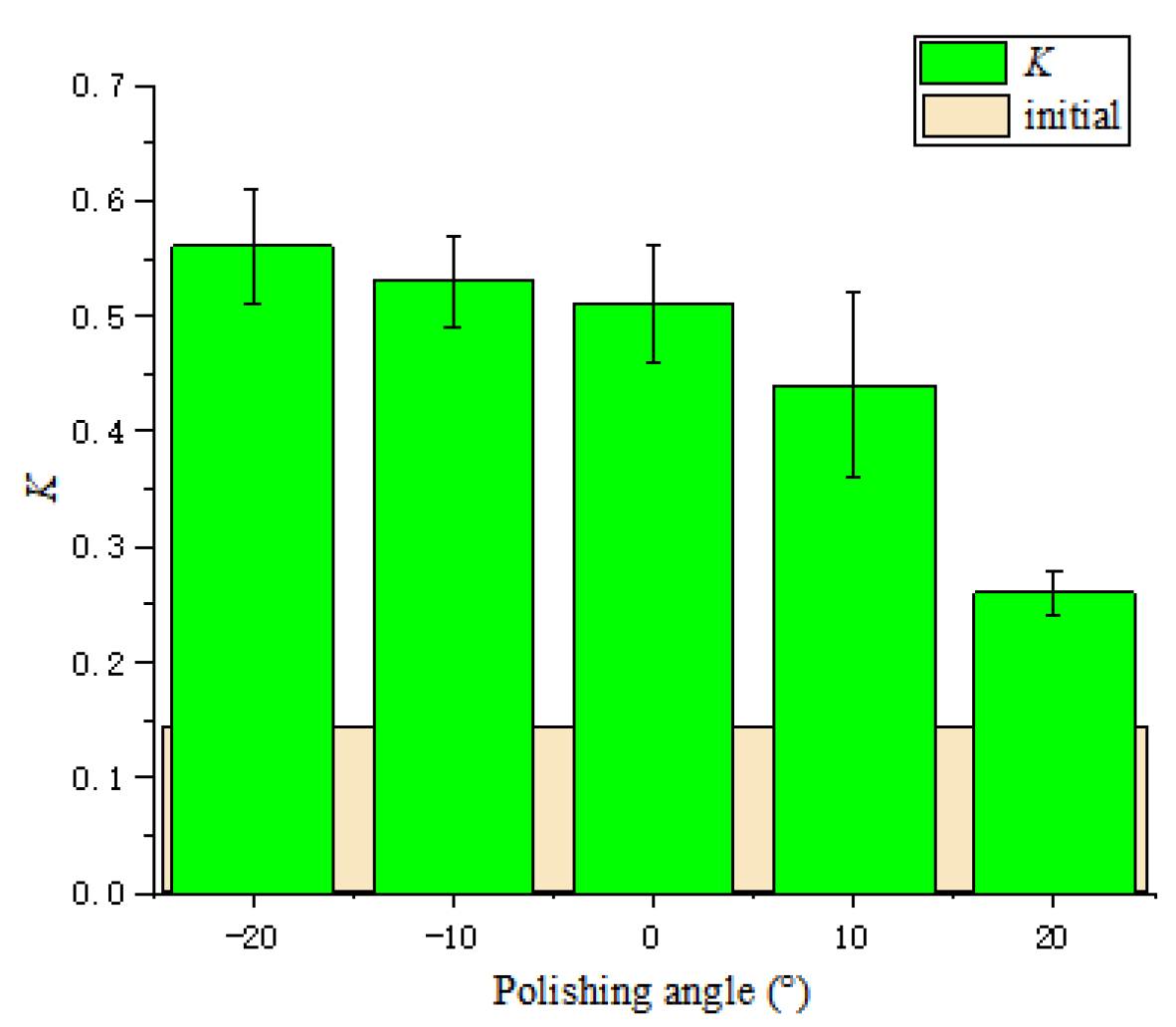

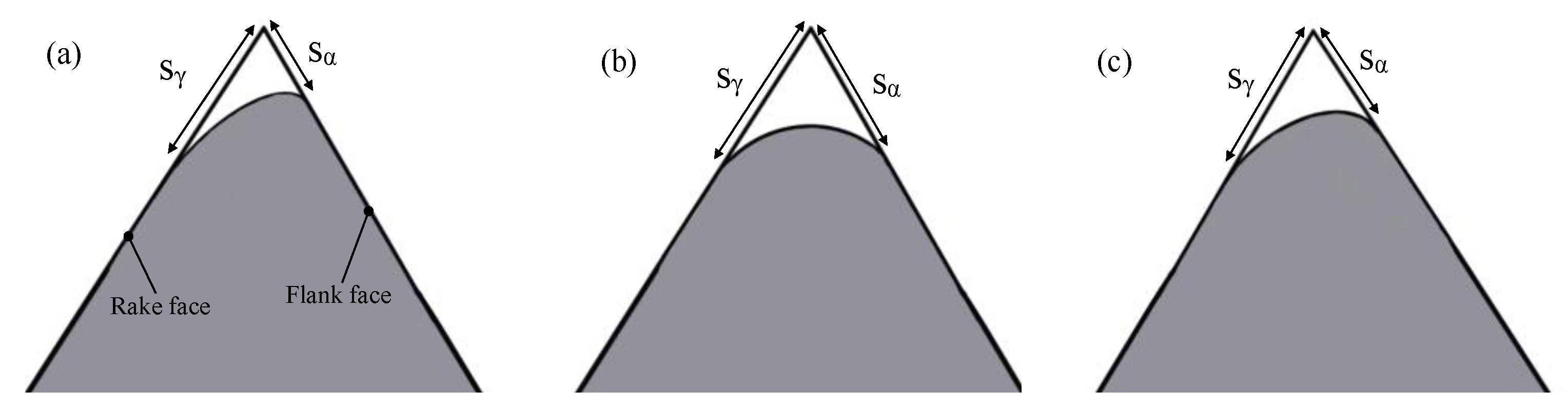

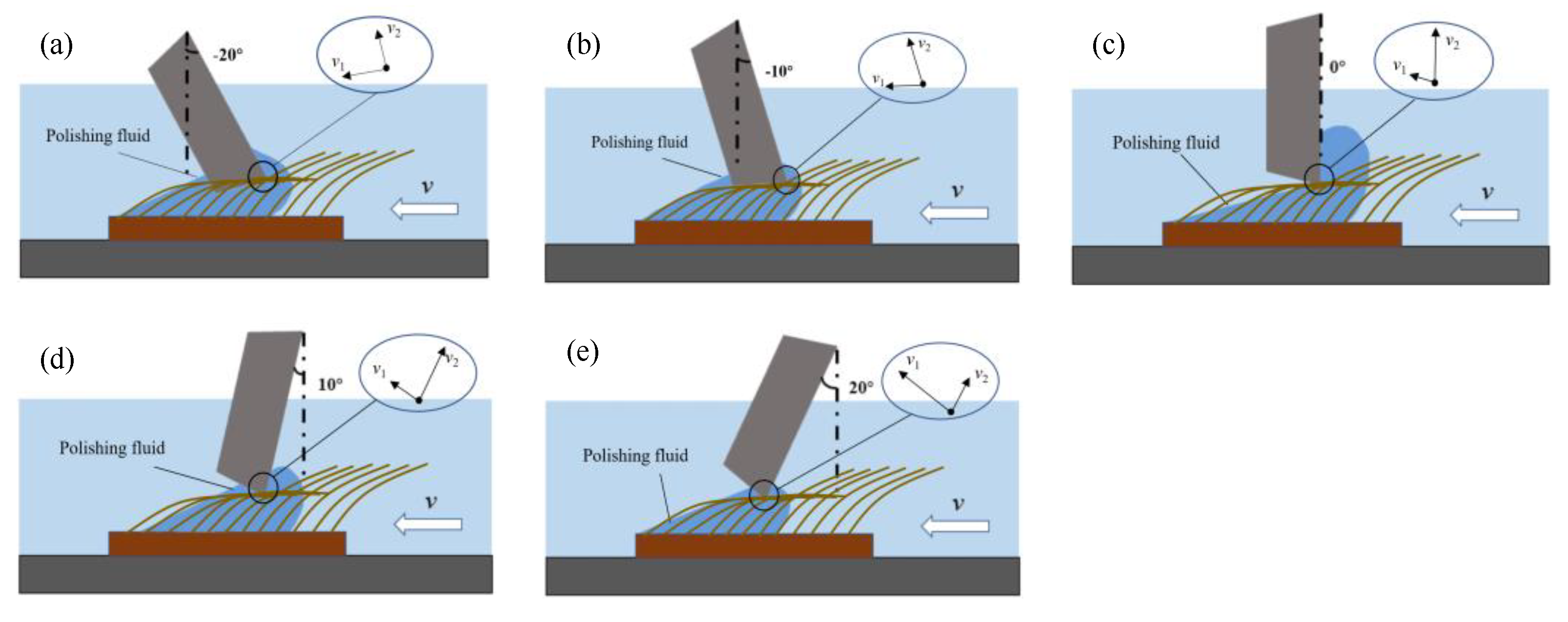

4.2. Influence of Polishing Angle

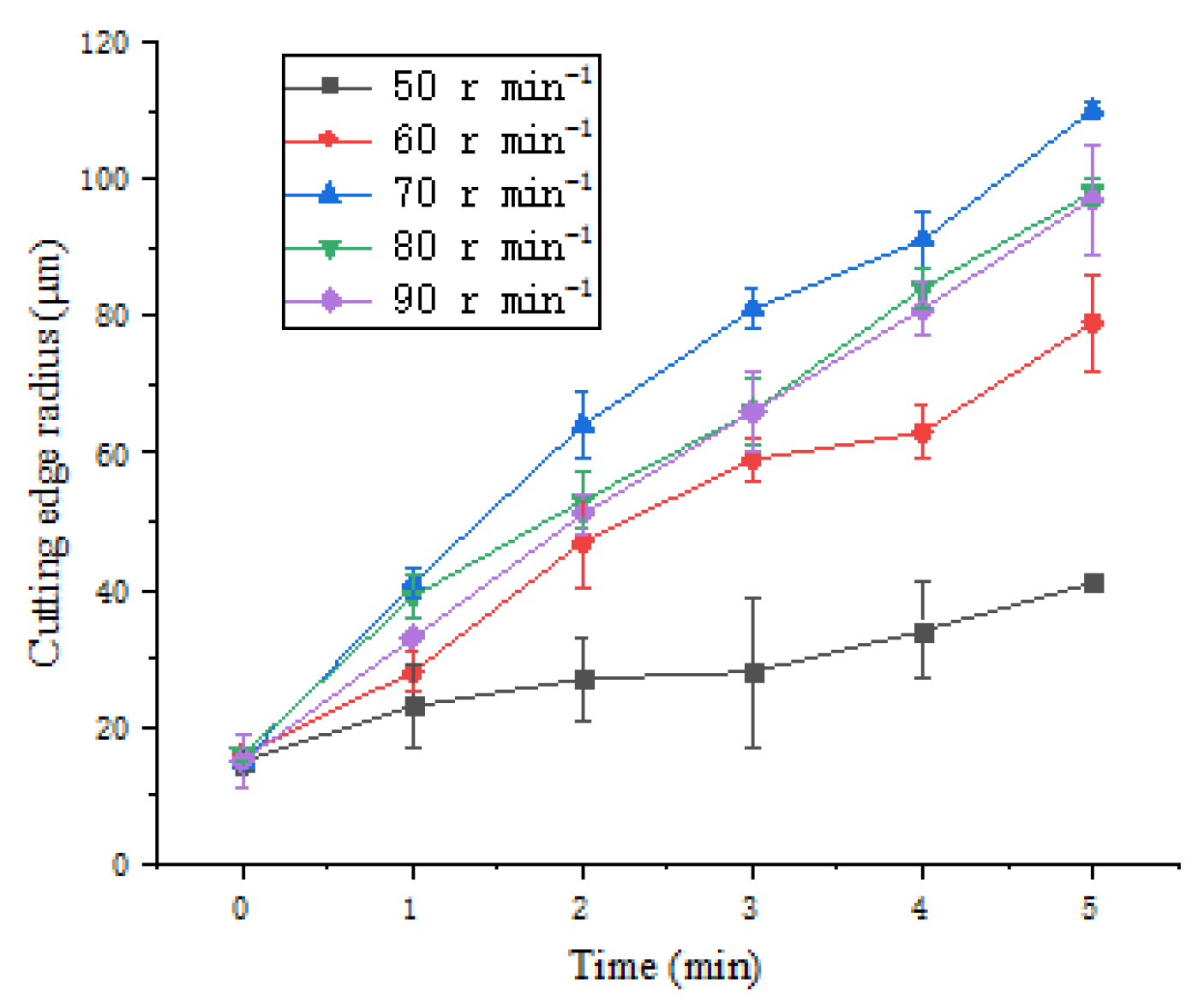

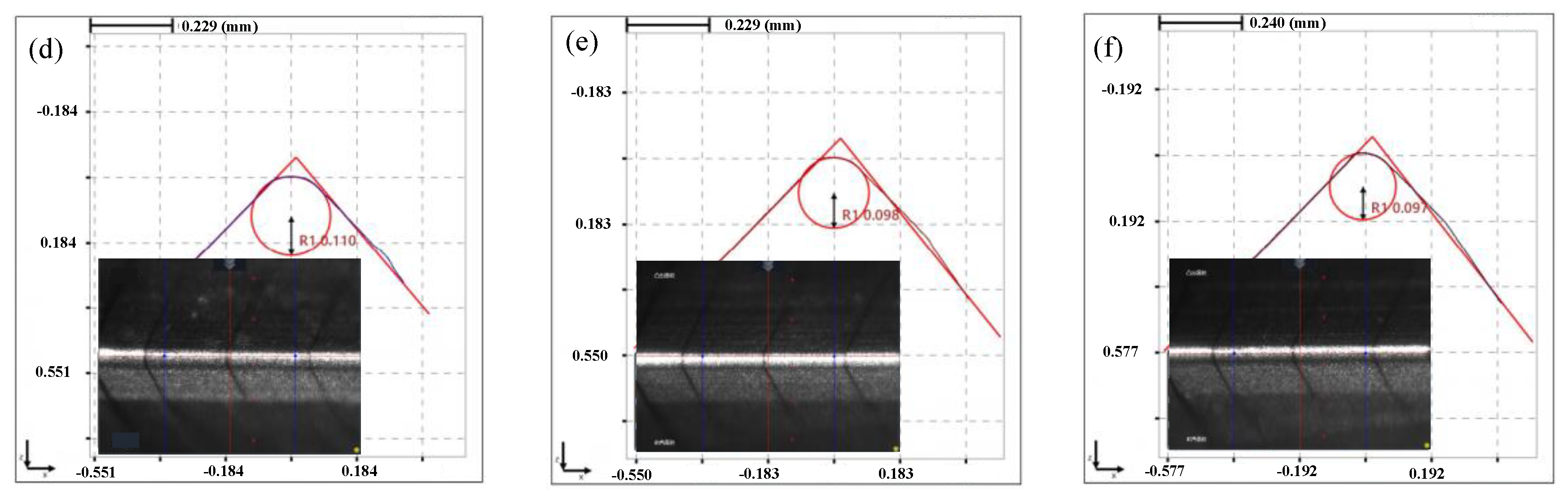

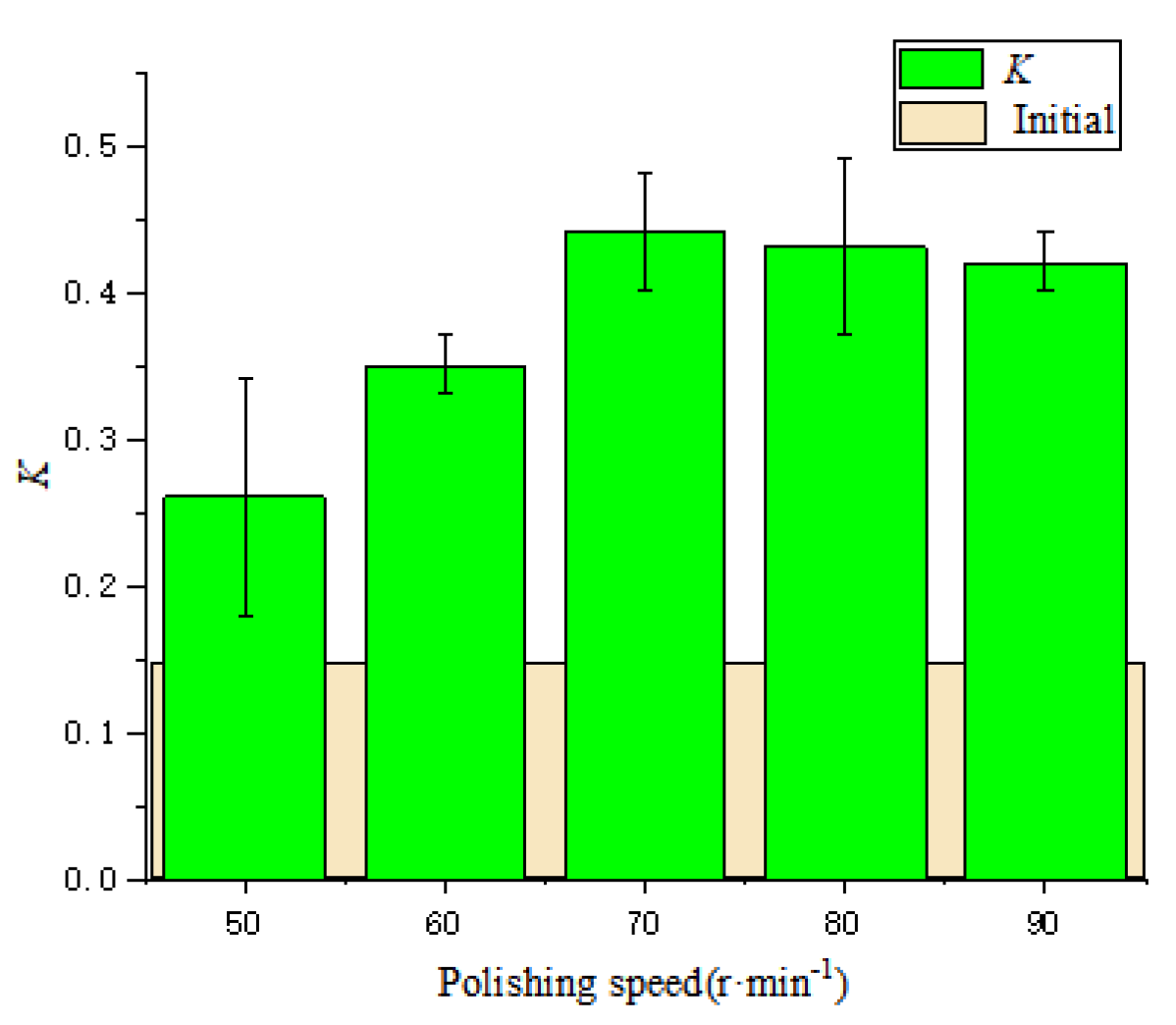

4.3. Influence of Polishing Speed

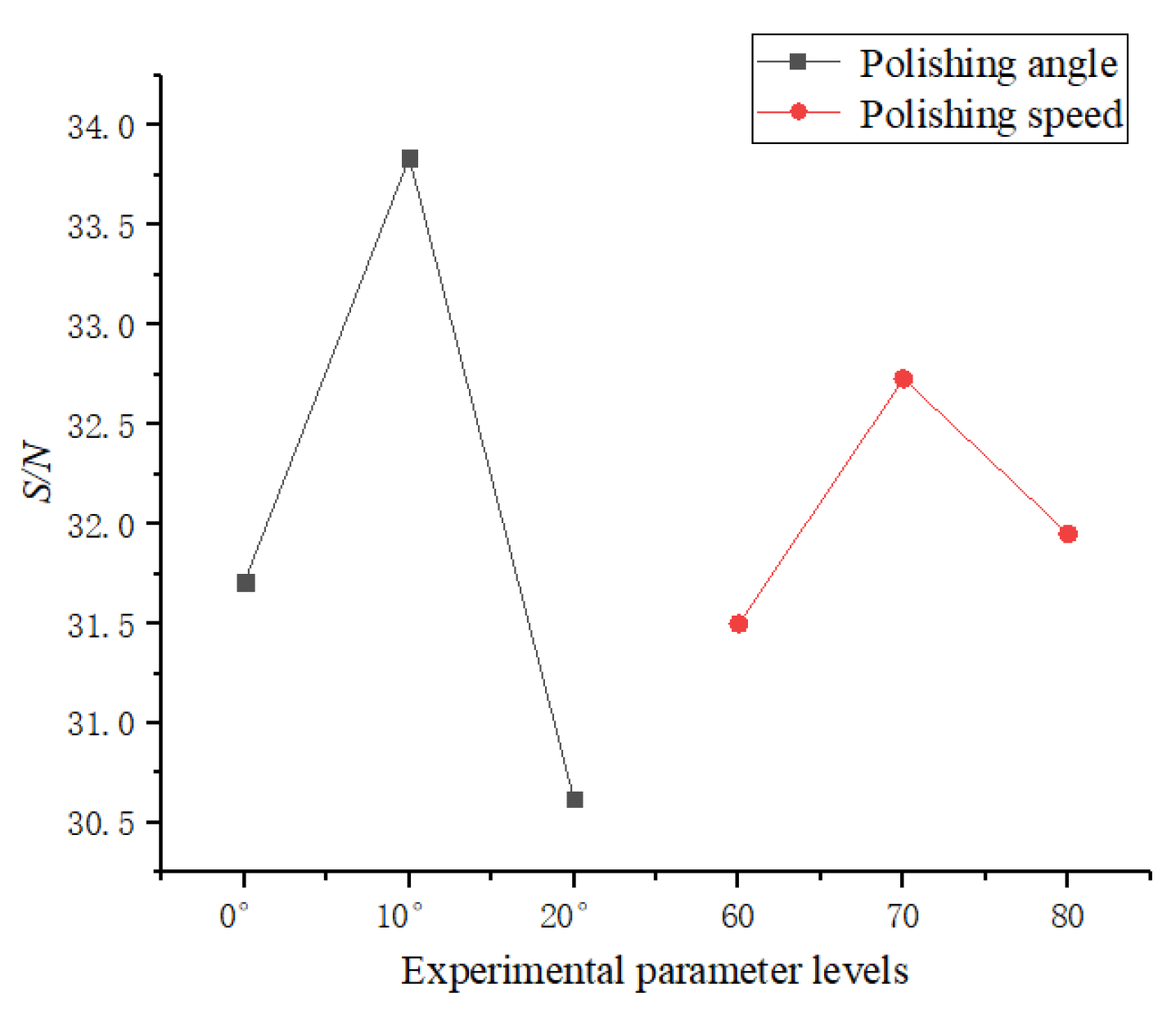

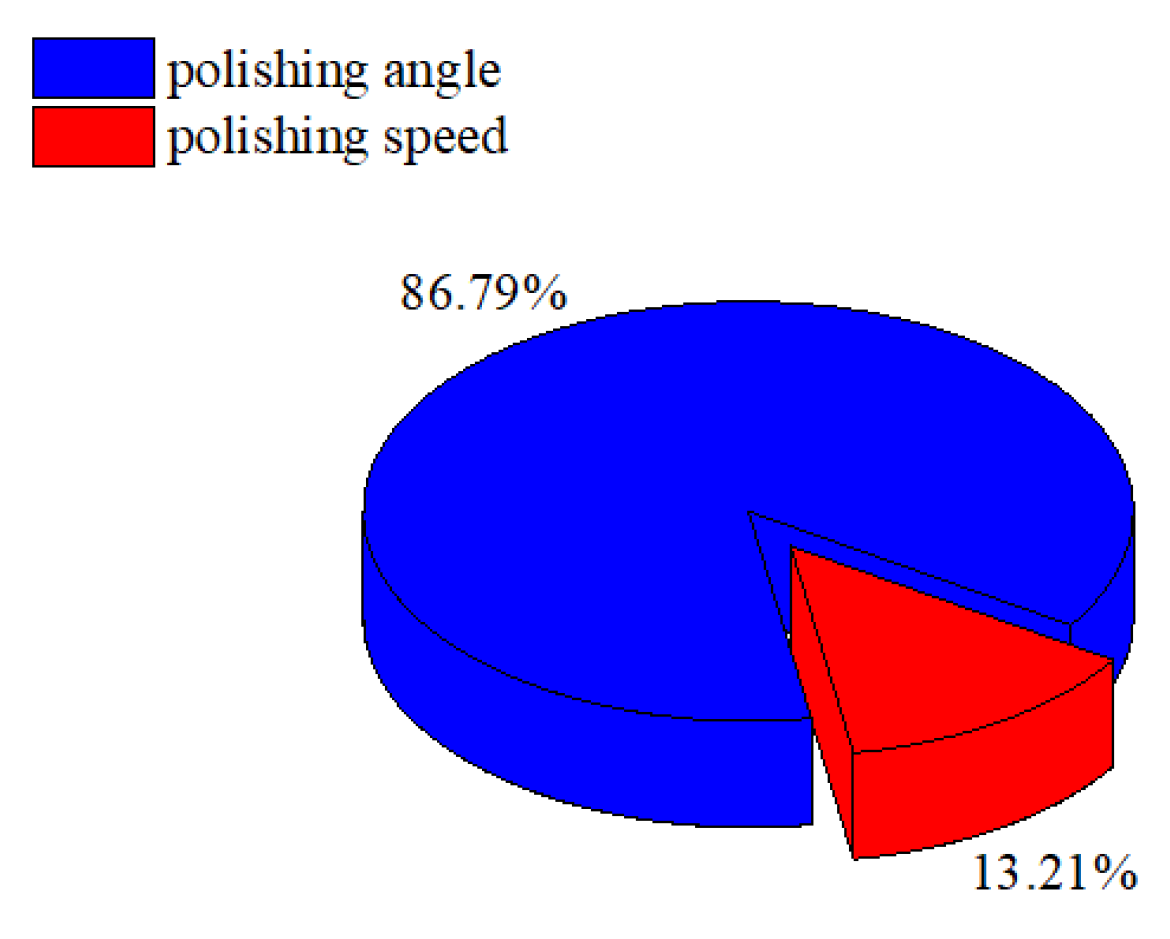

4.4. Analysis of Orthogonal Experiment Results

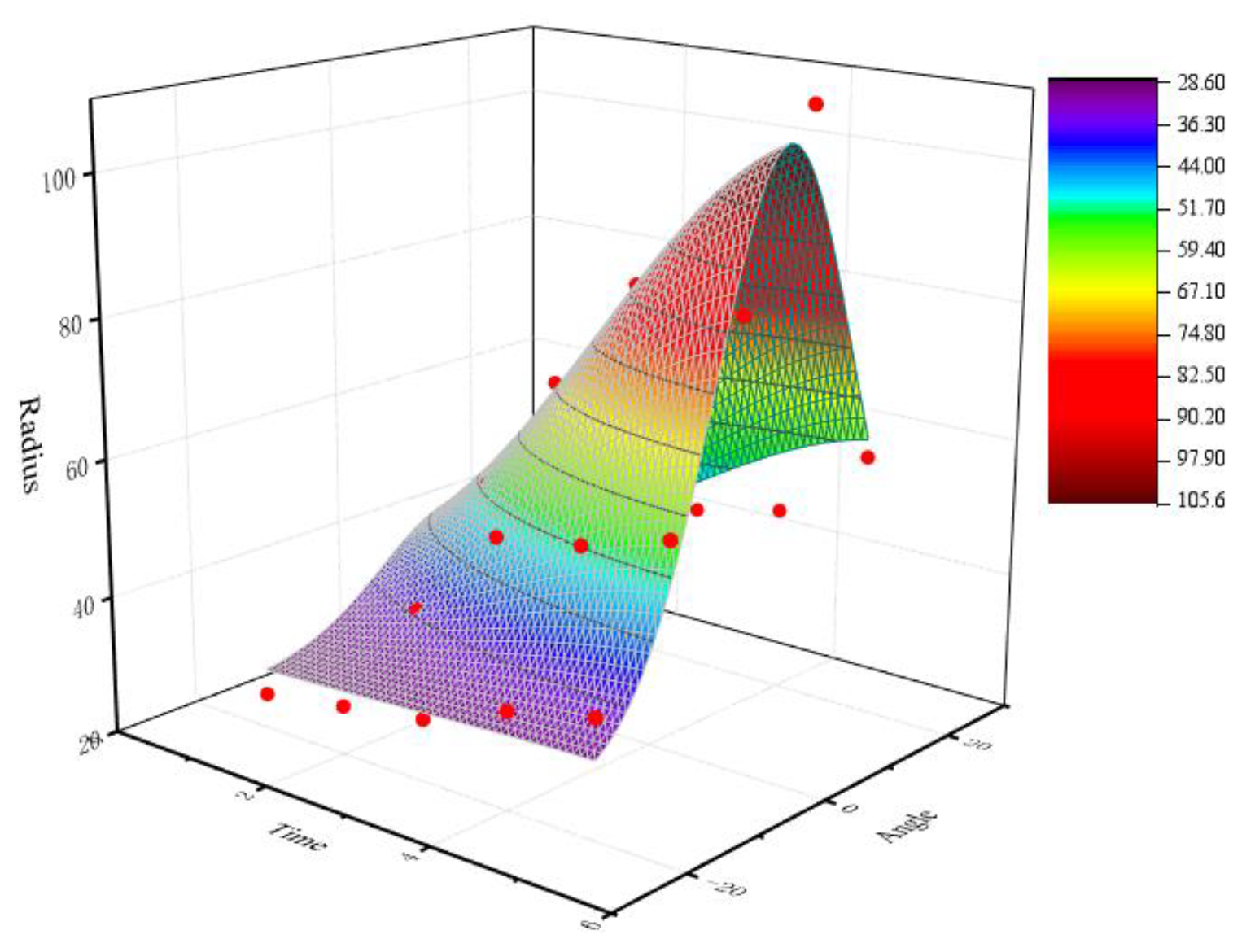

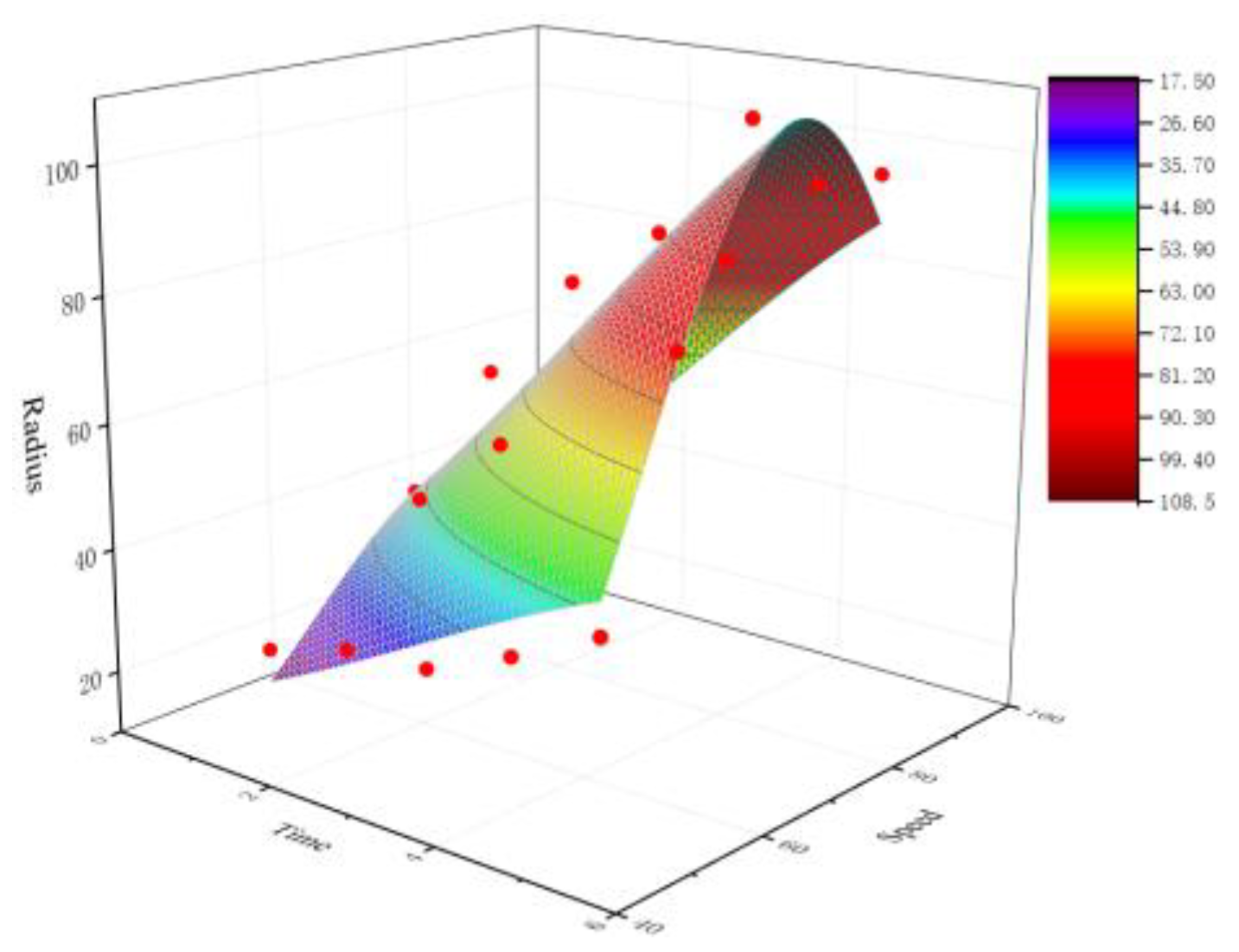

5. Cutting Edge Radius Model

6. Conclusions

- The efficiency of the cutting edge preparation by FF-STP is higher than STP. The flexible fibers play the role of pushing the polishing slurry to the cutting edge to increase its material removal rate, which achieves cutting edge preparation effectively.

- The polishing angle has a more significant effect on the cutting edge radius during the process. The cutting edge preparation efficiency is the highest under the polishing angle of 10°, where the cutting edge radius increased from the 15 ± 2 μm to 110 ± 5 μm in 5 min. The cutting edge shape can be controlled by adjusting the polishing angle, and K-factor varies from 0.14 ± 0.03 to 0.56 ± 0.05. The polishing speed has a less effect on the cutting edge radius and shape, but increasing the polishing speed within a certain range can improve the efficiency of cutting edge preparation.

- Two models that the cutting edge radius can be predicted as a function of polishing angle and polishing speed are established and the R-square of the two equations were 0.93815 and 0.94947, respectively, which proved the rationality of the established model.

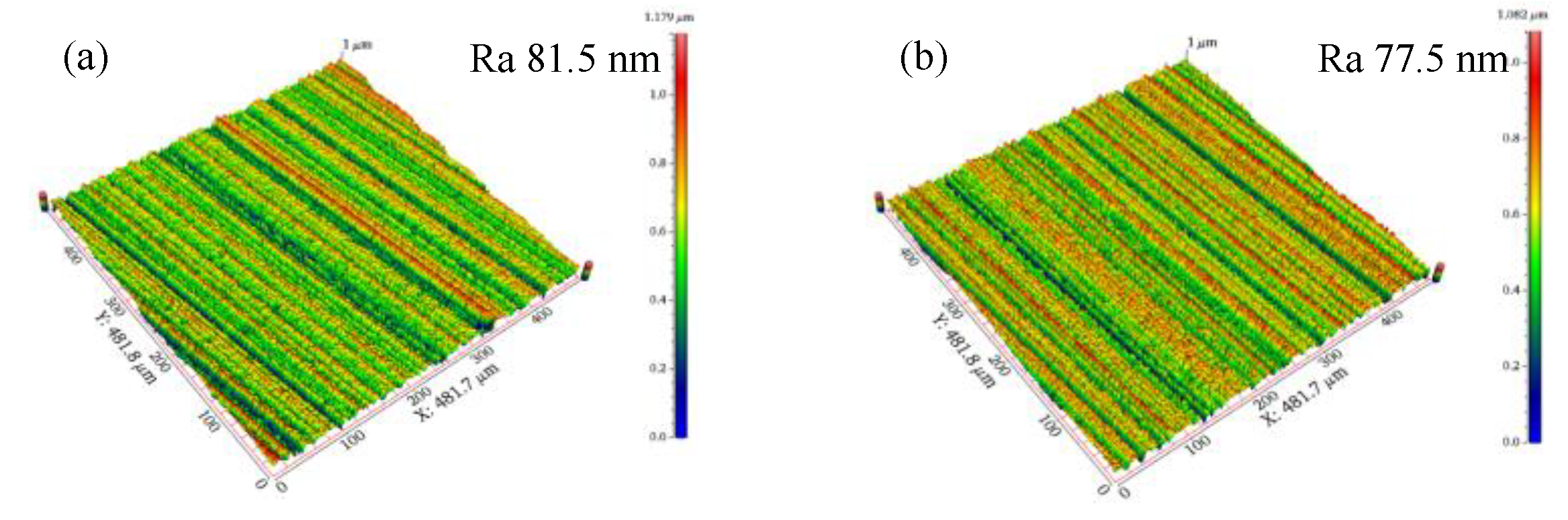

- FF-STP can not only achieve the controllable change of the cutting edge radius and shape but also have a significant impact on the improvement of the insert surface quality. In the future, extensive research is required to clarify the material removal mechanism of the cutting edge during FF-STP processing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qin, C.J.; Hu, Z.H.; Tang, A.M.; Yang, Z.P.; Luo, S. An efficient material removal rate prediction model for cemented carbide inserts chemical mechanical polishing. Wear 2020, 452, 203293. [Google Scholar] [CrossRef]

- Krebs, E.; Wolf, M.; Biermann, D.; Tillmann, W.; Stangier, D. High-quality cutting edge preparation of micromilling tools using wet abrasive jet machining process. Prod. Eng. Res. Dev. 2018, 12, 45–51. [Google Scholar] [CrossRef]

- Bassett, E.; Kohler, J.; Denkena, B. On the honed cutting edge and its side effects during orthogonal turning operations of AISI1045 with coated WC-Co inserts. CIRP J. Manuf. Sci. Technol. 2012, 5, 108–126. [Google Scholar] [CrossRef]

- Pokorný, P.; Pätoprstý, B.; Vopát, T.; Peterka, J.; Vozár, M.; Šimna, V. Cutting edge radius preparation. Mater. Today Proc. 2020, 22, 212–218. [Google Scholar]

- Lv, D.; Wang, Y.; Yu, X.; Chen, H.; Gao, Y. Analysis of abrasives on cutting edge preparation by drag finishing. Int. J. Adv. Manuf. Technol. 2022, 119, 3583–3594. [Google Scholar] [CrossRef]

- Zhao, X.F.; Zheng, P.F.; He, L.; Tao, M. Cutting edge preparation using the discrete element software EDEM. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–10. [Google Scholar] [CrossRef]

- Zlamal, T.; Mrkvica, I.; Szotkowski, T.; Malotova, S. The Influence of Surface Treatment of PVD Coating on Its Quality and Wear Resistant. Coatings 2019, 9, 439. [Google Scholar] [CrossRef]

- Voina, I.D.; Sattel, S.; Contiu, G.; Faur, A.; Luca, B. Reamers cutting edge preparation for improvement the GGG 40 machining. MATEC Web Conf. EDP Sci. 2018, 178, 01014. [Google Scholar] [CrossRef]

- Vopát, T.; Podhorsk, T.; Sahul, M.; Haráni, M. Cutting edge preparation of cutting tools using plasma discharges in electrolyte. J. Manuf. Process. 2019, 46, 234–240. [Google Scholar] [CrossRef]

- Zimmermann, M.; Kirsch, B.; Kang, Y.; Herrmann, T.; Aurich, J.C. Influence of the laser parameters on the cutting edge preparation and the performance of cemented carbide indexable inserts. J. Manuf. Process. 2020, 58, 845–856. [Google Scholar] [CrossRef]

- Vopát, T.; Sahul, M.; Haršáni, M.; Vortel, O.; Zlámal, T. The Tool Life and Coating-Substrate Adhesion of AlCrSiN-Coated Carbide Cutting Tools Prepared by LARC with Respect to the Edge Preparation and Surface Finishing. Micromachines 2020, 11, 166. [Google Scholar] [CrossRef]

- Denkena, B.; Krodel, A.; Hein, M. Innovative method for cutting edge preparation with flexible diamond tools. 7th CIRP Global Web Conference, Towards shifted production value stream patterns inference of data, models and technology. Procedia CIRP 2019, 89, 121–125. [Google Scholar] [CrossRef]

- Bergs, T.; Schneider, S.A.M.; Amara, M.; Ganser, P. Preparation of symmetrical and asymmetrical cutting edges on solid cutting tools using brushing tools with filament-integrated diamond grits. Procedia CIRP 2020, 93, 873–878. [Google Scholar] [CrossRef]

- Li, M.; Lyu, B.H.; Yuan, J.L.; Dong, C.C.; Dai, W.T. Shear-thickening polishing method. Int. J. Mach. Tools Manuf. 2015, 94, 88–99. [Google Scholar] [CrossRef]

- Lyu, B.H.; Ke, M.F.; Fu, L.; Duan, S.X.; Shao, Q.; Zhou, Y.F.; Yuan, J.L. Experimental Study on the Brush Tool-Assisted Shear-Thickening Polishing of Cemented Carbide Insert with Complex Shape. Int. J. Adv. Manuf. Technol. 2021, 115, 2491–2504. [Google Scholar] [CrossRef]

- Chan, J.; Koshy, P. Tool edge honing using shear jamming abrasive media. CIRP Ann.-Manuf. Technol. 2020, 69, 289–292. [Google Scholar] [CrossRef]

- Denkena, B.; Biermann, D. Cutting edge geometries. CIRP Ann. 2014, 63, 631–653. [Google Scholar] [CrossRef]

- Lyu, B.H.; Shao, Q.; Hang, W.; Chen, S.H.; He, Q.K.; Yuan, J.L. Shear Thickening Polishing of Black Lithium Tantalite Substrate. Int. J. Precis. Eng. Manuf. 2020, 21, 1663–1675. [Google Scholar] [CrossRef]

- Yang, W.H.; Tarng, Y.S. Design optimization of cutting parameters for turning operations based on the Taguchi method. J. Mater. Process. Technol. 1998, 84, 122–129. [Google Scholar] [CrossRef]

- Liu, D.; Sun, J.W.; Wei, G.; Liu, X. Application of Moving Least Squares to Multi-sensors Data Reconstruction. Acta Autom. Sin. 2007, 33, 823–828. [Google Scholar]

- Castillo, E.; Hadi, A.S.; Minguez, R. Diagnostics for non-linear regression. J. Stat. Comput. Simul. 2009, 79, 1109–1128. [Google Scholar] [CrossRef]

| Material | Density (g/cm3) | Flexural Strength (MPa) | Hardness (HRA) | Fracture Toughness (MPa m1/2) |

|---|---|---|---|---|

| YG8 | 14.7 | 1500 | 89 | 2.5 |

| Parameters | Values | |

|---|---|---|

| Group 1 | Group 2 | |

| Polishing angle (°) | −20, −10, 0, 10, 20 | 10 |

| Polishing speed (r·min−1) | 70 | 50, 60, 70, 80, 90 |

| Processing time per trial (min) | 1 | |

| Abrasive | Diamond, 5000#, 6 wt.% | |

| Symbol | Factors | |

|---|---|---|

| Trial No. | A Polishing Angle (°) | B Polishing Speed (r min−1) |

| 1 | 0 | 60 |

| 2 | 0 | 70 |

| 3 | 0 | 80 |

| 4 | 10 | 60 |

| 5 | 10 | 70 |

| 6 | 10 | 80 |

| 7 | 20 | 60 |

| 8 | 20 | 70 |

| 9 | 20 | 80 |

| No. | A | B | R (μm) | (dB) |

|---|---|---|---|---|

| 1 | 0 | 60 | 35 | 30.88 |

| 2 | 0 | 70 | 43 | 32.67 |

| 3 | 0 | 80 | 38 | 31.60 |

| 4 | 10 | 60 | 46 | 33.26 |

| 5 | 10 | 70 | 54 | 34.64 |

| 6 | 10 | 80 | 48 | 33.62 |

| 7 | 20 | 60 | 33 | 30.37 |

| 8 | 20 | 70 | 35 | 30.88 |

| 9 | 20 | 80 | 34 | 30.63 |

| R-Square R2: 0.93815 | ||||

|---|---|---|---|---|

| DOF | Sum of Square | Mean Square | F-Measure | |

| Regression Coefficient | 6 | 78,835.0221 | 13,139.17035 | 343.40004 |

| Residual Error | 19 | 726.9779 | 38.26199 | |

| R-Square R2: 0.94947 | ||||

|---|---|---|---|---|

| DOF | Sum of Square | Mean Square | F-Measure | |

| Regression Coefficient | 6 | 102,858.13579 | 17,143.02263 | 414.47037 |

| Residual Error | 19 | 785.86421 | 41.36127 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, L.; Zhou, Y.; Fang, W.; Wang, J.; Wang, X.; Deng, Q.; Lyu, B. Preparation of Cemented Carbide Insert Cutting Edge by Flexible Fiber-Assisted Shear Thickening Polishing Method. Micromachines 2022, 13, 1631. https://doi.org/10.3390/mi13101631

Shao L, Zhou Y, Fang W, Wang J, Wang X, Deng Q, Lyu B. Preparation of Cemented Carbide Insert Cutting Edge by Flexible Fiber-Assisted Shear Thickening Polishing Method. Micromachines. 2022; 13(10):1631. https://doi.org/10.3390/mi13101631

Chicago/Turabian StyleShao, Lanying, Yu Zhou, Wei Fang, Jiahuan Wang, Xu Wang, Qianfa Deng, and Binghai Lyu. 2022. "Preparation of Cemented Carbide Insert Cutting Edge by Flexible Fiber-Assisted Shear Thickening Polishing Method" Micromachines 13, no. 10: 1631. https://doi.org/10.3390/mi13101631

APA StyleShao, L., Zhou, Y., Fang, W., Wang, J., Wang, X., Deng, Q., & Lyu, B. (2022). Preparation of Cemented Carbide Insert Cutting Edge by Flexible Fiber-Assisted Shear Thickening Polishing Method. Micromachines, 13(10), 1631. https://doi.org/10.3390/mi13101631